#Textile Rotary Printing Machine

Explore tagged Tumblr posts

Text

1. Essential Sewing Techniques

Basting: Temporary long stitches to hold fabric before final sewing.

Backstitch: Strong hand stitch for seams that need durability.

French Seam: Elegant finish that hides raw edges inside a folded seam (common in high-end garments).

Gathering: Creates controlled fullness (e.g., ruffles on sleeves or skirts).

Zigzag Stitch: Prevents fabric fraying on raw edges; used in stretch fabrics.

Quilting: Combines piecing (sewing fabric patches) and stitching through layers for texture.

2. Cultural & Historical Significance

Ancient Egypt: Linen garments were hand-sewn with flax thread; some stitches survive today.

Japan: Sashiko embroidery (functional decorative stitching) reinforced workwear.

Europe: The 18th-century mantua dress required intricate draping and sewing skills.

Industrial Revolution: Sewing machines (like Singer’s 1851 model) democratized fashion but also fueled sweatshop labor debates.

3. Must-Have Sewing Tools

Fabric Shears: Sharp scissors reserved only for fabric.

Seam Ripper: Fixes mistakes without damaging material.

Tailor’s Chalk/Marking Pens: For tracing patterns.

Thimble: Protects fingers when hand-sewing thick fabrics.

Bobbins: Hold thread in sewing machines.

Rotary Cutter & Mat: Precision cutting for quilters.

4. Modern Sewing Innovations

Computerized Machines: Auto-threading, embroidery designs via USB, and touchscreen controls.

3D Printing: Custom buttons, accessories, or even fabric-like materials.

Smart Fabrics: Sewable LED circuits, conductive thread for wearable tech.

Sustainable Stitches: Growing use of upcycled materials and zero-waste pattern design.

5. Famous Figures in Sewing

Coco Chanel: Started as a seamstress; revolutionized women’s fashion.

Elizabeth Keckley: Former enslaved woman who became Mary Todd Lincoln’s dressmaker.

Yves Saint Laurent: Master of precision tailoring.

Contemporary Makers: Blogs like Tilly and the Buttons and YouTube sewists inspire DIY fashion.

6. Sewing’s Psychological & Social Benefits

Mindfulness: Repetitive stitching can reduce stress (like "textile therapy").

Community: Quilting bees, online sewing forums, and #SewingTwitter foster connection.

Empowerment: Self-sufficiency in making/modifying clothes challenges fast fashion.

8 notes

·

View notes

Text

It all started with a reddit post.

No it didn’t. It started when I was 5 and my mom handed me fabric and thread and buttons to keep me busy while she sewed. It started with the Christmas and Easter dresses my grandmother turned out every year without fail. It started with holding tapestries my other grandmother wove. It started with listening to my great-grandmother talk about the quilts city women paid her to finish for them and the rugs she wove on her floor.

I’ve always said that I had textiles in the blood, as a genetic legacy. While only one of the women who came before me called herself an artist (my maternal grandmother) they all chose textiles as their medium.

I made my first quilt in middle school, I think. My grandmother spent decades as purely a garment seamstress, working in a suit store and altering prom dresses on the side, sewing for herself and her loved one. She loved clothes and her huge basement was packed with everything she had made herself. She found herself seeking a new challenge. She’d avoided quilting (possibly because her mother was a quilter and they had a complex relationship) but she decided to give it a go. Her first quilt was a pinwheel, pieced by machine and then hand quilted while she recovered from a knee surgery. She let me quilt a block. I decided I’d make a quilt too, pinwheels the same as her. I didn’t have a book, or a pattern, or the internet and she wasn’t there when I started. I cut my triangles mostly by eye, with scissors, on the living room floor. They were big, maybe 10 inches. I sewed them up and wonky is the kindest word I could give them now, but I felt like a genius. I didn’t know you were supposed to quilt it before binding so I bound it, and pinned the layers together. I even quilted some of the squares. And then I slept with it, pinned together for roughly a decade. It was never fully quilted. It wasn’t long enough to cover both my shoulders and feet, but it was the perfect weight for a summer quilt. I wish I knew what had happened to it.

My second quilt was a whole cloth quilt. I was in grad school. I had the internet, but I didn’t use it. I wanted something the same weight as the first quilt, but long enough to cover my feet. I bound it with satin blanket binding, and quilted a cross, one row up the length through the middle, and one row across the width. I did not read the directions on the batting about how far apart the quilting lines should be. It is now my son’s favorite blanket. It hasn’t fallen apart.

I did a lot more learning (but not enough) and a lot of growing before I tried quilting again. By this time I was a parent and I had learned the value of measuring and rotary cutting. Again I’d make a pinwheel quilt. I learned how to make half square triangles four at a time. My grandmother passed either shortly before or after I started it and I think of her when I work on it. It took me a long time to make the blocks, it took me even longer to put them together. I thread basted it on the floor. I knew enough not to bind before quilting, but I hadn’t yet learned to start in the center of quilt. I worked around the edges and learned even more. I learned that if I quilt too much my hands hurt, I learned that my spouse will sleep under a quilt left on the couch even if it isn’t finished or bound. I eventually learned I should have started in the middle. I started it in 2019, its 2024 and I’m still slowly quilting the blocks. I bound it eventually because the edges were showing a lot of wear (because my spouse has been sleeping under it). Someday it will be done, but it makes me laugh to know that it is serving its purpose regardless, and has been for years.

Another chapter in my quilting story. It was roughly 4am and I was sick. Hopped up on every medication known to humankind and scrolling through my phone. I stumbled across a video of someone stitching fabric wrapped around hexagons together by hand. Half a dozen videos later I was sitting at a computer printing out templates onto cardstock paper and digging through the remains of pandemic mask making fabric. I made a coaster, and then I made a pillow. Before I even made it past the fog of flu I started a hexagon quilt. I didn’t plan, but I kept a somewhat cohesive color story. 900+ hexagons later I had a finished quilt top, it took me about a year, and eventually I chose a backing and used my sewing machine to quilt it together, starting from the center working out, binding at the end. And that is the moment that I finally felt like a quilter.

Its been a while since that night scrolling. I’ve made more quilts, large and small. Not a lot, but enough. I spend a lot of my down time thinking about quilts. When I’m quilting I think about those who came before me, I think about my grandmother’s hands. I think about how intrinsic quilting is to the place I grew up, all the hands that came before my grandmother, and her mother, and the lineage going back through the largely unrecorded history of poor women in rural Appalachia.

Getting back to reddit. The other day I was scrolling through and was struck by this quilt posted on reddit by u/karenosmile.

Classic and yet it is also intrinsically modern.Chaotic and random, but also a repeated pattern of the same simple block. It brought to mind quilts I’d seen while looking through museum collections online (which is a delightful activity for slow afternoons). I went back through my links and the collections again, looking at other examples of quilts that feature that classic ageless block - the half square triangle, also known as the HST. I wanted to know what made that quilt on reddit feel so modern.

The oldest quilt I found in my brief review that felt like it had the same feel as the reddit quilt was this quilt from the 1840s. It is orderly, but combining different sizes of half square triangles. I would not see this as old fashioned if I saw this quilt posted online tomorrow.

The next quilt has been printed out and taped to my wall for months. It was made in 1898 by one Lura, for another Lura. Another lineage. This quilt only has one size of HST and they are orderly arranged to create strong diagonal lines of color across the quilt.

Coming to the 20th century we have another quilt* that uses half square triangles of different sizes, however this one uses blocks of HSTs arranged and combined with large white triangles to form yet another larger HST.

Ultimately I think the thing that sets the original reddit quilt apart is the scattered variety of block sizes and the seemingly random placement of the blocks. The varying size abandons the strict repetition of the museum pieces while maintaining the simple geometry of the block itself.

*Link may not work as it is from Jstor

#quilting#hand quilting#historical quilt#quilt history#half square triangles#hst#classic quilt blocks

16 notes

·

View notes

Text

Nickel Rotary Screen & Nickel Screen Engraving Chemical Manufacturer, Supplier & Export in India

Welcome to Roopa Screen Private Limited. We are one of the most recognized and leading manufacturers, suppliers and exporters of various engraving products, rotary screen printing machine, nickel rotary screen, textile spares.

