#Cold Chain monitoring

Explore tagged Tumblr posts

Text

How IoT Transform Cold Chain Monitoring

IoT technology is revolutionizing cold chain monitoring, offering unprecedented control, visibility, and efficiency.

0 notes

Text

What is Cold Chain Monitoring?

Cold chain monitoring is a critical component in the logistics and supply chain management of temperature-sensitive products. It involves a series of procedures and technologies used to maintain and monitor the temperature conditions of perishable goods throughout their journey from production to consumption. This process is essential for ensuring the quality, safety, and efficacy of products such as pharmaceuticals, food, and chemicals.

Importance of Cold Chain Monitoring

The integrity of temperature-sensitive products can be compromised if they are exposed to unsuitable conditions. For instance, vaccines may lose their potency if not stored within a specific temperature range, and food products may spoil, leading to potential health risks for consumers. Effective cold chain monitoring helps prevent such scenarios by ensuring that products are kept within their required temperature range throughout the supply chain.

Components of a Cold Chain Monitoring System

A comprehensive cold chain monitoring system consists of several key components:

Temperature Sensors: These are placed in various locations along the supply chain to continuously monitor the temperature. They can be simple thermometers or advanced digital sensors connected to the internet.

Data Loggers: Devices that record temperature data over time. Data loggers are often used for monitoring shipments, providing a detailed record of the conditions the products were exposed to.

GPS Trackers: These devices help in tracking the real-time location of shipments. Coupled with temperature sensors, they provide a comprehensive view of the conditions and whereabouts of the products.

Monitoring Software: Software platforms collect data from sensors and data loggers, providing real-time monitoring and alert systems. These platforms often offer dashboards for easy visualization and management of the cold chain data.

Cloud Storage: Storing data in the cloud allows for real-time access and analysis from any location, enhancing the ability to quickly respond to any issues that arise.

How Cold Chain Monitoring Works

The cold chain process starts from the point of production, where temperature-sensitive products are manufactured. From there, the products are stored in temperature-controlled warehouses before being transported to distribution centers and finally to the end consumer. Throughout this journey, cold chain monitoring ensures that the products remain within the specified temperature range.

Production: At the manufacturing site, temperature sensors and data loggers are used to monitor storage conditions. This data is continuously recorded and analyzed to ensure compliance with the required standards.

Storage: In warehouses, a network of sensors monitors the ambient temperature. Data is collected in real-time and can trigger alerts if temperatures deviate from the set parameters, allowing for immediate corrective action.

Transportation: During transport, mobile sensors and data loggers track the temperature and location of the shipment. GPS trackers provide real-time updates on the shipment's location, while temperature data loggers record any fluctuations in temperature.

Distribution: At distribution centers, similar monitoring systems are in place to ensure that the products remain within the desired temperature range before being dispatched to retail outlets or directly to consumers.

End Consumer: Upon delivery, the final temperature readings can be checked to ensure that the product has been maintained properly throughout its journey.

Technologies in Cold Chain Monitoring

Advancements in technology have significantly improved cold chain monitoring systems. Some of the latest technologies include:

Internet of Things (IoT): IoT devices are widely used in cold chain monitoring for real-time data collection and transmission. These devices can be integrated with sensors and data loggers to provide continuous monitoring.

Blockchain: Blockchain technology ensures the transparency and immutability of cold chain data. It provides a secure way to record and track temperature data, ensuring that the information cannot be tampered with.

Artificial Intelligence (AI): AI algorithms can analyze large datasets collected from cold chain monitoring systems to predict potential issues and optimize logistics operations.

5G Connectivity: The introduction of 5G networks enhances the speed and reliability of data transmission in cold chain monitoring systems, allowing for real-time updates and faster response times.

Benefits of Cold Chain Monitoring

The implementation of cold chain monitoring systems offers several significant benefits:

Product Safety: Ensures the quality and safety of temperature-sensitive products by maintaining the required temperature conditions throughout the supply chain.

Regulatory Compliance: Helps companies comply with stringent regulations and standards for the storage and transportation of perishable goods.

Reduced Waste: Minimizes product spoilage and waste by promptly identifying and addressing temperature deviations.

Cost Savings: Reduces financial losses associated with spoiled or compromised products, leading to cost savings for businesses.

Customer Satisfaction: Enhances customer satisfaction by ensuring that products are delivered in optimal condition.

Challenges in Cold Chain Monitoring

Despite the numerous benefits, cold chain monitoring also faces several challenges:

Cost: Implementing and maintaining a comprehensive cold chain monitoring system can be expensive, particularly for small and medium-sized enterprises.

Complexity: Managing and analyzing large volumes of data from various sensors and devices can be complex and requires sophisticated software solutions.

Connectivity Issues: In remote areas, maintaining reliable connectivity for real-time data transmission can be challenging.

Training: Proper training is required for personnel to effectively use and maintain cold chain monitoring systems.

Conclusion

Cold chain monitoring is an essential process for ensuring the integrity of temperature-sensitive products. By leveraging advanced technologies, businesses can maintain the required conditions for these products, ensuring their safety, quality, and compliance with regulatory standards. Despite the challenges, the benefits of implementing an effective cold chain monitoring system far outweigh the costs, making it a critical investment for companies dealing with perishable goods.

0 notes

Text

Pharmaceutical Cold Chain Monitoring:Maintaining Medicinal Excellence at Every Step

Pharma cold chain monitoringᅠregulates environmental factors for medications, including temperature, humidity, and light,ᅠduring the whole process from production to consumption.ᅠDrugs need to go through a series of transportation and storage proceduresᅠfrom the manufacturing facility to the hospital or retail pharmacy. Cold chain monitoring based on IoT plays an important role during the process.

