#borosilicate glass reactors

Explore tagged Tumblr posts

Text

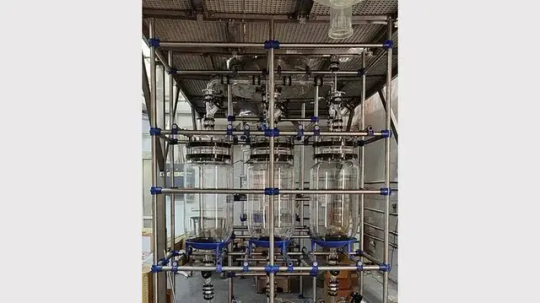

Scientific Glass Reactor | saskatchewan | Canada | Goel Scientific | USA

Goel Scientific provides a Glass Reactor System made of High-Quality Borosilicate Glass. which is used for chemical compounds, mixing chemicals, and carrying out chemical reactions. We are a manufacturer & supplier of Glass Reactor in Alberta, Canada, And the USA.

#Glass Reactor#Glass Reactor System#High-Quality Borosilicate Glass#Glass Reactor System manufactur#Glass Reactor System suppliers#Glass Reactor System in saskatchewan Canada#best Glass Reactor System in USA

0 notes

Text

Glass Reactor Market Emerging Trends: Key Innovations and Growth Drivers Shaping the Industry

The glass reactor market is undergoing notable evolution, fueled by technological advancements, growing industrial applications, and increasing focus on process efficiency and safety. Glass reactors are indispensable equipment used for chemical reactions, mixing, and crystallization, particularly in pharmaceuticals, chemicals, and biotechnology. Emerging trends in this market are steering it towards smarter, more flexible, and sustainable solutions.

Rise of Automation and Smart Glass Reactors

A major trend transforming the glass reactor market is the incorporation of automation and digital technologies. Smart glass reactors equipped with IoT sensors and advanced control systems enable real-time monitoring of reaction parameters such as temperature, pressure, and mixing speeds. These reactors offer enhanced precision, reproducibility, and safety, minimizing human intervention and errors. Remote operation and automated data logging further streamline workflows and improve process consistency, which is crucial for sensitive chemical and pharmaceutical applications.

Modular and Customizable Designs

Flexibility is becoming increasingly important for glass reactor users, especially in research and small-batch production. Manufacturers are responding by offering modular reactor systems that can be easily configured, scaled, and adapted to specific process needs. Modular designs allow users to interchange components such as vessel sizes, stirrers, and condensers, providing versatility and reducing downtime. This trend supports industries requiring a variety of reaction conditions without the need for multiple fixed systems.

Advancements in Material Technology

While borosilicate glass remains the material of choice for its chemical and thermal resistance, innovations in glass production are enhancing durability and thermal shock resistance. Additionally, hybrid designs combining glass with materials like stainless steel and PTFE enhance mechanical strength and expand operating ranges for temperature and pressure. These improvements allow glass reactors to handle more aggressive chemicals and demanding processes, broadening their industrial applicability.

Focus on Sustainability and Energy Efficiency

Environmental concerns are influencing the design and manufacturing of glass reactors. There is a growing emphasis on eco-friendly and energy-efficient equipment. Enhanced insulation, energy-saving heating systems, and process designs that minimize waste are increasingly common. The transparency of glass reactors also facilitates visual process monitoring, helping prevent batch failures and reduce material loss. This trend aligns with broader moves toward green chemistry and sustainable manufacturing practices.

Pharmaceutical and Biotechnology Sector Driving Demand

Pharmaceutical and biotech industries continue to be key end-users, driving demand for high-precision, contamination-free reactors. The rise of complex drug synthesis, biopharmaceutical development, and strict regulatory standards for purity boost the need for reliable glass reactors. The trend toward personalized medicine and small-scale production further emphasizes reactors that are adaptable, easy to clean, and precise in control, supporting innovation in drug development.

Strategic Collaborations Accelerating Innovation

Collaboration between glass reactor manufacturers and end-users is becoming more prevalent. Joint development efforts enable faster innovation, customization, and the creation of reactors tailored to specific industry challenges. These partnerships often focus on improving automation capabilities, integrating analytical instruments, and expanding reactor capacities to meet industrial-scale demands. Such collaborations are expected to accelerate technological advancements and strengthen market growth.

Regional Market Dynamics

Geographically, North America and Europe remain mature markets with strong demand driven by pharmaceutical and chemical industries. Meanwhile, the Asia-Pacific region is emerging rapidly due to industrial growth, increasing pharmaceutical manufacturing, and investment in R&D. Improving safety regulations and quality standards in emerging economies are also accelerating glass reactor adoption. Market players are expanding their footprint in these regions through partnerships, localized manufacturing, and enhanced support services.

Conclusion

The glass reactor market is witnessing transformative trends that focus on automation, flexibility, material innovation, sustainability, and strategic collaboration. These developments respond to the evolving needs of industries seeking safer, more efficient, and environmentally conscious process equipment. As technologies advance and applications diversify, the market is set for robust growth, providing innovative reactor solutions tailored to modern industrial and research requirements.

