#Weighing machine Market Manufactures

Text

Best weighing scale machine Manufacturer, Top 10 Weighing Scale Company in India best weighing scale manufacturer in savarkundla, gujarat, india.

Galaxy scale weighing scales are commonly extra cost-friendly scales that supply measurements for purposes such as easy weighing, counting, formula or recipe weighing, mixing, batching, and filling and dosing.Best Digital weighing scales aid these equal purposes however provide greater precision and more desirable noise immunity to supply dependable effects in difficult industrial environments. To go one step further,science Galaxy scale liminates the want for a junction container in your scale or weighing device to in addition Top weighing scale export accuracy and gives situation monitoring abilities to make certain procedure visibility and long-term overall performance of your industrial weighing solutions.

Your interior employer necessities and applicable enterprise guidelines will decide if your weighing strategies require verification. Galaxy Scale presents Good Weighing Practice Verification, which archives the size uncertainty of weighing tools below actual running stipulations and can provide documentation to assist make certain you are organized to ignore any audit.

Best weighing scale machine Manufacturer, Top 10 Weighing Scale Company in India best weighing scale manufacturer in savarkundla, gujarat, india.

#galaxyscalecompany#galaxyscale#galaxyscaleindustries#savarkundlaindia#exporter#savarkundlagujaratindia#gujaratindia#supplier#weighing machine manufacturers#best weighing scale for home#best digital marketing agency#top weighing scale manufacturing companies#top counter scale manufacturer

0 notes

Link

#Automated Dispensing Machines Market#au#Automated weighing systems#Automated precision weighing applications#australia#Soil Testing#water dispensers#soil analysis#soil test#Carbon sulfur analyzer#lab equipment manufacturers#Laboratory sample weight loss#total organic carbon#thermogravimetric analysis#soil ph

0 notes

Photo

Suzuki RE-5 1974 – Extraordinary rotary engine!

In 1971 Suzuki bought a license from Wankel, precursor of the rotary piston, in order to develop a new engine for its motorcycles. Suzuki's investment in this project was significant because at that time Dr. Felix Wankel's rotary engine was a revolution and was just beginning to be mass-produced. For Suzuki, it was necessary to start from scratch and launch, something that many manufacturers will never do. Suzuki works hard and invests a lot to produce a reliable and robust engine. After two years of development, 200 modifications and 20 patents filed, the fruit of this hard work ensured the creation of a reliable machine called Rotary RX-5, presented at the Tokyo Motor Show in November 1973. Following slight modifications , the concept became RE-5 and was marketed in 1974.

The engine of the RE-5 is a single-piston rotary 497 cm3 developing 62 HP. To control its operating temperature, Suzuki adopts liquid cooling and uses the imposing radiator which was nicknamed at the time "the hot water bottle". The RE-5 had a rather high power and torque for the time compared to the displacement, and above all immediately available with very linear revs! The very particular melody of the rotary engine confirms that we are dealing with an engine like no other. It picks up low with flexibility, offers generous torque worthy of a big 4-stroke, and is characterized by the almost total absence of vibrations, a real treadmill! Weighing 230 kg on the scale, the RE-5 inherited the best technology of the time to be able to stop it: a double disc at the front.

The design of the motorcycle was entrusted to the coachbuilder Giorgetto Giugiaro who endeavored to recall the principle of the rotary engine through many details: the dashboard is cylindrical, the indicators are all round, the rear light is also cylindrical and circles appear on the side covers, all in an atmosphere inspired by the futuristic universe at the time straddling the Star Trek series and the Star Wars trilogy! The Suzuki logo, for its part, takes up the design of the rotor, in a triangle. This original line, to say the least, arouses astonishment and takes you directly to the 70s, certainly the most prosperous in terms of technological innovation. When you turn the ignition key to the first notch, the translucent cylinder of the dashboard opens (hence its nickname "bread box"! ) on a row of indicator lights, including the one that validates the two oil pumps. There is even a small digital window that indicates the gear engaged. Guaranteed sci-fi atmosphere!

The RE-5 is nothing conventional and never goes unnoticed. Sold in only 6000 copies worldwide between 1974 and 1976, it is the only rotary engine motorcycle in the world to have been mass produced. Unjustly misunderstood at the time because of its atypical design and the unknown that reigned around the Wankel engine devoid of camshaft, valve and connecting rod, the RE-5 whose consumption was relatively high had the misfortune to fall into the context of an oil shock. It did not have the success expected by Suzuki and the rotary engine was abandoned despite the colossal sums committed to this project. Today the RE-5 looks like an alien and is a fascinating machine with mind-boggling technology. This absolute rarity will find its place with an eclectic collector. Our very nice example Firemist produced in October 1974 has frame 10702 and engine RE5-10394. In perfect condition with its original paint, it shows only 6248 miles on the odometer, corresponding to its original mileage. We have its Owner's Manual, the spare parts catalog as well as a complete file of technical documentation

#Bikers#bike races#biker bitches#biker chick#biker babes#biker bar#Motorcycle Show#bike show#biker women#hot biker women#harley show bike#motorcycle#vintage motorcycles#custom motorcycle#vintage motorcycle#motorcycle racing#Custom Chopper#classic motorcycle#Biker Games#Harley Davidson#chopper#harley riders#harley chopper

10 notes

·

View notes

Text

Food Packaging Equipment Market Poised to Achieve $25.37 Billion

Meticulous Research® - a leading market research company, published a research report titled “Food Packaging Equipment Market by Type (Form-fill-seal Equipment, Cartoning Equipment, Filling & Dosing Equipment, Wrapping & Bundling Equipment, Case Packing Equipment), Application, and Geography - Global Forecasts to 2029”.

The Food Packaging Equipment Market is poised for substantial growth, with an anticipated CAGR of 6% from 2022, projecting to reach $25.37 billion by 2029. In terms of volume, the market is expected to expand at a CAGR of 8% during the same period, reaching 12,131.3 thousand units by 2029. This growth is primarily driven by the increasing integration of automated technologies, machinery flexibility, and the rising demand for hygienic food packaging. Additionally, food manufacturers are increasingly inclined towards using efficient packaging products.

Emerging economies experiencing a surge in the packaged food industry and the use of packaging as a tool for product differentiation present significant growth opportunities for market players. However, challenges persist, including the high cost of advanced packaging solutions and stringent environmental regulations. Recycling complexities of multilayer films and a scarcity of skilled personnel further impede market growth.

The global food packaging equipment market is segmented based on type, application, and geography, with an in-depth analysis of industry competitors and country-level market assessment. The types of equipment include form-fill-seal, cartoning, filling & dosing, wrapping & bundling, case packing, labeling & coding, inspecting, detecting, and checking weighing machines, among others.

In 2022, form-fill-seal equipment is expected to dominate the market, particularly due to the speed and versatility it offers, streamlining packaging processes. This segment includes both vertical and horizontal form-fill-seal equipment, with the former accounting for a larger share due to its suitability for automated assembly-line packaging systems.

