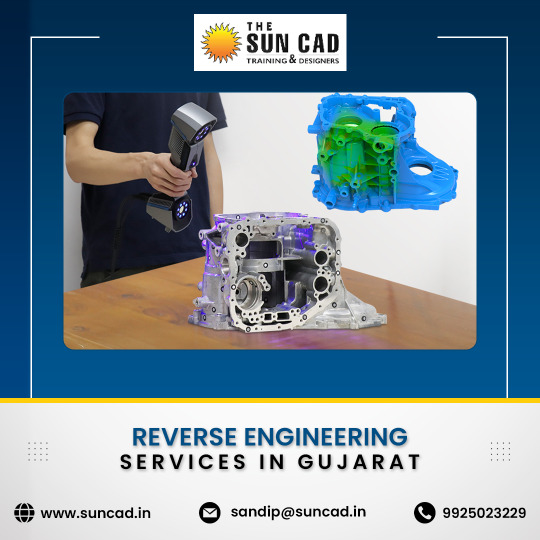

#Reverse Engineering in Gujarat

Text

Sun Cad provides the Professional Surveying In Gujarat for the purpose of land and construction projects among which are the professional and reliable solutions. The surveyors with experience in our team are using advanced tools and technologies to carry out precise measurements and surveys. Whether it is through boundary surveys to topographic mapping, we provide all-round surveying services to cater for your project requirements and to make your project successful. For more information visit on : https://www.suncad.in or call us on : +91-9925023229.

0 notes

Text

The Leading Check Valve and SS Check Valve Manufacturer in India

India's industrial landscape is growing exponentially, and with this growth comes the increasing demand for high-quality industrial components such as check valves. Pedlock is a premier check valve and SS check valve manufacturer in Chennai, Ahmedabad, Mumbai, Bangalore, Rajasthan, Gujarat, Delhi and Ghaziabad in India, has carved a niche for itself in this competitive space by providing top-notch products that meet international standards. If you're looking for reliability, efficiency, and precision-engineered solutions, is the name to trust. This article delves into why Pedlock Valves is the best choice for check valves in India, detailing their offerings and industry expertise.

What Are Check Valves and Why Are They Important?

Check valve and ss check valve play a critical role in a wide range of industries, including oil & gas, petrochemicals, water treatment, and power generation. These one-way valves prevent reverse flow, ensuring that fluids move in a single direction through pipelines. Their primary function is to protect equipment from damage, maintain process efficiency, and prevent backflow contamination. Pedlock Valves specializes in manufacturing check valves that provide superior reliability, durability, and performance under the most demanding conditions.

Pedlock Valves: The Benchmark in Check Valve Manufacturing

Pedlock Valves has established itself as a leading check valve and ss check valve manufacturer in India, thanks to its focus on quality, innovation, and customer satisfaction. The company adheres to stringent quality standards and uses state-of-the-art manufacturing processes to deliver products that meet or exceed industry expectations.

Key Features of Pedlock Check Valves

Hydraulic Flow control valve: Pedlock is valves manufacturer, exporters and supplier of world class range of Hydraulic Flow Control Valves Manufacturer in Ahmedabad, Mumbai, Vadodara, Ghaziabad, Rajasthan, Chennai, Bangalore, Delhi, Gujarat in India.

Hydraulic Check valve: Pedlock is hydraulic ball valves and Hydraulic Check valves manufacturer in Ahmedabad, Mumbai, Delhi, Chennai, Bangalore, Rajasthan, Ghaziabad, Vadodara, Gujarat.

SS Needle valve: Pedlcok is a leading needle valves and ss needle valves manufacturer in Ahmedabad, Vadodara, Mumbai, Delhi, Chennai, Bangalore, Ghaziabad, Rajasthan, Gujarat India.

Types of Check Valves Offered by Pedlock

Pedlock offers a comprehensive range of check valve and ss check valve designed to meet the varied needs of different industries. Their product portfolio includes:

1. Check Valve

Check valves are ideal for systems where low-pressure drop and flow efficiency are essential. These valves feature a disc that swings on a hinge or shaft, allowing fluid to flow in one direction and preventing reverse flow. Swing check valves are designed to offer smooth operation and minimal maintenance.

2. SS Check Valve

SS check valve are compact and lightweight, making them a popular choice for industries where space is at a premium. These valves fit between two flanges, offering easy installation and cost-effective solutions for preventing backflow in pipeline systems.

3. Dual Plate Check Valve

Dual plate check valves are designed for high-pressure applications. These valves feature two spring-loaded plates that close automatically when flow reverses, offering enhanced durability and superior performance in challenging environments.

4. Lift Check Valve

Lift check valves are used in high-pressure and high-temperature applications. The valve disc lifts automatically with the flow of fluid and falls back into place when the flow stops, preventing reverse flow. These valves are ideal for steam, gas, and other high-pressure media.

5. Ball Check Valve

Ball check valves are a versatile and cost-effective solution for industries dealing with slurries and viscous fluids. Our company manufactures these valves with a focus on durability and efficient operation, ensuring reliable performance in the toughest industrial conditions.

Why Choose Pedlock Valves for Your Check Valve and SS Check Valve Needs?

Choosing the right check valve manufacturer is critical to ensuring the long-term success of your operations. This company offers a variety of benefits that make them the preferred choice for many industries in India and abroad:

1. Uncompromised Quality

Our places a strong emphasis on quality at every stage of the manufacturing process. From material selection to final inspection, each valve is subjected to strict quality controls to ensure it meets the highest standards.

2. Extensive Industry Experience

With decades of experience has a deep understanding of the challenges faced by industries that rely on check valves. Their expert team is dedicated to providing innovative solutions that cater to the specific needs of each sector.

3. Advanced Technology

Pedlock is committed to staying at the forefront of technological advancements. The company continually invests in research and development to improve the efficiency, performance, and reliability of its check valve products.