Why Does the Pharmaceutical Cold Chain Need IoT Monitoring?

The pharmaceutical cold chain monitoring has stricter requirements for maintaining a certain temperature and humidity environment to ensure the quality of pharmaceuticals, compared with general food cold chain. Throughout the supply chain, warehousing, and shipping of some pharmaceutical items, temperature and humidity variations can have a significant impact on drug quality.

The deterioration caused by temperature changes directly affects the quality and curative effect of medicines. Raising the temperature is easy to volatilize and reduce the dosage, and lowering the temperature is easy to freeze and inactivate.

Meanwhille, according to Goog Storage and Distribution Practices for Drug Products: All drug products have storage requirements that may contain specific controls. The container used for transporting the drug product should be qualified on the basis of labeled conditions of the product as well as anticipated environmental conditions. Consideration should be made for seasonal temperature differences, transportation between hemispheres, and the routes and modes of transport. The type, size, location, and amount of the temperature stabilizers required to protect the product should be based on documented studies of specific distribution environments including domestic and international lanes, mode(s) of transport, duration, temperature, and other potential environmental exposures or sensitivities that may impact product quality.

Therefore, it has become a demand of more and more businesses and users to realize the whole process management and traceability of medical cold chain with the aid of IoT, in order to strengthen the monitoring of temperature and humidity and the data management of the entire process of medical cold chain.

What is IoT-based Medical Cold Chain Monitoring System?

The IoT pharmaceutical cold chain monitoringᅠis a system that employs sensors, network communications, cloud computing and other technologies to implement real-time monitoringᅠand control ofᅠpharmaceutical storage, transportation, etc. The system can continuously track the temperature, humidity, light, and other environmental factors affecting medications, alert when something is out of the ordinary, record it, and transfer the information to a cloud platform for storage and analysis.

Temperature and Humidity Monitoring

In a strict sense, cold chain logistics nowadays should be referred to as temperature-controlled logistics. The pharmaceutical cold chain monitoring system makes it possible to keep an eye on the conditions of pharmaceutical goods, particularly those that are susceptible to humidity and temperature during storage or transportation. Embedded sensors may collect and process data from any object, including a pallet and a medicine crate. Additionally, temperature data, ETAs, and historical temperature records may be provided through the IoT cold chain system. Furthermore, they may notify users when temperatures change, which helps businesses manage temperature-controlled goods more effectively.

Supply Chain Management

In addition to detecting temperature, the IoT pharmaceuticalᅠcold chain monitoring system may use real-time location tracking to guarantee the validity and safety of commodities. To prevent the items from being stolen, lost, or misplaced during transit, the location information of the goods may be traced in real time using GPS positioning and other technology. Location data may also be utilized to streamline logistics processes, boost productivity, and guarantee that items arrive at their destinations on schedule and accurately. Environmental factors for the items, such as temperature and humidity, may also be tracked in real time and changed as needed to maintain their efficacy and safety throughout transportation.

Architecture of IoT Pharmaceutical Cold Chain Monitoring System

The architecture of the Internet of Things medical cold chain monitoring system includes three parts: hardware equipment, software system and communication protocol.

IoT Hardware

For the storage, transportation, handover and other links of the pharmaceutical cold chain, the IoT hardware includes temperature and humidity sensors for monitoring the warehouse storage environment, temperature and humidity monitors for monitoring cold chain transportation vehicles, and tags installed on the incubator for monitoring the temperature inside the box label etc.

Software

The software system includes data acquisition, storage, analysis, visualization and other modules. The temperature and humidity monitoring dataᅠuploaded by various smart IoT devices are then presented in the form of a sizable visual supervisory screen, which showsᅠdata servingᅠas the foundation for the visual monitoring of the medical cold chain, including monitored temperature and humidity values, abnormal situation alerts, transportation process trajectories, door or box opening details, etc.

Communication Protocols

LoRa, Zigbee, etc., are communication protocols are utilized to gather data. LoRa is a low-power WAN communication protocol suitable for long-distance transmission, while Zigbee is a short-range wireless communication protocol suitable for small-scale connections.

Advantages of IoT Pharmaceutical Cold Chain Monitoring System

Medicine Quality Assurance: real-time monitoring of medicine storage and transportation environment ensures quality and safety of pharmaceutical goods as well as minimizes their damage and pollution during their storage and transit.

Reduce Costs: Drug damage and returns due to environmental variables may be decreased, and the cost and risk of the business can be decreased.

Improve Efficiency: By tracking and controlling the environment for drug storage and transportation, it is possible to optimize drug storage and transportation routes as well as the effectiveness and speed of the logistics process.

Increase Traceability: the whole process of drug manufacture, storage, transportation, and sales may be tracked through real-time monitoring and control of the environment.

Final Words

The Internet of Things medical cold chain monitoring system is an advanced management method that can provide more accurate, real-time and traceable management methods for the pharmaceutical industry. The medical cold chain monitoring system of the Internet of Things can be applied to scenarios such as drug storage and transportation, cold storage management, pharmaceutical retail, and medical waste treatment. Safety.

Pharmaceutical cold chain monitoringᅠoffers an innovative management technique that can offer the pharmaceutical business more precise, real-time, and traceable management approaches. It can be applied to cold storage facilities, pharmaceutical retail, and the treatment of medical waste, etc., to preserveᅠpotencyᅠand safeguardᅠpharmaceuticalᅠquality at every round of the supply chain.

Reference:

0 notes

Text

Optimize Your Cold Chain with Real-Time IoT Monitoring Solutions

The global demand for efficient and reliable cold chains has never been higher. With the rise of pharmaceuticals, fresh food logistics, and sensitive chemical transport, maintaining temperature control across the supply chain has become a top priority. In India and around the world, businesses are turning to real-time cold chain tracking and monitoring to manage and optimize their cold chain systems. This data-driven analysis explores how companies can enhance performance, ensure compliance, and reduce waste through real-time IoT implementation.