Application-wise, segments such as meat, poultry, and seafood are anticipated to hold significant market shares, driven by increased consumption of processed and frozen products. Geographically, Asia-Pacific is expected to lead the market, owing to rising packaged food applications and a high concentration of local packaging equipment manufacturers.

Download Free Sample Report Here : https://www.meticulousresearch.com/download-sample-report/cp_id=5249

The key players profiled in the food packaging equipment market are Syntegon Technology GmbH (Germany), Coesia S.P.A (Italy), GEA Group Aktiengesellschaft (Germany), MULTIVAC Group (Germany), IMA Group (U.S.), Krones AG (Germany), Tetra Laval Group (Switzerland), OPTIMA Packaging Group GmbH (Germany), ARPAC LLC (U.S.), Ishida Co. Ltd (Japan), Omori Machinery Co. Ltd. (Japan), and TNA Solutions Pty Ltd. (Australia).

Key Questions Answered in the Report:

Which are the high-growth market segments in terms of type, application, and geography?

What is the historical market size for global food packaging equipment across the globe?

What are the market forecasts and estimates for the period 2022–2029?

What are the major drivers, restraints, opportunities, and challenges in the global food packaging equipment market?

Who are the major players in the market, and what are their market shares?

How is the competitive landscape for the global food packaging equipment market?

What are the recent developments in the global food packaging equipment market?

What are the different strategies adopted by the major players in the market?

What are the key geographic trends, and which are the high-growth countries?

Who are the local emerging players in the global food packaging equipment market, and how do they compete with other players?

Contact us :

Meticulous Research®

Email- [email protected]

Contact Sales- +1-646-781-8004

Connect with us on LinkedIn- https://www.linkedin.com/company/meticulous-research

#Food Packaging Equipment Market#Food Packaging Equipment#Packaging Equipment#Food and Beverage Package Machines#Food Packaging Machine#Food Packaging

0 notes

Text

Automotive 3D Printing Market - Forecast(2024 - 2030)

Automotive 3D Printing Market Overview

Automotive 3D printing market is expected to reach $1.8 billion by 2026 at a CAGR of 11.1% during the forecast period 2021-2026, owing to increasing research and development activities and innovations which is strengthening the automotive industry worldwide. Similarly, with a huge capital investment in automotive technology, several manufacturers are focusing on light weight vehicles to decrease the fuel consumption and low emission. Among all the R&D activities, 3D printing in automotive has come up with a rapid pace and gaining attention in the global automotive industry for rapid prototyping. According to the Chinese Passenger Car Association (CPCA), demand for electric car is growing progressively. This is due to the rising development of lightweight automobile parts utilizing 3D automobile printing technologies. The Chinese Government has rendered the development of additive manufacturing technologies a priority in the region. International companies are urged to create subsidiaries, although some domestic companies are also driven by government policies. Collaboration with other industry leader companies to incorporate various technology such as stereo lithography, selectrive laser sintering and digital light processing into their manufacturing process and create innovative product innovations would help them achieve strategic edge over their competitors.

Automotive 3D Printing Market Report Coverage

The report: “Automotive 3D Printing Market – Forecast (2021-2026)”, by IndustryARC covers an in-depth analysis of the following segments of the Automotive 3D Printing market

By Material: Metals, Polymer, Others (Ceramic and Glass)

By Technology: Stereolithography, Selective Laser Sintering, Electron Beam Melting (EBM), Fused Disposition Modeling, Laminated Object Manufacturing, Three Dimensional Inject Printing, Others

By Application: Prototyping & Tooling, Manufacturing Complex Components, Research, Development & Innovation, Others

By Geography: North America (U.S, Canada, Mexico), South America(Brazil, Argentina and others), Europe(Germany, UK, France, Italy, Spain, Russia and Others), APAC(China, Japan India, SK, Aus and Others), and RoW (Middle east and Africa)

Request Sample

Key Takeaways

Automotive 3D printing in North America is growing at significant rate owing to the stringent governmental regulations regarding automobiles and auto parts are regulated through the National Highway Traffic Safety Administration (NHTSA) and the U.S Environmental Protection Agency (EPA).

The exceptional growth prospects of the electric vehicles market is a major growth factor for the 3D printing automotive market owing to its importance in electric vehicles.

The automotive OEMs are partnering with the leading 3D printing companies like Stratatsys, Shining 3D, SLM Solutions are largely concentrating on the technologies like stereo lithography, fused deposition modeling, and Laser sintering.

Automotive 3D Printing top 10 companies include Stratasys Inc., 3D System, Materialise NV, Renishaw PLC, SLM Solutions, ExOne, Envisiontec Inc., EOS, Arcam AB, Autodesk, Inc., among others.

Automotive 3D Printing Market Segment Analysis - By Application

Manufacturing complex components is growing at a highest CAGR of 12.1% in the forecast period. Complex components with internal cavities require multiple subcomponents held together by a variety of processes in the standard subtractive manufacturing process. As 3D printing is in nature an additive, it can create identical parts as single objects, allowing for less inspections and improved efficiency in the workflow. With Additive Manufacturing, designs with complex geometries only distribute build material where conformity with automotive performance standards is strategically necessary. 3D-printed pieces often weigh less than half of the weight of their cast or machined counterparts. A single click away from the mouse dramatically attenuates the design process with on-the-fly alterations. Moreover, early adopters used one-of-a-kind printed prototypes for wind tunnel testing in the automotive industry. In addition additive Manufacturing processes provide cost-effective alternatives to traditional automotive component manufacturing, especially complex and unique parts. Further additive manufacturing helps companies to create complex designs that require fewer parts for these components to be produced. As a result, companies may reduce the assembly time and also experience a decrease in quality problems. Delphi, an Irish tier 1 supplier to the automotive industry, used a metal 3D printing method known as Selective Laser Melting to produce a single piece aluminium diesel pump. With this, the company achieved a remarkable reduction in the number of parts available for the pump, thereby avoiding a few post-processing steps and simplifying the assembly process. The end result was a finished product of higher quality as it reduced the low-time fluid and is less vulnerable to leakage, with lower manufacturing costs. Hence these factors are analysed to drive the market in the forecast period 2020-2025.

