#HASTELLOY C22 BUTTWELD FITTINGS

Text

What is the use of Hastelloy c22 Buttweld Fittings in Aerospace industry?

The aerospace enterprise soars at the wings of innovation, pushing the bounds of what is viable. From conquering the skies to venturing past our surroundings, success hinges on sturdy materials that could resist excessive situations. Enter Hastelloy c22 buttweld fittings suppliers in India, a nickel-chromium-molybdenum alloy that rises to the project. But its electricity isn't always restricted to the material itself – the fittings that be part of Hastelloy C22 pipes play a crucial function in making sure the integrity of those excessive-ordinary performance systems. Here, we delve into the area of Hastelloy c22 fittings, Hastelloy C22 buttweld fittings, exploring their crucial packages inside the aerospace business enterprise and why MV Super Alloys is your relied on organization in India.

Hastelloy C22: A Champion in Demanding Environments

Hastelloy C22 is renowned for its splendid resistance to a multitude of worrying conditions, consisting of:

High Temperatures: Aerospace programs regularly comprise extreme warmness, and Hastelloy C22 remains unflinching, keeping its structural integrity even at advanced temperatures.

Corrosion: Exposure to harsh chemical substances and fuels is a truth in aerospace structures. Hastelloy C22's extraordinary corrosion resistance safeguards against the ones threats.

Oxidation: High-temperature environments can result in oxidation, however Hastelloy C22 stands for company, resisting this terrible way.

Stress: Aerospace additives go through notable pressure, and hastelloy c22 buttweld fittings own the electricity to cope with the ones stressful hundreds.

These incredible houses make Hastelloy C22 the tremendous choice for numerous aerospace applications, which includes:

Engine Components: From exhaust manifolds and afterburners to warm temperature exchangers and bleed air structures, Hastelloy C22 ensures reliable everyday normal universal overall performance beneath immoderate warmth and strain.

Fuel Systems: Piping systems for transporting corrosive fuels and propellants revel in the amazing corrosion resistance of Hastelloy C22.

Landing Gear: Exposed to an mixture of harsh climate conditions and notable weight, Hastelloy C22 components make a contribution to the sturdiness of landing gadgets.

Auxiliary Power Units (APUs): These crucial structures require dependable materials, and Hastelloy C22's energy and corrosion resistance make it the suitable desire for APU components.

The Unsung Heroes: Hastelloy C22 Buttweld Fittings

While Hastelloy C22 itself is a splendid cloth, its real strength in aerospace packages is further amplified through the usage of Hastelloy C22 buttweld fittings. These everlasting fittings, moreover known as socket-welded fittings, create a strong and leak-evidence connection among Hastelloy C22 pipes. Let's discover why they will be critical for aerospace piping structures:

Permanent Bond: The welding manner creates a continuing and inseparable joint, removing the danger of leaks in excessive-strain and excessive-temperature environments.

Unshakeable Strength: The welded connection paperwork an exceptionally robust bond, making sure the piping device can resist the annoying situations internal and aircraft.

Space Optimization: The compact layout of buttweld fittings reduces the overall footprint of the piping device, a precious gain in region-restricted plane environments.

Your Trusted Partner for Hastelloy C22 Buttweld Fittings in India

As a primary provider of Hastelloy C22 buttweld fittings in India, we are committed to imparting the aerospace company agency with the very splendid first-class substances.

Here's what units us aside:

Extensive Inventory: We hold a massive stock of Hastelloy C22 buttweld fittings in diverse sizes, wall thicknesses, and strain ratings to satisfy your unique aerospace mission requirements.

Quality Assurance: We supply our Hastelloy C22 from expert manufacturers and cling to rigorous remarkable manipulation methods, ensuring you obtain certified and reliable fittings.

Technical Expertise: Our institution of skilled professionals possesses in-intensity knowledge of Hastelloy C22 and aerospace programs. We can guide you in choosing the right fittings for your assignment's particular desires.

On-Time Delivery: We recognize the importance of properly timed venture final touch. We prioritize inexperienced logistics to make certain your Hastelloy C22 buttweld fittings arrive on time.

Beyond Products: Supporting Aerospace Innovation

We bear in mind to foster prolonged-time-duration partnerships with our clients inside the aerospace business company employer. We provide more than simply merchandise; we offer a self-discipline on your achievement:

Compliance Support: We assist you with navigating applicable aerospace agency necessities and rules related to material desire.

