#Conveyor Automation solutions

Explore tagged Tumblr posts

Text

#Truck loading conveyor system manufacturer#Vertical lift for material handling manufacturer#Flow wrap machine for FMCG packaging manufacturer#Vertical reciprocating conveyor (VRC) manufacturer#Goods lift manufacturer India#Industrial conveyors for packaging lines manufacturer#End-of-line packaging solutions manufacturer#Smart packaging and conveyor integration manufacturer#Heavy-duty goods lifts manufacturer#Automated truck loading and unloading system manufacturer#Conveyor belt manufacturer#Horizontal flow wrap machine India manufacturer#Horizontal packaging machine for high-speed wrapping manufacturer#Industrial palletizing and packaging line manufacturer#Intralogistics solutions manufacturer#Telescopic boom conveyor manufacturer#Telescopic conveyor for truck loading manufacturer#Warehouse automation manufacturer#FMCG packaging machinery manufacturer

0 notes

Text

Truck Loading Conveyor Manufacturers in Faridabad: Leaders in Innovation

Looking for cutting-edge truck loading conveyor solutions? Discover why Faridabad is the heart of conveyor manufacturing in India. Home to industry-leading companies, Faridabad-based manufacturers are known for their technological innovation, customized designs, and cost-effective solutions for modern logistics and warehousing.

From telescopic conveyors to hydraulic truck loaders, these manufacturers are empowering India’s supply chains with faster, safer, and more efficient material handling systems. Whether you're in e-commerce, FMCG, agriculture, or manufacturing, these conveyors are engineered to deliver unmatched performance.

#truck loading conveyor#Faridabad manufacturers#conveyor systems India#telescopic conveyor#hydraulic loading conveyor#material handling India#warehouse automation#belt conveyor#loading solutions India

0 notes

Text

Streamlining Industrial Success With Reliable Spare Parts Supply

The industrial sector relies on the effectiveness of its processes and machinery; hence, spare parts suppliers are the backbone of this success. These suppliers provide key parts that keep production lines rolling without any form of delay. Their main priority is to deliver high-quality parts that meet industrial standards while focusing on timeliness. This way, industries can continue without being interrupted, minimize downtime, and maintain operational integrity. With a well-established network, a Spare Parts Supplier for the Industrial Sector helps to streamline procurement and logistics for industries worldwide.

Their solutions cater to diverse operational challenges, from filtration systems to specialized machinery components. Suppliers are a vital part of operational success, combining experience, efficiency, and technological knowledge. Businesses rely on their expertise to quickly access the right spare parts when needed, empowering industries to thrive even in unforeseen disruptions. Through trusted supply chains and industry partnerships, they provide strategic solutions that sustain industries’ global demand.

#Control and automation systems Offenburg#VBN Hydraulic equipment#Conveyor equipment Offenburg#spare parts Supplier for industrial sector#industrial automation service providers#flexible export solutions offenburg#industrial spare parts

0 notes

Text

How Inventory Shelving Systems and Warehouse Fitting Drive Operational Streamlining

One of the most important objectives for companies that want to keep their competitive edge and satisfy the ever-changing requirements of the market is to streamline their operations and improve the efficiency with which they manage their inventory and warehouses' operations. When it comes to establishing operational excellence, one of the most important factors is the integration of advanced systems for inventory management and warehouse fittings, such as inventory shelving systems. This paper investigates the significance of implementing integrated systems that not only maximize the efficiency of storage solutions but also guarantee that warehouse operations are carried out without any gaps.

A Brief Introduction to Integrated Systems for the Management of Inventory and Warehouse Conditions

The idea of integration is the fundamental component of a strategy for managing inventory and warehouses that is effective and well-organized. The goal of integrated systems is to create a unified platform that consolidates a variety of operational operations, such as managing order fulfillment and shipping, tracking inventory levels, and so on. Through the utilization of technology, these systems guarantee that every component of the warehouse, including inventory storage systems and warehouse fittings, functions in harmony to facilitate the streamlining of operations and the enhancement of production efficiency.

Role of Inventory Shelving Systems

Inventory shelving solutions are critical for maximizing the storage and accessibility of items in a warehouse. These systems are intended to maximize space usage, improve inventory visibility, and provide quick access for picking and stocking processes. Businesses that use adjustable and modular shelf solutions may alter their storage spaces to fit a wide range of product sizes and quantities, saving waste and enhancing overall warehouse management.

The integration of inventory shelving systems with warehouse management software enables real-time inventory level and location tracking. This harmonization ensures that inventory data is constantly current, decreasing errors in order fulfillment and the danger of stockouts or overstocking. Furthermore, by designing shelf systems to be compatible with automated picking solutions, organizations can drastically reduce the time and manpower necessary for inventory management, hence increasing operational efficiency.

Warehouse Fitting for Improved Operations

Warehouse fitting is the strategic design and layout of warehouse areas to improve the flow of goods from reception to shipment. This includes the design of shelving systems, the location of picking and packing stations, and the integration of conveyor belts and other automated systems. The purpose of warehouse fitting is to establish an atmosphere that allows for effective operation processes, shortens handling times, and lowers warehouse personnel migration.

The implementation of integrated systems in warehouse fittings can have a considerable impact on order fulfillment speed and accuracy. For example, a well-designed warehouse plan that incorporates smart shelving solutions and automated conveyor systems can speed up the transportation of items through the warehouse, from storage to the packing room, and finally to the shipping dock. This not only speeds up the order fulfillment process, but also decreases the possibility of errors and damage to items.

The advantages of integration

The integration of inventory storage systems and warehouse fittings into a single management system provides various advantages. These include increased inventory accuracy, more efficient space utilization, lower operational expenses, and more customer satisfaction. By offering real-time visibility into inventory levels and improving the flow of items throughout the warehouse, firms can better satisfy customer requests and adjust to market changes.