0 notes

Text

Glass Reactor Market Growth Challenges Impact Innovation, Investment, and Regional Expansion in Developing Industrial Sectors

Glass reactors are widely used in chemical, pharmaceutical, and biochemical industries for their transparency, corrosion resistance, and ease of monitoring reactions. While the global glass reactor market continues to grow due to increasing demand for advanced lab equipment and chemical processing solutions, it also faces several significant challenges that could potentially hinder its development. Understanding these obstacles is crucial for manufacturers, suppliers, and investors to strategize effectively and ensure sustainable growth.

1. High Initial Investment and Operating Costs

One of the primary challenges in the glass reactor market is the high cost of manufacturing and maintenance. Borosilicate glass, commonly used in reactors, is expensive to produce and shape, especially for large-scale industrial applications. Additionally, the supporting hardware, safety mechanisms, and specialized installation increase overall operational expenses. For small and medium enterprises (SMEs), the high entry cost often acts as a barrier to adoption.

2. Fragility and Risk of Breakage

Despite being durable against thermal and chemical reactions, glass reactors are still prone to physical damage. Their fragility makes them less suitable for rough handling or high-impact environments, unlike their stainless steel counterparts. The fear of accidental breakage deters many industries, especially those handling large-scale or heavy-duty operations, from fully transitioning to glass-based systems.

3. Complex Supply Chain and Raw Material Dependency

The glass reactor industry relies heavily on specific raw materials such as high-grade borosilicate and specialized seals and valves. These materials often have limited sources and are subject to global supply chain disruptions. Geopolitical tensions, trade restrictions, and fluctuations in raw material prices can directly affect production timelines and costs, creating uncertainty in the market.

4. Limited Application in High-Pressure Environments

Glass reactors, by their very nature, are not ideal for processes that require very high pressure. While advances in design have improved their pressure tolerance, they are still unsuitable for certain chemical or pharmaceutical processes that demand extreme operating conditions. This limitation confines the market potential within specific segments, hindering universal applicability.

5. Lack of Awareness in Emerging Economies

In many emerging markets, awareness about the advantages and capabilities of glass reactors is still low. Traditional equipment continues to dominate due to its familiarity, lower cost, and perceived durability. This lack of market education, coupled with insufficient technical expertise, restricts market penetration in regions like Africa, parts of Southeast Asia, and Latin America.

6. Stringent Regulatory and Safety Standards

Glass reactors must meet rigorous safety and regulatory standards due to the sensitive nature of their applications. These regulations vary by country, requiring manufacturers to adapt products to different compliance frameworks, often increasing production costs and time-to-market. Non-compliance can lead to heavy penalties, product recalls, or outright bans, especially in pharmaceuticals and biotech industries.

7. Technological Competition from Alternative Materials

Alternative materials like stainless steel, polymer-lined vessels, and hybrid reactors offer tough competition to glass systems. These alternatives often provide better durability, pressure handling, and cost-effectiveness in certain applications. Technological advancements in these areas continue to put pressure on glass reactor manufacturers to innovate and justify their relevance.

Conclusion

The global glass reactor market holds promising growth potential, especially with rising demands in pharmaceuticals, chemical processing, and academic research. However, the path to expansion is riddled with challenges—ranging from economic constraints and material fragility to regulatory complexity and limited awareness. Addressing these issues through innovation, strategic partnerships, and targeted education campaigns will be key to overcoming growth barriers and establishing long-term market resilience.

0 notes

Text

Sight Glass Valve vs Sight Glass Set: What’s the Difference?

Sight Glass Valves control and monitor flow, while Sight Glass Sets include both glass indicators and isolation valves. Valves offer direct shut-off; sets offer complete flow observation with safety. Both are vital in industrial Udyogs for steam, oil, and chemical pipelines. This guide compares features, price, and applications.

🧰 What is a Sight Glass Valve?

A Sight Glass Valve combines a visual flow indicator with a valve function, allowing operators to monitor and control media like gas, steam, or liquid.

🔹 Key Features:

Integrated shut-off or control mechanism

Glass inspection window

Threaded or flanged ends

Brass, bronze, SS, or cast iron body

What is a Sight Glass Set?

A Sight Glass Set includes a sight glass body, valves on both ends (typically isolation valves), and accessories like seals and gaskets. It provides full visibility and safety during inspection.

🔸 Key Components:

Sight glass tube (borosilicate)

Isolation valves (2 pcs)

Gaskets & fittings

Drain cock (optional)

📊 Sight Glass Valve vs Sight Glass Set: Comparison Table

Feature Sight Glass Valve Sight Glass Set Function View + Control Flow View + Isolate + Replace Sight Glass Installation Single unit Multi-component system Cost₹700 – ₹3,000₹2,500 – ₹7,500 Material SS, Bronze, Cast Iron Borosilicate + Metal Valves Pressure Rating Up to 25 bar10–40 bar (depends on set) Applications Inline flow regulation Continuous process inspection

🏭 Industrial & Udyog Applications

✅ Sight Glass Valve Uses:

Water treatment plants

Chemical dosing systems

HVAC and boiler systems

Oil refineries

✅ Sight Glass Set Uses:

High-pressure steam pipelines

Food & pharma Udyogs

Effluent treatment units

Chemical reactors

💰 Sight Glass Valve & Set Price in India (2025)

Product TypeSizePrice Range (INR)Sight Glass Valve½"–2"₹700 – ₹3,000Sight Glass Set½"–2"₹2,500 – ₹7,500

Prices vary by brand, pressure rating, and body material. For Udhhyog-grade fittings, SS and bronze are preferred.

