#RF Interference Filter

Explore tagged Tumblr posts

Text

RF Chambers | DMCRF

High-Performance RF Chambers for Precise Testing. Looking for reliable RF (Radio Frequency) chambers for electromagnetic compatibility (EMC), antenna testing, or wireless device validation? DMC RF offers state-of-the-art RF shielded chambers designed for accuracy, durability, and superior performance.

Our RF test chambers are used in industries such as:

✔ Telecommunications (5G, IoT, Wi-Fi testing)

✔ Aerospace & Defense (radar, avionics, military comms)

✔ Automotive (connected cars, EV systems)

✔ Consumer Electronics (smartphones, wearables, IoT devices)

Why Choose Our RF Chambers?

✅ Customizable Designs – Tailored to meet specific testing requirements (size, frequency range, shielding effectiveness).

✅ High Shielding Effectiveness – Ensures minimal interference for accurate test results.

Sturdy Construction: Long-term dependability is ensured by the use of premium materials.

✅ Compliance with Global Standards – Meets FCC, CE, MIL-STD, and ISO regulations.

✅Expert Support: From design to installation, our team ensures seamless integration.

Applications of Our RF Chambers

EMC/EMI Testing – Ensure devices meet electromagnetic compatibility standards.

The Complete Guide to RF Chambers: Technology, Applications, and Selection Criteria

Introduction to RF Chambers

Radio Frequency (RF) chambers, also known as shielded enclosures or anechoic chambers, are specialized testing environments designed to control electromagnetic interference (EMI) and ensure accurate measurement of radio frequency signals. At DMC RF (https://www.dmcrf.com/), we understand the critical role these chambers play in today's wireless technology landscape.

RF chambers create isolated electromagnetic environments that allow engineers and researchers to:

Conduct precise measurements without external interference

Test device emissions and immunity

Validate wireless communication performance

Ensure regulatory compliance

Understanding RF Chamber Technology

Basic Principles of Operation

RF chambers work on two fundamental principles:

Shielding: Blocks external electromagnetic waves from entering

Absorption: Minimizes internal reflections for accurate measurements

The effectiveness of an RF chamber is measured by its:

Shielding effectiveness (typically 60-120 dB)

Frequency range (from kHz to mmWave)

Field uniformity (for immunity testing)

Key Components

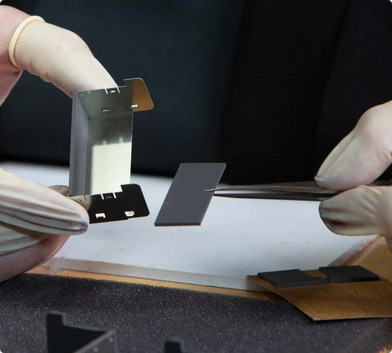

Several layers of conductive materials, usually copper or steel, make up a shielding enclosure.

Absorber Materials: Pyramid foam, ferrite tiles, or hybrid absorbers

Filtered Penetrations: For power and signal lines

Access Systems: RF-tight doors and interlock mechanisms

RF chambers remain essential tools for ensuring the reliability and compliance of modern wireless technologies. Whether you're developing next-generation 5G devices, automotive radar systems, or medical IoT solutions, having the right RF testing environment is crucial.

Antenna & OTA Testing – Measure radiation patterns and signal strength.

Contact Us:

Phone No : +1 (613) 915 5533

Website : https://www.dmcrf.com/

0 notes

Text

RF Filter Market Witnessing Strong Demand from Asia-Pacific Amidst Telecom Infrastructure Expansion

The RF filter market is gaining significant momentum in today’s wireless-driven world. With the explosive growth in mobile communications, satellite technologies, and the rollout of 5G, RF filters have become essential components in communication systems. These filters help eliminate unwanted frequencies, ensuring signal clarity and device performance. The RF filter market is poised for substantial expansion as more advanced telecommunication systems demand high-quality filtering components.

Market Overview

RF filters are integral to wireless devices, allowing specific frequency bands to pass while blocking others. They are widely used in smartphones, tablets, base stations, GPS devices, and other wireless communication equipment. As the number of connected devices grows globally, so does the need for efficient RF filters. The emergence of 5G networks, IoT ecosystems, and AI-integrated communication platforms are also key drivers accelerating market demand.

The global RF filter market was valued at around USD 12 billion in 2023 and is projected to grow at a CAGR of over 14% from 2024 to 2030. The rise in spectrum crowding due to multiple wireless services operating simultaneously has further boosted the demand for precision filtering solutions.

Key Drivers

1. 5G Deployment The transition from 4G LTE to 5G has increased the complexity of radio frequencies used in mobile devices. 5G technology requires more frequency bands, increasing the demand for RF filters that can handle these multiple bands without compromising on performance.

2. Growth of IoT Devices With billions of IoT devices expected to come online in the coming years, the need for reliable wireless communication will intensify. RF filters play a crucial role in maintaining signal integrity in densely populated frequency environments, making them indispensable to IoT growth.

3. Military and Aerospace Applications RF filters are vital in military and aerospace communication systems, where secure and interference-free transmissions are critical. These sectors are continuously adopting advanced RF filter technologies, thus boosting market expansion.

4. Smartphone Penetration The global demand for smartphones is another key factor. With each generation of smartphones supporting more frequency bands, the role of RF filters becomes increasingly important. This has led to innovations in filter technologies such as SAW (Surface Acoustic Wave), BAW (Bulk Acoustic Wave), and MEMS-based filters.

Market Segmentation

The RF filter market can be segmented by product type, frequency range, application, and geography.

By Type:

SAW Filters

BAW Filters

Others (LC, Cavity filters)

By Frequency:

Up to 1 GHz

1 GHz–3 GHz

Above 3 GHz

By Application:

Mobile phones

GPS devices

Tablets

Base stations

Military & aerospace

IoT modules

By Region:

North America

Europe

Asia-Pacific

Latin America

Middle East & Africa

Asia-Pacific holds the largest market share due to high smartphone production in countries like China, South Korea, and India. North America follows closely, driven by technological advancements and early 5G adoption.

Challenges in the Market

Despite its growth potential, the RF filter market faces challenges such as:

High development cost of advanced filter technologies

Miniaturization demand leading to complex designs

Thermal and frequency drift issues in extreme environments

Moreover, manufacturing filters for high-frequency bands used in 5G requires precision engineering and materials, which adds to the cost.

Future Outlook

The future of the RF filter market looks promising. As 6G research gains pace and next-generation wireless devices continue to emerge, the demand for advanced RF filtering solutions will only grow. Companies are investing heavily in R&D to develop smaller, more efficient, and more reliable RF filters. Additionally, partnerships between telecom giants and component manufacturers are creating new opportunities for innovation.