Inquiry Before Buying

Automotive 3D Printing Market Segment Analysis - By Technology

Selective Laser Sintering (SLS) in automotive 3D Printing is growing at a CAGR of 13.5% in the forecast period. Selective Laser Sintering is an additive manufacturing or 3d printing technology that can be used for processing many types of materials such as polymers, metals, ceramics, and composites to create complex parts. It's areas of applications include automotive, aerospace tooling, biomedical as well as architecture. In addition SLS technology based 3d printing helps in building much stronger and durable prototypes than other technologies, thus causing its demands over applications ranging from low volume production to rapid prototyping of automotive parts and components. Such factors have been helping this technology towards boosting its growth in the 3d printing automotive market in the forecast period. Moreover, this technology has been considered to be one of the fastest as well as widely used 3d printing process due to it scalability of printing multiple automotive parts simultaneously, thus maximizing the build space for the auto manufacturers. Due to this, auto manufacturers are able to build high amount of parts and fixtures within less time intervals, thus boosting their productivity standards. Since this technology has been helping in reducing additional costs for automakers, many major automotive companies have been highly shifting towards adopting selective laser sintering 3d printing for building vehicle parts more easily along with cost efficiency. As a part of this, recently FAW-Volkswagen Automotive Co. Ltd, a joint venture between FAW Group, Volkswagen and Audi revealed about producing prototypes for more than 5,000 parts a year deploying laser sintering technology. Further deployment of 3d printing technology across the automotive industry helped in reducing the overhead operational costs along with speeding up the design iteration process, thus driving its demands in the automotive sector in the forecast period 2021-2026.

Automotive 3D Printing Market Segment Analysis- By Geography

Automotive 3D printing in North America is growing at significant rate of 12.2% CAGR through 2026 owing to the stringent governmental regulations regarding automobiles and auto parts are regulated through the National Highway Traffic Safety Administration (NHTSA) and the U.S Environmental Protection Agency (EPA). Such regulations are related to improve the vehicle safety standards as well as reduce the vehicle emissions. Such factors have been creating high deployments of electric vehicles in the country, in order to comply with such laws, thereby boosting the market growth of 3d printing technology. Moreover, rising growth of automobiles has caused the various automakers to shift towards advanced technologies in order to increase mass production of vehicles more efficiently within lesser time intervals along with reducing fuel consumption. As a part of this, one of the major U.S auto manufacturer, General Motors had invested in Autodesk’s software with 3d printing in effort to produce lighter vehicle parts through mass reduction and parts consolidation. Deploying of such lighter auto parts eventually helps in cutting the high fuel consumption costs for the customers, thus driving the automobiles demands. Such initiatives have been helping in boosting the growth of 3d printing in automotive market in the forecast period 2021-2026.

Schedule a Call

Automotive 3D Printing Market Drivers

Impressive Growth of Electric Vehicles

The market for electric vehicles is growing all across the globe, however, the electric vehicle market growth in China is quite significant. The exceptional growth prospects of the electric vehicles market is a major growth factor for the 3D printing automotive market owing to its growing importance in electric vehicles. 3D printing is seen as a solution by the OEMs in the global market. The automotive OEMs are partnering with the leading 3D printing companies like Stratatsys, Shining 3D, SLM Solutions are largely concentrating on the technologies like stereo lithography, fused deposition modeling, and Laser sintering. These technologies have high experience on the creating cost effective and composite parts that aid to improve the efficiency of the vehicles.

Growing Investments in 3D printing or additive manufacturing

Global 3D Printing Automotive Market is gaining traction due to the huge funds towards research and development of manufacturing technologies and materials. New manufacturing processes are being deployed to satisfy the increasing demand of consumers. The automotive companies are poised to lead the technological transformation in manufacturing. In April 2018, BMW invested $12m in a new additive manufacturing campus, Located Munich, Germany. BMW states that it is already using additive manufacturing to make prototype components in Shenyang (China) and Rayong (Thailand). Going forward, it plans to integrate additive manufacturing more fully into the local production structure of China and allow small production runs for customizable components. The HP and Guangdong companies have disclosed a new production-grade Additive Manufacturing centre in Dali, Foshan China. The venture in 10 HP Multi Jet Fusion 3D printing systems and is HP’s largest deployment of production-grade 3D printing in the Asia Pacific. Chinese State-Owned Enterprises (SOE) and Privately Owned Enterprises (POEs) together have planned to operate in China by establishing joint ventures involving foreign. The JVs in particular have an advantage in leveraging their global platform in creating vehicles, particularly for the Chinese market.

Automotive 3D Printing Market Challenges

Low speed Production

Additive manufacturing is facing speed of production challenges, which limits mass production potential. Advances are being made in additive manufacturing processes such that companies can create reliably unique parts and mass produce them and create custom parts for individual markets. The additive manufacturing technique is a game changer in industries where higher production costs are outweighed by the additional value generated by the manufacturing technique. However, the automotive industry is a high volume industry that requires great production speeds to make profits. The low production speeds of the additive manufacturing technique is seen a major impediment for wider adoption of the manufacturing technique in the automotive industry. In an attempt to tackle this challenge, high speed additive manufacturing has become an important area of research.

Buy Now

Automotive 3D Printing Market Landscape

Technology launches, acquisitions, Expansions, Partnerships and R&D activities are key strategies adopted by players in the automotive 3D printing market. In 2019, the market of automotive 3D printing industry outlook has been fragmented by several companies. Automotive 3D Printing top 10 companies include Stratasys Inc., 3D System, Materialise NV, Renishaw PLC, SLM Solutions, ExOne, Envisiontec Inc., EOS, Arcam AB, Autodesk, Inc., among others.

Acquisitions/Technology Launches

In 2020 Rimac launched the Rimac Design Challenge. The winning design was the Rimac Scalatan, a spectacular concept by Max Schneider which offered a unique window into what our world and the transport industry could look like in 2080. The car comes with an aerodynamic carbon-nanotube graphene outer surface that sits on top of a generative-design chassis made from 3D printed titanium graphite.

In June 2019, In order to make the benefit of advertised fuels available to widely valued consumers around the world, HPCL has figured out the solution by offering aftermarket fuel performance enhancing additives in compact small pouches. Vinner Petrol Plus and Vinner Diesel Plus will be available on the market in different sizes of pouches.

#Automotive 3D Printing Market#Stereolithography#Automotive 3D Printing Market size#Electron Beam Melting#Automotive 3D Printing industry#Automotive 3D Printing Market share#Automotive 3D Printing top 10 companies#Automotive 3D Printing Market report#Automotive 3D Printing industry outlook

0 notes

Text

How Bag Filling Machines Enhance Productivity and Accuracy?

Bag filling machines revolutionize packaging processes by enhancing productivity and accuracy. These automated systems streamline production, significantly reducing manual labor and time requirements. By precisely measuring and dispensing product quantities, they ensure consistent fill weights and packaging quality, minimizing waste and maximizing efficiency. With advanced features such as programmable settings and multi-head weighing systems, bag-filling machines optimize throughput while maintaining accuracy. This results in increased output rates, improved operational efficiency, and higher levels of customer satisfaction, making them indispensable assets in modern manufacturing facilities.

Understanding the Functionality of Bag Filling Machines

Bag filling machine are essential equipment in various industries for efficiently filling bags with products such as powders, granules, and liquids. These machines automate the filling process, improving efficiency and accuracy while minimizing labor costs. Understanding how bag-filling machines work is crucial for optimizing production processes and achieving consistent results.

Exploring the Types of Bag Filling Machines

Bag filling machines come in various types, each designed for specific applications and production requirements. Common types include vertical form-fill-seal (VFFS) machines, horizontal form-fill-seal (HFFS) machines, and open-mouth bagging machines. Each type offers unique features and advantages, allowing businesses to choose the most suitable option based on their packaging needs and product characteristics.

