#Membrane Cleaning Chemicals Market

Text

So I just started reading A Court of Thorns and Roses (audiobook), and am I the only one who is wondering if the author did any research into poor subsistence living or the lives of peasants? Because wow, I know Feyre’s family used to be rich, but if that was 8 years ago and y’all are poor as dirt now, somehow in the intervening period you might have learned:

- trap lines in the winter are far superior to active hunting. It burns less calories, you can use it with fish and land animals, and it will save you from frostbite bc instead of sitting in a blind for hours, you can go to your lines at certain times and head home, or drive animals toward your lines.

- buying flower seeds - or any garden seeds - is a suckers game when you’re poor. You only really need to buy seeds once!! Once you harvest, you let stuff ‘go to seed’ and then you collect it and store it for the winter, often trading seeds with your neighbours.

- they let things actively RUN OUT before doing anything about it. That’s absolutely buckwild if you’ve ever been poor — when you’re poor, you know how to make a meal stretch, and you DO IT.

- there is hunting, but no gathering?? This family has not stored any veg for winter, but neither do they go gather mushrooms, rosehips, roots, tubers, nuts, or even fucking bark?? What happened to their cottage garden?? Was it just flowers?! Were they that rich that they don’t understand that a garden produces food? Did they close their eyes as they walked past all their peasant neighbours and their gardens? Bc that’s maybe the wildest thing I’ve seen from both a historical and a ‘grew up so close to dirt poor you couldn’t tell the difference’ perspective!

- She left a whole ass Giant wolf carcass when her family is starving. Nah nah nah no that is the universe smiling on you when you’re subsistence! You will make a travois or somehow find a way to tie that to you and drag it along - that’s double the food, and possibly more money, because you could live off the wolf (which I assume does not taste great) and sell off some of the deer (which is delicious).

- she didn’t at least do a basic clean of her kill out in the woods?! She did not tan the hides?! Y’all, you do not want to be cleaning any kill on the kitchen table. Why? Because cleaning involves removing the intestines and stomach. That means shit and piss and food digestion in different stages, and the gases produced. You do that *outside*, typically at least close to where you made your kill, because you don’t want to have to have any…spills, and because it makes things a bit lighter to carry. Butchering? For sure do it on a table, but cleaning is an outdoor chore. Also, tanning a hide is not just skinning a creature! It’s scraping all the membranes off it, stretching and drying it, and curing the skin - sometimes with smoke, but often with a pretty gross solution (often including brain oil, and historically, I believe urine and/or feces, and other things with the right chemical components). It’s not a simple or quick task!

- soups, pottages, stews, with dried lentils, beans, or peas would have been the staple meals (depending on the climate and environment, but it feels fairly British thus far). Just having roasted venison (def not the best way to eat venison just from taste alone) would likely be a very very rare occurrence, because, as noted earlier, they’re so poor they would need to make it stretch. You would cure it or dry it or turn it into sausage. You would use it sparingly within a meal, not to serve as the whole meal.

- the market. If you were poor, you would likely be a stranger to spices, but not to salt. Salt is deeply necessary to survive in that period, as it’s one of the only ways of safely processing and storing meat with any longevity. And? If you got the money that they did while being as poor and as starving as they were? The first thing you would do — even if you were the most stupid rich person before then — is stock up your stores of dry goods! Flour, salt, honey, dried beans/peas/lentils, vegetables that store - onions, squashes, potatoes, root vegetables like carrots. It’s straight up Maslow’s Hierarchy of Needs here - you will not give a shit about a new cloak before you give a shit about saying your hunger. They are said to be ‘starving’. Sorting out your survival comes before sorting out your fashion.

Anyways, this has been me for channel 4, reporting on anachronisms and misrepresentations in fantasy fiction. More news at 10.

#which is not to say I’m not enjoying the book#though I am glad I got past the poor people stuff#because tell me you’ve never been a peasant without telling me you’ve never been a peasant#I thought a lot of this was common sense but then a lot of people don’t need sense this common I guess#but it’s a fun book so far#acotar#a court of thorns and roses

349 notes

·

View notes

Text

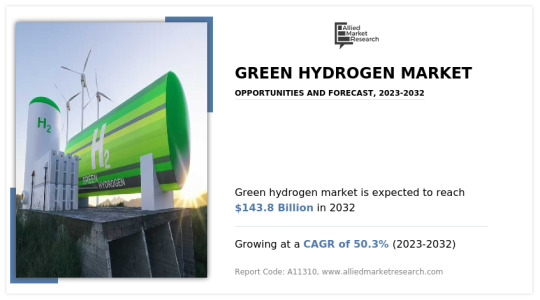

The Role of Renewable Energy Sources in Powering the Green Hydrogen Market

According to a new report published by Allied Market Research, the green hydrogen market was valued at $2.5 billion in 2022, and is estimated to reach $143.8 billion by 2032, growing at a CAGR of 50.3% from 2023 to 2032.

Green hydrogen, also known as renewable hydrogen, is a form of hydrogen produced using renewable energy sources, such as solar, wind, or geothermal power. Furthermore, the demand for proton exchange membrane electrolyzer is anticipated to witness growth during the forecast period, owing to economic growth in emerging markets continues to surge.

Request Sample Pages: https://www.alliedmarketresearch.com/request-sample/11675

In 2023, Asia-Pacific accounts for the largest green hydrogen market share, followed by Europe and North America.

Major Companies

Green Hydrogen Systems, Air Liquide, Shell plc, Enapter S.r.l., Plug Power Inc., Ballard Power Systems, Linde plc, Reliance Industries, GAIL (India) Limited and Adani Green Energy Ltd.

The green hydrogen market is expected to be driven by factors such as the promising growth of the food and beverages, medical, chemical, and petrochemical industries.

Demand for power generation has escalated due to global population growth, coupled with urbanization and industrialization, leading to increase electricity consumption.

The food and beverage segment are projected to manifest a CAGR of 51.6% from 2023 to 2032, and has significant proportion in green hydrogen market size. Rise in the food and beverage industry significantly influences the green hydrogen market, primarily due to intensive energy demand of the industry.

Food and beverage production requires substantial energy for processing, packaging, refrigeration, and transportation. Green hydrogen presents a sustainable solution to meet these escalating energy demands, especially in processes were direct electrification not efficient.

Rise in living standards and technological advancements also contribute to higher energy needs, especially in emerging economies where electricity access has expanded rapidly.

Ongoing R&D efforts focus on enhancing electrolyzer efficiency, durability, and scaling up production, leading to cost reductions and improved performance. This trend aligns with ambitious governmental targets and corporate commitments aimed at fostering the green hydrogen industry, spurring innovation and market growth.

Increasingly stringent regulations and carbon pricing mechanisms incentivize to transition of industries into low-carbon alternatives, propelling its market penetration. These converging green hydrogen market trends collectively position green hydrogen as a pivotal player in the sustainable energy landscape, driving a fundamental shift toward cleaner, more resilient energy systems across the globe.

Enquiry Before Buying: https://www.alliedmarketresearch.com/purchase-enquiry/11675

the electrification of transportation and heating sectors, driven by the push for cleaner energy sources, further amplifies the demand for power generation. This growth in demand provides a significant opportunity for the green hydrogen market.

Green hydrogen emerges as a versatile solution as traditional energy sources struggle to meet these escalating demands while maintaining environmental sustainability.

This symbiotic relationship between the rise in demand for power generation and the need for clean energy solutions positions green hydrogen as a key player in meeting the escalating energy needs sustainably.

The push toward decarbonization and the reduction of greenhouse gas emissions in the transportation sector amplifies the appeal of green hydrogen market opportunities.

Carbon Solutions, a greenhouse gas reduction consultancy, in May 2023, stated that less than 1% of the 10 million metric tons of hydrogen produced in the U.S. at present counts as green hydrogen. Instead, 76% is derived from natural gas or coal, and 23% is a by-product of petroleum refining or other chemical processes.