Custom Solutions: For unique challenge necessities, we're capable of discover custom-made Hastelloy C22 buttweld fittings

Fueling Innovation: Partner with us for Your Hastelloy C22 Buttweld Fitting Needs

MV Super Alloys is your one-prevent hold for top notch Hastelloy C22 buttweld fittings in India. Contact us nowadays for a quote and experience the distinction of walking with a dependable company committed to supporting your aerospace responsibilities.

1. Download a Resource:

Taking Flight with Confidence: Download Our Guide to Selecting Hastelloy C22 Buttweld Fittings for Aerospace Applications

To make certain crucial traditional general performance and protection on your aerospace tasks, we deliver a loose downloadable guide on deciding on the right Hastelloy C22 buttweld fittings. Download your replica in recent times and take flight with self notion!

2. Explore Our Products:

Explore the Full Range of Hastelloy C22 Products at MV Super Alloys

Beyond buttweld fittings, we offer a complete desire of Hastelloy C22 merchandise for the aerospace business enterprise. Visit our internet internet web page to discover our whole style of offerings and find out how we will boom your tasks.

3. Connect with Our Experts:

Ready to Take Your Aerospace Project to New Heights? Connect with Our Hastelloy C22 Experts

Our group of skilled experts is devoted to providing you with expert recommendation and assistance. Connect with us nowadays to talk about your particular necessities and discover the proper Hastelloy C22 buttweld fittings for your aerospace utility.

#hastelloy c22 buttweld fittings suppliers in india#hastelloy c22 fittings#hastelloy c22 buttweld fittings

0 notes

Text

Hastelloy C22 Pipe Fittings Manufacturers In India

Hastelloy C22 is a versatile nickel-chromium-molybdenum-tungsten alloy known for its exceptional resistance to a wide range of corrosive environments, including pitting, crevice corrosion, and stress corrosion cracking. This alloy is particularly suitable for chemical processing, pollution control, and waste treatment applications. Hastelloy C22 pipe fittings are vital components in various industries requiring high corrosion resistance and reliability. This article explores the manufacturing process of Hastelloy C22 pipe fittings, current trends, their impact on industries, applications, future prospects, and recommendations for top manufacturers in India.

Background Process of Hastelloy C22 Pipe Fittings

The production of Hastelloy C22 pipe fittings involves several meticulous steps to ensure their quality and performance. The process begins with the selection of high-purity raw materials, followed by melting and alloying to achieve the desired composition. The alloy is then cast and forged into various pipe fitting shapes, such as elbows, tees, reducers, and flanges. Heat treatment is applied to enhance the mechanical properties and corrosion resistance of the fittings. Precision machining ensures the fittings meet the required dimensions and surface finish. Finally, rigorous testing and inspection are conducted to ensure compliance with stringent industry standards.

Current Trends in Hastelloy C22 Pipe Fittings

The demand for Hastelloy C22 pipe fittings is increasing due to their superior performance in highly corrosive environments. Industries such as chemical processing, pharmaceuticals, and pollution control are adopting these fittings for critical applications. The trend towards sustainability and cost efficiency is driving the use of Hastelloy C22, as it offers a longer service life and reduced maintenance costs. Additionally, advancements in manufacturing technologies are improving the quality and affordability of these fittings, making them more accessible to various industries.

Suggestions for Major Industries

For industries seeking reliable and durable piping solutions, Hastelloy C22 pipe fittings are an excellent choice. The chemical processing industry can benefit from their resistance to a wide range of corrosive chemicals, ensuring safe and long-lasting performance. In the pharmaceutical sector, these fittings provide exceptional resistance to various acids and solvents, crucial for maintaining the integrity of production processes. Pollution control and waste treatment applications also benefit from the excellent corrosion resistance and durability of Hastelloy C22.

Impacts on Industry Due to Hastelloy C22 Pipe Fittings

The widespread use of Hastelloy C22 pipe fittings has significantly impacted various industries by enhancing the reliability and longevity of piping systems. These fittings have reduced the frequency of maintenance and downtime, leading to increased operational efficiency and cost savings. Their superior properties also enable more innovative and flexible design solutions, allowing industries to address complex challenges and improve overall competitiveness.

Applications and Future Prospect

Hastelloy C22 pipe fittings find applications in numerous sectors, including:

Chemical Processing: Used in reactors, heat exchangers, and piping systems handling highly corrosive substances.