Furthermore, integrated systems make data collecting and analysis easier, allowing firms to see patterns, estimate demand, and make informed decisions about inventory purchases and warehouse operations. This data-driven approach to inventory and warehouse management not only boosts operational efficiency, but it also aids strategic planning and corporate expansion.

Challenges and Considerations

Even while it is obvious that integrating inventory systems and warehouse fitting will result in a number of benefits, the implementation of such systems is not without its difficulties. The initial cost of investment, the difficulty of integrating new technologies with current systems, and the requirement to train workers in order to successfully use and maintain the integrated system are some examples of these potential challenges. To guarantee a seamless transition and achieve the highest possible return on investment, businesses need to give serious consideration to the aforementioned aspects and plan their implementation strategy.

The Finalization

When it comes to inventory and warehouse management, it is crucial for firms that want to achieve excellence in inventory and warehouse management to integrate inventory systems and warehouse fittings into a unified management approach. Not only can integrated systems improve operational efficiency, but they also contribute to improved customer satisfaction and corporate growth. This is because integrated systems optimize storage solutions and enhance the efficiency of warehouse operations while simultaneously improving operational efficiency. It is without a doubt that the implementation of integrated systems will become increasingly important for organizations that are striving to preserve their competitiveness in the ever-changing market landscape as technology continues to advance.

#inventory shelving systems#automated shelving systems#custom fitting solutions#shop fitting equipment#merchandising solutions#display shelving systems#shelving systems#warehouse fittings solutions#warehouse fitting manufacturer#retail display manufacturers#warehouse fitting equipment manufacturer#warehouse fitting#shopfitting warehouse shelves#workspace planners#warehouse planners#warehouse management#integrated systems#inventory systems#inventory storage systems#automated conveyor systems

0 notes

Text

Industrial Overload Relays Market Industry Analysis Outlook by 2032

Market Overview:

Intrinsic safety modules are crucial components used in hazardous environments to ensure the safe operation of electronic equipment. These modules are designed to limit electrical energy and prevent the generation of sparks or excessive heat that could ignite flammable gases, vapors, or dust present in the surrounding atmosphere. By employing intrinsic safety modules, industries can reduce the risk of explosions and fires in potentially explosive atmospheres.

Intrinsic safety is a widely adopted protection technique in industries such as oil and gas, petrochemicals, mining, pharmaceuticals, chemicals, and others where flammable substances are present. These modules are typically used with sensors, transmitters, and other electronic devices that need to operate in hazardous locations.

The Global Intrinsic Safety Modules Market size is projected to grow from $2.7 billion in 2021 to a billion by 2028, at a CAGR of 7% 2023-2031.

Industrial Overload Relays: Overview Industrial overload relays are electrical devices used to protect motors and other electrical equipment from damage due to overcurrent conditions. They are an essential component of motor control systems in industrial settings. These relays monitor the current flowing through a motor and can trip the circuit if the current exceeds a predefined threshold, thus preventing overheating and potential damage.

Industry Analysis and Trends:

Industrial Automation: The increasing adoption of industrial automation across various sectors has driven the demand for overload relays. Automation requires efficient motor protection to ensure smooth operation and prevent downtime.

Energy Efficiency: There is a growing emphasis on energy efficiency and reducing operational costs. Modern overload relays often come with features that enable energy monitoring and optimization.

Smart Technologies: The integration of smart technologies, such as IoT and connectivity, into industrial equipment has led to the development of smart overload relays. These relays can provide real-time data, remote monitoring, and predictive maintenance insights.

Safety Regulations: Stringent safety regulations and standards in industrial environments have led to the increased adoption of protective devices like overload relays. Compliance with these regulations is crucial for safe operations.

Miniaturization and Integration: The trend toward miniaturization and integration has led to the development of compact and multifunctional overload relay solutions, saving space and enhancing functionality.

Customization and Flexibility: Industries often have specific requirements for their motor protection needs. Manufacturers are focusing on offering customizable overload relay solutions to cater to various applications.

Global Industrial Growth: As industries continue to grow worldwide, the demand for machinery and equipment, including motors and overload relays, also increases.

Demand and Scope:

The demand for industrial overload relays is closely tied to the overall industrial growth, especially in sectors like manufacturing, oil and gas, utilities, mining, and more. As these industries expand, the need for reliable motor protection solutions becomes more critical. Moreover, the increasing adoption of automation and the integration of advanced technologies further contribute to the demand for modern overload relays.

The scope of the industrial overload relays market extends across various industries and applications, including conveyor systems, pumps, fans, compressors, HVAC systems, and more. As technologies evolve, the scope of overload relays may expand to include smarter and more advanced features, addressing emerging challenges in motor protection and predictive maintenance.

We recommend referring our Stringent datalytics firm, industry publications, and websites that specialize in providing market reports. These sources often offer comprehensive analysis, market trends, growth forecasts, competitive landscape, and other valuable insights into this market.

By visiting our website or contacting us directly, you can explore the availability of specific reports related to this market. These reports often require a purchase or subscription, but we provide comprehensive and in-depth information that can be valuable for businesses, investors, and individuals interested in this market.

“Remember to look for recent reports to ensure you have the most current and relevant information.”