🛒 Where to Buy: Verified Suppliers

🔧 Platforms:

IndiaMART – Bulk buyers & manufacturers

TradeIndia – Udyog-grade suppliers

Justdial – Dealers in Delhi, Mumbai, Ahmedabad

FAQ

What is the difference between sight glass valve and sight glass set?

A sight glass valve combines visual flow check and control, while a sight glass set includes separate components like glass and isolation valves for complete system inspection and maintenance.

Which one is better for industrial Udyogs?

For high-pressure and continuous processes, a Sight Glass Set is ideal. For simple flow control with monitoring, use a Sight Glass Valve.

How much does a sight glass valve cost in India?

Prices range from ₹700 to ₹3,000 depending on size, pressure rating, and material (bronze, SS, cast iron).

Where to find the best sight glass valve suppliers near me?

Search on IndiaMART, Justdial, or TradeIndia with your city name for verified Udyog suppliers.

0 notes

Text

What Are the Key Features of the 1L Double Glazed Reactor?

A 1L double glazed reactor is an essential tool in laboratory and industrial settings, designed to facilitate precise chemical reactions under controlled conditions. These reactors, such as those offered by EquilRxnLab, integrate advanced engineering to enhance efficiency, safety, and reproducibility in various applications, including pharmaceutical synthesis, material science, and chemical engineering.

1. Dual-Layer Glass Structure for Superior Thermal Control

One of the standout features of a 1L double glazed reactor is its double-walled borosilicate glass construction, which provides excellent thermal insulation. The outer jacket allows for the circulation of heating or cooling fluids, enabling precise temperature regulation during reactions. This feature is particularly beneficial for temperature-sensitive processes, ensuring optimal reaction conditions and minimizing heat loss.

2. High Chemical Resistance and Durability

Constructed from high-quality borosilicate glass, these reactors exhibit remarkable resistance to thermal shock and chemical corrosion. This durability makes them suitable for handling aggressive solvents and reagents, ensuring long-term reliability and operational stability.

3. Efficient Mixing and Reaction Control

The integrated stirring system plays a crucial role in reaction uniformity. Equipped with a variable-speed motor, the reactor ensures thorough mixing of reactants, promoting consistent results. The stirring mechanism also prevents localized overheating or concentration gradients, enhancing process reproducibility.

4. Vacuum and Pressure Compatibility

Many 1L double glazed reactors support vacuum operation, allowing for reduced reaction temperatures and solvent recovery. This capability is essential for processes such as distillation and crystallization, improving yield and purity. Additionally, they can withstand moderate pressure variations, expanding their applicability in various experimental setups.

5. Versatile Applications in Research and Industry

From pharmaceutical research to chemical synthesis and nanotechnology, these reactors are indispensable in numerous scientific fields. Their precise temperature and reaction control make them ideal for studies requiring repeatability and accuracy.

For those seeking a high-performance 1L double glazed reactor, EquilRxnLab offers industry-leading solutions designed to meet the demands of modern laboratories. More details about the AKF-1L Double Glazed Reactor can be found here.

Learn More & Stay Connected

To explore the complete range of laboratory reactors, visit the official EquilRxnLab product catalog. Stay updated with the latest innovations by following us on YouTube, Instagram, and Facebook. For inquiries or technical support, feel free to reach out via our contact page.

0 notes

Text

Enhance your lab with the StonyLab 10L Glass Reactor! 🌟 Choose between single or dual jacketed systems for optimal temperature control and mixing efficiency. Ideal for high-precision research, synthesis, and production.

For just $4150, upgrade your lab with this advanced reactor! 💥

0 notes

Text

How to Integrate a Jacketed Glass Reactor Vessel into Your Lab’s Workflow

Modern laboratories rely on advanced equipment to enhance productivity, ensure precision, and optimize chemical processes. Among the essential tools in many labs is the jacketed glass reactor, a versatile apparatus integral to a variety of chemical process systems.

The effective integration of a jacketed glass reactor into your lab’s workflow can significantly enhance efficiency and expand experimental possibilities. In this comprehensive guide, we’ll explore the steps to achieve seamless integration, delve into different reactor jacket types, and provide insights to help you make the most of this critical piece of equipment.

Understanding the Jacketed Glass Reactor

A jacketed glass reactor is a sophisticated piece of laboratory equipment designed for chemical reactions under controlled temperature conditions. It consists of a glass vessel encased in an outer layer, or jacket, through which a heating or cooling medium circulates. This design facilitates precise thermal management, making it invaluable in research and industrial settings.

Key Features

Material Transparency: The borosilicate glass construction allows for visual monitoring of chemical reactions.

Temperature Control: The jacket accommodates fluids such as water, oil, or glycol, enabling controlled heating or cooling.

