#distributed acoustic sensors

Explore tagged Tumblr posts

Text

Costa Rica Is Saving Forest Ecosystems by Listening to Them - by Geraldine Castro | WIRED - SCIENCE | 25th/02/2025

Monitoring Noises in Eco-Systems Reveals Their Health, Allowing Researchers to Monitor Bio-Diversity Changes, Detect Threats & Asess the Effectiveness of Conservation Strategies.

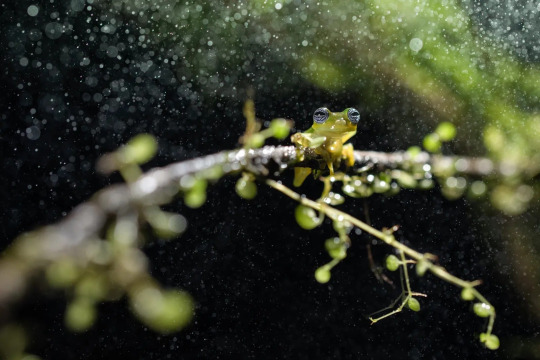

Photograph: Charlie Fayers/Getty Images

Monica Retamosa was in the middle of changing the batteries of a tape recorder when she heard a bellbird for the first time. Standing on a forest floor, she looked up into the trees, scanning for the source of its metallic and powerful sound, searching for the bird for half an hour to no avail. The bellbird sings from the treetops where it is visible to its peers but invisible to those below. Still, Retamosa smiled: She cares for ecosystems in Costa Rica’s AmistOsa Biological Corridor by listening to them.

In nature, living things use sound for almost everything. They make calls to attract mates, communicate identities, warn of dangers, guide the way, and help in hunting or defense. For decades, researchers have tracked species with recorders in hand, and still do, though increasingly are using remote recording devices too. The study of the sounds organisms make is known as bioacoustics. Retamosa has been doing this work for 10 years. Using bio-acoustic recordings, studies have shown that some birds shout loudly to make themselves heard in cities and that sea turtle hatchlings communicate from the nest to coordinate their hatching. And when bioacoustics is combined with other sounds—those made by humans, as well as the natural sounds of the landscape, such as the crashing of waves in the sea—it is possible to interpret deeper ecological meaning. It becomes possible to monitor changes in biodiversity, detect threats, and measure the effectiveness of conservation strategies. This wider analysis of sound is known as eco-acoustics—and it is exactly the work underway here in Costa Rica.

A three-wattled bellbird (Procnias tricarunculatus) in Costa Rica. Photograph: Juan Carlos Vindas/Getty Images

The development of automated recordings revolutionized bioacoustics and ecoacoustics. Now, research groups can hang sensors that record snippets of the day for months at a time without interfering with wildlife. Retamosa likes this strategy because it’s non-invasive to animals, makes it easier to have ears in large areas and hard-to-reach places, and occasionally helps discover mysterious species.

Although she prefers to monitor ecosystems from a distance, Retamosa still has to go deep into the forest to set up recorders. Visits to the field are fascinating, but never a Sunday stroll. She has hiked miles through mud and branches, along with her colleagues Jimmy Barrantes and Randall Jiménez. They have gone up and down endless slopes. Once, she fell and fractured her ribs. But the work doesn’t end with the installation: they have to go back to change batteries and memory cards. In other countries, they use solar panels and the internet to receive real-time data; in the dark, humid rainforests of Costa Rica, it’s still done by hand.

Acoustic-monitoring fieldwork in Costa Rica. Photograph: Courtesy of Jimmy Barrantes & Randall Jiménez.

That’s what Retamosa was doing when she heard the bellbird. That recording forms part of a project to track the movement and distribution of these birds, which migrate between different altitudes in the region. Their presence could be a functional indicator of the state of the AmistOsa Biological Corridor, which connects La Amistad International Park, on the border with Panama, with other reserves in southern Costa Rica.

The biological corridor was shaped by the passage of wildlife that emerged following the 1990 Forestry Law, which protected wilderness areas and encouraged reforestation on farms through payments for environmental services. In 2010, it was officially mapped. Today it runs through indigenous territories and crosses the country’s largest wetland. Across the Costa Rica there are now 53 corridors, covering 38 percent of its territory.

The project data will help the committee in charge of Costa Rica’s biodiversity and natural resources make decisions. “The idea is to make a monitoring protocol, linking the government, the communities, and us as academia, providing support for analysis and interpretation,” Retamosa says.

A Limón giant glass frog in the rain in Braulio Carillo National Park in Costa Rica. Photograph: Christopher Jimenez Nature Photo/Getty Images

Recorders hung in the wild capture many terabytes of data, so listening to every recording is not feasible. With an eye toward making it a cost-efficient strategy, researchers have developed acoustic indices: mathematical formulas to interpret ecosystem traits from the recorded sounds. “They can reflect the acoustic energy of a place, activity, or frequency diversity,” Retamosa explains. When she started in this field, there were only eight acoustic indices. Now there are more than 80.

The discipline is advancing so rapidly that the scope of these indices is currently being debated. In some of her early research, Retamosa found that certain acoustic measurements show variations between tropical and temperate regions. One of the best known, acoustic complexity—the degree of variation and intricate structure of bioacoustic sound—has been used as a descriptor of bird diversity in temperate environments. However, in tropical areas, different investigations have shown that it does not reflect species diversity, but rather the level of acoustic activity; that is, instead of indicating the presence of multiple species, it seems to show the intense vocalization of one or a few birds.

Careful analysis of these indices can be used to reveal the health of the forest. In a report with Jimmy Barrantes, Retamosa outlines that measuring acoustic entropy—the variation of sound intensity across time and audio frequencies—and acoustic diversity helped them to classify the state of disturbance of some sites, while those of acoustic activity and energy did not. “You can use the indices for a first exploration of the site, to do studies over time, looking for specific changes associated with human disturbances and work with key species,” she explains.

Listening for the Impacts of Tourism

Every region has its own environmental concerns. In Costa Rica, tourism has grown dramatically: between 1984 and 1989, international arrivals increased 37 percent, from 273,900 to 375,900 visitors. But since 1990, the pace has skyrocketed: last year the country received 2.6 million tourists. This boom poses sustainability challenges. To address them, the International Institute for Conservation and Wildlife Management team analyzes sounds inside and outside protected areas. One of its tools is an index that measures the ratio between biological sounds and human-made noises.

The acoustic quality of the landscape must be monitored to conserve the country’s ecotourism. Photograph: Jordan Siemens/Getty Images

In recent years, automated acoustic detection, using artificial intelligence and machine learning, has revolutionized species identification. Previously, advanced programming skills were required to use AI, but with the advent of accessible interface models, it’s becoming more popular. Exoacoustics is increasingly focused on developing more accurate models for classifying sounds.

And it’s becoming possible to pick out individual species in the soundscape using these tools. In a study of farms conducted as part of the Bosque Vivo project, run by Costa Rica’s National Forest Financing Fund, the research team found that Hylopezus perspicillatus, a bird species sensitive to landscape disturbance, was only present in the control sites of Corcovado National Park and in the forests of the best-conserved farms.

In Guanacaste, Retamosa is also working on a long-term monitoring protocol to evaluate how ecosystems and biodiversity are responding to climate variability. In other countries, similar projects are recording sound baselines in sites with minimal human intervention that, in the future, could be compared with up-to-date recordings to detect changes. Although storing all these records is costly, Retamosa believes that they’ll form an invaluable historical archive, which one day can be returned to when technology allows further analysis.

This story originally appeared on WIRED en Español and has been translated from Spanish.

2 notes

·

View notes

Text

Insulation Market Size, Trends, Growth & Industry Outlook | 2034

Insulation Market Outlook

According to the report by Expert Market Research (EMR), the global insulation market attained a value of approximately USD 62.91 billion in 2024. Aided by the growing emphasis on energy efficiency in residential, commercial, and industrial buildings, along with expanding infrastructure development globally, the insulation market size is projected to grow at a CAGR of 4.30% between 2025 and 2034, reaching nearly USD 95.84 billion by 2034.