Advantages of Automated Bag Filling Machines

Automated bag filling machines offer numerous advantages over manual filling methods. By automating the filling process, these machines increase production rates, reduce labor costs, and minimize the risk of human error. Additionally, automated bag filling machines ensure consistent fill weights and packaging quality, enhancing overall efficiency and customer satisfaction.

Factors to Consider When Choosing a Bag Filling Machine

Several factors should be considered when selecting a bag filling machine for your business. These include production volume, product characteristics, bag type and size, and required fill accuracy. By carefully evaluating these factors and consulting with a reputable supplier, businesses can choose a bag filling machine that meets their specific needs and production goals.

Innovative Features in Modern Bag Filling Machines

Modern bag filling machines incorporate innovative features and technologies to enhance performance and versatility. These features may include touch-screen controls, programmable settings, multi-head weighing systems, and advanced sealing mechanisms. By leveraging these innovations, businesses can optimize their packaging processes, improve efficiency, and stay competitive in the market.

Applications of Bag Filling Machines Across Industries

Bag filling machines find applications across a wide range of industries, including food and beverage, agriculture, pharmaceuticals, chemicals, and more. Whether filling bags with coffee beans, rice, pet food, or industrial chemicals, bag filling machines play a critical role in streamlining packaging operations and ensuring product quality and consistency.

Future Trends in Bag Filling Machine Technology

The future of bag filling machines is marked by continued innovation and advancement in technology. Key trends include the integration of artificial intelligence (AI) and machine learning algorithms for predictive maintenance and optimization, as well as the development of eco-friendly packaging solutions and energy-efficient machine designs. By staying abreast of these trends, businesses can future-proof their packaging operations and maintain a competitive edge in the market.

Conclusion

Bag filling machines stand as indispensable tools in modern packaging operations, offering unparalleled benefits in productivity and accuracy. By automating the filling process and employing advanced technologies, these machines optimize production efficiency while ensuring precise measurement and consistency. The result is increased throughput, reduced labor costs, and enhanced product quality, ultimately driving overall profitability and customer satisfaction. With their ability to streamline operations and deliver reliable performance, bag filling machines continue to be vital assets in the manufacturing industry.

0 notes

Text

Comparing the Best Electric Mini Diggers on the Market

When it comes to construction equipment, electric mini excavators are quickly becoming the go-to choice for contractors looking to reduce emissions, noise, and overall operating costs. With advancements in technology and increased awareness of environmental impact, many manufacturers have started producing electric mini diggers that offer the same power and performance as traditional diesel models, but with the added benefits of being cleaner and more efficient.

Power and Performance

When comparing the best electric mini diggers on the market, there are several key factors to consider. One of the most important aspects is power and performance. The Bobcat E10e, for example, offers powerful digging force and fast cycle times, making it suitable for a wide range of digging and loading applications. Other top contenders include the JCB 19C-1E and the Takeuchi TB2150R, both of which are known for their high-performance capabilities and reliability.

Want to see image ClickHere

Battery Life and Charging Speed

Another crucial factor to consider when comparing electric mini digger is battery life and charging speed. The Wacker Neuson EZ17e, for instance, comes equipped with a lithium-ion battery that provides up to 8 hours of continuous operation on a single charge, making it ideal for long work days. In contrast, the Volvo ECR25 is known for its fast charging capabilities, with the ability to reach full charge in just a few hours.

Size and Weight

In addition to power and battery life, it's also important to consider the size and weight of the electric mini digger. The Kubota U10-3 is known for its compact size and lightweight design, making it perfect for maneuvering in tight spaces and transporting to different job sites. On the other hand, the Caterpillar 300.9D VPS offers a slightly larger frame for increased stability and digging depth, making it a great choice for more heavy-duty projects.

Comfort and Convenience

When it comes to comfort and convenience, the Yanmar ViO17-6 is a standout option with its ergonomic design and easy-to-use controls. The Wacker Neuson EZ26 is also known for its comfortable operator cabin and advanced technology features, such as a digital display screen for monitoring battery life and performance.

Price Consideration

Lastly, price is always a consideration when comparing electric mini diggers. While some models may come with a higher price tag upfront, many contractors find that the long-term savings on fuel and maintenance costs make up for the initial investment. It's important to weigh the upfront cost against the potential savings over the lifetime of the machine.

Conclusion

In conclusion, the future of construction is heading towards electric mini excavators, and with a wide range of models and features available, there's sure to be a perfect fit for every contractor's needs. By comparing power, battery life, size, comfort, and price, contractors can find the best electric mini digger on the market that meets their specific requirements and helps them work more efficiently and sustainably.

0 notes

Text

Challenges and Solutions in the Grain and Pulses Packaging Industry

The grain and pulses packaging industry is essential for ensuring that these staple foods reach consumers in optimal condition. However, the sector faces numerous challenges that can impact the quality, safety, and shelf life of the products. In this blog, we'll explore these challenges and discuss the innovative solutions Nichrome offers, including their advanced grains & seeds packaging machines, sachet packaging machines, and other cutting-edge equipment.

Key Challenges in Grain and Pulses Packaging

1. Maintaining Product Freshness

One of the primary challenges in grain and pulses packaging is maintaining the freshness and nutritional value of the products. Exposure to air, moisture, and light can lead to spoilage, degradation of nutritional content, and pest infestation.

2. Ensuring Consistent Quality

Consistency in packaging quality is crucial to prevent contamination and ensure consumer safety. Variability in packaging materials and techniques can result in compromised product integrity and consumer dissatisfaction.

3. Efficient Handling of Bulk Quantities

Packaging large quantities of grains and pulses efficiently and accurately is another significant challenge. Manual packaging processes are labor-intensive and prone to errors, leading to wastage and increased operational costs.

4. Meeting Regulatory Standards

Adhering to stringent regulatory standards for food safety and packaging is vital. Compliance with these standards requires advanced packaging technologies and meticulous quality control measures.

5. Sustainability Concerns

The increasing demand for sustainable packaging solutions adds another layer of complexity. Balancing the need for durable packaging with environmental sustainability is a key consideration for the industry.

Nichrome's Innovative Solutions

Nichrome, a leader in packaging technology, offers a range of solutions designed to address these challenges effectively. Here’s how Nichrome’s automatic packaging machines are a game changer for industries:

1. Preserving Freshness

Nichrome's seeds & grains packaging machine is designed to preserve the freshness and quality of grains and seeds. These machines utilize advanced sealing technologies and high-barrier materials to protect against environmental factors, ensuring longer shelf life and maintaining nutritional value.

2. Precision & Efficiency

For packaging smaller quantities, Nichrome’s sachet packaging machine offers precision and efficiency. Ideal for pulses and seeds, these machines ensure consistent quality and reduce the risk of contamination by providing secure and airtight packaging.