Click Here, To Get Free Sample Report: https://stringentdatalytics.com/sample-request/intrinsic-safety-modules-market/13068/

Market Segmentations:

Global Intrinsic Safety Modules Market: By Company • Eaton • Rockwell Automation • Schneider Electric • Siemens • ABB • Pepperl+ Fuchs • OMEGA • Rotork • IMI Sensors • Extronics Global Intrinsic Safety Modules Market: By Type • Zener Barriers • Isolator Barriers • Converter Barriers Global Intrinsic Safety Modules Market: By Application • Oil and Gas • Mining • Power • Chemicals and Petrochemicals Global Intrinsic Safety Modules Market: Regional Analysis The regional analysis of the global Intrinsic Safety Modules market provides insights into the market's performance across different regions of the world. The analysis is based on recent and future trends and includes market forecast for the prediction period. The countries covered in the regional analysis of the Intrinsic Safety Modules market report are as follows: North America: The North America region includes the U.S., Canada, and Mexico. The U.S. is the largest market for Intrinsic Safety Modules in this region, followed by Canada and Mexico. The market growth in this region is primarily driven by the presence of key market players and the increasing demand for the product. Europe: The Europe region includes Germany, France, U.K., Russia, Italy, Spain, Turkey, Netherlands, Switzerland, Belgium, and Rest of Europe. Germany is the largest market for Intrinsic Safety Modules in this region, followed by the U.K. and France. The market growth in this region is driven by the increasing demand for the product in the automotive and aerospace sectors. Asia-Pacific: The Asia-Pacific region includes Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, China, Japan, India, South Korea, and Rest of Asia-Pacific. China is the largest market for Intrinsic Safety Modules in this region, followed by Japan and India. The market growth in this region is driven by the increasing adoption of the product in various end-use industries, such as automotive, aerospace, and construction. Middle East and Africa: The Middle East and Africa region includes Saudi Arabia, U.A.E, South Africa, Egypt, Israel, and Rest of Middle East and Africa. The market growth in this region is driven by the increasing demand for the product in the aerospace and defense sectors. South America: The South America region includes Argentina, Brazil, and Rest of South America. Brazil is the largest market for Intrinsic Safety Modules in this region, followed by Argentina. The market growth in this region is primarily driven by the increasing demand for the product in the automotive sector.

Click Here, To Purchase Premium Report: https://stringentdatalytics.com/purchase/intrinsic-safety-modules-market/13068/?license=single

Reasons to Purchase Intrinsic Safety Modules Market Report:

• To obtain insights into industry trends and dynamics, including market size, growth rates, and important factors and difficulties. This study offers insightful information on these topics.

• To identify important participants and rivals: This research studies can assist companies in identifying key participants and rivals in their sector, along with their market share, business plans, and strengths and weaknesses.

• To comprehend consumer behaviour: these research studies can offer insightful information about customer behaviour, including preferences, spending patterns, and demographics.

• To assess market opportunities: These research studies can aid companies in assessing market chances, such as prospective new goods or services, fresh markets, and new trends.

In general, market research studies offer companies and organisations useful data that can aid in making decisions and maintaining competitiveness in their industry. They can offer a strong basis for decision-making, strategy formulation, and company planning.

About US:

Stringent Datalytics offers both custom and syndicated market research reports. Custom market research reports are tailored to a specific client's needs and requirements. These reports provide unique insights into a particular industry or market segment and can help businesses make informed decisions about their strategies and operations.

Syndicated market research reports, on the other hand, are pre-existing reports that are available for purchase by multiple clients. These reports are often produced on a regular basis, such as annually or quarterly, and cover a broad range of industries and market segments. Syndicated reports provide clients with insights into industry trends, market sizes, and competitive landscapes. By offering both custom and syndicated reports, Stringent Datalytics can provide clients with a range of market research solutions that can be customized to their specific needs

Contact US:

Stringent Datalytics

Contact No - +1 346 666 6655

Email Id - [email protected]

Web - https://stringentdatalytics.com/

#Industrial Overload Relays#Motor Protection#Overcurrent Protection#Industrial Automation#Energy Efficiency#Smart Technologies#IoT Integration#Predictive Maintenance#Safety Regulations#Miniaturization#Customizable Solutions#Global Industrial Growth#Manufacturing#Oil and Gas#Utilities#Mining#Conveyor Systems#Pumps#Fans#Compressors#HVAC Systems#Market Trends#Demand Analysis#Industry Insights#Industrial Equipment#Motor Control#Electrical Protection.

0 notes

Text

The Role of Relays and Timers in Industrial Automation Systems

In the world of industrial automation, efficiency, safety, and precision are crucial. Among the many components that contribute to a well-functioning automated system, relays and timers play a foundational role. These devices act as control elements that manage the flow of electricity, signal processes, and coordinate timing sequences — ensuring that operations run smoothly and safely.

In this article, we’ll explore how relays and timers work, their types, applications in automation systems, and how high-quality products — like those offered by Enza Electric — can enhance performance and reliability in industrial settings.

What Are Relays?

A relay is an electromechanical or electronic switch used to control a circuit by a separate low-power signal or multiple signals. In industrial automation, relays act as a bridge between the control system and the equipment being operated — allowing machines to be turned on or off automatically.

Types of Relays Commonly Used in Automation:

Electromechanical Relays (EMRs): Use physical moving parts; reliable and easy to maintain.

Solid-State Relays (SSRs): No moving parts; faster switching, longer lifespan, and better for high-speed applications.

Thermal Overload Relays: Protect motors and equipment from overheating.

Control Relays: Designed for controlling multiple contacts simultaneously in automation systems.

What Are Timers?

Timers are devices used to delay or repeat electrical signals at predetermined intervals. They help synchronize tasks, automate sequences, and provide controlled outputs over time — critical for complex industrial processes.

Common Timer Functions:

On-delay and off-delay timing

Interval timing

Cyclic or repeat cycle operation

Flashing and sequencing operations

Types of Timers:

Analog Timers: Manual dial settings, simple and cost-effective.

Digital Timers: Offer precise programming, displays, and flexible timing ranges.

Programmable Timers: Ideal for complex automation routines requiring multiple sequences.

Key Roles in Industrial Automation Systems

1. Process Control and Sequencing

Relays and timers enable automated machines to follow a specific sequence — turning motors, lights, or pumps on and off in a logical order. For example, a conveyor system can use a relay-timer combination to control material flow with millisecond precision.