Globally, the hydrogen market is about 96 million metric tons per year. The report from Carbon Solutions puts number of electrolyzers operating in the U.S. at just 42, with a combined hydrogen production capacity of about 3,000 tons per year.

Get a Customized Research Report: https://www.alliedmarketresearch.com/request-for-customization/11675

The U.S. Department of Energy (DOE) aims to have 10 million tons of clean hydrogen flowing per year by 2030, 20 million tons by 2040, and 50 million tons by 2050. About half that production is expected to come from renewably powered electrolysis. The U.S. government is projected to invest $8 billion in several hydrogen hubs across the country by 2026 and produce about 250 times as much hydrogen per day.

About Us

Allied Market Research (AMR) is a full-service market research and business-consulting wing of Allied Analytics LLP based in Portland, Oregon. Allied Market Research provides global enterprises as well as medium and small businesses with unmatched quality of "Market Research Reports" and "Business Intelligence Solutions." AMR has a targeted view to provide business insights and consulting to assist its clients to make strategic business decisions and achieve sustainable growth in their respective market domain.

Pawan Kumar, the CEO of Allied Market Research, is leading the organization toward providing high-quality data and insights. We are in professional corporate relations with various companies and this helps us in digging out market data that helps us generate accurate research data tables and confirms utmost accuracy in our market forecasting. Each and every data presented in the reports published by us is extracted through primary interviews with top officials from leading companies of domain concerned. Our secondary data procurement methodology includes deep online and offline research and discussion with knowledgeable professionals and analysts in the industry.

2 notes

·

View notes

Text

Application of bitumen in building

Bitumen has numerous applications in the construction industry, primarily serving as an adhesive and waterproofing material. Its versatile properties make it indispensable in various building-related functions. Here are some key applications of bitumen in construction:

1. Roofing and Waterproofing:

Bitumen 60/70 is extensively used in roofing systems to provide waterproof membranes for flat roofs. Traditional bitumen roofing membranes consist of layers of bitumen sprayed with aggregate, with a carrier fabric made of polyester or glass in between. Polymer-modified bitumen sheets have become the standard for flat roof waterproofing. Bituminous roofing membranes can also be recycled easily, enhancing their sustainability.

2. Wall Sealing:

Bitumen 60/70 plays a crucial role in sealing walls, providing protection against water and moisture intrusion. It is applied to substrates such as bathrooms and toilets, which are constantly exposed to moisture, to prevent water penetration and safeguard the underlying structures.

3. Floor and Wall Insulation:

Bitumen 80/100 insulation is widely employed for building waterproofing, both horizontally and vertically. It effectively prevents water penetration into floorboards and walls, offering reliable protection. Bitumen's chemical and physical properties make it easy to work with and highly durable.

4. Sound Insulation:

Bitumen's sound-absorbing properties find applications beyond construction. It helps reduce noise transmission, such as the sound of footsteps under floor coverings. Special tar mats in cars and elevators utilize Bitumen 80/100 for sound insulation.

5. Electrical Cable Insulation:

Bitumen's low electrical conductivity makes it suitable for use as an insulating material for electrical cables. It helps protect the cables and prevent electrical hazards.

6. Other Uses:

Bitumen 80/100 & bitumen 60/70 finds application in various other areas, such as the paper industry and the manufacturing of paints and varnishes. Its thermal insulation properties are beneficial in different contexts.

From an ecological standpoint, bitumen is highly regarded for its long lifespan. It remains a popular construction material, with significant demand both domestically and in international markets. The producer of bitumen in Iran exports a large percentage of its production to other countries such as Singapore, Dubai, Panama.

In residential construction, plastic-modified bitumen (KMB) coatings are commonly used for insulation. They compete with bitumen-free FPD (Flexible Polymer Disc) seals, which are easier to apply and offer faster repair options.

Overall, the applications of bitumen in the construction industry are extensive, ranging from roofing and waterproofing to sound insulation and electrical cable insulation. Its versatility and durability make it a valuable material in various building-related functions.

Important Considerations Before Using Bitumen:

1. Surface Preparation:

Before applying bitumen, it is crucial to ensure that the surface is clean, dry, and free from any contaminants. Even the presence of dust, dirt, or grease can hinder the adhesion of the bitumen coating and compromise the effectiveness of the seal. Additionally, the surface should be free from frost. If there are old incompatible coatings, they must be removed. In the case of older buildings, previous applications of bituminous paints may not provide a suitable surface for polymer-modified bitumen (PMB) coatings.

2. Repairing Cracks and Unevenness:

Prior to applying bitumen, any cracks or unevenness on the surface should be repaired using appropriate materials like repair mortar or leveling compounds. This ensures a smooth and uniform surface, promoting better adhesion and a more effective seal.

3. Additional Preparatory Measures:

In some cases, additional preparatory measures may be necessary. One option is to use a layer of synthetic resin on the coarse-pored bed or to apply a sealing slurry. A sealing slurry is a waterproof mixture of cement and plastic that allows water vapor to pass through. The advantage of using a sealing slurry is that it can adhere well to old bituminous coatings, providing an ideal substrate for applying a thick new bituminous coating.

By following these steps and ensuring proper surface preparation, you can optimize the adhesion and effectiveness of bitumen coatings in various applications.

What are the suitable means for repairing cracks and unevenness on the surface before applying bitumen?

There are several suitable means for repairing cracks and unevenness on the surface before applying bitumen. The choice of repair method depends on the severity of the damage and the specific requirements of the project. Here are some common methods for repairing cracks and unevenness:

1. Crack Fillers and Sealants:

For smaller cracks, crack fillers or sealants can be used. These materials, such as asphalt-based crack fillers or specialized concrete crack sealants, are designed to fill and seal cracks, preventing water infiltration and further damage. They are typically applied using a caulk gun or trowel.

2. Repair Mortar:

Repair mortars are suitable for filling larger cracks, holes, or areas of unevenness. These mortars are made from a blend of cement, sand, and additives to enhance adhesion and strength. They can be mixed with water to create a workable paste and then applied to the damaged areas using a trowel or other appropriate tools. Repair mortars are commonly used for repairing concrete surfaces.

3. Leveling Compounds:

Leveling compounds, also known as self-leveling underlayments or floor levelers, are used to create a smooth and level surface. These compounds are typically made from a blend of cement, fine aggregates, and additives. They have a fluid consistency that allows them to flow and self-level over uneven areas. Leveling compounds are commonly used to repair uneven concrete or subfloor surfaces before applying flooring materials.

4. Patching Mixtures:

Patching mixtures, such as asphalt patching compounds or repair mixes, are specifically designed for repairing asphalt surfaces. They typically contain a combination of asphalt binder, aggregates, and additives. These mixtures can be applied to fill potholes, repair damaged areas, or smooth out unevenness in asphalt surfaces.

5. Resurfacing:

In cases where the damage or unevenness is more extensive, resurfacing the entire surface may be necessary. This involves applying a new layer of bitumen or asphalt mixture over the existing surface to create a smooth and uniform finish. Resurfacing can help address multiple issues, including cracks, potholes, and unevenness.

It's important to follow the manufacturer's instructions and best practices when using any repair materials. Additionally, proper surface preparation, including cleaning and removing loose debris, is essential before applying any repair method.

ATDM CO is a manufacturer and exporter of Bitumen 60/70, offering three different quality grades available in drums, bags, and bulk quantities. Our products are classified into premium, second, and third types, each with varying production costs and facilities. We provide a wide range of options to accommodate different customer needs and volume requirements.

#bitumen#bitumen 60/70#bitumen 80/100#bitumen 60/70 specs#bitumen penetration grade 60/70#bitumen 60/70 specification#bitumen 60 70#atdm co llc.