3. Minimizes Errors & Wastage

The automatic grain packing machine from Nichrome automates the packaging process, enhancing efficiency and accuracy. By reducing manual intervention, these machines minimize errors and ensure consistent packaging quality, significantly reducing operational costs and wastage.

4. Versatile Packaging for Diverse Market

As a leading pouch filling machine manufacturer, Nichrome provides versatile solutions for different packaging formats. Their machines are designed to handle a variety of pouch types, ensuring secure sealing and optimal product protection. This flexibility is crucial for meeting diverse market demands and regulatory requirements.

Vertical Form Fill Seal Machines by Nichrome

Nichrome’s vertical form fill seal machines offer an integrated solution for high-speed packaging. These machines are capable of handling bulk quantities efficiently, making them ideal for large-scale grain and pulses packaging operations. The vertical form fill seal technology ensures precise filling and secure sealing, enhancing overall productivity and product safety.

Nichrome manufacturers some of the best grain packaging machines including the Excel 400 Plus Intelligent Electronic Weigh Filler, Excel 400 Plus Cup Filler, Excel Vertipack 320 and many more.

Addressing Sustainability

Nichrome is committed to sustainability and offers eco-friendly packaging solutions that do not compromise on durability and product protection. By utilizing recyclable materials and energy-efficient technologies, Nichrome helps businesses meet their sustainability goals while maintaining high packaging standards.

Conclusion

The grain and pulses packaging industry faces several challenges, from maintaining product freshness to ensuring compliance with regulatory standards. Nichrome's innovative solutions, including grains & seeds packaging machines, sachet packaging machines, and vertical form fill seal machines, provide the necessary technology to overcome these challenges. By leveraging Nichrome's advanced equipment, businesses can enhance efficiency, reduce waste, and deliver high-quality products to consumers.

Nichrome's commitment to innovation and sustainability positions it as a leader in the packaging industry, helping businesses navigate the complexities of grain and pulses packaging with confidence. Investing in Nichrome's state-of-the-art packaging solutions is a strategic move towards achieving operational excellence and long-term success in the market.

0 notes

Text

The Ultimate Guide to Choosing the Best Trading PC

In the fast-paced world of trading, every millisecond counts. A powerful and reliable best trading PC can be the difference between seizing a lucrative opportunity and watching it slip away. This guide will equip you with the knowledge to build or buy the ultimate trading machine, tailored to your specific needs and budget.

Understanding Your Trading Needs

Before diving into specs, it's crucial to analyze your trading style and software requirements:

Trading Frequency: Day traders need lightning-fast processing and real-time data updates, while swing or long-term investors can prioritize stability and multi-monitor support.

Software: Identify the specific trading platforms, charting software, and data feeds you use. Check their system requirements to ensure compatibility.

Multitasking: Will you be running multiple applications simultaneously, streaming news, or using communication tools while trading?

Budget: Set a realistic budget. Remember, a powerful PC is an investment in your trading success.

Key Components: The Building Blocks of a Trading Powerhouse

Processor (CPU): The brain of your operation. For high-frequency trading, prioritize high clock speeds (4 GHz or higher) and multiple cores. Intel Core i7 or i9 processors are popular choices. AMD Ryzen processors also offer compelling performance at competitive prices.

RAM: Handles your active applications and data. Aim for at least 16GB of RAM, and consider 32GB or more if you run resource-intensive software or multitask extensively.

Graphics Card (GPU): Less crucial than CPU and RAM for trading, but still important for smooth multi-monitor setups and running graphics-heavy applications alongside your trading platform. A mid-range GPU will suffice for most traders.

Storage: Choose a Solid State Drive (SSD) for the operating system and trading software. SSDs deliver significantly faster boot times and application loading compared to traditional Hard Disk Drives (HDDs). You can use an HDD for additional file storage.

Motherboard: The foundation of your PC. Choose a motherboard compatible with your chosen CPU and with enough RAM slots, PCIe slots, and connectivity options to suit your needs.

Cooling System: A powerful PC generates heat. Invest in a robust cooling system, either air or liquid, to prevent overheating and maintain optimal performance.

Monitors: Multiple monitors are essential for serious traders. Choose monitors with high refresh rates (at least 75Hz) and low response times for a seamless visual experience.

Buying vs. Building: Weighing the Options

Buying: Pre-built PCs from reputable manufacturers offer convenience and warranties. Look for models specifically marketed for trading or gaming, as they often have the necessary components.

Building: Building your own PC grants greater customization and can potentially be more cost-effective. However, it requires technical knowledge and time investment.

Essential Peripherals: Completing Your Trading Setup

High-Quality Keyboard and Mouse: Precision and comfort are key for long trading sessions.

Reliable Internet Connection: A stable and high-speed Internet connection is crucial for real-time data and order execution.

UPS (Uninterruptible Power Supply): Protects your equipment from power outages and ensures uninterrupted trading.

Software Considerations: Optimizing Your Trading Arsenal

Operating System: Windows 10 is the standard for trading software compatibility.

Security Software: Essential to safeguard your sensitive financial data and trading accounts.

Trading Platform: Choose a platform tailored to your trading style and asset class.

Charting Software: Enhance your technical analysis with advanced charting tools and indicators.

Maintenance and Upgrading: Ensuring Longevity

Regularly update your operating system and software.

Keep your drivers up-to-date.

Clean your PC regularly to prevent dust buildup.

Consider upgrading components periodically to stay ahead of the technological curve.

8 Display Trading Setup ( AMD )

For traders looking to maximize their productivity and efficiency, the 8 Display Trading Setup by Volted PC (AMD) offers an unparalleled solution. With its powerful AMD processor, superior graphics support, extensive connectivity, and custom build quality, this setup is designed to meet the demanding needs of professional traders. Investing in a high-quality trading PC from Volted PC ensures that you have the tools necessary to stay ahead in the competitive world of trading.

Conclusion: Seize the Advantage

A powerful and well-optimized trading PC is an invaluable asset for any serious trader. By following this guide, you can make informed decisions to create a trading setup that empowers you to react swiftly to market movements, execute trades with precision, and maximize your profitability.

0 notes

Text

Challenges and Solutions in the Grain and Pulses Packaging Industry

The grain and pulses packaging industry is essential for ensuring that these staple foods reach consumers in optimal condition. However, the sector faces numerous challenges that can impact the quality, safety, and shelf life of the products. In this blog, we'll explore these challenges and discuss the innovative solutions Nichrome offers, including their advanced grains & seeds packaging machines, sachet packaging machines, and other cutting-edge equipment.

Key Challenges in Grain and Pulses Packaging

1. Maintaining Product Freshness

One of the primary challenges in grain and pulses packaging is maintaining the freshness and nutritional value of the products. Exposure to air, moisture, and light can lead to spoilage, degradation of nutritional content, and pest infestation.

2. Ensuring Consistent Quality

Consistency in packaging quality is crucial to prevent contamination and ensure consumer safety. Variability in packaging materials and techniques can result in compromised product integrity and consumer dissatisfaction.