4. Competitive Pricing

We are focuses on delivering premium products, they also ensure that their pricing is competitive. This balance of quality and affordability makes them the go-to manufacturer for businesses looking for cost-effective solutions without compromising on performance.

5. Excellent Customer Support

We are is renowned for its customer-centric approach. The company provides comprehensive support throughout the entire purchasing process, from product selection to after-sales service, ensuring a seamless experience for its clients.

Conclusion

Pedlock stands out as a leader in the check valves & SS Check Valves Manufacturer in Mumbai, Delhi, Ahmedabad, Chennai, Vadodara, Gujarat, Rajasthan, Ghaziabad, Bangalore industry in India, providing solutions that meet the highest standards of quality, performance, and reliability. Whether you’re in the oil and gas sector, water treatment, or power generation, Our Company has the expertise and product range to cater to your specific needs. Their dedication to customer satisfaction, combined with advanced manufacturing techniques, makes them a trusted partner for businesses seeking durable and efficient check valve solutions.

#Check valve manufacturer in India#Mumbai#Chennnai#Ahmedabad#Vadodara#Gujarat#rajasthan#ghaziabad#bangalore#Delhi#SS Check valve manufacturer in India

0 notes

Text

Exporter of Multi Effect Evaporator in Zimbabwe

Drytech Engineering Systems is your trusted partner for advanced Exporter of Multi Effect Evaporator in Zimbabwe.

Our manufacturing unit is based in Ahmedabad, Gujarat, India.

We specialize in providing high-quality evaporator solutions that meet the rigorous demands of various industrial applications.

Our Expertise: As a leading manufacturer, supplier, and exporter, we offer a diverse range of equipment including Flash Dryers, Spray Dryers, Spin Flash Dryers, Fluid Bed Dryers, and Evaporator Dryers, Rotary Valves, Rotary Atomizers, Hot Air Generators, Centrifugal Blowers, Dust Collector Systems.

Multi Effect Evaporators are sophisticated systems designed to concentrate solutions by removing solvents, primarily water, through the application of heat.

These systems operate through multiple evaporation stages arranged in series, each stage operating at progressively lower pressures to enhance energy efficiency and reduce operational costs.

Types of Multi Effect Evaporators We Offer:

Fully Automatic Multi-Effect Evaporator

Semi-Automatic Multi-Effect Evaporator

Features of Our Multi Effect Evaporators:

Oily Emulsions: Efficiently handle oily emulsions and similar substances.

Coolant Fluids: Manage coolant fluids used in various industrial processes.

Mold Release Agents: Ideal for the removal of mold release agents.

Water Removal: Effective for purging water from washing floors, tanks, and reactors.

Galvanic Processes: Suitable for working and washing baths in galvanic processes and surface treatments.

Penetrating Liquids: Capable of processing penetrating liquids.

Water Treatment Plant Rejection: Handles water from reverse osmosis and demineralization processes.

Drytech Engineering Systems is an Exporter of Multi Effect Evaporator in Zimbabwe including locations Harare, Bulawayo, Chitungwiza, Mutare, Epworth, Gweru, Kwekwe, Kadoma, Masvingo, Chinhoyi, Norton, Marondera, Ruwa, Chegutu, Zvishavane, Bindura, Beitbridge, Redcliff, Victoria Falls, Hwange, Rusape, Chiredzi, Kariba, Karoi, Chipinge, Gokwe, Shurugwi.

For detailed information and inquiries, please feel free to contact us.

View Product: Click Here

Read the full article

0 notes

Text

Top-rated reverse osmosis plant manufacturer in Mumbai. Offering advanced water purification solutions for residential, commercial, and industrial needs. Experience pure, clean water with Water Enviro Engineers.

0 notes

Text

Monofilament Extrusion Plant Manufacturers | Aawadkrupa Plastomech

Monofilament Extrusion Plant Manufacturers | Akiropes

At Aawadkrupa Plastomech Pvt. Ltd., we're a top manufacturer of monofilament extrusion plants in India. Our machines are top-notch and go all around the world. They work really well and save time and energy because we use the latest technology. We can even customise our machines to fit exactly what you need. Plus, we're always here to help you with setup and maintenance. We've been doing this for a long time, and we're always trying to make our machines even better for you.

Key Features

Extra strength & shining to yarn.

Longer life of screw & barrel.

AC inverter & motor which synchronises the entire extruder.

PP, HDPE & LD can be processed due to its special screw design.

Latest technology used to force the melt into the die very effectively.

Less noisy pollution.

Less power consumption.

More power saving in heater due to self-calibration Technology.

Use a friendly touch screen display with a separate desk.

All parameters and reading will be shown on display.

Timer based Auto-startup and shutdown heating system.

Reverse heating interlocking system to avoid damage to the machine.

Emergency full length foot switches parallel to the godded length for both godded.

Available Models

1 APPL / MF – 55 AC

2 APPL / MF – 65 AC

3 APPL / MF – 75 AC

4 APPL / MF – 90 AC

5 APPL / MF – 100AC

6 APPL / MF – 80 GF

7 APPL / MF – 110AC

8 APPL / MF – 120AC

9 APPL / MF – 75 AC

10 APPL / MF – 90 AC

11 APPL / MF – 110 AC

Unrivalled Quality and Precision

Akiropes' monofilament extrusion plants are engineered to deliver unrivalled quality and precision in every strand. With a keen focus on innovation and meticulous attention to detail, these plants are designed to produce monofilaments of exceptional consistency and durability. Whether you're extruding nylon, polyethylene, or any other material, Akiropes' machinery ensures superior performance and reliability.

Global Reach, Local Support

With a strong presence in over 65 countries, Akiropes understands the diverse needs of customers worldwide. Whether you're located in Asia, Africa, Europe, or the Americas, Akiropes provides localised support and service to ensure seamless integration of their monofilament extrusion plants into your production process. Their team of experts is available 24/7 to address any queries or concerns, ensuring a hassle-free experience from start to finish.