2 notes

·

View notes

Text

Sodium Hypochlorite Prices Trend, Pricing, Database, Index, News, Chart, Forecast

Sodium Hypochlorite Prices a widely used chemical compound with significant applications in water treatment, disinfection, and bleaching, has experienced fluctuating prices influenced by various factors. The market for sodium hypochlorite, commonly known as bleach, is primarily driven by demand from the municipal water treatment sector, the healthcare industry, and household cleaning products. Over the years, the price dynamics of sodium hypochlorite have been affected by raw material costs, production processes, regulatory changes, and global economic conditions.

The production of sodium hypochlorite typically involves the reaction of chlorine with sodium hydroxide, both of which are derived from salt through the chlor-alkali process. Therefore, any changes in the prices of these raw materials directly impact the cost of producing sodium hypochlorite. For instance, fluctuations in the price of chlorine and caustic soda can lead to corresponding changes in sodium hypochlorite prices. Additionally, energy costs play a significant role, as the chlor-alkali process is energy-intensive. As energy prices rise, so too does the cost of production, ultimately affecting market prices.

In recent years, regulatory changes aimed at reducing environmental impact and improving safety standards have also influenced sodium hypochlorite prices. Stricter regulations often necessitate the adoption of advanced technologies and more robust safety measures, which can increase production costs. These additional costs are typically passed on to consumers in the form of higher prices. Moreover, regulatory requirements can vary by region, leading to price disparities in different parts of the world.

Get Real Time Prices of Sodium Hypochlorite: https://www.chemanalyst.com/Pricing-data/sodium-hypochlorite-1560

The global economic environment significantly impacts sodium hypochlorite prices. Economic downturns, such as the recession caused by the COVID-19 pandemic, can lead to reduced industrial activity and lower demand for sodium hypochlorite. Conversely, economic recovery and industrial growth spur increased demand, driving prices higher. During the COVID-19 pandemic, the demand for sodium hypochlorite surged due to its essential role in disinfection and sanitization. This increased demand led to a temporary spike in prices, as manufacturers struggled to keep up with the sudden surge.

Supply chain disruptions have also played a role in shaping sodium hypochlorite prices. Natural disasters, geopolitical tensions, and logistical challenges can interrupt the supply of raw materials and finished products. For example, hurricanes in key production regions can damage infrastructure and halt production, leading to shortages and price hikes. Similarly, geopolitical issues can affect the availability of chlorine and caustic soda, further influencing sodium hypochlorite prices.

The market structure and competitive landscape of the sodium hypochlorite industry also affect prices. The presence of numerous small and large manufacturers leads to varying pricing strategies and market competition. Large manufacturers with significant production capacities can often leverage economies of scale to offer competitive prices. In contrast, smaller manufacturers might face higher production costs, leading to higher prices. Additionally, market consolidation and mergers and acquisitions can alter the competitive dynamics, potentially impacting prices.

Technological advancements in the production process can lead to cost efficiencies and affect sodium hypochlorite prices. Innovations that improve yield, reduce energy consumption, or enhance safety can lower production costs, which may be reflected in market prices. For example, improvements in membrane cell technology in the chlor-alkali process have contributed to more efficient and environmentally friendly production, potentially stabilizing prices.

Seasonal variations can also influence sodium hypochlorite prices. For instance, the demand for sodium hypochlorite typically increases during the summer months when water usage is higher, leading to greater demand for water treatment chemicals. This seasonal demand can create temporary price fluctuations. Furthermore, the agricultural sector's demand for sodium hypochlorite for crop protection and irrigation purposes can vary seasonally, adding another layer of complexity to pricing dynamics.

In conclusion, the prices of sodium hypochlorite are shaped by a multitude of factors, including raw material costs, regulatory changes, global economic conditions, supply chain disruptions, market competition, technological advancements, and seasonal variations. Understanding these factors is crucial for stakeholders in the sodium hypochlorite market, including manufacturers, distributors, and consumers, as they navigate the complexities of pricing and ensure a steady supply of this essential chemical compound. As the market continues to evolve, staying informed about these influencing factors will be key to anticipating and managing price changes in the sodium hypochlorite industry.

Get Real Time Prices of Sodium Hypochlorite: https://www.chemanalyst.com/Pricing-data/sodium-hypochlorite-1560

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

0 notes

Text

Find The Top Commercial RO Plant Manufacturer In Noida

Introduction

The population now faces a serious freshwater shortage as a result of the incapacity to recycle & repurpose wastewater by installing an appropriate wastewater treatment plant. It goes without saying that as the population grows, water becomes increasingly significant while utilizing the advanced technology that is already available to assist address this issue.

One of the technologies we previously discussed, the commercial reverse osmosis plant, is what we at Netsol Water & Commercial RO Plant are here to instruct, educate, & make aware of our readers today. This kind of water treatment plant system incorporates reverse osmosis as a technology to filter wastewater in order to get rid of contaminants. These facilities, which are found in a variety of commercial settings & industries, are also referred to as reverse osmosis plants.

Numerous wastewater treatment plants including Commercial RO Plant manufacturers readily provide these treatment plant systems around the market, while others will also provide you discounts & extra services for positioning the plant to assist your clients get the required outcomes. Commercial RO Plant is the best commercial RO Plant manufacturer in Noida at best affordable price.

The reverse osmosis method employs a semi-permeable membrane in commercial RO (reverse osmosis) plant facilities to filter water & remove impurities like microbes, bacteria, or dispersed salts. They consist of several components, with prominent designers & producers falling into the following categories:

Before the Pre-treatment Phase: At this stage, larger particles, suspended solids, & sediments are removed using a variety of techniques such as chemical treatment, sedimentation, & filtration. It keeps the membrane of the reverse osmosis plant system from being clogged & polluted.

High-Pressure Pumps: Next, to compensate for the osmotic pressure & let the water pass through the RO membrane, pressure is added to the water implementing a pump.

Semipermeable RO membranes: It is acting as the brain of the system, they allow water molecules to pass through but reject contaminants or suspended mixed particles.

Post-Treatment: To further improve the water after it has passed through the RO membrane, further treatment is applied. Remineralization, pH correction, & disinfection can be necessary to meet acceptable water quality requirements.

Here are the Top two Commercial RO plant Manufacturers based In Noida.

This was a quick summary of the principles of commercial reverse osmosis plant systems, which are implemented in many different sectors to clean wastewater. We prioritize delivering high-quality services above concentrating just on profit, so we can guarantee our clients that the goods & services we offer them are of the greatest caliber. The Two of them are:

Netsol Water

Among the companies on the list is Netsol Water, a Noida-based company that provides its customers with top-notch support by matching them with an expert from the company that specializes in each of these fields.

youtube

They can provide a broad range of services or amenities which can be online as well as offline since they have offices all across the country of India. Therefore, this is a company you should consider when looking to buy a WTP (Water Treatment Plant), its equipment, or other related services.

Commercial RO Plant

Beyond just a name but a reputable & an accredited industrial company in Noida that leads the market in the manufacture & supply of premium water treatment plant systems.

To ensure that clients or consumers do not hesitate to acquire different kinds of WTPs (Water Treatment Plants) & related services or facilities, the experts or technocrats here are constantly accessible to assist them in a courteous & comprehensive manner.

Conclusion

The goals of Netsol Water & its various branch companies, such as Commercial RO Plant, are to improve, investigate, & sustain our water treatment technology. Additionally, our Product Accreditation provides our customers or clients with additional assurance regarding the product's quality & longevity.

No one else in the water treatment business is as knowledgeable about the problems associated with providing water treatment for cities as Netsol Water & the staff at the Commercial RO Plant are. Together, Netsol Water & Commercial RO Plant set itself apart from their rivals by emphasizing customer service & technological innovation.