2. Safety and Protection

Relays protect systems by interrupting circuits in case of faults. Combined with timers, they can ensure delay before activating emergency stop functions, preventing false triggers and increasing worker safety.

3. Load Management

In high-demand industrial environments, relays help manage load distribution by selectively energizing or de-energizing machinery. Timers assist in staggered starts, reducing power surges.

4. Energy Efficiency

By automating start/stop functions and managing operation durations, timers help reduce unnecessary energy use. Relays ensure only the necessary loads are powered, minimizing wastage.

5. System Monitoring and Feedback

In smart automation, relays provide feedback signals to the control system. Timers assist with diagnostics by creating intervals for testing or data collection.

Benefits of Using High-Quality Relays and Timers

Choosing the right components significantly impacts system performance and longevity. Enza Electric’s relays and timers are engineered with:

High durability for tough industrial environments

Precision timing for reliable operation

Easy installation and compact designs

Compliance with international safety and quality standards

By integrating Enza’s low-voltage solutions, businesses in the GCC, MENA, and Africa regions benefit from cost-effective, scalable automation that supports both current needs and future expansion.

Common Applications in Industrial Sectors

Manufacturing Plants: Control of motors, robotic arms, and production lines.

HVAC Systems: Timed control of fans, compressors, and dampers.

Water Treatment Facilities: Sequenced operation of pumps and valves.

Packaging Machinery: Relay and timer-based coordination of packing, sealing, and labeling.

Food and Beverage Industry: Process automation with hygiene-compliant controls.

Final Thoughts

Relays and timers are the silent operators behind the success of industrial automation systems. From process optimization to enhanced safety and energy management, these components are indispensable.

When sourced from a trusted manufacturer like Enza Electric, businesses are not only investing in reliable hardware but also in the longevity, scalability, and safety of their entire operation.

Ready to Power Your Automation?

Explore Enza Electric’s wide range of relays, timers, and other low-voltage switchgear solutions designed to meet the evolving demands of modern industries. Visit www.enzaelectric.com to learn more or request a quote today.

9 notes

·

View notes

Text

Best Namkeen Bhujiya Continuous Fryers Manufacturing Company in India

Gulab Singh and Co is a renowned manufacturer and supplier of Namkeen Bhujiya Continuous Fryers in India, providing efficient frying solutions for the food processing industry. These continuous fryers are widely used for frying traditional snacks like namkeen, bhujiya, sev, and other fried food products in bulk quantities. Uses: Namkeen Bhujiya Continuous Fryers are designed for mass production in the snack industry. They are ideal for frying a wide range of products, including namkeen, potato chips, sev, and other crispy snacks. These fryers are commonly used in commercial kitchens, snack manufacturing units, and large-scale food processing industries to ensure uniform frying with minimal oil usage. Features: High Efficiency: Designed for continuous operation, the fryer ensures high production capacity with uniform frying. Oil Filtration System: Equipped with an advanced oil filtration system, it ensures clean and reusable frying oil, enhancing product quality. Temperature Control: Digital temperature controllers ensure consistent heat levels for precise frying, preventing over or under-cooking. Energy Efficient: The fryers are designed for low energy consumption, ensuring cost-effective production. Durable Construction: Made from high-grade stainless steel, the fryers are resistant to corrosion and built to last, even in demanding industrial environments. Automatic Operation: The automated system allows for continuous frying without manual intervention, ensuring efficiency and uniformity in the process. Safety Features: Over-temperature protection, automatic cut-offs, and easy-to-clean designs ensure both safety and hygiene. Working Principle: The Namkeen Bhujiya Continuous Fryer operates by heating the frying oil to a desired temperature, while snacks are fed into the fryer via a conveyor belt. As the snacks pass through the fryer, they are submerged in hot oil, ensuring uniform cooking. The conveyor system ensures that the snacks are consistently fried as they move through the fryer. An oil filtration system continuously removes debris and maintains the quality of the oil, allowing for extended frying cycles without oil replacement. With Gulab Singh and Co, snack manufacturers benefit from high-quality, efficient fryers designed for bulk production with consistent results. For more information Visit our Website :- https://www.gulabsinghandco.com Contact us :- +91–9953108079, +91–9313119875

#Namkeen Bhujiya Continuous Fryers#Namkeen Bhujiya Continuous Fryers Manufacturer#Namkeen Bhujiya Continuous Fryers Supplier

2 notes

·

View notes

Text

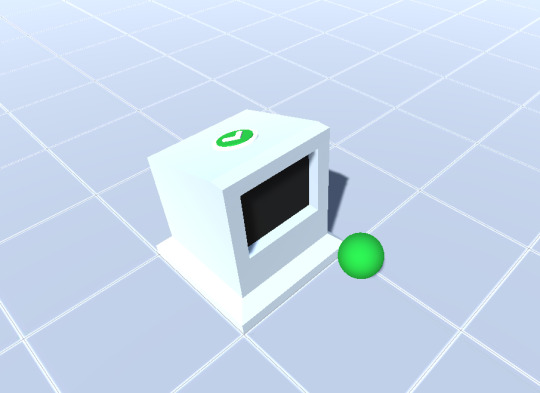

A little output

I spent my lunch programming rather than eating, which is very typical of me when I get deeply involved in a project. I must make sure I don't fall into that obsession trap again, which has caused many burnouts in the past! 😅

My current task was to get the new generation machine to spit items out onto a connected belt. This was mostly straightforward, though it was a little tricky getting my head around supporting rotation.

Ultimately it came down to making things simple. Machines can either have an input or an output, or both. Since the side with which the machine accepts either inputs and outputs is defined at the prefab level (i.e. it's fixed based on what I set the model to), I just had to write some code to shift those input/output 'sides' depending on which of the 4 possible directions the model was placed in.