Technological trends such as AI-based frequency management, satellite broadband, and autonomous vehicles will likely add new dimensions to RF filter applications. As the world becomes more connected, RF filters will remain a cornerstone in ensuring that connectivity is not just fast, but also interference-free.

0 notes

Text

Improve ADS-B Reception Performance Using an Effective LNA Solution

In the world of aviation, Automatic Dependent Surveillance–Broadcast (ADS-B) plays a crucial role in enhancing flight tracking and air traffic management. Enthusiasts, professionals, and organizations rely on ADS-B technology to track aircraft positions in real time. However, maximizing the reception of ADS-B signals requires specialized hardware, and one key component that significantly improves signal quality is the ADS-B Low Noise Amplifier (LNA).

What is ADS-B?

ADS-B is a surveillance technology in which aircraft automatically transmit their position, velocity, and other data to ground stations and other aircraft. This data transmission operates at 1090 MHz in most regions and is received by ADS-B ground stations, satellites, or enthusiasts using software-defined radios (SDRs). Due to the relatively weak signal strength over long distances, receiving these transmissions with high accuracy requires specialized components like an ADS-B LNA iridium satellite antenna.

Understanding Low Noise Amplifiers (LNAs)

A Low Noise Amplifier (LNA) is an essential component in RF (radio frequency) reception systems. It amplifies weak signals received by an antenna while adding minimal noise to the system. LNAs improve the signal-to-noise ratio (SNR), which is crucial for capturing ADS-B transmissions with higher accuracy and over greater distances.

Why Use an LNA for ADS-B?

ADS-B signals at 1090 MHz are susceptible to attenuation, interference, and environmental factors such as buildings, trees, and weather conditions. An LNA helps mitigate these challenges by amplifying weak signals before they reach the SDR or receiver. Here are the key benefits of using an ADS-B LNA:

Improved Reception Range: Amplifying weak signals allows users to track aircraft farther from their location.

Enhanced Signal Quality: By boosting ADS-B signals while adding minimal noise, an LNA improves decoding accuracy.

Better Performance in Urban Areas: Buildings and other obstacles can weaken signals; an LNA helps overcome such losses.

Optimized SDR Performance: Many SDRs have limited sensitivity, and an LNA provides the necessary boost to receive clearer signals.

Choosing the Right ADS-B LNA

When selecting an ADS-B LNA, several factors should be considered:

● Gain: A gain of around 20–30 dB is typically ideal for ADS-B reception.

● Low Noise Figure: A lower noise figure (around 1 dB) ensures minimal added interference.

● Built-in Filters: Some LNAs come with bandpass filters to block unwanted signals from nearby frequencies.

● Powering Options: LNAs may require power via Bias-T, USB, or an external power supply.

Installing an ADS-B LNA

To set up an ADS-B LNA, follow these steps:

Place the LNA close to the antenna to amplify the signal before cable losses occur.

Ensure proper power supply based on the LNA’s requirements.

Use high-quality coaxial cables to minimize signal loss.

Pair with a bandpass filter if experiencing interference from other RF signals.

Conclusion

An ADS-B LNA is a game-changer for aviation enthusiasts and professionals looking to improve aircraft tracking performance. By amplifying weak signals and reducing noise, an LNA significantly enhances ADS-B reception, allowing users to track aircraft with greater accuracy and over longer distances. Whether you're a hobbyist or an aviation expert, integrating an LNA into your ADS-B setup is a worthwhile investment for superior tracking capabilities.

#own weather satellite#iridium satellite antenna#tactical antenna#iridium antenna#ads-b lna#vhf antenna#vhf antennas#VHF Mobile Band Antenna#VHF Mobile Antenna#low noise amplifier#iridium external antenna#antenna amplifier#custom antenna design#antenna preamplifier#wifi antenna booster#Low Noise Amplifiers#wifi signal enhancer#wifi signal booster#external wifi booster#improve wifi signal#wifi enhancer#antenna manufacturer

0 notes

Text

EMI RFI power line Filters - Diamond Microwave Chambers Ltd

In today's technologically advanced world, electronic devices are more sensitive than ever to electromagnetic interference (EMI) and radio frequency interference (RFI). These disturbances can degrade performance, cause malfunctions, and even lead to equipment failure. To combat these issues, EMI/RFI power line filters are essential for maintaining clean and stable power supply.

At DMC RF, we offer a range of high-performance RFI/EMC filters designed to suppress unwanted noise and ensure compliance with electromagnetic compatibility (EMC) standards. Whether you need filters for industrial, medical, or commercial applications, our solutions provide reliable protection against power line disturbances.

Why Use EMI/RFI Power Line Filters?

EMI/RFI filters are crucial for:

Preventing interference from disrupting sensitive electronics.

Ensuring compliance with EMC regulations.

Improving system reliability by reducing electrical noise.

Protecting equipment from surges and transients.

DMC RF’s High-Quality RFI/EMC Filters

1. RFI/EMC Filters (5 to 300 AMP) – FCL-66, -660 Series

Our FCL-66 and FCL-660 series are robust power line filters designed for applications requiring 5 to 300 AMP current ratings. These filters effectively suppress conducted noise while maintaining high efficiency.

Key Features:

High current handling (5A to 300A)

Effective EMI/RFI suppression

Compact and durable design

Suitable for industrial and heavy-duty applications

2. 25 to 200 AMP RFI/EMC Filters: DMC FCL-11, -110, -14, -140, -1 Series

The FCL-11, FCL-110, FCL-14, FCL-140, and FCL-1 series are engineered for 25 to 200 AMP applications, providing superior noise attenuation in demanding environments.

Key Features:

Wide current range (25A to 200A)

High-performance filtering for industrial equipment

Reliable protection against power line disturbances

Meets stringent EMC standards

3. RFI/EMC Filters Accessories – FCL-55, -66, -660 Series

To complement our filter lineup, we offer accessories for the FCL-55, FCL-66, and FCL-660 series, ensuring seamless integration and optimal performance.

Available Accessories Include:

Mounting brackets

Connectors and terminals

Shielding components

Applications of EMI/RFI Power Line Filters

Our filters are widely used in:

Industrial automation (PLCs, motor drives)

Medical equipment (diagnostic machines, imaging systems)

Telecommunications (data centers, RF systems)

Renewable energy systems (solar inverters, wind turbines)

Choose DMC RF for Reliable EMI/RFI Filter Solutions

High-performance EMI/RFI power line filters that provide clean power and safeguard delicate devices are our specialty at DMC RF. Our filters are made to fit your unique needs, whether you prefer basic or customized solutions.