Insulation plays a critical role in improving energy conservation by minimizing heat transfer in buildings and industrial equipment. It enhances comfort, reduces utility costs, and contributes to environmental sustainability by lowering carbon emissions. The increasing demand for sustainable construction materials and stricter building energy codes across the world are significantly propelling the adoption of various insulation materials. From thermal and acoustic insulation in buildings to process insulation in industrial applications, the versatility and necessity of insulation are reinforcing its growth in the global market.

Insulation Market Size

The global insulation market has witnessed robust expansion over the past several years due to its widespread applicability across multiple sectors. In 2024, the market value stood at USD 62.91 billion, driven by ongoing urbanisation, rising energy costs, and the enforcement of environmental regulations. With governments and private sectors striving to achieve energy efficiency and sustainability targets, the demand for advanced insulation solutions has surged. The market is expected to maintain steady growth over the next decade, reaching approximately USD 95.84 billion by 2034, supported by technological innovation and regulatory compliance.

Insulation Market Share

The insulation market is comprised of several key players including Owens Corning, Rockwool International A/S, Knauf Insulation, Saint-Gobain S.A., and Johns Manville. These companies account for a significant share of the global market due to their extensive product portfolios, global distribution networks, and ongoing investments in research and development. North America holds a substantial market share due to well-established construction regulations and high awareness regarding energy conservation. Europe follows closely, driven by the region’s strong environmental policies and retrofit initiatives in old buildings. The Asia Pacific region, led by China and India, is witnessing the fastest growth due to rapid industrialisation, urban infrastructure projects, and increasing construction spending.

Download a free sample report, complete with the Table of Contents - https://www.expertmarketresearch.com/reports/insulation-market/requestsample

Insulation Market Trends

Several emerging trends are shaping the global insulation market. One of the major trends is the increasing shift towards eco-friendly and sustainable insulation materials. Products such as cellulose, sheep’s wool, aerogels, and recycled denim are gaining popularity among environmentally conscious consumers and builders seeking green certifications such as LEED and BREEAM.

Another significant trend is the rising adoption of high-performance insulation solutions that offer multifunctional benefits, such as thermal insulation combined with moisture resistance or acoustic dampening. Vacuum insulation panels (VIPs) and aerogels are gaining traction in applications requiring superior thermal resistance within limited space.

Moreover, there is a growing focus on retrofitting existing buildings with modern insulation systems to meet energy performance standards. With aging infrastructure prevalent in many developed economies, the retrofitting trend is likely to play a pivotal role in market expansion. Additionally, smart insulation systems integrated with sensors to monitor temperature and energy usage are gaining interest, especially in commercial and industrial applications.

Drivers of Growth

Several factors are driving the growth of the insulation market. Chief among these is the increasing demand for energy efficiency in buildings. With heating and cooling accounting for a large portion of energy consumption in buildings, insulation emerges as a key solution for reducing overall energy demand and associated costs. Government regulations such as energy performance certificates and minimum energy efficiency standards are encouraging the use of insulation materials in both new constructions and renovation projects.

The rise in global construction activities, especially in emerging economies, is another major growth driver. The growth of residential complexes, commercial offices, industrial warehouses, and public infrastructure is creating continuous demand for effective thermal and acoustic insulation materials.

The industrial sector also plays a vital role in boosting insulation demand. In industries such as petrochemicals, power generation, and manufacturing, insulation is essential to maintain process temperatures, prevent energy loss, and enhance operational safety. As industries aim to reduce operational costs and comply with emission regulations, the need for industrial insulation is growing rapidly.

Furthermore, the increasing awareness among consumers and developers regarding indoor comfort, noise control, and environmental impact is contributing to the adoption of high-quality insulation products. Technological advancements and product innovations offering better performance, fire resistance, and sustainability are also attracting end-users, thereby driving market growth.

Technology and Advancement

Technological advancements in materials science and manufacturing processes are contributing significantly to the growth of the insulation market. New insulation materials with higher R-values (thermal resistance), greater durability, and lower environmental impact are being developed. Innovations such as vacuum insulation panels, aerogels, and phase change materials are pushing the boundaries of insulation performance, particularly in high-end residential and commercial projects.

Automation and robotics in the manufacturing of insulation products have enhanced production efficiency and consistency, reducing costs and expanding accessibility. Additionally, digital tools such as Building Information Modeling (BIM) are improving insulation design and planning in construction projects, allowing for precise material use and enhanced energy modelling.

Moreover, the use of recycled content in insulation products is gaining momentum. Manufacturers are incorporating post-consumer recycled materials into fiberglass, cellulose, and foam products, addressing environmental concerns and supporting circular economy initiatives.

Insulation Market Segmentation

The market can be divided based on product, application, and region.

Breakup by Product

Glass Wool

Mineral Wool

EPS

XPS

CMS Fibres

Calcium Silicate

Aerogel

Cellulose

PIR (Polysio)

Phenolic Foam

Polyurethane

Breakup by Application

Infrastructure

Industrial

HVAC and OEM

Transportation

Appliances

Furniture

Packaging

Breakup by Region

North America

Europe

Asia Pacific

Latin America

Middle East and Africa

Industry Key Players

Some of the major players explored in the report by Expert Market Research are as follows:

GAF

Huntsman International LLC

Johns Manville

Cellofoam North America, Inc.

ROCKWOOL International A/S

DuPont de Nemours, Inc.

Owens Corning

Others

Challenges and Opportunities

Despite its promising growth, the insulation market faces certain challenges. One major challenge is the fluctuation in raw material prices, particularly for synthetic insulation materials like polystyrene and polyurethane, which are derived from petrochemicals. Volatility in oil prices and supply chain disruptions can impact production costs and profit margins.

Additionally, the lack of awareness about modern insulation solutions in some developing regions can hinder market penetration. Limited technical knowledge among contractors and resistance to change in construction practices can slow the adoption of advanced materials.

However, the market offers numerous opportunities. The increasing focus on climate change mitigation and energy-efficient construction provides a strong foundation for growth. Government incentives, subsidies, and green building codes are creating a favourable environment for insulation adoption. Retrofitting older buildings with modern insulation materials offers vast untapped potential, especially in Europe and North America.

Moreover, advancements in bio-based and recyclable insulation products offer significant potential for differentiation and value creation. Companies that invest in sustainable innovations, strategic partnerships, and customer education are well-positioned to seize these opportunities and strengthen their market presence.

Insulation Market Forecast

The global insulation market is set to experience stable and sustained growth over the forecast period. With a market value of USD 62.91 billion in 2024, it is expected to reach approximately USD 95.84 billion by 2034, growing at a CAGR of 4.30%. This growth will be underpinned by rising construction activities, regulatory mandates, and growing demand for energy efficiency across sectors.

As sustainability, performance, and cost-efficiency become central to construction and industrial practices, the insulation market will continue to evolve. Innovations in material science, smart insulation systems, and increased global collaboration for climate goals are expected to shape the future of this dynamic and essential industry.

Media Contact:

Company Name: Claight Corporation Email: [email protected] Toll Free Number: +1–415–325–5166 | +44–702–402–5790 Address: C-130 Sector 2 Noida, Uttar Pradesh 201301 Website: https://www.expertmarketresearch.com

#tumbler posts#business#marketsize#marketreport#Insulation Market#insulation services#manufacturing#market research#marketgrowth

0 notes

Text

High-Temperature Fiber Optic Cable Solutions for Oil & Gas Pipelines

High-temperature fiber optic cable plays a vital role in oil and gas pipelines. Modern outdoor fiber optic cable and underground fiber optic cable withstand pressures up to 25,000 psi and temperatures up to 347°F. Fiber cable enables real-time, distributed sensing, providing accurate data for pipeline safety and operational efficiency.

