#Semiconductor Assembly and Testing Services

Link

#market research future#semiconductor assembly testing#semiconductor testing services#semiconductor assembly service#assembly and testing

0 notes

Text

Global Top 9 Companies Accounted for 60% of total Flow Drilling Screw (FDS) and Driving Machine market (QYResearch, 2021)

Flow drill screw driving (FDS) is a one–sided thermomechanical assembly process based on heat generation by frictional force and plastic deformation. A special screw, known as hole forming and self-tapping screw, is used in this process as both fastener and tool. Moreover, rotational and translation movements are applied to the screw to create special friction conditions with the workpiece. Furthermore, unlike traditional drilling and thread milling processes, there is no chip or waste of material in FDS and the machining operations are realized through plastic deformation. The report study flow drilling screw (FDS) and the driving machine.

According to the new market research report “Global Flow Drilling Screw (FDS) and Driving Machine Market Report 2023-2029”, published by QYResearch, the global Flow Drilling Screw (FDS) and Driving Machine market size is projected to reach USD 0.09 billion by 2029, at a CAGR of 3.7% during the forecast period.

Figure. Global Flow Drilling Screw (FDS) and Driving Machine Market Size (US$ Million), 2018-2029

Figure. Global Flow Drilling Screw (FDS) and Driving Machine Top 9 Players Ranking and Market Share(Based on data of 2021, Continually updated)

The global key manufacturers of Flow Drilling Screw (FDS) and Driving Machine include EJOT Holding, Arnold Umformtechnik, Weber, Atlas Copco, Deprag, etc. In 2021, the global top four players had a share approximately 60.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

1 note

·

View note

Text

Plastic Bucket Market: Dissecting the Factors Steering Growth and Potential Risks

Plastic Bucket Market provides in-depth analysis of the market state of Plastic Bucket manufacturers, including best facts and figures, overview, definition, SWOT analysis, expert opinions, and the most current global developments. The research also calculates market size, price, revenue, cost structure, gross margin, sales, and market share, as well as forecasts and growth rates. The report assists in determining the revenue earned by the selling of this report and technology across different application areas.

Geographically, this report is segmented into several key regions, with sales, revenue, market share and growth Rate of Plastic Bucket in these regions till the forecast period

North America

Middle East and Africa

Asia-Pacific

South America

Europe

Key Attentions of Plastic Bucket Market Report:

The report offers a comprehensive and broad perspective on the global Plastic Bucket Market.

The market statistics represented in different Plastic Bucket segments offers complete industry picture.

Market growth drivers, challenges affecting the development of Plastic Bucket are analyzed in detail.

The report will help in the analysis of major competitive market scenario, market dynamics of Plastic Bucket.

Major stakeholders, key companies Plastic Bucket, investment feasibility and new market entrants study is offered.

Development scope of Plastic Bucket in each market segment is covered in this report. The macro and micro-economic factors affecting the Plastic Bucket Market

Advancement is elaborated in this report. The upstream and downstream components of Plastic Bucket and a comprehensive value chain are explained.

Browse More Details On This Report at @https://www.globalgrowthinsights.com/market-reports/plastic-bucket-market-101475

Global Growth Insights

Web: https://www.globalgrowthinsights.com

Our Other Reports:

Plastic Bucket Market Analysis

Solar Photovoltaic Glass Market Share

Swimming Pool Treatment Chemicals Market Growth

Kids Smartwatch Market

Global Pigmentation Disorders Treatment Market Size

Global Air Disinfection and Purification Machine Market Growth

Premium Audio Market Forecast

Global Waterproof Breathable Textiles (Wbt) Market Share

Testing, Inspection, and Certification (TIC) Market Growth Rate

Sharing Economy Market Size

Virtual Production Market Share

Drone Defense System Market Analysis

Digital Media Market

Tire Fabrics Market Growth

Global Pharmacy Automation Equipment Market Growth

Global Semiconductor Packaging And Assembly Equipment Market Size

Global Carbon Management Software Market Share

Paints and Varnishes Market Forecast

Web to Print Software Market Size

Through Wall Radar Market Growth Rate

Auction House Market Analysis

Disposable Camera Market Share

Bioreactor Market Growth

Zinc Aluminum Magnesium Coated Steel Market

Global Freeze Drying Market Size

Global Fireproofing Material Market Growth

E-Commerce Of Agricultural Chemicals Products Market Forecast

Global Machinable Ceramic Market Share

Self Injection Device Market Growth Rate

Touch Based Human Machine Interface (Hmi) Market Size

NGOs and Charitable Organizations Market Share

Electro Hydraulic Servo Valve Market Analysis

Collaborative Robots Market

Diaphragm Valves for Pharmaceutical Process Market Growth

Global Robotic Vacuum Cleaner Market Growth

Global Personal Care Wipes Market Size

Global Document Scanning Services Market Share

Baby Wipes Market Forecast

Military Laser Designator Market Size

Automatic License Plate Recognition (ALPR) Market Growth Rate

#Plastic Bucket Market Size#Plastic Bucket Market Share#Plastic Bucket Market Trends#Plastic Bucket Market Industry#Plastic Bucket Market Growth

0 notes

Text

Semiconductor Capital Equipment Market Outlook to 2030

The Insight Partners recently announced the release of the market research titled Semiconductor Capital Equipment Market Outlook to 2030 | Share, Size, and Growth. The report is a stop solution for companies operating in the Semiconductor Capital Equipment market. The report involves details on key segments, market players, precise market revenue statistics, and a roadmap that assists companies in advancing their offerings and preparing for the upcoming decade. Listing out the opportunities in the market, this report intends to prepare businesses for the market dynamics in an estimated period.

Is Investing in the Market Research Worth It?

Some businesses are just lucky to manage their performance without opting for market research, but these incidences are rare. Having information on longer sample sizes helps companies to eliminate bias and assumptions. As a result, entrepreneurs can make better decisions from the outset. Semiconductor Capital Equipment Market report allows business to reduce their risks by offering a closer picture of consumer behavior, competition landscape, leading tactics, and risk management.

A trusted market researcher can guide you to not only avoid pitfalls but also help you devise production, marketing, and distribution tactics. With the right research methodologies, The Insight Partners is helping brands unlock revenue opportunities in the Semiconductor Capital Equipment market.

If your business falls under any of these categories – Manufacturer, Supplier, Retailer, or Distributor, this syndicated Semiconductor Capital Equipment market research has all that you need.

What are Key Offerings Under this Semiconductor Capital Equipment Market Research?

Global Semiconductor Capital Equipment market summary, current and future Semiconductor Capital Equipment market size

Market Competition in Terms of Key Market Players, their Revenue, and their Share

Economic Impact on the Industry

Production, Revenue (value), Price Trend

Cost Investigation and Consumer Insights

Industrial Chain, Raw Material Sourcing Strategy, and Downstream Buyers

Production, Revenue (Value) by Geographical Segmentation

Marketing Strategy Comprehension, Distributors and Traders

Global Semiconductor Capital Equipment Market Forecast

Study on Market Research Factors

Who are the Major Market Players in the Semiconductor Capital Equipment Market?

Semiconductor Capital Equipment market is all set to accommodate more companies and is foreseen to intensify market competition in coming years. Companies focus on consistent new launches and regional expansion can be outlined as dominant tactics. Semiconductor Capital Equipment market giants have widespread reach which has favored them with a wide consumer base and subsequently increased their Semiconductor Capital Equipment market share.

Report Attributes

Details

Segmental Coverage

equipment type

Automated Test Equipment

Die-Level Packaging and Assembly Equipment

Wafer-Level Manufacturing Equipment

end-user

Water and Sewage Treatment

Food and Beverage

Pharmaceuticals

Oil and Gas

Power Plants

Pulp and Paper

Others

Regional and Country Coverage

North America (US, Canada, Mexico)

Europe (UK, Germany, France, Russia, Italy, Rest of Europe)

Asia Pacific (China, India, Japan, Australia, Rest of APAC)

South / South & Central America (Brazil, Argentina, Rest of South/South & Central America)

Middle East & Africa (South Africa, Saudi Arabia, UAE, Rest of MEA)

Market Leaders and Key Company Profiles

Tencor

Kulicke and Soffa

Lam Research

Nikon

Planar

Tokyo Electron

Other key companies

What are Perks for Buyers?