Explore our range today:

RFI/EMC Filters FCL-66, -660, 5 to 300 AMP

RFI/EMC Filters FCL-11, -110, -14, -140, -1, 25 to 200 AMP

RFI/EMC Filters Accessories – FCL-55, -66, -660 Series

Ensure optimal performance and compliance with DMC RF���s advanced EMI/RFI filtering solutions!

Contact us

Phone number : +1(613) 915 5533

Website: https://www.dmcrf.com/

0 notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] Bring the studio home with the new SM4 Home Recording Microphone. Capture professional recordings of vocals and instruments with mix-ready audio and interference protection. The 1” brass dual-diaphragm capsule is engineered to consistently reproduce every element of your performance with remarkable accuracy and exceptional low-frequency control. Patent-Pending Interference Shielding Technology blocks unwanted RF noise from wireless devices including cellphones, laptops and wi-fi routers, while the internal pop filter minimizes plosives. A sleek, low-profile design with all-metal construction delivers the perfect upgrade for your home studio. SMOOTH AUDIO REPRODUCTION - The SM4 microphone features a brass 1-inch dual-diaphragm capsule, providing clean, controlled low-end frequencies and smooth, detailed highs for natural audio reproduction. SUPERIOR NOISE REJECTION - The SM4's uniform cardioid polar pattern ensures superior off-axis rejection of unwanted noise, capturing your sound source with clarity and precision. REDUCES PROXIMITY EFFECT - Designed with a large “sweet spot,” the SM4 reduces the proximity effect, offering more consistent audio quality, making it ideal for close-miking vocals and instruments. INTERFERENCE SHIELDING - The SM4 microphone employs patent-pending interference shielding technology, effectively blocking RF noise from cell phones, laptops, and Wi-Fi routers for cleaner audio. RECORD WITHOUT DISTORTION - Capable of capturing sounds up to 140dB, the SM4 ensures your loud instruments come through clearly without any distortion, thanks to its high-SPL handling. [ad_2]

0 notes

Text

5G RF Components: $25.3B by 2034 – The Secret Behind Ultra-Fast Speeds!

5G RF Components Market is at the forefront of the telecommunications revolution, enabling ultra-fast, low-latency communication. These components — filters, amplifiers, antennas, and transceivers — are critical to expanding 5G networks worldwide, supporting IoT devices, industrial automation, and enhanced mobile broadband. As demand for seamless connectivity surges, manufacturers and tech innovators are capitalizing on new growth opportunities in this dynamic industry.

To Request Sample Report : https://www.globalinsightservices.com/request-sample/?id=GIS33026 &utm_source=SnehaPatil&utm_medium=Article

📊 Market Growth & Key Insights

✅ Filters lead due to their role in frequency selection & interference mitigation. ✅ Power amplifiers rank second, enhancing signal strength & coverage. ✅ Asia-Pacific dominates, fueled by massive 5G infrastructure investments. ✅ North America follows closely, benefiting from early adoption & strong telecom sectors. ✅ China & the U.S. drive global innovation, spearheading 5G deployments.

🔍 Market Segmentation & Trends

🔹 Type: Filters, Amplifiers, Duplexers, Switches, Antennas 🔹 Technology: Sub-6 GHz, mmWave, Massive MIMO, Beamforming 🔹 Application: Smartphones, Base Stations, IoT Devices, Automotive 🔹 Key Players: Qualcomm, Skyworks Solutions, Qorvo

🚀 Future Outlook & Challenges

The 5G RF Components Market is projected to grow at a CAGR of 22% over the next decade. With IoT, smart cities, and autonomous vehicles gaining traction, RF components will play a crucial role in next-gen connectivity. However, cybersecurity threats, high infrastructure costs, and regulatory policies remain key challenges. The evolution of 6G research, AI-driven network optimization, and edge computing promises an exciting future for the market.

#5gtechnology #rfcomponents #wirelesstechnology #telecominnovation #mmwave #networkinfrastructure #iotdevices #smartcities #nextgenconnectivity #semiconductors #mobilebroadband #antennaengineering #automotiveconnectivity #5gbasebands #industrialautomation #lowlatency #techinnovation #futureoftelecom #beamforming #massivemimo #networksecurity #cloudnetworking #basebandchips #wirelesscommunication #datatransmission #techadvancements #5gspectrum #edgecomputing #digitalevolution #sustainabletech #5grollout #nextgenwireless #mobiletechnology #highspeedinternet #smartmanufacturing

Research Scope:

· Estimates and forecast the overall market size for the total market, across type, application, and region

· Detailed information and key takeaways on qualitative and quantitative trends, dynamics, business framework, competitive landscape, and company profiling

· Identify factors influencing market growth and challenges, opportunities, drivers, and restraints

· Identify factors that could limit company participation in identified international markets to help properly calibrate market share expectations and growth rates

· Trace and evaluate key development strategies like acquisitions, product launches, mergers, collaborations, business expansions, agreements, partnerships, and R&D activities

About Us:

Global Insight Services (GIS) is a leading multi-industry market research firm headquartered in Delaware, US. We are committed to providing our clients with highest quality data, analysis, and tools to meet all their market research needs. With GIS, you can be assured of the quality of the deliverables, robust & transparent research methodology, and superior service.

Contact Us:

Global Insight Services LLC 16192, Coastal Highway, Lewes DE 19958 E-mail: [email protected] Phone: +1–833–761–1700 Website: https://www.globalinsightservices.com/

0 notes

Text

EMI Non-Metallic & RF Shielding Solutions By Laird - Techni3 Ltd

EMI Non-metallic

Why Laird Performance Materials? Discover world-class EMI shielding expertise in one company.

When electromagnetic waves flow, interference can put your most essential devices and the lives of people who depend on them at risk. That’s why our skilled engineers use coordinated systems designed to help you build your best EMI defenses. For more than two decades, we’ve perfected the integrated art of creating high-quality EMI shielding materials that:

Suppress interference and meet immunity requirements.

Isolate offending circuits by filtering, grounding and shielding.

Desensitize devices by increasing their immunity to susceptible circuits.

Solve your most complex EMI dilemmas from PC board emissions to conductive radiation.

Customize Your EMI Essentials

Unlike our competitors, Laird takes complete ownership of our process. We embed Laird engineers and technical specialists in every phase of your design to provide the highest-quality products that are timely, cost-effective, and tailored to your needs.

We offer thousands of standard EMI shielding materials and unlimited custom options for a variety of metal components. Explore our catalog offered here or contact an engineer through our customer service center. In only an hour, you can create your own EMI application.