Key Takeaways

High-temperature fiber optic cables withstand extreme heat, pressure, and chemicals, enabling safe and efficient monitoring of oil and gas pipelines. Distributed sensing technologies like DTS and DAS provide real-time data to detect leaks, blockages, and other issues early, reducing risks and costs. Choosing the right cable type and coating ensures reliable performance in harsh environments, supporting long-term pipeline safety and operational success.

Fiber Optic Cable Challenges and Requirements in Oil & Gas Pipelines

High Temperatures and Corrosive Environments Oil and gas pipelines expose fiber optic cable to extreme conditions. Operators demand cables that withstand high temperatures, intense pressure, and corrosive chemicals. The following table highlights key performance statistics for cables used in these environments: Parameter / Feature Details / Statistics Operational Temperature Range Exceeds 300°C for downhole sensing fibers Pressure Resistance Up to 25,000 psi in unconventional reservoirs Corrosion Resistance Features Hydrogen-darkening immunity, carbon-coated fibers for hydrogen-induced attenuation Coating Technologies Polyimide, carbon, and fluoride coatings enhance chemical resistance Regulatory Temperature Standards -55°C to 200°C, up to 260°C in aerospace, 175°C for 10 years (Saudi Aramco SMP-9000 spec) Specialized Applications Subsea well monitoring, offshore drilling, petrochemical plants Real-Time Monitoring and Data Accuracy Fiber optic cable enables continuous, real-time monitoring of temperature, pressure, and strain along pipelines. Distributed fiber optic sensing (DFOS) technology detects anomalies and leaks over long distances, supporting immediate intervention and risk mitigation. Operators have used distributed temperature and acoustic sensing to monitor cement integrity, identify cross flow between reservoir zones, and detect plugged inflow control devices. These applications improve productivity and reduce intervention time. Fiber optic cable systems deliver high bandwidth and immunity to electromagnetic interference, ensuring reliable data transmission for remote monitoring. Safety, Reliability, and Compliance Pipeline operators face several challenges when installing and maintaining fiber optic cable systems: Precise sensor installation is critical to avoid disturbing fluid flow. Fiber Bragg Grating sensors become costly for long pipelines. Distributed fiber optic sensors require complex layout designs. The viscoelastic behavior of materials like HDPE complicates measurement accuracy. Distributed Acoustic Sensing methods need advanced signal processing due to variable vibrational signatures. Sensor networks in remote areas require reliable energy supply and add to operational costs. Note: Fiber optic cable solutions help operators meet regulatory standards, enhance safety, and ensure reliable operation in harsh environments.

Fiber Optic Cable Technologies and Solutions for High Temperatures

Distributed Temperature Sensing (DTS) and Distributed Acoustic Sensing (DAS) Distributed Temperature Sensing (DTS) and Distributed Acoustic Sensing (DAS) have transformed pipeline monitoring in the oil and gas industry. DTS uses the scattering of light within a fiber optic cable to measure temperature changes along its entire length. This technology provides continuous, high-resolution thermal profiles, which are essential for detecting leaks, blockages, or abnormal heat signatures in pipelines. Recent advancements in DTS include active methods, such as deploying heat sources to enhance sensitivity. These methods—thermal advection tests, hybrid cable flow logging, and heat pulse tests—offer operators the ability to monitor deep wells with high spatial and temporal resolution. DTS outperforms traditional point sensors, especially in high-temperature environments where accurate, distributed data is critical. DAS, on the other hand, detects acoustic signals and vibrations along the fiber optic cable. This system can monitor thousands of points simultaneously, capturing events such as leaks, flow changes, or unauthorized activities. DAS measures longitudinal strain with directional sensitivity, but its performance depends on factors like fiber orientation and strain coupling efficiency. In high-temperature settings, the mechanical and optical properties of the cable may change, requiring robust design and advanced signal processing. Together, DTS and DAS enable real-time, distributed monitoring, supporting proactive maintenance and rapid response to incidents. Dowell integrates DTS and DAS technologies into its high-temperature fiber optic cable solutions, ensuring reliable performance in the most demanding oil and gas environments. Types of High-Temperature Fiber Optic Cable Selecting the right fiber optic cable for high-temperature applications involves understanding the unique challenges of oil and gas pipelines. Manufacturers design specialty optical fibers to withstand extreme temperatures, corrosive chemicals, and high-pressure hydrogen-rich environments. The following table summarizes common types of high-temperature fiber optic cable and their key features: Cable Type Temperature Range Coating Material Application Area Polyimide-coated Fiber Up to 300°C Polyimide Downhole sensing, well monitoring Carbon-coated Fiber Up to 400°C Carbon, Polyimide Hydrogen-rich environments Metal-coated Fiber Up to 700°C Gold, Aluminum Extreme temperature zones Fluoride Glass Fiber Up to 500°C Fluoride Glass Specialized sensing applications Engineers often deploy these cables in permanent installations, such as well casings, wireline logging cables, and slickline cables. The choice of coating and fiber type depends on the specific temperature, chemical exposure, and mechanical stress expected in the field. Dowell offers a comprehensive portfolio of high-temperature fiber optic cable solutions, tailored to meet the rigorous demands of oil and gas operations. Real-World Applications and Benefits High-temperature fiber optic cable solutions deliver significant benefits across the oil and gas value chain. Operators use distributed sensing technologies—DTS, DAS, and Distributed Vibration Sensing (DVS)—to monitor downhole activities, including hydraulic fracturing, drilling, and production. These systems provide real-time insights into well performance, enabling operators to maximize output and reduce downtime. Specialty fiber optic cables endure harsh conditions, including high temperatures and corrosive chemicals. Distributed sensing enables continuous monitoring for leak detection, flow measurement, and reservoir management. Operators achieve early detection of leaks or blockages, reducing environmental risk and maintenance costs. Fiber optic cable systems replace multiple point sensors, simplifying installation and lowering long-term expenses. Permanent installations in well casings and pipelines ensure reliable, long-term data collection. A comprehensive numerical study, supported by experimental field tests, demonstrates the effectiveness of high-temperature fiber optic cable technologies in monitoring buried high-pressure natural gas pipelines. Researchers used advanced simulation methods and found that cables placed within 100 mm of the pipeline reliably detected leakage-induced temperature changes. The study recommends laying four fiber optic cables evenly around the pipeline circumference for optimal coverage. Experimental results closely matched simulations, confirming the feasibility and accuracy of this approach for high-pressure pipeline leakage detection. Peer-reviewed studies and technical papers document the ongoing innovation in fiber optic sensing technologies. These works validate the reliability and effectiveness of distributed temperature sensing and fiber optic sensors in harsh oilfield environments. Sensuron’s Fiber Optic Temperature Sensing (FOSS) systems, for example, provide continuous, high-resolution temperature monitoring along pipelines, enabling early detection of leaks or blockages. The technology’s chemical inertness and immunity to electromagnetic interference make it ideal for oil and gas applications. Operators benefit from improved efficiency, reduced downtime, and overall cost savings, despite higher initial investments. Companies like Dowell continue to advance fiber optic cable solutions, helping operators achieve safer, more efficient, and more reliable pipeline operations. Selecting the right high-temperature cable ensures safe and efficient pipeline operations. Real-world deployments highlight key benefits: Early threat detection through advanced monitoring systems. Reliable surveillance with integrated audio and video recognition. Improved risk management using predictive models for pipeline failures. Consulting industry experts helps operators achieve compliance and long-term reliability. By: Eric Tel: +86 574 27877377 Mb: +86 13857874858 E-mail: [email protected] Youtube: DOWELL Pinterest: DOWELL Facebook: DOWELL Linkedin: DOWELL Read the full article

0 notes

Text

0 notes

Text

Global Drinking Water Pipe Repair Market to Reach $128.5 Bn by 2031

The global drinking water pipe repair market, valued at US$ 71.1 Bn in 2022, is on a growth trajectory, projected to reach US$ 128.5 Bn by 2031, expanding at a CAGR of 6.8% from 2023 to 2031. This market is gaining momentum as concerns around water scarcity, aging infrastructure, and rapid urbanization continue to intensify across the globe.