We are technically advanced and well equipped with manufacturing facilities, we are competent of fabricating and offering a wide range of engraving products, rotary screen printing machine, nickel rotary screen, textile spares and nickel screen engraving chemicals like photo emulsion for rotary screens. Our range of machines are known for their durability, efficiency, precision, technical superiority and are also easy to operate.

2 notes

·

View notes

Text

Current Scope, Trend, Top Players of Finishing Machinery Market

Global “Finishing Machinery Market” research report is a comprehensive analysis of the current status of the Finishing Machinery industry worldwide. The report categorizes the global Finishing Machinery market by top players/brands, region, type, and end-user. It also examines the competition landscape, market share, growth rate, future trends, market drivers, opportunities, and challenges in the global Finishing Machinery market. The report provides a professional and in-depth study of the industry to help understand its current state and future prospects. What Are The Prominent Key Player Of the Finishing Machinery Market?

SANTEX RIMAR GROUP

Dalal Engineering

Navis TubeTex

FLAINOX

Biancalani

ActOn

Alliance Machines Textiles

Brugman Holland

VOLPATO

Benninger

Kusters Zima

WAM GROUP

CHTC Fong

CERLASE

Miyakoshi Printing Machinery

Huzhou Inovatec Machinery Co., Ltd.

Production by Region

North America

Europe

China

Japan

Consumption by Region

North America

U.S.

Canada

Europe

Germany

France

U.K.

Italy

Russia

Asia-Pacific

China

Japan

South Korea

India

Australia

Taiwan

Indonesia

Thailand

Malaysia

Philippines

Vietnam

Latin America

Mexico

Brazil

Argentina

The Primary Objectives in This Report Are:

To determine the size of the total market opportunity of global and key countries

To assess the growth potential for Finishing Machinery

To forecast future growth in each product and end-use market

To assess competitive factors affecting the marketplace

This report also provides key insights about market drivers, restraints, opportunities, new product launches or approvals.

Regional Segment of Finishing Machinery Market:

Geographically, the report includes research on production, consumption, revenue, market share, and growth rate of the following regions:

United States

Europe (Germany, UK, France, Italy, Spain, Russia, Poland)

China

Japan

India

Southeast Asia (Malaysia, Singapore, Philippines, Indonesia, Thailand, Vietnam)

Latin America (Brazil, Mexico, Colombia)

Middle East and Africa (Saudi Arabia, United Arab Emirates, Turkey, Egypt, South Africa, Nigeria)

The global Finishing Machinery Market report answers the following questions:

What are the main drivers of the global Finishing Machinery market? How big will the Finishing Machinery market and growth rate in upcoming years?

What are the major market trends that affecting the growth of the global Finishing Machinery market?

Key trend factors affect market share in the world's top regions?

Who are the most important market participants and what strategies being they pursuing in the global Finishing Machinery market?

What are the market opportunities and threats to which players are exposed in the global Finishing Machinery market?

Which industry trends, drivers and challenges are driving that growth?

Browse More Details On This Report at - https://www.businessresearchinsights.com/market-reports/finishing-machinery-market-104420

Contact Us:

Business Research Insights

Phone:

US: (+1) 424 253 0807

UK: (+44) 203 239 8187

Email: [email protected]

Web: https://www.businessresearchinsights.com

Other Reports Here:

Rotary Pulverizers Market

Power Bits Market

Gasoline Marine Fuel Filter Market

Soil Aeration Machines Market

Smoothing Spray Market

Hydraulic Punching Machine Market

Marine Tourism Market

Perfluorosulfonic Acid Proton Exchange Membrane Market

Employer of Record Market

Enriched Flour Market

Other Reports Here:

Paper Bed Filter Market

Breathing Machines Market

Credit And Collections Software Market

Flour Improver Market

Auxiliary Power Supply System Market

Pharmaceutical Grade CBD Oil Market

Styrene Maleic Anhydride (SMA) Copolymer Market

Business Music Software Market

OLED Display Materials Market

Smart Formaldehyde Detector Market

0 notes

Text

How Digital Textile Printing is Revolutionizing the Fabric Industry

The Need for Innovation in Textile Printing

Historically, fabric printing relied on methods like screen printing or rotary printing. These techniques are cost-effective for large runs but are inefficient for small batches or designs requiring intricate detail. Enter the digital textile printing revolution. This method allows for direct-to-fabric printing using inkjet technology, providing limitless design freedom without the setup costs of conventional techniques.

The Role of the Modern Printing Machine

At the heart of this innovation lies the printing machine itself. Today’s advanced machines come equipped with high-resolution nozzles, AI-based controls, and specialized software that ensure sharp, vibrant prints. These machines can handle complex designs, multiple colors, and even print on various types of fabrics—from cotton and silk to synthetic blends.

More importantly, digital textile printers enable on-demand production. This means that designers can now test patterns, release limited collections, or even allow customers to personalize products—without worrying about inventory waste or long lead times.

Delivering on True Colour Accuracy

One of the standout features of digital textile printing is its ability to maintain true colour accuracy across batches. Traditional methods often suffer from color bleeding or tone shifts due to manual ink mixing and inconsistent application. But with digital technology, color management systems ensure consistency and precision.

This fidelity is crucial for fashion brands where brand identity depends heavily on specific color palettes. Interior designers also benefit, as they can now match fabrics precisely to walls, furnishings, or other décor elements.

Sustainability and Efficiency Go Hand-in-Hand

In an era where environmental responsibility matters, digital textile printing scores high on sustainability. It uses less water, reduces chemical waste, and minimizes leftover stock—making it a greener choice for both small and large textile businesses.

Traditional dyeing methods consume vast amounts of water and produce effluents that are difficult to treat. Digital systems, however, print only what is needed, drastically cutting down pollution and energy usage. A modern textile printing machine can now create hundreds of designs per day with minimal environmental impact.

Applications Beyond Fashion

While fashion remains the most visible industry adopting this technology, digital textile printing also plays a pivotal role in sportswear, accessories, interior décor, and even technical textiles. Whether it’s vibrant cushions, printed upholstery, or personalized yoga mats, the possibilities are endless.

For startups and indie brands, this levels the playing field. High-quality, custom products can be created with relatively low capital investment—thanks to compact printing machines suited for studio-scale operations.

Final Thoughts

The rise of digital textile printing marks a shift from mass production to mass customization. With capabilities that ensure true colour, faster turnaround times, and eco-conscious operations, the modern textile printing machine is more than just a tool—it’s a gateway to the future of design and manufacturing. As technology advances further, the textile industry can only expect better precision, scalability, and creative freedom.

0 notes

Text

Revolutionizing Fabric Design: The Rise of the Textile Printing Machine

In today’s fast-paced textile industry, innovation is the heartbeat of production—and nothing exemplifies this better than the Textile printing machine. From vibrant fashion wear to customized home furnishings, this advanced machinery is transforming how designs are printed on fabric. Whether you’re a large-scale manufacturer or a boutique designer, investing in a high-performance textile printing machine is no longer a luxury—it's a necessity.

At the forefront of this revolution is Orange O Tech, a leading name in textile printing solutions. Known for its cutting-edge technology and reliable service, Orange O Tech has emerged as a trusted partner for businesses looking to scale with precision, speed, and sustainability.

What Is a Textile Printing Machine?

A textile printing machine is an advanced piece of equipment used to apply color, patterns, and designs directly onto fabric or garments. Unlike traditional dyeing methods, which can be labor-intensive and environmentally taxing, modern textile printers offer high-resolution prints with minimal waste and quicker turnaround times.

There are various types of textile printing machines available, such as:

Digital Textile Printers – Perfect for small to medium batches with complex designs.

Rotary Screen Printers – Ideal for large-scale repetitive patterns.

Flatbed Printers – Used for smaller-scale, high-precision projects.

Sublimation Printers – Best for synthetic fabrics and sportswear.

Why the Demand for Textile Printing Machines Is Growing

Customization Boom: Consumers today want unique, personalized products. A textile printing machine allows for low-volume runs with customized designs.

Eco-Friendly Printing: Digital textile printers reduce water consumption and chemical use, making them more sustainable.

High-Speed Production: Brands like Orange O Tech provide machines that combine speed with uncompromising quality—perfect for scaling production.

Design Freedom: Unlike older methods, you can now print intricate, full-color designs with ease.