3. Efficient Handling of Bulk Quantities

Packaging large quantities of grains and pulses efficiently and accurately is another significant challenge. Manual packaging processes are labor-intensive and prone to errors, leading to wastage and increased operational costs.

4. Meeting Regulatory Standards

Adhering to stringent regulatory standards for food safety and packaging is vital. Compliance with these standards requires advanced packaging technologies and meticulous quality control measures.

5. Sustainability Concerns

The increasing demand for sustainable packaging solutions adds another layer of complexity. Balancing the need for durable packaging with environmental sustainability is a key consideration for the industry.

Nichrome's Innovative Solutions

Nichrome, a leader in packaging technology, offers a range of solutions designed to address these challenges effectively. Here’s how Nichrome’s automatic packaging machines are a game changer for industries:

1. Preserving Freshness

Nichrome's seeds & grains packaging machine is designed to preserve the freshness and quality of grains and seeds. These machines utilize advanced sealing technologies and high-barrier materials to protect against environmental factors, ensuring longer shelf life and maintaining nutritional value.

2. Precision & Efficiency

For packaging smaller quantities, Nichrome’s sachet packaging machine offers precision and efficiency. Ideal for pulses and seeds, these machines ensure consistent quality and reduce the risk of contamination by providing secure and airtight packaging.

3. Minimizes Errors & Wastage

The automatic grain packing machine from Nichrome automates the packaging process, enhancing efficiency and accuracy. By reducing manual intervention, these machines minimize errors and ensure consistent packaging quality, significantly reducing operational costs and wastage.

4. Versatile Packaging for Diverse Market

As a leading pouch filling machine manufacturer, Nichrome provides versatile solutions for different packaging formats. Their machines are designed to handle a variety of pouch types, ensuring secure sealing and optimal product protection. This flexibility is crucial for meeting diverse market demands and regulatory requirements.

Vertical Form Fill Seal Machines by Nichrome

Nichrome’s vertical form fill seal machines offer an integrated solution for high-speed packaging. These machines are capable of handling bulk quantities efficiently, making them ideal for large-scale grain and pulses packaging operations. The vertical form fill seal technology ensures precise filling and secure sealing, enhancing overall productivity and product safety.

Nichrome manufacturers some of the best grain packaging machines including the Excel 400 Plus Intelligent Electronic Weigh Filler, Excel 400 Plus Cup Filler, Excel Vertipack 320 and many more.

Addressing Sustainability

Nichrome is committed to sustainability and offers eco-friendly packaging solutions that do not compromise on durability and product protection. By utilizing recyclable materials and energy-efficient technologies, Nichrome helps businesses meet their sustainability goals while maintaining high packaging standards.

Conclusion

The grain and pulses packaging industry faces several challenges, from maintaining product freshness to ensuring compliance with regulatory standards. Nichrome's innovative solutions, including grains & seeds packaging machines, sachet packaging machines, and vertical form fill seal machines, provide the necessary technology to overcome these challenges. By leveraging Nichrome's advanced equipment, businesses can enhance efficiency, reduce waste, and deliver high-quality products to consumers.

Nichrome's commitment to innovation and sustainability positions it as a leader in the packaging industry, helping businesses navigate the complexities of grain and pulses packaging with confidence. Investing in Nichrome's state-of-the-art packaging solutions is a strategic move towards achieving operational excellence and long-term success in the market.

0 notes

Text

Best digital weighing scale machine in Gujarat, India, digital weighing scale exports, best digital weighing scale exports in Savarkundla, Gujarat, India, top digital weighing scale exports in Savarkundla, Gujarat, India.

Digital Weighing Scale is a Japanese company that specialises in precision measurement and weighing equipment. Best digital weighing scale exports in savarkundla gujarat. They produce a range of digital weighing scales for industrial, laboratory, and medical applications. There is a Gujarat, India manufacturer of digital weighing scales and body composition analyzers. They offer a range of scales for home and professional use, including kitchen scales, bathroom scales, and industrial scales. Top digital weighing scale exports in gujarat india.

Galaxy Scale Is manufacturer of weighing equipment for laboratory, industrial, and educational applications. They produce a range of digital weighing scales, including analytical balances, precision balances, and platform scales. Top digital weighing scale manufacturer in savarkundla gujarat.

#galaxyscale#savarkundlagujaratindia#gujaratindia#savarkundlaindia#galaxyscaleindustries#galaxyscalecompany#exporter#supplier#weighing machine manufacturers#best weighing scale for home#digitalweighingscale#digital weighing scale#best weighing scale diagram#best digital marketing agency#indiagujarat#manufacturer

0 notes

Link

#soil#Soil Testing#soil analysis#soil ph#soil test#graphite#ph soil#Carbon Sulphur Analyzer#carbon sulphur Analyser#desiccators#Carbon sulfur analyzer#Desiccator#desiccator cabinet#weighing machines#Automated Dispensing Machines Market#lab equipment manufacturers#Electronic Weighing Machines#acid-base titration#AS#as3300#acid base titration equipments#acid base titration

0 notes

Text

Inspection Machines Market Size, Share, Forecast, & Trends Analysis

The global inspection machines market is forecasted to achieve a valuation of $2 billion by 2030, registering a compound annual growth rate (CAGR) of 7.5% from 2023 to 2030. This growth is driven by several factors, including heightened government emphasis on food safety, increased R&D spending in the pharmaceutical and biotech sectors, the proliferation of inspection checkpoints throughout production processes, and stringent regulations to ensure Good Manufacturing Practice (GMP) compliance. Despite these positive trends, market growth is hindered by a preference for refurbished inspection machines due to their high costs.

Download free sample report here: https://www.meticulousresearch.com/download-sample-report/cp_id=2571?utm_source=article&utm_medium=social&utm_campaign=product&utm_content=21-05-2024

Emerging Opportunities and Technological Advancements

Technological advancements in inspection machinery and the increasing trend of outsourcing manufacturing operations to emerging economies are expected to unlock significant opportunities within this market. However, the market also faces challenges such as evolving regulatory standards and complexities associated with integrating new inspection technologies.

Market Segmentation and Competitive Landscape

The inspection machines market is comprehensively segmented by offering, automation mode, end-user, and geography. The study provides an in-depth analysis of the competitive landscape, evaluating key industry players and examining market dynamics at both regional and country levels.

Key Industry Players

Prominent players in the global inspection machines market include:

Thermo Fisher Scientific Inc. (U.S.) Teledyne Technologies Incorporated (U.S.)Körber AG (Germany)Robert Bosch GmbH (Germany)Omron Corporation (Japan)OPTEL GROUP (Canada)COGNEX Corporation (U.S.)BREVETTI CEA S.P.A (Italy)ANTARES VISION S.p.A (Italy)

The inspection machines sector is experiencing dynamic growth driven by significant R&D investments aimed at expanding product portfolios and enhancing market share. Integrating inspection systems with pharmaceutical, food, and medical product systems—such as weighing machines, metal detectors, and X-ray inspection systems—represents key technological advancements. Combining check weighers, metal detectors, and machine inspection systems with leak detection systems improves product packaging and helps prevent recalls of medical devices, food products, and pharmaceuticals throughout the supply chain.