Pharmaceuticals: Employed in production processes involving aggressive chemicals and solvents.

Pollution Control: Applied in systems designed for pollution control and waste treatment.

Marine Engineering: Utilized in seawater handling systems and marine structures.

Food and Beverage: Suitable for applications requiring high corrosion resistance to maintain product purity.

Looking ahead, the future prospect for Hastelloy C22 pipe fittings is promising. Continuous advancements in material science and manufacturing techniques will further enhance their performance and cost-efficiency. As industries continue to seek high-performance materials for critical applications, the demand for Hastelloy C22 is expected to grow.

Conclusion

In summary, Hastelloy C22 pipe fittings are crucial components in various highly corrosive environments. Their exceptional properties and durability make them a preferred choice for industries aiming to enhance operational efficiency and reduce maintenance costs. For reliable and high-quality Hastelloy C22 pipe fittings, we recommend Manilaxmi Industrial. For more information, you can reach them at:

Manilaxmi Industrial

Email: [email protected]

Phone: +91-7710800415

Website: www.manilaxmifittings.com

#Hastelloy C22 Stub End#Hastelloy C22 Buttweld Elbow#ASTM B366 Hastelloy Alloy C22 Pipe Fittings#Hastelloy C22 Reducing Tee#Hastelloy® C22 Pipe Fittings in India#ASME SB366 Hastelloy® Alloy C22 Pipe Cap#Hastelloy C22 Buttweld Fittings#Hastelloy C22 45 deg.Elbow#Hastelloy C22 Reducer#Hastelloy C22 90 deg Elbow#ANSI B16.9 Hastelloy C22 Buttweld Pipe Fittings Suppliers in India

1 note

·

View note

Text

#hastelloy c22 fittings supplier#hastelloy c22 fittings#hastelloy c22 fittings manufacturer#hastelloy c22 fittings manufacturer & Exporter

0 notes

Text

All you need to know about Butt Weld Fittings

Butt weld fittings are essential components used in various industries to join and connect pipes or tubes seamlessly. These fittings play a crucial role in creating a robust and leak-free piping system. As a leading butt weld fittings manufacturer and supplier, stockist, and exporter in India. Bullion Pipes & Tubes LLP offers an extensive range to suit various project needs. Our fittings are available in different sizes, specifications, material grades, and types, ensuring you find the perfect fit for your specific application.

In this comprehensive guide, we will delve into all you need to know about butt weld fittings and how they cater to the needs of different applications.

What Are Butt Weld Fittings?

Butt weld fittings are designed to have smooth inner surfaces, ensuring minimal friction and pressure drop in the flow of fluids. This characteristic makes them ideal for applications where flow velocity and efficiency are critical factors. Additionally, the absence of crevices or threads in butt weld fittings prevents the accumulation of debris, reducing the chances of contamination and facilitating easy cleaning and maintenance.

Comprehensive Range of Butt Weld Fittings

We take pride in offering a comprehensive range of buttweld pipe fittings, including

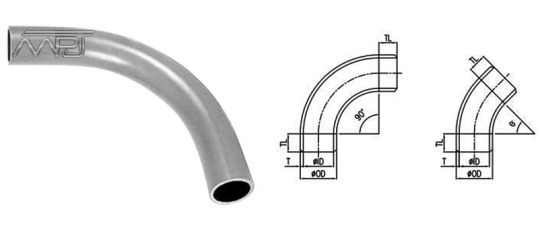

Butt Weld Elbows: Available in 45-degree, 90-degree, and 180-degree angles, providing flexibility in directing the flow of fluids.

Butt Weld Crosses: Ideal for intersecting pipelines, ensuring smooth fluid flow in multiple directions.

Butt Weld Caps: Used to seal the end of a pipe, protecting it from contaminants and preventing leakage.

Butt Weld Tees: Available as equal and unequal tees, facilitating even or uneven flow distribution.

Butt Weld Reducers: Both concentric and eccentric reducers for smooth transitions between pipes of different diameters.

Butt Weld Stub Ends: Facilitating easy flange connections without welding.

Advantages of Butt Weld Fittings

Excellent Structural Integrity: Butt weld fittings create a continuous and strong joint that enhances the structural integrity of the entire piping system. This is especially important in applications where safety and reliability are paramount.