On-Time Delivery

In today's fast-paced business environment, timely delivery is essential. Akiropes recognizes the importance of meeting deadlines and strives to ensure that orders are processed and dispatched promptly. Their streamlined manufacturing processes and efficient logistics management guarantee on-time delivery, allowing you to stay ahead of schedule and meet your production targets with confidence.

Comprehensive Solutions

Akiropes offers a comprehensive range of monofilament extrusion plants to cater to a variety of applications and requirements. Whether you're in need of a standard model or a customised solution tailored to your specific needs, Akiropes has the expertise and capability to deliver. Their experienced engineers work closely with customers to understand their unique challenges and provide optimal solutions that maximise efficiency and productivity.

Conclusion

In conclusion, Akiropes is your trusted partner for high-quality monofilament extrusion plants. With a commitment to excellence, global reach, 24/7 support, and on-time delivery, they offer a comprehensive solution for businesses worldwide. Whether you're looking to expand your production capabilities or upgrade your existing machinery, Akiropes has the expertise and resources to meet your needs. Get in touch with them today to request a quote and experience the Akiropes difference firsthand!

For More Information:

"Aawadkrupa" survey no-131-A,Navagam Bhavnagar-Rajkot highway Bhavnagar, Gujarat 364060

9510186014,9879615963

#monofilament extrusion#monofilament extrusion plant#monofilament extrusion machine#monofilament extrusion plant for sale#monofilament extrusion plant price#monofilament extrusion plant manufacturer#monofilament extrusion plant exporter#monofilament extrusion plant in india#monofilament extrusion machine in india

0 notes

Text

The Ultimate Guide to Choosing the Best Hydraulic Check Valve Manufacturer in India

Hydraulic check valves play a crucial role in many hydraulic systems, ensuring the smooth and safe operation of machinery. Whether you’re working in manufacturing, automotive, or construction, the right hydraulic check valve can make all the difference. Today, we spotlight Pedlock, a leading manufacturer renowned for its quality and innovation in hydraulic check valves manufacturer in Mumbai, Ahmedabad, Chennai, Delhi, Vadodara, Rajasthan, Ghaziabad, Bangalore, Gujarat in India.

Understanding Hydraulic Check Valves

What are Hydraulic Check Valves?

Hydraulic ball valves and check valves are devices that allow fluid to flow in one direction while preventing backflow. They are essential components in hydraulic systems, ensuring that the flow of fluid is controlled and directed as needed.

Key Functions and Applications

These valves are used in various applications, from industrial machinery to automotive systems. They help maintain pressure, prevent contamination, and protect equipment from damage caused by reverse flow.

Types of Hydraulic Check Valves

There are several types of hydraulic check valves, including ball check valves, swing check valves, and lift check valves. Each type has its specific applications and advantages, depending on the system’s requirements.

Why Quality Matters in Hydraulic Ball Valves & Check Valves

Impact on System Efficiency

A high quality hydraulic Ball valve and check valve ensures that your system operates efficiently. Poor-quality valves can lead to leaks, pressure drops, and overall system inefficiencies.

Long Term Cost Savings

Investing in quality valves from a reputable manufacturer like Pedlock can save you money in the long run by reducing maintenance costs and preventing expensive system failures.

Safety Considerations

Safety is paramount in any hydraulic system. Reliable check valves help prevent accidents and ensure the safe operation of your equipment.

Pedlock: A Pioneer in Hydraulic Check Valve Manufacturing

Company History and Background

Pedlock has been a trusted name in the hydraulic check valve industry for decades. Founded with a commitment to quality and innovation, Pedlock has grown to become a leader in the field.

Core Values and Mission

Pedlock’s mission is to provide the best hydraulic solutions with a focus on quality, reliability, and customer satisfaction. Their core values include integrity, innovation, and excellence.

Innovation and Technology

Pedlock invests heavily in research and development, ensuring that their products incorporate the latest technologies and innovations in hydraulic engineering.

Product Range Offered by Pedlock

Overview of Different Hydraulic Check Valves

Pedlock offers a wide range of hydraulic check valves manufacturer Mumbai, Ahmedabad, Chennai, Delhi, Vadodara, Rajasthan, Ghaziabad, Bangalore, Gujarat in India to suit various applications. Their product line includes ball check valves, swing check valves, and more.

Special Features and Benefits

Each Pedlock valve is designed with unique features that enhance performance and durability. For example, their ball check valves are known for their robust construction and reliable sealing.

Customization Options

Pedlock understands that every system is unique. They offer customization options to tailor their valves to your specific needs, ensuring optimal performance and compatibility.

Manufacturing Excellence at Pedlock

State of the Art Facilities

Pedlock’s manufacturing facilities are equipped with the latest machinery and technology, allowing them to produce high-quality valves with precision and efficiency.

Quality Control Processes

Every valve undergoes rigorous testing and quality control processes to ensure it meets Pedlock’s high standards. This commitment to quality ensures reliable and long-lasting products.

Certifications and Standards

Pedlock is certified by various industry standards organizations, reflecting their commitment to quality and safety. These certifications give customers confidence in the reliability of Pedlock’s products.

The Pedlock Advantage

Superior Materials and Durability

Pedlock uses only the best materials in their valves, ensuring they can withstand harsh conditions and heavy use. This durability translates to longer lifespans and fewer replacements.

Advanced Design and Engineering

Pedlock’s team of engineers is dedicated to designing valves that meet the highest performance standards. Their advanced designs help improve system efficiency and reliability.

Customer Support and Service

Pedlock prides itself on providing excellent customer service. Their knowledgeable support team is always ready to assist with any questions or concerns, ensuring a smooth experience from purchase to installation.

Case Studies and Success Stories

Real-World Applications

Pedlock’s valves are used in a variety of industries, from automotive to industrial machinery. Real-world case studies demonstrate how their products have improved system performance and reliability.

How to Choose the Right Hydraulic Check Valve

Factors to Consider

When choosing a hydraulic check valve, consider factors such as the type of fluid, pressure requirements, and the specific application. Pedlock offers a range of options to meet different needs.