As far as handling exactly where the machine should look for an input / output belt, I kinda cheated a bit on this one.

The reason this was a little more complex is because machines can have a footprint of more than just 1x1, they can be 2x2 as well. A 2x2 machine will have a inputs / outputs on specific grid positions around its outside perimeter. How do I allow for this whilst enabling rotation of the placed object?

This. This is my cheat.

The little blob in the above image is an object that represents which grid position I want the machine to look for a belt (specifically an output belt). Because this blob is a child object of the machine, when the machine rotates - so the blob does too. At runtime, when I configure the machine, I can simply read the real-world position of the blob to get its grid coordinates. Neat!

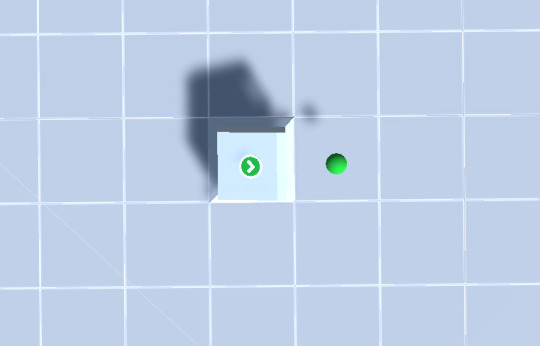

It's easier to see top-down here:

The machine lives at grid position [6,4] and the blob lives inside the machine object at position [1,0]. Translated to absolute world position the blob lives at [7,4] - exactly where I need to be checking for belts!

I'm sure there are much better ways of doing this, but this was a pretty straightforward solution that only requires a tiny amount of preprocessing when the object is first placed, after which no additional calculation is needed.

With the positioning and belt-lookup code added, it was just a case of writing up a short Machine class, from which I derived a special 'InputMachine' class that only spits out items of a specific type.

The result you can see below!

Where is this all leading?

I suppose it's a good a time as any to review my future plans for these developments. What good are little prototypes without some larger goal in mind?

In one of my earliest posts I details the kind of game I'm hoping to make. Mechanically it's not super complicated, but it required figuring out some of the technical stuff I've been showing in recent posts - namely conveyor belts and moving items around.

I'm hoping to create a game that fits in the automation / factory genre. You'll be playing the role of someone setting up an automated factory that has been deposited and unpacked on a remote asteroid. You place down drills (inputs) that dig and spit out raw materials into your factory, and you move these around and process them in various machines in the name of science!

As I said this isn't the most complex of concepts. From a programming complexity point of view some of the legwork has already done (problem solving belts, specifically). There are areas that still need consideration, but looking over what's left to come I'm quietly confident it falls within my skill set to execute.

A cut down the middle

I expect anybody familiar with game development is aware of the term 'vertical slice'. It refers to the practice of developing a small segment of a product, but to a very polished state that could be considered represetative of its final form.

You see this a lot in game development. Particularly at conferences and exhibitions where publishers want to whip up excitement about games that could be years away from release. But there should be some delineation between a vertical slice for a trailer, and a playable vertical slice. I'm aiming for the latter.

In order to decide how to put something like that together, I need a broader understanding of the scope of the game. A vertical slice should demonstrate all the key concepts in the game, but leaving room to expand those ideas later without changing the core experience too much. It doesn't have to look like the final game either, though I would like to put some effort in there where possible.

I'll probably end this post here for now, but I'll probably detail out the main efforts I'm likely to be aiming for in order to reach this vertical slice. I will, of course, continue posting updates when I can with more details about the game's development.

And if you read this far and found some small measure of interest in here, thanks for your time and have yourself a great day! 😊

5 notes

·

View notes

Text

Uses and Advantages of Chain Conveyor

A chain conveyor is a mechanical system designed for automated material handling in industrial settings. It consists of interconnected chains running on sprockets, facilitating the continuous and reliable movement of goods or materials. Widely used in manufacturing and distribution, these conveyors are known for their durability, versatility, and ability to handle heavy loads. They offer customization options, reducing manual labor, minimizing downtime, and optimizing material flow, thereby enhancing overall operational efficiency in various industries.

Uses of Chain Conveyors:

Material Handling in Manufacturing: Chain conveyors play a pivotal role in manufacturing processes by efficiently transporting raw materials, components, and finished products from one point to another. They ensure a smooth flow of materials, reducing manual handling and enhancing overall production efficiency.

Automated Assembly Lines: In industries where precision and speed are paramount, chain conveyors are employed to facilitate the movement of products along assembly lines. This helps streamline the production process, allowing for consistent and timely assembly of intricate components.

Distribution and Warehousing: The logistics and distribution sector heavily relies on chain conveyors to handle the seamless movement of packages and goods within warehouses. These systems can be customized to suit the specific needs of different industries, enabling efficient order fulfillment and timely dispatch of products.

Automotive Industry: In the automotive sector, where precision and efficiency are crucial, chain conveyors are used for transporting vehicle parts during the manufacturing process. This ensures a continuous and reliable flow of components, contributing to the overall productivity of the assembly line.

Advantages of Chain Conveyors:

Reliability and Durability: Chain conveyors are known for their robust construction, making them highly reliable in demanding industrial environments. The durable chains and sprockets used in these systems contribute to their long lifespan and minimal maintenance requirements.

Versatility: Chain conveyors are incredibly versatile and can be adapted to suit a wide range of applications. They can handle various types of materials, including bulk items, heavy loads, and irregularly shaped products, making them suitable for diverse industries.

Customization Options: These conveyors offer extensive customization options, allowing businesses to tailor the system to their specific needs. Whether it’s the size, speed, or configuration, chain conveyors can be designed to optimize the workflow within a particular facility.