Orange O Tech – Pioneers in Textile Printing Technology

Orange O Tech has earned a reputation for delivering high-performance textile printing machines designed for today’s complex production environments. The company offers a range of machines that cater to multiple printing needs:

High-resolution digital printers for precise image quality.

Eco-solvent textile printers that minimize environmental impact.

User-friendly interfaces that make operation seamless, even for new operators.

After-sales support and maintenance services to ensure long-term productivity.

Whether you're upgrading your equipment or stepping into fabric printing for the first time, Orange O Tech ensures you get top-tier machinery backed by expert consultation and technical support.

Key Features to Look for in a Textile Printing Machine

When choosing the right textile printing machine, consider the following features:

Print Resolution: Higher DPI ensures clearer, more detailed designs.

Ink Compatibility: Machines that work with eco-friendly inks are better for both your business and the planet.

Fabric Versatility: Choose a machine that supports various materials—cotton, silk, polyester, blends, etc.

Speed & Efficiency: Look for models that balance print speed with energy efficiency.

Automation & Software: Modern printers often come with software that streamlines the entire print workflow.

Industries Benefiting from Textile Printing Machines

Fashion & Apparel: Custom clothing, fast fashion, and limited-edition collections.

Home Decor: Printed curtains, bed linens, upholstery fabrics.

Sportswear: Quick-drying, vibrant, and branded athletic wear.

Promotional Products: Tote bags, caps, and T-shirts for branding.

No matter the industry, having a reliable textile printing solution like those offered by Orange O Tech can be a game-changer for operational efficiency and product quality.

Conclusion

The textile printing machine has evolved from a niche piece of equipment into a must-have for forward-thinking manufacturers. As trends move toward personalization, sustainability, and high-speed production, investing in the right technology is essential.

Orange O Tech continues to lead this transformation by providing versatile, robust, and future-ready textile printing machines. If you’re ready to elevate your fabric printing operations, there’s no better partner to start with.

Explore Orange O Tech's full range of textile printing machines today and bring your fabric designs to life—faster, cleaner, and sharper than ever.

0 notes

Text

Nickel Screens: Precision Tools for High-Performance Rotary Printing

In the world of modern industrial printing, especially textile printing, precision, durability, and consistency are non-negotiable. Among the most essential components driving this precision are nickel screens—fine, high-strength cylindrical screens used predominantly in rotary screen printing. These specialized screens offer unmatched performance and reliability, making them indispensable in various printing applications.

What Are Nickel Screens?

Nickel screens are seamless, cylindrical screens made from electroformed high-purity nickel. These screens are primarily used in rotary screen printing machines to apply color and patterns onto a wide range of substrates, including textiles, wallpaper, packaging materials, and ceramics.

The screen’s surface contains a precise mesh of microscopic holes or apertures that allow ink to be transferred onto the substrate in controlled patterns. The combination of high strength, fine resolution, and uniform ink distribution makes nickel mesh screens essential for high-speed, high-volume printing operations.

Key Features of Nickel Screens

Material: Made from high-grade nickel via electroforming, ensuring superior strength and corrosion resistance.

Seamless Design: Uniform cylinder with no visible joins, preventing distortions and ensuring smooth ink flow.

Customizable Mesh Counts: Available in a range of mesh sizes (from 40 to 165 mesh or more), allowing for both fine-detail and high-volume ink applications.

Excellent Dimensional Stability: Maintains shape even under high tension and speed during printing operations.

Applications of Nickel Screens

Nickel screens are used across several industries for rotary screen printing and other precision processes, including:

Textile Industry

Printing on cotton, polyester, silk, rayon, and blended fabrics.

Widely used for decorating garments, upholstery, and home furnishings.

Packaging & Labels

Ideal for printing on flexible packaging materials and product labels.

Wallpaper & Decorative Surfaces

High-resolution designs printed on decorative paper and wall coverings.

Ceramics

Used for transferring intricate patterns onto tiles and ceramic items.

Nonwoven & Technical Textiles

Applied in printing or coating nonwoven fabrics used in medical and industrial applications.

Benefits of Using Nickel Screens

High Precision Printing

The fine, uniform mesh allows for accurate and detailed pattern reproduction.

Durability and Long Lifespan

Resistant to wear and corrosion, ensuring a long operational life even in high-speed production lines.

Reduced Downtime

Strong and stable screens reduce breakage and stretching, which helps minimize machine stops and increases productivity.

Customizability

Available in various diameters, lengths, and mesh counts to suit specific printing needs.

Smooth Ink Transfer

The seamless surface of the screen ensures consistent ink flow and avoids smudging or uneven prints.

Choosing the Right Nickel Screen

When selecting a nickel screen, consider the following factors:

Mesh Count: Higher mesh counts are better for detailed work; lower mesh counts allow for more ink flow.

Screen Thickness: Thicker screens last longer and resist deformation.

Screen Diameter and Length: Must match the rotary screen printing machine specifications.

Type of Ink and Substrate: Some inks or materials may require specialized screen coatings or mesh sizes.

Conclusion

Nickel screens are a critical component in achieving high-quality, efficient rotary printing across various industries. Their precision engineering, strength, and versatility make them the preferred choice for manufacturers seeking flawless results at high speeds.

#nickel screens#rotary nickel screen manufacturers#nickel screen manufacturer#nickel screen for rotary printing#nickel mesh screen

0 notes

Text

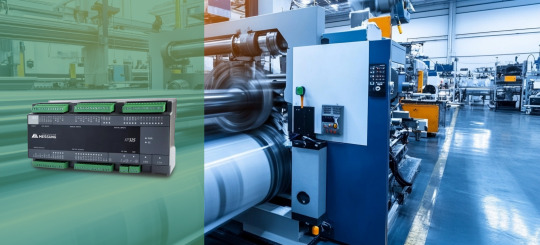

Enhancing Textile Machinery Efficiency with Messung's NX-ERA Xpress PLC

The textile industry, being a part of global manufacturing, has witnessed a massive transformation in recent years due to accelerated technological advancements. From yarn making to dyeing yarns with complex patterns, each process of textile production has been streamlined for higher productivity, accuracy, and efficiency. The need for high-quality products and shorter production cycles has generated fertile ground for automation, especially with the use of Programmable Logic Controllers (PLCs)in textile manufacturing.

This is where we at Messung Industrial Automation come in the picture with our cutting-edge automation solutions. With our strong heritage of delivering strong and scalable automation solutions, we have been the industry leader in industrial automation. Our innovative and compact PLC, NX-ERA Xpress has been crafted to specifically address the specific requirements of industries such as textile manufacturingwith the ideal combination of performance, flexibility, and energy efficiency. In this blog, let’s explore the revolutionary potential of NX-ERA Xpress PLCand its impact on textile machinery, with an emphasis on how it improves operational efficiency, cuts costs, and accelerates the journey towards Industry 4.0.

The Role of PLCs in Modern Textile Manufacturing

Programmable Logic Controllers (PLCs) form the foundation of automation in textile manufacturing, especially in the "cotton to yarn" and "yarn to fabric" segments where their role is most critical. These rugged, industrial-grade controllers ensure precision, speed, and efficiency by managing machinery and processes in real time. From ginning and bale plucking to spinning, carding, drawframe, combing, ring frame machines, and autoconers, PLCs are deeply embedded in every stage of the cotton-to-yarn journey.

In the yarn-to-fabric sector, PLCs continue to play a significant role in the operation of warping machines, twisting machines, and various types of looms such as shuttle, airjet, and rapier looms. They are equally vital in fabric processing lines, managing singeing, bleaching, dyeing, and a wide range of finishing machines designed to enhance textile properties like softness, wrinkle resistance, or water repellency. Printing lines, including rotary and flat bed printing machines, also rely heavily on PLC-controlled automation.

Across these applications, PLCs are integrated with Human Machine Interfaces (HMI), Variable Frequency Drives (VFDs), and in high-speed machines like spinning lines, Servo amplifiers and Servo motors are used for superior speed and torque control.

While the garment sector (fabric to garment) does involve automation, Messung’s core expertise and solutions, including the NX-ERA Xpress PLC and NX-ERA Jet PLC, are primarily focused on the earlier and more automation-intensive stages of textile manufacturing.