Smooth Inner Surface: The absence of internal disruptions such as threads or flanges ensures a smooth inner surface, minimizing turbulence and pressure loss during fluid flow.

Strong and Reliable Joints: The welding process used to join the pipes ensures a permanent and robust connection, reducing the risk of leaks or failures.

Suitable for High-Pressure and High-Temperature Applications: Butt weld fittings are capable of withstanding extreme pressures and temperatures, making them suitable for critical and demanding industries.

Disadvantages of Butt Weld Fittings

Skilled Labor for Welding: Proper welding requires skilled labor, which may increase the installation cost compared to other types of fittings that do not require welding.

Slightly More Expensive: Butt weld fittings can be slightly more expensive than other fittings due to the welding process and the need for precision manufacturing.

Materials & Grades we offer - Buttweld Fittings

Stainless Steel Buttweld Fittings

SS 904L

SS 304/304L/304H, 316/316L/316Ti, 321/321H, 310/310S, 317/317L, 347/347, 446

Titanium Buttweld Fittings

Titanium Alloy Gr 2

Titanium Alloy Gr 5

Monel Buttweld Fittings

Monel K500

Monel 400

Carbon Steel Buttweld Fittings

Inconel Buttweld Fittings

Inconel 718

Inconel 600

Inconel 601

Inconel 625

Alloy Steel Buttweld Fittings

Alloy Steel P5

Alloy Steel P9

Alloy Steel P11

Alloy Steel P12

Alloy Steel P22

Alloy Steel P91

Aluminium Buttweld Fittings

Nickel Buttweld Fittings

Nickel Alloy 200/201

SMO 254 Buttweld Fittings

Duplex Steel Buttweld Fittings

Duplex UNS S32205

Duplex UNS S31803

Hastelloy Buttweld Fittings

Hastelloy C22, Hastelloy B2

Hastelloy C276

Super Duplex Steel Buttweld Fittings

Super Duplex Steel S32750

Super Duplex Steel S32760

Incoloy Buttweld Fittings

Incoloy 800/800H/800HT

Incoloy 825

Alloy 20 Buttweld Fittings

Applications of Buttweld Fittings

Buttweld fittings are a type of pipe fittings used to connect pipes or tubes with a butt welding process. They are widely used in various industries for a range of applications due to their structural integrity and reliability. Some of the common applications of buttweld fittings include:

Plumbing and Water Supply

Oil and Gas Industry

Chemical Processing

Petrochemical Industry

Power Generation

Pharmaceutical Industry

Food and Beverage Industry

HVAC Systems

Shipbuilding

Construction

Nuclear Power Plants

Other Application

How to Select the Right Butt Weld Fitting?

Choosing the right butt weld fitting is essential to achieve an efficient and reliable piping system. Consider the following factors during selection:

Project Requirements: Understand the specific needs of your project, such as fluid type, pressure, temperature, and flow rate.

Material Compatibility: Ensure that the material of the fitting is compatible with the material of the pipes to prevent corrosion and ensure longevity.

Fitting Dimensions: Select fittings with dimensions that match the pipe size to achieve a secure and leak-free joint.

Industry Standards and Codes: Adhere to industry-specific standards and codes to maintain the quality and safety of the piping system.

Installation and Welding Process of Buttweld Fittings

Proper installation and welding are critical to ensuring the effectiveness of buttweld pipe fittings. Follow these steps for a successful installation:

Preparation: Clean the pipe ends and fittings thoroughly to remove any dirt, grease, or debris that could affect the quality of the weld.

Alignment: Ensure precise alignment of the pipes and fittings before welding to create a strong and reliable connection.

Welding: Employ the appropriate welding method, such as TIG or MIG, to create a robust and leak-proof joint.

Inspection: Thoroughly inspect the welds for defects using non-destructive testing methods to ensure the integrity of the joints.

Leak Testing: Before putting the system into service, conduct a leak test to verify the integrity of the joints and prevent potential leaks.

Final Thoughts!..

Butt weld fittings are vital components in creating strong and reliable connections within piping systems. Bullion Pipes & Tubes LLP stands at the forefront as the leading butt weld fitting supplier, manufacturer, stockist, and exporter in India. With an extensive range of fittings and a commitment to quality, we cater to diverse industrial needs across India and various countries as well including Asia, Saudi Arabia, Singapore, Oman, Maldives, Vietnam, United Arab Emirates, Turkey, Qatar, Europe, Italy, Romania, Chile, Australia, Brazil, and Russia. Our buttweld pipe fittings offer exceptional strength, leak resistance, and versatility, making them the ideal choice for critical applications. When selecting the right fitting, consider the specific project requirements, material compatibility, and adherence to industry standards.

