#fuel consumption monitoring software

Explore tagged Tumblr posts

Text

What is Enterprise Fleet Management?

As is revealed in today’s world business environment, any organization must manage its resources appropriately. Thus, for companies and firms having major operations related to transportation and logistics, it becomes even more essential to manage their fleets.

Now, let’s start with the basics: what does enterprise fleet management mean? Now let’s discuss this idea and figure out how it can be of great benefit to the business processes.

Understanding what is Enterprise Fleet Management

Fleet management within an enterprise could be described as a strategic approach to managing and supervising such a company's vehicle fleet. The areas include its acquisition and maintenance, driver and vehicle management, and laws governing the automobile industry. Fleet management is prospective to optimize the operating costs and enhance the safety and productivity of both fleets and their drivers.

In an enterprise environment, fleet management goes beyond tracking the vehicles; it is more about getting improved ways of running organizations. Fleet management is important irrespective of whether it involves delivery vans, trucks, or even corporate cars if the business owns a set of cars for business use.

The outcome highlights the fundamental issues of fleet management.

Vehicle Acquisition and Disposal: Picking the correct car for your fleet, beginning from procurement to the time of disposal.

Maintenance and Repair: Managing to schedule vehicles for maintenance and repairs regularly to make sure that they are in good working condition to reduce time loss.

Fuel Management: Fuel efficiency management by controlling consumption and considering these to minimize fuel expenses by using fuel-efficient driving techniques and other energy resources.

Driver Management: Incorporating training and supervision of drivers as well as planning meals nt to support safety, compliance, and efficiency among the drivers.

Compliance and Risk Management: The safety of all the used vehicles as well as the used drivers with brutal and international requirements and managing of risk exposures of operating fleets.

Here we will discuss the concept of Fleet Management Software. Inefficiently managing all these components, many businesses turn to the use of fleet management software. This is because it acts as a platform for accessing any information regarding the fleet, including real-time data and automated operations of the fleet.

Key Features of Fleet Management Software

GPS Tracking: Precise vehicle location in real-time to increase efficiency and controllers.

Maintenance Scheduling: Schedule reminders in case of preventive maintenance and repairs to avoid ‘bottlenecks Management: Proper equipment that tracks fuel usage and gives an indication of wasteful activities.

Compliance Management: Material properties garages need to comply with set safety measures as well as regulatory requirements.

Driver Performance Monitoring: Measures to monitor and measure drivers’s performance, detect their training requirements, and incentivize them over safe behavior on roads.

Why Enterprise Fleet Management is So Important

To large companies, fleet management is not only limited to planning on how to ensure that vehicles are running. It’s about being able to harness data and technology in a way that will put you ahead of the competition. Effective management of fleets is known to have numerous benefits, such as cutting costs, satisfying customers, and reducing risks involving drivers and cars, among others.

However, due to emerging issues such as global warming, companies are now focusing on the use of fleets to be environmentally friendly. This is done through the optimization of routes, timely maintenance of vehicles, and training of the drivers to ensure they are conscious of the impact they make on the environment.

Being a web-based service, the most advantageous aspect related to an FMS or a Fleet Management Software Development Service is that it can be easily and effectively utilized across the corporate fleet range.

This has led to the increasing need for the development of fleet management software to be able to meet the expanding market need. Custom software, as the name suggests, is designed to improve organizational operations to suit a company’s needs, making it more flexible than packaged software.

A fleet management software development service typically includes

Consultation and Needs Assessment: Ah, awareness of the particular requirements and objectives of your fleet. You need to hire a professional fleet management software development company.

Custom Software Development: Constructing a custom fit that incorporates into the complex structures of the organization and fits the needs of the organization perfectly.

Integration with IoT Devices: The use of Internet of Things (IoT) devices such as GPS trackers or sensors to input real-time information and data.

Ongoing Support and Maintenance: Needed to make sure the software will continue to include all the features and incorporate the latest technologies and that it will cover all current needs of the business.

Conclusion

Okay, then, Fleet management is a system that encompasses all activities that involve control of a company’s fleet of vehicles with the use of the latest technologies in software and quality practices. Fleet management is not only a good idea but a necessity for any business that depends on transportation, where proper management of the company’s fleet is critical to achieving success.

Let it be a handful of vehicles or a multitude, the appropriate strategy in fleet management as enhanced by software changes the equation, provides steps towards optimizing your operations, lowers costs, and enhances the performance of an organization. The fast advancement of technology means that the means and ways used in the implementation of the strategies by the f managers are ever-changing and therefore a very promising industry to follow.

#business growth#fleet management#fleet maintenance#enterprise software#enterprise application development#business solutions#software#trending#viralpost#viral trends

2 notes

·

View notes

Text

SAP's Role in Building Smart Cities for a Brighter Tomorrow

The globe is quickly urbanizing, and cities face the task of effectively managing resources and services while enhancing citizens' quality of life. Smart cities are developing as the solution to these urban difficulties, fueled by technology and data-driven solutions. In this blog, we'll look at how SAP, a global leader in enterprise software, is transforming cities into smart, sustainable, and networked centres of innovation and advancement.

Deciphering Smart Cities

Before we get into SAP's smart solutions for smart cities contributions, we need define what we mean by "smart cities." These cities use digital technology, data analytics, IoT (Internet of Things), AI (Artificial Intelligence), and cloud computing to improve transportation, energy use, waste management, public safety, and other areas of city life. The main objective is to build urban settings that are responsive, adaptive, and environmentally friendly.

SAP's Impact on Smart Cities

SAP's extensive experience in enterprise software and data management positions it as a key player in the smart city revolution. Here's a closer look at how SAP smart solutions for smart cities is shaping the future of cities:

Data Integration: Smart cities generate vast amounts of data from diverse sources, including sensors, mobile apps, and government systems. SAP's data integration and analytics tools empower cities to efficiently collect, process, and analyze this data in real time. Such smart solutions for smart cities insights prove invaluable for informed decision-making on resource allocation, infrastructure maintenance, and service optimization.

IoT Empowerment: IoT forms the bedrock of smart cities, and SAP's IoT solutions facilitate the seamless connection and management of countless devices and sensors. From smart traffic lights to waste bins, this connectivity allows real-time monitoring and control, enhancing everything from traffic management to environmental sustainability.

Predictive Analytics: SAP's predictive analytics tools enable cities to foresee trends and challenges. For instance, predictive maintenance identifies when critical infrastructure, like bridges or water pipes, may need attention before a major issue arises, saving both time and resources.

Citizen Engagement: Smart cities thrive on citizen involvement in decision-making. SAP provides platforms for citizen engagement, such as mobile apps and online portals, where residents can report issues, take part in surveys, and access information on city services and projects.

Energy Efficiency: Energy management is a top priority for smart cities, and SAP's smart solutions for smart cities help cities monitor and optimize energy consumption in public buildings, street lighting, and other municipal facilities. This smart solutions for smart cities reduces costs and environmental impact.

Conclusion

SAP's essential role in smart city development is assisting cities throughout the world in addressing the complex issues of rising urbanization and resource management. Cities are becoming more efficient, sustainable, and responsive to their inhabitants' demands by leveraging SAP's expertise in data management, IoT, and analytics. The influence of SAP smart business on the future of smart cities is poised to grow as technology progresses, providing more livable, connected, and resilient urban settings for future generations.

3 notes

·

View notes

Text

DG Service | DG Service in Gurgaon | Best DG genset AMC in Gurgaon - PAL Svam

DG Dual Fuel Kit

DG dual fuel kit is one of the most cost-effective innovations in the generator industry. By allowing diesel generators to operate on a blend of diesel and alternative fuels such as CNG or natural gas, this kit drastically reduces diesel consumption.