The research will guide you in decisions and technology trends to adopt in the projected period.

Take effective Semiconductor Capital Equipment market growth decisions and stay ahead of competitors

Improve product/services and marketing strategies.

Unlock suitable market entry tactics and ways to sustain in the market

Knowing market players can help you in planning future mergers and acquisitions

Visual representation of data by our team makes it easier to interpret and present the data further to investors, and your other stakeholders.

Do We Offer Customized Insights? Yes, We Do!

The The Insight Partners offer customized insights based on the client’s requirements. The following are some customizations our clients frequently ask for:

The Semiconductor Capital Equipment market report can be customized based on specific regions/countries as per the intention of the business

The report production was facilitated as per the need and following the expected time frame

Insights and chapters tailored as per your requirements.

Depending on the preferences we may also accommodate changes in the current scope.

About Us:

The Insight Partners is a one-stop industry research provider of actionable intelligence. We help our clients in getting solutions to their research requirements through our syndicated and consulting research services. We specialize in industries such as Semiconductor and Electronics, Aerospace and Defense, Automotive and Transportation, Biotechnology, Healthcare IT, Manufacturing and Construction, Medical Devices, Technology, Media and Telecommunications, Chemicals and Materials.

Contact Us: www.theinsightpartners.com

0 notes

Text

0 notes

Text

0 notes

Text

0 notes

Text

Absolute EMS Inc.: Leading the Charge in High-Reliability Manufacturing for Next-Generation Satellites

The aerospace industry is characterized by continuous development. Miniaturization of satellites combined with increasing demand for highly functional and stable satellite systems necessitate a focus on manufacturing solutions. Absolute EMS Inc. is an established EMS manufacturing company that plays a crucial role in enriching the development of next-generation satellites due to its focus on high-reliability manufacturing and serving its customers with exceptional Electronic Manufacturing Services (EMS).

Introduction to High-Reliability Manufacturing

High-reliability manufacturing is a concept of manufacturing that can be described as a process that uses various strategies for the intended purpose of getting the parts in electronics to have a longer life span that conforms to their use and delivers the intended service. We, at Absolute EMS, strongly hold the belief that our clients are entitled to the best and most reliable EMS services in the industry.Concerning quality assurance, it is clear that our company holds itself to high standards that are reflected in each step of the manufacturing processes that involve the selection of the components and established testing techniques.

What is EMS Manufacturing?

Electronic Manufacturing Services (EMS) may refer to a wide variety of services delivered by one company to another within the electronics industry.

Absolute EMS is functioning as a full-service EMS manufacturing company, focused on providing high-quality Made in USA solutions. By extending its core competency to target more sustainable clients, namely the medical industry, Absolute EMS established itself as a leader in niche services.

At Absolute EMS, it is our goal to strive as the perfect EMS partner where we provide prototype to full turn-key, miniaturization & mid to high volume assembly services.

These services typically include:

Printed Circuit Board (PCB) Assembly

Box Build Assembly

Testing and Inspection

Supply Chain Management

Programming and Customization:

Absolute EMS and High-Reliability Manufacturing

High-reliability manufacturing is a specialized subset of EMS focusing on producing electronic devices with minimal failure rates. These devices are often mission-critical, meaning their failure could have severe consequences. They are typically used in industries like:

Medical Devices: Medical device manufacturing

Military and Defense: Avionics, communication equipment, and weapons systems.

Aerospace: Control systems, navigation equipment, and communication devices.

Industrial Automation: Control systems, Robotics, Networking, and Semiconductor for critical infrastructure and manufacturing processes.

Absolute EMS caters to these demanding industries by prioritizing several key aspects of their manufacturing processes:

Advanced Manufacturing Techniques: 4.0 touchless manufacturing line with built-in automated optical inspection stations throughout the process which increases the quality of work produced.

Process Control and Repeatability: The key elements of effective manufacturing processes include following manufacturing procedure manuals. It enables the exact repetition of admired production runs and also reduces the possibility of making some errors in the process.