Choose Bullion Pipes & Tubes LLP for all your butt weld fitting needs, and experience excellence in quality and service. Contact us today to explore our vast range of fittings and find the perfect solution for your piping requirements.

0 notes

Link

Neminox Steel is India based Manufacturer, Stockist and Exporter of Piping Accessories & Industrial Steel Products such as pipes, tubes, flanges, buttweld fittings, rods, bars, plates, sheets, wires, fasteners and forged fittings

1 note

·

View note

Link

#Hastelloy B2 Buttweld Fittings#Hastelloy C22 Buttweld Fittings#Buttweld Fittings Supplier#Buttweld Fittings Manufacturers

0 notes

Text

Concentric Reducers Manufacturers In India

Omaa Metal Sources is maker of Concentric Reducer Type B. We are creating ASME B16.9 Reducer, Stainless Steel Concentric Reducer B16.9, Stainless Steel Concentric Reducer Fitting and Hastelloy C22 Reducer suitably considering reasonable specialist hours in India and uncommon wellspring of first rate Alloy 20 Concentric Reducer, most ideal situation, cost open in Mumbai, India.

Concentric Reducers,Concentric Reducers Manufacturers, Concentric Reducers Exporters, Concentric Reducers Suppliers, Concentric Reducers Stockists,Concentric Reducers Buttweld Fittings Manufacturers, Concentric Reducers Buttweld Fittings Exporters, Concentric Reducers Buttweld Fitting Suppliers, Concentric Reducers Buttweld Fitting Stockists.

0 notes

Text

PIPE FITTING COLLAR

COLLAR PIPE FITTINGS TUBING, COLLAR PIPE FITTINGS EXPORTER, CARBON STEEL COLLAR PIPE FITTINGS, SS 310/310S COLLAR PIPE FITTINGS, STAINLESS STEEL 316/316S COLLAR FITTINGS, ANSI B16.9 BUTTWELD COLLAR FITTINGS, COLLAR PIPE FITTINGS WITH FERRULE FITTINGS SUPPLIER, COLLAR PIPE FITTINGS CONNECTOR, ASME B16.9 BUTT WELD COLLOR, COLLAR PIPE FITTINGS STOCKIST, ALLOY STEEL COLLAR PIPE FITTINGS EXPORTER, SS 304/304L COLLAR FITTINGS, SS 904L COLLAR FITTINGS, NICKEL ALLOY COLLAR PIPE FITTINGS, COLLAR PIPE FITTINGS INSTRUMENTATION PIPE FITTING,LEADING COLLAR PIPE FITTINGS MANUFACTURER, INCONEL 600/601/625 COLLAR FITTINGS, STAINLESS STEEL COLLAR PIPE FITTINGS STOCKIST, HASTELLOY C22/C276 COLLAR FITTINGS.

We have specialization to manufacture customized ANSI/ASME B16.9 Butt Weld Collar per customers’ specifications, we welcome small quantity order.

Mcneil Instruments Inc (India) is Manufacturer, Stockists & Supplier of premium quality range of ANSI/ASME B16.9 Butt Weld Collar, Stainless Steel Flanges & Other Stainless Steel Pipe fittings that are manufactured under the expert guidance of our diligent workforce. we are highly experienced company in ANSI/ASME B16.9 Butt Weld Collar & other pipe fittings. our ANSI/ASME B16.9 Butt Weld Collar & Other Fitting products are manufactured using quality material and go through a rigorous quality check at all stages of production to ensure quality. Designed in compliance with international quality standards, these ANSI/ASME B16.9 Butt Weld Collar are corrosion resistance, sturdy and durable. we also supply ANSI/ASME B16.9 Butt Weld Collar & other pipe fittings Flanges in customized size. Our Product Supply Division offers a broad portfolio of Steel Flanges and ANSI/ASME B16.9 Butt Weld Collar. When you place an order with Mcneil Instruments Inc (India), you will receive the products that will stand up in service from people that will stand behind their product.

