#in a vessel the gas is at pressure p

Text

SA387 Grade 11 Alloy Steel: Key Features and Industrial Applications

In the world of industrial materials, SA387 Grade 11 Alloy Steel is renowned for its exceptional ability to withstand high temperatures, pressures, and corrosive environments. This chromium-molybdenum alloy steel has become a staple in industries such as petrochemicals, power generation, and oil and gas. This blog will explore the key features of SA387 Grade 11 Alloy Steel and its widespread applications, demonstrating why it remains a material of choice for engineers and industry professionals.

1. Composition and Characteristics of SA387 Grade 11 Alloy Steel

SA387 Grade 11 is part of the ASTM A387 family, a specification for pressure vessel plates made from chromium-molybdenum alloy steel. Its composition is specifically designed to enhance its mechanical properties, making it suitable for high-stress environments.

Key Elements of SA387 Grade 11:

Chromium (Cr): 1.00-1.50%

Molybdenum (Mo): 0.45-0.65%

Carbon (C): 0.05-0.17%

Manganese (Mn): 0.30-0.60%

Silicon (Si): 0.50% max

Phosphorus (P) and Sulfur (S): 0.025% max each

This chemical composition gives SA387 Grade 11 its distinct properties, particularly its ability to maintain strength and durability at elevated temperatures. The chromium content provides resistance to oxidation and corrosion, while molybdenum enhances the steel's strength and heat resistance.

2. Key Features of SA387 Grade 11 Alloy Steel

SA387 Grade 11 Alloy Steel is known for several key features that make it ideal for use in demanding industrial applications.

High-Temperature Strength:

One of the standout features of SA387 Grade 11 is its ability to retain its mechanical strength at high temperatures. This makes it an excellent choice for applications involving heat, such as in power plants and chemical processing facilities, where materials are exposed to sustained high temperatures.

Corrosion and Oxidation Resistance:

The presence of chromium in SA387 Grade 11 provides excellent resistance to corrosion and oxidation, even in harsh environments. This is particularly important in industries where the material is exposed to corrosive chemicals or gases.

Toughness and Ductility:

SA387 Grade 11 offers a balance of toughness and ductility, which is crucial for applications that involve high pressures and temperatures. The alloy can absorb significant energy without fracturing, making it a reliable material for critical components such as pressure vessels and boilers.

Versatility in Heat Treatment:

The alloy’s mechanical properties can be further enhanced through heat treatment processes such as annealing, quenching, and tempering. These treatments allow engineers to tailor the material’s properties to specific applications, ensuring optimal performance in various conditions.

Good Weldability:

Despite its high strength and toughness, SA387 Grade 11 is relatively easy to weld. This feature is crucial for the fabrication of large structures or components that require precise and reliable welding.

3. Industrial Applications of SA387 Grade 11 Alloy Steel

SA387 Grade 11 Alloy Steel is extensively used in industries that require materials capable of withstanding extreme conditions. Here’s a look at some of its most common applications:

Petrochemical Industry:

In the petrochemical sector, SA387 Grade 11 is widely used for the construction of pressure vessels, reactors, and heat exchangers. These components must endure high temperatures and pressures, as well as exposure to corrosive substances. The alloy’s high-temperature strength and corrosion resistance make it an ideal choice for these demanding applications.

Power Generation:

SA387 Grade 11 is a critical material in the power generation industry, particularly in the construction of boilers and steam turbines. These components operate under extreme conditions, with temperatures often exceeding 500°C. The alloy’s ability to maintain its strength and resist oxidation at high temperatures ensures the safe and efficient operation of power plants.

Oil and Gas Industry:

The oil and gas industry often involves challenging environments, where materials are exposed to high pressures, corrosive substances, and fluctuating temperatures. SA387 Grade 11 is used in the fabrication of pipelines, pressure vessels, and separators. Its corrosion resistance and mechanical strength make it suitable for both onshore and offshore applications.

Industrial Boilers:

The construction of industrial boilers requires materials that can withstand high temperatures and pressures. SA387 Grade 11 is a popular choice for boiler manufacturing due to its high-temperature strength and ability to resist oxidation. This ensures the longevity and reliability of boilers in various industrial settings.

Heat Exchangers:

Heat exchangers are critical components in many industrial processes, where efficient heat transfer is essential. SA387 Grade 11 is often used in the construction of heat exchangers due to its thermal stability and resistance to corrosion, ensuring efficient operation and minimal maintenance.

Pressure Vessels:

Pressure vessels are used to store and transport gases or liquids under high pressure. The safety and reliability of these vessels depend on the material used in their construction. SA387 Grade 11 is commonly used in pressure vessels due to its high strength, toughness, and resistance to high temperatures and pressures.

4. Heat Treatment Processes and Their Impact

The performance of SA387 Grade 11 Alloy Steel can be significantly enhanced through various heat treatment processes. Each process alters the microstructure of the alloy, thereby changing its mechanical properties to suit specific industrial needs.

Annealing:

Annealing involves heating the alloy to a specific temperature and then cooling it slowly. This process enhances the ductility and reduces the hardness of the material, making it easier to shape and fabricate.

Quenching:

Quenching involves heating the alloy to a high temperature and then rapidly cooling it in water or oil. This process increases the hardness and strength of the alloy but can also make it more brittle.

Tempering:

After quenching, tempering is often used to reduce brittleness while maintaining strength. This process involves reheating the alloy to a temperature below its critical point and then cooling it slowly. Tempering improves the toughness of the material, making it more resistant to impact and stress.

Stress Relieving:

Stress relieving is a heat treatment process that involves heating the alloy to a temperature below its critical point and then cooling it slowly. This process reduces residual stresses in the material, improving its dimensional stability and resistance to cracking.

Each of these heat treatment processes can be applied to SA387 Grade 11 Alloy Steel to optimize its performance for specific applications, ensuring that the material meets the stringent requirements of various industries.

5. Conclusion

SA387 Grade 11 Alloy Steel is a versatile and reliable material that plays a critical role in industries where high performance under extreme conditions is essential. Its key features, including high-temperature strength, corrosion resistance, toughness, and weldability, make it an ideal choice for demanding applications in the petrochemical, power generation, and oil and gas industries.

The alloy’s ability to undergo various heat treatment processes further enhances its versatility, allowing it to be tailored to meet the specific needs of different applications. Whether it’s in the construction of pressure vessels, industrial boilers, or heat exchangers, SA387 Grade 11 Alloy Steel stands out as a material that delivers exceptional performance, ensuring safety, efficiency, and durability in the most challenging environments.