Material Traceability: Preservation of records of all such components that were used in each of the devices so that in case of any failure in any of the components, the faulty component can be replaced.

Highly Skilled Workforce: Hiring technical staff that has adequate experience and relevant qualifications to the job and putting them to task with high production standards.

Continuous Improvement and Innovation

Absolute EMS has been driven by the principles of ongoing improvement and reinvention in the field of high-reliability manufacturing. We are committed to working hand in hand with our clientele and other stakeholders in the market to meet or even go a step further in adapting to innovations in technology or higher reliability requirements. This creates the systems to develop new materials and processes, as well as test methods, that when combined help us produce products that achieve the highest reliability standards.

Quality Assurance: The Bedrock of High-Reliability Manufacturing

Absolute EMS has made a name for itself as a leading provider of EMS manufacturing services by rigorously focusing on sustaining consistent quality throughout its manufacturing processes. They have established magnificent quality control measures and are certified to meet international standards including the ISO 9001 and AS 9100 for use in aerospace companies. This means that there is a careful examination of the product for defects and this is done throughout the manufacturing process with the help of tools such as the AOI or the X-ray checker. In addition, another strength that Absolute EMS highlights is the application of Statistical Process Control, which enables the firm to perpetually refine its manufacturing procedures while ensuring that the satellites being churned out are high quality, dependable, and can withstand rigorous use and often harsh environments commonly associated with space science and telecommunications.

The Final Say:

In conclusion, Absolute EMS is committed to being a company that provides EMS solutions that adhere to the highest level of reliability in manufacturing electronic products. Through the client-oriented approach and employing state-of-the-art materials, innovative design techniques, extensive testing procedures, and constant improvement in the company, we guarantee that customers will get the best quality and reliable products.

Come to Absolute EMS for high-reliability manufacturing services and let us show you just how much better business can be when your service provider serves as an extension of your team.

0 notes

Text

0 notes

Text

Darshan Hiranandani Foresees Government Green Light for Chip Fab Venture Soon

The Hiranandani group, famous for its real estate ventures, is stepping into the semiconductor industry with Tarq Semiconductors. Darshan Hiranandani, the group's CEO, hopes that the government will approve their compound semiconductor fab project within the next two months.

They have applied to set up two things in Uttar Pradesh: an assembly, testing, marking, and packaging unit (ATMP), and a compound semiconductor fab plant. Compound semiconductors are crucial for making LED lights, radios, and cars because they can handle high power and temperatures. ATMP involves putting chips together and packaging them, which happens after making the semiconductors.

"We've submitted applications for the ATMP and the compound semiconductor fab project to the government. We're expecting approval within the next 30 to 60 days," said Hiranandani.

To start the fab and assembly, packaging, and testing unit, they'll partner with another company in a joint venture. They've also teamed up with firms from the US and Japan to ensure they have everything they need for both projects.

The semiconductor business appeals to companies like Hiranandani because running the fabrication unit in India is cheaper than in other countries. Plus, with a compound semiconductor ecosystem, they can create devices that use less energy, cutting down costs even further.

Explaining their decision to get into compound semiconductors, Darshan Hiranandani said they want to save energy and make things more efficient in India. With so many products like cars, washing machines, and mobile phones being made in India, they saw it as a good opportunity.

They plan to invest around Rs 2,500 crore to start the ATMP facility in Uttar Pradesh. Also, in addition to their real estate ventures, Hiranandani's company Yotta provides comprehensive data center services. They aim to become the largest data center provider in India by the end of the year.

"In October, we'll be launching our own public cloud platform," added Hiranandani.

0 notes

Text

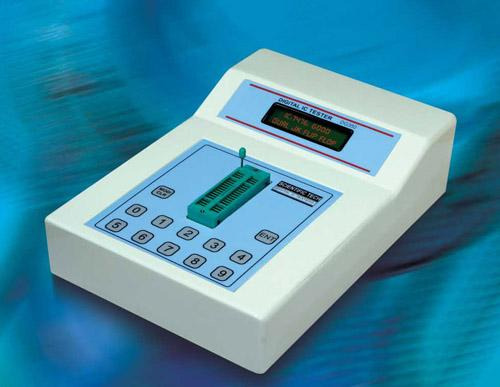

Navigating Complexity: Exploring Types of Digital IC Testers

Digital integrated circuits (ICs) are the backbone of modern electronic devices, powering everything from smartphones and computers to automotive systems and IoT devices. Ensuring the functionality, reliability, and quality of these digital ICs is essential to delivering superior performance and user experience. Digital IC testers play a crucial role in this process, enabling manufacturers to validate the functionality and performance of digital ICs before they are integrated into electronic systems. In this article, we'll explore the various types of digital IC testers available in the market, their features, capabilities, and applications.