Checkout Technical Specification & Material of Construction — http://www.mcneilinstruments.com/collar-pipe-fitting.html

Copyright 2021 Mcneil Instruments — http://www.mcneilinstruments.com/

#plumber#fitting#pipe#industrial#valve#valveman#valvesupplier#pipeline#elbw#tee#vessel#chemical#contractor#waterplant

0 notes

Text

Super Duplex Steel Uns S32750 Astm A815 Fittings Flanges

Red Earth Steels Pvt. Ltd. is a private organization that deals with high quality 100 percent flawless pipefittings, buttweld, fasteners and flanges made out of alloy steel, stainless steel and nickel alloys. Get more info:- http://redearthsteel0.blogspot.in/2018/05/hastelloy-c22-fittings-flanges.html

#A234 Wpb Wpc Elbow Tee Reducer Flanges#Alloy Steel Wp11 Elbow Tee Reducer Flanges#A403 Wp 317l Elbow Tee Reducer Flanges#Paddle Blind Flanges Manufacturer#Low Temperature Carbon Steel Flanges Fittings Manufacturer#A403 Wp 316/316h/316l Elbow Tee Reducer Flanges

7 notes

·

View notes

Link

Neminox Steel is India based Manufacturer, Stockist and Exporter of Piping Accessories & Industrial Steel Products such as pipes, tubes, flanges, buttweld fittings, rods, bars, plates, sheets, wires, fasteners and forged fittings

0 notes

Text

What is the Types of Hastelloy C22 Buttweld Fittings?

In the symphony of industrial operations, piping structures play a crucial function, transporting fluids and gasses that maintain the heart of a facility. But the authentic electricity of these structures lies not just within the pipes themselves, however inside the silent heroes that connect them – Hastelloy C22 buttweld fittings. Here, we delve into the arena of these essential additives, exploring their types, benefits, applications, and why they're crucial for ensuring a strong and leak-loose gadget in worrying environments.

Hastelloy C22: A Material Forged for Resistance

Hastelloy C22 is a nickel-chromium-molybdenum alloy that stands tall in the face of a number of the most corrosive environments industry can throw at it. This flexible material well-known shows notable resistance to a wide variety of challenges, along with:

Acids: From the bite of hydrochloric acid to the fuming wrath of sulfuric acid and the gnawing of phosphoric acid, Hastelloy C22 remains undeterred.

Alkalis: Highly alkaline solutions pose no risk to this strong alloy.

Oxidizing Environments: Even in environments wealthy in oxygen, hastelloy c22 pipe fitting keeps its structural integrity.

High Temperatures: When the heat is on, Hastelloy C22 does not flinch, appearing admirably at elevated temperatures.

These incredible properties make Hastelloy c22 pipe fittings supplier, the move-to material for piping structures in various industries, such as:

Chemical Processing: Handling a various variety of corrosive chemical compounds, from acids and alkalis to oxidizing sellers.

Oil and Gas: Navigating the cruel international of hydrocarbon processing, resisting corrosion from fluids and gasses.

Pulp and Paper: Enduring the effective chemical substances utilized in pulp and paper production.

Pharmaceutical: Ensuring the purity and sterility of pharmaceutical techniques.

Future of the Industry: Briefly comment on the future of the industry and the way Hastelloy C22 buttweld fittings would possibly play a role in improvements.

Sustainability Angle: If applicable, point out how your company prioritizes accountable sourcing of substances or environmentally pleasant practices associated with Hastelloy C22 fittings.

Call to Action Reinforcement: Briefly reiterate the CTA from the previous paragraph, imparting further sources or emphasizing the blessings of contacting your organization.

Here's an instance incorporating these factors:

The Unsung Heroes Take Center Stage

Although regularly disregarded, Hastelloy C22 buttweld fittings play a vital function in the success of excessive-overall performance piping structures. Their sturdy production, super corrosion resistance, and leak-proof connections make certain the safe and reliable transportation of fluids and gasses in stressful environments. As the industry pushes barriers and explores new frontiers, excessive-overall performance materials like Hastelloy C22 will continue to be crucial for efficient and sustainable operations.

By partnering with a reliable provider like MV Super Alloys , you could ensure you have got the right Hastelloy C22 buttweld fittings to construct a strong and lasting piping gadget on your crucial programs. Not handiest will we offer a comprehensive choice and exceptional warranty, but our team of experts can manual you through every step of the technique.