Benefits of Implementing PLCs on Textile Machinery

Increased Efficiency: PLCs allow streamline operations by automating processes that were previously manual, significantly reducing downtime and increasing throughput

Improved Accuracy: The high-level precision control afforded by PLCs ensures each activity in the fabric process, whether spinning or weaving, is undertaken with perfection.

Real-Time Monitoring: PLC-based systems make equipment monitoring in real-time a certainty, where defects are flagged off early and avoid costly downtime along with plant operation performance improvements.

As the textile industry advances, compact PLCs are not an indulgence but a must-have. Automation is the key to staying competitive, and industrial automation PLC systems like the NX-ERA Xpress are at the forefront of this revolution.

Learning More About NX-ERA Xpress PLC

The NX-ERA Xpress PLC is our response to the increasing needs of the textile industry. By harnessing the capability of Programmable Logic Control Systems and the flexibility of contemporary communication protocols, the NX-ERA Xpress provides a powerful and scalable solution for numerous industrial automation applications.

Features of NX-ERA Xpress PLC:

High-Density Digital and Analog I/O: The NX-ERA Xpress PLC features a high-density I/O design that is capable of processing vast amounts of data input and output at one time. This is important for the textile industry, where real-time data from many machines need to be processed efficiently in order to optimize performance.

Programming through Codesys® (IEC 61131 Standard): Among the most impressive aspects of the NX-ERA Xpress PLC is its support for Codesys®, an open-source programming platform. This standardization enables seamless integration with industrial equipment across the board, which makes it an attractive option for PLC manufacturing companies.

Integrated Communication Protocols: With inbuilt compatibility for communication protocols such as Ethernet TCP/IP, Modbus, and CANopen, the NX-ERA Xpress PLC facilitates smooth connectivity among various machines and devices on the shop floor. This connectivity is vital for ensuring smooth operation throughout the complete manufacturing process.

Industry 4.0 Readiness: NX-ERA Xpress PLC comes with OPC-UA and MQTT readiness, making it Industry 4.0-ready. These are technologies that support data exchange over different platforms, and they simplify the integration of machines by manufacturers into a smart factory environment.

Integrated HTML Web Server for Remote Monitoring: Remote monitoring has never been simpler. The integrated HTML web server enables operators to monitor and control the PLC remotely, offering flexibility and real-time visibility into machine performance.

The high-performance features and compact PLC design of NX-ERA Xpress PLC make it perfect for the textile industry. Whether you're automating cotton spinning, weaving, or dyeing, the NX-ERA Xpress provides all the power you need to optimize your operations.

Advantages of NX-ERA Xpress in Textile Applications

The textile industry requires solutions that are capable of providing not just high performance but also cost-effectiveness and sustainability. Our NX-ERA Xpress PLC provides a number of benefits for applications in textile machinery, such as:

Energy Efficiency

In the textile industry, energy consumption is a major operational expense. The NX-ERA Xpress PLC is built to maximize control and minimize power consumption, especially in power-hungry processes such as spinning. Through automation processes and optimizing machine efficiency, the PLC ensures textile plants make substantial savings on energy.

High-Speed Processing

Textile production processes often involve rapid and adaptive control systems that are necessary for handling high-speed manufacturing lines. The processing of high speeds facilitated by the NX-ERA Xpress PLC helps data move faster to provide instant adjustment capabilities, ensuring minimum lags in manufacturing processes.

Precision Control

The clothing industry is based on the effective control of variables like thread tension, fabric alignment, and dying processes. NX-ERA Xpress PLC ensures accurate control in order to match every parameter in the manufacturing process to the prescribed specifications. The result is repetitive product quality, and less it is defective.

Scalability

As textile factories develop and expand, scalable automation systems become increasingly relevant. NX-ERA Xpress PLC uses a modular construction that means that automation systems can be expanded as they are required by manufacturers, presenting a great solution for expanding businesses in the textile industry in the long term.

Cost-Effectiveness

Automation must not be expensive. The NX-ERA Xpress PLC is an affordable solution for textile producers that offers high-end features without an exorbitant price tag. It is meant to offer high-performance at an affordable rate, so any textile firm can use it.

Textile Machinery Applications: PLC Precision for a Modern Mill

As textile factories embrace digital transformation, the NX-ERA Xpress PLC emerges as a compact yet powerful solution tailored for automation-ready textile machinery. With its robust control features and Industry 4.0 connectivity, the NX-ERA Xpress brings intelligence and agility to a wide range of textile processes.

Let’s explore key use cases across the textile value chain:

Yarn Steaming Machine:

Steaming is a critical stage in yarn preparation where temperature, pressure, and timing must work in harmony. The NX-ERA Xpress PLC ensures:

Precise control of temperature and steam pressure for consistent yarn conditioning

Regulation of steaming duration to match different yarn types and production speeds

Automation of loading and unloading mechanisms, reducing manual intervention and boosting throughput

With its real-time responsiveness and compact design, the NX-ERA Xpress PLC enhances efficiency, consistency, and reliability in yarn steaming operations.

Heat Setting and Space Dyeing Machine Integration:

In advanced textile finishing, seamless integration between heat setting and dyeing is essential. NX-ERA Xpress PLC brings synchronization and control to:

Temperature management for precise heat setting, improving dimensional stability and dye fixation

Control of dye application in the space dyeing process, enabling unique patterns with consistent results

Coordination of material flow between machines, ensuring smooth transitions and avoiding process bottlenecks

The result is an integrated, high-performance workflow for specialty dyeing applications, digitally governed for optimal output and reduced waste.

Integration with Messung's Automation Ecosystem

One of the major strengths of the NX-ERA Xpress PLC is that it can integrate smoothly with all our other products, like the XM-PRO remote I/O modules. This makes it possible to have a unified automation solution that simplifies the control and monitoring of your entire textile plant.

With a single provider for all automation needs, textile manufacturers can enjoy streamlined operations, reduced complexity, and improved support. The synergy between the NX-ERA Xpress PLC and our other products ensures that your factory is fully equipped to tackle the challenges of modern textile manufacturing.

Conclusion

In summary, our NX-ERA Xpress PLC is a game-changer in the textile sector, providing powerful, scalable, and affordable automation. With its high-performance capabilities, energy efficiency, and accurate control, the NX-ERA Xpress PLC is ideally positioned to address the changing needs of textile producers.

With the NX-ERA Xpress PLC, you can elevate your textile manufacturing process to the next level. Whether you want to optimize spinning, weaving, or dyeing processes, Messung's automation solutions provide the reliability and performance that you require to remain ahead in a competitive market.

So, why wait? Consult Messung today for a customized automation solutionthat suits your textile manufacturing needs. It’s time to embrace the future of textile production with the NX-ERA Xpress PLC - where automation meets innovation

#textile manufacturers#Programmable Logic Controllers (PLCs)#textile manufacturinG#cutting-edge automation solutions#compact PLC#NX-ERA Xpress PLC#textile machinery#Industry 4.0#spinning#carding#drawframe#combing#ring frame machines#autoconers#singeing#bleaching#dyeing#PLC-controlled automation.#NX-ERA Jet PLC#industrial automation#PLC systems#IEC 61131 Standard#Ethernet TCP/IP#Modbus#CANopen#cotton spinning#automation processes#remote I/O modules#automation needs#customized automation solution

0 notes

Text

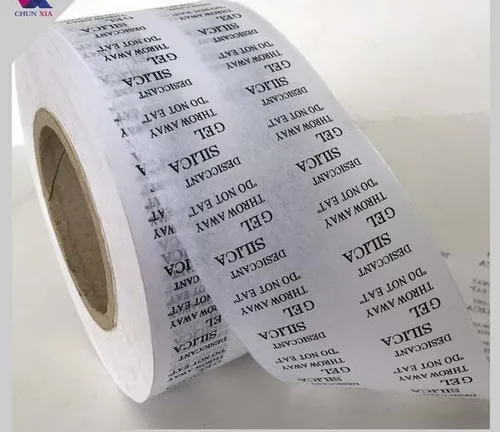

Silica gel packing roll

In industries where moisture control is crucial, silica gel is a widely trusted solution. However, for high-speed, bulk, and automated silica gel sachet production, you need a reliable packaging material that is both breathable and strong. This is where the Silica Gel Packing Roll becomes essential. It is specifically designed for manufacturing silica gel sachets efficiently while ensuring maximum moisture absorption performance.