Automated Test Equipment (ATE):

Automated Test Equipment (ATE) is the most common type of digital IC tester used in semiconductor manufacturing and testing facilities. ATE systems are highly sophisticated, computer-controlled test platforms capable of performing a wide range of tests on digital ICs with high throughput and accuracy. These systems typically consist of test instruments, such as digital pattern generators, logic analyzers, and mixed-signal oscilloscopes, integrated with test software for stimulus generation, data acquisition, and analysis. ATE systems are capable of testing digital ICs for functional operation, timing characteristics, power consumption, and other performance parameters, making them ideal for high-volume production testing.

Benchtop Testers:

Benchtop testers are compact, standalone test instruments designed for laboratory and research environments. These testers offer a cost-effective solution for testing digital ICs in small to medium-scale production runs or prototyping applications. Benchtop testers typically feature built-in test instruments, such as function generators, oscilloscopes, and digital multimeters, as well as user-friendly interfaces for test setup, execution, and result analysis. While benchtop testers may not offer the throughput and automation capabilities of ATE systems, they provide flexibility and ease of use for design verification, troubleshooting, and low-volume production testing.

Portable Testers:

Portable testers are handheld or portable devices designed for on-site or field testing of digital ICs in electronic systems and devices. These testers are lightweight, compact, and battery-powered, making them ideal for applications where portability and mobility are critical, such as field service, maintenance, and repair. Portable testers typically feature simplified user interfaces, basic test functions, and connectivity options for interfacing with digital ICs in situ. While portable testers may lack the advanced capabilities and precision of ATE systems or benchtop testers, they provide a convenient solution for quick, on-the-go testing and validation of digital ICs in real-world environments.

Specialized Testers:

Specialized testers are custom-designed or application-specific test solutions tailored to the unique requirements of specific digital ICs or test scenarios. These testers are often developed by semiconductor manufacturers, third-party test equipment vendors, or in-house engineering teams to address specific testing challenges, such as high-speed interface testing, mixed-signal testing, or power management testing. Specialized testers may incorporate advanced test algorithms, proprietary test patterns, and custom hardware interfaces optimized for the target IC or application, enabling comprehensive testing and characterization of digital ICs in specialized domains.

In-Circuit Testers:

In-Circuit Testers (ICT) are specialized test systems used for testing digital ICs on populated printed circuit boards (PCBs) or electronic assemblies. ICT systems typically feature a bed-of-nails test fixture that makes physical contact with the IC pins or test points on the PCB, enabling functional testing, boundary-scan testing, and other tests without removing the IC from the circuit board. ICT systems are commonly used for testing digital ICs in complex electronic assemblies, such as computers, telecommunications equipment, and automotive electronics, where functional verification and fault detection are critical for ensuring product quality and reliability.

In conclusion, the choice of digital IC tester depends on factors such as testing requirements, production volume, budget, and application-specific considerations. Whether you're manufacturing digital ICs in high volume, conducting research and development in a laboratory setting, performing field testing in real-world environments, or addressing specialized testing challenges, there's a digital IC tester available to meet your needs. By selecting the right type of tester and leveraging its features and capabilities effectively, manufacturers can ensure the quality, reliability, and performance of digital ICs in electronic systems and devices.

0 notes

Text

0 notes

Text

Global Top 24 Companies Accounted for 45% of total Machine Screw Jacks market (QYResearch, 2021)

A Machine Screw Jack is a gearbox assembly (either worm gear or bevel gear) and a transmission product (lead screw, ball screw or roller screw) which through use of a motor is used to convert rotary into linear motion. They can be used to push, pull, tension, lock, unlock, tilt, pivot, roll, slide and lift or lower loads.