#hastelloy c22 pipe fittings#hastelloy c22 fittings#hastelloy c22 pipe fittings supplier#hastelloy c22 buttweld fittings

0 notes

Text

Piggable bends

M P Jain Tubing Solutions LLP is one of the leading Manufacturer, Stockist, and Exporter of ANSI/ASME B16.9 Piggable Bend in Mumbai, India. We are in this domain since 1972. We are ISO 9001:2015 certified company and most trusted Suppliers of Piggable Pipe Bends. We keep intensive stock of SS Piggable Bend to fulfill urgent requirements of our clients at reasonable prices.

One of the oldest Manufacturer, Stockist, Exporter of ANSI and ASME B16.9 Piggable Bend, Piggable Pipe Bends, Piggable Bend Suppliers at best price in India. We keep the largest stock of stainless steel Piggable bends, carbon steel Piggable bends, nickel alloy Piggable bends, alloy steel Piggable bends, Monel Piggable bends in all dimensions.

Benefits of Butt Weld Pipe Fittings

Butt welding fittings have the following benefits

Welded connection offers more robust connection

Continuous metal structure adds to the strength of the piping system

An option of various turn radius using Short Radius (SR), Long Radius (LR) or 3R Elbows

Cost effective compared to their expensive threaded or socket weld counterparts.

Stainless Steel Welded Fittings are also available in SCH 10, allowing a thinner wall option.

Stainless Steel Butt Weld Fittings are more common in SCH 10 and SCH 40 configuration.

allow a strong and leak-proof pipe to fitting connection

minimize the pressure drops and the turbulence along the pipeline

have a long service life

are rather cheap to purchase and deploy

Butt weld fittings with matching pipe schedules offer seamless flow inside the pipe. A full penetration weld and properly fitted LR 90 Elbow, Reducer, Concentric reducer etc. offers gradual transition via welded pipe fitting.

ANSI and ASME B16.9 Piggable Bend Specifications

Type: Butt weld (BW)

Standards: ASME / ANSI – B 16.9

ASTM A403 – ASME SA403 – ‘Standard Specification for Wrought Austenitic Stainless steel Piping Fittings’

API 590-605

ASME B16.9 – ‘Factory-Made Wrought Buttwelding Fittings’

ASME B16.25 – ‘Buttwelding Ends’

ASME B16.28 – ‘Wrought steel Buttwelding Short Radius Elbows and Returns’

MSS SP-43 – ‘Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion Resistant Applications’

Dimension: A NSI B16.9, ANSI B16.28, MSS-SP-43 Type A, MSS-SP-43 Type B, JIS B2312, JIS B2313

Thickness: Schedule 5S, 10S, 20S, S10, S20, S30, STD, 40S, S40, S60, XS, 80S, S80, S100, S120, S140, S160, XXS and etc.

Schedule: Sch 5 TO Sch XXS.

Size: 1/2” TO 36”, (Seamless up to 24”), (Welded 8” TO 36”)

ANSI and ASME B16.9 Piggable Bend Material and Grades

Stainless Steel Piggable Bend:

ASTM A403 WP316/316L

ASTM A403 WP304/304L

ASTM A182 F316L, 304L

DIN 1.4301, DIN1.4306, DIN 1.4401, DIN 1.4404

Carbon Steel Piggable Bend:

ASTM A234 Gr. WPB

ASTM A420 Gr. WPL6

ASTM A105

ASTM A350 Gr. LF2

Nickel Alloy Piggable Bend:

Monel 400 & 500

Inconel 600 & 625

Incolloy 800, 825

Hastelloy C22, C276

Hastelloy

Nickel

Monel

Inconel

Alloy20

Copper Nickel

Cupro-Nickel 90/10

Cupro-Nickel 70/30

Standard:

ASTM / ASME SB 336

UNS 10276 HASTELLOY C 276 Bend

UNS 2200 NICKEL 200 Bend

UNS 2201 NICKEL 201 Bend

UNS 4400 MONEL 400 Bend

UNS 8020 ALLOY 20 Bend

UNS 8825 INCONEL 825 Bend

UNS 6600 INCONEL 600 Bend

UNS 6601 INCONEL 601 Bend

UNS 6625 INCONEL 625 Bend

Alloy Steel Piggable Bend:

ASTM a234 wp1 / wp5 / wp9 / wp11 / wp22 / wp91

As a leading manufacturer, stockist, and exporters of ANSI and ASME B16.9 Piggable bend, we are providing high-quality Piggable bends, SS piggable bend, piggable bend radius at best price in India.