Why Cold Chain Optimization Matters

The cold chain refers to the temperature-controlled supply chain used to preserve and transport perishable goods. This includes vaccines, dairy products, seafood, meat, and flowers. According to a 2023 report by MarketsandMarkets, the global cold chain market is expected to reach USD 647.47 billion by 2028, growing at a CAGR of 8.4% from 2023 to 2028. With increasing global trade, regulatory pressure, and customer expectations, optimizing this process is no longer optional.

Cold chain failures can lead to spoilage, lost revenue, and reputational damage. According to the Food and Agriculture Organization (FAO), around 14% of global food is lost between harvest and retail, a significant portion of which is due to temperature control issues. This has pushed companies to seek smarter, data-driven solutions to enhance cold chain logistics.

Real-Time IoT Monitoring: A Game Changer

Real-time cold chain monitoring solutions are transforming how cold chains are managed. These systems consist of sensors, connectivity modules, and cloud platforms that gather, transmit, and analyze temperature data from every segment of the supply chain.

Data Accuracy and Timely Alerts

IoT sensors are embedded within storage units, vehicles, and containers to continuously track temperature, humidity, and location. The collected data is transmitted to a central dashboard, where stakeholders can monitor real-time conditions. If a deviation occurs, alerts are instantly sent to responsible personnel via SMS, email, or mobile apps.

According to a 2022 report by DHL, companies that implemented real-time IoT monitoring observed up to 40% fewer cold chain breaches compared to those relying on manual or delayed monitoring methods.

Predictive Maintenance and Analytics

Predictive analytics is another strength of IoT solutions. By analyzing historical data patterns, systems can identify potential equipment failures before they occur. This reduces downtime, ensures consistent temperature control, and minimizes losses. An IBM study highlighted that predictive maintenance can reduce maintenance costs by up to 25% and eliminate breakdowns by up to 70%.

End-to-End Visibility

IoT-based platforms offer complete visibility from the point of origin to the final delivery destination. For instance, logistics teams can track a shipment of vaccines from a manufacturing unit in Hyderabad to a hospital in Delhi, monitoring temperature fluctuations at every checkpoint. Such transparency is critical for pharmaceutical compliance and consumer trust.

Industry Applications

Pharmaceuticals

Temperature-sensitive vaccines and medications require strict adherence to cold storage requirements. With real-time IoT monitoring, pharmaceutical companies can meet WHO and FDA regulations more efficiently.

Food and Beverage

FMCG companies use IoT to manage perishables such as dairy, seafood, and meat. Cold storage units, transport vehicles, and retail refrigerators are all interconnected, ensuring that goods remain within optimal temperature ranges throughout their journey.

Agriculture and Floriculture

Fresh produce and flowers demand consistent cooling. Real-time data helps farmers and exporters avoid spoilage, maintain freshness, and improve shelf life. IoT platforms also aid in auditing and certification processes.

Key Metrics That Matter

Temperature Deviation Time: The duration a product remains outside the permissible temperature range.

Time to Respond: How quickly personnel address an alert.

Spoilage Rate: Percentage of products discarded due to temperature failure.

Energy Efficiency: Reduction in energy consumption through intelligent cooling system management.

According to Frost & Sullivan, companies using real-time monitoring solutions reported a 30% improvement in spoilage rates and a 20% increase in energy efficiency over traditional cold chain systems.

Choosing the Right Solution

When investing in real-time IoT monitoring, businesses should evaluate the following criteria:

Sensor Accuracy: Choose sensors with high precision and reliability.

Connectivity: Opt for solutions offering 4G, Wi-Fi, or satellite communication based on your logistics routes.

Cloud Analytics: Ensure the platform offers actionable insights and predictive analytics.

Compliance: Verify adherence to global and national regulations.

Customer Support: Look for vendors with strong local support and SLA guarantees.

Integration with Existing Systems

Modern IoT platforms are designed to integrate seamlessly with existing enterprise systems like WMS (Warehouse Management Systems), ERP (Enterprise Resource Planning), and TMS (Transport Management Systems). This ensures that all stakeholders—from warehouse staff to delivery drivers—have access to real-time insights without switching platforms.

Case Study: Indian Dairy Supply Chain

Amul, one of India’s largest dairy cooperatives, recently integrated IoT monitoring into its cold chain network. By deploying over 10,000 sensors across its storage and transportation units, Amul reported a 35% decrease in spoilage and a 25% reduction in energy bills within a year.

Future Trends

Blockchain Integration: Ensures data immutability and enhances traceability.

AI and Machine Learning: Improves predictive analytics and automated decision-making.

Edge Computing: Allows real-time data processing without reliance on cloud connectivity.

Sustainable Cold Chains: Emphasis on eco-friendly refrigerants and energy-efficient systems.

Conclusion

As the demand for temperature-sensitive goods continues to rise, optimizing your cold chain with real-time IoT monitoring solutions is a strategic imperative. The benefits are measurable: reduced spoilage, regulatory compliance, better energy efficiency, and greater customer trust.

Adopting cold chain IoT solutions, even on a modest scale, provides a competitive edge. Now is the time for Indian businesses to embrace the digital transformation of their cold chains and reap the benefits of precision and predictability.