Explore Solutions

Wire Mesh and Knitted EMI Shielding Gaskets

Review our solutions for effective shielding and grounding of electronic/electric applications.

Vent Panels

High-performance panels that provide EMI shielding and allow airflow in and out of the application.

SMD Grounding Contacts

Foam cored and solder reflow compatible, our contacts come with polyimide film outer coverings.

Metalized (Conductive) Fabrics

Our metal-plated flexible fabrics and non-woven textiles produce effective EMI shielding.

Board Level Shielding

Surface mount PCB shields that protect at the component level.

Form-in-Place Gaskets and Sealer

Get reliable protection for compartmentalized cast or plastic enclosures or electronic assemblies.

Conductive Foam Gaskets

Ecofoam™ offers innovative X, Y and Z-axis conductivity, aiding effectiveness.

Fingerstock – Enclosure Shielding Gaskets and Contact Strips

Thin strip metal solutions for high frequency EMI shielding and grounding.

Conductive Tapes and Adhesives

EMI issues in high dynamic flex conditions meet their match with durable solutions.

Conductive Elastomers

Our elastomers offer EMI shielding in harsh conditions and good mechanical functionality.

Fingerstock – Metal Connector Shields

Thin-strip, miniature-engineered metals include more than 500 standard parts.

Fabric-over-Foam

Engineered fabric-over-foam gaskets deliver superior low EMI shielding attenuation.

EMI Non-metallic Groups

Conductive Foam Gaskets

Solve your enhanced EMI shielding needs. Laird Ecofoam™ offers innovative X, Y and Z-axis conductivity, aiding effectiveness in low-cycling applications. Customize Ecofoam by die-cutting, hole-punching and notching. One side offers conductive PSA

EMI Tapes

Resolve EMI with thinner tapes. Our thin, highly conductive tapes, fabrics and adhesives are your ideal solution. Made from nickel/copper metalized fabric with a conductive PSA, they deliver exceptional EMI shielding, grounding and flexibility.

Form in Place (FIP) Elastomers

Optimize electronic performance. Ensure reliable protection for compartmentalized cast or plastic enclosures or electronic assemblies with cost-saving, molded form-in-place gaskets. Benefit from shielding effectiveness of 85-100 dB up to 10 GHz.

Soft SMD Contacts

Complete circuit grounding the soft way. Foam cored, soft SMD foam contacts are designed with a metalized polyimide film outer covering. Our circuit grounding solution are solder reflow compatible and suitable for automatic processing.

Electrically Conductive Elastomers (ECE)

Seal slight openings to your shielding. When closure issues create an easy-access path to shielding systems, electrically conductive elastomers can stop the problem, even in harsh conditions by conforming to surface irregularities. See our ECE line.

Fabric-over-Foam (FOF) Gaskets

Get soft shielding in a durable design. Achieve superior low shielding attenuation with Laird Ni/Cu and Sn/CU fabric-over-foam gaskets. They are ideal for applications requiring low compression force and high conductivity and shielding attenuation.

Sample Kits and Accessories

Our variety of EMI shielding materials sample kits put products and data in your hands. Examine board level shield, elastomer, gasket, fingerstock and tape solutions. Review the kit’s reference documents to gain better understanding.

Wire Mesh Knitted Conductive Gaskets

Ensure high-performance EMI shielding and grounding. Laird knitted wire or conductive thread gaskets are preferred choices of design engineers worldwide for effective EMI shielding and grounding of electronic devices and electric applications.

0 notes

Text

How to Install & Optimize Your RFID Tag Reader System

Introduction

Radio Frequency Identification (RFID) technology has revolutionized asset tracking, inventory management, and supply chain operations. However, the efficiency of an RFID tag reader system depends on proper installation and optimization. In this comprehensive guide, we will walk you through the best practices for setting up and enhancing your RFID reader system to ensure maximum efficiency and accuracy.

Step 1: Understanding RFID Components

Before installation, it’s crucial to understand the essential components of an RFID system:

RFID Tags: These contain embedded microchips and antennas that store data.

RFID Readers: Devices that emit radio waves to communicate with RFID tags.

Antennas: Transmit signals between the tags and the reader.

Middleware & Software: Process and interpret RFID data for integration with business systems.

Step 2: Selecting the Right RFID System

Choosing the right RFID system is critical for achieving optimal results. Consider the following factors:

Frequency Range: RFID operates in different frequency bands: Low Frequency (LF), High Frequency (HF), and Ultra High Frequency (UHF). Choose one based on your operational needs.

Read Range Requirements: Determine whether you need short-range or long-range reading capabilities.

Environmental Conditions: Harsh environments may require ruggedized RFID tags and readers.

Data Storage & Integration: Ensure the system can seamlessly integrate with your ERP or inventory management system.

Step 3: Planning RFID Reader Placement

Proper placement of RFID readers is crucial for ensuring accurate tag detection. Consider these best practices:

Minimize Interference: Avoid placing readers near metallic surfaces, electronic equipment, or sources of radio noise.

Optimize Read Zones: Position antennas strategically to maximize coverage and minimize blind spots.

Test Placement: Conduct a site survey to identify optimal reader locations before final installation.

Consider Orientation: The angle and distance between tags and readers affect read accuracy.

Step 4: Installing RFID Hardware

1. Setting Up RFID Readers & Antennas

Mount readers securely in designated locations.

Connect antennas to readers using RF coaxial cables.

Ensure antennas are aligned properly for maximum signal strength.

2. Deploying RFID Tags

Select Appropriate Tags: Choose tags based on application needs (passive, active, or semi-passive).

Ensure Proper Tag Placement: Place tags where they are easily scannable and not obstructed by materials that can interfere with radio signals.

Test Tag Readability: Before full deployment, test tags under real-world conditions to ensure they are readable from different angles and distances.

3. Connecting to the Network

Connect readers to the local network via Ethernet, Wi-Fi, or Bluetooth.

Configure IP addresses and establish communication with the central server.

Ensure adequate power supply to all components.

Step 5: Configuring & Optimizing the RFID System

After installation, fine-tuning the system ensures optimal performance.

1. Configuring RFID Reader Settings

Adjust read power settings to avoid interference and improve accuracy.

Set up data filtering to eliminate duplicate or incorrect tag reads.

Define read zones to control where and when tags are read.

2. Software Integration

Connect the RFID system to inventory management, asset tracking, or ERP software.

Implement automated data logging and reporting for streamlined operations.

Ensure real-time data synchronization with enterprise systems.

3. Conducting Performance Testing

Run benchmark tests to measure read rates and system efficiency.