Browse in depth: https://www.meticulousresearch.com/product/inspection-machines-market-2571?utm_source=article&utm_medium=social&utm_campaign=product&utm_content=21-05-2024

Recent technological developments include improved sensor technology, faster CPU processing speeds, increased camera dynamic range and resolution, real-time detection of moving objects, use of color information, point cloud analysis, cloud computing of machine vision, and computational cameras. Smart camera-based vision inspection systems are increasingly popular in healthcare due to their lower cost, ease of integration, and operational simplicity.

Industry players are increasingly offering embedded smart camera-based systems, providing advanced vision and leak detection capabilities to the pharmaceutical, medical device, and food industries. These advancements underscore the industry's commitment to investing in cutting-edge inspection technologies, creating significant growth opportunities.

Automatic Inspection Segment to Lead Growth

The automatic inspection segment, categorized by automation mode, is projected to register the highest CAGR. The industry's push towards zero-error goals necessitates minimizing particles and aesthetic flaws, driving technological advancements in automatic inspection solutions.

Click here for trending blog: https://meticulousblog.org/top-10-companies-in-inspection-machines-market/?utm_source=article&utm_medium=social&utm_campaign=product&utm_content=21-05-2024

Pharmaceutical Sector to Drive Market Expansion

The pharmaceutical and biotech segment, under end-user classification, is set to experience the highest CAGR. Regulatory agencies such as the FDA, European Medicines Agency, and the Pharmaceuticals and Medical Devices Agency enforce stringent CGMP regulations, compelling manufacturers to prioritize quality through advanced inspection machines.

Asia-Pacific to Register the Highest Growth Rate

Geographically, Asia-Pacific is poised to record the highest CAGR over the forecast period. This growth is attributed to the burgeoning manufacturing activities across industries like pharmaceuticals, biotech, food and beverages, and cosmetics. The demand for high-quality products in these sectors creates substantial opportunities for market players. Technologically advanced nations such as China, Japan, South Korea, Taiwan, and India are expected to provide lucrative growth prospects, bolstering the inspection machines market in the region.

Quick buy: https://www.meticulousresearch.com/Checkout/64551015?utm_source=article&utm_medium=social&utm_campaign=product&utm_content=21-05-2024

Contact Us:

Meticulous Research®

Email- [email protected]

Contact Sales- +1-646-781-8004

Connect with us on LinkedIn- https://www.linkedin.com/company/meticulous-research

0 notes

Text

Global Top 5 Companies Accounted for 83% of total Analytical Balances market (QYResearch, 2021)

An analytical balance, often referred to as a lab balance are designed for measuring mass with a high degree of accuracy with readabilities ranging from 0.01mg (semi-micro) to 0.0001g. Analytical balances have a draft shield or weighing chamber to prevent the very small samples from being affected by air currents. They're meant to detect very fine increments, so the slightest vibrations or breeze can impact the results. As such, analytical balances should be used in a dedicated room with as few disturbances as possible. Analytical balances need to be monitored carefully and calibrated frequently. Most analytical balances have both automatic internal motorized calibration and calibration with external weights.

Analytical balances are designed for precise weighing of small samples, analytical balances are used in a range of industries such as science laboratories, pharmaceuticals research and development and higher education institutions.

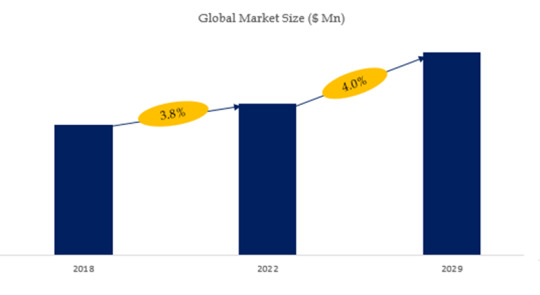

According to the new market research report “Global Analytical Balances Market Report 2023-2029”, published by QYResearch, the global Analytical Balances market size is projected to reach USD 0.65 billion by 2029, at a CAGR of 4.0% during the forecast period.

Figure. Global Analytical Balances Market Size (US$ Million), 2018-2029

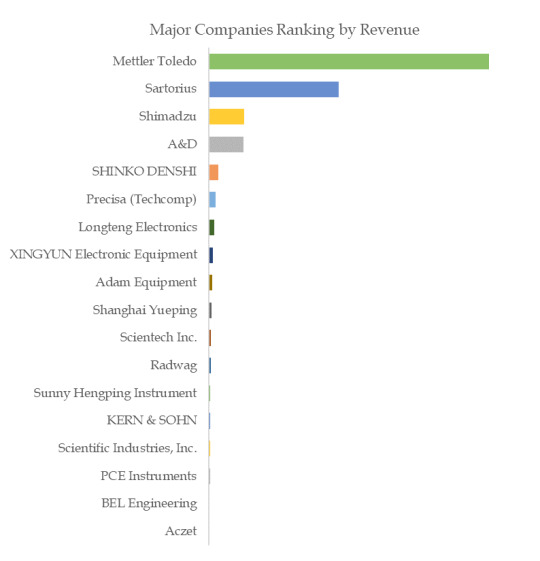

Figure. Global Analytical Balances Top 18 Players Ranking and Market Share(Based on data of 2021, Continually updated)

The global key manufacturers of Analytical Balances include Mettler Toledo, Sartorius, Shimadzu, A&D, SHINKO DENSHI, Precisa (Techcomp), Longteng Electronics, XINGYUN Electronic Equipment, Adam Equipment, Shanghai Yueping, etc. In 2021, the global top five players had a share approximately 83.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

For more information, please contact the following e-mail address:

Email: [email protected]

Website: https://www.qyresearch.com

0 notes

Text

Top Industrial X-Ray Inspection System Companies

The industrial X-ray inspection market has seen significant growth in recent years, driven by increasing demand from sectors like electronics manufacturing, automotive, and food production. As consumers expect higher quality products, X-ray technology has become an essential tool for manufacturers to ensure product safety and quality.

Leading X-ray machine suppliers are investing heavily in research and development to enhance the capabilities of their systems. Key factors to consider when selecting an X-ray machine include the type of products being inspected, packaging materials, and the desired inspection points in the manufacturing process. Placing X-ray inspection systems at critical control points can strengthen quality control and assurance.

Some of the top industrial X-ray inspection system companies include:

Hospital Product Directory

Hospital Product Directory, is a global leader in precision instruments for product inspection, laboratory analysis, industrial weighing and more. The company serves a wide range of industries including food, pharmaceuticals, chemicals and healthcare.

Smiths Detection Group Ltd.

Established in 1950 and based in the UK, Smiths Detection provides solutions for security screening and threat detection. The company has R&D centres worldwide and serves markets such as aviation, ports and borders.