0 notes

Text

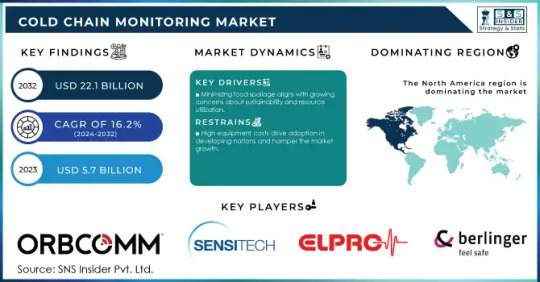

Cold Chain Monitoring Market Analysis: Key Players and Competitive Landscape

Rising Demand for Temperature-Sensitive Logistics Drives Growth in the Cold Chain Monitoring Market.

The Cold Chain Monitoring Market Size was USD 5.7 Billion in 2023 and is expected to reach USD 22.1 Billion by 2032 and grow at a CAGR of 16.2% over the forecast period of 2024-2032.

The Cold Chain Monitoring Market is driven by the increasing need for temperature-sensitive logistics solutions across industries such as pharmaceuticals, food & beverages, and chemicals. Cold chain monitoring systems ensure that perishable goods and temperature-sensitive products maintain their required storage conditions throughout the supply chain. The rising demand for biopharmaceuticals, vaccines, and fresh food products, coupled with stringent regulations on storage and transportation, is fueling the adoption of advanced cold chain monitoring solutions.

Key Players

ORBCOMM (US) – (IoT-based cold chain monitoring solutions, Fleet Management Systems)

Sensitech (US) – (TempTale Data Loggers, Cold Chain Monitoring Software)

Elpro-buchs (Switzerland) – (ELPRO Monitoring Solutions, e-Transcript System)

Berlinger & Co. (Switzerland) – (ThermoTrack Temperature Monitoring, ActiveSense Monitoring System)

Monnit (US) – (Monnit Wireless Sensors, Monnit Cloud Platform)

Controlant (Iceland) – (Controlant Smart Cold Chain, Real-time Monitoring Solutions)

Lineage Logistics Holding – (Cold Storage Solutions, Lineage Link Digital Platform)

Tagbox – (Cold Chain IoT Sensors, Tagbox Data Analytics Platform)

DAIKIN Industries – (Refrigeration Solutions, Remote Monitoring Systems)

Savi Technology – (SaviTrack RFID Solutions, SaviSense Sensor Platform)

Future Scope

The Cold Chain Monitoring Market is set for substantial expansion as supply chain digitization, IoT-based tracking systems, and AI-driven predictive analytics enhance real-time monitoring capabilities. Government regulations and quality control mandates for pharmaceutical and food safety are pushing businesses to integrate automated and cloud-based monitoring systems. Innovations in blockchain technology for supply chain transparency and the integration of smart sensors with predictive maintenance capabilities are expected to revolutionize cold chain management, reducing spoilage and ensuring compliance.

Emerging Trends

The industry is shifting toward real-time and AI-powered cold chain monitoring solutions, ensuring greater accuracy and efficiency in tracking temperature-sensitive shipments. The demand for wireless and cloud-based monitoring systems is rising, offering 24/7 remote access to temperature data and ensuring compliance with regulatory standards. Additionally, blockchain technology is being explored to enhance supply chain transparency and prevent counterfeiting in pharmaceuticals. The rise of automated alert systems, GPS tracking, and energy-efficient refrigeration technologies is also contributing to market growth.

Key Points

Rising demand for temperature-sensitive logistics in pharmaceuticals and food industries.

Increased adoption of IoT, AI, and blockchain for real-time supply chain monitoring.

Stringent regulatory requirements driving investments in advanced cold chain technologies.

Growing use of cloud-based and wireless temperature monitoring systems.

Expansion of automated alert systems and GPS tracking for improved shipment security.

Conclusion

The Cold Chain Monitoring Market is poised for significant growth, fueled by technological advancements, regulatory compliance requirements, and increasing demand for perishable goods logistics. As smart monitoring solutions, blockchain integration, and predictive analytics continue to evolve, the industry is set to enhance supply chain efficiency, reduce product wastage, and ensure the safe delivery of temperature-sensitive goods worldwide.

Read Full Report: https://www.snsinsider.com/reports/cold-chain-monitoring-market-1974

Contact Us:

Jagney Dave — Vice President of Client Engagement

Phone: +1–315 636 4242 (US) | +44- 20 3290 5010 (UK)

#Cold Chain Monitoring Market#Cold Chain Monitoring Market Size#Cold Chain Monitoring Market Share#Cold Chain Monitoring Market Report#Cold Chain Monitoring Market Forecast

0 notes

Text

Cold Chain Monitoring Market was valued at US$ 5.42 Bn in 2023, and is projected to reach US$ 15.52 Bn by 2031, growing at a CAGR of 12.4% from 2024 to 2031.

0 notes

Text

Real-time Monitoring Solutions For Cold Chain Market Outlook, Competitive Strategies And Forecast

The global real-time monitoring solutions for cold chain market size was valued at USD 12,427.8 million in 2023 and is expected to grow at a CAGR of 23.1% from 2024 to 2030. The rising demand for global real-time monitoring solutions in the cold chain market is driven by the need for greater control and efficiency in temperature-sensitive supply chains, particularly in industries such as pharmaceuticals, food and beverages, and chemicals. With stricter regulations on product safety, companies are increasingly adopting these solutions to ensure compliance with international standards.

Additionally, the growing trend of online retail, particularly for groceries and pharmaceuticals, is amplifying the need for precise cold chain management. Companies delivering fresh food, dairy, frozen products, and medicines must guarantee that their goods remain within ideal temperature conditions from dispatch to doorstep. Real-time monitoring solutions allow companies to provide end-to-end visibility into cold chain logistics, helping mitigate the risks of spoilage, reducing waste, and enhancing customer satisfaction through reliable delivery of fresh goods.