What is a Silica Gel Packing Roll?

A Silica Gel Packing Roll is a specially formulated roll made from breathable laminated non-woven fabric or paper, used for automatic and manual silica gel sachet making. It allows moisture to pass through easily while retaining the silica gel securely inside the sachets. These rolls are suitable for high-speed automatic packing machines, making sachet production fast and consistent.

Features of Silica Gel Packing Roll

✅ Excellent Breathability The roll material allows moisture to enter easily, ensuring silica gel works effectively.

✅ High Strength & Durability Designed to withstand high-speed machine operations without tearing or breaking.

✅ Smooth Surface for Machine Compatibility Ensures trouble-free performance in both automatic and semi-automatic sachet packing machines.

✅ Available in Custom GSM & Sizes We supply rolls in different GSM (20 to 60 GSM) depending on your sachet size and packing needs.

✅ Eco-Friendly Option Available We also offer eco-friendly and food-grade silica gel packing rolls suitable for pharmaceutical and food industries.

Advantages of Using Silica Gel Packing Roll

Increases the productivity of silica gel sachet production

Provides uniform and high-quality sachets

Reduces wastage during the packaging process

Compatible with both rotary and vertical form fill seal (VFFS) machines

Helps in cost-effective and efficient mass production

Applications of Silica Gel Packing Roll

Silica Gel Packing Rolls are widely used in the manufacturing of:

Electronics protection sachets

Pharmaceutical-grade silica gel sachets

Leather goods and shoe packaging

Garments and textile packaging

Machinery & metal components packaging

Food-grade moisture absorber packs (with food-safe certification)

Available Sizes

WidthGSMRoll LengthUsage80mm20-25 GSMCustomizableSmall sachets100mm25-35 GSMCustomizableMedium sachets150mm30-50 GSMCustomizableLarge sachetsCustomAs per requirementCustomizableOEM production

Why Choose Our Silica Gel Packing Roll?

At [Your Company Name], we specialize in manufacturing high-quality Silica Gel Packing Rolls that meet the global standard for moisture-absorbing sachets.

✅ Consistent Roll Quality ✅ Compatible with All Major Sachet Packing Machines ✅ Bulk Production & Timely Delivery ✅ Custom Printing & Private Label Options ✅ Competitive Wholesale Prices

Frequently Asked Questions (FAQs)

Q1: Is this roll suitable for automatic sachet packing machines? Yes, our rolls are designed for both automatic and semi-automatic sachet packing machines.

Q2: Can I get custom-printed rolls for my brand? Yes, we offer custom printing on silica gel packing rolls for branding purposes.

Q3: What is the minimum order quantity (MOQ)? MOQ depends on the GSM and roll width; please contact us for the latest MOQ.

Q4: Is food-grade packing roll available? Yes, we provide food-grade breathable laminated non-woven rolls for food and pharma use.

0 notes

Text

High-Performance Printing & Converting Machines | Advanced Solutions

In the modern world, the printing and packaging industry has started to completely rely on precision, effectiveness, and novelty. Advanced technology such as slitting rewinding machines, label die cutting machines, paper core cutting machines, hot foil stamping machines, and UV curing systems is among the most significant tools rendering final mba product quality.

Machine manufacturers and converters rely heavily on high-level technological tools to speed up the process of production, increase accuracy, and aid versatility of their machines. The description of the machines' importance in various industrial applications has been outlined in a set of present practice method, showing machines' necessity in printing and packaging industries today.

Slitting Rewinding Machine

A slitting rewinding machine is a vital component in industries dealing with flexible packaging, paper, films, and foil materials. It enables the precise slitting and rewinding of large master rolls into smaller rolls with accurate tension control.

Key Features of a Slitting Rewinding Machine:

High-Speed Performance: Ensures rapid slitting and rewinding without compromising quality.

Precision Cutting: Adjustable slitting blades provide clean and accurate cuts.

Tension Control Mechanism: Maintains optimal tension for smooth rewinding.

User-Friendly Interface: Automated controls for easy operation and reduced downtime.

Versatile Applications: Suitable for plastic films, aluminum foils, paper rolls, and adhesive tapes.

Applications of Slitting Rewinding Machines:

Flexible Packaging Industry: For slitting plastic films and foils.

Label Production: Converts large rolls into label-sized formats.

Printing Industry: For handling coated and laminated materials.

Label Die Cutting Machine

A label die cutting machine is essential for the precise cutting of labels, stickers, and adhesive sheets. It ensures clean edges, intricate shapes, and high-speed production for industries requiring mass labeling.

Key Features of a Label Die Cutting Machine:

Rotary & Flatbed Cutting: Supports various die-cutting methods for different label types.

Automatic Waste Removal: Ensures a cleaner output with no excess material.

High Cutting Accuracy: Ideal for custom shapes and intricate label designs.

Multi-Layer Processing: Allows multiple layers for enhanced durability.

User-Friendly Control Panel: Simplifies operation and reduces labor requirements.

Applications of Label Die Cutting Machines:

Food & Beverage Labeling: Used for bottle and container labeling.

Pharmaceutical Industry: For precision-cut medical labels.

Cosmetic & Personal Care Products: Ensures premium quality label cutting.

Paper Core Cutting Machine

A paper core cutting machine is used to cut paper tubes and cores to the desired length, ensuring smooth edges and accurate dimensions for various industrial applications.

Key Features of a Paper Core Cutting Machine:

High Cutting Precision: Produces accurate and smooth cuts for uniform core sizes.

Adjustable Cutting Lengths: Allows customization for different applications.

Heavy-Duty Construction: Ensures durability and longevity.

Automatic & Manual Operation: Supports both automatic and manual cutting modes.

Dust-Free Operation: Minimizes waste and enhances cleanliness.

Applications of Paper Core Cutting Machines:

Packaging Industry: For manufacturing paper cores for packaging rolls.

Printing Sector: Used for paper roll cores and film winding.

Textile Industry: For fabric and yarn core cutting.

Hot Foil Stamping Machine

A hot foil stamping machine enhances the visual appeal of printed products by adding metallic and holographic foil designs. It is widely used in luxury packaging, book covers, greeting cards, and promotional materials.

Key Features of a Hot Foil Stamping Machine:

Advanced Foil Transfer Technology: Ensures sharp and clean imprints.

Temperature & Pressure Control: Allows precise adjustments for different materials.

Multi-Purpose Applications: Works on paper, plastic, leather, and fabric.

Automatic Foil Feeding System: Ensures smooth and continuous foil application.

Energy-Efficient Design: Reduces operational costs and improves efficiency.

Applications of Hot Foil Stamping Machines:

Luxury Packaging: Enhances premium product packaging.

Branding & Promotions: Used for high-end business cards and brochures.

Security Printing: Adds holographic elements for anti-counterfeiting.

UV Curing Systems

A UV curing system is an advanced technology used for instant drying and curing of inks, coatings, and adhesives using ultraviolet light. This method ensures high-quality finishes, durability, and eco-friendly operations.

Key Features of a UV Curing System:

Instant Drying & Curing: Reduces production time significantly.

Energy Efficiency: Consumes less power compared to traditional drying methods.

Eco-Friendly Operation: Eliminates the need for solvents and harmful chemicals.

High Durability: Ensures scratch-resistant and long-lasting prints.

Wide Compatibility: Suitable for offset, flexographic, and screen printing.

Applications of UV Curing Systems:

Printing Industry: For UV-cured inks and coatings.

Electronics & PCB Manufacturing: Ensures durable protective coatings.

Medical Devices: Used for adhesive bonding in healthcare applications.

Why Invest in High-Performance Printing & Converting Machines?

Enhanced Production Efficiency – Reduces downtime and increases output.

Precision & Quality – Ensures accurate cutting, stamping, and curing.

Cost-Effective Solutions – Optimizes material usage and reduces waste.

Versatile Applications – Suitable for various industries, from packaging to textiles.

Advanced Automation – Minimizes manual labor and improves operational accuracy.

By integrating the latest slitting rewinding machine, label die cutting machines, paper core cutting machines, hot foil stamping machines, and UV curing systems, manufacturers can achieve superior productivity and quality.