Analyst Viewpoint

The growing pressure to ensure access to clean water is driving governments, municipalities, and private stakeholders to invest in water infrastructure upgrades, especially in pipe rehabilitation. A significant focus is being placed on detecting leaks, reducing non-revenue water (NRW), and modernizing aging systems to prevent wastage and health hazards. Technological innovations such as acoustic monitoring, trenchless repair, and advanced pipe materials are transforming how drinking water pipe repairs are approached.

Market Dynamics

Water Scarcity: A Global Crisis

Water scarcity is no longer a distant concern—it is a pressing global issue. According to the UN, 2.2 billion people lacked safely managed drinking water in 2022, and 703 million had no access to basic water services. In parallel, 3.5 billion people lacked safely managed sanitation. Leaks and damaged water pipes contribute to massive water losses, further exacerbating the issue.

Governments worldwide are launching water conservation initiatives to mitigate this challenge. In the U.S., the WaterSense program promotes water-efficient products and infrastructure. Singapore’s NEWater initiative and Israel’s water recycling and desalination programs are prime examples of public sector innovation aimed at addressing water scarcity through better water management.

Repairing damaged water pipes is emerging as a practical and cost-effective way to reduce NRW losses and ensure sustainable supply.

Urbanization and Population Growth

The UN forecasts that the global population will hit 9.7 billion by 2050, with 7 billion people living in urban areas. As urban populations grow, the demand for reliable drinking water distribution systems also increases. Poorly maintained or outdated infrastructure cannot support this demand, making repair and upgrade efforts a top priority.

According to the American Society of Civil Engineers, the U.S. alone witnesses 240,000 water main breaks per year. These incidents cause service disruptions, property damage, and massive financial losses, reinforcing the need for proactive repair strategies.

Infrastructure Challenges and Investment Opportunities

Many water systems around the world operate on decades-old pipelines that are approaching or have surpassed their operational lifespan. The shift toward preventive maintenance and system modernization is driving investments in pipe repair services.

Cities and governments are allocating substantial budgets to update their water networks. This presents a lucrative opportunity for repair service providers, pipe material manufacturers, and leak detection technology companies.

Technology Trends in Pipe Repair

The market is witnessing rapid adoption of trenchless pipe repair techniques, which enable underground repairs with minimal surface disruption. Additionally, remote assessment and monitoring technologies using acoustic sensors or smart metering systems are helping utilities detect issues before they escalate.

Manufacturers are also innovating with new plastic and composite materials that resist corrosion and offer longer service life in urban environments. Companies like 3M, Aegion Corporation, and Kurita Water Industries Ltd. are expanding their offerings through R&D investments and acquisitions.

In 2022, Kurita Water Industries Ltd. launched the Kurita Innovation Hub, while Corrpro UK (Holdings) Limited acquired Corrpro Companies Europe Limited in 2024, signaling industry consolidation and capability expansion.

Segment Insights

The pipes & connectors segment held the largest market share in 2022 due to increased use in addressing leakages and preventing pipe bursts. This is driven by construction booms in emerging economies, especially in the Asia Pacific region.

Trenchless pipe repair is another high-growth segment, appealing to utilities looking for cost-effective and non-intrusive solutions in dense urban settings.

Regional Outlook

Asia Pacific leads the global market, with China and India driving the demand. Government-backed programs like India’s Atal Bhujal Yojana are helping communities manage groundwater usage, while simultaneously promoting investment in clean water infrastructure.

Other high-growth regions include North America and Europe, where old infrastructure and strict water quality regulations fuel demand for pipe repair and modernization.

Key Players and Competitive Landscape

The drinking water pipe repair market is moderately consolidated, with key players including:

These companies are focusing on product innovation, strategic partnerships, and geographical expansion to strengthen their market presence.

Conclusion

The drinking water pipe repair market plays a crucial role in shaping the future of sustainable water management. As water scarcity looms and infrastructure ages, the market offers significant opportunities for innovation, investment, and impact. With strategic policies, public-private partnerships, and technology-led solutions, the industry is well-positioned to meet the growing global demand for safe, clean, and uninterrupted drinking water.

0 notes

Text

Predictive Maintenance in Oil & Gas: The Role of IoT and Smart Sensors

In the high-stakes world of oil and gas, where equipment failure can lead to millions in losses, environmental damage, and safety hazards, predictive maintenance is quickly becoming a cornerstone of operational strategy. Leveraging the IoT in oil gas industry and smart sensors, companies can now anticipate failures before they happen—transforming reactive maintenance into a proactive, data-driven approach.

The Challenge of Traditional Maintenance

Traditionally, oil and gas companies have relied on two primary forms of maintenance: reactive and preventive. Reactive maintenance waits for equipment to break down before fixing it—a risky and expensive approach. Preventive maintenance, while more responsible, follows a fixed schedule, replacing parts regardless of actual wear. Both methods can result in unnecessary downtime, wasted resources, or worse—unexpected failures in mission-critical equipment.

Enter predictive maintenance: a smarter alternative that uses real-time data and analytics to forecast when maintenance should be performed, based on actual equipment conditions rather than arbitrary timelines.

How IoT and Smart Sensors Enable Predictive Maintenance

Predictive maintenance hinges on data—and this is where IoT and smart sensors come in. By embedding connected sensors in key equipment such as pumps, compressors, turbines, and pipelines, companies can collect continuous streams of operational data like:

Vibration frequency

Temperature changes

Pressure levels

Flow rates

Acoustic emissions

Lubrication quality

These data points are sent in real time to cloud-based platforms or edge computing systems, where they're analyzed using AI and machine learning models to detect patterns and anomalies that indicate early signs of wear or malfunction.

For example, a sudden increase in vibration on a gas compressor may suggest an impending bearing failure. With this insight, maintenance can be scheduled before the problem escalates—minimizing downtime and extending equipment lifespan.

Real-World Applications in Oil & Gas

Upstream (Exploration and Drilling): Drilling operations are complex and high-risk. Smart sensors monitor drill bit integrity, mud pumps, and downhole tools to predict failures that could lead to costly rig downtime.

Midstream (Transportation and Storage): In pipelines and storage tanks, IoT sensors detect corrosion, pressure anomalies, and potential leaks. Predictive maintenance here helps prevent spills, regulatory penalties, and safety hazards.

Downstream (Refining and Distribution): Refineries rely on an array of rotating equipment—motors, pumps, heat exchangers. IoT-enabled predictive maintenance ensures these assets perform efficiently and safely, reducing unplanned outages.

Benefits of Predictive Maintenance with IoT

Reduced Downtime: Unplanned outages can cost hundreds of thousands of dollars per day. Predictive maintenance significantly lowers this risk by identifying issues before they disrupt operations.

Lower Maintenance Costs: Companies can optimize maintenance schedules and reduce unnecessary part replacements, labor costs, and overtime.

Improved Safety: Early detection of faults minimizes the likelihood of catastrophic failures that could endanger workers or lead to environmental incidents.

Extended Asset Life: Monitoring wear in real-time allows for timely interventions that preserve equipment health and prolong asset lifespans.

Data-Driven Decision-Making: Maintenance teams can prioritize work orders based on real risk, improving resource allocation and operational efficiency.

Challenges to Implementation

While the benefits are clear, implementing IoT-driven predictive maintenance in oil and gas does come with challenges:

High Upfront Costs: Sensors, connectivity, data platforms, and integration with legacy systems require investment. However, long-term ROI often justifies the initial spend.

Cybersecurity Risks: As operations become increasingly connected, protecting critical infrastructure from cyber threats becomes crucial.