According to the new market research report “Global Machine Screw Jacks Market Report 2023-2029”, published by QYResearch, the global Machine Screw Jacks market size is projected to reach USD 0.35 billion by 2029, at a CAGR of 4.9% during the forecast period.

Figure. Global Machine Screw Jacks Market Size (US$ Million), 2018-2029

Figure. Global Machine Screw Jacks Top 24 Players Ranking and Market Share(Based on data of 2021, Continually updated)

The global key manufacturers of Machine Screw Jacks include Columbus McKinnon, ZIMM, Joyce Dayton, Power Jacks, Nippon Gear, Nook Industries, Unimec, Chiaravalli Group, INKOMA-GROUP, Altra Industrial Motion, etc. In 2021, the global top 10 players had a share approximately 45.0% in terms of revenue. The global key manufacturers of Machine Screw Jacks include Columbus McKinnon, ZIMM, Joyce Dayton, Power Jacks, Nippon Gear, Nook Industries, Unimec, Chiaravalli Group, INKOMA-GROUP, Altra Industrial Motion, etc. In 2021, the global top 10 players had a share approximately 45.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

For more information, please contact the following e-mail address:

Email: [email protected]

Website: https://www.qyresearch.com

0 notes

Text

Indian semiconductors on the rise: Tata plans to build manufacturing facility in Sanand, Gujarat

【Lansheng Technology News】The rise of Indian semiconductors: Tata plans to build Micron’s US$2.75 billion chip manufacturing facility in Sanand, Gujarat. The company said in a statement that the contract award to Tata Projects solidifies the company's presence in the development of large-scale, sustainable infrastructure in the Indian manufacturing sector. Tata Projects has won a construction contract from Micron Technologies for its state-of-the-art semiconductor assembly and testing facility in Sanand, Gujarat.

“This long-lasting project is a major milestone and the largest investment by an Indian semiconductor delegation,” he said, adding that the first phase of construction will include 500,000 square feet of clean room space and is scheduled to be operational by the end of 2024.

The project includes the design and construction of a first-of-its-kind DRAM and NAND assembly and testing facility in India. The Tata project aims to accelerate construction through 4D BIM and hybrid modularization using modern construction methods and technologies involving integrated EPC delivery, it added. The Sanand factory will be designed in compliance with LEED Gold Standard Green Building Council and will also integrate advanced water-saving technologies.

Union Minister Ashwini Vaishnaw said on Saturday that two large semiconductor proposals are under process and expected to take shape in the next few months. Without revealing details of the proposals, the minister said the projects will be focused on a special area where India can become a leader at the global level.

Talking to PTI on the sidelines of the groundbreaking ceremony of Micron's semiconductor plant, Vaishnaw said the global semiconductor company has taken note of India's progress in the field and Prime Minister Narendra Modi's ability to execute major and complex policy decisions.

"This makes India a major trusted geographic region for global industry players to look to enter. We could see at least two more large semiconductor proposals taking shape in the coming months," Vaishnaw said.

Lansheng Technology Limited, which is a spot stock distributor of many well-known brands, we have price advantage of the first-hand spot channel, and have technical supports.

Our main brands: STMicroelectronics, Toshiba, Microchip, Vishay, Marvell, ON Semiconductor, AOS, DIODES, Murata, Samsung, Hyundai/Hynix, Xilinx, Micron, Infinone, Texas Instruments, ADI, Maxim Integrated, NXP, etc

To learn more about our products, services, and capabilities, please visit our website at http://www.lanshengic.com

0 notes

Text

FEP Encapsulated O-rings

FEP Encapsulated O-rings: The Ultimate Solution for Sealing Excellence

When it comes to sealing applications that demand exceptional performance and durability, FEP encapsulated O-rings stand out as the ultimate solution. These advanced sealing components combine the best of both worlds, offering the resilience of elastomers and the chemical resistance of fluoropolymers. In this article, we will explore the remarkable characteristics and applications of FEP encapsulated O-rings, shedding light on why they are the preferred choice in various industries.