The integration of IoT (Internet of Things) devices in cold chain logistics is further driving demand for real-time monitoring solutions. IoT sensors placed within storage units and transport vehicles can continuously track environmental conditions and transmit data in real-time to centralized monitoring platforms. This ensures uninterrupted monitoring and reporting, providing companies with the ability to act immediately if parameters deviate from safe levels. The advent of AI and machine learning is also helping companies predict potential risks in the cold chain, optimize routes, and manage fleet operations more efficiently.

Gather more insights about the market drivers, restrains and growth of the Real-time Monitoring Solutions For Cold Chain Market

Key Real-time Monitoring Solutions for Cold Chain Company Insights

Some of the key companies operating in the market include Carrier (Sensitech), among others.

• Carrier (Sensitech) is a prominent player in real-time monitoring solutions for cold chain logistics, specializing in temperature monitoring and data logging technologies. Sensitech is a subsidiary of Carrier Global Corporation, a leading global provider of heating, ventilation, air conditioning, refrigeration, and fire and security solutions. It offers a range of temperature monitoring solutions designed to ensure the integrity of temperature-sensitive products throughout the cold chain. Their products include data loggers, wireless monitoring systems, and integrated software platforms that provide real-time tracking and data management.

• Accent Advanced Systems, SLU is a technology company specializing in advanced solutions for real-time monitoring in various industries, including cold chain logistics. Their offerings include advanced monitoring systems that track temperature and humidity, utilizing Internet of Things (IoT) technology for seamless data collection and transmission. These solutions provide stakeholders with real-time access to critical environmental data and alerts, supported by analytics software that helps optimize logistics operations and ensure compliance with regulatory standards.

Recent Developments

• In August 2024, Carrier (Sensitech) announced that it had completed the acquisition of Berlinger & Co. AG, a provider of temperature monitoring solutions for the cold chain logistics industry. This strategic acquisition aims to enhance Sensitech's product offerings and strengthen its position in the pharmaceutical and food sectors. This move aligns with Sensitech's commitment to delivering comprehensive solutions that meet the evolving demands of customers in global supply chains.

• In June 2024, ELPRO-BUCHS AG and Cold Chain Technologies announced a partnership to enhance cold chain monitoring solutions. This collaboration aims to integrate ELPRO's advanced temperature monitoring technology with Cold Chain Technologies' logistics expertise. Together, they will provide comprehensive solutions for temperature-sensitive products, ensuring compliance with regulatory standards and maintaining product integrity throughout the supply chain.

Global Real-time Monitoring Solutions For Cold Chain Market Report Segmentation

This report forecasts revenue growth at global, regional, and country levels and provides an analysis of the latest industry trends in each of the sub-segments from 2017 to 2030. For this study, Grand View Research has segmented the global real-time monitoring solutions for cold chain market report based on component, application, and region:

Component Outlook (Revenue, USD Million, 2017 - 2030)

• Hardware

o Sensors

o RFID Devices

o Telematics

o Networking Devices

o Others

• Software

o On-premise

o Cloud

Application Outlook (Revenue, USD Million, 2017 - 2030)

o Food & Beverages

o Pharmaceuticals

o Others

Regional Outlook (Revenue, USD Million, 2017 - 2030)

• North America

o U.S.

o Canada

o Mexico

• Europe

o UK

o Germany

o France

• Asia Pacific

o China

o Japan

o India

o South Korea

o Australia

• Latin America

o Brazil

• Middle East and Africa (MEA)

o KSA

o UAE

o South Africa

Order a free sample PDF of the Real-time Monitoring Solutions For Cold Chain Market Intelligence Study, published by Grand View Research.

#Real-time Monitoring Solutions For Cold Chain Market#Real-time Monitoring Solutions For Cold Chain Market Size#Real-time Monitoring Solutions For Cold Chain Market Share#Real-time Monitoring Solutions For Cold Chain Market Analysis#Real-time Monitoring Solutions For Cold Chain Market Growth

0 notes

Text

Digital data loggers enable real-time tracking and remote temperature monitoring across industries, ensuring accurate data collection and analysis. These devices capture, store, and transfer data like temperature and humidity, providing reliable insights for efficient operations.

HUSE Live also offers advanced Railcar GPS tracking systems, delivering real-time updates, container tracking, and enhanced fleet management for improved logistics and predictive maintenance.

0 notes

Text

5 Key Benefits of Integrating Predictive Maintenance with IoT Technology

Integrating predictive maintenance with IoT technology offers five key benefits: improved equipment efficiency through real-time monitoring, reduced downtime by predicting potential failures, cost savings from optimized maintenance schedules, enhanced safety by preventing unexpected breakdowns, and better decision-making with data-driven insights.

#artificial intelligence#software engineering#gps asset tracking#html#cold chain monitoring#machine learning

0 notes

Text

The cold chain temperature monitoring market plays a pivotal role in ensuring the safety, quality, and efficiency of temperature-sensitive products, such as pharmaceuticals, perishable food, and chemicals. With increasing demand for global trade and a rising focus on consumer health and product quality, the cold chain monitoring industry is experiencing rapid growth. In this article, we explore the factors driving the market, key technologies, industry trends, and the future outlook for cold chain temperature monitoring.

0 notes

Text

How Thingsup Is Reinventing The Cold Chain Monitoring

In today’s fast-paced world, the management of the cold chain has become an integral part of ensuring the quality and safety of perishable goods. Cold chain monitoring involves maintaining a consistent temperature throughout the supply chain to preserve the freshness and extend the shelf life of products. Traditional cold chain monitoring methods, while effective, often suffer from inefficiencies, lack of real-time data, and potential risks of product spoilage. No matter what happens to other companies, Thingsup Track cold chain monitoring reinventing comes with the best innovative ideas and developments. we have helped companies in many different industries conquer capacity constraints, overcome margin pressure, embrace the latest digital technologies, and fully align their supply chain capabilities with their strategic ambition.