Project Name: UV Graphic Technologies Pvt. Ltd

Address: Plot 15, Sector 140A, Noida UP 201305

Contact No: 919810114365

Email ID: [email protected]

Our Website: https://gtigti.com/

Linkedin ID: https://www.linkedin.com/company/uv-graphic-technologies-pvt-ltd/

You tube: https://www.youtube.com/watch?v=EleXfuBanIk&ab_channel=AbhayDatta

0 notes

Text

youtube

Wallpaper - Paste It Up

Wallpaper is a material that we use to cover and decorate the interior walls of homes, offices and other buildings. Wallpaper is sold in rolls and is put click here onto walls with wallpaper paste. Wallpaper began as an inexpensive substitute for paneling and tapestries.

Paper was invented in ancient China. They use to glue rice paper to their walls. A court official of the Chinese invented paper from rags. By the 10th century Arabs used wood and bamboo to create thin sheets of paper. During the 12th century Europeans commissioned artists to paint paper for their walls. In 1675 a French engraver made block designs on the wallpaper and this was very much like the wallpaper of today.

Wallpaper finally came to America in 1739. Right after the revolutionary war it was all the fashion. Everyone wanted it in their homes. In 1839 a 4 color wallpaper printing machine was invented and by 1874 there was a 12 color wallpaper printing machine in use. In 1888 the first ready to use wallpaper paste was invented. Pasting machines were not developed until the 20th century.

If you lived in the ‘20s you were sure to have one room of your house that had wallpaper. Over 400 million rolls were sold during that time. Soon after, people started to frown on embellishments. Wallpaper fell to disfavor for a time for its lavish effects and cost.

Wallpaper has had its ups and downs but after World War Two it picked up in popularity. This happened because of wall coverings that were available were easy to maintain and affordable. This new wallpaper had structural integrity as opposed to the older flimsy kind.

There is a large variety to choose from. There is wallpaper that comes plain, that you can paint your own design or others that have patterned graphics. Some printing techniques include surface, gravure, screen and rotary. You can also purchase pre-pasted paper that is easy to hang. Begin choosing your wallpaper by considering the space you are decorating and the type of surface you will be covering. Make certain you measure to ensure you will complete your project. When in doubt always order more then you will need.

I had my own experience with wallpaper. In the 1980’s I purchased wallpaper that had a twist. It was wallpaper that you could write on. I hung this in my bathroom and it had a special pen that was attached. Who ever visited me got to write a special message or saying. Don’t worry because it was also washable and believe me I had to wash it away quite a lot!

Here is a list of some of the different styles that are offered and a brief review of its character. The most popular is vinyl for its durability and easy upkeep. Another choice is fabric backed vinyl. This is usually unpasted but washable and moisture resistant. The next option is paper backed vinyl. It is prepasted and light weight. It creates a three dimensional effect and it works best on rough surfaces. Next there are textiles.

1 note

·

View note

Text

Encoder Market Report: An Overview of Current Trends and Key Players

Encoder Market Report: An Overview of Current Trends and Key Players

The global encoder market, valued at approximately $2.4 billion in 2021, is anticipated to grow significantly, reaching $4.5 billion by 2030, with a compound annual growth rate (CAGR) of 7.83% during the forecast period from 2022 to 2030. This growth reflects the increasing demand for automation across various industries and the integration of advanced technologies.

The global encoder market is a vital segment of the automation and control systems industry, encompassing devices that convert motion or position into a coded signal. Encoders play a crucial role in various applications, including robotics, industrial automation, automotive systems, and consumer electronics. These devices ensure precise measurements of rotational position, speed, and direction, which are essential for the efficient operation of machinery and equipment.

Market Definition and Latest Trends

Encoders are essential devices that convert motion or position into an electrical signal, which can then be read by a controller or a computer. They play a critical role in various applications, including robotics, industrial automation, and automotive systems. The encoder market is witnessing several notable trends:

Increased Adoption of Industry 4.0: The shift towards smart manufacturing and Industry 4.0 is driving the demand for encoders as industries seek to enhance operational efficiency and precision.

Integration with IoT and AI: The growing integration of encoders with Internet of Things (IoT) devices and artificial intelligence (AI) systems is enabling more sophisticated data analysis and machine learning applications.

Rising Demand in Automotive Sector: The automotive industry is increasingly utilizing encoders for applications such as electric vehicles and advanced driver-assistance systems (ADAS), contributing to market growth.

Get a Report Request Sample Link:https://straitsresearch.com/report/encoder-market/request-sample

Key Opportunities

The encoder market presents significant opportunities for growth due to the following factors:

Technological Advancements: Continuous innovations in encoder technology, such as the development of more reliable and efficient models, are expected to create new market opportunities.

Emerging Markets: Rapid industrialization in regions like Asia-Pacific offers lucrative prospects for encoder manufacturers as demand for automation solutions increases.

Market Segmentation

The encoder market can be segmented based on type, technology, and end-user:

By Type

Rotary Encoder

Linear Encoder

By Technology

Optical

Magnetic

Photoelectric

Others

By End-User

Automotive

Electronics

Textile

Printing Machinery

Industrial

Medical

Others

Key Players in the Encoder Market

Several prominent companies are leading the encoder market, including:

Omron Corporation

Honeywell International

Schneider Electric

Rockwell Automation Inc.

Panasonic Corporation

Baumer Group

Renishaw PLC

Dynapar Corporation (Fortive Corporation)

FAULHABER Drive Systems

Buy Now Link:https://straitsresearch.com/buy-now/encoder-market

These companies are focusing on strategic partnerships, mergers, and acquisitions to expand their market presence and enhance product offerings.

Why Straits Research?

Straits Research is a trusted market research provider known for its in-depth analysis and strategic insights. With a team of experts, Straits Research offers comprehensive market reports that help businesses and stakeholders make informed decisions.

0 notes

Text

Air Compressors and Their Impact on Manufacturing Productivity

In the world of manufacturing, where speed, precision, and efficiency determine success, air compressors stand as unsung heroes. These versatile machines quietly power countless tools and processes, enabling industries to meet high production demands. From streamlining operations to supporting cutting-edge technology, air compressors play a key role in boosting productivity. But how do they make such a profound impact? Let’s explore the world of compressed air and uncover how it pushes innovation, reduces costs, and ensures sustainable growth in modern manufacturing.

Impact of air compressors on manufacturing productivity:

Powering seamless operations:

Air compressors are the backbone of efficiency in manufacturing, delivering reliable energy for an array of tools and machinery.

Uninterrupted power: Unlike electric tools prone to fluctuations, air-powered systems maintain constant performance, ensuring smooth workflows.

Multi-tool capability: A single air compressor can power multiple devices simultaneously, eliminating the need for multiple energy sources and reducing working complexities.

Ease of maintenance: Pneumatic tools powered by air compressors have fewer moving parts, resulting in reduced wear and tear and less downtime.

Imagine an assembly line breaking due to tool failure; it’s costly and time-consuming. Air compressor manufacturers minimise such risks, keeping production lines buzzing efficiently.

Lowering costs:

One of the biggest advantages of high pressure air compressor manufacturers in India is their ability to reduce production costs while increasing output.

Energy efficiency: Modern air compressors, like rotary screw and oil-free models, consume less energy while delivering high output, making them cost-effective.

Durable and long-lasting: Air-powered tools have longer lifespans compared to their electric counterparts, reducing the need for frequent replacements.

Labour savings through automation: Many manufacturing processes, such as material handling and packaging, can be automated using compressed air, cutting labour costs and enhancing precision.

For example, automated spray painting powered by air compressors not only saves paint but also ensures a flawless finish, reducing waste and rework.

Driving advanced manufacturing techniques:

Modern high pressure air compressor manufacturers in India thrive on innovation, and air compressors are key enablers of advanced techniques.

Laser cutting and 3D printing: Compressed air ensures precise cutting by removing waste and keeping systems cool. In 3D printing, it powers pneumatic systems to control material deposition accurately.

Robotics: Many robotic arms depend on pneumatic systems for their movements, offering flexibility and speed in tasks like assembly and quality checks.

By empowering such techniques, air compressor manufacturers stay ahead in an increasingly competitive market.

Ensuring workplace safety and quality:

Safety and quality are non-negotiable in manufacturing, and air compressors contribute greatly to both.

Cleaner processes: Oil-free air compressors ensure contamination-free production, which is important in industries like food, pharmaceuticals, and electronics.