#industrial ro plant manufacturers#commercial ro plant manufacturer#commercial ro plant manufacturers#commercialroplant#netsolwater#commercial ro plant#Youtube

0 notes

Text

Water Treatment Companies in Saudi Arabia

Ion Exchange Saudi Arabia is a prominent water treatment company operating within the Kingdom of Saudi Arabia. As a subsidiary of Ion Exchange (India) Ltd., the company leverages decades of experience and advanced technology to address the water purification needs of various sectors, including industrial, municipal, and residential.

Key Services and Solutions:

Water Treatment Plants: Design, construction, and maintenance of water treatment plants that purify water for industrial and municipal use.

Wastewater Treatment: Comprehensive solutions for the treatment and recycling of wastewater, ensuring environmental compliance and resource efficiency.

Desalination: Advanced desalination technologies to convert seawater into potable water, crucial for arid regions like Saudi Arabia.

Ion Exchange Resins: Supply of high-quality ion exchange resins used in various water treatment processes to remove impurities and soften water.

Chemical Solutions: A range of water treatment chemicals that enhance the efficiency and effectiveness of water purification processes.

Innovative Technologies:

Membrane Filtration: Use of ultrafiltration and reverse osmosis membranes for high-quality water purification.

Biological Treatments: Advanced biological processes to treat organic contaminants in wastewater.

Zero Liquid Discharge (ZLD): Systems designed to recycle and recover water, minimizing discharge and environmental impact.

Commitment to Sustainability: Ion Exchange Saudi Arabia emphasizes sustainable practices in water management, focusing on reducing water wastage, recycling, and utilizing eco-friendly technologies. Their solutions are tailored to the unique needs of the Saudi market, addressing challenges such as water scarcity and stringent regulatory requirements.

Overall, Ion Exchange Saudi Arabia plays a vital role in ensuring the availability of clean and safe water, supporting the country's economic growth and public health objectives.If you are looking for environmental solutions and services then visit our website-https://sa.ionexchangeglobal.com/

0 notes

Text

What Are Ro “Reverse Osmosis” Systems

Reverse osmosis (RO) is a top method for filtering water and creating clean, delicious water for homes, restaurants, aquariums, and water treatment facilities. RO water systems provide high-quality water tailored to different needs and sources. In this blog, we'll explore what reverse osmosis is, how it works, its benefits, and how to choose the right RO water purifier. We'll also highlight some of the best options on the market.

What is Reverse Osmosis?

Reverse osmosis is a water filtration process that uses pressure to push water through a semi-permeable membrane, removing impurities like dissolved solids and contaminants. This leaves behind clean, purified water. The process is efficient at producing high-quality water and was first developed in the 1950s to desalinate seawater. Since then, it has been adapted for use in homes, industries, and public facilities, making it a standard water filtration method worldwide.

How do Reverse Osmosis systems work?

RO systems work by using pressure to push water through a semi-permeable membrane. This membrane filters out impurities such as salts, minerals, bacteria, and other contaminants. The clean, purified water is collected for use, while the unwanted substances are flushed away.

The main component of an RO system is the membrane, which has tiny pores that let only water molecules through while blocking larger particles. These RO systems often include multiple stages of filtration:

Pre-filtration removes larger particles, such as sediment and chlorine, to protect the RO membrane.

RO Membrane: Filters out most contaminants, including dissolved solids.

Post-filtration often includes activated carbon to polish the water and improve the taste.

Why Do You Need an RO Storage Tank for Clean Water?

An RO storage tank collects and stores purified water after it passes through the system. This way, you always have clean water ready to use, even when you need a lot at once. Without a storage tank, you might have to wait for the water to filter, especially when the system is busy.

The storage tank also keeps the water pressure steady, making it easier to use the water for cooking, cleaning, and drinking.

What does reverse osmosis remove?

Reverse osmosis water systems can remove a wide range of contaminants, including:

Heavy metals, such as lead, mercury, and arsenic, can be harmful to health.

Salts and minerals, including calcium and magnesium, can cause hard water.

Chlorine is a common water treatment chemical that can affect taste and odor.

Pesticides and herbicides are agricultural chemicals that may find their way into water sources.

Bacteria and viruses are harmful microorganisms that can cause illness.

Pharmaceuticals and Other Chemicals: Trace amounts of drugs and other chemicals that may enter the water supply.

What pretreatment does a RO system need?

Water may require pretreatment to get rid of bigger particles and silt before it enters the RO system. To protect the RO membrane and improve system performance, pre-filters and carbon filters may be used. Pretreatment increases the system's efficiency and helps the RO membrane last longer. It lessens the possibility of blockage or damage by making sure the water is as pure as possible before it reaches the membrane.

Read more: RO Booster Pumps - What are they and how do they work?

Do You Need a Booster Pump for Your RO System?

For best results, certain RO systems may require a booster pump to increase the water pressure, particularly in low-water locations. Insufficient pressure could make it difficult for the system to filter water properly. The RO system runs more smoothly with the assistance of a booster pump, giving you the highest-quality water possible.

The Advantages of an RO System

Improved Water Quality: Nanshe RO systems produce clean, great-tasting water by removing impurities and contaminants.

Cost-effective: Investing in an RO system can save you money over time by reducing the need for bottled water.

Environmentally Friendly: By using an RO system, you can reduce plastic waste from single-use water bottles.

Versatile: RO systems can be used for a variety of applications, including drinking water, aquariums, and even cooking.

Healthier Water: Removing contaminants from the water helps protect your health and the health of your family.

Read more: Best Water Purifiers for Home: Clean and Safe Drinking Water Solutions

Is RO Water Good for You?

It is safe and healthy to drink reverse osmosis water. It preserves vital minerals while eliminating impurities. Due to its ability to enhance the flavor of food and beverages, RO water is also ideal for cooking and beverage preparation. Consuming RO water can also be beneficial to your health, particularly if the toxins in your present water supply are dangerous. You may enhance the quality of your water and benefit from the assurance that it is pure by installing a Nanshe RO system.

Water Capacity: It depends on how much water you need each day, so find a system that matches your daily usage.

Ease of Installation: Pick a system that is simple to install and maintain.

Filter Replacement:Check how easy it is to get replacement filters and how much they cost.

Quality and Safety: Certifications prove that the system meets quality and safety standards.

Budget:Think about the initial cost of the system and ongoing maintenance expenses.

Space Requirements:You need enough room to set up the system, especially if you want a whole-house RO system.

The ideal technology for cleaning water is a reverse osmosis water filtration system, which can be utilized in homes, restaurants, and aquariums. We provide a variety of solutions to meet your needs since we recognize that every person has unique demands. You must first consider features like capacity, ease of installation, and filter replacement to select the best RO system that gives you delicious and pure water daily. Investing in a commercial RO system or a home RO system is the best choice. At Nanshe, we offer the highest quality reverse osmosis systems and other RO products to ensure you enjoy clean, refreshing water every day.

0 notes

Text

Superior Corrosion Resistance Enamel Tanks are The Ideal Choice for Agricultural Water Storage

Superior Corrosion Resistance Enamel Tanks are The Ideal Choice for Agricultural Water Storage

In the realm of agricultural water storage, the quality and durability of tanks play a pivotal role in ensuring efficient water management. Among the array of options available, enamel tanks stand out as a testament to superior corrosion resistance, offering a robust solution for farmers and agricultural enterprises.

As a leading storage tank manufacturer in China. Center Enamel can provide GFS Tanks, SS Tanks, Epoxy Coated Bolted Steel Tanks, Galvanized Tank, Aluminum Dome Roofs, Wastewater and Biogas Project Equipments for global customers.