Versatility: Suitable for a variety of applications, including synthesis, mixing, distillation, and crystallization.

Why Choose a Jacketed Glass Reactor?

The jacketed glass reactor offers several advantages:

Enhanced Temperature Precision: Ideal for reactions requiring specific thermal conditions.

Scalability: Available in various sizes, from small-scale lab units to industrial-scale systems.

Chemical Resistance: Borosilicate glass resists corrosion, making it compatible with a wide range of chemicals.

Customizable Options: From reactor jacket types to stirring mechanisms, these reactors can be tailored to specific needs.

By incorporating a jacketed glass reactor into your chemical process systems, you can achieve greater control, reproducibility, and efficiency in your lab operations.

Preparing Your Lab for Integration

Before installing a jacketed glass reactor, it’s crucial to assess your lab’s layout and workflow. Follow these preparatory steps to ensure a smooth integration:

Step 1: Evaluate Space RequirementsMeasure the available space in your lab to ensure the reactor fits comfortably. Account for additional components like circulators, pumps, and control systems.

Step 2: Define Process ObjectivesIdentify the types of reactions or processes you’ll perform, such as synthesis or distillation. Determine the temperature range and pressure requirements for your applications.

Step 3: Select the Right Reactor Jacket TypeThe reactor jacket type you choose will directly impact the reactor’s performance.

Common types include:

Single Jacket: Simplest design, ideal for basic heating or cooling needs.

Double Jacket: Provides more uniform temperature control by circulating the thermal fluid between two layers.

Triple Jacket: Offers additional insulation and is suitable for extreme temperature conditions.

Installing the Jacketed Glass Reactor

Proper installation is key to ensuring optimal performance. Follow these steps to set up your jacketed glass reactor:

Step 1: Assemble the ComponentsUnpack and inspect all components, including the reactor vessel, jacket, and accessories. Secure the reactor to a sturdy stand or frame. Attach the stirring mechanism, thermocouples, and other monitoring devices.

Step 2: Connect the Thermal CirculatorSelect a compatible circulator for your chemical process systems. Ensure it meets the required temperature range and fluid capacity.

Connect the inlet and outlet ports of the reactor jacket to the circulator using high-quality tubing.

Step 3: Ensure Proper SealingCheck all joints and connections for leaks. Use appropriate sealing materials, such as PTFE gaskets, to maintain a tight seal.

Step 4: Test the SystemPerform a dry run to verify that all components are functioning correctly. Monitor temperature and pressure readings to ensure accurate operation.

Optimizing Workflow with a Jacketed Glass Reactor

Once installed, the jacketed glass reactor should integrate seamlessly into your lab’s workflow. Here’s how to maximize its efficiency:

Automate Processes

Use digital controllers to automate temperature adjustments and stirring speeds. Implement data logging systems to track reaction parameters in real time. Standardize Protocols

Develop standard operating procedures (SOPs) for common reactions. Train lab personnel on proper handling and maintenance of the reactor. Maintain Equipment Regularly

Clean the reactor and its components after each use. Schedule routine maintenance checks to prevent wear and tear. Scale Up Operations

If your experiments require larger volumes, consider scaling up to a larger jacketed glass reactor without altering the core process.

Applications of Jacketed Glass Reactors in Chemical Process Systems

The jacketed glass reactor is indispensable in various chemical process systems. Common applications include:

Synthesis and Mixing: Combine reactants under controlled temperature and agitation to achieve desired products.

Distillation: Separate components of a mixture by exploiting differences in boiling points. Use the reactor’s jacket to control reflux conditions.

Crystallization: Achieve precise temperature control to promote the formation of crystals in solution.

Extraction: Extract desired compounds from mixtures using solvents and temperature manipulation.

Troubleshooting Common Issues

Despite its robustness, the jacketed glass reactor may encounter operational challenges. Here’s how to address them: Problem: Inconsistent Temperature

Solution: Check for blockages in the thermal fluid circulation system. Ensure the circulator is operating within its specified range.

Problem: Leakage

Solution: Tighten connections and replace worn gaskets. Inspect the glass vessel for cracks or damage.

Problem: Stirring Mechanism Failure

Solution: Verify the motor’s power supply and inspect the stirrer blade for obstructions.

Conclusion

Integrating a jacketed glass reactor into your lab’s workflow is a strategic investment that enhances your lab’s capabilities in chemical process systems. By selecting the appropriate reactor jacket types, preparing your lab, and maintaining the equipment, you can achieve precise control over a wide range of chemical reactions. With proper planning and execution, the jacketed glass reactor will become a cornerstone of your laboratory, driving innovation and efficiency in your experiments.