Pedlock’s Recommendations

Pedlock’s experts can help you choose the right valve for your system. Their recommendations are based on years of experience and a deep understanding of hydraulic systems.

Installation and Maintenance Tips

Best Practices for Installation

Proper installation is crucial for the optimal performance of hydraulic check valves. Follow Pedlock’s installation guidelines to ensure a secure and efficient setup.

Maintenance Guidelines to Extend Lifespan

Regular maintenance can extend the lifespan of your hydraulic check valves. Pedlock provides detailed maintenance guidelines to help you keep your valves in top condition.

Industry Trends and Future Outlook

Emerging Technologies

The hydraulic industry is constantly evolving, with new technologies emerging regularly. Pedlock stays ahead of the curve by incorporating the latest advancements into their products.

Future Developments in Hydraulic Check Valves

Looking ahead, Pedlock is committed to continuing their tradition of innovation. They are actively working on new designs and technologies to meet the future needs of the industry.

Environmental and Sustainability Efforts

Pedlock’s Commitment to Sustainability

Pedlock is dedicated to sustainability and environmental responsibility. They strive to minimize their environmental impact through eco-friendly practices and products.

Eco-Friendly Products and Practices

From using sustainable materials to implementing energy-efficient manufacturing processes, Pedlock is committed to protecting the environment while delivering high-quality products.

Conclusion

Choosing the right hydraulic check valve manufacturer Mumbai, Ahmedabad, Chennai, Delhi, Vadodara, Rajasthan, Ghaziabad, Bangalore, Gujarat in India is crucial for the efficiency and safety of your hydraulic system. Pedlock stands out as a leading manufacturer, offering high-quality, reliable, and innovative hydraulic check valves. With their extensive product range, commitment to quality, and excellent customer support, Pedlock is the go-to choice for all your hydraulic check valve needs.

#Hydraulic Check valve manufacturer in Mumbai#Hydraulic Check valve manufacturer in Ahmedabad#Hydraulic Check valve manufacturer in Chennai#Hydraulic Check valve manufacturer in Bangalore#Hydraulic Check valve manufacturer in Vadodara#Hydraulic Check valve manufacturer in Gujarat#Hydraulic Check valve manufacturer in Delhi#Hydraulic Check valve manufacturer in Ghaziabad#Hydraulic Check valve manufacturer in Rajasthan

0 notes

Text

Hydraulic Flow Control valve manufacturer in India

Looking for a Hydraulic Flow Control Valve manufacturer in Ahmedabad, Vadodara, Mumbai, Delhi, Chennai, Bangalore, Ghaziabad, Rajasthan, Gujarat India. Ped-lock valves and fittings Explore wide range of precision-engineered valves designed for controlling hydraulic flow in industrial applications.

We are one of the pioneered manufactures, exporters and supplier of world class range of Hydraulic Flow Control Valve Manufacturer in Ahmedabad, Mumbai, Vadodara, Ghaziabad, Rajasthan, Chennai, Bengalore, Delhi, Gujarat in India. Highly demanded in the market, these valves come in different specifications. We offer Hydraulic Flow Control Valves at cost effective prices.

The scale on the lower edge of the control knob enables accurate repeat setting. The DRV is a flow control valve in the same design which also allows the same fine flow adjustment, but in one direction only. Unrestricted flow in the reverse direction is via the built-in check valve – cracking pressure 7 psi (0.5 bar)It is used in various applications suitable for steam, hydraulics, oil and gas media and all high pressure fluid in various industries. We use finest quality materials to manufacture these valves.

0 notes

Text

Export of Heavy Duty Conveyor in Israel

Laxmi Pharma Equipment is a leading Manufacturer, Supplier, and Export of Heavy Duty Conveyor in Israel, specializing in pharmaceutical machinery.

Established in 1985 in Phase III, Vatva, Ahmedabad, Gujarat, India, the company offers a comprehensive range of high-quality equipment, including Washing Machines, Filling Machines, Stoppering Machines, Capping Machines, Labelling Machines, Packaging Machines, Process Equipment, and more.

Heavy-duty conveyors play a significant role in enhancing efficiency, safety, and productivity in the pharmaceutical sector.

These conveyors operate using a motor to drive a belt or chain, facilitating the movement of materials or products within a facility.

Features:

Durability: Built to withstand demanding industrial environments, ensuring longevity.

Handling Capacity: Engineered to handle substantial weights, suitable for transporting large and heavy products or materials.

Variety: Available in various types, including belt conveyors, roller conveyors, and chain conveyors, catering to different material handling needs.

Customization: Can be customized to fit specific requirements, offering flexibility in design and functionality.

Variable Speed Control: Many heavy-duty conveyors feature variable speed control, allowing operators to adjust speed based on production or processing requirements.

Directional Movement: Capable of moving materials in different directions (forward, reverse, incline/decline), providing flexibility in material flow.

Ease of Maintenance: Designed for easy maintenance, with accessible components like bearings and belts for inspection and replacement.

Geographical Availability:

Laxmi Pharma Equipment Export of Heavy Duty Conveyor in Israel Including Ashdod, Ashqelon, Bat Yam,

Beersheba, Bet Sheʾan, Bet Sheʿarim, Bnei Brak, Caesarea, Dimona, Dor, Elat, ʿEn Gedi, Givʿatayim, H̱adera,

Haifa, Herzliyya, H̱olon, Jerusalem, Karmiʾel, Kefar Sava, Lod, Meron, Nahariyya, Nazareth, Netanya, Petaẖ Tiqwa, Qiryat Shemona, Ramat Gan, Ramla, Reẖovot, Rishon LeẔiyyon, Sedom, Tel Aviv–Yafo, Tiberias, Ẕefat.

For inquiries and information, customers are welcome to contact Laxmi Pharma Equipment.