Identify and troubleshoot weak signal areas or interference zones.

Conduct stress tests to determine system reliability under high workloads.

Step 6: Maintaining & Troubleshooting Your RFID System

Regular maintenance is essential to prevent downtime and performance issues.

1. Routine Inspections

Check for loose connections, damaged antennas, or misplaced readers.

Ensure RFID tags are intact and not obstructed by environmental factors.

2. System Performance Monitoring

Use RFID analytics tools to monitor tag reads and identify irregularities.

Regularly update firmware and software to keep the system up-to-date.

3. Troubleshooting Common Issues

Interference Problems: Reposition readers and reduce external RF noise sources.

Tag Read Failures: Adjust reader power settings and verify tag placement.

Connectivity Issues: Restart network connections and check system logs for errors.

Conclusion

Installing and optimizing an RFID tag reader system requires careful planning, proper hardware setup, and continuous performance monitoring. By following these best practices, businesses can achieve enhanced tracking efficiency, improved accuracy, and seamless data integration. Implementing these steps will ensure your RFID system operates at peak performance, leading to increased operational efficiency and cost savings.

0 notes

Text

High Frequency Board Design

High-frequency PCB design is a specialized field that requires careful attention to signal integrity, impedance control, and electromagnetic interference (EMI) mitigation. Designing a PCB for high-frequency signals (typically above 100 MHz) or microwave frequencies (GHz range) demands a solid understanding of electrical engineering principles and the unique properties of materials and components at high frequencies.

Key Considerations in High-Frequency PCB Design:

1. Signal Integrity and Transmission Lines

Transmission Line Effects: At high frequencies, the PCB trace behaves like a transmission line, and signal degradation can occur if not properly designed. Transmission line impedance must be matched to the source and load impedance to avoid reflections.

Impedance Control: The characteristic impedance (typically 50 ohms for RF signals) of traces should be precisely controlled. The design needs to ensure that trace width, spacing, and the dielectric material thickness are optimized for the desired impedance.Microstrip Lines: These are traces on the surface of the PCB, with a reference plane (ground) below them.Stripline: Traces are sandwiched between two ground planes, providing better shielding and lower susceptibility to external EMI.Coplanar Waveguides: Similar to microstrips, but with the ground plane adjacent to the signal trace.

2. Material Selection

High-frequency PCBs require materials with low loss and stable dielectric properties at high frequencies:

PTFE-based materials like Rogers laminates, Teflon, and ceramic materials are common choices because they offer low loss and stable electrical performance.

FR-4 can be used for lower-frequency applications, but higher-performance materials are preferred for GHz designs due to the higher loss tangent of FR-4 at high frequencies.

3. Component Placement

Minimize Trace Lengths: The shorter the trace, the lower the loss and the higher the signal integrity. High-frequency signals degrade over distance due to resistance, capacitance, and inductance.

Strategic Grounding: Grounding is crucial for high-frequency PCBs. Poor grounding can cause noise, EMI, and ground bounce. Ensure the PCB has a solid, continuous ground plane and use via stitching to connect the ground planes together.

Decoupling Capacitors: These are used to filter out noise from power supply lines. At high frequencies, the placement of decoupling capacitors should be as close as possible to the components to reduce inductance.

4. Cross-Talk and EMI Control

Reduce Cross-Talk: Cross-talk between adjacent signal traces can cause unwanted coupling of signals. To minimize this, maintain a sufficient distance between traces carrying high-speed signals or use ground planes to shield them.

EMI Shielding: High-frequency designs are more susceptible to EMI. Techniques like using shielding cans, keeping high-frequency traces short, and maintaining a continuous ground plane can help mitigate EMI. Additionally, proper via placement and PCB layer stacking are critical in controlling the return currents of high-frequency signals.

5. Via Design

Via Inductance: Vias introduce inductance, which can degrade signal integrity at high frequencies. Microvias (small vias) and buried vias are used to reduce the inductance of traditional vias.

Via Size: Keep via sizes small to reduce their impact on the signal path. A smaller via reduces its inductance, making it less of a bottleneck at high frequencies.

6. Thermal Management

High-frequency signals generate heat, so thermal management is crucial in high-frequency PCB designs. Ensure that heat can dissipate from components and traces by using thermal vias, heat sinks, and adequate spacing between high-power components.

In some cases, ceramic PCBs are used because of their excellent thermal conductivity.

7. Simulation and Testing

Simulations: Use simulation tools like HFSS, ADS (Advanced Design System), and Ansys to simulate the behavior of high-frequency circuits before fabrication. This helps to verify signal integrity, impedance matching, and EM radiation.

Prototyping and Testing: After fabrication, high-frequency PCBs should be tested using tools like vector network analyzers (VNA) and time-domain reflectometers (TDR) to measure the reflection and loss of signals at various frequencies.

Design Process for High-Frequency PCBs:

Step 1: Understand the Frequency Range and Requirements

Identify the frequency range the design will operate in and the critical parameters like impedance, signal-to-noise ratio, and power handling capabilities.

Step 2: Choose the Right Materials

Based on the frequency and performance requirements, select appropriate PCB materials (e.g., PTFE, ceramic, Rogers laminates) that offer low loss and stable dielectric properties.

Step 3: Design Transmission Lines

Use tools like CAD software (e.g., Altium Designer, Eagle, OrCAD) to design traces that maintain controlled impedance and avoid sharp turns in the signal paths.

Implement proper via types and trace geometries for impedance matching.

Step 4: Grounding and Shielding

Ensure continuous and solid grounding to minimize noise and EMI.

Use ground planes for shielding and reduce cross-talk between high-frequency traces.

Step 5: Component Selection and Placement

Choose components that are designed for high-frequency applications (e.g., low parasitic inductance and capacitance).

Place components close to one another and ensure the power and ground planes are properly integrated.

Step 6: Use Simulation Tools

Before finalizing the design, simulate the circuit’s behavior using electromagnetic simulation software. This helps identify potential problems with signal integrity, impedance mismatch, and power delivery.

Step 7: Prototyping and Testing

Fabricate a prototype and perform tests like S-parameter measurements, time-domain reflectometry (TDR), and network analysis to ensure the PCB operates as expected in the high-frequency range.

Common Applications of High-Frequency PCBs:

Telecommunications: For RF circuits, antennas, and communication devices.

Microwave and Radar Systems: For military, aerospace, and scientific applications.

Satellite Communication: For high-frequency signal transmission in space systems.

Consumer Electronics: In products like smartphones, Wi-Fi devices, and Bluetooth.

Automotive: For radar systems and wireless communication in vehicles.