Configuration of Customized Storage Tanks

Storage tanks

Volume

Roofs

Application

Design Requirements

GFS Tanks

SS Tanks

Fusion Bonded Epoxy Tanks

Galvanized Steel Tanks

<1000m³

1000-10000m³

10000-20000m³

20000-25000m³

>25000m³

ADR Roof

GFS Roof

Membrane Roof

FRP Roof

Trough Deck Roof

Wastewater Treatment Project

Drinking Water Project

Municipal Sewage Project

Biogas Project

Fire Water Storage Project

Oil Storage Project

Water Supply & Drainage System

Seismic Design

Wind Resistant Design

Lightning Protection Design

Tank Insulation Design

WasteWater Treatment Project Equipment Supply

Pretreatment Equipment

Resource Utilization System

Sludge Treatment System

Other Equipment

Mechanical Bar Screen

Solid-liquid Separator

Submersible Mixer

Gas Holder

Boiler System

Boost Fan

Biogas Generator

Torch System

Dehydration and Desulfurization Tank

PAM Integration Dosing Device

Screw Sludge Dewatering Machine

Slurry Separation Centrifuge

Sewage Pump

Mud Scraper

Submersible Sewage Pump

Three-phases Separator

Enamel tanks are assembled on-site from specialized enamel steel plates, hoops, self-locking bolts, sealing glue, and other components. The steel plate raw material utilizes titanium alloy-specialized enamel hot-rolled plates developed in collaboration with leading domestic iron and steel enterprises, and it is shaped using fast and low-consumption on-site assembly technology. After high-temperature enameling at 820°-930°, the enamel glaze fuses with the surface of the steel plate, forming a solid and chemically inert inorganic coating with outstanding corrosion resistance. The enamel process is currently an advanced coating and corrosion protection technology in the steel tank market.

Enamel tanks parameters

Category

Specification

Coating Color

Black blue, Grey olive, Forest green, Cobalt blue, Desert tan etc.

Coating thickness

0.25-0.45mm

Acid and alkalinity proof

Standard PH: 3~11, Special PH:1~14

Adhesion

3450N/cm²

Hardness

6.0 (Mohs)

Service life

≥30 Years

Holiday test

>1500V

Permeability

Gas liquid impermeable

Easy to clean

Smooth, glossy, inert, anti-adhesion

Corrosion resistance

Excellent, suitable for harsh environment

Enamel tanks Advantages

Unmatched Durability

Enamel tanks, also known as Glass-Fused-to-Steel (GFS) tanks, are crafted through a meticulous process that combines glass and steel, resulting in a product renowned for its durability. This fusion creates a non-porous surface that is resistant to corrosion, rust, and chemical reactions, making it ideal for storing various types of agricultural water, including irrigation water, rainwater harvesting, and livestock drinking water.

Longevity and Low Maintenance

One of the key advantages of enamel tanks is their longevity. Unlike traditional metal tanks that may succumb to rust and degradation over time, enamel tanks offer a prolonged lifespan, often exceeding decades with proper maintenance. This longevity translates to cost savings for agricultural operations, reducing the need for frequent replacements and repairs.

Moreover, enamel tanks require minimal maintenance compared to other tank materials. Their smooth, non-porous surface prevents the buildup of algae, bacteria, and other contaminants, reducing the frequency of cleaning and disinfection processes. This low maintenance requirement not only saves time and effort but also ensures the water stored remains clean and safe for agricultural use.

Environmental Sustainability

In today's environmentally conscious landscape, the sustainability of water storage solutions is a crucial consideration. Enamel tanks align with sustainability goals by promoting water conservation and reducing environmental impact. By efficiently storing water, farmers can optimize irrigation practices, minimize water wastage, and contribute to sustainable agriculture practices.

Additionally, the recyclability of steel components in enamel tanks further enhances their eco-friendly profile. At the end of their lifespan, enamel tanks can be recycled, reducing waste and supporting circular economy principles.

Versatility and Customization

Enamel tanks offer versatility in design and customization to meet the specific needs of agricultural applications. They are available in various sizes, capacities, and configurations, allowing farmers to choose the right tank size based on their water storage requirements. Whether for small-scale farming or large agricultural operations, enamel tanks provide a scalable solution.

Furthermore, enamel tanks can be equipped with additional features such as insulation for temperature control, agitators for mixing additives, and monitoring systems for water quality management. This customization ensures that farmers can tailor their water storage infrastructure to optimize agricultural processes.

Center Enamel is a comprehensive high-tech enterprise primarily engaged in the research, development, manufacturing, and sales of enamel-assembled tanks and diversified environmental protection equipment, as well as undertaking environmental protection EPC projects and anaerobic process segments. Throughout its project practices, the company continuously increases research and development efforts, gathers scientific and technical forces, and establishes a service system covering everything from research and development to after-sales, providing tailored solutions to customers quickly and with high quality.

The measurement standards for projects not only need to meet technical and quality requirements but also must shift towards overall standards of sustainability, quality improvement, energy efficiency, and carbon reduction. In response to market and policy changes, Center Enamel actively leverages its rich experience and research and development strength to empower innovative research and development technologies for enamel-assembled tanks, contributing to the smart manufacturing of diversified environmental protection equipment and environmental protection EPC projects. This aims to meet the diverse needs and project requirements of customers.

Currently, Center Enamel's business covers areas such as kitchen waste, leachate, municipal sewage, biogas projects, aquaculture wastewater, industrial wastewater, drinking water, and firefighting water. In the future, the company's research and development achievements will be further promoted and applied in more projects, striving to achieve a win-win situation for economic, environmental, and social benefits, driving the high-quality development of the environmental protection industry.

0 notes

Text

Polyvinyl Fluoride (PVF) Market Report: Trends, Analysis, and Projections

Polyvinyl Fluoride (PVF) is a high-performance fluoropolymer known for its exceptional chemical resistance, weatherability, and dielectric properties. This blog delves into the dynamics of the global PVF market, analyzing key drivers, applications across industries, emerging trends, and future growth prospects.

Understanding the PVF Market:

Polyvinyl Fluoride (PVF) Is a specialty fluoropolymer derived from vinyl fluoride monomers. It offers outstanding properties such as excellent chemical resistance, UV resistance, weatherability, low permeability, and electrical insulation, making it a valuable material in various applications.

Market Dynamics:

Architectural and Construction: PVF films are used in architectural membranes, coatings for building materials, and protective films for glass surfaces due to their transparency, weather resistance, and durability against harsh environmental conditions.

Chemical Processing: PVF coatings and linings are utilized in chemical processing equipment, tanks, pipes, and valves due to their exceptional chemical resistance to acids, bases, solvents, and corrosive chemicals.

Photovoltaic (PV) Backsheets: PVF films are used as backsheet materials in photovoltaic (PV) modules due to their excellent weatherability, UV resistance, electrical insulation, and moisture barrier properties, enhancing solar panel performance and longevity.

Automotive and Aerospace: PVF coatings and films find applications in automotive and aerospace components for their chemical resistance, thermal stability, and ability to withstand harsh operating conditions.

Applications Across Industries:

Construction: Architectural membranes, protective coatings.

Chemical Processing: Coatings, linings for equipment.

Renewable Energy: PV backsheet materials for solar panels.

Automotive and Aerospace: Coatings, films for components.

Market Trends:

Focus on Sustainable Materials: Increasing demand for eco-friendly and recyclable materials drives research and development efforts towards bio-based PVF formulations, sustainable production processes, and recycling initiatives.

Advanced Coating Technologies: Innovations in PVF coating technologies, including anti-graffiti coatings, self-cleaning coatings, and high-performance corrosion-resistant coatings, cater to specific industry needs and enhance product functionalities.

Renewable Energy Growth: The expanding renewable energy sector, particularly solar power generation, drives the demand for PVF films as backsheet materials in PV modules, contributing to sustainable energy solutions globally.