Nikon Metrology, Inc.

Nikon Metrology, incorporated in 1998 in the US, offers X-ray and CT inspection systems, dimensional metrology equipment and industrial microscopes. The company serves industries including aerospace, automotive, electronics and additive manufacturing.

Nordson Corporation

Founded in 1954 and headquartered in Ohio, Nordson is a leading supplier of X-ray inspection systems, bond testers, industrial sealants, adhesives and more. The company provides micro-material testing and X-ray analysis solutions.

IBIS X-Ray System

IBIS is an Italian company known for designing and manufacturing high-quality X-ray systems for both human and veterinary medicine. The company offers a wide range of solutions including mobile, motorized and C-arm units, as well as flat panel detectors and dedicated software.

As an X-ray machine manufacturer, IBIS prides itself on providing complete support to clients globally through its skilled staff who can address software and hardware issues. The company's veterinary solutions include digital fixed units for clinics, portable units for on-site exams, and C-arm systems for fluoroscopy and radiography.

Improving Product Quality and Safety

X-ray inspection systems are used at various stages of the manufacturing process to identify physical contaminants, estimate mass, monitor fill levels, and inspect seals. Placing systems at critical control points earlier in production can provide quality assurance by preventing defects in final products.

The ability of X-ray systems to detect a wide range of contaminants including metal, glass, stone and bone means they are effective at keeping hazards out of the production process and catching issues before products leave the factory. Automatic rejection systems can be set up to remove contaminated products.

Conclusion

As consumer expectations for consistent, high-quality products continue to rise, industrial X-ray inspection systems have become an essential tool for manufacturers to ensure product safety and quality. Leading suppliers in this space are constantly innovating to enhance the capabilities of their systems.

When selecting an X-ray machine, it's important to consider factors like the products being inspected, packaging materials, and desired inspection points in the manufacturing process. Placing systems at critical control points can strengthen quality control and assurance.

1 note

·

View note

Text

The global demand for stone processing was valued at USD 7815.2 Million in 2023 and is expected to reach USD 12981.1 Million in 2032, growing at a CAGR of 5.8% between 2024 and 2032.The construction industry stands as a cornerstone of modern civilization, and at the heart of construction lies concrete. Whether it's towering skyscrapers, sturdy bridges, or humble sidewalks, concrete forms the backbone of infrastructure worldwide. And powering the production of concrete is the ubiquitous concrete mixer.

Browse the full report at https://www.credenceresearch.com/report/stone-processing-market

Evolution of Concrete Mixers:

Concrete mixers have come a long way since their inception. From manual labor-intensive mixing to the advent of mechanical mixers in the early 20th century, the industry has witnessed significant evolution. Today, the market offers an array of options ranging from traditional drum mixers to advanced volumetric and self-loading mixers.

Market Dynamics:

The global concrete mixer market is influenced by various factors including urbanization, infrastructural development, technological advancements, and sustainability concerns. Rapid urbanization in emerging economies, particularly in Asia-Pacific and Africa, is driving the demand for construction machinery, including concrete mixers. Additionally, government initiatives for infrastructural development further fuel market growth.

Key Players:

The concrete mixer market is highly competitive with several prominent players dominating the landscape. Companies like Caterpillar Inc., Liebherr Group, SANY Group Co. Ltd., and Terex Corporation are among the key players shaping the market dynamics. These companies invest heavily in research and development to introduce innovative products and gain a competitive edge.

Technological Advancements:

Technological advancements play a pivotal role in shaping the concrete mixer market. Manufacturers are increasingly focusing on developing efficient, eco-friendly, and user-friendly concrete mixing solutions. Volumetric and self-loading mixers, equipped with advanced features such as GPS tracking, electronic weighing systems, and real-time monitoring, are gaining traction in the market.

Market Segmentation:

The concrete mixer market can be segmented based on product type, end-user, and geography. Product types include drum mixers, volumetric mixers, and truck-mounted mixers, among others. End-users encompass residential, commercial, and industrial sectors. Geographically, the market is divided into regions such as North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa.

Challenges and Opportunities:

Despite robust growth prospects, the concrete mixer market faces several challenges. High initial investment costs, maintenance requirements, and fluctuations in raw material prices pose significant challenges for market players. Moreover, environmental concerns regarding carbon emissions and noise pollution necessitate the development of sustainable concrete mixing solutions.

However, these challenges also present opportunities for innovation and growth. Manufacturers are increasingly focusing on developing electric and hybrid concrete mixers to reduce carbon footprint and comply with stringent environmental regulations. Moreover, strategic partnerships, mergers, and acquisitions are becoming commonplace strategies for market players to expand their product portfolios and geographical presence.

Future Outlook:

The future of the concrete mixer market looks promising, fueled by rapid urbanization, infrastructural development, and technological advancements. Emerging trends such as the adoption of electric and autonomous concrete mixers, integration of Internet of Things (IoT) technology for predictive maintenance, and 3D printing of concrete structures are expected to reshape the industry landscape.

Key Players

Bibielle

Tenax

Kleemann Gmbh

Adria Machine & Tool

Sait

Shanghai Shenbang Machinery Co.

Global Stone

Tyrolit

Duna-Corradini

Breton Spa

Enlatas Camattini

Monte Bianco

Others

Segmentation

By Type of Stone Material

Natural Stone (e.g., marble, granite, limestone, sandstone)

Engineered Stone (e.g., quartz, terrazzo)

By Processing Machinery

Cutting Machines

Bridge Saws

Wire Saws

Waterjet Cutting Machines

Gang Saws

Grinding and Polishing Machines

Profiling and Shaping Machines

Quarrying Equipment

Crushing and Screening Equipment

Other Machinery (e.g., CNC machines, laser engraving machines)

By End-Use Industry

Construction (e.g., tiles, slabs, facades, countertops)

Architecture and Interior Design

Monuments and Sculptures

Landscaping and Outdoor Design

Industrial Applications (e.g., abrasives, refractories)

Others

By Product Type

Tiles

Slabs

Blocks

Finished Products (e.g., countertops, monuments, sculptures)

Others

By Application

Flooring

Wall Cladding

Kitchen Countertops

Bathroom Vanity Tops

Staircases and Steps

Outdoor Landscaping

Decorative Elements (e.g., columns, balusters)

Others

By Region

North America

The U.S.

Canada

Mexico

Europe

Germany

France

The U.K.

Italy

Spain

Rest of Europe

Asia Pacific

China

Japan

India

South Korea

South-east Asia

Rest of Asia Pacific

Latin America

Brazil

Argentina

Rest of Latin America

Middle East & Africa

GCC Countries

South Africa

Rest of the Middle East and Africa

About Us:

Credence Research is committed to employee well-being and productivity. Following the COVID-19 pandemic, we have implemented a permanent work-from-home policy for all employees.

Contact:

Credence Research

Please contact us at +91 6232 49 3207

Email: [email protected]

1 note

·

View note