Efficient Material Flow: The continuous and automated nature of chain conveyors ensures a smooth and efficient flow of materials. This not only reduces the risk of bottlenecks but also enhances overall productivity by minimizing downtime and optimizing resource utilization.

Cost-Effective Solution: Chain conveyors are a cost-effective solution for material handling, especially when compared to alternative methods like manual labor or other conveyor systems. The initial investment is often offset by the long-term savings in labor costs and increased operational efficiency.

Conclusion:

In conclusion, chain conveyors have become indispensable in modern industries, offering a reliable and efficient solution for material handling. Their versatility, durability, and customizable features make them a preferred choice for businesses aiming to enhance their production processes and streamline logistics. As industries continue to evolve, chain conveyors will undoubtedly play a vital role in shaping the future of automated material handling systems.

#chain conveyor#chain conveyor manufacturer#chain conveyor system manufacturer#chain conveyor system supplier#chain conveyor supplier in India#chain conveyor manufacturer in India

2 notes

·

View notes

Text

#Truck loading conveyor system manufacturer#Vertical lift for material handling manufacturer#Flow wrap machine for FMCG packaging manufacturer#Vertical reciprocating conveyor (VRC) manufacturer#Goods lift manufacturer India#Industrial conveyors for packaging lines manufacturer#End-of-line packaging solutions manufacturer#Smart packaging and conveyor integration manufacturer#Heavy-duty goods lifts manufacturer#Automated truck loading and unloading system manufacturer#Conveyor belt manufacturer#Horizontal flow wrap machine India manufacturer#Horizontal packaging machine for high-speed wrapping manufacturer#Industrial palletizing and packaging line manufacturer#Intralogistics solutions manufacturer#Telescopic boom conveyor manufacturer#Telescopic conveyor for truck loading manufacturer#Warehouse automation manufacturer#FMCG packaging machinery manufacturer

0 notes

Text

''Understanding Their Key Functions"

Introduction

Small gear motors are essential components used in various industries and applications. These compact devices play a crucial role in converting electrical energy into mechanical power, enabling precise and controlled motion. In this blog, we will explore the primary function of small gear motors and their significance in modern-day technology.

Function of Small Gear Motors

Power Transmission: The primary function of small gear motors is to transmit power from the input source (typically an electric motor) to the output shaft. The motor generates rotational energy, which is then transmitted to the gear assembly. The gears inside the motor are designed to mesh with each other, creating a mechanical advantage that enables the motor to deliver higher torque at reduced rotational speeds. This power transmission allows small gear motors to efficiently drive various mechanisms and devices.

Speed Reduction: Another critical function of small gear motors is speed reduction. By using gears with different numbers of teeth, the rotational speed of the output shaft can be reduced relative to the input shaft speed. This feature is particularly useful in applications that require slower, controlled movements, such as robotics, automated systems, and precise machinery.

Torque Amplification: Gear motors are also known for their ability to amplify torque. The gear assembly increases the torque output, making it easier for the motor to overcome resistance or load in the system. This torque amplification ensures that the motor can perform tasks that would be challenging or impossible with a direct drive system.

Directional Control: Small gear motors offer precise directional control. By reversing the rotation of the input motor or changing the gear arrangement, the output shaft can rotate in the opposite direction. This capability is crucial in applications where bidirectional motion is required, like in the operation of conveyor belts, valves, and actuators.

Compact Size and Efficiency: The compact size of small gear motors makes them ideal for applications with limited space. Their efficiency in converting electrical energy into mechanical power also contributes to their widespread use. They can achieve efficiency levels of 70-90%, making them highly energy-efficient solutions.

Conclusion

In conclusion, small gear motors play a pivotal role in modern engineering and technology. Their primary functions include power transmission, speed reduction, torque amplification, directional control, and efficiency. As these devices continue to evolve and improve, we can expect them to remain a key component in various industries, ranging from robotics and automation to automotive and aerospace.

2 notes

·

View notes

Text

Industrial Spare Parts Suppliers In Germany

VBN Vertriebs GmbH is one of the leading industrial spare parts suppliers in Germany, offering an extensive range of components to meet the needs of various industries. Our parts are sourced from reputable manufacturers, ensuring you receive high-quality and durable products. With quick delivery and exceptional customer service, we help keep your operations running smoothly. Visit our website today to explore our inventory and place your order.

#industrial spare parts suppliers#spare parts supplying company#Electric motors Offenburg#VBN Conveyor equipment#SEW Geared motor Offenburg#automation solutions Offenburg#tailor-made sensors solutions Offenburg

0 notes

Text

What are the latest warehouse automation technologies?

Gone are the days of manual labour and static, inefficient operations. Today, we stand at the forefront of a revolution driven by the latest warehouse automation technologies. These innovations reshape how businesses handle inventory, fulfil orders, and optimize supply chains.

From autonomous robots and artificial intelligence to the Internet of Things (IoT) and advanced data analytics, we'll explore how these technologies enhance efficiency, reduce costs, and ensure seamless operations in modern warehouses.

1-Robotic Process Automation (RPA): RPA involves using software robots to automate repetitive tasks like data entry, order processing, and inventory tracking. The robots interact with various systems and applications to streamline workflows.

2-Autonomous Mobile Robots (AMRs): Robotic vehicles called AMRs navigate and operate in warehouses without fixed infrastructure, such as conveyor belts or tracks. They perform tasks like picking, packing, and transporting goods.

3-Automated Guided Vehicles (AGVs): AGVs are similar to AMRs but typically follow fixed paths or routes guided by physical markers or magnetic tape. They are commonly used for material transport in warehouses and distribution centres.

4-Goods-to-Person Systems: This approach involves bringing the items to the workers rather than having workers travel throughout the warehouse to pick items. Automated systems retrieve and deliver goods to a workstation, reducing walking time and improving efficiency.