Data Overload: The sheer volume of data can be overwhelming. Without strong analytics tools, it's difficult to derive meaningful insights.

Workforce Readiness: Technicians and engineers need training to interpret sensor data and use predictive tools effectively.

Future Outlook

As sensor technology becomes more affordable and machine learning models grow more accurate, predictive maintenance is poised to become standard across the oil and gas industry. In fact, many forward-thinking companies are already moving toward Prescriptive Maintenance—an advanced level where AI not only predicts failures but recommends specific maintenance actions and optimal timing.

With the growing pressure to reduce operational costs, maximize asset uptime, and meet stricter safety and environmental standards, predictive maintenance supported by IoT is not just a technical upgrade—it’s a strategic necessity.

Conclusion

The integration of IoT and smart sensors into predictive maintenance is reshaping the oil and gas landscape. What once required manual checks and reactive responses can now be managed with precision and foresight. Companies that embrace this digital evolution will not only protect their assets and people—they’ll gain a competitive edge in an increasingly data-driven energy sector.

0 notes

Text

Europe Hydrographic Survey Equipment Market Trends and Forecast: Size, Demand, Innovation & Competitive Analysis

"Executive Summary Europe Hydrographic Survey Equipment Market : Europe hydrographic survey equipment market size was valued at USD 658.34 million in 2024 and is projected to reach USD 973.37 million by 2032, with a CAGR of 5.2% during the forecast period of 2025 to 2032.

This Europe Hydrographic Survey Equipment Market research report takes into account several industry verticals such as company profile, contact details of manufacturer, product specifications, geographical scope, production value, market structures, recent developments, revenue analysis, market shares and possible sales volume of the company. Businesses can gain current as well as upcoming technical and financial details of the industry to 2025 with this Europe Hydrographic Survey Equipment Market report. Europe Hydrographic Survey Equipment Market report has been mainly designed by keeping in mind the customer requirements which will ultimately assist them in boosting their return on investment (ROI).

The company profiles of all the top market players and brands with moves like product launches, joint ventures, mergers and acquisitions which in turn is affecting the sales, import, export, revenue and CAGR values are revealed in this Europe Hydrographic Survey Equipment Market industry report. With this market report, it becomes easy to get an in-depth market analysis and thrive in this competitive environment. The report will surely aid in growing your sales and improve return on investment (ROI). Europe Hydrographic Survey Equipment Market research report makes available wide-ranging analysis of the market structure along with evaluations of the various segments and sub-segments of the market.

Discover the latest trends, growth opportunities, and strategic insights in our comprehensive Europe Hydrographic Survey Equipment Market report. Download Full Report: https://www.databridgemarketresearch.com/reports/europe-hydrographic-survey-equipment-market

Europe Hydrographic Survey Equipment Market Overview

**Segments**

- **Product Type**: The Europe hydrographic survey equipment market can be segmented based on product type into acoustic sensors, echo sounders, sonar systems, positioning systems, and others. The echo sounders segment is expected to witness significant growth due to the increasing demand for precise depth measurement in underwater survey applications.

- **Application**: In terms of application, the market can be segmented into hydrographic charting, offshore oil & gas, coastal engineering, port & harbor management, dredging, and others. The hydrographic charting segment is expected to dominate the market owing to the rising demand for accurate mapping of water bodies for navigation and resource exploration purposes.

- **End-User**: Based on end-user, the Europe hydrographic survey equipment market can be categorized into government, oil & gas industry, construction industry, mining industry, maritime archaeology, and others. The government segment is anticipated to hold a significant market share due to the increasing investments in marine infrastructure development and oceanographic research activities.

**Market Players**

- **Kongsberg Gruppen**: Kongsberg Gruppen is a key player in the Europe hydrographic survey equipment market, offering a wide range of products including multibeam echo sounders, sonar systems, and underwater positioning systems. The company's focus on technological advancements and strategic acquisitions has helped it maintain a strong market position.

- **Teledyne Technologies Incorporated**: Teledyne Technologies is another prominent player in the market, known for its innovative hydrographic survey equipment such as acoustic imaging systems, subsea navigation solutions, and marine sensors. The company's strong distribution network and emphasis on R&D activities have contributed to its market growth.

- **Trimble Inc.**: Trimble Inc. is a leading provider of positioning technology solutions for various industries, including hydrographic surveying. The company offers GNSS receivers, marine antennas, and software solutions for accurate data collection and analysis in marine environments.

- **Thales Group**: Thales Group specializes in providing advanced maritime solutions, including hydrographic survey equipment for defense and commercial applications. The company's expertise in navigation systems and maritime security technology has positioned it as a key player in the market.

The Europe hydrographic survey equipment market is characterized by intense competition among key players striving to enhance their product offerings and expand their market presence through collaborations, partnerships, and product innovations. The increasing emphasis on marine resource exploration, coastal infrastructure development, and maritime security measures is expected to drive market growth in the region.

The Europe hydrographic survey equipment market is poised for significant growth in the coming years, driven by various factors such as technological advancements, increasing demand for accurate mapping in underwater environments, and the rising investments in marine infrastructure development. One key trend shaping the market is the adoption of advanced acoustic sensors, echo sounders, sonar systems, and positioning systems for precise data collection in hydrographic survey applications. These high-tech solutions not only enhance the efficiency and accuracy of hydrographic charting but also cater to the evolving needs of industries such as offshore oil & gas, coastal engineering, dredging, and maritime archaeology.

Moreover, the market landscape is witnessing a surge in demand for hydrographic survey equipment from government entities, oil & gas companies, construction firms, mining industry players, and maritime archaeologists. Governments across Europe are increasingly investing in marine infrastructure projects and oceanographic research initiatives, thereby fueling the adoption of advanced surveying technologies. Similarly, the oil & gas industry relies heavily on hydrographic survey equipment for offshore exploration activities, pipeline routing, and environmental monitoring, further propelling market growth.

In terms of market players, key companies such as Kongsberg Gruppen, Teledyne Technologies Incorporated, Trimble Inc., and Thales Group are at the forefront of innovation and product development in the Europe hydrographic survey equipment market. These players leverage their expertise in multibeam echo sounders, acoustic imaging systems, GNSS receivers, and navigation solutions to cater to a diverse set of end-users and applications. Strategic collaborations, acquisitions, and R&D investments are key strategies adopted by these players to strengthen their market position and expand their product portfolios.

Looking ahead, the Europe hydrographic survey equipment market is poised for further expansion, driven by the continued focus on marine resource exploration, coastal infrastructure development, and maritime security measures. The integration of advanced technologies such as artificial intelligence, cloud computing, and autonomous surveying systems is expected to revolutionize the way hydrographic surveys are conducted, offering more efficient and cost-effective solutions to end-users. Overall, the market is set for dynamic growth and innovation, presenting lucrative opportunities for both established players and new entrants in the industry.The Europe hydrographic survey equipment market is witnessing significant growth driven by the increasing demand for precise mapping of water bodies for various applications such as navigation, resource exploration, and marine infrastructure development. The market segmentation based on product type highlights the importance of echo sounders in providing accurate depth measurements in underwater survey applications. This segment is expected to experience substantial growth as industries seek more precise data collection capabilities. Additionally, the emphasis on advanced acoustic sensors, sonar systems, and positioning systems underscores the trend towards adopting high-tech solutions for efficient hydrographic surveying.

In terms of applications, hydrographic charting is expected to dominate the market due to the need for accurate mapping of water bodies for navigation and resource exploration purposes. The offshore oil & gas segment is also a key driver of market growth, as the industry relies heavily on hydrographic survey equipment for exploration activities, pipeline routing, and environmental monitoring. The coastal engineering and dredging segments further contribute to the market expansion by requiring precise data collection and analysis for infrastructure development projects.