Read the full article

#Ashdod#Ashqelon#BatYam#Beersheba#BetSheʾan#BetSheʿarim#BneiBrak#bottlefillingmachines#Caesarea#Cosmetics#Dimona#Dor#Elat#ExportofHeavyDutyConveyor#ExportofHeavyDutyConveyorinIsrael#Exporter#Givʿatayim#H̱adera#Haifa#HeavyDutyConveyorinIsrael#Herzliyya#H̱olon#India#Jerusalem#Karmiʾel#KefarSava#liquidfillingmachines#Lod#Manufacturer#ManufacturerofHeavyDutyConveyor

0 notes

Text

HVLS Ceiling Fan Manufacturer from Ahmedabad

AUSTAR HVLS FANS are manufactured by Austar Technologies having a manufacturing facility at well-known industrial city Ahmedabad Gujarat INDIA. Austar Technologies have a dedicated manufacturing facility for HVLS Fans of 20000 Square Feet Area and have a manufacturing capacity of 200 Fans per month

What are HVLS ceiling fans?

The mechanical fan type known as a high-volume low-speed (HVLS) fan is larger than seven feet (2.1 metres) in diameter. Ahmedabad-based manufacturer of HVLS ceiling fans. The phrase "high volume, low speed" refers to HVLS fans because they rotate slowly and disperse a lot of air at a low speed.

What is The Purpose of HVLS Ceiling Fans?

HVLS fans are typically employed to provide cooling for spaces larger than 40,000 square feet. Really, any big place where a steady, comfortable, and secure atmosphere is necessary may benefit greatly from the installation of a commercial HVLS fan. HVLS Ceiling Fans can aid in employee retention, control moisture and humidity, and generate year-round energy savings.

Advantages of Our HVLS Ceiling Fans

Exceptional Air Circulation

Energy Efficiency

Cost-Effective Cooling Solution

Quiet Operation

Enhanced Ventilation

Year-Round Comfort

Customizable Designs

OUR HVLS FAN:-

Geared HVLS Fan

Gearless HVLS Fan

Geared HVLS Fan: - Geared HVLS Fan: Austar's GEARED HVLS Fans are energy-efficient, silent, precision-engineered wonders that maximise air circulation in huge areas. These fans are quite comfortable and are perfect for use in commercial and industrial environments.

A Geared HVLS (High Volume Low Speed) Fan refers to a type of large ceiling fan that incorporates a gearing system in its design. HVLS fans are known for their ability to move large volumes of air at low rotational speeds, typically in the range of 60 to 120 revolutions per minute (RPM). The addition of a gear mechanism allows for greater control over the fan's speed and performance.

Gearless HVLS Fan: - HVLS Fan Without Gear: - With its maintenance-free design and strong, quiet air circulation in wide expanses, Austar's GEARLESS HVLS Fan is the epitome of innovation for commercial and industrial applications.

0% depreciation of the fan's performance throughout their lifetime.

Geared HVLS Fan Gearless HVLS Fan

Industrial HVLS fans are used in a variety of industries.

Manufacturing and Warehousing

Distribution canters and Logistics

Automotive Industry

Agriculture and Farming

School, University, etc.

(Frequently Asked Questions) for HVLS Ceiling Fan Manufacturer

How do HVLS fans work?

HVLS fans work by moving large volumes of air at low speeds. The size and shape of the fan blades, coupled with the low rotational speed, create a gentle breeze that improves air circulation and enhances thermal comfort.

What size options are available for HVLS fans?

HVLS fans come in various sizes, typically ranging from 6 to 24 feet in diameter. The appropriate size depends on factors such as the size of the space, ceiling height, and specific airflow requirements.

Are HVLS fans suitable for both summer and winter use?

Yes, HVLS fans are versatile and can be used year-round. In the summer, they create a cooling effect through air movement, while in the winter, they can be reversed to gently circulate warm air trapped near the ceiling.

Contact Us: - +91 9824685566, [email protected]

Address: - 14, Satvam Industrial Park, Dhamatvan – Vanch road, Village: Dhamatvan, Ta : Daskroi, Ahmedabad – 382435

Visit for More Information: - https://www.austarfansindia.com/

0 notes

Text

Best 3D Scanning Services in Vadodara, Gujarat. ✓3D Laser Scanner Services, ✓3D Scanning Services , ✓Portable CMM Laser Tracker Services, ✓ Reverse Engineering, ✓ 3D Plant Scanning.

1 note

·

View note

Text

Through Reverse Engineering Services In Gujarat provided by Sun Cad, businesses can restore, copy and better already existing products or components by simply pressing a button. Our well-experienced engineers employ different modern technologies to deconstruct and analyse the particular object, gathering information on its dimensions, materials and functionality. Companies can solve the issues of improving performance, optimising manufacturing, and keeping ahead of competitors by reverse engineering their existing products. For more information visit on : https://www.suncad.in or call us on : +91-9925023229.

0 notes

Text

How to Choose the SS Check Valve Manufacturer in India for Your Industry

In the industrial world, choosing the right components is crucial for ensuring efficiency and safety. One such critical component is the SS check valve. As a leading SS check valve and check valve manufacturer in Mumbai, Ahmedabad, Delhi, Chennai, Rajasthan, Ghaziabad, Vadodara, Gujarat, and Bangalore India Padlock provides superior products designed to meet the stringent demands of various industries.

Why Choose Padlock for SS Check Valves?

Pedlock stands out as a top SS check valve manufacturer due to its commitment to quality, innovation, and customer satisfaction. Our check valves are made from high-grade stainless steel, ensuring durability, corrosion resistance, and reliable performance in harsh environments. Whether you’re in the oil and gas sector, chemical processing, or water treatment, our valves are designed to perform under the most demanding conditions.

Understanding SS Check Valves

SS check valves are essential in preventing backflow in piping systems. These valves allow fluid to flow in one direction while automatically preventing reverse flow, thereby protecting equipment from damage and maintaining process integrity. At Pedlock, we offer a variety of SS check valves, each designed to cater to specific industrial needs.