Noise reduction: Advanced models operate quietly, creating a safer and more comfortable environment for workers.

Enhanced tool safety: Air-powered tools are commonly lighter and safer to use than electric tools, reducing the risk of injuries.

In a factory producing electronics, for example, even minor contamination can lead to defective products. Oil-free compressors ensure the highest standards of cleanliness and reliability.

Customisation for diverse industries:

One of the standout features of air compressor manufacturers is their adaptability to different manufacturing needs.

Automotive: From spray painting to assembling components, air compressors support various processes.

Textile: They automate weaving, spinning, and dyeing machines, improving speed and consistency.

Food and beverage: Compressors help in packaging, cooling, and even producing carbonated drinks.

Healthcare: Oil-free compressors provide the clean air required in pharmaceutical manufacturing.

This versatility allows air compressor manufacturers across industries to tailor air compressor solutions to their unique requirements, maximising efficiency.

Supporting sustainable manufacturing:

Sustainability is no longer a choice; it’s a necessity. Air compressors align with this vision by promoting eco-friendly operations.

Energy conservation: Variable speed drive (VSD) compressors adjust their output to match demand, significantly reducing energy waste.

Waste reduction: Compressed air systems minimise material wastage in processes like painting, packaging, and assembly.

Lower emissions: Efficient air compressors contribute to reduced carbon footprints, making them a vital component of green manufacturing initiatives.

Innovation in compressor technology:

The evolution of air compressors continues to redefine their role in manufacturing.

IoT and smart systems: Internet-connected compressors allow real-time monitoring, predictive maintenance, and operational insights, preventing downtime and maximising productivity.

High-pressure models: These are ideal for heavy-duty tasks like forging and metal fabrication.

Portable compressors: Lightweight and mobile, they offer flexibility for smaller manufacturing setups.

By investing in these advancements, high pressure air compressor manufacturers in India can future-proof their operations and adapt to changing industry demands.

A future built on compressed air:

The role of air compressors in manufacturing is only set to grow. As industries adopt poor practices and aim for higher efficiency, these machines will remain indispensable. Arising trends like additive manufacturing, smart factories, and sustainable production further underscore the importance of investing in advanced air compressor systems.

Summary:

Air compressors are more than just tools; they are motivations for transformation in manufacturing. By powering critical operations, enabling innovation, and supporting sustainability, they help manufacturers achieve higher productivity and profitability. As the industry evolves, air compressor manufacturers will resume to play a central role, ensuring businesses remain competitive and environmentally responsible. Investing in the right air compressor technology can unlock significant productivity gains and give manufacturers a competitive edge in today’s dynamic market.

0 notes

Text

Industrial Automatic Cloth,Carpet Cutting Machine

In the textile and garment industry, precision cutting of fabrics is a critical step in the manufacturing process. Traditional manual cutting methods are time-consuming, labor-intensive, and prone to errors. However, with the advent of industrial automatic fabric cutting machines, these challenges are being overcome.

Industrial automatic Cloth cutting machines are advanced cutting systems designed specifically for the textile industry. These machines utilize cutting-edge technology to automate the fabric cutting process, increasing efficiency, accuracy, and productivity. They employ various cutting methods, such as rotary blade cutting, laser cutting, or ultrasonic cutting, to achieve precise and clean cuts on different types of fabrics.

Carpet Cutting Machine

Cloth Digital Cutter

The Cloth Digital Cutter is a versatile cutting solution suitable for a wide range of materials, including wide range of soft and hard materials. Some examples include foam, rubber, leather, fabrics, composites, plastics, cork, paper, and even wood.. It offers high-speed cutting, exceptional precision, and a modular design that allows for customization and future upgrades. The Digital Cutter incorporates advanced cutting tools, intelligent software, and automated material handling systems, ensuring efficient and accurate fabric cutting.

A cloth digital cutter, also known as a computerized cutting machine or plotter cutter, is a device that combines the power of computer technology with precision cutting mechanisms. These machines are equipped with cutting tools, such as blades or lasers, and are controlled by specialized software that allows for precise and automated cutting of various materials. Digital cutters can handle a wide range of materials, including paper, vinyl, fabric, foam, leather, and more.

Our machine adopts advanced and mature rolling table design, the cutting width of your material can be customized according to your request, the theoretical cutting length is unlimited, with vacuum suction design (small sample adsorption is no longer difficult) and automatic camera positioning function , it can automatically finish the positioning and cutting of printing materials, and the contour can be cut without manual positioning.

The configuration of oscillating knife, drag knife strokes, tools and optional half knife, cutter, slotted knife, knife, cutter, indentation knife and other tools, can achieve the office of line drawing, cutting, cutting, dotted half cut off all the cutting and milling cutter cutting, various materials, V-CUT slot milling, pressing wheel, indentation size the utility function and so on scratch hard materials.

Benefits of cloth Digital Cutters

1. Precision and Accuracy

One of the primary advantages of digital cutters is their ability to deliver precise and accurate cuts. The advanced software used in these machines allows for intricate designs and complex cutting patterns to be executed with exceptional precision. This level of accuracy is crucial in industries where precise cutting is essential, such as graphic design and packaging.

2. Increased Efficiency and Productivity

Digital cloth cutter significantly improve efficiency and productivity by automating the cutting process. These machines can quickly and accurately cut multiple pieces in a fraction of the time it would take using manual methods. This increased efficiency allows businesses to meet tight deadlines, handle larger volumes of work, and reduce labor costs.

3. Versatility in Material Handling

Digital cutter is designed to handle a wide range of materials, making them highly versatile machines. Whether it’s cutting paper for intricate designs, vinyl for signage, or fabric for apparel production, digital cutters can adapt to different materials with ease. This versatility makes them valuable assets in industries that require diverse cutting capabilities.

4. Waste Reduction

By utilizing precise cutting patterns and nesting algorithms, digital cutters help minimize material waste. The software used in these machines optimizes the placement of designs on materials, ensuring maximum utilization and reducing unnecessary waste. This not only saves costs but also contributes to sustainable and eco-friendly practices.

5. Design Flexibility

Digital cutters offer unparalleled design flexibility, allowing businesses to create intricate and complex designs without limitations. The software used in these machines enables designers to translate their creative visions into reality, opening up a world of possibilities for customization and personalization. This flexibility is particularly valuable in industries such as signage, packaging, and apparel, where unique and eye-catching designs are essential.

Applications of Industrial Automatic Fabric Cutting Machines

Industrial automatic Carpet cutting machine find applications ina variety of industries and sectors. Some of the key applications include:

Apparel and Fashion Industry: Industrial automatic fabric cutting machines are extensively used in the apparel and fashion industry for cutting fabrics for garments, accessories, and other textile products. These machines enable precise and efficient cutting of various fabric types, helping manufacturers meet the demands of fast-paced fashion trends.

Upholstery and Furniture Manufacturing: Fabric cutting machines play a crucial role in the upholstery and furniture manufacturing industry. They ensure accurate and clean cuts of upholstery fabrics, leather, and other materials used in furniture production. The machines’ ability to handle different fabric thicknesses and textures makes them ideal for creating customized and high-quality furniture pieces.

Automotive and Aerospace Industries: Industrial automatic fabric cutting machines are also utilized in the automotive and aerospace sectors. These machines can cut fabrics used for car interiors, seat covers, headliners, and aircraft interiors. The precision cutting capabilities of these machines ensure that the fabrics fit perfectly and meet the stringent quality standards of these industries.

Technical Textiles and Industrial Applications: Technical textiles, such as those used in protective clothing, medical textiles, and industrial applications, require precise cutting to meet specific requirements. Industrial automatic fabric cutting machines can handle technical textiles with ease, ensuring accurate and clean cuts for applications such as protective gear, filtration materials, and industrial components.

Home Furnishings and Interior Design: From curtains and drapes to bedding and upholstery, industrial automatic fabric cutting machines are essential for the home furnishings and interior design industry. These machines enable manufacturers to cut fabrics in bulk, ensuring consistency and precision in the production of home textiles. They also help reduce material waste, making them cost-effective and sustainable solutions.

Fabric Cutters FAQ (Frequently Asked Questions)

1. What types of materials can be cut with a digital cutter?

Fabric Digital cutters can handle a wide range of materials, including paper, vinyl, fabric, foam, leather, cardboard, corrugated board, acrylic, and wood.