Current Process of Cold Chain Monitoring:

The current cold chain monitoring process relies heavily on manual intervention and outdated technologies. Temperature-sensitive products such as pharmaceuticals, fresh produce, and vaccines require meticulous attention to detail during transportation and storage. However, the traditional methods, involving temperature loggers and periodic checks, are not only labor-intensive but also prone to errors and delays in detecting temperature fluctuations. These issues can result in compromised product quality, increased costs, and even regulatory non-compliance.

What You Can Expect from Thingsup Cold Chain Monitoring:

Thingsup is at the forefront of transforming cold chain monitoring through its innovative Internet of Things (IoT) based platform. By harnessing the power of IoT, Thingsup provides real-time tracking, visibility, and actionable insights into the cold chain process, ensuring the highest level of product integrity.

Real-Time Monitoring:

Thingsup’s cutting-edge sensors are strategically placed within the cold chain infrastructure, continuously monitoring temperature, humidity, and other critical parameters. This real-time data is transmitted to a centralized platform, enabling businesses to track the conditions of their products throughout the entire supply chain journey.

2. Asset Monitoring and Fleet Management:

Thingsup goes beyond temperature monitoring, offering comprehensive asset tracking and fleet management capabilities. Businesses can track the exact location and condition of their assets and vehicles in real-time, optimizing routes, ensuring timely deliveries, and improving overall efficiency.

3. History Data Analysis:

Thingsup’s platform also provides historical data analysis, allowing businesses to gain insights into temperature trends and performance over time. This information is invaluable for process optimization and quality assurance.

4. Location Sharing and Time-Bound Geofencing:

The platform enables location sharing and time-bound geofencing, ensuring that assets are within designated areas during specific time windows. This feature enhances security, prevents unauthorized access, and promotes adherence to regulatory requirements.

5. Fuel Monitoring:

For businesses managing a fleet of vehicles, Thingsup’s fuel monitoring feature offers a cost-effective solution to track fuel consumption, optimize routes, and reduce operational expenses.

6.Shipment Management:

With Thingsup, shipment management becomes streamlined and efficient. Businesses can monitor the entire journey of their products, ensuring they reach their destination in optimal condition and within the specified time frame.

Example of Cold Chain Monitoring Solution:

Let’s take a look at how one of a global pharmaceutical company, significantly enhanced their revenue and operational efficiency through the implementation of IoT-based cold chain monitoring solution.

Challenge:

The pharmaceutical company faced challenges in maintaining the required temperature range during the distribution of sensitive medications. Temperature deviations led to product spoilage, regulatory fines, and reputational damage.

Solution:

By integrating IoT sensors and platform, the pharmaceutical company gained real-time visibility into their cold chain. Automated alerts notified them of any temperature fluctuations, enabling swift corrective actions. The predictive analytics feature allowed them to identify potential issues beforehand and prevent spoilage.

Results:

With cold chain monitoring solution in place, the pharmaceutical company achieved a remarkable reduction in product losses due to temperature variations. This not only ensured the safety and efficacy of their medications but also led to improved customer trust. Additionally, the company optimized its distribution routes and storage facilities based on the insights provided by the platform, resulting in reduced operational costs and enhanced revenue.

Conclusion:

In an era where precision, efficiency, and sustainability are paramount, traditional cold chain monitoring methods fall short in meeting the demands of modern businesses. Thingsup’s revolutionary IoT-based platform redefines the cold chain monitoring landscape by offering real-time monitoring, predictive analytics, and actionable insights, along with features such as asset monitoring, fleet management, history data analysis, location sharing, time-bound geofencing, fuel monitoring, and shipment management. The success story of the pharmaceutical company highlights the tangible benefits that Thingsup brings to the table – from safeguarding product quality to optimizing operations and boosting revenue. As more industries recognize the transformative potential of IoT, Thingsup is leading the way in reinventing cold chain monitoring and ensuring the seamless journey of perishable goods from farm to table.

0 notes

Text

Why Your Business Needs a Cold Chain Temperature Monitoring System?

Cold chain temperature monitoring provides end-to-end transparency and helps assure product integrity across storage and distribution. Investing in such systems generates multifaceted operational, financial and reputational benefits for enterprises dealing with perishables. As technology advances, the scope of applications will continue expanding across sectors where product quality is tied closely to temperature.

0 notes

Text

Keeping It Cool: Easy Cold Chain Temperature Monitoring

Ensure the integrity of your products with Cold Chain Temperature Monitoring by Shenzhen Eelink Communication Technology Co. Ltd. Cold chain sensors are vital in a number of industries: Medical – Most recently, vaccines needed to be shipped at extremely low temperatures. Cold chain temperature monitoring devices were placed in each box to ensure the vaccine was never allowed to warm up. Blood and plasma shipments need to be kept at low temperatures so that those vital, life-saving fluids aren’t allowed to spoil.

0 notes

Text

The global cold chain tracking and monitoring market size reached US$ 6.4 Billion in 2023. Looking forward, IMARC Group expects the market to reach US$ 15.4 Billion by 2032, exhibiting a growth rate (CAGR) of 10.07% during 2024-2032.