Types of SS Check Valves

Check Valves: Ideal for pipelines with low flow velocities, these valves have a disc that swings open to allow flow and swings back to block reverse flow.

Safety Valves: These are used in systems where the flow is typically unidirectional, and the flow force lifts the disc to allow passage. When the flow stops, the disc drops to prevent backflow.

SS Ball Valves: Suitable for systems where low-pressure drop and minimal backflow are crucial. The ball inside the valve moves to block or allow flow depending on the pressure differential.

Advantages of Using SS Check Valves

Corrosion Resistance: Made from high-quality stainless steel, our valves are highly resistant to corrosion, making them suitable for use in corrosive environments.

Durability: Our check valves are designed to withstand extreme temperatures and pressures, ensuring long service life and reduced maintenance costs.

Leak-Proof Design: Precision engineering ensures that our valves offer a leak-proof solution, critical for maintaining system integrity.

Customizable Solutions: Pedlock provides customized SS check valves to meet specific client requirements, ensuring optimal performance in your application.

Conclusion

When it comes to choosing an SS check valve and check valve manufacturer in Mumbai, Ahmedabad, Delhi, Chennai, Rajasthan, Ghaziabad, Vadodara, Gujarat, and Bangalore India. Pedlock is the name you can trust. Our commitment to quality, extensive product range, and customer-focused approach make us the ideal partner for all your valve needs. Contact us today to learn more about our products and how we can help you achieve your operational goals.

#SS Check valve manufacturer in mumbai#SS Check valve manufacturers in Delhi#SS Check valve manufacturers in chennai#ss check valves manufacturers in bangalore#SS Check valve manufacturers in Rajasthan#SS Check valve manufacturers in ghaziabad#ss check valves manufacturer in gujarat#SS Check valve manufacturers in Vadodara#ss check valves manufacturer ahmedabad

0 notes

Text

Post # 124

The economics, humanities and politics of "Sarai"...

In February, 2014, the Andhra Pradesh Reorganization Bill was passed and Telangana broke away. The resultant state of Andhra now looks like this. :-)

In 2019, state general elections were held in A.P and YSR Congress won hands down. YS Jaganmohan Reddy became Chief Minister and set out to fulfill a unique electoral promise to his vote bank - Prohibition of Liquor in the state of A.P.

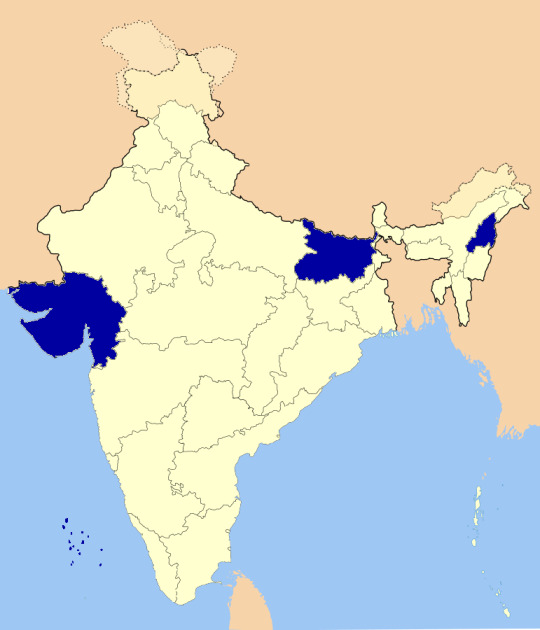

The new liquor policy, which includes a 40% reduction in bar licences, exorbitant hike of new license fees, closure of some 40000 illegal outlets, time restrictions and take over of bars by A.P State Beverages Corporation, aims to make Andhra Pradesh alcohol-free by 2024. A.P will then join Gujarat, Bihar, Mizoram, Nagaland and Lakshadweep as states/territories which have successfully implemented liquor prohibition.

But will Jagan be able to make this initiative a success in A.P? Because, this is not the first time such a thing has been tried in Andhra. In 1995, in a strange reversal of roles, Telugu Desam Party won the state elections, crushing Congress, and TDP Chief N T Rama Rao banned the sale of liquor in A.P. In 1995, his son-in-law, N. Chandrababu Naidu, staged a coup-of-sorts, toppled NTR, became Chief Minister and in 1997, reversed the decision.

But what was all that drama back then in 1990s? Therein lies a tale.

First of all, let's understand the economics of Liquor production and sale. Why is the state government so interested in it? It's very simple. Liquor fills the state government's revenue coffers in form of excise duty on its production. The state government also makes money from the issuance of licenses for its sale. Liquor boosts tourism and entertainment industries too.

The A.P state government discovered this golden hen sometime in the 1970s and since then, liquor has become a state policy. In 1970, the excise duty collected from liquor was INR 40 crores, which jumped to INR 800 crores in early 1990s and quantum leaped to INR 12000 crores in 2015. That's big money coming into the state revenue coffers.

In 1983, when NT Rama Rao came to power for the first time, he introduced a particularly aggressive liquor policy called Varuna Vahini (literally meaning Flood of Liquor), which delivered government-manufactured country liquor - Sarai, in Telugu, Arrack in English - to doorsteps, in easily affordable plastic sachets and bottles. He used some of this revenue to subsidise other populist schemes, like Rs 2 per kilo rice scheme.

Andhra Pradesh typically constitutes about 3-5% of sales of major liquor manufacturers like United Breweries and United Spirits. So, they usually have a word or two to say in this regard.

Oh! By the way, liquor contractors make a truck load of money too, which they invest in real estate, films, finance and construction projects, and make donations to cultural and religious institutions, thus strengthening their socio-political clout.

So, net-net, liquor manufacturing and sale is a well-oiled economic engine for any state, especially for Andhra Pradesh.

Now, let's understand the human aspects of state-promoted liquor sales.

I read a report that said, in 1991-92, the average annual income of a family in Andhra was, hold your breath, INR 1840. This was the total family income, for the entire year!