Genset Battery

Genset Battery is essential for initiating your generator instantly when a power outage strikes. Whether it's for a small office or a large industrial unit, a dependable battery ensures immediate activation.

Pulse Battery

Pulse Battery is ideal for standby generators that remain idle but must start instantly. Its pulse charging technology prevents sulfation and extends battery life, making it perfect for critical applications like hospitals and telecom towers.

Genset Service

Genset Service is essential for keeping your generator in top working condition. It involves key maintenance tasks like oil changes, coolant level checks, and filter replacements.

Genset Service in Gurgaon

Genset Service in Gurgaon provides NCR businesses with fast, reliable, and region-specific generator maintenance, ensuring quick response, emergency support, and consistent servicing for uninterrupted power.

Dual Fuel Conversion Kit

Dual fuel conversion kit is a smart solution for businesses seeking energy savings without investing in a brand-new generator. This kit modifies your current diesel generator to run partially on natural gas, offering a cleaner and more cost-effective alternative.

Best DG Genset AMC in Gurgaon

Best DG Genset AMC in Gurgaon offers businesses complete peace of mind with all-inclusive maintenance plans. These Annual Maintenance Contracts cover preventive checks, emergency repairs, load testing, control panel diagnostics, and predictive monitoring.

Cummins Service

Cummins Service is crucial for maintaining the performance and reliability of your Cummins generator. Authorized service centers provide expert, brand-specific care, including software updates and OEM part replacements.

Cummins DG Service in Gurgaon

Cummins DG Service in Gurgaon offers expert local support with trained technicians for maintenance, load management, and emergency repairs, ensuring fast response and minimal downtime for reliable power backup.

DG Service

DG Service ensures your generator is always ready to deliver when needed. It includes everything from routine maintenance to breakdown repair, fuel system tuning, alternator servicing, and control panel inspection.

DG Service in Gurgaon

DG Service in Gurgaon provides a competitive advantage to local businesses by delivering industry-specific solutions and prompt support. With expert engineers, readily available spare parts, and fast response times, these services ensure your operations continue smoothly without interruptions.

Related Tags

DG dual fuel kit, Genset Battery, Pulse Battery, Genset Service, Genset Service in Gurgaon, Dual fuel conversion kit, Best DG genset AMC in Gurgaon, Cummins Service, Cummins DG service in Gurgaon, DG Service, DG Service in Gurgaon

#DG dual fuel kit#Genset Battery#Pulse Battery#Genset Service#Genset Service in Gurgaon#Dual fuel conversion kit#Best DG genset AMC in Gurgaon#Cummins Service#Cummins DG service in Gurgaon#DG Service#DG Service in Gurgaon

0 notes

Text

Black Box's GPS-Based Waste Management Fleet Software in India

Waste management is an essential requirement in the present-day urbanising India. As the cities have grown in population density and the number of services offered by the municipality, the task of managing the garbage collection fleets has become more complicated than ever before. Local governing systems and waste collection agents encounter many operational challenges--in the form of inefficiencies in routing, loss of fuel, and the issue of maintenance and regulatory compliance. That is when Waste Management Fleet Management Systems steps in.

Businesses such as BlackBox GPS, which provides Waste Management Fleet Software solutions as the leading firm in India, are assisting towns in making their waste collection process efficient by using smart technology. Such solutions have been used to handle complete fleets in real-time, safety, minimisation of costs and simplification of overall operations.

Key Benefits of Waste Management Fleet Systems

Advanced Waste Management Fleet Tracking Systems deliver elegant solutions to universal problems in waste collecting- maximising efficiency, cutting expenses and increasing transparency in the daily operations.

Optimisation of Routes: Intelligent routing decreases fuel consumption, heightens pickups and minimises wasted bins.

Vehicle Maintenance: Breakdowns are avoided, and vehicle lifetimes are prolonged through Predictive alerts.

Fuel Monitoring: Monitors to improve fuel use and minimise wastage, block fuel theft.

Transparency & Accountability: Tracks bin picks and adherence to the route, and driver behaviour.

Regulatory Compliance: Timely inspection, checking emissions, and observing safety rules.

Data Management: Collects all information in one place, helping to make better decisions and operational plans.

Challenges in Waste Management Fleet Operations

In the absence of digital solutions, there is a lack of waste fleet operations as follows:

Challenge in monitoring several vehicles

Real-time visibility deficiency

Inadequate route management

Reckless driving and late services

The frequent breakdowns and consumption of fuel

Non-compliance Failure

Poor reporting of data and decision-making

The problems lead to cost increase, operational delays and customer dissatisfaction.

Comprehensive Solution by BlackBox GPS

BlackBox GPS has the most reliable waste management tracking platform in India. It integrates real-time GPS tracking and monitoring, fuel analytics, route planning, predictive maintenance with driver monitoring. It does not require separate anti-theft equipment or programs, the built-in BlackBox system can provide both safety and schedule and analytics services.

Key benefits include:

Live tracking of trucks with zone-based alerts

Notifications when vehicles overstay at collection points

Driver behaviour monitoring to prevent rash driving

Fuel usage tracking to reduce costs and detect theft

Predictive maintenance to avoid service delays

Data-driven dashboards for efficient fleet planning

BlackBox GPS - Transforming Waste Management in India with Smart Fleet Tracking Solutions

Established in 2008, BlackBox GPS Technology Pvt Ltd is a leading provider of GPS-based fleet management solutions for waste management in India. We are one of the first companies to receive AIS 140 IRNSS certification and partner with major telecom providers like Google, Airtel, BSNL, and Jio to ensure seamless connectivity. Our company’s real-time tracking and data-driven insights help optimise routes, cut fuel costs, reduce delays, and streamline waste collection for municipalities and private operators.

Certified with AIS 140, ARAI, ISO 9001, 14001, 27001 & IATF 16949.

Trusted by 10,000+ clients across India.

Partnered with ISRO, DHBVN, Haryana & Punjab Police.

Early adopter of GPS fleet tech for Smart City & Swachh Bharat.

Provides nationwide support and personalised service.

In-house hardware and software development for full control.

0 notes

Text

How Fleet Logistics Support Can Transform Operations

In today’s hyper-competitive and fast-paced world, businesses across industries are increasingly realizing the value of streamlined logistics operations. Whether it’s a logistics firm, a delivery company, or an enterprise with a vast field service network, fleet logistics support is no longer just a back-end function—it is the engine that drives success.

But how can fleet logistics support improve operations in a measurable, meaningful way? The answer lies in a combination of technology, planning, and strategic execution that enables real-time visibility, cost-effectiveness, and performance optimization.

Understanding Fleet Logistics Support

Fleet Logistics Support refers to the set of services and systems used to manage the movement, maintenance, and utilization of a company’s fleet—be it trucks, vans, ships, or aircraft. This support system ensures that each vehicle or asset is performing at peak efficiency, and that logistics operations are carried out with minimal delays or disruptions.

Key components of fleet logistics support include:

Vehicle tracking and telematics

Route optimization software

Predictive maintenance and diagnostics

Fuel management systems

Driver behavior monitoring and safety protocols

Inventory and supply chain integration

Boosting Efficiency and Reducing Costs

Fleet logistics support helps businesses identify inefficiencies that may otherwise go unnoticed. By using real-time GPS and telematics data, companies can monitor vehicle usage patterns, optimize routes, and reduce unnecessary mileage. This directly translates to lower fuel costs, reduced wear and tear, and less time spent idling or rerouting.

For instance, a delivery company can shave off hours of drive time each week by simply rerouting vehicles to avoid traffic congestion using live data. Similarly, predictive maintenance alerts can prevent costly vehicle breakdowns by identifying issues before they become problems.