Future Prospects:

The global PVF market is poised for steady growth, propelled by increasing demand from construction, renewable energy, automotive, and industrial sectors. Technological advancements, sustainable practices, and market collaborations will play a pivotal role in shaping the market's evolution and unlocking new opportunities.

Conclusion:

Polyvinyl Fluoride (PVF) emerges as a crucial fluoropolymer offering exceptional properties for diverse applications across industries such as construction, renewable energy, automotive, and chemical processing. Understanding market trends, sustainability imperatives, and technological innovations is key for stakeholders in the PVF market to capitalize on growth opportunities effectively. With a focus on sustainability, advanced coatings, and expanding application areas, the PVF market presents promising prospects for continued growth and innovation in the global polymer industry landscape.

0 notes

Text

High Purity Methane Gas Market Analysis 2023 Dynamics, Players, Type, Applications, Trends, Regional Segmented, Outlook & Forecast till 2033

High Purity Methane Gas Market size is expected to grow from USD 6.91 billion in 2023 to USD 11.37 billion in 2033 at a CAGR of 6.6% during forecast period 2024-2033.

Introduction:

The High Purity Methane Gas Market deals with the production, distribution, and application of methane gas with exceptionally high purity levels, typically exceeding 99.95%. This gas finds use in various critical industries due to its specific properties and minimal contamination. expand more

Definition:

High purity methane gas, also referred to as UHP (Ultra High Purity) methane, is a refined version of natural gas. expand more While natural gas itself is primarily composed of methane (CH₄), it also contains other hydrocarbons and impurities. Expand more Through various purification processes, such as cryogenic distillation and adsorption, methane is separated and its concentration is significantly increased.

Market Trends:

Several key trends are shaping the High Purity Methane Gas Market:

Growth of Electronics Industry: The high purity methane market is heavily driven by the electronics industry, particularly in the production of semiconductors and integrated circuits. Expand more Methane plays a vital role in etching processes and maintaining inert atmospheres.

Rising Demand for Clean Energy Sources: High purity methane can be used as a bio-methane or renewable natural gas (RNG) source when produced from biomass. This is gaining traction due to environmental concerns and the push for cleaner energy alternatives.

Advancements in R&D: Continuous research and development are leading to the creation of new applications for high purity methane gas, such as in the production of graphene and other advanced materials.

Objectives of the Market:

Meeting Stringent Industry Requirements: Providing high purity methane gas that meets the extremely low contamination levels required by various industries, particularly electronics and scientific research.

Developing Sustainable Production Techniques: Enhancing production processes to ensure efficient purification while minimizing environmental impact.

Expanding Market Applications: Exploring and developing new applications for high purity methane gas across diverse industries.

Market Scope:

The High Purity Methane Gas Market can be segmented based on various factors:

Purity Level: UHP methane (typically >99.95%), research grade methane (99.999% and above)

Application: Electronics, chemical synthesis, medical applications, scientific research, etc.

Production Technology: Cryogenic distillation, pressure swing adsorption (PSA), membrane separation

Geographic Region: Asia Pacific, North America, Europe, etc.expand_more

By analyzing these segments, market participants can identify target markets, optimize production strategies, and capitalize on growth opportunities.

Conclusion:

The High Purity Methane Gas Market is a dynamic and growing sector driven by the ever-evolving needs of critical industries. As technological advancements emerge and the focus on clean energy intensifies, the market is expected to witness significant expansion in the foreseeable future.

Receive the FREE Sample Report of High Purity Methane Gas Market Research Insights @ https://stringentdatalytics.com/sample-request/high-purity-methane-gas-market/13378/

Market Segmentations:

Global High Purity Methane Gas Market: By Company

• Advanced Specialty Gases

• AGT International

• Air Liquide

• American Welding & Gas

• Axcel Gases

• Bhuruka Gases

• Chemix Gases

• Chengdu Taiyu Industrial Gases Co. Ltd.

• Cryocarb

• Electronic Fluorocarbons LLC

• Gas Innovation.

Global High Purity Methane Gas Market: By Application

• Chemical Synthesis

• Heat Detection

• R &D Laboratory

• Transistors & Sensors

• Power Electronic

• Others

Regional Analysis of Global High Purity Methane Gas Market

All the regional segmentation has been studied based on recent and future trends, and the market is forecasted throughout the prediction period. The countries covered in the regional analysis of the Global High Purity Methane Gas market report are U.S., Canada, and Mexico in North America, Germany, France, U.K., Russia, Italy, Spain, Turkey, Netherlands, Switzerland, Belgium, and Rest of Europe in Europe, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, China, Japan, India, South Korea, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), and Argentina, Brazil, and Rest of South America as part of South America.

Click to Purchase High Purity Methane Gas Market Research Report @ https://stringentdatalytics.com/purchase/high-purity-methane-gas-market/13378/?license=single

Key Report Highlights:

Key Market Participants: The report delves into the major stakeholders in the market, encompassing market players, suppliers of raw materials and equipment, end-users, traders, distributors, and more.

Comprehensive Company Profiles: Detailed company profiles are provided, offering insights into various aspects including production capacity, pricing, revenue, costs, gross margin, sales volume, sales revenue, consumption patterns, growth rates, import-export dynamics, supply chains, future strategic plans, and technological advancements. This comprehensive analysis draws from a dataset spanning 12 years and includes forecasts.

Market Growth Drivers: The report extensively examines the factors contributing to market growth, with a specific focus on elucidating the diverse categories of end-users within the market.

Data Segmentation: The data and information are presented in a structured manner, allowing for easy access by market player, geographical region, product type, application, and more. Furthermore, the report can be tailored to accommodate specific research requirements.

SWOT Analysis: A SWOT analysis of the market is included, offering an insightful evaluation of its Strengths, Weaknesses, Opportunities, and Threats.

Expert Insights: Concluding the report, it features insights and opinions from industry experts, providing valuable perspectives on the market landscape.

Report includes Competitor's Landscape:

➊ Major trends and growth projections by region and country

➋ Key winning strategies followed by the competitors

➌ Who are the key competitors in this industry?

➍ What shall be the potential of this industry over the forecast tenure?

➎ What are the factors propelling the demand for the High Purity Methane Gas?

➏ What are the opportunities that shall aid in significant proliferation of the market growth?

➐ What are the regional and country wise regulations that shall either hamper or boost the demand for High Purity Methane Gas?

➑ How has the covid-19 impacted the growth of the market?

➒ Has the supply chain disruption caused changes in the entire value chain?

Customization of the Report:

This report can be customized to meet the client’s requirements. Please connect with our sales team ([email protected]), who will ensure that you get a report that suits your needs. You can also get in touch with our executives on +1 346 666 6655 to share your research requirements.

About Stringent Datalytics

Stringent Datalytics offers both custom and syndicated market research reports. Custom market research reports are tailored to a specific client's needs and requirements. These reports provide unique insights into a particular industry or market segment and can help businesses make informed decisions about their strategies and operations.

Syndicated market research reports, on the other hand, are pre-existing reports that are available for purchase by multiple clients. These reports are often produced on a regular basis, such as annually or quarterly, and cover a broad range of industries and market segments. Syndicated reports provide clients with insights into industry trends, market sizes, and competitive landscapes. By offering both custom and syndicated reports, Stringent Datalytics can provide clients with a range of market research solutions that can be customized to their specific needs.

Reach US

Stringent Datalytics

+1 346 666 6655

Social Channels:

Linkedin | Facebook | Twitter | YouTube

0 notes

Text

Which technology is best for water purifier?

The Crystal Maze: Unveiling the Best Water Purifier Technology for You

Imagine a world where every sip of water is a dance on your taste buds, a symphony of purity. But between tap water and that refreshing dream lies a labyrinth of filtration options. Each technology in the water purifier market promises a crystal-clear path, but how do you choose the best one? Fear not, fellow water warriors, for this article will be your compass, navigating the maze of Reverse Osmosis (RO), Ultraviolet (UV), and Activated Carbon filtration.