For More Details

Address: 205 Kika Street, Gulalwadi Mumbai, India

Tel: 022-23465538 / 022-23460403

Fax: +91-22-23424250

Mob: +91 9619390230

Email: [email protected]

Visit our site: http://www.mpjainco.com/

0 notes

Text

Alloy C22 Hastelloy Supplier Manufacturer Exporter Stockist

Alloy C22 Hastelloy Supplier Manufacturer Exporter Stockist

Alloy C22 Hastelloy supplied by Siddhagiri Metals and Tubes is a high quality Hastelloy C22 Alloyin forms like C22 Hastelloy Pipe, C22 Hastelloy Tube, C22 Hastelloy Flanges, C22 Hastelloy Fasteners, C22 Hastelloy Fittings, C22 Hastelloy Pipe Fittings, C22 Hastelloy Tube Fittings, C22 Hastelloy Buttweld Fittings, C22 Hastelloy Compression Fittings, C22 Hastelloy Forged Fittings, C22 Hastelloy…

View On WordPress

0 notes

Text

https://bullionpipe.com/our-product/hastelloy-products/hastelloy-buttweld-fittings/hastelloy-c22-b2-buttweld-fittings-exporters/

Hastelloy B2 Buttweld Fittings - Bullion Pipe

Bullion pipe is the Manufacturer, Exporter & Suppliers of Hastelloy B2 Buttweld Fittings & Hastelloy C22 Buttweld Fittings, Hastelloy Buttweld Fittings in India. Hastelloy ASTM B366 Seamless Buttweld Fittings, Hastelloy Buttweld Fittings, Hastelloy Alloy Elbow these are types of Hastelloy B2 Buttweld Fittings. For more information visit the website today !!

0 notes

Link

316L Socket Weld Tee DN20 3000LBS

FOB PriceUSD 1 - 1,700/Piece

PortNingbo or Shanghai Port

MOQ1 Piece

Supply Ability1000 Pieces Per Day

Payment TermsL/C,T/T,Western Union,MoneyGram

PackagingSeaworthy plywood cases or pallets

Delivery2 - 10days

Quick Details

Material: 316L

Technics: Forged

Type: Socket Weld Tee

Place of Origin: Zhejiang, China (Mainland)

Model Number: 316L-Socket-Weld-Tee-20

Brand Name: Yaang

Pressure: 3000LBS

Size: DN20

Ends: Socket Weld Ends

Packaging & Delivery

Plywood case or fumigated woodern case

or as per customers' requests.

Specifications

Type: Socket Weld Tee

Material: 316L

Pressure: 3000LBS

Size: DN20

Ends: Socket Weld Ends

A Socket Weld Tee is a pipe attachment detail in which a pipe is inserted into a recessed area of a Valve, fitting or flange. In contrast to buttweld fittings, Socket Weld Tees are mainly used for small pipe diameters (Small Bore Piping); generally for piping whose nominal diameter is NPS 2 or smaller.

China Socket Weld Tee Manufacturer yaang supplies 316L Socket Weld Tee, DN20, 3000LBS.

If any inquiry, please feel free to contact by email [email protected]

Chemical Composition and Mechanical Property For 316L

Steel Grade

Chemical Composition

Mechanical Performance

C(Max)

Si(Max)

Mn(Max)

P(Max)

S(Max)

Ni

Cr

Mo

N

Tensile Strength

(Min)

Yield Strength

(Min)

psi

Mpa

psi

Mpa

316L

0.03

0.75

2.00

0.045

0.03

10.0–14.0

16.0–18.0

2.00–3.00

0.1

485

170

Related products:

More>>

stainless steel elbow 1/2 - 48 Inch 90 degree

ASME B16.11 A105 Threaded Full Coupling 2 Inch 3000PSI

ASTM B366 UNS N06022 Hastelloy C22 Concentric Reducer

A815 S32750 pipe fitting

ASTM B366 UNS N10665 Hastelloy B2 Eccentric Reducer

Butt Weld Eccentric Reducer Stainless Steel Pipe Fittings ASTM A105 WPB/A403 WP304

Stainless Steel 304 316 WELDOLET MSS SP-97

1.4462 duplex pipe stub end

0 notes