5-Automated Storage and Retrieval Systems (AS/RS): AS/RS systems use robotics to store and retrieve items from racks or shelves automatically. These systems can significantly increase storage density and optimize space utilization.

6-Collaborative Robots (Cobots): Cobots are designed to work alongside human workers. They can assist with tasks like picking, packing and sorting, enhancing efficiency and safety.

7-Warehouse Management Systems (WMS): While not a physical automation technology, modern WMS software uses advanced algorithms and AI to optimize inventory management, order fulfilment, and warehouse processes.

8-Vision Systems and Machine Learning: Computer vision technology combined with machine learning can be utilized for tasks such as object recognition, inventory movement tracking, and quality control.

9-IoT and Sensor Networks: Internet of Things (IoT) devices and sensors collect real-time data on inventory levels, environmental conditions, equipment health, and more, enabling better decision-making and predictive maintenance.

10-Voice and Wearable Technologies: Wearable devices and voice-guided picking systems can provide workers with real-time information and instructions, improving accuracy and efficiency.11-Automated Packaging Solutions: These systems automate the packaging process by selecting the appropriate box size, sealing packages, and applying labels, reducing manual labour and ensuring consistent packaging quality.

1 note

·

View note

Text

Precision in Every Mix: The Power of Automatic Batching Systems

In the realm of industrial processing—whether in food production, pharmaceuticals, construction, or chemical manufacturing—precision isn't just a goal, it's a necessity. The automatic batching system (ABS) has emerged as a key innovation in achieving this precision, offering automated control of ingredient measurement, mixing, and record-keeping. By minimizing human error and increasing consistency, these systems are transforming how products are made around the globe.Get more news about automatic batching system,you can vist our website!

What Is an Automatic Batching System?

An automatic batching system is a computerized solution that automates the weighing and distribution of raw materials in specified proportions. These materials might include powders, granules, liquids, or gases depending on the industry. At its core, the system controls the sequence, quantity, and timing of material input to ensure a repeatable, high-quality output—be it concrete, dough, fertilizer, or medication.

The system typically integrates load cells, storage hoppers, conveyors, mixers, and programmable logic controllers (PLCs) to execute commands and monitor performance in real time.

Key Benefits Across Industries

The advantages of using an automatic batching system are multifold:

Improved Accuracy: Automated weighing and dosing eliminates the inconsistencies of manual measurement, ensuring consistent product quality.

Time Efficiency: Automated sequencing accelerates batch cycles, optimizing production time without compromising precision.

Data Traceability: Built-in software records every batch’s recipe and performance metrics, useful for quality control and regulatory compliance.

Reduced Waste: Efficient resource management minimizes overuse or spillage of costly materials.

Labor Savings: Automation reduces the need for manual oversight, allowing staff to focus on higher-value tasks.

In industries like food processing, this technology ensures that every loaf of bread or bottle of sauce meets exact taste and texture standards. In pharmaceuticals, strict compliance with ingredient ratios is critical to ensure drug safety. Meanwhile, the construction sector uses these systems to achieve precise mixtures of concrete or asphalt, essential for structural integrity.

Components and Workflow

A typical ABS begins with material identification—receiving commands either from a central SCADA system or manually selected recipes. The system then activates feeders or valves that dispense the correct quantity of each component into a scale or mixer. Once batched, the mixture is delivered to the next processing stage.

Safety protocols such as alarms, interlocks, and emergency stop mechanisms are standard to prevent overloads, cross-contamination, or mechanical faults.

Digital Integration and Innovation

Modern automatic batching systems increasingly leverage IoT (Internet of Things) and cloud technologies. Operators can remotely monitor batching status, adjust parameters, or receive alerts about anomalies. Some advanced setups include predictive maintenance capabilities powered by AI, which minimize downtime by identifying wear and tear before failure occurs.

Additionally, multilingual interfaces, recipe libraries, and batch comparison tools are making the systems more user-friendly and globally adaptable.

Outlook and Applications

As sustainability and production transparency become more important, automatic batching systems will play a pivotal role in helping manufacturers reduce energy consumption and optimize resource utilization. Their ability to ensure repeatable results while minimizing human error makes them indispensable in industries striving for consistent output and rigorous quality standards.

With global competition intensifying and regulations tightening, the implementation of automatic batching systems is no longer a luxury—it’s a strategic imperative.

Conclusion

In essence, automatic batching systems are the quiet drivers of precision manufacturing. They bridge the gap between raw material handling and finished product excellence. As industries evolve and demand greater efficiency, ABS technology will continue to provide the foundation for smarter, faster, and more sustainable production.

0 notes

Text

Choosing the Right Pallet Conveyor Manufacturer: Key Factors to Consider

In the world of material handling and logistics, pallet conveyors play a critical role in streamlining operations, improving safety, and boosting efficiency. Whether you're managing a warehouse, distribution center, or manufacturing facility, choosing the right pallet conveyor manufacturer can significantly impact your productivity and ROI.

Here’s what you need to know when selecting a reliable manufacturer for pallet conveyor systems.

Why Pallet Conveyors Matter

Pallet conveyors are designed to transport heavy loads—typically pallets of goods—smoothly across production lines or storage areas. They are widely used in industries like:

Warehousing and logistics

Food and beverage

Pharmaceuticals

Automotive

FMCG and more

By automating material movement, these systems reduce manual handling, enhance safety, and ensure consistent workflow.

What to Look for in a Pallet Conveyor Manufacturer

1. Industry Experience and Expertise

Choose a manufacturer with a strong track record in designing and installing pallet conveyor systems. Years of experience often translate to better product knowledge, problem-solving capabilities, and tailored solutions.

2. Customization Capabilities

No two facilities are the same. A good manufacturer will offer custom conveyor solutions that fit your unique space, load requirements, and workflow.