Understanding FEP Encapsulated O-rings:

FEP, short for Fluorinated Ethylene Propylene, is a thermoplastic fluoropolymer known for its exceptional chemical resistance, thermal stability, and non-stick properties. When FEP is used to encapsulate an elastomeric core, such as silicone or Viton, it creates a hybrid sealing element with remarkable capabilities. The elastomeric core provides elasticity and sealing properties, while the FEP outer layer shields it from aggressive chemicals, high temperatures, and extreme environments.

Key Advantages of FEP Encapsulated O-rings:

Chemical Resistance: FEP encapsulated O-rings exhibit unparalleled resistance to a wide range of aggressive chemicals, acids, bases, and solvents. This makes them ideal for industries where chemical compatibility is critical, such as pharmaceuticals, chemicals, and petrochemicals.

Temperature Resistance: FEP is capable of withstanding extreme temperatures, ranging from -200°C (-328°F) to 205°C (401°F), ensuring reliable sealing performance in both cryogenic and high-temperature applications.

Non-Stick Properties: The non-stick surface of FEP prevents the O-ring from sticking to mating surfaces, reducing friction, wear, and the risk of damage during assembly or disassembly.

Longevity: FEP encapsulated O-rings have a longer service life compared to traditional O-rings, thanks to their resistance to wear, tear, and environmental degradation.

Sealing Excellence: These O-rings maintain a secure and effective seal even in demanding conditions, providing leak-free performance in critical applications.

Applications of FEP Encapsulated O-rings:

Chemical Processing: FEP encapsulated O-rings are extensively used in the chemical industry for sealing pumps, valves, and flanges, where exposure to corrosive chemicals is common.

Pharmaceuticals: In pharmaceutical manufacturing, where sterility and chemical resistance are paramount, these O-rings are employed in aseptic processing equipment.

Food and Beverage: They are used in food and beverage processing equipment due to their compliance with FDA regulations and resistance to cleaning chemicals.

Oil and Gas: FEP encapsulated O-rings play a crucial role in sealing applications in the oil and gas sector, including downhole equipment and wellhead components.

Aerospace: In aerospace applications, these O-rings are utilized to seal hydraulic systems, fuel systems, and aerospace instrumentation, ensuring safety and reliability.

Semiconductor Industry: Their purity and resistance to aggressive chemicals make them indispensable in semiconductor manufacturing equipment.

Environmental Testing: FEP encapsulated O-rings are used in environmental testing chambers, where they maintain seals under extreme temperature and pressure conditions.

In conclusion, FEP encapsulated O-rings are a testament to the advancement of sealing technology. Their ability to combine the flexibility of elastomers with the robustness of fluoropolymers makes them indispensable in industries where sealing performance is critical. Whether you are working with corrosive chemicals, extreme temperatures, or high-pressure environments, these O-rings are your reliable partner in achieving leak-free and long-lasting seals. Consider FEP encapsulated O-rings for your sealing needs, and experience the difference they can make in your applications.

0 notes

Text

US Semiconductor Assembly and Testing Services Market Forecast 2024 to 2032

Semiconductor assembly and testing services play a critical role in the semiconductor industry by providing the final stages of manufacturing for integrated circuits (ICs) or chips. These services involve the assembly of individual semiconductor components onto a package and the testing of the finished packaged chips to ensure functionality and quality. Semiconductor assembly and testing services are vital to ensure that semiconductor devices meet performance specifications and are ready for use in various electronic products.

The US Semiconductor Assembly and Testing Services Market was valued at USD 55.63 Billion in 2022 and is expected to register a CAGR of 5.27% by 2032.

The trend towards smaller and more compact electronic devices, such as smartphones, wearables, and IoT devices, drives the need for semiconductor assembly services that can accommodate miniaturized chip packages.

Get a Free Sample Pdf

Key Companies

ASE Group

Unisem Group

DPA Components International (DPACI)

GlobalFoundries U.S. Inc.

Golden Altos Corporation

Grinding & Dicing Services, Inc.

Micross

Precision Test Solutions

Promex Industries Inc.

SkyWater Technology

By Service

Assembly and packaging services

Testing services

By Application

consumer electronics

automotive

medical

industrial

Read More

1 note

·

View note