Conclusion:

High-frequency PCB design requires specialized knowledge of electromagnetic theory, materials science, and circuit design. By focusing on key areas like signal integrity, impedance control, and EMI management, engineers can ensure that high-frequency circuits perform reliably even at the most challenging frequencies. Proper simulation and testing are essential to validate the design and avoid performance issues during real-world use.

Let me know if you need more details or specific resources on any of these topics!

0 notes

Text

RF Chambers| Anechoic Chambers | dmcrf

Perfect radio frequency (RF) performance is essential for wireless communication, radar systems, and Internet of Things (IoT) devices in today's hyper-connected world. Ensuring these systems operate without interference requires specialized testing environments—RF chambers. These shielded enclosures, also known as Anechoic Chambers or EMC (Electromagnetic Compatibility) chambers, are critical for industries ranging from defense to telecommunications.

What Are RF Chambers?

An RF Chamber is a controlled environment designed to block external electromagnetic interference (EMI) while allowing precise RF testing. These chambers come in two primary forms:

Shielded Chambers – Block outside RF signals to create an interference-free zone.

Anechoic Chambers – Absorb internal reflections using RF-absorbing materials (ferrite tiles, foam pyramids).

How Do RF Chambers Work?

Faraday Cage Principle: Metal walls (usually steel or aluminum) block external RF signals.

RF Absorbers: Interior linings minimize reflections for accurate antenna and radar testing.

Filtered Ports: Allow power and data cables to enter without leaking interference.

Without RF Chambers, wireless devices could suffer from signal degradation, failed compliance tests, or even security vulnerabilities.

Industries That Rely on RF Chambers

Defense & Aerospace

Radar cross-section testing for stealth aircraft.

Secure communications (TEMPEST certification).

Satellite and avionics testing.

Telecommunications

5G base station validation.

IoT device certification.

Mobile phone RF performance testing.

Automotive

Electric vehicle (EV) EMC compliance.

Autonomous vehicle radar testing.

Medical Devices

Ensuring wireless medical implants (pacemakers) don’t interfere with other devices.

Consumer Electronics

FCC/CE certification for Wi-Fi routers, Bluetooth devices.

Why Choose DMC RF for Your RF Chamber Needs?

DMCRF specializes in custom RF testing solutions, offering:

Tailored chambers for defense, telecom, and automotive sectors.

Global compliance expertise (FCC, CE, MIL-STD).

Cutting-edge absorber technology for accurate measurements.

RF Chambers play a pivotal role in wireless innovation, from 5G deployment to military communications. As technology advances, the demand for more sophisticated, AI-integrated, and sustainable Rf Testing Solutions will grow. Companies like DMCRF are at the fore front, providing the infrastructure needed to keep our connected world running smoothly.

Contact us

Phone Number : +1(613) 915 5533

Website: https://www.dmcrf.com/

0 notes

Text

RF Filter Market Accelerates Amid Rising Mobile Connectivity and Expanding Global Communication Infrastructure

The RF filter market has become a key component of the global wireless communication infrastructure, growing rapidly due to increased mobile device usage, emerging 5G technology, and demand for high-speed data services. RF filters, also known as radio frequency filters, are essential in selecting desired frequencies and eliminating unwanted signals within electronic devices. They play a crucial role in improving signal clarity, reducing interference, and enhancing overall system performance in a wide array of applications, including smartphones, tablets, laptops, automotive systems, and base stations.

Market Overview

The RF filter market has witnessed remarkable growth over the past decade. According to industry analysts, the market size was valued at several billion dollars in recent years and is expected to continue expanding at a significant compound annual growth rate (CAGR) over the next five years. This growth is primarily driven by the proliferation of wireless communication standards (such as 4G and 5G), the rising penetration of IoT (Internet of Things) devices, and the increasing demand for spectrum efficiency.

Moreover, RF filters are being increasingly integrated into consumer electronics to support various communication protocols like Wi-Fi, Bluetooth, GPS, and LTE. With the transition from 4G to 5G, the complexity of wireless devices has increased, creating a higher need for advanced RF filters capable of managing signal integrity across different frequency bands.

Technology Landscape

There are several types of RF filters available in the market, including surface acoustic wave (SAW) filters, bulk acoustic wave (BAW) filters, and ceramic filters. SAW and BAW filters dominate the market due to their compact size, high performance, and ability to operate at higher frequencies.

SAW Filters: These are widely used in low- to mid-frequency applications and offer good performance at a relatively low cost. They are suitable for applications up to 3 GHz, making them a popular choice for 4G LTE networks.

BAW Filters: These filters are more advanced and support higher frequencies (up to 6 GHz), making them ideal for 5G applications. BAW filters offer better thermal stability and higher power handling, which are crucial for next-generation communication systems.

Technological advancements have led to the development of hybrid and tunable RF filters, which provide greater flexibility and improved performance. These innovations are helping manufacturers meet the growing demand for compact, energy-efficient, and high-performance wireless solutions.

Market Segmentation and Applications

The RF filter market is segmented by type, frequency range, end-use industry, and region. By application, the market serves several sectors:

Consumer Electronics: Smartphones, tablets, smartwatches, and other connected devices use RF filters to manage multiple radio frequency bands.

Telecommunications: Base stations, antennas, and network infrastructure equipment rely on RF filters for enhanced connectivity and data transmission.

Automotive: Advanced driver-assistance systems (ADAS), infotainment systems, and vehicle-to-everything (V2X) communication systems use RF filters to ensure clear signal transmission.

Aerospace and Defense: RF filters are critical in radar systems, satellite communication, and navigation systems to ensure reliable and interference-free performance.

Regional Analysis

Asia-Pacific dominates the RF filter market due to the presence of major smartphone manufacturers, rapid deployment of 5G infrastructure, and robust consumer demand. Countries like China, Japan, South Korea, and India are at the forefront of this growth.

North America is also a key player, driven by technological innovation and heavy investment in telecommunications infrastructure. Europe shows steady growth, supported by government initiatives for digital transformation and smart city projects.

Key Players and Competitive Landscape

Major companies operating in the RF filter market include Murata Manufacturing, Qorvo, Broadcom, Skyworks Solutions, TDK Corporation, Taiyo Yuden, and Kyocera. These companies are focusing on R&D, strategic partnerships, and mergers to gain a competitive edge.

Intense competition has led to innovations in filter miniaturization, integration with RF front-end modules, and the development of AI-based tuning for adaptive signal filtering.

Future Outlook

The future of the RF filter market looks promising, fueled by continuous advancements in mobile communication technologies, increased adoption of connected devices, and the ongoing rollout of 5G networks. The market is expected to witness strong demand from new application areas such as wearable electronics, industrial automation, and smart homes.