The end-user segmentation in the Europe hydrographic survey equipment market showcases the diverse set of industries leveraging this technology, with government entities, oil & gas companies, construction firms, mining industry players, and maritime archaeologists driving market demand. Governments' increasing investments in marine infrastructure projects and research initiatives, along with the oil & gas industry's reliance on surveying equipment for offshore activities, are key factors propelling market growth. The collaboration and partnerships among key market players such as Kongsberg Gruppen, Teledyne Technologies Incorporated, Trimble Inc., and Thales Group highlight the competitive landscape characterized by innovation, product development, and strategic initiatives focused on enhancing market presence and expanding product portfolios.

Looking ahead, the Europe hydrographic survey equipment market is poised for further expansion driven by the integration of advanced technologies like artificial intelligence, cloud computing, and autonomous surveying systems. These technological advancements are expected to revolutionize hydrographic surveys by offering more efficient and cost-effective solutions to end-users. Overall, the market presents lucrative opportunities for both established market players and new entrants, signaling a dynamic growth trajectory and ongoing innovation in the industry.

The Europe Hydrographic Survey Equipment Market is highly fragmented, featuring intense competition among both global and regional players striving for market share. To explore how global trends are shaping the future of the top 10 companies in the keyword market.

Learn More Now: https://www.databridgemarketresearch.com/reports/europe-hydrographic-survey-equipment-market/companies

DBMR Nucleus: Powering Insights, Strategy & Growth

DBMR Nucleus is a dynamic, AI-powered business intelligence platform designed to revolutionize the way organizations access and interpret market data. Developed by Data Bridge Market Research, Nucleus integrates cutting-edge analytics with intuitive dashboards to deliver real-time insights across industries. From tracking market trends and competitive landscapes to uncovering growth opportunities, the platform enables strategic decision-making backed by data-driven evidence. Whether you're a startup or an enterprise, DBMR Nucleus equips you with the tools to stay ahead of the curve and fuel long-term success.

What insights readers can gather from the Europe Hydrographic Survey Equipment Market report?

Learn the behavior pattern of every Europe Hydrographic Survey Equipment Market -product launches, expansions, collaborations and acquisitions in the market currently.

Examine and study the progress outlook of the global Europe Hydrographic Survey Equipment Market landscape, which includes, revenue, production & consumption and historical & forecast.

Understand important drivers, restraints, opportunities and trends (DROT Analysis).

Important trends, such as carbon footprint, R&D developments, prototype technologies, and globalization.

Browse More Reports:

Global Thermosetting Aerospace Composites Market Middle East and Africa Lung Cancer Diagnostics Market Global Block Chain in Manufacturing Market Global Baselayer Compression Shirts Market Global Financial Analytics Market Global Co-polyester-Ether Elastomers (COPE) Market Global Payment Gateway Market Global Yeast Based Ingredients Market Global Vascular Graft Market Global Exterior Sheathing Market Europe Personal Care Ingredients Market North America Flight Data Recorder Market Global Special Effect Pigments Market Global Business To Business (B2b) Cartridge Filter Water Filtration Market Europe Xylose Market North America Weight Loss and Obesity Management Market Global Pulse Market Global Weight Loss and Obesity Management Market Global Opioids Market Global Thermal Imaging Cameras Market Global Flotation Reagents Market Middle East and Africa Dental Practice Management Software Market Global Veterinary Telehealth Market Global Automotive Open Differential Market Middle East and Africa Commercial Cleaning Equipment Market Global Demolition Robots Market Australia and New Zealand Concrete Admixture Market Middle East and Africa Infection Surveillance Solution Systems Market Global Chronic Kidney Disease Medication Market Global Video Surveillance as a Service Market Global Sailing Yatch Market

About Data Bridge Market Research:

An absolute way to forecast what the future holds is to comprehend the trend today!

Data Bridge Market Research set forth itself as an unconventional and neoteric market research and consulting firm with an unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process. Data Bridge is an aftermath of sheer wisdom and experience which was formulated and framed in the year 2015 in Pune.

Contact Us: Data Bridge Market Research US: +1 614 591 3140 UK: +44 845 154 9652 APAC : +653 1251 975 Email:- [email protected]

Tag

"

0 notes

Text

Application of Captive Load Testing in Aircraft Wing Load Analysis

In the aerospace industry, ensuring the structural integrity and safety of aircraft components is paramount. One critical aspect of this is the testing and validation of aircraft wings, which endure significant aerodynamic loads during flight. Among the various testing methodologies, Captive Load Testing (CTS Testing) has emerged as a crucial technique for accurately assessing wing load responses under controlled conditions. This article explores the application of Captive Load Testing in aircraft wing load analysis, highlighting its importance, methodology, benefits, and real-world applications.

Understanding Aircraft Wing Loads

Aircraft wings are primary load-bearing components designed to generate lift and support the weight of the aircraft during flight. Wings experience a wide range of loads, including aerodynamic forces, inertial loads during maneuvers, gust loads, and ground handling stresses. These loads vary dynamically and can cause complex stress distributions throughout the wing structure.

Accurate assessment of wing load response is essential to:

Ensure structural safety and reliability

Optimize wing design for weight and performance

Comply with certification standards set by aviation authorities

Predict the lifespan and maintenance needs of the wing

Traditional analytical and computational methods, such as finite element analysis (FEA), provide valuable insights, but physical testing remains indispensable for validation.

What is Captive Load Testing?

Captive Load Testing (CTS Testing) is a testing methodology used to apply controlled loads to a component or structure in a fixed setup, often referred to as "captive," because the test specimen is restrained or supported in a specific test fixture. Unlike free or full-scale flight testing where loads vary uncontrollably, captive load testing allows precise application and measurement of loads in a repeatable environment.

In the context of aircraft wings, captive load testing involves mounting a wing or wing section in a test rig where hydraulic actuators or mechanical devices apply loads that simulate aerodynamic forces experienced during flight. The wing is instrumented with strain gauges, displacement sensors, and other instrumentation to record its response.

Objectives of Captive Load Testing in Wing Load Analysis

The primary goals of captive load testing for aircraft wings include:

Validation of Design Assumptions: Verifying that the wing structure behaves as predicted by design models under simulated load conditions.

Structural Integrity Assessment: Identifying any weak points, stress concentrations, or potential failure modes.

Certification Support: Providing evidence to aviation authorities such as the FAA or EASA that the wing meets safety and durability requirements.

Damage Tolerance Evaluation: Understanding how cracks, corrosion, or fatigue affect load carrying capacity.

Material and Component Testing: Evaluating performance of composite materials, fasteners, and bonding under load.

The CTS Testing Setup for Aircraft Wings

A typical captive load testing setup for aircraft wings consists of:

Test Fixture or Rig: A large, robust frame designed to hold the wing securely in place while allowing controlled application of loads at various points.

Load Application System: Hydraulic actuators or servo-controlled mechanical devices that apply forces and moments to simulate aerodynamic and inertial loads.

Instrumentation: A network of strain gauges, displacement transducers, accelerometers, and sometimes acoustic emission sensors attached to critical areas of the wing to monitor structural response.

Data Acquisition System: High-speed data recorders and analysis software collect and process the sensor data for real-time monitoring and post-test evaluation.

Depending on the wing size and test objectives, captive load testing can be conducted on full-scale wings, subassemblies, or scaled-down models.

How Captive Load Testing is Conducted

The process of captive load testing on aircraft wings typically follows these steps:

1. Preparation and Instrumentation

The wing or wing section is prepared by installing sensors at predetermined locations based on structural analysis. Strain gauges measure surface strain, while displacement sensors track deflections.

2. Mounting

The wing is carefully mounted in the test rig, ensuring alignment and support points simulate real-world boundary conditions such as fuselage attachments.

3. Load Application

Using hydraulic actuators, loads are applied incrementally to simulate various flight conditions, including:

Static loads representing steady-state flight

Gust loads simulating atmospheric turbulence

Maneuver loads from sharp turns or sudden pitch changes

Each load case is applied under controlled conditions while continuously monitoring wing response.