Enhancing Decision-Making with Real-Time Insights

Fleet managers can access a central dashboard with data on vehicle location, driver behavior, and delivery schedules. This real-time visibility allows for faster, better-informed decisions—whether it’s rerouting a truck due to weather disruptions or reallocating vehicles during peak demand.

The integration of AI and data analytics in fleet logistics support systems helps forecast demand, allocate resources intelligently, and balance loads across the network. This leads to smarter scheduling, better utilization of fleet assets, and an overall improvement in service delivery.

Strengthening Safety and Compliance

Fleet logistics support plays a critical role in ensuring driver and vehicle safety. With telematics and sensor-based monitoring, fleet managers can track driver behavior such as harsh braking, overspeeding, or sudden turns. This data not only promotes a culture of accountability but also allows for driver training and improvement programs.

Additionally, fleet systems can keep track of regulatory compliance, such as vehicle inspection timelines, emissions standards, and licensing. This helps businesses avoid fines, improve safety scores, and maintain a trustworthy brand image.

Supporting Sustainability and Green Initiatives

As environmental consciousness grows, businesses are being held accountable for their carbon footprint. Fleet logistics support empowers companies to take measurable steps toward sustainability.

By optimizing routes, reducing fuel consumption, and embracing electric or hybrid fleets, organizations can significantly reduce emissions. Many modern fleet systems offer carbon tracking reports, which help in aligning with corporate sustainability goals and ESG (Environmental, Social, and Governance) benchmarks.

Enabling Scalability and Business Growth

Perhaps one of the most strategic advantages of fleet logistics support is its role in scaling operations. As a business grows, so does its logistics complexity. Fleet logistics systems offer the scalability needed to manage expanding fleets, increased order volumes, and more complex delivery networks without compromising service quality.

With cloud-based fleet solutions, even small to medium-sized businesses can access enterprise-grade tools that automate routine tasks, reduce human error, and provide robust analytics for strategic planning.

Real-World Applications Across Industries

Retail & E-commerce: Fleet logistics ensures timely deliveries, efficient reverse logistics, and improved last-mile performance.

Construction: Heavy equipment and materials are tracked and scheduled for optimal usage, reducing project delays.

Healthcare & Pharma: Temperature-controlled fleet systems ensure sensitive deliveries like vaccines and medicines are safely transported.

Oil & Gas: Fleet logistics enables efficient transport of hazardous materials while ensuring strict regulatory compliance.

Conclusion: The Road Ahead

Fleet logistics support is not a one-time fix—it’s a long-term investment in efficiency, agility, and operational excellence. Businesses that adopt advanced fleet solutions gain a competitive edge through enhanced customer satisfaction, cost savings, and future-ready infrastructure.

As the world shifts toward automation and data-driven logistics, companies must ask not if, but how they can implement fleet logistics support to transform their operations and thrive in a challenging economic landscape.

0 notes

Text

Maritime Software Industry Set to Transform with Real-Time Fleet Capabilities

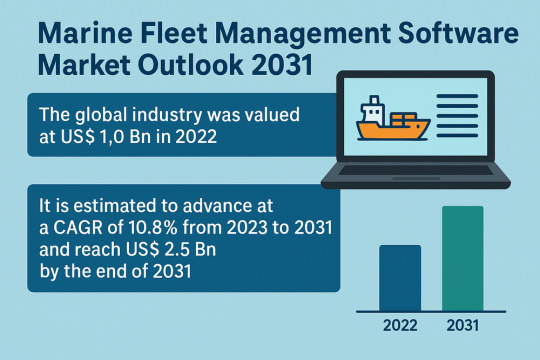

The global marine fleet management software market is poised for robust growth, expected to rise from USD 1.0 Bn in 2022 to USD 2.5 Bn by the end of 2031, expanding at a healthy CAGR of 10.8%. This dynamic growth is fueled by the increasing digitalization of the maritime industry, the growing demand for real-time fleet insights, and a sharp focus on operational efficiency, safety, and compliance.

Marine fleet management software plays a vital role in optimizing vessel operations, streamlining maintenance, managing crew and inventory, and ensuring regulatory compliance. As maritime trade continues to expand, the need for centralized, cloud-based fleet management tools is becoming increasingly critical.

Market Drivers & Trends

One of the key market drivers is the global push for digital transformation in the maritime sector. Fleet operators are seeking intelligent software platforms that integrate real-time monitoring, performance analysis, predictive maintenance, and regulatory compliance all in one solution.

Rising fuel costs and stringent environmental regulations are pushing companies to adopt fleet management solutions that offer optimization tools to reduce fuel consumption and carbon emissions. Furthermore, the maritime industry's commitment to sustainability and operational transparency is accelerating the adoption of energy-efficient and smart digital systems.

Latest Market Trends

Several trends are shaping the future of the marine fleet management software market:

Cloud-based Deployments: There is a notable shift from on-premise solutions to cloud-based platforms, providing scalability, mobility, and cost efficiency.

AI & Data Analytics: Integration of artificial intelligence and big data analytics to predict equipment failures, optimize routing, and assess performance.

Sustainability Integration: Tools that monitor emissions and fuel usage are increasingly in demand to comply with decarbonization goals.

Customization & Modularity: Solution providers are offering customizable modules to suit specific business needs, from cargo tracking to crew scheduling.

Key Players and Industry Leaders

The market features a competitive landscape with the presence of established software developers and emerging innovators. Noteworthy players include:

ABS Group of Companies, Inc.

BASS Software Ltd.

ConnectShip, Inc.

DNV AS

Hanseaticsoft GmbH

JiBe ERP

Kongsberg Gruppen ASA

MariApps Marine Solutions Pte Ltd

PRIME Marine

Micromarin

Norcomms

SBN Technologies Pvt. Ltd.

seaspeedmarine

SERTICA

Shipamax Ltd.

Shipnet

Softcom Solutions

SpecTec

Star Information System AS

Tero Marine (Ocean Technologies Group)

Veson Nautical

These companies are investing heavily in R&D to deliver next-generation platforms tailored to the evolving needs of global fleet operators.

Recent Developments

JiBe ERP, in April 2023, partnered with Claus Peter Offen, implementing JiBe’s ERP system across 34 container vessels to enhance digital fleet operations.

Hanseaticsoft GmbH, in March 2023, collaborated with Exploris SAS, enabling the latter to adopt its integrated Cloud Fleet Manager (CFM) system for better operational control.

Such strategic alliances signify the rising emphasis on modernizing marine operations through cutting-edge software integration.

Access key findings and insights from our Report in this sample - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=79029

Market Opportunities

The growing need for smart shipping and operational efficiency opens new avenues for solution providers:

Custom Software Development: Maritime software vendors are focusing on tailored solutions to meet client-specific demands, including voyage planning, compliance, and predictive maintenance.

SME Adoption: Small and medium-sized shipping firms are increasingly leveraging cloud-based fleet management tools, thanks to their affordability and ease of deployment.

Carbon Footprint Reduction Tools: With decarbonization at the forefront, tools that support emission tracking and optimization present a critical growth opportunity.

Future Outlook

The outlook for the marine fleet management software market remains highly promising. The increase in maritime trade, aging fleets, rising fuel costs, and demand for safer, more compliant, and energy-efficient vessel operations will continue to fuel demand for digital solutions.

The market will likely witness increased integration with IoT, machine learning, and blockchain technologies in the near future. Stakeholders focusing on these advanced capabilities will position themselves as frontrunners in a competitive and rapidly evolving space.

Market Segmentation

By Component:

Software Modules: Safety Management, Procurement, Navigation & Tracking, Compliance, Accounting, Document Management, and more.