#Cold Chain Tracking and Monitoring Market#Cold Chain Tracking and Monitoring#Cold Chain Tracking#Cold Chain

0 notes

Text

Cold Chain Tracking & Monitoring Market, To Witness the Highest Growth Globally in Coming Years

The report begins with an overview of the Cold Chain Tracking & Monitoring Market, 2025 Size and presents throughout its development. It provides a comprehensive analysis of all regional and key player segments providing closer insights into current market conditions and future market opportunities, along with drivers, trend segments, consumer behavior, price factors, and market performance and estimates. Forecast market information, SWOT analysis, Cold Chain Tracking & Monitoring Market, scenario, and feasibility study are the important aspects analyzed in this report.

The Cold Chain Tracking & Monitoring Market, is experiencing robust growth driven by the expanding globally. The Cold Chain Tracking & Monitoring Market, is poised for substantial growth as manufacturers across various industries embrace automation to enhance productivity, quality, and agility in their production processes. Cold Chain Tracking & Monitoring Market, leverage robotics, machine vision, and advanced control technologies to streamline assembly tasks, reduce labor costs, and minimize errors. With increasing demand for customized products, shorter product lifecycles, and labor shortages, there is a growing need for flexible and scalable automation solutions. As technology advances and automation becomes more accessible, the adoption of automated assembly systems is expected to accelerate, driving market growth and innovation in manufacturing.

Rising pharmaceutical and healthcare requirements and growing fresh food and perishable goods market will drive the market growth within the forecast period.

Get Sample PDF Report: https://www.fortunebusinessinsights.com/enquiry/request-sample-pdf/109688

Key Strategies

Key strategies in the Cold Chain Tracking & Monitoring Market, revolve around optimizing production efficiency, quality, and flexibility. Integration of advanced robotics and machine vision technologies streamlines assembly processes, reducing cycle times and error rates. Customization options cater to diverse product requirements and manufacturing environments, ensuring solution scalability and adaptability. Collaboration with industry partners and automation experts fosters innovation and addresses evolving customer needs and market trends. Moreover, investment in employee training and skill development facilitates seamless integration and operation of Cold Chain Tracking & Monitoring Market,. By prioritizing these strategies, manufacturers can enhance competitiveness, accelerate time-to-market, and drive sustainable growth in the Cold Chain Tracking & Monitoring Market,.

Major Cold Chain Tracking & Monitoring Market, Manufacturers covered in the market report include:

The report includes the profiles of key players, such as Orbcomm (U.S.), Sensitech Inc. (U.S.), Berlinger & Co. AG (Switzerland), Monnit Corporation (U.S.), Controlant (Iceland), ELPRO-BUCHS AG (Switzerland), Infratab (U.S.), Zest Labs (U.S.), Klinge Corporation (U.S.), Lineage Logistics (U.S.), Copeland (U.S.), and TempSen Electronics (China).

Effective cold chain tracking and monitoring are essential for maintaining the quality and efficacy of temperature-sensitive products, reducing waste and product loss, and meeting regulatory requirements in pharmaceuticals, food, and chemical industries. Rising pharmaceutical and healthcare requirements and growing fresh food and perishable goods market will drive the market growth within the forecast period.

Trends Analysis

The Cold Chain Tracking & Monitoring Market, is experiencing rapid expansion fueled by the manufacturing industry's pursuit of efficiency and productivity gains. Key trends include the adoption of collaborative robotics and advanced automation technologies to streamline assembly processes and reduce labor costs. With the rise of Industry 4.0 initiatives, manufacturers are investing in flexible and scalable Cold Chain Tracking & Monitoring Market, capable of handling diverse product portfolios. Moreover, advancements in machine vision and AI-driven quality control are enhancing production throughput and ensuring product consistency. The emphasis on sustainability and lean manufacturing principles is driving innovation in energy-efficient and eco-friendly Cold Chain Tracking & Monitoring Market, Solutions.

Regions Included in this Cold Chain Tracking & Monitoring Market, Report are as follows:

North America [U.S., Canada, Mexico]

Europe [Germany, UK, France, Italy, Rest of Europe]

Asia-Pacific [China, India, Japan, South Korea, Southeast Asia, Australia, Rest of Asia Pacific]

South America [Brazil, Argentina, Rest of Latin America]

Middle East & Africa [GCC, North Africa, South Africa, Rest of the Middle East and Africa]

Significant Features that are under offering and key highlights of the reports:

- Detailed overview of the Cold Chain Tracking & Monitoring Market,.

- Changing the Cold Chain Tracking & Monitoring Market, dynamics of the industry.

- In-depth market segmentation by Type, Application, etc.

- Historical, current, and projected Cold Chain Tracking & Monitoring Market, size in terms of volume and value.

- Recent industry trends and developments.

- Competitive landscape of the Cold Chain Tracking & Monitoring Market,.

- Strategies of key players and product offerings.

- Potential and niche segments/regions exhibiting promising growth.

Frequently Asked Questions (FAQs):

► What is the current market scenario?

► What was the historical demand scenario, and forecast outlook from 2025 to 2032?

► What are the key market dynamics influencing growth in the Global Cold Chain Tracking & Monitoring Market,?

► Who are the prominent players in the Global Cold Chain Tracking & Monitoring Market,?

► What is the consumer perspective in the Global Cold Chain Tracking & Monitoring Market,?

► What are the key demand-side and supply-side trends in the Global Cold Chain Tracking & Monitoring Market,?

► What are the largest and the fastest-growing geographies?

► Which segment dominated and which segment is expected to grow fastest?

► What was the COVID-19 impact on the Global Cold Chain Tracking & Monitoring Market,?