0 notes

Text

Maximize ADS-B Range: The Power of Low Noise Amplifiers

In the world of aviation, Automatic Dependent Surveillance–Broadcast (ADS-B) plays a crucial role in enhancing flight tracking and air traffic management. Enthusiasts, professionals, and organizations rely on ADS-B technology to track aircraft positions in real time. However, maximizing the reception of ADS-B signals requires specialized hardware, and one key component that significantly improves signal quality is the ADS-B Low Noise Amplifier (LNA).

What is ADS-B?

ADS-B is a surveillance technology in which aircraft automatically transmit their position, velocity, and other data to ground stations and other aircraft. This data transmission operates at 1090 MHz in most regions and is received by ADS-B ground stations, satellites, or enthusiasts using software-defined radios (SDRs). Due to the relatively weak signal strength over long distances, receiving these transmissions with high accuracy requires specialized components like an ADS-B LNA.

Understanding Low Noise Amplifiers (LNAs)

A Low Noise Amplifier (LNA) is an essential component in RF (radio frequency) reception systems. It amplifies weak signals received by an antenna while adding minimal noise to the system. LNAs improve the signal-to-noise ratio (SNR), which is crucial for capturing ADS-B transmissions with higher accuracy and over greater distances.

Why Use an LNA for ADS-B?

ADS-B signals at 1090 MHz are susceptible to attenuation, interference, and environmental factors such as buildings, trees, and weather conditions. An LNA helps mitigate these challenges by amplifying weak signals before they reach the SDR or receiver. Here are the key benefits of using an ADS-B LNA:

Improved Reception Range: Amplifying weak signals allows users to track aircraft farther from their location.

Enhanced Signal Quality: By boosting ADS-B signals while adding minimal noise, an LNA improves decoding accuracy.

Better Performance in Urban Areas: Buildings and other obstacles can weaken signals; an LNA helps overcome such losses.

Optimized SDR Performance: Many SDRs have limited sensitivity, and an LNA provides the necessary boost to receive clearer signals.

Choosing the Right ADS-B LNA

When selecting an ADS-B LNA, several factors should be considered:

● Gain: A gain of around 20–30 dB is typically ideal for ADS-B reception.

● Low Noise Figure: A lower noise figure (around 1 dB) ensures minimal added interference.

● Built-in Filters: Some LNAs come with bandpass filters to block unwanted signals from nearby frequencies.

● Powering Options: LNAs may require power via Bias-T, USB, or an external power supply.

Installing an ADS-B LNA

To set up an ADS-B LNA, follow these steps:

Place the LNA close to the antenna to amplify the signal before cable losses occur.

Ensure proper power supply based on the LNA’s requirements.

Use high-quality coaxial cables to minimize signal loss.

Pair with a bandpass filter if experiencing interference from other RF signals.

Conclusion

An ADS-B LNA is a game-changer for aviation enthusiasts and professionals looking to improve aircraft tracking performance. By amplifying weak signals and reducing noise, an LNA significantly enhances ADS-B reception, allowing users to track aircraft with greater accuracy and over longer distances. Whether you're a hobbyist or an aviation expert, integrating an LNA into your ADS-B setup is a worthwhile investment for superior tracking capabilities.

#uhf vhf antennas#wifi antenna booster#vhf antennas#antenna development engineer#antenna design company#external wifi booster#improve wifi signal#vhf antenna#wifi signal enhancer#iridium external antenna

0 notes

Text

RF Filter - RFI EMC Filter

In an era where electronic devices dominate industrial, medical, and commercial applications, maintaining clean and stable power is more critical than ever. Electromagnetic Interference (EMI) and Radio Frequency Interference (RFI) can severely disrupt sensitive equipment, leading to malfunctions, data corruption, and even system failures. This is where RFI EMC Filters come into play—providing essential protection by filtering out unwanted noise and ensuring compliance with global Electromagnetic Compatibility (EMC) standards.

At DMC RF, we specialize in manufacturing high-performance EMI/RFI power line filters, including the RFI EMC Filter 5 to 300 AMP (FCL-66, -660 Series), RFI EMC Filters 25 to 200 AMP (DMC FCL-11, -110, -14, -140, -1 Series), and a wide range of RFI EMC Filter Accessories (FCL-55, -66, -660 Series). Our filters are designed to meet the most stringent industry requirements, ensuring optimal performance and reliability.

Understanding EMI, RFI, and EMC Filters

What is EMI and RFI?

EMI (Electromagnetic Interference): Unwanted disturbances caused by electromagnetic radiation from external sources, affecting electronic circuits.

RFI (Radio Frequency Interference): A subset of EMI, specifically caused by high-frequency signals that disrupt communication and electronic systems.

Why Are EMC Filters Necessary?

Modern electronic devices must comply with EMC regulations (FCC, CISPR, IEC) to ensure they neither emit excessive interference nor are susceptible to external noise. RFI EMC Filters suppress conducted and radiated emissions, protecting both the equipment and surrounding devices from interference.

How Do RFI EMC Filters Work?

These filters use a combination of inductors (chokes), capacitors, and ferrite cores to:

Block high-frequency noise from entering or exiting a device.

Allow clean power to pass through without disruption.

Reduce electromagnetic emissions to meet regulatory standards.

DMC RF’s High-Performance RFI EMC Filters

1. RFI EMC Filter 5 to 300 AMP (FCL-66, -660 Series)

Designed for high-power industrial applications, this series ensures robust noise suppression in demanding environments.

Key Features:

Current Range: 5A to 300A

Voltage Rating: Up to 660V

High Attenuation: Effective noise reduction across a broad frequency spectrum

Rugged Construction: Built to withstand harsh industrial conditions

Compliance: Meets CISPR, EN 55011, and MIL-STD-461 standards

Applications:

✔ Industrial motor drives & servo systems ✔ Medical imaging & diagnostic equipment ✔ Renewable energy inverters & solar power systems ✔ Data centers & telecom infrastructure

2. RFI EMC Filters 25 to 200 AMP (DMC FCL-11, -110, -14, -140, -1 Series)

Ideal for medium-power applications, these filters provide reliable EMI suppression for commercial and industrial equipment.