0 notes

Text

I have been down the rabbit holes and I come back slightly further down the dunning-kruger curve and with three unlikely suggestions. Initially, 'water being actively heated, not at a rolling boil, suddenly producing a large bubble all at once' sounds like bumping. This might be caused by very clean/smooth cookware, which has no nucleation points for the liquid->gas reaction to occur at, so the heat continues to build up until a transient event triggers the vaporisation, at which point the whole lot goes at once. But, you've got 'weird mineral crap', which sound like Great nucleation points. Also cooking pots generally aren't smooth enough, unless your cookware is borosilicate glass, or maybe ceramic coated? Maybe something something carbon dioxide? Hard water is probably calcium carbonate. Heating that will shove the calcium carbonate back out of solution (very likely you weird mineral crap) and produce carbon dioxide, because of Le Chatelier. Which.... maybe crashes out of solution all at once for Some Reason. Lake Nyos is a famous case of 'large CO2 bubble comes out of solution all at once', And also are you aware of the Crystal Geyser, Utah, which is a cold water geyser that is also powered by CO2 solutions?? V cool But, I can't conceive of how your presumably standard-issue kitchen could create the hydrostatic pressure variation that is a core factor in those phenomena. Especially not with convection currents in play. CO2 LOVES being a gas, it's gonna bubble out Immediately from hot water.

Departure from nucleate boiling? If the base of your cookpot is reaching temperatures of like, 130+ degrees C, then maybe you're getting critical heat flux phenomena? Boiling is happening just fine, convection currents pulling heat from the cookpot surface into the pool of water, but when heat is being delivered via the pot's bottom surface faster than can be dissipated, a film of vapour develops, which impedes heat transfer since gas is an insulator. The bulk of the water cools somewhat, and then.. does your heating element stay on, or does it turn itself off? Let's say it does. The vapour layer collapses, liquid hits the now-superheated bottom surface, and it goes WOOMPH. But, film boiling seems to be not the sort of thing you expect to see in a kitchen. Not with a cookpot volume of water. It's a cryolab, nuclear reactor, industrial heat transfer phenom. I found this one video which does show the like, pulsing bubble behaviour around critical heat flux, but also is definitely not happening on the timescale you describe. (the behaviour of interest starts at 1:48) https://www.youtube.com/watch?v=GA9MBdePwmo

I shall watch this space for further suggestions.

i am boiling a large pot of water. it is simmering, so its making a nice little sssssssssssssss in the background but every once in a while there will be this large THWUMP and a bubble roughly the size of a tangerine will burst up from the water. i know this because i got curious about the TWUMP and walked over to watch it until it happened again. it is as if the water momentarily becomes extremely viscous, before realizing that is silly and inconvenient and that it should stop.

is this a thing that water does, or am i experiencing some kind of reality glitch that will get smoothed over in the next patch?

#I have assumed this is a kitchen phenomenon#and that babylon's kitchen is what I would consider typical#I've assumed regular atmospheric pressures and temperatures#volumes on the order of litres#but if it's actually a nuclear reactor then option 3#DNB#coupla sci ed pages confidently asserted I would not be able to observe film boiling in a kitchen cook pot but they didn't say why#they don't know what im capable of

180 notes

·

View notes

Text

Ablaze Export Pvt. Ltd. is an innovative leader and developer of cutting-edge pilot plants for chemists and researchers in laboratories and commercial settings. With 34 years of experience serving customers across India, we are a leading manufacturer and supplier of superior quality chemical process systems. Our expertise lies in designing, fabricating, and engineering equipment made of borosilicate glass, ranging from R&D scale to pilot plant and production scale. Our products include reactors, rotary evaporators, gas generators, filters, heat exchangers, distillation systems, and more. We provide not only state-of-the-art equipment but also installation, operation, and maintenance services, backed by our skilled technical team. Visit our website at https://www.ablazeexport.com/ or call us at +919377552542 for further details.

0 notes

Text

Scientific Glass Reactor | Alberta | Canada | Goel Scientific | USA

Goel Scientific provides a Glass Reactor System made of High-Quality Borosilicate Glass. which is used for chemical compounds, mixing chemicals, and carrying out chemical reactions. We are a manufacturer & supplier of Glass Reactor in Alberta, Canada, And the USA.

#Glass Reactor#Glass Reactor System#High-Quality Borosilicate Glass#Glass Reactor System manufactur#Glass Reactor System suppliers#Glass Reactor System in Canada#best Glass Reactor System in USA

0 notes

Text

Glass Reactor Market Potential: Growth Drivers, Trends, and Future Outlook

The global glass reactor market is poised for significant growth, propelled by increasing demand across pharmaceuticals, chemicals, and biotechnology sectors. With projections indicating a rise from USD 967.4 million in 2024 to USD 1.83 billion by 2034, the market is expected to exhibit a compound annual growth rate (CAGR) of 5.9% during the forecast period .

Key Market Drivers

1. Pharmaceutical and Chemical Industry Expansion

Glass reactors are integral to chemical synthesis, purification, and process development, making them indispensable in pharmaceutical and chemical manufacturing. The surge in demand for active pharmaceutical ingredients (APIs), specialty chemicals, and biopharmaceuticals is driving the adoption of glass reactors, particularly in regions with robust pharmaceutical sectors like North America .

2. Advancements in Research and Development

The escalating investment in research and development activities, especially in drug discovery and material science, necessitates reliable and versatile equipment. Glass reactors, known for their chemical resistance and transparency, are preferred for laboratory experiments and pilot-scale productions, facilitating precise monitoring and control of reactions .