Ask about:

System layout design

Weight/load capacity

Automation and integration options

Conveyor length and material type

3. Quality of Materials and Engineering

Durability is key. Ensure the manufacturer uses high-grade steel, rollers, motors, and controls that comply with international standards. The build quality will determine the longevity and maintenance needs of your conveyor system.

4. After-Sales Support & Maintenance Services

A good conveyor system is only as good as the support that comes with it. Check if the manufacturer offers:

Installation support

Staff training

Regular maintenance plans

Spare parts availability

Emergency response time

5. Technology Integration

Modern pallet conveyors often come with smart features like:

IoT-enabled tracking

Automated sensors

Integration with warehouse management systems (WMS)

Partner with a manufacturer who stays ahead of the tech curve.

Benefits of Working with a Trusted Manufacturer

Improved workflow efficiency

Reduced downtime and labor costs

Enhanced workplace safety

Scalable systems for future growth

Compliance with industry regulations

Final Thoughts

Investing in a pallet conveyor is a long-term decision. Take the time to research and compare different manufacturers. Look for one that not only delivers high-quality products but also becomes a strategic partner in your material handling journey.

Are you searching for a reliable pallet conveyor manufacturer in the UK or globally? Choose a company that combines engineering excellence with customer-focused service.

0 notes

Text

How to Choose the Right Water Bottle Filling Machine for Your Business

The selection of an ideal water bottle filling machine is the most critical decision to be made by any business involved in beverage manufacturing, especially mineral water and bottled water. It truly depends on the ideal equipment one selects for production, efficiency, quality, and even profitability.

This comprehensive guide will take you through understanding how to choose the water bottle filling machine that suits your business, including the major factors and the sophisticated solutions that Aim Technologies provide.

Understanding the Importance of a Water Bottle Filling Machine

The water bottle filling machine is a very crucial apparatus in the water bottling plant. It fills bottles with water, automating the process with utmost hygiene, speed, and accuracy. Any small mineral water filling plant or large water bottling plant preferring to see its production line streamlined and to look into good standards would probably prefer having the right water filling machine.

Also, to know more about water filling machine specifications, read our blog on: Cost vs ROI: Is a Water Bottle Filling Machine Worth the Investment?.

Key Factors to Consider When Choosing a Water Bottle Filling Machine

1. Type of Bottles and Production Capacity

The first step is to evaluate the types of bottles you plan to fill-plastic, glass, or PET and their sizes. Different machines are designed to handle specific bottle materials and sizes. Additionally, consider your production capacity requirements. Machines vary from semi-automatic to fully automatic systems, capable of filling anywhere from a few hundred to several thousand bottles per hour.

2. Production Speed & Bottle Size

Machines are differentiated in speed::

40 BPM Water Filling Machine: ideal for the small setups; 200-2,000 ml bottles.

60 BPM Water Bottle Filling Machine: suited for the mid-sized plants, with demo videos testifying to its performance.

120 BPM & 200 BPM Filling Machines: built for high-volume, fully automatic plants.

It all depends on your anticipated demand and bottle formats.

3. Automation Level

Automating processes work towards fostering consistency and reducing labor costs. Aim Technologies offers various options ranging from semi-automatic to fully automatic Water Filling Machines that entail:

Mono-block rotary systems

Non-contact sensors

In-feed/out-feed conveyors

Cap feeders with 3,000-4,500 cap capacity

The systems assure "no bottle, no rinse, no fill, no cap," thereby enhancing safety and efficiency.

4. Hygienic Design & Material

For beverage safety, stainless steel contact parts are preferable (SS316L/SS304). Aim's machines have rotary filling valves, rinsing nozzles, and capping heads made from those materials essential in Water Bottling Plant operations.

5. Ancillary Systems & Turnkey Setup

A Water Bottling Plant includes:

RO plant & Mineral Water Plant for purification

Bottle rinsing, filling & capping unit

Labeling and shrink-wrapping systems

Bottle blowing machine (for PET bottles)

Aim Technologies supports full turnkey installations.

6. Budget & ROI Considerations

High-speed models (120/200 BPM) could cost more up front but promise faster returns from increased throughput. On the other hand, a Mineral Water Filling Machine at 40-60 BPM might just be in the realm of possibilities for a startup. Our turnkey and modular options provide flexibility by production stage and budget.

Get in touch with us today to find the right Water Filling Machine solution for your business.

7. Future Growth & Scalability

Select systems capable of upscaling: Aim's modular plants, together with their Water Bottling Plant equipment range, would allow you to quickly increase capacity from entry-level to industrial scale.

Why Choose Aim Technologies?

Aim Technologies deals with Water Bottle Filling Machine, Mineral Water Filling Machine, Water Bottling Plant, and Water Filling Machine systems. Since 2011, they have supplied dependable machines made of stainless steel with full-service support. Their range of products include:

40 BPM, 60 BPM automated fillers

120 BPM, 200 BPM high-speed rotary systems

Purification plants (RO/Mineral Water Plant)

Ancillary equipment: labeling, shrink-wrapping, pet blowing

Final Thoughts: Invest Wisely for Long-Term Bottling Success

A Water Bottle Filling Machine is not generally chosen by subjective whims or present needs in the sense that it breeds growth, efficiency, and profitability for the business. Aim Technologies offers a broad selection of filling machines in conjunction with complete purification systems tapping turnkey solutions, enabling the user to start with small capacity and expand easily.

Being a partner who guarantees through expert support, high-quality machinery, and commitment to its Customer Success, it is the right option of choice in the bottling industry. Be it a Mineral Water Filling Machine, a Water Bottling Plant, or an advanced Water Filling Machine; we have just exactly what you are looking for to better place you to realize your goals. Choosing a partner that grows with your business is just the smart choice to make today.

#Water Bottle Filling Machine#Mineral Water Filling Machine#Water Filling Machine#Water Bottling Plant

0 notes