2. How precise are digital cutters?

Digital cutters offer exceptional precision and accuracy, allowing for intricate designs and complex cutting patterns. The advanced software used in these machines ensures precise cuts, minimizing errors and wastage.

3. Can digital cutters handle large volumes of work?

Yes, Fabric digital cutter are designed to handle large volumes of work efficiently. These machines automate the cutting process, significantly improving productivity and reducing production time.

4. Are digital cutters user-friendly?

Most digital cutters come with user-friendly interfaces and intuitive software, making them accessible to users with varying levels of expertise. Manufacturers often provide training and support to ensure users can maximize the capabilities of the machines.

5. How do digital cutters contribute to sustainability?

Digital cutter help reduce material waste by optimizing cutting patterns and nesting algorithms. This minimizes unnecessary waste and promotes sustainable practices. Additionally, the automation and efficiency of digital cutters reduce energy consumption and carbon footprint.

CNC DIGITAL KNIFE CUTTERProjecttion Visual Vibrating Knife Cutting Machine

CNC DIGITAL KNIFE CUTTERPP Foam | PE Foam | PVC Foam | EVA Foam Cutting Machine

CNC DIGITAL KNIFE CUTTEROscillating Cutting Machine with Automatic Feeding Device

CNC DIGITAL KNIFE CUTTEROscillating Cutter for Cardboard Craft Paper Fabric Die

CNC DIGITAL KNIFE CUTTERMulti Layer Fabric Cutting Machine

CNC DIGITAL KNIFE CUTTERIndustrial Automatic Cloth Cutting Machine

How Many Types of Automatic Digital Cutters?

Digital cutting machines are divided into digital gasket cutter, carpet cutter, fabric cutter, leather cutting tool, cardboard cutter, foam cutting system, paper cutter, film cutting tool, vinyl cutter and fiberglass cutting system.

What Are CNC Digital Knife Cutting Machines Used For?

CNC digital knife cutters are used for the cuts of special-shaped graphics made of non-metallic flexible materials. It can quickly complete various processes such as full-cut, half-cut, milling, perforate, crease and mark, solving the problems of special-shaped picture cuts, improving production efficiency, and reducing labor cost. It can reduce the defect rate caused by manual tool errors, help users complete high-quality cuts faster, more stable, and more accurately at low cost, improve user market competitiveness, and seize more market shares. Digital flatbed cutters are used in advertising packaging, clothing and footwear, automotive interiors, luggage, composite materials and other industries.

Graphics Industry

Applications: Outdoor advertising, displays, traffic signs, fleet graphics, exhibits, illuminated signage, store décor, decals, floor graphics, etc.

References: 3M, Airbus, Avery Dennison, Christinger, Fair-play, Fastsigns, Graphics Gallery, Imaba, Lufthansa, netService, PlotFactory, Quarmby Colour Studio, Sin Fung Advertisement, Stylographics, Supersine Duramark, Zebra Graphics, etc.

Packaging Industry

Applications: Printed or unprinted packaging, POP/POS displays, foam inserts, dies making.

References: Beiersdorf, Chesapeake, Edelmann, Hasbro Toys, Heidelberg, International Paper, Long Chen Paper, Mauro Benedetti, Mondi, Packaging Cooperation of America (PCA), Panther Packaging, Philip Morris, sanovi aventis, SCA,Seda, Smurfit Kappa, STI, TetraPack, Thimm Verpackung, Triwall, etc.

Leather Industry

Applications: Shoes, garments, upholstery, handbags, briefcases, car and airplane seats, etc.

References: Adidas, Akris, Bally, Cavallo, Clarks, Ecco, Gabor, Geox, Gucci, Louis Vuitton, Nike, Prada, Puma, Recaro, Rolf Benz, Samsonite, de Sede, Sergio Rossi, Timberland, etc.

Textile Industry

Applications: Garments, upholstery, airbags, flags, sun shades/umbrellas, car and airplane seats, etc.

References: BMW, Diesel, Ford, Hugo Boss, Interstuhl, Jil Sander, Joop, Levi Strauss, Mercedes, Triumph, Volkswagen, Zodiac, etc.

Composite Industry

Applications: Defense, functional textiles, rotor blades for wind wheels and helicopters, aircraft and automotive parts, etc.

References: 3C-Carbon Composite Company, ACE, Airbus, Audi, Bell Helicopter, BMW, Carbo Tech, DLR, Dyneema, Eurocopter, FACC, Ferrari, McLaren, Pilatus, Red Bull Racing, Scuderia Toro Rosso, SGL Group, ThyssenKrupp, etc.

Techtex Industry

Applications: Truck tarpaulin, carpets, awnings, hot-air balloons, sails, outdoor equipment, inflatable boats, etc.

References: Badertscher, Barrisol, Bieri, Daedler, de Sede, Eschenbach Zeltbau, Estrella Betten, Höcker HTS Structures, interstuhl, Kusch+Co, Quelli In Luce, Ruckstuhl, Sachsen Fahnen, W.Schillig, etc.

0 notes

Text

Some of the best cheap laser machine for sale

If you're looking for cheap laser machine, there are several options available that cater to different needs and budgets. Here are some of the best cheap laser machine for sale:

Comgrow Z1 Engraver: This is a compact and affordable option that comes with either a 5W or 10W diode laser. It's easy to set up and offers good precision for engraving on materials like wood, leather, and acrylic. The 10W model is particularly good for cutting tougher materials and comes with a rotary roller upgrade option for engraving on rounded objects. It's a great entry-level laser engraver for those on a budget.

SainSmart Genmitsu LE 5040: With a slightly larger cutting area of 500mm x 400mm, this laser cutter offers a 5.5W laser module and is user-friendly. It's suitable for a variety of materials, including wood, MDF, anodized aluminum, paper, textiles, and acrylic. It works with both LaserGRBL and Lightburn software.

Ortur Laser Master 2: This model has a 390 x 410 mm cutting area and features a 5.5W laser beam output. It includes a G-Sensor safety feature that stops the laser beam in case of an outage or computer malfunction. It also comes with an upgraded motherboard and is compatible with LaserGRBL and Lightburn software.

Jinsoku LC-60A: This is a new budget laser engraver with a larger cutting area of 23.6″ x 23.6″ and an integrated Air Assist feature that reduces burning for cleaner cuts. It's one of the more expensive options in the budget category but comes with added safety and performance features.

OMTech Desktop K40: For those looking for a CO2 laser engraver under $500, this 40W model offers a smaller engraving surface of 300mm x 200mm but with more power than diode lasers. It includes a built-in exhaust fan and water cooling system, making it suitable for small businesses.

Atomstack A5 M50 Pro Laser Cutter: Known for its laser compression feature, this model can cut up to 0.8″ of wood and 0.6″ of acrylic material. It has a sturdy metal frame and a 410mm x 400mm cutting area, making it a great hobby-level engraver.

Sculpfun S9 Laser Cutter: With a 5.5W laser output and a 410 x 410 mm cutting area, this model is ideal for engraving projects. It has a thin 0.1mm laser beam for precise engravings on various materials.

ANYCUBIC Mega Pro FDM 3D Printer & Laser 2-in-1: This machine combines 3D printing with laser engraving, offering a smaller engraving area but the added capability of 3D printing. It's a versatile option for makers and crafters.

LaserPecker Pro Mini Engraver: This is a portable and compact laser engraver that can be controlled via Bluetooth using a smartphone app. It's suitable for engraving on softer materials and is ideal for those who need portability.

P7 Laser Engraver: This portable laser engraver comes pre-assembled and offers 5.5W of power with 0.01mm accuracy. It's a user-friendly option with a smooth stepping motor and includes a protective eye shield for safety.

When choosing a cheap laser machine, consider the size of the projects you'll be working on, the power of the cheap laser machine, the materials you intend to use, and your budget. It's also important to consider the safety features and the software compatibility of the cheap laser machine. These affordable options provide a range of capabilities for different needs and are suitable for both hobbyists and small businesses.

0 notes

Text

Enhance Textile Production with ATE's Advanced Rotary Printing Machines

ATE stands as a leader in the textile engineering sector. It offers an array of machinery and accessories that cover the entire textile value chain. ATE types of machinery include conventional and technical textiles and encompass everything from spinning, weaving, and knitting.