Out of this, the working male spent INR 830 on liquor. So, the man of the house spent 45% of his measly income on Sarai - Arrack. It was the norm. Every man, in every house, did it. And the government promoted it, supported it and benefited from it.

The logic was - the poor man had spent a miserable day, doing a miserable job, for a miserable pay. So it's ok, if he drowns his misery in a drink after sunset. Hmm. The problem was - the miserable man had a family - a wife, who slogged all day to make ends meet and feed her children. And god forbid, if there was an illness in the family, begging was the only way out.

On top of it, any body who has had a drink in their life knows, liquor is ok as a socializing drink. But it doesn't alleviate a man's misery. Infact, it compounds it.

This foul smelling man, in his foul mood, came home at midnight, in stupor, and sparks flew. Domestic violence, physical and mental abuse, were rampant. Suicides, rapes and murders were common.

Net-net, life in a village in Andhra Pradesh, which had a government-promoted arrack shop, was living hell, especially for the women folk. And because Arrack sale filled government coffers, there was an Arrack shop in every village. So life, in pretty much every village in Andhra Pradesh, was living hell for its women folk.

All of this was indicating an impending change. And change happened - in form of a massive, state level, Anti-Arrack movement, led by the women folk of Andhra Pradesh, which resulted in the prohibition of alcohol in the state!

In 1988, the Government of India launched the National Literacy Mission (NLM). In January 1990, the NLM was launched in Nellore district in Andhra Pradesh. The state-organised mass-literacy campaigns led to women getting together and discussing their problems. The awareness brought on by these group discussions resulted in the women discovering that the consumption of locally made, cheap Arrack was the main source of their unsettled domestic life. This awareness resulted in a spontaneous movement in the small village of Dubagunta in Nellore district of Andhra Pradesh.

The rural women of the village, who had no autonomy in any sphere of life, took it in their hands to fight against the production and sale of Arrack. They raided the Arrack shops with broomsticks and chili powder and cowered the owner into shutting the shop.

What started as an agitation in a single village, soon turned into a state-wide movement. In each village, women simply destroyed the ingredients used for the production of liquor. They also started policing the men in their individual households against consuming Arrack.

They then started speaking against the liquor contractors, local bureaucracy, police officials and even the Chief Minister. They started questioning the government on the availability of basic amenities like water, schools etc, which were in a dearth, as opposed to Arrack, which was always easily available. When the government insisted that the excise collected from the production of Arrack was used for welfare programmes, like the subsidy of rice, the women even agreed to contribute a day’s wages to help in the welfare schemes.

For them, it was clear. The cost-benefit equation of government-promoted liquor policies on human indices simply didn't match up to the economics. They put their foot down. Finally, when the movement had gained momentum in three districts, the government had to buckle under the pressure and ban Arrack in the state.

Now, let's go to the politics of the matter. Where there is a people's movement, there will be politics. And political parties.

It was 1994 - the election year in A.P. NT Rama Rao of TDP, the main opposition party, promised his electorate that, if they elected him to power, he would ban all forms of alcohol from the state (Toddy and IMFL - Indian made foreign liquor - were still available.) Ironically, it was his Varuna Vahini programme that was responsible for this situation. But, it was a powerful promise. So, he won a landslide election, came to power, and fulfilled his promise.

In 1995, Andhra Pradesh became alcohol free!

But this situation was shortlived. Within 9 months, NTR's son-in-law, N Chandrababu Naidu, staged a coup against his father-in-law, stating excessive interference of his second wife Parvathy Laxmi, in the party politics. Both NTR and Parvathy Laxmi were ousted from the party.

In 1997, Chandrababu Naidu, repealed the prohibition, stating that the exchequer has lost INR 1200 crores that year in excise revenue, illegal bootlegging had become unstoppable and that he was under pressure from all quarters to repeal the "dry rule." A few hushed and a few not-so-hushed voices say that there was no intent in the first place.

That's why there is some scepticism about Jaganmohan Reddy's latest initiative. Is there political will?

Post Script::

In 2016, 93 year old Dubagunta Rosamma, one of the early Anti-Arrack crusaders passed away, in Nellore.

Inspired by the story Seethamma kadha (the story of Seethamma) taught as part of the adult literacy programme in the night school in her village, the women of Dubagunta, led by Rosamma, destroyed the pots storing Arrack, after giving assurance to the families depending on the trade, thus sparking the first light of what would soon become a state-level agitation.

May this post be a small tribute to her!

4 notes

·

View notes

Link

Design & Automations Services provides a full range of CAD services, including Conversion, 2D drafting, 3D modeling, 3D scanning, rendering, reverse engineering and Design & automation services provider in India since 2010. Our goal is to ensure each and every client receives the highest possible level of quality and service, at a rate well below what they would pay for in-house or domestic services.

Design and Automation Services provides Design Outsourcing Services, Solidworks modeling, Sheet metal design services, Hollow metal door and frame design services,Reverse Engineering Services provider in India.

With highly skilled staff members available, representing a range of expertise, we can provide exceptional service no matter the complexity or size of your project. Each member of our team is continuously trained to use state of the art technology including up-to-date workstations and software.

Contact D&A Services today for all of your CAD conversion, drafting, 3D scanning, reverse engineering and modeling needs or to learn more about our services and pricing.

#Solidworks modeling in India#Design Automation#Reverse Engineering Services in India#Hollow metal door and frame design services in india#Sheet metal design services in India

1 note

·

View note

Text

Hydraulic Press Manufacturers in Gujarat

A hydraulic press by Srichakra Engineering Equipments delivers compressive force through a hydraulic chamber. The example is scheduled to be pressed for test planning inside a hydraulic press. Hydraulic presses are used in a variety of business and mechanical applications. Deep drawing operations, blanking and punching riveting, stepping and pressing, powder compacting and so on are some of the applications.

Hydraulic presses feature solid casings made of ultrasonically tested steel outlines, in addition to accuracy and precision. For better quality and unbending nature, edges are made from prime steel plates of appropriate thickness.