Key Features:

Current Range: 25A to 200A

High Efficiency: Minimizes conducted and radiated interference

Flexible Mounting Options: Panel or chassis mounting available

Compact Design: Space-saving without compromising performance

Applications:

✔ CNC machines & robotics ✔ Power supplies & UPS systems ✔ HVAC & refrigeration units ✔ Laboratory & test equipment

3. RFI EMC Filter Accessories (FCL-55, -66, -660 Series)

To ensure seamless integration, DMC RF offers a range of compatible accessories, including:

Available Accessories:

Mounting brackets & hardware for secure installation

Shielded enclosures for enhanced EMI protection

Terminal connectors & cable glands

Customizable solutions for specialized applications

Why RFI EMC Filters Are Essential for Your Industry

1. Industrial Automation & Machinery

Prevents interference in PLC systems, servo drives, and robotics.

Ensures smooth operation of CNC machines and conveyor systems.

2. Medical & Healthcare Equipment

Protects sensitive MRI machines, X-ray systems, and patient monitors from noise.

Ensures compliance with medical EMC standards (IEC 60601).

3. Telecommunications & Data Centers

Reduces signal distortion in 5G infrastructure, servers, and networking equipment.

Enhances data integrity and transmission reliability.

4. Renewable Energy Systems

Filters noise from solar inverters, wind turbines, and battery storage systems.

Improves efficiency and lifespan of power electronics.

Choosing the Right RFI EMC Filter

Factors to Consider:

Current & Voltage Ratings – Match the filter to your system’s power requirements.

Attenuation Level – Ensure sufficient noise suppression for your application.

Mounting Style – Panel-mount, chassis-mount, or DIN rail options.

Regulatory Compliance – Check for FCC, CE, CISPR, and UL certifications.

Environmental Conditions – Consider temperature, humidity, and vibration resistance.

Why Choose DMC RF?

✔ Industry-Leading Quality – Rigorously tested for performance & durability. ✔ Wide Range of Options – From 5A to 300A, covering all industrial needs. ✔ Global Compliance – Meets international EMC/EMI standards. ✔ Expert Technical Support – Assistance in selecting the right filter for your application.

In today’s electrically noisy environment, RFI EMC Filters are indispensable for ensuring the reliable operation of sensitive electronic systems. Whether you need a 5A filter for small devices or a 300A industrial-grade solution, DMC RF provides high-performance, compliant, and durable filters tailored to your needs.

By integrating DMC RF’s EMI/RFI power line filters, you can reduce downtime, improve efficiency, and meet global EMC standards with confidence. Contact us now to find the perfect filter solution for your application!

Contact US :

Phone Number : +1(613) 915 5533

Website: https://www.dmcrf.com/emi-rfi-power-line-filters/

1 note

·

View note

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] Bring the studio home with the new SM4 Home Recording Microphone. Capture professional recordings of vocals and instruments with mix-ready audio and interference protection. The 1” brass dual-diaphragm capsule is engineered to consistently reproduce every element of your performance with remarkable accuracy and exceptional low-frequency control. Patent-Pending Interference Shielding Technology blocks unwanted RF noise from wireless devices including cellphones, laptops and wi-fi routers, while the internal pop filter minimizes plosives. A sleek, low-profile design with all-metal construction delivers the perfect upgrade for your home studio. SMOOTH AUDIO REPRODUCTION - The SM4 microphone features a brass 1-inch dual-diaphragm capsule, providing clean, controlled low-end frequencies and smooth, detailed highs for natural audio reproduction. SUPERIOR NOISE REJECTION - The SM4's uniform cardioid polar pattern ensures superior off-axis rejection of unwanted noise, capturing your sound source with clarity and precision. REDUCES PROXIMITY EFFECT - Designed with a large “sweet spot,” the SM4 reduces the proximity effect, offering more consistent audio quality, making it ideal for close-miking vocals and instruments. INTERFERENCE SHIELDING - The SM4 microphone employs patent-pending interference shielding technology, effectively blocking RF noise from cell phones, laptops, and Wi-Fi routers for cleaner audio. RECORD WITHOUT DISTORTION - Capable of capturing sounds up to 140dB, the SM4 ensures your loud instruments come through clearly without any distortion, thanks to its high-SPL handling. [ad_2]

0 notes

Text

Test Enclosures: Designing for Accurate and Reliable RF Measurements

In the realm of radio frequency (RF) engineering, accurate and reliable measurements are paramount. External electromagnetic interference (EMI) can significantly distort test results, leading to erroneous conclusions and potentially costly design flaws. To mitigate these challenges, engineers rely on specialized enclosures designed to isolate the device under test (DUT) from external electromagnetic influences.

Key Considerations in Test Enclosure Design

Shielding Effectiveness: This critical parameter quantifies the enclosure's ability to attenuate external electromagnetic fields. It's typically measured in decibels (dB) and depends on factors such as: Material: Conductive materials like copper, aluminum, and steel are commonly used.

Thickness: Thicker materials generally provide better shielding. Seams and Joints: Proper construction is vital. Seams must be carefully sealed to minimize leakage paths for electromagnetic waves. Techniques like welding, brazing, and the use of conductive gaskets are employed.

Frequency Range: The enclosure must effectively shield against the specific frequency range of interest. Higher frequencies often require more robust shielding.

Ventilation: Adequate ventilation is essential to prevent overheating of the DUT. Vents must be designed to minimize electromagnetic leakage while allowing for efficient airflow. This can be achieved through the use of shielded vents or filters.

Grounding: Proper grounding is crucial to minimize ground loops and ensure a stable test environment. All conductive components within the enclosure should be properly grounded to a common ground point.

Aperture Effects: Any openings in the enclosure, such as cable ports or ventilation slots, can compromise shielding effectiveness. Careful design and the use of specialized filters are necessary to minimize these effects.

Mode Stirring: For accurate antenna measurements, mode stirrers can be incorporated within the enclosure to create a more uniform electromagnetic field distribution.

Types of Test Enclosures

Shielded Rooms: Large, dedicated enclosures providing high levels of shielding. They are often used for precise measurements and testing of sensitive equipment.

Shielded Boxes: Smaller, portable enclosures offering a convenient and cost-effective solution for shielding smaller devices and components.

Anechoic Chambers: These specialized enclosures are lined with absorbing materials to minimize reflections and create a nearly free-space environment for antenna measurements.

Applications of Test Enclosures

EMC Testing: Assessing the electromagnetic compatibility of electronic devices.

Antenna Measurements: Characterizing antenna performance in a controlled environment.

RF Component Testing: Evaluating the performance of RF components such as filters, amplifiers, and mixers. Wireless Device Testing: Assessing the performance of wireless devices in various communication scenarios.

Conclusion

Test enclosures are indispensable tools for accurate and reliable RF measurements. By carefully considering the factors outlined above and implementing appropriate design and construction techniques, engineers can create controlled environments that minimize the impact of external electromagnetic interference, ensuring the integrity of their test results.

0 notes