Services: Training & Consulting, Integration & Implementation, Support & Maintenance

By Deployment Type:

Premise-based Deployment

Cloud Deployment

By End-user:

Ports & Terminals

Shipping Industries

Maritime Freight Forwarders

Regional Insights

North America dominates the global market, driven by technological readiness, robust port infrastructure, and early adoption of digital tools.

Asia Pacific is projected to register the highest CAGR through 2031. The presence of some of the world's busiest ports, including those in China, Singapore, and India, combined with growing maritime trade, makes this region a hotbed for marine software deployment.

Europe also represents a significant market, especially in countries with stringent maritime compliance standards and sustainability initiatives.

Why Buy This Report?

In-depth analysis of market dynamics, segmentation, and growth prospects

Insights into leading players’ strategies and innovations

Comprehensive regional and country-level data

Recent developments and strategic partnerships

Exclusive forecasts for the marine fleet management software market through 2031

Frequently Asked Questions

1. What is the projected market size for marine fleet management software by 2031? The market is forecast to reach US$ 2.5 Bn by 2031, expanding at a CAGR of 10.8% from 2023.

2. What is driving growth in this market? Key drivers include digitalization of the maritime sector, demand for operational efficiency, environmental compliance, and rise in maritime trade.

3. Which regions offer the most promising opportunities? Asia Pacific is set to grow at the fastest pace due to expanding port infrastructure and high-volume trade. North America remains a technological leader.

4. Who are the key players in the market? Prominent companies include DNV AS, ABS Group, JiBe ERP, Hanseaticsoft, MariApps, and Kongsberg Gruppen ASA.

5. What are the current trends shaping the market? Cloud deployment, AI integration, customized software, and sustainability-focused fleet management tools are major trends.

Explore Latest Research Reports by Transparency Market Research: AI in Healthcare Market: https://www.transparencymarketresearch.com/ai-in-healthcare-market.html

Edge Computing in IoT Market: https://www.transparencymarketresearch.com/edge-computing-in-iot-market.html

Digital Risk Management Market: https://www.transparencymarketresearch.com/digital-risk-management-market.html

AI (Artificial Intelligence) in Medical Imaging Market: https://www.transparencymarketresearch.com/ai-in-medical-imaging-market.html

About Transparency Market Research Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information. Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports. Contact: Transparency Market Research Inc. CORPORATE HEADQUARTER DOWNTOWN, 1000 N. West Street, Suite 1200, Wilmington, Delaware 19801 USA Tel: +1-518-618-1030 USA - Canada Toll Free: 866-552-3453 Website: https://www.transparencymarketresearch.com Email: [email protected]

0 notes

Text

Integrating Real-Time Control Systems for Manufacturing with Embedded Edge Intelligence

The industrial manufacturing landscape is undergoing a profound transformation. Increasing demands for efficiency, customization, and agility are prompting manufacturers to rethink how they manage operations and control systems. Central to this evolution is the integration of real-time control systems with embedded edge intelligence. These integrations represent more than just a technological upgrade; they symbolize a shift toward smarter, faster, and more adaptive manufacturing environments.

Real-time control systems have been the backbone of manufacturing automation for decades. They ensure machines operate within defined parameters, maintain synchronization across processes, and prevent errors that could lead to downtime or defective products. Traditionally, these systems relied on centralized architectures and predetermined logic. However, with the rise of edge computing, manufacturers are now able to decentralize decision-making and enable more nuanced, context-aware responses directly at the site of data generation.

This article explores the symbiosis of real-time control and embedded edge computing in manufacturing. It examines how these technologies work together, the benefits and challenges of implementation, and the future prospects of this integrated approach. As the manufacturing sector embraces Industry 4.0, the fusion of edge intelligence with control systems is poised to redefine operational excellence.

Understanding Real-Time Control Systems in Manufacturing

Real-time control systems are essential for maintaining the integrity and efficiency of industrial operations. These systems continuously monitor and adjust manufacturing processes to ensure optimal performance. They are designed to respond to inputs and changes within milliseconds, making them indispensable in environments where timing is critical, such as robotic assembly lines or chemical mixing.

Typically, real-time control systems involve a combination of sensors, actuators, and controllers. Sensors gather data on variables like temperature, pressure, or position. Controllers process this data and make decisions based on pre-set algorithms, which then drive actuators to perform necessary adjustments. This closed-loop control ensures that any deviation from the desired outcome is immediately corrected.

The reliability of these systems is paramount. Any delay or failure in processing can result in costly downtime or product defects. For this reason, traditional real-time control architectures have been centralized and rigid, favoring stability over flexibility. However, as manufacturing processes become more complex and variable, the limitations of such centralized systems become apparent.

Manufacturers are now looking to enhance these systems with local, intelligent processing capabilities. By bringing computational power closer to the machinery, they can enable real-time analytics, adaptive control strategies, and quicker response times. This is where embedded edge intelligence becomes a game-changer.

The Rise of Embedded Edge Intelligence

Embedded edge intelligence refers to the capability of computing devices to process data locally, at or near the source of data generation, without relying on centralized cloud systems. In the context of manufacturing, this means that machines and control systems can independently analyze sensor inputs and execute actions based on real-time insights.

The adoption of embedded edge intelligence is fueled by several technological advancements. Miniaturization of hardware, improvements in processor performance, and reductions in power consumption have made it possible to embed significant computing capabilities within small devices. These devices can be integrated into machinery, control panels, or even individual sensors.

Moreover, the development of edge-focused software platforms allows for sophisticated analytics, machine learning, and condition monitoring to be performed on-site. These capabilities enable predictive maintenance, anomaly detection, and adaptive control strategies that go beyond traditional static logic.

By decentralizing computation, manufacturers reduce latency and increase system resilience. If a centralized server goes offline, edge-enabled systems can continue to operate autonomously. This is particularly valuable in remote or high-risk environments where continuous connectivity cannot be guaranteed.

Embedded edge intelligence not only enhances performance but also supports scalability and modularity. New machines or sensors can be added to the system without overhauling the entire architecture. This flexibility is critical as manufacturers seek to respond quickly to changing market demands and production requirements.

Benefits of Integrating Edge Intelligence with Real-Time Control

The integration of embedded edge intelligence into real-time control systems offers a host of benefits that are transforming manufacturing operations. One of the most significant advantages is enhanced responsiveness. Traditional systems often depend on cloud-based analytics, which introduces latency due to data transmission and processing delays. Edge computing eliminates this bottleneck by processing data locally, enabling near-instantaneous reactions to changes in the production environment.

Another key benefit is improved reliability and resilience. By distributing processing capabilities across edge devices, manufacturers reduce their dependence on central servers. This decentralized approach minimizes the risk of system-wide failures and ensures that individual machines can continue functioning even if network disruptions occur.

Operational efficiency also sees a marked improvement. Edge-enabled systems can optimize processes in real time based on current conditions rather than pre-programmed rules. For instance, a packaging line equipped with edge intelligence can adjust its speed or pressure dynamically to accommodate variations in material thickness or temperature.

Moreover, this integration supports advanced analytics and machine learning. Embedded edge devices can continuously learn from operational data, identifying patterns and making predictive adjustments. This leads to proactive maintenance, reduced downtime, and extended equipment life.

Finally, integrating edge intelligence into real-time control systems facilitates greater flexibility and scalability. Manufacturers can easily reconfigure or upgrade individual components without disrupting the entire system. This adaptability is crucial in modern manufacturing, where agility and responsiveness are key competitive differentiators.

Technical Components and Architectures

Implementing embedded edge intelligence in real-time control systems involves a blend of hardware and software components that work together to deliver localized processing and decision-making. The architecture typically comprises edge devices, sensors, actuators, communication interfaces, and integration middleware.

Edge devices are at the core of this setup. These may include microcontrollers, embedded systems, or industrial PCs equipped with sufficient processing power to handle data analytics and control algorithms. The choice of device depends on the complexity of the application and the computational requirements.

Sensors and actuators form the physical interface with the manufacturing process. Sensors collect real-time data on parameters such as temperature, vibration, or flow rate. Actuators execute commands generated by the control algorithms, affecting physical changes in the system.

Communication interfaces play a critical role in enabling seamless data exchange between components. Common protocols include Ethernet/IP, Modbus, OPC UA, and MQTT. These ensure reliable and standardized communication across different devices and systems.

Middleware and software platforms provide the necessary tools for data aggregation, analytics, and visualization. They often include machine learning frameworks, condition monitoring tools, and control algorithm libraries. These platforms must be optimized for low latency and high reliability to support real-time operations.

Security is another crucial aspect of the architecture. Embedded edge systems must include robust cybersecurity measures such as encryption, authentication, and intrusion detection to protect against cyber threats and ensure data integrity.

Implementation Challenges and Mitigation Strategies

While the benefits of integrating embedded edge intelligence into real-time control systems are compelling, several challenges can arise during implementation. One major hurdle is the complexity of system integration. Manufacturing environments often consist of heterogeneous systems with legacy equipment, making interoperability a significant concern.

To address this, manufacturers should adopt open standards and modular architectures that facilitate integration across different platforms and devices. Middleware solutions that support various communication protocols can also help bridge compatibility gaps.

Another challenge is ensuring real-time performance. Edge devices must be capable of processing data with minimal latency to maintain control accuracy. This requires careful selection of hardware components and optimization of software algorithms.

Data management is also a critical consideration. With vast amounts of data being generated at the edge, efficient storage, retrieval, and analysis mechanisms are essential. Manufacturers must implement data governance strategies that define how data is collected, used, and protected.

Cybersecurity risks cannot be overlooked. As edge devices become more connected, they also become more vulnerable to attacks. Implementing multi-layered security protocols, regular updates, and monitoring systems is essential to safeguard operations.

Finally, skill gaps may pose a barrier to adoption. Integrating edge intelligence requires expertise in embedded systems, data analytics, and industrial automation. Investing in training and collaboration with technology partners can help build the necessary capabilities.

Use Cases in Modern Manufacturing

The application of embedded edge intelligence in real-time control systems is already yielding tangible benefits across various manufacturing sectors. In automotive assembly, for instance, edge-enabled robots are used to perform precise welding and painting tasks. These robots can adjust their operations in real time based on feedback from vision systems, ensuring consistent quality and reducing waste.

In the food and beverage industry, real-time monitoring of temperature and humidity is crucial for maintaining product integrity. Embedded edge devices can process this data locally and make immediate adjustments to climate control systems, ensuring compliance with safety regulations and reducing spoilage.

Pharmaceutical manufacturing also benefits significantly. Edge intelligence allows for precise control over mixing and compounding processes, which are sensitive to variables like pH and viscosity. Real-time analytics ensure that deviations are detected and corrected instantly, maintaining batch consistency and regulatory compliance.

In discrete manufacturing, such as electronics or consumer goods, embedded edge systems are used to monitor equipment health. Vibration and thermal sensors provide continuous data that is analyzed on-site to predict potential failures. Maintenance can then be scheduled proactively, minimizing downtime and extending asset life.

These use cases demonstrate the versatility and value of integrating edge intelligence with real-time control, paving the way for more adaptive and efficient manufacturing operations.

Strategic Roadmap for Adoption

For manufacturers looking to adopt embedded edge intelligence in their control systems, a strategic roadmap is essential. The first step involves assessing current capabilities and identifying gaps in technology and skills. A thorough audit of existing systems helps determine which components can be upgraded or integrated with edge devices.

Next, manufacturers should define clear objectives for the deployment. Whether the goal is to reduce downtime, improve product quality, or enhance operational visibility, having a focused vision ensures alignment across teams and stakeholders.

Pilot projects are a critical phase in the roadmap. These allow manufacturers to test edge integration in a controlled environment, gather performance data, and identify potential issues. Lessons learned from pilot implementations can then inform broader rollouts.

Investing in scalable infrastructure is another key consideration. Manufacturers should choose edge platforms and hardware that can grow with their needs. Modular systems and open standards facilitate future upgrades and integration with emerging technologies.

Partnerships with technology providers, system integrators, and research institutions can also accelerate adoption. These collaborations bring in specialized expertise and access to cutting-edge solutions.

Finally, continuous evaluation and optimization are essential. Edge systems should be regularly monitored and updated to ensure optimal performance and security. Feedback loops that incorporate operational insights into system improvements can drive sustained value.

Looking Ahead: The Future of Edge in Manufacturing

As manufacturing continues its digital transformation, the role of edge intelligence will become increasingly prominent. Advances in artificial intelligence, 5G connectivity, and sensor technologies will further enhance the capabilities of embedded edge systems. These developments will enable even more sophisticated control strategies and real-time decision-making.

One emerging trend is the convergence of edge and cloud computing into hybrid architectures. While edge systems handle time-sensitive tasks, cloud platforms can be used for long-term analytics, machine learning model training, and strategic planning. This hybrid approach leverages the strengths of both paradigms.

Another area of innovation is the use of digital twins—virtual replicas of physical assets that are synchronized in real time with edge data. These twins can simulate scenarios, optimize processes, and support predictive maintenance, providing a powerful tool for operational excellence.

As these technologies evolve, the adoption of embedded edge intelligence will become a standard practice in manufacturing. Companies that embrace this integration will gain a competitive edge through improved agility, efficiency, and product quality.

For example, advanced solutions built on embedded edge computing frameworks are already demonstrating how localized data processing can drive smarter control strategies. Similarly, platforms powered by the imx8 som are proving instrumental in delivering high-performance, real-time control capabilities in compact and energy-efficient form factors.

Conclusion

Integrating real-time control systems with embedded edge intelligence is not merely a technological trend—it is a foundational shift in how manufacturing operates. By enabling localized, responsive, and intelligent decision-making, this integration empowers manufacturers to achieve higher levels of performance, flexibility, and resilience.

As industry standards evolve and technology matures, the barriers to adoption will continue to diminish. Manufacturers that invest today in understanding, piloting, and implementing these integrated systems will be well-positioned to lead in the competitive landscape of tomorrow.

The journey toward smarter manufacturing begins at the edge. With thoughtful strategy, robust infrastructure, and a commitment to continuous improvement, companies can unlock the full potential of real-time control augmented by embedded edge intelligence.

0 notes

Text

🚚 Why Every Logistics Business Needs a Custom Driver App in 2025

In today’s competitive landscape, logistics companies can no longer rely on outdated systems and generic delivery software. The demand for real-time delivery tracking, route optimization, and digital proof of delivery is higher than ever — and the solution lies in building a custom driver app tailored to your logistics business.

📈 The Digital Shift in Logistics

The U.S. logistics industry moves over 13 billion tons of freight annually, making efficient delivery operations critical. Yet many businesses still operate with disconnected systems, paper-based processes, or off-the-shelf apps that don’t match their unique delivery models.

This is where a custom logistics delivery app solution becomes a game-changer.

What Is a Custom Driver App?

A custom driver app for logistics is a mobile application built specifically for your fleet, routes, service areas, and operational workflows. Unlike generic apps, it integrates directly into your , warehouse management system (WMS), CRM, and dispatching tools.

It provides features such as:

Real-time GPS tracking

delivery route optimization

Digital proof of delivery (POD)

Geofencing and ETA alerts

Driver behavior analytics

Two-way in-app messaging

🚀 7 Reasons Why Your Logistics Business Needs a Custom App

1. 🔍 Real-Time Visibility for Dispatch & Customers

A logistics driver app with real-time tracking provides both customers and dispatchers with location updates, estimated delivery times, and status changes — improving satisfaction and reducing inbound support calls.

2. 🧭 Optimize Delivery Routes

Using smart delivery route optimization software, custom apps reduce fuel consumption, avoid traffic congestion, and boost delivery speed by up to 30%.

3. 📲 Improve Driver Efficiency & Safety

A logistics mobile app enables digital checklists, shift scheduling, and driver behavior monitoring to ensure compliance, performance, and safety.

4. 📦 Proof of Delivery — No More Paper

Collect digital signatures, scan barcodes, and capture delivery photos, all within the app — eliminating paperwork and disputes.

5. 🔗 Integrate With Existing Software

A custom app connects directly with your logistics software ecosystem, providing end-to-end visibility across order management, inventory, dispatch, and analytics.

6. 📊 Own Your Data & Analytics

Custom-built logistics apps allow full ownership and control of performance data, giving your operations team real-time KPIs and insights.

7. 📈 Scalable for Growth

As your logistics business grows, your app grows with it — adding new features, supporting more users, and adapting to new delivery models.

🚀 Can a Custom Driver App Really Boost Your Logistics Business Revenue?

Yes — and here’s how.

In a fast-paced logistics world, outdated systems and one-size-fits-all apps are costing you time, money, and customers. By switching to a custom logistics delivery app solution, businesses across the U.S. are seeing increases in delivery efficiency, cost savings, and customer satisfaction — all of which translate into direct revenue growth.

🧭 How Can Smart Route Optimization Save You Thousands?

With rising fuel costs and driver shortages, efficiency is everything. A custom app uses delivery route optimization software to:

Reduce fuel usage

Shorten delivery times

Increase driver output per day

✅ This means fewer trucks on the road, faster deliveries, and higher profit margins.

📦 Is Your Business Still Using Paper PODs and Spreadsheets?

If so, you're leaving money on the table.

A proof of delivery app digitizes every delivery with:

e-Signatures

Barcode scans

Delivery photos

Geo-tagged timestamps

📉 This cuts down on lost shipments, fraud, and disputes — directly increasing revenue and customer retention.

📊 How Does This Directly Impact Revenue?

Here’s how logistics companies using custom mobile apps are growing revenue:

🚚 Deliveries completed 20–30% faster

⛽ Fuel costs reduced by up to 25%

📉 Missed deliveries cut by over 40%

🧾 Paperwork errors eliminated

🧑💼 More deliveries handled per driver per day

💰 These efficiencies lead to stronger margins and exponential growth — especially in competitive markets like same-day or last-mile delivery.

📲 Why Settle for Generic When You Can Build for Scale?

Every logistics business is unique — from routing challenges to proof-of-delivery needs. So why rely on cookie-cutter solutions?

A custom driver app for logistics is tailored to your business, fully integrated into your workflows, and designed to grow with you.

👉 More revenue. Fewer delays. Complete visibility.

Read more....

0 notes

Text

Routing Optimization Software: Transforming Modern Delivery Operations

In today’s fast-paced logistics and delivery industry, efficiency is everything. As companies scale and consumer expectations rise, traditional routing methods often fall short. That’s where routing optimization software steps in revolutionizing the way businesses plan, manage, and execute their deliveries.

With the help of advanced algorithms and real-time data, this powerful technology has become an indispensable tool for logistics managers, delivery companies, and fleet operators. In this blog, we’ll explore what routing optimization software is, its core benefits, and why your business needs it now more than ever.

What is routing optimization software?

Routing optimization software is a technology solution that uses algorithms, GPS data, traffic patterns, and delivery constraints to calculate the most efficient routes for delivery drivers. Unlike static route planning or manual mapping, this software dynamically adjusts based on real-time conditions like traffic congestion, road closures, or last-minute delivery changes.

Whether you're operating a small fleet or managing nationwide logistics, routing optimization software automates a complex task that would otherwise take hours to plan manually—while offering better accuracy and adaptability.

Key Features of Routing Optimization Software

To understand why routing optimization software is essential, let’s look at the features that make it powerful:

1. Dynamic Route Planning

It continuously adjusts routes based on live data—traffic jams, weather disruptions, or sudden delivery changes are automatically accounted for.

2. Multi-Stop Route Optimization

Efficiently handles multiple delivery stops, reducing the distance and fuel consumption while ensuring timely arrivals.

3. Driver Assignment and Load Balancing

Automatically assigns deliveries to the right drivers based on vehicle capacity, location, and time windows.

4. Geofencing and Route Deviation Alerts

Get notified if a driver veers off the planned route, helping maintain delivery accuracy and security.

5. Integration with Fleet Management Tools

Syncs with telematics, fuel management, and last-mile delivery platforms like Cigo Tracker’s Optimized Routing for seamless operations.

Benefits of Using Routing Optimization Software

Adopting routing optimization software isn’t just about convenience it directly impacts your business's bottom line. Here’s how:

1. Reduced Operational Costs

By finding the most efficient delivery routes, companies can cut fuel usage, reduce wear and tear on vehicles, and lower overtime costs.

2. Improved Delivery Timeliness

Deliveries arrive on time more often, which improves customer satisfaction and builds brand trust.

3. Increased Delivery Capacity

With optimized routes, the same number of drivers can handle more deliveries per day, scaling operations without expanding the fleet.

4. Lower Environmental Impact

Reducing travel distance and fuel consumption also lowers your company’s carbon footprint—a win for sustainability goals.

5. Real-Time Visibility

Track deliveries in real-time, provide ETAs to customers, and monitor driver performance with data-rich dashboards.

Industries That Benefit From Routing Optimization Software

1. E-commerce and Retail

With high delivery volumes and strict timelines, e-commerce companies rely on optimized routing for next-day or same-day deliveries.

2. Food and Beverage Delivery

Time-sensitive deliveries such as meal prep, catering, or grocery services need efficient route scheduling to maintain product freshness.

3. Field Service and Maintenance

Technicians can visit more service locations per day, increasing productivity and reducing customer wait times.

4. Healthcare and Pharmacy Delivery

Quick, accurate deliveries of medical supplies or prescriptions are crucial and routing optimization software ensures reliability.

Cigo Tracker’s Approach to Routing Optimization

Cigo Tracker’s routing optimization software is designed to meet the demands of modern delivery operations. Its intelligent routing engine adapts to various delivery models and includes:

Real-time traffic intelligence

Customizable delivery windows

Proof of delivery (POD) features

Driver mobile app for live updates

Seamless integration with dispatching and customer engagement tools

Whether you're managing last-mile logistics or a specialized delivery fleet, Cigo Tracker ensures you stay efficient and competitive.

Explore the Optimized Routing page to learn how it integrates into your workflow.

How to Choose the Right Routing Optimization Software

When selecting the ideal routing software for your business, consider the following:

Scalability: Can it handle future growth and increasing delivery volumes?

Ease of Use: Is the dashboard user-friendly for dispatchers and drivers?

Integration Capabilities: Can it sync with your existing systems?

Customer Support: Is help available when issues arise?

Customization: Does it allow configuration based on your unique delivery constraints?

Remember, the right solution should not only optimize routes but also empower your team to perform better with fewer resources.

Real-World Impact of Routing Optimization Software

Let’s consider a quick case study. A mid-sized meal delivery company using manual planning switched to Cigo Tracker’s routing optimization software. The results:

25% increase in daily deliveries

30% reduction in fuel costs

40% fewer customer complaints related to late deliveries

These figures illustrate how powerful the right technology can be for operational efficiency and customer satisfaction.

The Future of Routing Optimization Software

As AI and machine learning continue to evolve, routing optimization software will become even more predictive. Expect features like

AI-based delivery time forecasting

Predictive maintenance alerts

Automated rescheduling

Voice-assisted route updates

With growing demands for faster, greener, and more reliable deliveries, routing software is set to become the backbone of logistics automation.

Conclusion

If your business depends on deliveries, investing in routing optimization software is no longer optional; it’s essential. With benefits ranging from cost reduction to improved delivery times and better customer experiences, this technology provides a competitive edge in a crowded market. Cigo Tracker’s optimized routing solution is built for businesses like yours. Ready to elevate your operations? Visit Cigo Tracker Optimized Routing page to get started today.

1 note

·

View note

Text

Fuel Management Systems: Powering Efficiency and Control in Industrial Operations

In today’s fast-paced industrial landscape, managing fuel consumption effectively is critical to maintaining operational efficiency, reducing costs, and ensuring uninterrupted service. This is where Fuel Management Systems (FMS) play a transformative role. Whether in logistics, manufacturing, construction, mining, or any other fuel-intensive sector, the implementation of a robust fuel management system can directly contribute to business continuity and profitability.

What is a Fuel Management System?

A Fuel Management System is a technology-driven solution designed to monitor, control, and optimize fuel usage across an organization’s operations. These systems typically include hardware like fuel sensors, flow meters, tank level indicators, and software platforms that offer real-time data insights.

The core purpose of an FMS is to:

Track fuel consumption in real-time.

Prevent fuel theft and pilferage.

Monitor fuel quality and stock levels.

Generate detailed reports for compliance, audits, and performance tracking.

Optimize refueling schedules based on actual demand and historical usage patterns.

Importance in the Indian Industrial Context

In India, where industries operate in diverse terrains and often in remote areas with limited infrastructure, having control over fuel resources becomes even more crucial. Inefficiencies in fuel usage, leakage, and unmonitored consumption can lead to significant financial and operational setbacks.

With the rising cost of fuel and increased focus on energy efficiency, businesses are rapidly adopting fuel management systems to:

Reduce fuel wastage

Improve fleet and equipment productivity

Strengthen accountability at the ground level

Ensure better environmental compliance

Moreover, India’s growing dependence on uninterrupted fuel supply for sectors like telecom, warehousing, data centers, and logistics underscores the need for intelligent systems that offer visibility and control at all times.

How Fuel Management Systems Work

Fuel Management Systems generally operate through a combination of hardware and cloud-based software. Key components include:

Fuel Sensors: Installed on tanks or fuel bowsers to track fuel levels and flow.

GPS Integration: To monitor the movement of fuel and assets.

Automated Dispensing Units: That record each transaction with time, location, and volume details.

User Authentication: Ensuring only authorized personnel can initiate refueling or fuel access.

Dashboards & Reporting Tools: For centralized visibility, historical analysis, and real-time decision-making.

These systems can be deployed across fuel tanks at stationary sites or mobile fuel delivery units for enhanced control.

MyFuels: Delivering Comprehensive Fuel Management Solutions

At MyFuels, we go beyond traditional fuel delivery to offer an integrated suite of energy management solutions tailored to the dynamic needs of modern industries. Our Fuel Management System is built to ensure that every litre of fuel is accounted for, every refueling is traceable, and every decision is backed by data.

Our Offerings Include:

On-Demand Fuel Delivery: Timely and safe doorstep diesel refueling services for fleets, machinery, and generators.

Advanced Fuel Monitoring Systems: Real-time tracking of consumption, stock levels, and alerts for unauthorized usage.

Genset Rentals: Reliable power backup solutions with remote fuel monitoring.

Dual Fuel Converters: Reduce diesel dependency and costs by enabling cleaner alternative fuel use.

Lubricant Supply: Quality lubricants tailored for industrial-grade engines and heavy equipment.

Data-Driven Insights: Actionable analytics and reports to drive operational improvements and budgeting accuracy.

We work closely with sectors such as logistics, manufacturing, mining, telecom, construction, and infrastructure, ensuring uninterrupted energy flow while helping clients maintain complete control over their fuel ecosystem.

The Future of Fuel Management

As industries in India continue to adopt digital transformation, fuel management will become increasingly intelligent, automated, and integrated. From IoT-powered sensors to AI-driven consumption forecasting, the future of fuel oversight lies in smarter technologies that not only prevent losses but also enable long-term sustainability and savings.

Organizations that embrace these systems today will be better positioned to face tomorrow’s operational challenges and energy demands.

Conclusion:

Fuel is more than just a resource — it is the backbone of industrial operations. Managing it efficiently can make the difference between operational excellence and escalating costs. With comprehensive fuel management systems like those offered by My Fuels, businesses gain not only visibility but also control, compliance, and continuity.

For organizations seeking to modernize their fuel operations and minimize risk, adopting a trusted, scalable fuel management solution is not just an option — it’s a necessity.

#on demand fuel delivery#fuel delivery service#smart storage solutions#Mobile Fueling Solutions#Fuel Management Systems#FMS

0 notes

Text

How to Reduce Operational Costs with Taxi Dispatch Software

In the competitive world of taxi services, operational costs can make or break a business. Taxi operators are constantly looking for ways to reduce expenses while improving service quality. One of the most effective tools for achieving this is taxi dispatch software, which can significantly streamline operations, enhance fleet management, and reduce costs.

If you are running a taxi service—whether it’s a small fleet or a large organization—implementing the right taxi dispatch software can lower overheads and increase profitability. Let’s explore how this technology can help businesses cut costs and improve efficiency.

1. Optimize Routes and Save on Fuel Costs

Fuel is one of the highest expenses for any taxi business. The longer drivers spend on the road, the more fuel they use, and this can significantly eat into profits. One of the core functions of taxi dispatch software is route optimization, which helps reduce fuel consumption.

By using real-time GPS tracking and traffic data, taxi dispatch software suggests the most efficient routes for drivers. This minimizes detours, avoids congestion, and ensures faster trips—resulting in lower fuel costs and higher productivity.

Benefits:

Reduced fuel consumption.

Shorter travel times.

Lower vehicle maintenance costs.

2. Reduce Idle Time and Improve Fleet Utilization

Idle time occurs when taxis are not in use—whether they’re stuck in traffic, waiting for a passenger, or parked waiting for the next ride. This is a major cost driver for many taxi companies.

With taxi dispatch systems, idle time can be minimized. The software automatically dispatches the nearest available driver to a new ride request. By analyzing real-time data, it reduces the time a vehicle is unproductive, increasing overall fleet utilization.

Benefits:

Maximized fleet usage.

Reduced downtime between rides.

Increased earnings per vehicle.

3. Automate Booking and Dispatching to Save Time

Traditionally, taxi services rely on manual systems to handle bookings and dispatch drivers. This can be time-consuming and error-prone. Taxi dispatch software automates these processes by offering online booking platforms, mobile apps, and automated dispatching.

When a customer books a ride, the system automatically assigns the nearest available driver, which speeds up the process and reduces the chances of errors. This automation reduces the need for manual intervention, freeing up resources and lowering labor costs.

Benefits:

Time-saving automation.

Reduced administrative workload.

Improved accuracy in dispatching.

4. Streamline Driver Management and Track Performance

Managing drivers, ensuring they follow company policies, and keeping track of hours can be a major challenge. Without proper monitoring, driver inefficiencies can lead to unnecessary costs. Taxi dispatch software allows businesses to track driver performance in real-time.

With features like shift scheduling, driver performance monitoring, and behavior analysis, taxi operators can better manage their workforce. By optimizing shifts and reducing overtime, businesses can lower labor costs and ensure drivers are operating at peak efficiency.

Benefits:

Improved driver accountability.

Reduced overtime costs.

More efficient driver scheduling.

5. Efficient Fleet Maintenance Tracking

Keeping a fleet of vehicles in optimal condition requires regular maintenance, inspections, and repairs. A lack of proper vehicle management can result in costly repairs and extended downtime.

Taxi dispatch software often includes maintenance tracking features, which allow operators to monitor vehicle health, schedule maintenance, and get reminders for inspections. By staying on top of vehicle condition, taxi businesses can avoid unexpected breakdowns and expensive repairs.

Benefits:

Proactive maintenance scheduling.

Fewer unexpected repairs.

Extended vehicle lifespan.

6. Implement Dynamic Pricing for Revenue Optimization

Dynamic pricing or surge pricing allows taxi businesses to adjust fares based on demand, time of day, weather, and other factors. During high-demand periods, such as rush hours or bad weather, taxi dispatch systems can automatically adjust prices to maximize revenue.

For example, if demand is high but supply is low, increasing prices can help compensate for the additional costs incurred by drivers. This ensures that businesses can continue to operate profitably even during peak times.

Benefits:

Increased revenue during high-demand periods.

Better price control.

Optimized earnings per ride.

7. Simplify Payments and Reduce Billing Errors

Managing payments and invoices manually can lead to errors, disputes, and inefficiencies. Taxi dispatch software often integrates payment gateways that support multiple payment methods, such as credit cards, digital wallets, and cashless transactions.

The system calculates the fare automatically based on distance, time, and other factors, ensuring accuracy. Automated invoicing also reduces the chances of errors, saving time for your team and providing a smoother customer experience.

Benefits:

Faster, more accurate payments.

Fewer payment-related disputes.

Lower administrative costs.

8. Analyze Data for Continuous Cost Improvements

One of the most valuable aspects of taxi dispatch software is the ability to gather and analyze data. From customer booking patterns to driver performance and vehicle efficiency, this data can help identify cost-saving opportunities.

By using analytics tools within the software, businesses can make data-driven decisions to optimize operations. For example, they can identify periods of low demand and adjust driver deployment, ensuring that resources are allocated efficiently.

Benefits:

Data-driven decision-making.

Continuous improvement in operational efficiency.

Increased profitability through better resource management.

Conclusion: How Taxi Dispatch Software Can Drive Cost Efficiency

Incorporating taxi dispatch software into your operations is an effective way to reduce operational costs while improving service quality. By leveraging key features like route optimization, automated dispatch, and dynamic pricing, taxi businesses can streamline their processes, improve fleet management, and boost profitability.

The future of the taxi industry is all about smart, data-driven solutions. With taxi dispatch software, taxi operators can stay competitive, cut costs, and continue to provide top-notch service to their customers.

Ready to reduce your operational costs and improve efficiency? Learn more about our taxi dispatch software solutions and see how we can help take your taxi business to the next level.

#taxi dispatch software#taxi dispatch system prices#best taxi dispatch software#taxi dispatch software free#taxi cab dispatch software#taxi cab dispatch system#cab dispatch software#cab dispatch system#software for taxi business#taxi software#software taxi dispatch#taxi booking software#taxi dispatch system#software taxi

0 notes

Text

Distribution Revolution: 8 Proven AI Wins for Smarter Logistics!

From Chaos to Control: How AI Is Revolutionizing Distribution

But this morning felt different. Because this time, Meera wasn’t alone in her fight against inefficiencies — she had AI by her side.

The Distribution Dilemma For years, distribution networks across industries have struggled with unpredictable demand, misrouted deliveries, stock shortages, and rising fuel costs. Meera knew this too well. On peak festival days, even the best planning would go haywire, warehouses would overflow, trucks would miss deadlines, and customer complaints would skyrocket.

Despite using software for route mapping and stock control, the system lacked one thing: intelligence — the ability to learn, predict, and optimize in real time.

That’s when Orion Logistics decided to introduce Artificial Intelligence into the mix.

Enter AI: Not Just Automation — Intelligence The transformation began with small steps.

First, they integrated an AI-powered demand forecasting tool. It analyzed past sales trends, seasonal fluctuations, market shifts, and even social media buzz. What once took a week of manual effort was now delivered in under a minute — accurate demand projections for each product, region, and store.

Then came intelligent route optimization. Using real-time traffic data, weather predictions, fuel efficiency stats, and even driver behavior, the AI platform re-routed deliveries dynamically. A delivery that previously took 4 hours was now done in 2.7 — with less fuel, fewer stops, and no delays.

For Meera, this was magic.

“We started delivering more, with fewer vehicles. Our distribution costs dropped by 22% in just two months,” she said, smiling at the dashboard flashing green metrics.

Predictive Maintenance: Trucks That Talk A week into the rollout, Meera received a ping: “Truck #14 likely to face engine issues in 3 days.”

It was no guesswork. The AI had monitored vibration sensors, fuel consumption, engine heat, and maintenance history — and predicted a failure before it even happened.

The vehicle was serviced preemptively. The delivery was not delayed. That truck was back on the road before anyone even knew there was a problem.

This wasn’t just logistics anymore. This was logistics with foresight.

Smart Warehousing: AI at the Heart of the Hub In the warehouse, things were changing too. AI-powered robots now picked, packed, and labeled items. Cameras equipped with computer vision checked for packaging defects. Inventory levels were monitored in real-time, and re-order requests were auto-triggered by intelligent algorithms — no more stockouts or overstocking.

Meera used to carry a stack of paper sheets and clipboards. Now, she carried just a tablet — and everything she needed was in it.

The Human Touch — Enhanced by AI Despite the tech transformation, Meera’s job didn’t vanish. It evolved.

Her team no longer wasted hours fixing broken processes. They now focused on customer satisfaction, strategy, and growth. AI handled the grunt work, the number crunching, and the patterns. Humans still made the final calls — with better insights and fewer errors.

The Results

28% Reduction in Delivery Time

40% Better Route Efficiency

19% Decrease in Operational Costs

24/7 Predictive Monitoring of Fleet Health

More importantly, customer satisfaction soared — because promises were kept, every single time.

For more detailed insights, on how AI is transforming the future please click the link below:

Final Thoughts: Distribution’s New Backbone

AI in distribution isn’t just a luxury — it’s becoming a necessity. Whether it’s last-mile delivery, inventory control, fleet management, or customer communication — AI is transforming distribution from a reactive task into a proactive, intelligent engine.

And for professionals like Meera, it’s not about losing control to machines — it’s about gaining superpowers.

With tools like Teemify, businesses can harness AI to automate logistics, predict disruptions, and drive smarter decisions in real time.

Because when artificial intelligence meets human experience, distribution becomes truly unstoppable.

#aiindistribution#smartdistribution#logisticsai#distributionautomation#intelligentsupplychain#distributiontechnology#smartdeliverysystems#intelligentlogistics#realtimelogistics

1 note

·

View note

Text

Smarter Fuel Logistics with Oil Tank Monitoring

Managing fuel logistics efficiently is no longer an optional optimization—it’s a necessity in today’s fast-moving business environment. Whether your organization operates a transport fleet, services multiple facilities, or runs continuous manufacturing lines, every drop of fuel counts. The use of oil tank monitoring technology has emerged as a game-changer, offering end-to-end visibility into fuel levels, consumption patterns, and inventory planning. This data-driven approach enables companies to streamline logistics, reduce waste, and avoid unexpected outages that can disrupt operations.

Historically, fuel management involved physical tank inspections or reliance on static data that quickly became outdated. These manual methods are not only labor-intensive but also vulnerable to errors and oversights. In contrast, modern tank monitoring services use real-time sensors and cloud-connected platforms to automate this process. Managers receive alerts when tanks are nearing empty, detect leaks early, and can view fuel trends across weeks or months. This predictive insight allows better coordination with suppliers, ensuring refills happen exactly when needed—not too soon, not too late.