There are also several types of directing game plans to fit the needs of varied applications. These presses may be customized for any industry and come in a variety of sizes and options. Every press has the most up-to-date hydraulic control technology.

Today's hydraulic press manufacturers in Gujarat at Srichakra Engineering Equipments are recognizing the advantages of hydraulic presses over mechanical presses. Hydraulic presses now provide limitless capability and dependability in virtually all applications, including stepping, punching, blanking, drawing, bowing and so on.

How Does It Work?

A hydraulic pump or a lever forces hydraulic fluid into a compact double-acting cylinder. The fluid comes into contact with a sliding piston, which tries to compress it.

Instead, the fluid is pushed through the tiny cylinder and into a bigger cylinder, where the procedure is repeated. The fluid is forced back into the smaller cylinder by the compressive force this time. Pressure builds when the fluid is passed back and forth between the cylinders. The pressure eventually builds up to the point where it reaches the anvil, base plate or dies. It deforms the material beneath the anvil, base plate or dies into the desired product shape.

When the fluid exceeds its pressure threshold, it activates a valve that causes pressure reversal, ensuring that the press does not overload the material.

Equipment Components

A hydraulic press contains all of the basic hydraulic system components. It consists of a series of cylinders, punches (or pistons), hydraulic pipes and a die (or anvil).

The pistons use liquid under pressure to provide a powerful push on the anvil. When the pump is turned on, the hydraulic fluid is pumped into the cylinder. The fluid (either oil or water) is put into the smaller of the two cylinders. The fluid is compressed when the little piston is pushed. The compressed fluid then goes to the master cylinder through the pipe. The flow is diverted back to the tiny cylinder due to the pressure on the large master cylinder and its piston.

When the smaller cylinder is forced back into the master cylinder, the force on the fluids in the smaller cylinder produces even more force. The punch is brought into contact with the die by this incredibly high force, which completes whatever press operation is being conducted.

How to Use It?

To operate a hydraulic press, you'll need someone to feed or place stock on the bottom die. Once the stock is appropriately positioned, the operator must activate the press cycle by pushing the pressure control switch. When the part is finished, the operator must remove it carefully.

Contact Us

If you are looking for a hydraulic provider you can trust, then you have come to the right place. At Srichakra Engineering Equipments, we will help you with your requirements. We always recommend our clients to take some time and think of their requirements closely. Keeping your specifications in mind, we manufacture the products likewise. You can contact us for your requirements, questions and concerns anytime, anywhere. We will get back to you in a short period!

0 notes

Text

Rise the Demand for Non Return Valve Manufacturers in All Over India

Valve is a kind of device that is vastly being used and applied in many industries because of its features and application. If you're like most people, you probably didn't know that Non Return Valves Manufacturer in Mumbai have a huge demand in the industry.

A non-return valve allows a medium to flow in only one direction and is fitted to ensure that the medium flows through a pipe in the right direction, where pressure conditions may otherwise cause reversed flow. A non-return valve restricts flow reversal in the system and ultimately keeps the water hammer at a lower magnitude. A check valve is a valve that closes to prevent the backward flow of liquid (backflow) and is required by law to prevent water that's already in your equipment from re-entering the main supply.

So, when you are across many different valves than at that you have to seek for, a cross sign (✖️) on the head of the spindle, seeing this you can easily figure out that the one with a cross sign is the non-return type. It is an easy way to identify the non-return valve among the bunch of many valves. It is required by law to prevent water that's already in your equipment from re-entering the main supply as the check valve closes to prevent the backward flow of liquid. Non Return Valve Manufacturers in Chennai are in enormous demand in the industry and the market is growing every day.

The rising use has emerged demand for valves in the oil & gas industry is the main factor anticipated to fuel the expansion of the global non-return valve market over the coming years. By 2030, there will be significant gains as a result of additional factors such as rising end-user demand, the high rate of adoption of these valves in developing nations, and an expanding economy through the demand for non-return valves.

An increase in the demand for the non-return valve in the market will mainly benefit the industry and related people as they will be the emergence of new opportunities. As new options are emerged to provide the best services there will be a depth analysis of the Non Return Valve Manufacturer in Kolkata market. Based on the result of the analysis there will be innovation and invention in the market.

The expansion of non-return valve manufacturers and the regional market is primarily driven by two factors: an increase in the demand for safety applications and an increase in R&D efforts of the use of automated valves. As we know these valves are used by the oil and gas industry. As we know that these oil and gas are supplied through a long pipeline connection, to maintain proper flow of the oil and gas non-return valve are used. As there is a huge expansion of oil and gas and automatic demand for the valve in the market.

The market is expanding as a result of the increasing export of Indian goods to overseas markets. The expansion of FDI in many sectors, notably the oil and gas industry, is assisting market expansion even water treatment using non-return valves during the process.

There are Various Types of Check Valve:

There are various types of Check Valves Manufacturers in Ahmedabad, Gujarat and other market such as lift check valves, Swing check valve, folding disc check valve, Tilting disc check valve, and vertical check valve.

Non-return valves exist in a variety of sizes and shapes, but they are typically small and affordable. A variety of non-return valve has a different purpose and their application as per the requirement of the industry.

Yakshita engineering has been the reputed manufacturer of the valves in the national and international markets for the past 10 years. Manufacturer of needle valve, Check Valve Manufacturer in Chennai, safety valve, check valve, tube fittings, and many other products in India. We export our high-quality goods to countries including Tanzania, Bangladesh, Vietnam, Egypt, Iran, Malaysia, Japan, Malaysia, Nepal, Oman, Spain, the United Kingdom, and the United States of America. As a manufacturer follow all applicable health and safety, environmental, process, and quality standards.

#Check Valve Manufacturer in Chennai#Check Valves Manufacturers in Ahmedabad#Check Valves Manufacturers in Gujarat#Non return Valves Manufacturers in Mumbai#Non return Valves Manufacturers in Chennai#Non return Valves Manufacturers in Kolkata

1 note

·

View note