3. Emphasis on Sustainable and Green Chemistry

The global shift towards sustainable practices and green chemistry has amplified the demand for equipment that supports environmentally friendly processes. Glass reactors, with their inert nature and recyclability, align with these sustainability goals, making them favorable choices in modern laboratories and production facilities .

Emerging Trends

1. Technological Innovations

The integration of advanced technologies, such as automation and digital monitoring systems, is enhancing the functionality of glass reactors. These innovations enable real-time data acquisition, improved safety, and process optimization, thereby increasing efficiency and reducing operational costs .

2. Customization and Scalability

Manufacturers are offering customizable glass reactors to cater to specific process requirements, ranging from small-scale laboratory setups to large-scale industrial productions. This scalability ensures that glass reactors can adapt to various operational scales, providing flexibility and cost-effectiveness .

3. Material Advancements

The development of high-quality materials, such as borosilicate glass, has improved the durability and thermal resistance of glass reactors. These materials enhance the reactors' ability to withstand harsh chemical reactions and temperature variations, extending their service life and reliability .

Regional Market Insights

North America

North America holds a significant share of the glass reactor market, attributed to its advanced pharmaceutical and chemical industries. The region's focus on innovation and stringent regulatory standards drives the adoption of high-quality glass reactors for research and production purposes .

Asia-Pacific

The Asia-Pacific region is experiencing rapid growth in the glass reactor market, fueled by expanding pharmaceutical manufacturing, increasing R&D activities, and supportive government initiatives. Countries like China and India are emerging as key players, offering lucrative opportunities for market expansion .

Europe

Europe's emphasis on sustainable practices and advanced research infrastructure contributes to the steady growth of the glass reactor market. The region's strong presence in chemical and pharmaceutical sectors supports the continuous demand for efficient and reliable glass reactor systems .

Future Outlook

The glass reactor market is set to witness robust growth, driven by technological advancements, increasing R&D investments, and the global shift towards sustainable practices. Manufacturers focusing on innovation, customization, and quality are likely to gain a competitive edge in this evolving market landscape.

As industries continue to seek efficient and environmentally friendly solutions, the demand for versatile and high-performance glass reactors is expected to rise, solidifying their role as essential components in modern chemical and pharmaceutical processes.

0 notes

Text

🔬Hey! Are you still struggling in cryogenic reactions?

Here, at Goel Scientific Glass Works Ltd. We have solutions to all your problems related to glass process equipment. Introducing the Cutting-Edge Glass Lab Reactor with an advanced Heating/Cooling System with temperature range: -70°C to 180°C designed to elevate your research to new heights! Are you looking to elevate your research to new heights? Step into the world of advanced chemistry and scientific discovery with our state-of-the-art Glass Lab Reactor! Engineered to perfection, this revolutionary tool is the key to unlocking limitless possibilities in your laboratory. 🔬 Limitless Applications: Whether you're working on chemical synthesis, pharmaceutical development, material research, or other scientific pursuits, our Glass Lab Reactor empowers you to tackle a wide range of applications with a capacity of jacketed reactors from 500ml to 20ltrs in ease. At Goel Scientific, you can select the system as per your requirement: Reactor Capacity: 500ml to 20ltrs - Jacket option: Single Jacketed / Double Jacketed - Operating Temperature range: -70°C to 180°C - East to setup and use - Flexible and adaptable - Quick release to swap the vessels. Checkout the Reactor in Action https://youtu.be/uQimMNFENY8 https://www.youtube.com/watch?v=uQimMNFENY8 The First jacket is provided for circulating the heating and cooling medium required for the process. Whereas the second jacket will act as a vacuum jacket which will help you in cryogenic reactions and prevent the heat loss and condensation of the main reactor during the process. The prevention of heat loss will save you time and energy and money on every reaction. ⚙️ Superior Design: With experience of more than 47 years and crafted with precision, our Glass Lab Reactor boasts a high-quality borosilicate glass body, ensuring superior resistance to heat, chemicals, and corrosion. Its durable construction guarantees prolonged usage, making it a long-term investment in your research endeavors. 🌀 Stir Up Your Curiosity: Equipped with a powerful magnetic stirring system, powerful motor and specially designed stirrer blades, our Glass Lab Reactor ensures efficient mixing and homogeneity of your reaction mixture. Say goodbye to clumps and uneven reactions and say hello to reproducible results. 🌐 Easy Monitoring & Control: Stay connected to your experiments with real-time monitoring. Adjust settings and track reaction progress, making your lab work more efficient and convenient. 💼 Compact & Modular: The compact design of our Glass Lab Reactor makes it easy to fit into any lab setup. Its modular construction allows for seamless customization, ensuring it aligns perfectly with your unique research needs. 🌿 Eco-Friendly & Sustainable: Committed to environmental responsibility, our Glass Lab Reactor is energy-efficient and reduces waste, making it a green choice for forward-thinking researchers. 🛡️ Quality Assurance: With experience of more than 47 years and our best Quality Control measures and rigorous testing ensure that each reactor reached to our customer have highest quality, adhere globally accepted standards and regulations. Rest assured that you are investing in the highest quality equipment. Don't miss the opportunity to revolutionize your scientific journey. Upgrade your lab today with the most innovative Glass Lab Reactor on the market. Contact us now for more information and secure your spot at the forefront of scientific breakthroughs! 🔍🔬 Read the full article

0 notes

Text

The robot prince of auchtertool is described to have "great boronic wings." Assuming that these wings are made of or derived from boron, and not just pure boron somehow, this can mean:

Borosilicate glass wings. Borosilicate glass is sometimes used to cover solar panels, maybe his wings are solar panels that give him an additional energy supply?