4. Data Collection and Analysis

Sensor data is collected throughout the test, allowing engineers to observe strain distribution, deflections, and any signs of structural distress. This data is compared against predicted values from computational models.

5. Post-Test Inspection

After load application, the wing undergoes detailed inspections for cracks, delaminations, or other damage. Sometimes non-destructive testing methods like ultrasonic or X-ray inspection are used.

Benefits of Using Captive Load Testing in Wing Load Analysis

There are several advantages to incorporating captive load testing in the wing design and certification process:

Accuracy and Repeatability

CTS Testing provides a controlled environment where loads can be precisely applied and repeated. This reduces variability and allows detailed assessment of wing behavior under specific load cases.

Early Detection of Structural Issues

Captive load testing can reveal stress concentrations and potential failure points before full-scale flight testing, reducing risks and development costs.

Validation of Computational Models

Physical test data serves to validate and calibrate computational models such as finite element models, improving their predictive accuracy for future designs.

Supports Certification and Compliance

Regulatory agencies require evidence of structural safety. CTS Testing provides robust, traceable data to support airworthiness certification.

Testing of Repair and Modification Effects

After repairs or structural modifications, captive load testing can assess if the wing maintains its load carrying capability.

Challenges and Limitations

While Captive Load Testing offers numerous benefits, it also comes with challenges:

High Cost and Complexity: Building test rigs and conducting tests on large wings can be expensive and resource-intensive.

Scaling Issues: For very large wings, testing full scale may be impractical, requiring scaled models and extrapolation.

Boundary Condition Replication: Perfectly simulating in-flight constraints on the wing in a fixed test rig can be difficult.

Limited Load Cases: Some complex dynamic loads experienced in flight may be hard to replicate precisely.

Despite these challenges, captive load testing remains a cornerstone in structural testing for aviation.

Real-World Applications and Case Studies

Example 1: Boeing 787 Dreamliner Wing Testing

During the development of the Boeing 787, captive load testing played a critical role in validating the composite wing design. Engineers applied simulated flight loads to full-scale wings to measure strain and deflection, confirming that the novel materials and structure met design expectations.

Example 2: Airbus A350 Wing Load Validation

Airbus employed captive load testing extensively for the A350 wing, which uses advanced composite materials. The testing helped verify the wing’s ability to handle gust loads and ensured compliance with stringent certification standards.

Example 3: Military Fighter Aircraft

Military aircraft wings undergo rigorous CTS Testing to ensure they can withstand extreme maneuver loads. For example, the F-35 Lightning II wings were tested under captive load conditions to validate structural integrity before flight trials.

The Future of Captive Load Testing in Aviation

With advances in materials science, aerospace design, and sensor technology, captive load testing continues to evolve:

Integration with Digital Twins: Real-time data from CTS Testing feeds digital twin models for improved predictive maintenance and design optimization.

Enhanced Sensor Networks: Wireless and fiber optic sensors enable more detailed and distributed monitoring of wing structures.

Automated Test Systems: Robotics and AI help automate load application and data analysis, increasing efficiency and accuracy.

Composite and Hybrid Structures: As composites become dominant, CTS Testing adapts to characterize their unique failure modes and load responses.

Advances in Sensor Technology and Data Acquisition for Captive Load Testing

One of the key drivers behind the evolution of Captive Load Testing (CTS Testing) in aviation is the rapid advancement in sensor technology and data acquisition systems. Historically, wing load testing relied heavily on strain gauges and displacement sensors connected via wired systems, which had limitations in terms of sensor placement, wiring complexity, and data fidelity.

Fiber Optic Sensors

Fiber optic sensors have revolutionized structural health monitoring and load testing. These sensors are lightweight, immune to electromagnetic interference, and capable of multiplexing many sensing points along a single fiber. Technologies such as Fiber Bragg Gratings (FBGs) can measure strain, temperature, and vibration with high accuracy and spatial resolution.

In captive load testing, the integration of fiber optic sensors allows for:

High-density sensor arrays: Providing detailed strain maps across the wing surface.

Real-time monitoring: Continuous data streams enable immediate detection of anomalies or unexpected responses.

Long-term durability: Fiber optics are less susceptible to environmental degradation compared to traditional strain gauges.

The use of fiber optic sensing during CTS Testing thus improves the granularity and reliability of load measurements, enabling better insight into wing behavior under complex loading scenarios.

Wireless Sensor Networks

Wireless sensor networks (WSNs) are gaining traction in captive load testing due to their ease of deployment and flexibility. These systems eliminate cumbersome wiring, reduce test setup times, and facilitate sensor placement in hard-to-reach areas.

In CTS Testing of aircraft wings, WSNs can:

Enable rapid instrumentation of test articles.

Allow dynamic reconfiguration of sensor placement during testing.

Facilitate integration with drones or robotic platforms for automated inspections.

Challenges remain in ensuring reliable data transmission in noisy electromagnetic environments and managing power consumption, but ongoing improvements in low-power protocols and robust communication technologies are addressing these issues.

Enhanced Data Acquisition and Analysis

Modern data acquisition systems used in captive load testing feature high sampling rates, multi-channel synchronization, and integrated signal processing. Coupled with advanced software tools, these systems support:

Automated anomaly detection: Machine learning algorithms can flag unusual strain or displacement patterns.

Real-time visualization: Engineers can monitor test progress and structural responses instantaneously.

Data fusion: Combining inputs from multiple sensor types (strain, acceleration, acoustic emission) for comprehensive analysis.

These advances are crucial for maximizing the value of CTS Testing by extracting detailed structural behavior information, reducing test durations, and enhancing safety margins.

Integration of Captive Load Testing with Digital Twin Technologies

Digital twin technology represents one of the most promising frontiers in aerospace engineering. A digital twin is a dynamic, virtual representation of a physical system that continuously integrates sensor data and simulation models to provide real-time insights into system performance and health.

Role of CTS Testing in Building Digital Twins

Captive load testing generates a rich dataset that forms the foundation for accurate digital twins of aircraft wings. Key contributions include:

Model Validation: Experimental strain and displacement data from CTS Testing validate and calibrate finite element models and other simulation tools.

Damage Modeling: CTS Testing under different load conditions reveals how damage initiates and propagates, informing damage tolerance models integrated into the digital twin.

Operational Scenarios: Realistic load cases applied during captive testing ensure the digital twin accurately reflects in-service conditions.

Once a digital twin is established, continuous sensor data from in-flight monitoring can update the model, enabling predictive maintenance and optimizing aircraft performance.

Benefits for Maintenance and Lifecycle Management

The integration of CTS Testing data into digital twins facilitates:

Condition-based Maintenance: Predicting when components require inspection or replacement before failure occurs.

Extended Service Life: By understanding actual load histories, wings can be certified for longer operational periods safely.

Design Improvement Feedback: Insights from digital twins enable iterative improvements in wing design and materials.

This synergy between captive load testing and digital twin technology is poised to transform aircraft lifecycle management from reactive to proactive strategies.

Advanced Materials and Their Impact on Captive Load Testing

The aviation industry is progressively adopting advanced materials such as carbon fiber reinforced polymers (CFRPs), titanium alloys, and hybrid composites in wing structures. These materials offer high strength-to-weight ratios but introduce new complexities for load testing.

Challenges with Composite Materials

Composites exhibit anisotropic behavior and complex failure mechanisms like delamination, fiber breakage, and matrix cracking. Unlike traditional aluminum alloys, composite damage is often internal and difficult to detect visually.

Captive load testing must therefore:

Use more sophisticated sensor arrays capable of detecting subtle changes within the material.

Apply multi-axial loading conditions to simulate real stress states.

Incorporate non-destructive evaluation techniques such as ultrasonic scanning or thermography alongside CTS Testing.