Table Of Contents:

1 Market Overview

1.1 Cold Chain Tracking & Monitoring Market, Introduction

1.2 Market Analysis by Type

1.3 Market Analysis by Applications

1.4 Market Analysis by Regions

1.4.1 North America (United States, Canada and Mexico)

1.4.1.1 United States Market States and Outlook

1.4.1.2 Canada Market States and Outlook

1.4.1.3 Mexico Market States and Outlook

1.4.2 Europe (Germany, France, UK, Russia and Italy)

1.4.2.1 Germany Market States and Outlook

1.4.2.2 France Market States and Outlook

1.4.2.3 UK Market States and Outlook

1.4.2.4 Russia Market States and Outlook

1.4.2.5 Italy Market States and Outlook

1.4.3 Asia-Pacific (China, Japan, Korea, India and Southeast Asia)

1.4.3.1 China Market States and Outlook

1.4.3.2 Japan Market States and Outlook

1.4.3.3 Korea Market States and Outlook

1.4.3.4 India Market States and Outlook

1.4.3.5 Southeast Asia Market States and Outlook

1.4.4 South America, Middle East and Africa

1.4.4.1 Brazil Market States and Outlook

1.4.4.2 Egypt Market States and Outlook

1.4.4.3 Saudi Arabia Market States and Outlook

1.4.4.4 South Africa Market States and Outlook

1.5 Market Dynamics

1.5.1 Market Opportunities

1.5.2 Market Risk

1.5.3 Market Driving Force

2 Manufacturers Profiles

Continued…

About Us:

Fortune Business Insights™ delivers accurate data and innovative corporate analysis, helping organizations of all sizes make appropriate decisions. We tailor novel solutions for our clients, assisting them to address various challenges distinct to their businesses. Our aim is to empower them with holistic market intelligence, providing a granular overview of the market they are operating in.

Contact Us:

Fortune Business Insights™ Pvt. Ltd.

US:+18339092966

UK: +448085020280

APAC: +91 744 740 1245

0 notes

Text

In sync

Pairing: Jack Abbott x Wife!Reader

Warnings: none

Summary: Two doctors work in perfect sync, sparking curiosity among new interns. After shift, subtle truths begin to surface.

Requests are open | Main Masterlist

[...]

The Pitt was humming with life, chaos, and fluorescent light. It was one of those shifts where no one had time to breathe, much less eat, yet somehow, Dr. Jack Abbot and Dr. Y/N L/N never missed a step.

It wasn’t flashy. It was like muscle memory, the way they moved together. Jack would glance at a monitor, and Y/N would already be adjusting a vent setting. She’d murmur a stat order under her breath, and he’d be handing over the form before she finished.

“Jesus,” Whitaker muttered as he watched them intubate a patient in tandem. “It’s like they’re… psychically linked.”

“Or they have earpieces we can’t see,” Javadi whispered, eyes darting back and forth between the two attendings.

“They don’t even look at each other,” Dr. Santos added. “It’s eerie. What are they? Married or something?”

“Old,” came a voice from behind them. Dr. Robby strolled by with a chart tucked under his arm and a half-grin tugging at the corner of his mouth. “Old and terrifying. You’ll get there in ten years.”

The newbies blinked. Still, none of the new hires knew the real kicker.

Because no one told them.

The nurses, the residents, even the cafeteria staff. They all kept the secret locked tight behind knowing smirks and barely-contained laughter. It was tradition.

And tonight, the setup was perfect.

The shift ended just past 8:00 p.m. The team trickled out to the park across from the hospital. An unofficial post-shift ritual. Six-packs were cracked open, greasy takeout was distributed, and bodies collapsed onto benches and grass with groans of exhaustion.

Jack sat down on the bench beneath the park’s old oak tree. Y/N followed a moment later, plopping down beside him and handing him a cold beer without a word. He took it, nodded once in thanks, and rested his hand casually behind her on the bench’s backrest.

The newbies were huddled together with their drinks, watching the two of them closely.

“She just… handed him a beer. Didn’t even ask.”

“He just leaned closer. Did he smile?”

“Is this… are they…?”

And then, it happened.

Y/N, hair frizzed from the day, leaned her head gently onto Jack’s shoulder. He didn’t flinch or look surprised. He just shifted slightly so she’d be more comfortable, gave her a kiss at the cheek, and took a slow sip of his beer.

Javadi gasped audibly.

Robby was right there. He stood up with theatrical slowness and clinked his bottle against Jack’s with a smirk. “About time. PDA on the first date, huh?”

Jack rolled his eyes, and Y/N chuckled, nudging him with her shoulder.

“Wait, wait, what?” Whitaker sputtered, beer halfway to his mouth. “Are they together?!”

Dr. Santos, three bites into her falafel wrap, didn’t even look up. “Called it”

"We are married" Y/N said with a chuckle

“What?!”

Jack reached into his scrub top and pulled out a thin chain. On it, a modest gold band. Y/N mirrored him, revealing the matching ring around her neck.

The interns looked like they’d just been hit by a trauma case themselves.

“Four and a half years,” Y/N said with a shrug, sipping her beer.

“You knew?” Mel asked Langdon, stunned.

Langdon snorted. “Of course I knew. Everyone knows.”

“Everyone?” Javadi asked, eyes darting around.

A chorus of nods followed

Matteo added “We like to see who figures it out. It’s the only entertainment we get some nights.”

The newbies just sat there, stunned.

Jack and Y/N? Married? The most professional, zero-nonsense duo in the hospital?

Robby smirked at their dumbfounded faces and muttered to Jack, “Still can’t believe she said yes to you, man.”

Jack didn’t respond. He just leaned a little closer to Y/N, who was now resting comfortably against his shoulder, completely at ease.

And in that moment, everything felt exactly where it was supposed to be.

#jack abbot x ofc#jack abbot x you#jack abbot x reader#jack abbott x reader#dr jack abbot#dr jack abbot x reader#jack abbott fanfic#dr. jack abbott#the pitt#the pitt fanfic

1K notes

·

View notes