Boronated fiberglass wings. Maybe his wings are more of a lightweight paraglider-like structure, and he uses boronated fiberglass as a textile for them.

Boronized wings. His wings are some sort of metal with boron added to them to increase their surface hardness.

Boron Shielding wings. Nuclear shielding can include boron. Maybe that'd be handy in an irradiated wasteland, in case, I dunno, a radioactive wizard chucks spells/nukes at you.

Flaming green wings. Boron burns green. I hate this idea because it would clash horribly with his "eyes ablaze with crimson fire." Maybe he makes it work?

Literal boronic acid wings. Steven Universe Lapis Lazuli style, but with acid instead of water. (idk how. Magnets? Magic?) I'm not sure what benefit this would serve, since boronic acid is not all that corrosive. I guess it's used similarly to boron nuclear shielding, added to coolant water in some reactors? Boronic acid is much handier in organic chemistry than it is in robot defense+transportation, though.

hate that Maleficus Geminus fucks so hard even though it has lyrics with word choices like "boronic." What does that MEAN.

#whyyyyyyyyyy didnt they sing 'bionic' wings#i aint a chemist though. maybe somebody who knows more about boron than a short browsing of wikipedia should weigh in.#...or maybe someone who knows more about gloryhammer should weigh in. i'm new to them!#having a lotta fun so far

23 notes

·

View notes

Text

Sight Glass: Types, Working & Industrial Applications (2025)

A sight glass is a transparent tube or window used to observe liquid or gas flow in pipelines, tanks, or boilers. This guide covers its working, types, uses in Udyog (industry), pricing, and trusted suppliers in India and Delhi for 2025.

🧪 What is a Sight Glass?

A sight glass is a visual indicator used in piping systems to monitor the flow, clarity, and level of liquids or gases. Commonly used in boilers, tanks, and chemical plants.

Key Functions:

Real-time fluid monitoring

Detect flow irregularities

Ensure quality control

Maintain safety in industrial Udyogs

⚙️ How Does a Sight Glass Work?

A transparent glass or acrylic window is installed in the line or tank.

Fluids or gases flow past the glass, allowing visual inspection.

Pressure and temperature resistance depends on material (borosilicate, SS, acrylic).

Most sight glasses are rated for 10-40 bar pressure and 120°C+ temperature depending on type.

🔄 Types of Sight Glasses

1. Based on Design:

Type Description Tubular Sight Glass Transparent tube for level indication Window Sight Glass Flat round or rectangular pane in pipelines Weld Pad Sight Glass Fused to tanks or pressure vessels Full View Sight Glass 360° visibility for flow monitoring

2. Based on Material:

MaterialUse CaseBorosilicateHigh-temp, chemical plantsStainless SteelSanitary, pharma UdyogsAcrylic/PlasticLow-pressure systems

🏭 Industrial & Udyog Applications

Industries Using Sight Glasses:

🏗️ Construction (water lines, tanks)

🧪 Chemical plants

🍶 Food & beverage

🩺 Pharmaceutical

🛢️ Oil & gas

💧 Effluent treatment plants

Common Applications:

Monitoring boiler feedwater

Visual inspection in reactors

Fluid level in storage tanks

Flow verification in pipelines

Sight glasses play a crucial role in Udyogs for safety, compliance, and operational monitoring.

💰 Sight Glass Price in India (2025)

TypeMaterialApprox Price Range (INR)TubularBorosilicate₹350 – ₹1,500WindowSS with Glass₹800 – ₹3,500Weld PadCarbon Steel₹2,000 – ₹5,500Full ViewSS/Borosilicate₹2,500 – ₹7,000

Prices vary by size, pressure rating, and brand.

📍 Trusted Sight Glass Suppliers in India

Top Platforms:

IndiaMART – Verified industrial valve manufacturers

TradeIndia – Supplier catalogs with direct RFQs

Justdial – City-wise PRV and sight glass dealers

Supplier Tips:

Ask for test certificates (TCs)

Check for ISO/ISI certified manufacturers

Prefer GMB-verified Udyog suppliers

FAQs

What is a sight glass used for?

A sight glass allows visual monitoring of fluids in pipelines, boilers, or tanks to detect flow, level, or contamination in real-time.

Which material is best for a sight glass?

Borosilicate is best for high-temperature industrial use. Stainless steel options are great for hygienic applications like pharma and food Udyogs.

What is the price of a sight glass in India?

Sight glasses range from ₹350 to ₹7,000 depending on design, size, and material.

Where can I find a sight glass supplier near me?

Check platforms like IndiaMART, TradeIndia, or search on Google Maps using “sight glass supplier near me” + your city.