The RO Renaissance: A Double-Edged Sword

RO, the reigning champion, boasts a semi-permeable membrane that acts like a microscopic bouncer, filtering out a vast array of contaminants – from heavy metals to bacteria. It's ideal for areas with high levels of Total Dissolved Solids (TDS), ensuring sparkling clean, albeit slightly flavorless, water.

However, the RO kingdom has a hidden foe – waste. The process generates a significant amount of rejected water, raising environmental concerns. Additionally, RO can strip away beneficial minerals, leaving some yearning for a more natural taste.

The UV Uprising: Shining a Light on Purity

UV technology, the knight in shining armor, utilizes ultraviolet light to neutralize bacteria and viruses. It's a swift and silent warrior, leaving the mineral composition of your water untouched. Perfect for those with municipal water supplies or private wells with moderate TDS, UV purifiers offer a quick sterilization punch.

But the UV realm has limitations. It can't tackle heavy metals or dissolved impurities. So, if your water source is questionable, UV might not be the sole champion for your quest.

The Activated Carbon Conclave: Nature's Workhorse

Activated carbon, the wise elder of the filtration council, is a naturally occurring material with a porous structure. It acts like a magnet, attracting and trapping contaminants like chlorine, organic chemicals, and unpleasant odors. This gentle giant enhances taste and odor while preserving essential minerals.

However, the power of activated carbon wanes over time. Regular filter replacements are crucial to maintain its effectiveness.

The Quest for the Perfect Blend: Combining Forces

So, is there a single, ultimate filtration technology? The answer, like the perfect cup of tea, lies in a thoughtful blend. Many purifiers combine RO with UV or carbon filtration, offering a multi-pronged attack on impurities.

For instance, an RO + UV combo delivers the heavy-duty filtration of RO with the added germicidal power of UV, ensuring comprehensive purification. RO + Carbon filtration tackles a wider range of contaminants while preserving taste.

Choosing Your Champion: A Guide for the Discerning Drinker

Here's a cheat sheet to navigate the filtration maze:

High TDS or questionable water source: RO + UV or RO + Carbon

Municipal water supply or moderate TDS: UV or UV + Carbon

Focus on taste and odor: Activated Carbon

Beyond Technology: Unveiling the Hidden Factors

Remember, the best technology is the one that addresses your specific needs. Consider these factors:

Water source: Test your water to understand the level of impurities.

Budget: Installation and maintenance costs vary across technologies.

Water usage: RO systems can be water-intensive, so consider your consumption habits.

The Final Sip: A Toast to Clean Water

Choosing the right water purifier technology empowers you to unlock a world of pure hydration. Whether you seek a technological marvel or a nature-inspired solution, there's a perfect fit waiting for you. So, embark on your quest, armed with this knowledge, and raise a glass (or a reusable water bottle!) to clean, healthy, and delicious water!

0 notes

Text

Dimethyl Sulfoxide Market Size Worth USD 258.3 million by 2031, with a CAGR 5.5%

The global dimethyl sulfoxide market was estimated to have acquired US$ 150.9 million in 2021. It is anticipated to register a 5.5% CAGR from 2022 to 2031 and by 2031, the market is likely to gain US$ 258.3 million.

Dimethyl Sulfoxide (DMSO) is utilized as a versatile solvent and reaction medium in various industrial processes. Its ability to dissolve a wide range of organic and inorganic compounds, coupled with its favorable physical properties, makes it a valuable component in chemical synthesis, extraction, and purification. The market is driven by the demand for efficient and high-quality chemical processes, particularly in the pharmaceutical, petrochemical, and electronics industries. DMSO's role in aiding the development of innovative materials and facilitating chemical reactions contributes to its continued growth in industrial applications.

Download PDF Brochure: https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=77228

Key Findings of the Market Report

The dimethyl sulfoxide market is segmented into three segments based on grade: electronics, medicines, and industrial.

In 2021, the medicines segment accounted for a sizable 48.4% of the global market.

A CAGR of 5.4% is projected for the segment over the projection period.

This is explained by DMSO's several medicinal qualities, which include anti-inflammatory and membrane penetration.

In 2021, the pharmaceutical application sector accounted for 47% of the dimethyl sulfoxide market, making it a significant segment.

Market Segmentation:

By Service Type:

Pharmaceutical Grade DMSO

Industrial Grade DMSO

By Sourcing Type:

Natural Extraction

Chemical Synthesis

By Application:

Pharmaceuticals

Electronics

Chemical Processing

Agriculture

Others

By Industry Vertical:

Healthcare & Pharmaceuticals

Electronics & Semiconductor

Chemicals & Petrochemicals

Agriculture & Agrochemicals

Others

By Region:

North America

Europe

Asia Pacific

Latin America

Middle East & Africa

Regional Analysis:

North America: Leading the market with a strong presence of pharmaceutical and electronic industries.

Europe: Witnessing significant adoption in pharmaceutical formulations and chemical processing sectors.

Asia Pacific: Emerging as a key market due to rapid industrialization, increasing R&D investments, and growing healthcare infrastructure.

Market Drivers and Challenges:

Drivers:

Rising demand for pharmaceutical formulations and electronic components.

Growing awareness about sustainable and eco-friendly solvents.

Technological advancements improving DMSO production efficiency.

Challenges:

Regulatory hurdles and safety concerns related to handling DMSO.

Fluctuating raw material prices impacting production costs.

Competition from alternative solvents and substitutes in certain applications.

Market Trends:

Pharmaceutical Applications: Increased use of DMSO in drug delivery systems and active pharmaceutical ingredient formulations.

Electronic Manufacturing: Growing demand for DMSO in semiconductor cleaning and electronic component manufacturing.

Green Solvents: Shift towards sustainable and bio-based solvents driving innovation in DMSO production processes.

Future Outlook:

The DMSO market is poised for steady growth, driven by expanding applications across multiple industries and increasing investments in R&D for novel formulations and production methods. Regulatory support for sustainable solvents and technological advancements will further bolster market expansion.

Key Market Study Points:

Market Size and Growth Rate Analysis

Regulatory Environment and Impact on Market Dynamics

Technological Innovations and Product Developments

Regional Market Trends and Opportunities

Competitive Landscape and Strategic Initiatives

Competitive Landscape and Recent Developments:

Key players in the DMSO market include:

Gaylord Chemical Company LLC

Arkema Group

Toray Fine Chemicals Co., Ltd.

Sigma-Aldrich Corporation (Merck KGaA)

Syntex Laboratories Pvt. Ltd.

Place an Order Copy of the Dimethyl Sulfoxide Market Report at: https://www.transparencymarketresearch.com/checkout.php?rep_id=77228<ype=S

Recent developments include collaborations for innovative product formulations, expansions into emerging markets, and investments in sustainable production practices to meet evolving industry demands.

About Transparency Market Research

Transparency Market Research, a global market research company registered in Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision-makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyze information.

Our data repository is continuously updated and revised by a team of research experts so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA – Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

0 notes

Text

Effective Non-Hazardous Fluid Waste Treatment Solutions

Non-hazardous fluid waste is generated in various markets, consisting of drugs, food and drink, and numerous others. It is important for organizations to take care of and treat this waste responsibly to adhere to laws and reduce ecological effect. Implementing efficient non-hazardous liquid waste therapy services is important for sustainable procedures and decreasing the carbon footprint of commercial procedures.

One of the main approaches for dealing with construction site dewatering is via physicochemical processes. These processes include techniques such as sedimentation, coagulation, filtration, and chemical rainfall to separate and remove pollutants from the liquid waste. By using these techniques, sectors can effectively clean up the waste before discharge or recycling, guaranteeing conformity with ecological criteria.