Role of CTS Testing in Composite Wing Certification

Regulatory agencies require thorough testing to certify composite wings. CTS Testing provides:

Validation of structural performance under various load spectra.

Data on fatigue behavior and damage progression.

Evidence for damage tolerance and fail-safe design concepts.

Effective captive load testing ensures composites meet stringent safety standards while optimizing weight savings.

Multidisciplinary Approaches Combining CTS Testing

Aircraft wing load analysis is inherently multidisciplinary, involving aerodynamics, structures, materials science, and controls engineering. Modern captive load testing integrates these domains through:

Aeroelastic Testing

Aeroelasticity examines the interaction between aerodynamic forces and structural deformation. CTS Testing setups increasingly incorporate wind tunnels or flow simulation combined with load application to capture aeroelastic effects such as flutter or divergence.

By applying captive loads while exposing the wing to airflow, engineers can:

Assess stability margins under coupled aerodynamic and structural loads.

Detect flutter onset and suppression techniques.

Validate computational aeroelastic models.

Thermal and Environmental Effects

Wings experience varying temperatures and environmental conditions in flight that affect material properties and load response. Advanced CTS Testing simulates these conditions by:

Heating or cooling the wing during load application.

Introducing humidity or corrosive atmospheres to study degradation effects.

Such combined environmental and load testing ensures wing designs are robust across the full range of operational conditions.

Industry Trends Driving Future CTS Testing Innovations

Automation and Robotics

The complexity and scale of captive load testing are pushing the industry towards greater automation. Robots and automated actuators can:

Precisely apply complex load profiles.

Handle heavy and awkward wing components safely.

Conduct repetitive test sequences with minimal human intervention.

Automation increases efficiency, reduces human error, and improves data consistency.

Artificial Intelligence and Machine Learning

AI algorithms analyze vast amounts of CTS Testing data to:

Detect early signs of structural anomalies.

Optimize load application sequences for thorough testing.

Predict remaining useful life based on load-response patterns.

Machine learning enhances decision-making and enables more intelligent testing regimes.

Virtual and Augmented Reality

Virtual reality (VR) and augmented reality (AR) tools allow engineers to visualize strain distributions and stress patterns in immersive environments during captive load testing. This improves understanding and supports collaborative problem-solving.

Economic and Environmental Impacts of Improved CTS Testing

Cost Reduction

Improved CTS Testing leads to:

Reduced development time: Faster identification of structural issues means quicker design iterations.

Lower certification costs: More precise testing data satisfies regulatory requirements efficiently.

Extended aircraft service life: Better damage tolerance reduces premature retirements and costly repairs.

Environmental Benefits

By enabling lighter and more durable wing designs through precise load characterization, CTS Testing contributes to:

Fuel efficiency: Weight savings translate to reduced fuel consumption and emissions.

Sustainable aircraft design: Optimized structures require fewer raw materials and generate less waste during manufacturing.

Summary

The application of Captive Load Testing in aircraft wing load analysis is evolving rapidly with advances in sensor technology, digital integration, materials science, and automation. CTS Testing remains essential for ensuring the safety, performance, and longevity of aircraft wings, while also supporting innovative design and certification processes.

As aviation pushes towards more efficient, lightweight, and sustainable aircraft, captive load testing will be at the forefront—providing the critical data and validation needed to make these advances a reality.

0 notes

Text

Global Distributed Fiber Optic Sensor Market to Hit $1.98 Billion by 2032

Distributed Fiber Optic Sensor (DFOS) Market Analysis:

The global Distributed Fibre Optic Sensing (DFOS) Market size was valued at US$ 1.42 billion in 2024 and is projected to reach US$ 2.71 billion by 2032, at a CAGR of 9.6% during the forecast period 2025-2032

Distributed Fiber Optic Sensor (DFOS) Market Overview

Distributed sensing technology enables continuous, real-time measurements of the entire length of the fiber optic cable.Unlike traditional sensors, which rely on discrete sensors measured at predetermined points, distributed sensing does not rely on manufactured sensors but USES optical fibers. Distributed fiber optic sensor (DFOS) is an ideal choice for monitoring critical infrastructure or facilities.These sensors are small in size, low in cost, impervious to electromagnetic interference, and mechanically and chemically compatible with most building materials, making them ideal for building very large monitoring networks.Distributed optical fiber sensor (DFOS) is commonly used to measure parameters in real time and is difficult to obtain at high resolution over long distances.This limitation can be overcome by using distributed sensors. Distributed optical fiber sensing system usually consists of laser light source, sensing optical fiber (cable) and detection unit. It is an automatic monitoring system.The measurement is based on the principle of backscattering of light transmitted in the optical fiber.Into a certain energy in the optical fiber and the width of laser pulse, it while they are in the optical fiber transmission to the scattering light, after the creation of the state of light scattering in optical fiber damage and the influence of the change, will not be back scattering of light after WDM, detection, demodulation, into the signal is real-time signal processing system can be displayed, and consists of light waves in optical fiber transmission speed and back light echo time for these information.The distributed optical fiber sensing (DFOS) counted in this report only includes the host system, not the sensing optical fiber (cable) and display equipment.

Distributed Fiber Optic Sensors (DFOS) are advanced sensing systems that utilize fiber optic cables to detect changes in temperature, strain, acoustics, and other environmental variables along the entire length of the fiber. These sensors are widely used in industries like oil & gas, civil engineering, power, and security monitoring due to their high sensitivity, real-time monitoring capabilities, and durability in harsh environments.

Key Players in the Global DFOS Market

The global DFOS market is moderately concentrated, with the top players holding significant shares. Leading companies include:

Schlumberger

Halliburton

Baker Hughes

These top three players together account for over 30% of the global market share, showcasing strong technological leadership and industry experience.

Regional Production Insights

North America: Dominates the market with over 40% share, attributed to a strong presence in the oil & gas industry and advanced technological infrastructure.

China: Holds approximately 30% of the global production, driven by rapid industrialization and infrastructure development.

Europe: Accounts for about 15% of global output, supported by growth in energy and construction sectors.

Market Segmentation by Type

DTS (Distributed Temperature Sensing): Holds the largest market share at approximately 55%, driven by its wide adoption in temperature-critical applications such as downhole monitoring and pipeline leak detection.

Other types include DAS (Distributed Acoustic Sensing) and DSS (Distributed Strain Sensing).

Market Segmentation by Application

Petroleum and Petrochemical: Dominates the application segment with a market share of over 45%, owing to its crucial role in wellbore monitoring, reservoir characterization, and pipeline management.

Other application areas:

Power & utility

Civil engineering (bridges, tunnels)

Safety and security (perimeter and intrusion detection)

Transportation infrastructure

We have surveyed the Distributed Fiber Optic Sensor (DFOS) manufacturers, suppliers, distributors, and industry experts on this industry, involving the sales, revenue, demand, price change, product type, recent development and plan, industry trends, drivers, challenges, obstacles, and potential risks This report aims to provide a comprehensive presentation of the global market for Distributed Fiber Optic Sensor (DFOS), with both quantitative and qualitative analysis, to help readers develop business/growth strategies, assess the market competitive situation, analyze their position in the current marketplace, and make informed business decisions regarding Distributed Fiber Optic Sensor (DFOS). This report contains market size and forecasts of Distributed Fiber Optic Sensor (DFOS) in global, including the following market information:

Global Distributed Fiber Optic Sensor (DFOS) market revenue, 2020-2025, 2026-2031, ($ millions)

Global Distributed Fiber Optic Sensor (DFOS) market sales, 2020-2025, 2026-2031, (Units)

Global top five Distributed Fiber Optic Sensor (DFOS) companies in 2024 (%)

Distributed Fiber Optic Sensor (DFOS) Key Market Trends :

Growing Adoption in Oil & Gas Industry DFOS is increasingly used in petroleum and petrochemical sectors for real-time well monitoring and pipeline inspection due to its reliability and long-distance sensing capabilities.