✅ Conclusion

Sight glasses are vital in Udyog operations for monitoring flow and maintaining safety. Choose the right type based on your industry and operating conditions. Always buy from trusted suppliers listed on IndiaMART, Justdial, or TradeIndia and optimize your Google My Business listing for better visibility.

Would you like a version tailored for PDF catalogs, WhatsApp marketing, or your GMB profile?

0 notes

Text

How to Choose the Best 1L Double Glazed Reactor for Your Lab: Key Features to Prioritize

Selecting the right 1L double glazed reactor is critical for optimizing chemical synthesis, distillation, or crystallization processes in your lab. With varying designs and functionalities available, understanding core features ensures you invest in equipment that aligns with your research needs. This guide breaks down the must-have 1L double glazed reactor features, offering insights to help you make an informed decision—while subtly highlighting how EquilRxnLab’s solutions excel in these areas.

1. Material Quality and Durability

The foundation of any reliable reactor lies in its construction. Double glazed reactors use two layers of borosilicate glass to create an insulating vacuum, minimizing heat loss and ensuring thermal stability. When evaluating a 1L reactor:

Verify Glass Grade: High-quality borosilicate glass (e.g., GG17 or equivalent) resists thermal shock and chemical corrosion.

Check Joints and Seals: Reinforced PTFE or fluoropolymer seals prevent leaks during high-pressure reactions.

EquilRxnLab’s AKF-1L Double Glazed Reactor employs precision-engineered glass and chemically inert seals, making it ideal for prolonged use under aggressive conditions. Explore their full product catalog for detailed specifications.

2. Temperature Control and Uniformity

Precise temperature regulation is non-negotiable for reproducibility. Look for:

Integrated Jacket Design: A double-layered jacket allows uniform heat distribution via oil or water circulation.

Compatibility with External Systems: Ensure the reactor integrates with your lab’s chillers, heaters, or cryostats.

EquilRxnLab’s design includes a seamless jacket interface, enabling precise control from -80°C to 250°C. For visual guidance, their YouTube channel demonstrates setup workflows.

3. Stirring Mechanism Flexibility

Efficient mixing is vital for homogeneous reactions. Prioritize reactors with:

Adjustable Speed: A motor capable of 0–600 RPM (or higher) accommodates viscous or shear-sensitive mixtures.

Modular Stirrers: Interchangeable impellers (e.g., anchor, propeller, or paddle) adapt to different viscosities.

The AKF-1L reactor supports variable-speed motors and customizable stirring configurations, ensuring adaptability across experiments.

4. Safety and User-Friendliness

Labs demand equipment that minimizes risks. Key safety features include:

Pressure Relief Valves: Automatic pressure regulation prevents over-pressurization.

Stable Mounting Frame: A rigid stainless-steel stand reduces vibration and tipping hazards.

EquilRxnLab incorporates these safeguards into their reactors, alongside ergonomic clamps and intuitive control panels. Follow their Instagram for safety tips and user testimonials.

5. Scalability and Compatibility

A 1L reactor should integrate seamlessly with peripheral lab tools:

Standard Ground Joints: Ensure compatibility with condensers, dosing pumps, or sensors.

Modular Ports: Multiple openings for thermocouples, reflux setups, or vacuum lines enhance versatility.

The AKF-1L’s standardized joints and ports simplify system expansion, as showcased in EquilRxnLab’s Facebook tutorials.

6. Maintenance and Support

Long-term value depends on ease of maintenance and vendor reliability:

Detachable Components: Easy-to-clean parts reduce downtime.

Warranty and Technical Support: Opt for brands offering responsive customer service.

EquilRxnLab provides comprehensive manuals and dedicated support via their contact page, ensuring your reactor remains operational for years.

Conclusion Choosing a 1L double glazed reactor hinges on balancing material robustness, temperature precision, safety, and scalability. By prioritizing these features, labs can enhance experimental accuracy while minimizing operational risks. EquilRxnLab’s AKF-1L model exemplifies this balance, offering a reliable, adaptable solution for diverse applications. For hands-on demos or inquiries, visit their product page or connect via their social channels.

Final Tip: Always cross-reference technical specs with your lab’s workflow requirements. A well-chosen reactor becomes a cornerstone of efficient, repeatable science.

0 notes

Text

STONYLAB Electrolytic Cell

with 5-Hole PTFE Lid

Capacity: 50ml; 100ml

Price from $244.99

Converting electrical energy to chemical energy, StonyLab electrolytic cell is mainly used in electrolysis of water, electrochemical reactions, experiments, and tests

Three electrode system for better control and measurement

Components include 100 ml borosilicate glass cell, hollow screws and sealing screws, PTFE cell lid with 2 gas holes and 3 electrode holes, together with 1 copper electrode and 1 platinum electrode

🧪An electrolytic cell is a device used to facilitate electrolysis, a chemical process driven by an electric current. It consists of two electrodes (an anode and a cathode) submerged in an electrolyte solution. The electrolyte is typically a liquid or molten ionic compound that allows ions to move freely within it.

Find more electrochemistry products, visit

0 notes