Bhavya Steel House of Stainless Steel

#stainless steel 409 sheet plates coils#sa 387 gr 11 in pune#sa387 grade 11 alloy steel#ss 387 grade 11 sheets#sa 387 gr 11 chemical composition#gr 11#ss347#alloy steel plates suppliers in mumbai#alloy steel grade#what are alloy steel#alloy steel type#low alloy steels#alloys steel#steel alloy grades#alloy steel material properties#gr steel

0 notes

Text

Efficient Solutions for Your Home: New Hot Water Heater Installation by Birkdale Plumber

Installing a hot water cylinder is a crucial task that ensures you have a reliable supply of hot water for your home or business. Proper installation enhances efficiency, safety, and longevity of the system. This guide will walk you through the essentials of hot water cylinder installation, offering tips to ensure a smooth and effective process.

Understanding Hot Water Cylinders

Hot water cylinders are storage tanks designed to heat and store hot water for domestic or commercial use. They come in two main types: vented (or open-vented) and unvented. Vented cylinders use a cold water storage tank, usually located in the attic, while unvented cylinders connect directly to the mains water supply.

Planning and Preparation

Choosing the Right Cylinder:

Capacity: Determine the right size based on your household's hot water usage. A typical household requires a cylinder that holds between 100 to 300 liters.

Type: Decide between vented and unvented systems. Unvented systems offer higher pressure and are more space-efficient as they don't require a separate cold water tank.

Location:

Ensure the chosen location can support the weight of the filled cylinder.

Consider accessibility for maintenance and repairs.

For unvented cylinders, ensure there is adequate space for the expansion vessel.

Permits and Regulations:

Check local building codes and regulations. Some installations may require a permit or need to comply with specific standards.

Installation Process

Preparation:

Tools and Materials: Gather necessary tools such as pipe cutters, wrenches, a spirit level, and materials like pipes, fittings, and insulation.

Safety Measures: Turn off the main water supply and electricity or gas supply to the current water heater. Drain the existing system if replacing an old cylinder.

Positioning the Cylinder:

Place the cylinder in the designated location, ensuring it is level and secure.

If installing an unvented system, attach the expansion vessel and pressure relief valve.

Connecting the Pipes:

Cold Water Inlet: Connect the cold water supply to the bottom inlet of the cylinder. Install a check valve and a pressure-reducing valve if required.

Hot Water Outlet: Connect the hot water outlet to the hot water distribution system. Insulate the pipes to reduce heat loss.

T&P Relief Valve: Install the temperature and pressure relief valve and ensure the discharge pipe directs to a safe location.

Electrical Connections:

For electric cylinders, connect the heating element to the electrical supply following manufacturer instructions. Ensure the system is grounded properly.

For gas systems, connect the gas supply line and ensure the venting system is correctly installed.

Filling and Testing:

Slowly fill the cylinder with water, checking for leaks at all connections.

Once filled, turn on the electricity or gas supply to start heating the water.

Check the system’s pressure and temperature settings. Ensure the T&P relief valve is functioning properly.

Final Checks and Maintenance

Insulation:

Insulate the cylinder and pipes to improve efficiency and reduce heat loss.

Consider adding a cylinder jacket for additional insulation.

Regular Maintenance:

Periodically check for leaks and inspect the T&P relief valve.

Schedule regular servicing to ensure the system operates efficiently and safely.

Conclusion

Proper Hot Water System Installation is vital for ensuring a steady supply of hot water, improving energy efficiency, and extending the lifespan of the system. By carefully planning, following the correct procedures, and performing regular maintenance, you can enjoy reliable hot water for years to come. Whether you choose a vented or unvented system, attention to detail during installation will pay off in the long run, providing comfort and convenience in your home or business.

0 notes

Text

Duplex Steel S31803 Wires Manufacturers in India

Introduction

Duplex Steel S31803, commonly known as Duplex 2205, is a high-performance stainless steel alloy widely recognized for its exceptional strength, corrosion resistance, and durability. It is a preferred choice in industries that demand high reliability and efficiency in harsh environments. Sankalp Alloys Overseas, a leading manufacturer and supplier of premium quality metal products, offers top-grade Duplex Steel S31803 Wires, catering to a diverse range of industrial applications.

Overview

Duplex Steel S31803 is a two-phase, ferritic-austenitic stainless steel characterized by a balanced combination of the best properties of both ferritic and austenitic steel. This unique composition provides superior resistance to pitting, stress corrosion cracking, and crevice corrosion, making it ideal for applications in aggressive environments. The wires produced by Sankalp Alloys Overseas are meticulously engineered to meet the highest standards of quality and performance.

Specifications

The Duplex Steel S31803 Wires offered by Sankalp Alloys Overseas come with the following specifications:

Grade: Duplex 2205 (S31803)

Chemical Composition:

Chromium (Cr): 22-23%

Nickel (Ni): 4.5-6.5%

Molybdenum (Mo): 3-3.5%

Manganese (Mn): 2% max

Silicon (Si): 1% max

Carbon (C): 0.03% max

Nitrogen (N): 0.14-0.20%

Phosphorus (P): 0.03% max

Sulfur (S): 0.02% max

Mechanical Properties:

Tensile Strength: 620 MPa min

Yield Strength: 450 MPa min

Elongation: 25% min

Hardness: 290 HV max

Standards: ASTM A240, ASTM A276, ASTM A479

Applications

Duplex Steel S31803 Wires are widely used in various industries due to their outstanding properties. Some of the key applications include:

Oil and Gas Industry:

Offshore platforms and pipelines

Heat exchangers and pressure vessels

Subsea equipment

Chemical Processing Industry:

Chemical storage tanks

Reactor vessels and piping systems

Acid production and transportation

Marine Industry:

Shipbuilding and repair

Marine hardware and components

Seawater desalination plants

Pulp and Paper Industry:

Digesters and bleaching equipment

Paper machine parts and components

Power Generation:

Nuclear power plant components

Turbine blades and cooling systems

Implications of Industry in Points

Enhanced Durability:

Duplex Steel S31803 Wires offer excellent resistance to wear and tear, extending the lifespan of industrial equipment and reducing maintenance costs.

Corrosion Resistance:

The alloy's superior resistance to various forms of corrosion ensures reliable performance in harsh and corrosive environments.

High Strength:

The combination of ferritic and austenitic phases provides high tensile and yield strength, allowing for the construction of robust and durable structures.

Cost-Effective:

Despite its premium properties, Duplex 2205 is cost-effective compared to other high-performance alloys, offering great value for investment.

Versatility:

Duplex Steel S31803 Wires are suitable for a wide range of applications across multiple industries, making them a versatile choice for various engineering and construction projects.

Conclusion Duplex Steel S31803 Wires by Sankalp Alloys Overseas is a testament to superior engineering and quality. With their exceptional strength, corrosion resistance, and durability, these wires are the perfect choice for demanding industrial applications. Sankalp Alloys Overseas is committed to providing the best-in-class metal products that meet and exceed industry standards, ensuring reliability and performance in every project.

0 notes

Text

Radiography Testing in Pune | Integrated NDE Solutions

Why Choose Integrated NDE for Radiography Testing?

At Integrated NDE, we pride ourselves on delivering top-notch radiography testing services in Pune. Our state-of-the-art facilities and experienced professionals ensure that you receive accurate and reliable results every time.Advanced Radiography Testing Techniques

We utilize the latest radiographic inspection technologies to provide comprehensive testing solutions. Our methods include:

Digital Radiography: Offering enhanced image clarity and faster results.

Computed Radiography: Combining traditional techniques with digital advancements for precise inspections.

Film Radiography: Providing detailed imaging for various industrial applications.

Applications of Radiography Testing

Our radiography testing services are ideal for a wide range of industries, including:

Construction: Ensuring the integrity of structural components.

Oil and Gas: Inspecting pipelines and pressure vessels.

Manufacturing: Verifying the quality of welds and castings.

Aerospace: Checking critical aircraft parts for defects.

Benefits of Our Radiography Testing Services

Accurate Defect Detection: Identify internal flaws and discontinuities with high precision.

Non-Destructive: Perform inspections without damaging the components.

Compliance with Standards: Adhere to national and international quality standards.

Expert Team: Our certified technicians bring extensive experience and expertise.

Our Commitment to Safety and Quality

At Integrated NDE, safety and quality are our top priorities. We follow strict safety protocols and quality control measures to ensure the best outcomes for our clients.

Get in Touch with Us

For reliable radiography testing in Pune, contact Integrated NDE today. Our team is ready to assist you with your inspection needs.

Contact Us:

Phone: +9170574 64149

Email: [email protected]

Address: Plot No. J/P-11/1 Bhurat Heights Ground Floor Indrayaninagar, Bhosari, Pune- 411026

Frequently Asked Questions (FAQs)

Q1: What is radiography testing?

Radiography testing is a non-destructive testing method used to inspect the internal structure of materials using X-rays or gamma rays.

Q2: How long does radiography testing take?

The duration of radiography testing depends on the size and complexity of the object being inspected. Our team will provide an estimated timeframe based on your specific requirements.

Q3: Is radiography testing safe?

Yes, radiography testing is safe when performed by trained professionals who follow proper safety protocols. Our team at Integrated NDE ensures all safety measures are in place during the inspection process.

#Non Detrsuctive Testing in pune#Ultrasonic testing#Radiogrpahy testing in pune#magnetic particle inspection in pune#dye penetrant inspection in pune#ferrite testing in pune#portable hardness testing#ndt testing#radiography testing services#ndt radiography testing#radiographic weld testing#non destructive radiography testing#non destructive testing radiography

0 notes

Text

Stainless Steel 904L Flanges Properties and Applications.|Metalforgeindia

Stainless Steel 904L is a tremendous-austenitic stainless steel alloy noted for its great corrosion resistance, immoderate electricity, and extraordinary weldability. It is often applied in numerous commercial enterprise applications in which resistance to competitive environments is crucial. In this blog, we can discover the composition, homes, and uses of Stainless Steel 904L flanges, with a focus on its software in buttweld fittings.

Composition of Stainless Steel 904L:

Stainless Steel 904L is a low carbon, excessive alloy austenitic stainless-steel grade with additions of nickel, chromium, and molybdenum. The composition of Stainless Steel 904L usually consists of:

- Carbon (C): Maximum 0.02%

- Silicon (Si): Maximum 1.Zero%

- Manganese (Mn): Maximum 2.0%

- Phosphorus (P): Maximum zero.Half%

- Sulfur (S): Maximum 0.Half%

- Chromium (Cr): 19.Zero% – 23.Zero%

- Nickel (Ni): 23.Zero% – 28.Zero%

- Molybdenum (Mo): 4.Zero% – five.0%

Properties of Stainless Steel 904L:

1. Corrosion Resistance:

Stainless Steel 904L well-knownshows incredible resistance to each lowering and oxidizing acids, making it appropriate for applications in aggressive environments which include sulfuric acid, phosphoric acid, and chloride solutions. It moreover gives appropriate resistance to crevice corrosion and strain corrosion cracking.

2. High Strength:

Stainless Steel 904L has immoderate tensile and yield electricity, permitting it to face up to excessive-strain and excessive-temperature conditions without gift technique deformation or failure. Its superior mechanical holmes make it perfect to be used in worrying industrial programs.

3. Weldability:

Stainless Steel 904L offers extremely good weldability and can be resultseasily welded the usage of conventional welding strategies inclusive of TIG (Tungsten Inert Gas) welding, MIG (Metal Inert Gas) welding, and SMAW (Shielded Metal Arc Welding). The alloy continues its corrosion resistance and mechanical homes after welding, making it appropriate for fabrication.

4. Heat Resistance:

Stainless Steel 904L is a famous suitable resistance to oxidation and scaling at extended temperatures, making it appropriate to be used in packages involving warmness publicity, which encompass warm temperature exchangers, furnace components, and annealing device.

Uses of Stainless Steel 904L Flanges:

Stainless Steel 904L flanges are widely implemented in severa industries for connecting pipes, valves, and gadgets in piping systems. Some common applications of Stainless Steel 904L flanges embody:

1. Chemical Processing:

Stainless Steel 904L flanges are substantially applied in chemical processing vegetation for connecting pipelines, reactors, and vessels handling corrosive chemical substances and acids. Their superior corrosion resistance and mechanical power make them best for withstanding harsh chemical environments.

2. Oil and Gas Industry:

In the oil and gasoline agency, Stainless Steel 904L flanges are implemented in offshore systems, refineries, and petrochemical plant life for connecting pipelines, valves, and system uncovered to corrosive fluids, seawater, and excessive-pressure situations.

3. Water Treatment:

Stainless Steel 904L flanges find packages in water remedy centers for connecting piping structures, pumps, and filters applied in desalination flowers, wastewater treatment flowers, and water distribution networks. Their resistance to corrosion and abrasion makes them suitable for handling corrosive and abrasive fluids.

4. Chemical Industry:

Stainless Steel 904L flanges are utilized in pharmaceutical production facilities for connecting pipeline devices, reactors, and storage tanks. Their hygienic houses, corrosion resistance, and compatibility with sterilization techniques reason them appropriate for pharmaceutical applications.

5. Food and Beverage Industry:

Stainless Steel 904L flanges are employed within the food and beverage enterprise for connecting pipelines, storage tanks, and processing systems. Their non-poisonous nature, hygienic houses, and resistance to corrosion make them suitable for dealing with food-grade merchandise and sanitization strategies.

Conclusion:

Stainless Steel 904L flanges are important additives in diverse organization programs wherein corrosion resistance, strength, and reliability are paramount. Their flexible homes motive them to be vital in chemical processing, oil and gas, water treatment, pharmaceutical, and food and beverage industries, contributing to the inexperienced and constant operation of enterprise strategies.

0 notes

Text

All You Need To Know About Alloy Steel Flanges

Alloy steel flanges are vital components in piping systems across various industries, offering durability, reliability, and resistance to corrosion and high temperatures. Understanding these critical elements is essential for anyone involved in piping projects or seeking to enhance their knowledge of industrial materials. As a leading Alloy Steel Flanges Manufacturer, Supplier, Stockist, and Exporter, Bullion Pipes & Tubes LLP takes pride in offering a diverse range of alloy steel flanges tailored to meet various project requirements.

In this comprehensive guide, we delve into everything you need to know about alloy steel flanges, from their composition and types to their applications and benefits.

What are Alloy Steel Flanges?

Alloy steel flanges are fittings used to connect pipes, valves, pumps, and other equipment in a piping system. They are made from alloy steel, a combination of iron with other elements such as chromium, nickel, molybdenum, and manganese, to enhance their mechanical properties. These flanges are available in various sizes, shapes, and pressure ratings to accommodate diverse industrial requirements.

Types of Alloy Steel Flanges

Weld Neck Flanges: These flanges are designed with a long neck, ideal for applications requiring high pressure and temperature conditions.

Slip-On Flanges: Offering easy installation, slip-on flanges are slipped over the pipe and then welded in place.

Socket Weld Flanges: Socket weld flanges feature a socket for pipe insertion, providing a strong connection and reducing leakage risk.

Blind Flanges: Used to seal the end of a piping system, blind flanges do not have a bore and are commonly used for pressure testing.

Threaded Flanges: These flanges have internal threads to facilitate connection with threaded pipes or fittings.

Lap Joint Flanges: Lap joint flanges are used in conjunction with a stub end to allow easy alignment and assembly.

Face Types: Our alloy steel flanges come in various face types, including flat face, raised face, and ring type joint (RTJ), catering to different sealing requirements.

Alloy Steel Flanges Grades:

Our alloy steel flanges are available in a range of grades, ensuring superior performance and durability. Some of the grades we offer include:

Alloy Steel P5 Flanges

Alloy Steel P9 Flanges

Alloy Steel P11 Flanges

Alloy Steel P12 Flanges

Alloy Steel P22 Flanges

Alloy Steel P91 Flanges

These grades are meticulously crafted to meet industry standards and exceed customer expectations.

Benefits of Alloy Steel Flanges:

Corrosion Resistance: Alloy steel flanges offer excellent resistance to corrosion, making them suitable for harsh environments with corrosive substances.

High-Temperature Resistance: Withstand elevated temperatures without compromising performance, making them ideal for high-temperature applications.

Durability: Alloy steel flanges are durable and long-lasting, reducing maintenance costs and downtime.

Versatility: Available in various sizes, pressure ratings, and configurations to meet diverse industrial requirements.

Reliability: Provide secure connections, preventing leaks and ensuring the integrity of piping systems.

Uses and Applications of Alloy Steel Flanges

Piping Systems

Pressure Vessels

Chemical Processing

Power Generation

Shipbuilding

Aerospace

Oil and Gas Exploration

Food and Beverage Industry

Construction

Renewable Energy

Other Applications

Final Words!

Alloy steel flanges from Bullion Pipes & Tubes LLP offer unmatched quality, versatility, and reliability, making them the preferred choice for various industrial applications. Whether you require a weld neck, slip-on, socket weld, or any other type of flange, we have you covered with our comprehensive range of offerings. Choose Bullion Pipes & Tubes LLP for your alloy steel flange needs and experience the difference in quality and service. Contact us today at [email protected] or [email protected] to discuss your requirements and place your order.

0 notes

Text

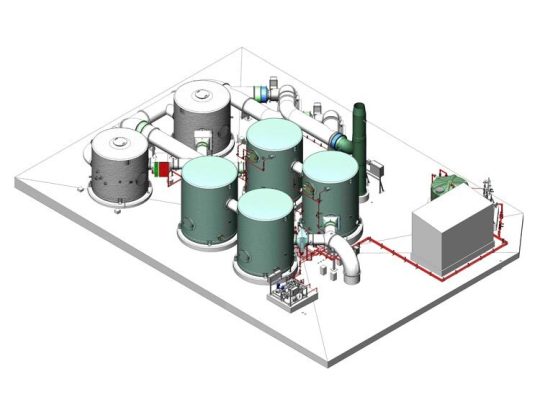

Pressure Vessel Manufacturers

An enclosed space with a pressure inside significantly higher or lower than the surrounding atmosphere. The typical operating pressure for Colt Equipment's (p) Ltd, the Pressure Vessel Manufacturers pressure vessel, is greater than 15 psig. Pressure vessels are containers for liquids or gases, typically cylindrical or spherical and made from carbon steel, stainless steel, aluminium, or other high-quality metals. Each type of pressure vessel has unique components, including a shell, nozzles, flanges, gaskets, baseplate, internals, and more. Naturally, they are sealed containers; otherwise, keeping the pressures inside from dropping would be impossible. Learn more about the pressure vessels manufactured by Colt Equipment (p) Ltd, the Pressure Vessel Manufacturers.

Pressure vessel function

Liquids, gases, and vapours used as inputs or outputs in production are kept in storage vessels. Depending on their composition and stability, it may be necessary to store these substances under carefully monitored conditions, such as temperature and pressure.

Pharmaceutical and industrial production processes rely heavily on heat exchangers, particularly double-sheet tubular heat exchangers. A service medium, typically a fluid or gas, flows through the tubes at high pressure to transfer heat to a product medium, typically a liquid or gas. As a result, heat exchangers are subject to temperature and pressure differentials, which strain the pharmaceutical machinery. You could learn about Plate Type Heat Exchangers from Colt Equipment's (p) Ltd.

Water, oil, and other liquids can be heated in a boiler by exposing the enclosed vessel to either fuel or electrical heat. The phase change that occurs when a liquid is heated has many practical uses. India's best Pressure Vessel Manufacturers use strong, heat-resistant, and corrosion-proof materials to withstand intense heat and pressure.

The definitive guide to finding a high-quality Indian producer of pressure vessels.

Safety

You've located an equipment partner who seems qualified for the task and dedicated to working together. How do you ensure that their services and goods are risk-free? Transparency is of the utmost importance to Colt Equipment's (p) Ltd, and it should also be to you. You can learn a lot about a company's dedication to safety by asking pointed questions about the equipment they plan to use.

When designing a pressure vessel, adhering to the guidelines outlined in ASME Section VIII is customary. You should conduct your evaluation of their pressure vessel design in addition to ensuring that they follow all applicable guidelines. You need to be familiar with the pressure vessel's thickness and diameter and its internal and external design pressures, test pressure, design temperature, type of support, construction material, tensile strength, and dimensions. When designing a pressure vessel, follow the ASME Section VIII, Division guidelines. You have a winner on your hands if the design satisfies your requirements and conforms to global norms.

Superior performance

Quality testing is a crucial part of manufacturing, just as in any other process or industry. When looking for reliable Pressure Vessels Suppliers and Manufacturers, such as Colt Equipment's (p) Ltd, it's important to inspect the gear they currently stock and may have produced for previous customers. Verify that the pressure vessel you expect is the one you get by reviewing the documentation for visual, ultrasonic, radiographic, magnetic particle, liquid penetrant, and pressure testing.

Conclusion Therefore, finding the right equipment partner from Colt Equipment's (p) Ltd is challenging in a competitive industry like pharma. Before making a choice, it's important to do your homework, cultivate trustworthy relationships, and monitor industry developments. Twenty years in business has given Colt Equipment's (p) Ltd. a depth of expertise that continues to grow. They're always up for a challenge and learning something new to help them complete your project successfully. Contact Pressure Vessel Manufacturers if you need high-quality pressure vessels made in India.

#Evaporative Condensors in India#Line Filter Manufacturers#Air Compressor on Rent in Delhi#Co2 reciprocating compressor#air compressor on rent near me

0 notes

Text

Pressure Relief Valves In-Depth Profiling With Key Players and Recent Developments, Forecast Period: 2021-2031

Pressure Relief Valves Market Research, 2031

The global pressure relief valves market size was valued at $4.4 billion in 2021, and is projected to reach $7 billion by 2031, growing at a CAGR of 4.6% from 2022 to 2031.Pressure relief valve (PRV) is also called as a relief valve. Pressure vessels and other equipment are protected by pressure relief valve from being subjected to pressures that exceed their design limits. The valve is used to control or limit the pressure built inside the equipment which may cause equipment or instrument failure, or fire. The pressure is relieved by allowing the pressurized fluid to flow from an auxiliary passage out of the system.

Pressure relief valve are used in the oil & gas industry for drilling and workover operations, which, in turn, increase demand for pressure relief valve, and is anticipated to boost growth of the pressure relief valve market. According to a report on North America Midstream Infrastructure through 2035 published in June 2018 by ICF International Inc., total investments in oil & gas infrastructure are projected to range between $685 billion and $895 billion from 2018 to 2035. In addition, pharmaceuticals and food & beverages industries are largely saturated in developing countries including European Union, such as the U.S. and China. Pressure relief valve have an important role in manufacturing of different types of medical devices and support key players to give opportunity during this pandemic situation. For instance, according to the India Brand Equity Foundation (IBEF), the food & beverage processing industry has emerged as a high-profit and high-growth sector, owing to its immense growth potential. Moreover, rise in number of industrial infrastructure projects in developing countries is driving the demand of pressure relief valves market. For instance, the government of China spent $10 billion on a new oil & gas refinery project, Guangdong refinery, which is expected to be completed by March 2022. Such instances are expected to drive the growth of the market. There are many domestic manufacturers present in places, which is expected to hamper growth of the pressure relief valve market. Domestic manufacturers provide pressure relief valve ranging from $100 to $200. However, key players offer pressure relief valve ranging from $100 to $2500. Hence, customer focuses more on adopting pressure relief valve from domestic manufacturers, which, in turn, hinders the pressure relief valves industry growth.

The global pressure relief valve market is segmented on the basis of valve type, pressure, end user, and region. Based on valve type, the market is divided into spring loaded, pilot loaded, dead weight and p and t actuated. Based on pressure, the market is divided into low, medium and high. Based on end user industry, the market is divided into oil & gas, chemical, power generation, food & beverage, manufacturing and water & wastewater.

COMPETITION ANALYSIS

The major players profiled in the pressure relief valve market include AGF Manufacturing, Inc., Alfa Laval, Curtis-Wright Corp, Emerson Electric Co., General Electric, Goetze KG Armaturen, IMI PLC, Mercury Manufacturing Company Limited, The Weir Group PLC, and Watts Water Technology, Inc.

Major companies in the market have adopted acquisition and product launch as their key developmental strategies to offer better products and services to customers in the pressure relief valve market.

Some examples of acquisition in the market

In February 2020, Curtiss-Wright Corporation, a leading provider of pressure safety and release valves, has acquired Dyna-Flo, a well-known designer and manufacturer of linear and rotary control valves, isolation valves, actuators, and level and pressure control systems for the chemical, petrochemical, and oil and gas markets, for $62 million. The acquired business will operate within commercial/industrial segment of Curtiss-Wright.

Some examples of product launch in the market

In December 2022, Emerson has launched two new-to-the-world technologies for the Crosby J-Series pressure relief valve (PRV) product line.

In April 2022, Lamot Valve & Arrestor has launched its new product: the Model L11E Weight-Loaded Pressure Relief Valve. The valve includes an option to add calibrated weights in 0.5 using increments, giving the operator the flexibility to adjust the set pressure of this valve from the top of the tank and eliminating the need to remove and retest in the shop on a test stand. It can be used as a stand-alone vent to the atmosphere pressure relief valve or can be used in addition to existing pressure relief valves to add additional flow capacity.

In December 2020, Weir Oil & Gas has launched latch back pressure valve system to increase safety, reliability of drill- thru operations.

In December 2020, Consolidated, a Baker Hughes subsidiary, has launched its new 1900 series dual media (DM) spring-loaded safety relief valve (SRV) with patented trim. The new series is designed to perform on both liquid and gas media and has dual certification (liquid and gas) nameplate capacity stamping in accordance with ASME (American Society of Mechanical Engineers) and BPVC (Boiler and Pressure Vessel) Code Case 2787. The 1900 DM series is the first and only spring-loaded safety relief valve in the industry that is ‘dual certified.’ Dual certified means the valve is both vapor/gas and liquid flow certified without making any modifications or adjustments to the relief device when switching fluids during the flow testing.

In November 2020, Danfoss has launched its new 65bar safety valve, SFA 10H, that offers reduced capacity, high reliability, and high-pressure for applications with CO2 and synthetic oils. The design and manufacturing of this product focuses on preventing leaks, providing perfect reseating after release, and keeping a stable set pressure over time.

In April 2020, Baker and Hughes has launched the 2900 series gen II pilot pressure relief valve (PRV). This innovative product has a full-nozzle main valve that easily threads in and out to save maintenance expenses while protecting the main valve body from corrosive service under normal operating circumstances.

In May 2019, Weir Oil & Gas has launched SPM SafeEdge ARC for Remote Setting and Digital Control of Relief Valves.

Full Report With TOC:-https://www.alliedmarketresearch.com/pressure-relief-valves-market-A16110#:~:text=The%20global%20pressure%20relief%20valves,called%20as%20a%20relief%20valve.

0 notes

Text

Characteristics and applications of hot-rolled stainless steel plates

Introduction to the characteristics of hot-rolled stainless steel plates:

1. Hot rolled stainless steel plate has low hardness, easy processing, and good ductility.

2. Hot rolled stainless steel plates have relatively low strength and poor surface quality (with oxidation or low surface finish), but have good plasticity and are generally medium thick plates. Cold rolled plates have high strength, high hardness, and high surface finish, and are generally thin plates, which can be used as stamping plates

3. Hot rolled stainless steel plates have mechanical properties far inferior to cold working and forging, but they have good toughness and ductility.

Introduction to the use of hot-rolled stainless steel plates:

1. The production of general structural steel and welded structural steel is mainly used for the production of steel structural components, bridges, ships, and vehicles.

2. Weathering resistant steel with special elements (P, Cu, C, etc.) has good corrosion resistance and atmospheric corrosion resistance, and is used in the production of containers and special vehicles, as well as in building structures.

3. High strength steel plates with good DRAWING and welding properties for automotive structures are used in the production of automotive frames, WHEEL, and other products.

4. Hot rolled special steel is generally used for mechanical structures, including carbon steel, alloy steel, and tool steel. After heat treatment engineering, it is used for the production of various mechanical components.

5. Cold rolled raw plates are used to produce various cold rolled products, including CR, GI, color coated plates, etc.

6. Steel plates for steel pipes have good processing performance and compressive strength, and are used for production with a total content of 500! The following high-pressure gas pressure vessels are filled with LPG, acetylene gas, and various gases.

7. The steel plate used for high-pressure vessels has good processing performance and compressive strength, and is used for producing 500 pieces of content! The following high-pressure gas pressure vessels are filled with LPG, acetylene gas, and various gases.

8. Stainless steel plate has good corrosion resistance and is mainly used in industries such as food industry, surgical equipment, aerospace, petroleum, and chemical industry.

0 notes

Text

HL.1602 Shock Wave Therapy Equipment Shock Wave Machine ED Shockwave Therapy Portable Compact in Carry Box Model

Contact us / What's app - 9711991264,9015251243,8076549111,8076205625,8

Website : www.solutionforever.com

https://lnkd.in/ejdC6Jy7

EMAIL : [email protected]

ADDRESS : F-400, Sudershan Park ,Moti Nagar ,Near Gopal ji Dairy ,ND-110015

HL.1602 Shock Wave Therapy Equipment Portable Shock Wave Machine ED Massager w/ Aluminum Box

Description:

There is a big difference in that Focused penetrate with greater accuracy and greater depth

This machine is a both radial and focused shockwave machine. It enables a good treatment effect of removing pain from a wide range of human tissue.

1.Shock wave pain therapeutic apparatus is a physics mechanism through the medium (air or gas) conduction of mechanical wave pulse pressure, produced by pneumatic pulse sound waves into precise ballistic shock wave, movement and positioning of probe through therapy, can happen to pain from a wide range of human tissue have good treatment effect.

2.Shock wave can change the chemical environment of the injury site, making the tissues produce and release pain-inhibiting chemicals. Meanwhile, shock wave can destroy the membrane of pain receptor, inhibit the production and propagation of pain signals. In addition, shock wave causes the production of endorphin, reducing the sensitivity of the injury site to pain.

3.Increase of cell wall permeability, stimulation of micro-circulation (Blood, Lymph), release of substance P, reduction of unmyelinated nerves, release of Nitric oxide (vasodilation, increased cell metabolism, neoangogenesis, anti-inflammatory effect), stimulation of Growth factors (neogenesis of vessels, bone, collagen) and stimulation of stem cells.

4. Pain relieve and treatment for plantar fasciitis, Achilles tendinitis, shoulder joint tendon inflammation and calcification, groin pain, epicondylitis.

5. The patients can feel first effects directly after treatment, pain relief after a few treating sessions, good treatment compliance.

Applications:

1. Shoulder pain, calcific tendonitis

2. Radial or ulnar humeral epicondylitis

3. Trochanteric tendonitis

4. Waist or stern pain

5. Patellar tendonitis

6. Tibial stress syndrome

7. Achillodynia

8. Plantar fascitis

9. ED Treatment

Specifications:

- Name: Electricity Shockwave Massage Machine

- Voltage: AC110V-AC220V

- Frequency: 50HZ/60HZ

- Power: 90W MAX

- Current: 2A MAX

- Output frequency Gear: 16

- Output level Gear: 12

#treatment #shockwavetherapy #shockwave #physiotherapy #physiotherapie #physiotherapists #physio #physiotherapystudent #chiropractic #chiropractor # #electricity #chiropractors #chiropracticcare #chiro #chiropracticworks #chiropracticadjustment #physiolife #physiotherapist #physiotherapie #hospital #medicaldevices #medical #health #wellness

0 notes

Text

HL.1602 Shock Wave Therapy Equipment Shock Wave Machine ED Shockwave Therapy Portable Compact in Carry Box Model

Contact us / What's app - 9711991264,9015251243,8076549111,8076205625,8

Website : www.solutionforever.com

https://lnkd.in/ejdC6Jy7

EMAIL : [email protected]

ADDRESS : F-400, Sudershan Park ,Moti Nagar ,Near Gopal ji Dairy ,ND-110015

HL.1602 Shock Wave Therapy Equipment Portable Shock Wave Machine ED Massager w/ Aluminum Box

Description:

There is a big difference in that Focused penetrate with greater accuracy and greater depth

This machine is a both radial and focused shockwave machine. It enables a good treatment effect of removing pain from a wide range of human tissue.

1.Shock wave pain therapeutic apparatus is a physics mechanism through the medium (air or gas) conduction of mechanical wave pulse pressure, produced by pneumatic pulse sound waves into precise ballistic shock wave, movement and positioning of probe through therapy, can happen to pain from a wide range of human tissue have good treatment effect.

2.Shock wave can change the chemical environment of the injury site, making the tissues produce and release pain-inhibiting chemicals. Meanwhile, shock wave can destroy the membrane of pain receptor, inhibit the production and propagation of pain signals. In addition, shock wave causes the production of endorphin, reducing the sensitivity of the injury site to pain.

3.Increase of cell wall permeability, stimulation of micro-circulation (Blood, Lymph), release of substance P, reduction of unmyelinated nerves, release of Nitric oxide (vasodilation, increased cell metabolism, neoangogenesis, anti-inflammatory effect), stimulation of Growth factors (neogenesis of vessels, bone, collagen) and stimulation of stem cells.

4. Pain relieve and treatment for plantar fasciitis, Achilles tendinitis, shoulder joint tendon inflammation and calcification, groin pain, epicondylitis.

5. The patients can feel first effects directly after treatment, pain relief after a few treating sessions, good treatment compliance.

Applications:

1. Shoulder pain, calcific tendonitis

2. Radial or ulnar humeral epicondylitis

3. Trochanteric tendonitis

4. Waist or stern pain

5. Patellar tendonitis

6. Tibial stress syndrome

7. Achillodynia

8. Plantar fascitis

9. ED Treatment

Specifications:

- Name: Electricity Shockwave Massage Machine

- Voltage: AC110V-AC220V

- Frequency: 50HZ/60HZ

- Power: 90W MAX

- Current: 2A MAX

- Output frequency Gear: 16

- Output level Gear: 12

#treatment #shockwavetherapy #shockwave #physiotherapy #physiotherapie #physiotherapists #physio #physiotherapystudent #chiropractic #chiropractor # #electricity #chiropractors #chiropracticcare #chiro #chiropracticworks #chiropracticadjustment #physiolife #physiotherapist #physiotherapie #hospital #medicaldevices #medical #health #wellness

0 notes

Text

Radar Level Transmitter : A new phase in contact-less level measurement

Controlling the liquid level in a reactor, tank, or other vessels accurately is critical in various, industrial applications. The container must be fitted with equipment that offers constant and precise level readings to ensure the profitability and safety of industrial activities. Inaccurate measurement leads to dangerously low or high levels in silos/vessels. While low levels cause damage to the equipment, high levels result in overflow and safety issues.

Radar Level Transmitters

Industrial Applications

As a concept, RADAR (Radio Detection and Ranging) is still evolving in industrial ‘level measuring’ applications. RADAR detects things within its range by achieving a reflection of electromagnetic waves sent by the instrument, calculating the precise time delay of reflection, and translating the reading into the level measurement.

Because of their adaptability and excellent safety, even when subjected to extreme pressure and temperature, radar-level transmitters are recommended for continuously monitoring solids such as stones, granules, fly ash, flakes, and powders.

Accurate radar-level transmitters are employed in essential engineering situations. These transmitters or level sensors have the following industrial uses.

Mining

Radar Level transmitters are used in the mining industry to verify the depth or length of mines, as well as the level of the ore’s surface. Depending on the air composition, even ultrasonic radar technology attachment may be employed.

Boilers

Due to extremely high water and stream temperatures, measuring fluid levels in boilers is particularly challenging. Guided wave radar level sensors are employed in such instances.

Since they are contactless & top-mounted, these guided probes are not affected by high temperatures. As a result, they are employed as fuel or fluid level indicators in boiler technology.

Aeronautics

In the automotive industry, gasoline levels are frequently measured with contact-type indicators. On the other hand, a fuel storage system is a little more complicated in aviation. As a result, radar-level transmitters are employed.

Paper and Pulp

These level transmitters are used in the paper and pulp industries to measure the level of slurry, water, and storage tanks. Because guided probes may be utilized in chemical environments, they are an excellent choice for the paper and pulp industries.

Bore Digging

Level transmitters are exposed to mud, slurry, and undersurface gases throughout the bore digging operation. Therefore, such instances use contactless radar level indicators to check surface levels.

Why One Should Shift To General Radar Level Transmitter

The following are the advantages of utilizing a General Radar Level Transmitter over alternative level measurement technologies:

1. Accurate Level Measurement up to 30 meters.

2. Suitable for both solid and liquid materials.

3. Ability to Remote Monitor in hazardous applications such as Oil & Gas, Chemicals, Pains

& Coatings to sterilised environments such as the Pharmaceutical and Food & Beverage

industries.

4. Even in rapidly changing levels, accurate and dependable level measurement with a

high signal-to-noise ratio is possible.

5. Because of the limited beam angle, the angle of repose is unaffected.

6. Suitable for dusty environments and changing silo process conditions.

7. Non-contact, with no moving parts, requires less maintenance or calibration

8. Top-mounted, simple installation and retrofit

9. HART 7 o/p is simple to set up.

10. Built-in surface profile settings avoid misleading readings caused by tank impediments.

General is well-known for offering a diverse selection of high-quality radar-level measurement devices and IIoT-based monitoring solutions. With an established legacy of 56 years, you can trust us with quality, reliability, and excellence.

Send us an email at [email protected] or call 022-24454387.

#Pressure Gauge Manufacturers in India#rtd temperature sensor#Gauge Manufacturers in India#radar level transmitter suppliers#Magnetic Level Gauge Manufacturer India

1 note

·

View note

Text

Pressure Vessels Suppliers and Manufacturers

How Oil Free Reciprocating Compressor

Pure compressed air is essential for proper operation. Oil spills make it more expensive to maintain clean air. Oil-free or oil-less air compressors are widely used to mitigate this issue. Compared to an oil-injected compressor, Colt Equipments' oil-free air compressor has fewer moving parts and requires no oil for lubrication.

Oil Free Reciprocating Compressor is gaining popularity today because of their low price, low environmental impact, and consistent output. Read on more about the machines' functionality and the advantages they can bring to your application.

How Oil-Free Air Compressors Work

Colt Equipments' oil-free air compressors either don't use moving parts within the compression chamber or employ other materials to shield the mechanism from wear and tear in place of lubrication.

Compressors that don't use oil often rely on water or a Teflon coating to prevent friction and wear. Proper sealing prevents oil from polluting the compressed air because the lubrication of bearings and gears occurs outside the compression chamber. The result is air that is completely free of oil. Several oil-free Pressure Vessels Suppliers and Manufacturers have further removed metal-to-metal contact within the compression chamber to eliminate the requirement for oil-based and synthetic lubrication.

Your total cost of ownership may decrease due to these improvements in cleanliness and the environment. Some things to think about if you're thinking about making the transition to an oil-free model:

Energy costs are kept to a minimum because there is no need to increase force, as some fluid-flooded units can experience a downstream pressure drop due to filtration, and oil-laden condensate does not need to be collected or disposed of.

The infrequent need to add oil to your compressor's tank means lower oil expenditures. When given the unload instruction, these machines can often begin unloading within two seconds, using roughly 18% of their full load horsepower.

It's tempting to save money in this way. If you're interested in using the oil-less compressors from Colt Equipments (P) Ltd. but need to know if you need them, it helps to understand how they operate, stack up against competing models, and what kinds of settings they thrive in.

Constructional Features

100% Oil Free Air

Oil Free Reciprocating Compressor and finished products are both vulnerable to contamination when oil is present in the air. Due to the absence of oil particles in the compressed air produced by Colt Reciprocating Compressors, the lifespan of the associated line equipment is extended. Oil is contained within the first section of the distance piece by packing efficient and wear-resistant rings.

No Foundation Required

Oil Free Reciprocating Compressor that has already been through rigorous testing can be safely installed on skids without causing damage. Anti-vibration mounts are standard on all Colt Compressors, making them the go-to option for installations on raised floors.

Complete Packaged Solution

Compressors are plug-and-play style for easy installation in this all-in-one solution. These units come complete with everything you need, including a programmable PLC control system, compressors, radiators, motors, air receivers, dryers, and more.

Pre - tested for Performance

Each Colt Oil Free Reciprocating Compressor goes through rigorous testing after assembly in a state-of-the-art testing Facility to ensure peak performance. After final assembly, packages are tested thoroughly on test beds under varying loads.

Engineering Excellence

Highly qualified, committed engineering project teams provide the most effective solutions for compression needs. Our commitment to constant technical innovation allows us to provide cutting-edge options to our customers.

Conclusion

"Colt" is synonymous with high-quality and long-lasting products like screw air compressors, reciprocating air and gas compressor units, chillers, ammonia refrigeration equipment, heat exchangers and pressure vessels. Over the past few years, the company's sales and service have skyrocketed thanks to its cutting-edge manufacturing facility in Nathupur, Sonepat District, Haryana. As a result of our technical expertise and familiarity with relevant terminology and tools, we have partnered with several companies in India and abroad as brand ambassadors.

0 notes

Text

Best Plant Design Service Shalin Designs

We offer impeccable enlisted services:

Process Engineering Design Services

Piping Design Services

PDFs or process flow diagrams in 2D drafting.

Support for steel detailing.

Offer study for process simulation.

Preparing manuals for plant operation & maintenance.

P&ID or piping & instrument diagrams in AutoCAD.

Point Clouds to CAD conversion for intelligent P&ID.

3D CAD modeling for piping arrangements.

FEA or Finite Element Analysis for measurement of stress tolerance and flexibility.

Preparation of construction documents for piping system.

GA drawing generation.

Mechanical Design or Equipment Design Services

Mechanical Design or Equipment Design Services

Using FEA and CED we offer engineering analysis for thermal, fluid flow, and structural elements.

Detailed 2D CAD drawings for tanks and fittings including, tank, valves, & pressure vessels.

Detailed designs for fluid handling and pumping equipment, such as pumps & turbines, heat exchanging equipment, & separators.

Equipment for material handling like cranes, hoists, receivers, etc.

Equipment for power generation, such as burners, furnaces, and boilers.

Standard Software & Tools for Plant Design

We use AutoCAD Plant 3D for the creation of plant layout, machine arrangements, and mechanical specifications for plants.

MEP (Mechanical, Electrical, Piping) 3D modeling by using Revit MEP & SolidWorks

BIM (Building Information Modeling) by Revit BIM & Tekla software, like BIM, helps in the efficient space utilization in the plant.

We provide design support and validation for mechanical, hydraulic, and pneumatic operated equipment by using ANSYS Fluent & ANSYS Mechanical tools.

We use reverse engineering tools for equipment replacement and assist OEM for manufacturing.

CADWorx, PDS- Plant design software, AutoPLANT

PDMS – Plant design & Management software, Smart® 3D

We deliver top quality Plant Design services to our global clientele based out of the USA, UK, Canada, Australia, Europe, Singapore, Norway, Ireland UAE region. Now, it is time to partner with the right CAD plant design services and Shalin Designs is an unbeatable selection for a wise business like you!

2 notes

·

View notes

Text

Next time you use the juice of a lemon don't throw out the peel! Lemon peels contain anywhere from 5-10 times the amount of vitamins than lemon juice. Lemons contain high amounts of vitamin C, minerals, fiber, antioxidants, and potassium. The peel contains important enzymes that help with digestion.

In TCM, lemon peels (and most citrus peels) help to move Qi stagnation in the Spleen and relieve poor appetite. When ingested, they aid in digestion, relieve gas and bloating and dissolve phlegm. Its nature is classified as sour, pungent, warm and slightly bitter entering through the Stomach and Spleen meridian channels. It also greatly helps the respiratory system.

More benefits of lemon peel:

🍋Lightens sun spots

🍋Relieves abdominal distension

🍋Aids with vomiting and diarrhea

🍋Prevents bacterial and fungal infections

🍋Treats high Blood pressure due to containing high levels of vitamin P

🍋Contains bioflavonoids which help to remove toxins within our bodies

🍋Helps with oral health and hygiene because the peels are rich in citric acid

🍋Prevents and treats the growth of cancer cells due to containing salvestrol Q40 and limonene

🍋Promotes weight loss due to containing pectin which helps us feel full and promote good bacteria and detoxification

🍋Helps to stabilize Blood vessels, especially the capillaries, making it ideal for healing varicose veins, bloodshot eyes, inflammation and hemorrhoids

Spring is a wonderful time to eat sour foods like citrus as it corresponds to the Five Element Framework, when the energy of the Liver is at its peak and sour is the flavor. Eating sour foods greatly benefits the health, function and healing of the Liver.

To consume lemon peel you can grate the skin and add it as zest to brighten up soups, rice dishes, vegetables, fish, meat, juices, tea and water. The options are endless! You can also freeze the lemon peel for a couple of hours and grate them. Lemon peel tea is amazing to consume in the morning or after a meal.

Bonus tip: lemon peels can be added to laundry to whiten clothing and you can distil it in white vinegar to make a natural, non-toxic household cleaner.

10 notes

·

View notes

Text

Characteristics and applications of hot-rolled stainless steel plates

Introduction to the characteristics of hot-rolled stainless steel plates:

1. Hot rolled stainless steel plate has low hardness, easy processing, and good ductility.

2. Hot rolled stainless steel plates have relatively low strength and poor surface quality (with oxidation or low surface finish), but have good plasticity and are generally medium thick plates. Cold rolled plates have high strength, high hardness, and high surface finish, and are generally thin plates, which can be used as stamping plates

3. Hot rolled stainless steel plates have mechanical properties far inferior to cold working and forging, but they have good toughness and ductility.

Introduction to the use of hot-rolled stainless steel plates:

1. The production of general structural steel and welded structural steel is mainly used for the production of steel structural components, bridges, ships, and vehicles.

2. Weathering resistant steel with special elements (P, Cu, C, etc.) has good corrosion resistance and atmospheric corrosion resistance, and is used in the production of containers and special vehicles, as well as in building structures.

3. High strength steel plates with good DRAWING and welding properties for automotive structures are used in the production of automotive frames, WHEEL, and other products.

4. Hot rolled special steel is generally used for mechanical structures, including carbon steel, alloy steel, and tool steel. After heat treatment engineering, it is used for the production of various mechanical components.

5. Cold rolled raw plates are used to produce various cold rolled products, including CR, GI, color coated plates, etc.

6. Steel plates for steel pipes have good processing performance and compressive strength, and are used for production with a total content of 500! The following high-pressure gas pressure vessels are filled with LPG, acetylene gas, and various gases.

7. The steel plate used for high-pressure vessels has good processing performance and compressive strength, and is used for producing 500 pieces of content! The following high-pressure gas pressure vessels are filled with LPG, acetylene gas, and various gases.

8. Stainless steel plate has good corrosion resistance and is mainly used in industries such as food industry, surgical equipment, aerospace, petroleum, and chemical industry.

1 note

·

View note