Biological treatment is an additional reliable method for handling non-hazardous fluid waste. This technique involves using microorganisms to damage down raw material in the waste, converting it right into harmless by-products like water and co2. Organic treatment is not only eco-friendly however additionally cost-efficient, making it a preferred option for firms looking to minimize their ecological effect.

Furthermore, advanced treatment innovations like membrane purification and reverse osmosis play an essential function in treating non-hazardous fluid waste. These methods use semi-permeable membranes to different pollutants from the waste stream, producing clean water that can be reused or securely released. Incorporating these modern technologies into waste therapy procedures can substantially boost effectiveness and lower water usage in commercial procedures.

To conclude, the appropriate non-hazardous liquid waste treatment is essential for services to support ecological policies, promote sustainability, and improve their credibility as liable company citizens. By utilizing a combination of physicochemical processes, organic treatment, and advanced modern technologies, industries can effectively handle their fluid waste streams and contribute to a cleaner, greener future for all. This post will help you understand the topic even better: https://en.wikipedia.org/wiki/Wastewater_treatment.

1 note

·

View note

Text

Powering the Future: Insights into the Membrane Electrode Assembly Market

In the pursuit of sustainable energy solutions, hydrogen fuel cells have emerged as a promising technology with the potential to revolutionize power generation and transportation. At the heart of hydrogen fuel cells lies the membrane electrode assembly (MEA), a critical component that facilitates the conversion of hydrogen and oxygen into electricity. This article explores the significance of MEAs, their applications, and the evolving landscape of the market.

MEA is a key component of proton exchange membrane fuel cells (PEMFCs), which are one of the most common types of hydrogen fuel cells used for stationary power generation, automotive propulsion, and portable electronics. The MEA consists of several layers, including a proton exchange membrane (PEM), catalyst layers, and gas diffusion layers, sandwiched between two electrodes—a hydrogen electrode (anode) and an oxygen electrode (cathode).

The primary function of the MEA is to facilitate the electrochemical reactions that occur within the fuel cell, namely the oxidation of hydrogen at the anode and the reduction of oxygen at the cathode. This process generates an electric current that can be used to power electric motors, vehicles, and electronic devices, with water vapor as the only byproduct.

Request the sample copy of report @ https://www.globalinsightservices.com/request-sample/GIS21995

One of the key attributes of MEAs is their efficiency in converting chemical energy into electrical energy, with high power density and low operating temperatures compared to other types of fuel cells. This makes PEMFCs and MEAs particularly well-suited for applications requiring clean, quiet, and reliable power generation, such as fuel cell vehicles, backup power systems, and off-grid power supply.

Moreover, MEAs offer scalability and versatility, allowing for customization and optimization to meet the specific requirements of different applications and operating conditions. Advances in materials science, manufacturing techniques, and catalyst formulations have led to improvements in MEA performance, durability, and cost-effectiveness, driving the widespread adoption of hydrogen fuel cell technology.

The market for MEAs is experiencing rapid growth and expansion, driven by increasing demand for clean energy solutions, government incentives and subsidies for fuel cell deployment, and advancements in hydrogen production and infrastructure. Automotive manufacturers, energy companies, and electronics manufacturers are investing heavily in research and development to commercialize hydrogen fuel cell vehicles and portable fuel cell devices, further stimulating market growth.

Moreover, the transition towards renewable energy sources and decarbonization efforts are creating new opportunities for MEAs in stationary power generation, grid stabilization, and energy storage applications. As governments and industries worldwide strive to reduce greenhouse gas emissions and mitigate the impacts of climate change, hydrogen fuel cells and MEAs are poised to play a significant role in powering the transition to a sustainable energy future.

In conclusion, MEAs are critical components of hydrogen fuel cells, offering efficient, clean, and reliable power generation solutions for a wide range of applications. With ongoing advancements in technology and increasing adoption of hydrogen fuel cell technology, the market for MEAs is poised for continued growth and innovation, driving the transition towards a more sustainable and resilient energy landscape.

0 notes

Text

Find The Top Commercial RO Plant Manufacturer In Noida

The population currently faces a serious freshwater shortage due to inadequate treatment plant systems that do not reprocess or reclaim wastewater. As the population grows, water becomes increasingly valuable, but we also need to consider how we can implement the new technical innovation that is now available to assist in addressing this issue.

Water treatment facilities, sometimes called RO plants, have applications in a wide range of business settings & industries. Wastewater Treatment Plant manufacturers make these treatment plant systems readily available for purchase. They will also give you discounts along with extra assistance during the plant's installation to enhance results.

When talking about commercial RO plants, it's important to remember that they incorporate semi-permeable membranes in their RO method to assist purify water & remove impurities like viruses, bacteria, or dipersed salts.

An Industrial RO plant system, cleans water molecules pass through that RO membrane at a greater pressure while impurities or contaminants being trapped following washing them away.

Top being the finest commercial RO (Reverse Osmosis) plant Manufacturers in Noida

This concludes our discussion of the fundamentals of commercial RO plants, which are utilized to purify wastewater in a variety of industries. However, we also want readers to be aware that numerous businesses exist that manufacture & supply these plants & systems to the market.

We guarantee our clients that the products & services we offer them are of the highest caliber(calibre) because we value providing high-quality services over focusing solely on profit.

The best businesses or companies in the industry that produce & provide premium commercial RO plants are discussed below.

NETSOL WATER: Netsol Water is an acclaimed as well as reputable firm that designs, produces & provides superior level of WTPs (Water Treatment Plants) to the market. Its locations include big urban cities like Noida. Netsol Water always comes in first place on the list.

Our technocrats & professionals are here to support you from every angle in a courteous, professional manner so that you, the customer, feel confidence when purchasing different kinds of Water Purification Plants & associated maintenances or servicing amenities.

COMMERCIAL RO PLANT: This further Gr. Noida-based business firm or company offers its clients high-quality services in Noida/NCR by assigning & giving them company expertize in all of these areas of knowledge. Commercial RO Plant is the best commercial ro plant manufacturer in Noida at best affordable price.

This firm has their branch or regional offices across the country, that eventually permits them to acquire & provide a variety of services that can be online assistance or offline. Consequently, purchasing a treatment plant machinery, or any associated amenities regarding commercial RO plant i.e., after-sale services, this company must be always in mind.

Commercial RO plants for treating raw water can be easily attainable from manufacturers of these RO plants, & they are assembled with a variety of components, some of which are listed below:

Prior to treatment (Pre-Treatment): Larger particles, suspended solids, & sediments are eliminated at this step using techniques including filtration, sedimentation, & chemical treatment. In this, RO membrane is kept away from being clogged thereby causing fouling in the system.

High Level Pressure in the Pump Implemented: High amount of Pressure is then incorporated to the water utilizing in the pump in order to pass the osmotic pressure that permits the water (H2O) to pass across the membrane in the RO system.

RO Membrane: The semi-permeable membrane known as the Reverse Osmosis membrane is the brain of the system; it allows water molecules to pass across the membrane while rejecting various impurities & dispersed particles.

Post or After the Main Treatment: Subsequently being transient across the RO permeable membrane, the partial refined water undergoes additional treatment & then more refining to improve it even better level that leads to processes such as pH correction besides remineralization, then followed by disinfection for an acceptable quality standards all around.

Concluding Review

For all the above discussed statements including reason, we at Netsol Water inform everyone to make them aware reading about one of best Water Treatment actively functioning technologies that is discussed earlier: The commercial RO plant This water treatment plant (Commercial RO Plant) systems offered alongside Netsol Water implements Reverse Osmosis to almost eliminate impurities from wastewater to nearly ~100%, thereby purifying the Wastewater.

#commercial ro plant manufacturer#industrial ro plant manufacturer#industrial ro plant manufacture#netsolwater#commercial ro plant

0 notes

Text

The Role of Hydrogen Electrolyzers in Energy Transition.

Introduction: