#industrial dryer manufacturers supplier

Text

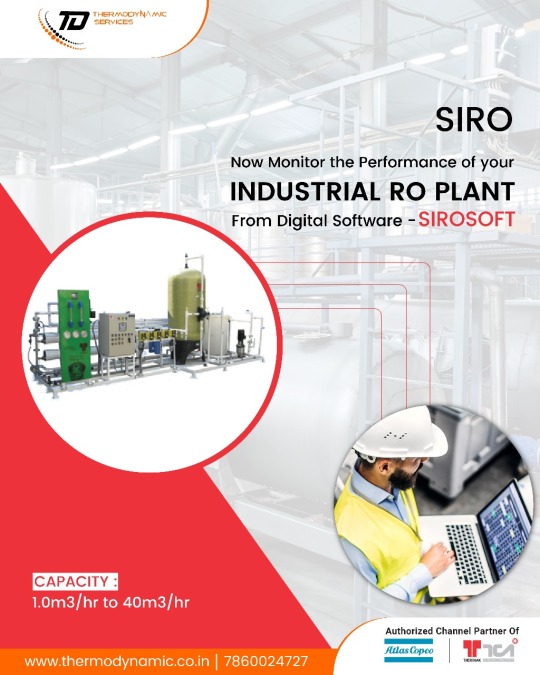

Atlas Copco Air Compressor Dealer in Uttar Pradesh - Thermodynamic Services

Welcome to Thermodynamic Services, your trusted partner for top-notch industrial air compressors and compressed air solutions in Uttar Pradesh. As the premier Atlas Copco dealer in the region, we take pride in delivering cutting-edge technology and reliable products to meet your diverse compressed air needs.

Atlas Copco Air Compressors in Uttar Pradesh:

At Thermodynamic Services, we specialize in offering a comprehensive range of Atlas Copco air compressors in Uttar Pradesh. Our commitment to quality and efficiency ensures that your industrial operations run smoothly with the most advanced and reliable compressed air solutions.

Atlas Copco Dealer in Kanpur:

If you are based in Kanpur and searching for a reliable Atlas Copco dealer, look no further than Thermodynamic Services. We bring you the latest models of Atlas Copco air compressors, combining innovation and durability to enhance your industrial processes.

Industrial Air Compressor Manufacturer & Supplier in Kanpur:

As a leading industrial air compressor manufacturer and supplier in Kanpur, Thermodynamic Services provides customized solutions tailored to meet the unique requirements of your business. Our state-of-the-art compressors are designed to optimize energy efficiency and minimize downtime.

Atlas Copco Compressed Air Dryer Dealer in Uttar Pradesh:

Thermodynamic Services is your go-to Atlas Copco compressed air dryer dealer in Uttar Pradesh. Our range of air dryers ensures that your compressed air is free from moisture, contaminants, and impurities, guaranteeing the longevity and efficiency of your equipment.

Unmatched Quality and Reliability:

When you choose Thermodynamic Services, you invest in unparalleled quality and reliability. Our partnership with Atlas Copco, a global leader in compressed air technology, ensures that you receive products that adhere to the highest industry standards.

Customer-Centric Approach:

At Thermodynamic Services, customer satisfaction is our priority. Our team of experienced professionals is dedicated to understanding your specific needs and providing tailored solutions. We believe in building lasting relationships with our clients through exceptional service and support.

Conclusion:

For all your industrial air compressor needs in Uttar Pradesh, Thermodynamic Services stands as the preferred choice. As the foremost Atlas Copco dealer in the region, we guarantee top-quality products, unmatched reliability, and a customer-centric approach. Elevate your industrial processes with Thermodynamic Services – your trusted partner for compressed air solutions.

conatct us on 91 78600 24711

#industrial air compressor dealer in uttar pradesh#Atlas Copco Air Compressor#Atlas Copco Air Compressors in Uttar Pradesh:#Atlas Copco Dealer in Kanpur#Industrial Air Compressor Manufacturer & Supplier in Kanpur:#Atlas Copco Compressed Air Dryer Dealer in Uttar Pradesh:#industrial air compressor needs in Uttar Pradesh

5 notes

·

View notes

Text

Drying Tumbler

Introducing our revolutionary Drying Tumbler – the pinnacle of innovation in the realm of laundry technology. This state-of-the-art appliance redefines the way you approach drying, providing a harmonious blend of efficiency, precision, and fabric care.

Avon Engineering's drying tumbler offers several advantages that make it a preferred choice in the laundry and textile industry:

Key Features Of Avon Drying Tumbler

Experience the future of laundry care with our Drying Tumbler's swift and efficient drying capabilities. In addition, it reduces drying time while maintaining fabric integrity. Our machine boasts cutting-edge airflow technology that evenly circulates warm air. Consequently, every garment is thoroughly and uniformly dried, from delicate fabrics to heavy textiles. Tailor your drying experience to perfection with our Drying Tumbler's range of customizable settings. Moreover, you can select drying times, temperatures, and programs that suit your laundry needs. We understand that fabric quality matters. Hence, with our carefully designed drying programs, your clothes are treated with care, preventing shrinkage, wrinkling, and maintaining their original texture. Committed to sustainability, our Drying Tumbler is engineered to optimize energy consumption without compromising performance. As a result, it reduces your carbon footprint and energy bills. Whether you have a few garments or a substantial laundry load, our Drying Tumbler's spacious interior accommodates it all. Furthermore, making laundry efficient and hassle-free. Simplifying your laundry routine, our machine features an intuitive interface. Consequently, you can easily navigate through drying options, monitor progress, and get perfectly dry clothes with ease. Embrace quiet laundry sessions with our Drying Tumbler. Additionally, it operates with minimal noise, ensuring a peaceful environment while your laundry dries to perfection. Crafted with precision and built to last, our Drying Tumbler is designed for durability. Therefore, you can count on it for consistent performance and reliability over the years.

#Drying Tumbler#Industrial Drying Tumbler#Commercial Drying Machine#Laundry Drying Equipment#Textile Drying Tumbler#Industrial Laundry Dryer#Clothes Drying Machine#Stainless Steel Drying Tumbler#High Capacity Drying Tumbler#Gas/Electric Drying Tumbler#Automatic Drying Machine#Tumble Dryer Manufacturer#Dryer Machine Supplier#Laundry Equipment Supplier#Energy Efficient Drying Tumbler#Bulk Drying Tumbler#Low Noise Drying Tumbler#Drying Tumbler for Garments#Laundry Dry Cleaning Tumbler#Heavy Duty Drying Machine

0 notes

Text

Comprehensive Solutions in Thermodynamic Services: A Leading Partner in Uttar Pradesh

Introduction: In the bustling industrial landscape of Uttar Pradesh, Thermodynamic Services emerges as a beacon of excellence, catering to a diverse range of thermodynamic needs. With a rich history of collaboration with industry giants like Thermax Limited, Atlas Copco (India) Limited, and Buhler India Pvt. Limited, Thermodynamic Services stands as a trusted partner offering comprehensive solutions. Specializing in industrial air compressors, compressed air dryers, thermic fluid heaters, industrial water treatment plants, STP plants for hospitals, and ETP plants for industrial use in Kanpur and beyond, Thermodynamic Services is committed to addressing the most challenging issues in heat, energy, air, water, solar, and grain processing.

Industrial Air Compressor Manufacturer & Supplier in Kanpur: As a premier industrial air compressor manufacturer and supplier in Kanpur, Thermodynamic Services delivers top-of-the-line equipment tailored to meet the rigorous demands of modern industries. Drawing from years of expertise and partnerships with leading manufacturers, we provide cutting-edge solutions that ensure optimal performance and efficiency for our clients' operations.

Compressed Air Dryer / Refrigerated Air Dryer Supplier in Kanpur: Recognizing the critical importance of quality compressed air in industrial processes, Thermodynamic Services offers premium compressed air dryers and refrigerated air dryers. Our products guarantee the delivery of clean, dry air, free from moisture and contaminants, thereby safeguarding the integrity of our clients' operations and prolonging the lifespan of their equipment.

Thermic Fluid Heater Supplier/Manufacturer in Uttar Pradesh: In the realm of thermic fluid heating systems, Thermodynamic Services stands as a distinguished supplier and manufacturer in Uttar Pradesh. Our thermic fluid heaters are engineered to deliver efficient heat transfer, ensuring consistent performance and reliability across various industrial applications. With a focus on innovation and quality, we empower our clients to optimize their processes while minimizing energy consumption.

Industrial Water Treatment Plants Supplier/Manufacturer in Uttar Pradesh: Water is a precious resource, and Thermodynamic Services is committed to its responsible management through advanced water treatment solutions. As a leading supplier and manufacturer of industrial water treatment plants in Uttar Pradesh, we offer customized systems designed to meet the unique needs of each client. From filtration to purification, our solutions ensure the availability of clean water for industrial processes, enhancing productivity and sustainability.

STP Plant for Hospitals: Ensuring safe and sustainable wastewater management is imperative for healthcare facilities, and Thermodynamic Services provides tailored solutions with our STP (Sewage Treatment Plant) plants for hospitals. Compliant with regulatory standards and designed for efficiency, our STP plants effectively treat wastewater, mitigating environmental risks and promoting a healthier community.

ETP Plant for Industrial Use in Kanpur: Industries in Kanpur rely on efficient wastewater treatment, and Thermodynamic Services meets this demand with our ETP (Effluent Treatment Plant) plants for industrial use. Through advanced technologies and expert engineering, our ETP plants efficiently remove pollutants from industrial effluents, ensuring compliance with environmental regulations and fostering sustainable industrial practices.

Conclusion: Thermodynamic Services stands as a testament to excellence in thermodynamic solutions, driven by a commitment to innovation, quality, and customer satisfaction. With a proven track record of serving esteemed clients and addressing complex challenges, we continue to be the preferred partner for industries across Uttar Pradesh. Whether it's industrial air compressors, compressed air dryers, thermic fluid heaters, water treatment plants, or wastewater management solutions, Thermodynamic Services remains at the forefront, empowering industries to thrive in an ever-evolving landscape.

#Industrial air compressor manufacturer & supplier in kanpur#Air compressor dealers in Kanpur/ Uttar Pradesh#compressed air dryer / refrigerated air dryer supplier in kanpur#STP plant for hospitals#ETP Plant for industrial use in kanpur

0 notes

Text

Drying System Manufacturer in Pune

After threshing, the moisture level of grains is typically more significant than the acceptable range for safe grain storage (13–14%). The post-harvest system's drying phase involves quickly drying the product until it reaches the "safe-moisture" threshold. The goal of drying is to reduce the grain's moisture content so that it can be stored safely and processed further.Reach out to the Drying System Manufacturer in Pune. For more details visit our website today https://www.arkchem.in/drying.html

#Drying System#Understand the Benefits#Industrial Dryers in Pune#Turnkey System Manufacturer Pune#Drying System Supplier in Pune#Mixing System Manufacturers Pune#Extraction System Manufacturer Pune#Process Engineering Company in Pune

0 notes

Text

Kinc Mineral Technologies Pvt Ltd introduces a wide assortment of drying plants including rotary dryer and rotary drum dryer. Owing to our wide industry expertise, we offer premium quality drying plants at affordable prices to our clients. For more information, get in touch with us.

#drying plant#drying plant manufacturers#drying plant suppliers#drying plant exporters#industrial plants#rotary dryer

0 notes

Text

What are the types of Industrial dryers?

Mathesis is the leading Industrial dryers manufacturer. Know about rotary drum dryer equipment, vacuum tray dryer, industrial tumble dryers, drum drying process and uses.

1) Thermal Desorption of Drilled Mud using Hollow Paddle Dryer

2) Agro Chemicals Drying-Spin Flash Dryer

3) Effluent Drying-Twin Drum Dryer

4) Hygroscopic Pharma Intermediates Drying-Contionous Fluidised Bed Dryer

5) Agrochemicals Drying-Vaccum Drum Dryer

6) Protein Concentration-Agitated Thin Film Evaporator

7) Agrochemicals Dryer-Continous Screen Conveyor Dryer

8) Biomass Drying-Hollow Paddle Dryer9) Agrochemicals Effluent Dryer-Agitated Thin Film Dryerhttps://www.mathesis.co.in/dryers.php

#industrial air dryer manufacturers#industrial tumble dryer manufacturers#industrial vacuum dryer manufacturers#industrial air dryer manufacturers in india#how does an industrial air dryer work#rotary vacuum dryer manufacturers in india#rotary drum dryer manufacturers india#industrial dryer suppliers#vacuum tray dryer manufacturers in india

0 notes

Text

#industrial#industries#dryer oven manufacturers in bangalore#climate control oven manufacturers in bangalore#oven#ovenparts#hot air dryer manufacturers in bangalore#hot air chamber manufacturers in india#hot air oven manufacturers in bangalore

2 notes

·

View notes

Text

Exporter of Spin Flash Dryer in Libya

Drytech Engineering Systems is an Exporter of Spin Flash Dryer in Libya.

We are based in Ahmedabad, Gujarat, India.

Drytech Engineering Systems is a Manufacturer, Supplier and Exporter of Spray Dryers, Flash Dryers, Spin Flash Dryers, and Multi Effect Evaporators.

Spin Flash Dryer is a specialized industrial drying equipment used to efficiently dry fine powders, granules, or slurries.

It operates by utilizing a combination of mechanical agitation, high-speed rotation, and hot air to remove moisture from the material.

The design promotes a continuous flow of materials, making it suitable for bulk processing in various industries.

Features:

High Efficiency: The dryer maximizes heat transfer and moisture removal, significantly reducing drying time compared to conventional methods.

Compact Design: Its space-saving design allows for easy integration into existing production lines without requiring extensive modifications.

Uniform Drying: The combination of spinning and airflow ensures even drying across all particles, preventing clumping and ensuring consistent product quality.

Adjustable Parameters: Users can modify drying temperatures, air velocity, and residence time to optimize the process for specific materials.

Continuous Operation: Designed for continuous feed, it allows for uninterrupted production, enhancing overall operational efficiency.

Energy Savings: The efficient drying process minimizes energy consumption, making it an environmentally friendly option.

Applications:

Food Industry

Chemical Industry

Pharmaceuticals

Minerals and Metals

Biotechnology

Drytech Engineering Systems is an Exporter of Spin Flash Dryer in Libya including locations

Tripoli, Benghazi, Ajdabiya, Misrata, Al Bayda, Al Khums, Az Zawiya, Gharyan, Al Marj, Tobruk, Sabratha, Al Jumail, Derna, Janzur, Zuwara, Masallata, Sirte, Yafran, Nalut, Bani Walid, Tajura, Birak, Shaahat, Murzuq, Awbari, Qasr al Qarabulli, Waddan, Al Qubbah, Al Aziziyah, Mizdah, Toukra, Ghat, Az Zuwaitina, Hun, Qaryat al Qiyan, Al Jawf, Zaltan, Az Zintan, Qaryat Suluq, Tarhuna, Umm ar Rizam, Qaminis, Kiklah, Ghadamis, Sukhna, As Sidrah, Al Bardiyah, Al Abraq, Bin Jawwad, Sousa, Martubah, Al Qayqab, Musaid, Taknis, Al Burayqah, Awjilah, Farzughah, Bir al Ashhab, Qaryat al Faidiya, Jardas al Abid, Qandulah, Kambut, Daryanah, Marawah, Jikharrah, Zawilah, Wazin, Qirnadah, Bir al Ghanam, Ar Rajmah, Al Jaghbub, Sabha.

Contact Us For detailed information and inquiries, please feel free to contact us.

View Product: Click Here

Read the full article

0 notes

Text

Industrial Oil Burner, Industrial Gas Burner | Narayan Burner

Find here best Industrial Gas Burner for Incinerator. It is highly acclaimed by the clients for a complete analysis of the Burner in accordance with the burn and other quality parameters. Pharmaceutical Dryer Burner acclaimed by the clients for best quality performance. We are a Leading Manufacturer, Supplier & Exporter of Industrial Oil Burner including Furnace Oil Burner, Heavy Oil Burners, Boiler Oil Burner, Fuel Oil Burners, Diesel Oil Burner, Pressure Jet Oil Burner in Surat, Gujarat, India.

Applications for industrial gas burners

Industrial Light Oil Burners

Industrial LPG Burners

Industrial Biogas Burner

Industrial Biogas Burner

High Temperature Burner

Dryer Burners

Powder Coating Oven Gas Burner

Powder Coating Oven Burner

Hot Water Generator Burner

Hot Water Generator Gas Burner

Bakery Oven Burner

Bakery Oven Gas Burner

Tea Dryer Burner

Pharmaceutical Dryer Burner

Pharmaceutical Dryer Gas Burner

Tray Dryer Burner

Tray Dryer Gas Burner

High Temperature Gas Burners

Commercial Gas Burners

Light Oil Burners

Sand Dryer Burner

Sand Dryer Gas Burner

Gas Burners for commercial application

Gas Burners for fryers

Gas Burners for Hot air generator

Gas Burners for Foundry

Gas burners for Metal industry

Gas burner for Aluminium Melting

Gas Burner for Metal Melting

Gas Burner for Furnace application

Gas Burners for Boilers

Gas Burner for thermic fluid heater

Gas Burner for Non-IBR boiler

Gas Burner for Incinerator

Gas Burner for Kiln

Gas Burners for Tin printing Dryer

Burners for Lead Melting Furnace

Paper Printing Dryer Burner

Roto Mould Oven Burner

Asphalt Plant Burners

Aluminium Curring Oven Burners

Ceramic Furnace Burners

Rotary Kiln Furnace Burners

Batch Oven Burners

Tumble Dryer Burners

Vertical Boiler Burner

Teflon Coating Oven Burner

Dual Fuel Burner for Boilers

Dual Fuel Burner for Hot Air Generators

Dual fuel burner for Thermic Fluid Heater

Industrial Burner for Powder Coating Oven

Dual Fuel Burners for Incinerator

Industrial Burners for Furnace

Industrial Burner for Bakery Oven

Industrial Burner for Hot Air Generator

Industiral Burner for Klin

Industrial Burner for Thermic Fluid Heater

Industrial Burner for Aluminium Melting Furnace

Industrial Burner for Metal Melting Furnace

Industrial Burner for Incinerator

Industrial Burner for Heat Treatment

Industrial Burner for Asphalt Plant

Industrial Burner for Glass Industry

For More Details

Click here : https://www.narayanburners.com/

0 notes

Text

Vertical Granule Mixer with Dryer in Tamil Nadu

Adroit Extrusion is a Supplier of Vertical Granule Mixer with Dryer in Tamil Nadu.

Our Manufacturing Unit is in Ahmedabad, Gujarat, India.

We provide a range of Multi-Layer Blown Film Machines, including 7/5 Layer Barrier, 5 Layer POD,

and 3 Layer Blown Film Plants.

Adroit Extrusion specializes in manufacturing, supplying, and exporting various types of blown film machines, including Monolayer Blown Film Machines, ABA and AB Blown Film Machines, as well as Multi-Layer Blown Film Machines.

We are a leading manufacturer and supplier of high-quality Vertical Granule Mixers with integrated dryers.

Our advanced equipment is designed to streamline your production processes, offering superior performance and efficiency.

Why Choose Us?

Expert Manufacturing: With years of industry experience, we provide reliable and high-performance mixers and dryers tailored to your specific needs.

Global Supplier: Serving clients worldwide with timely delivery and exceptional customer support.

Custom Solutions: We offer customization options to meet your unique production requirements and operational needs.

Features:

Efficient Mixing and Drying: Our vertical granule mixers come with built-in dryers, ensuring thorough mixing and quick drying of granules in one compact unit.

Advanced Technology: Equipped with state-of-the-art technology to deliver consistent and high-quality results, reducing production time and improving output.

User-Friendly Design: Engineered for ease of use, with intuitive controls and a robust build that ensures long-term durability and minimal maintenance.

Versatile Applications: Ideal for various industries including pharmaceuticals, chemicals, food processing, and plastics, accommodating a wide range of granule types and sizes.

Energy Efficiency: Designed to optimize energy consumption, helping you reduce operational costs and environmental impact.

Adroit Extrusion is a Supplier of Vertical Granule Mixer with Dryer in Tamil Nadu and includes locations like Chennai, Coimbatore, Madurai, Tiruchirappalli, Salem, Ambattur, Tirunelveli, Tiruppur, Avadi, Tiruvottiyur, Thoothukkudi, Nagercoil, Thanjavur, Pallavaram, Dindigul, Vellore, Tambaram, Cuddalore, Kancheepuram, Alandur, Erode, Tiruvannamalai, Kumbakonam, Rajapalayam, Kurichi, Madavaram, Pudukkottai, Hosur, Ambur, Karaikkudi, Neyveli, Nagapattinam.

For further details, please feel free to contact us.

View Product: Click Here

Read the full article

0 notes

Text

#Drying System#Understand the Benefits#Industrial Dryers in Pune#Turnkey System Manufacturer Pune#Drying System Supplier in Pune#Mixing System Manufacturers Pune#Extraction System Manufacturer Pune#Process Engineering Company in Pune

0 notes

Text

The Evolution of Food Freeze Dryers in India

In a nation renowned for its rich culinary heritage and diverse food practices, the advent of food freeze dryers represents a groundbreaking shift in food preservation and quality. India, with its booming food industry and growing demand for high-quality, shelf-stable products, is witnessing a surge in the adoption of food freeze dryers. This article explores the impact of food freeze dryers in India, the benefits they bring, key players in the market, and how they are transforming the food industry.

What Are Food Freeze Dryers?

Food freeze dryers, or lyophilizers, are specialized machines designed to remove moisture from food products while preserving their original flavor, texture, and nutritional value. The process of freeze-drying involves freezing the food, then placing it in a vacuum chamber where the frozen water sublimates directly from ice to vapor. This process results in a lightweight, shelf-stable product that can be rehydrated easily without compromising quality.

Benefits of Food Freeze Dryers

Preservation of Nutritional Value: Freeze-drying maintains the nutritional content of food, including vitamins and minerals, which are often lost in traditional drying methods. This ensures that consumers receive the full health benefits of the food.

Enhanced Flavor and Texture: Unlike other preservation methods that can alter the texture and taste of food, freeze-drying retains the original flavor and texture, making it a preferred choice for high-quality food products.

Extended Shelf Life: Freeze-dried foods have a significantly longer shelf life compared to other preserved foods. This makes them ideal for emergency supplies, military rations, and long-term storage.

Convenience and Portability: Freeze-dried foods are lightweight and compact, making them easy to transport and store. This is particularly advantageous for outdoor enthusiasts, travelers, and for use in space missions.

Reduced Waste: By preserving food effectively, freeze-drying helps reduce food waste. This is beneficial for both consumers and suppliers by extending the usability of perishable items.

The Growing Demand for Food Freeze Dryers in India

India’s food industry is undergoing a transformation driven by changing consumer preferences, technological advancements, and the need for efficient preservation methods. Several factors contribute to the growing demand for food freeze dryers in India:

Increasing Consumer Awareness: With a rising focus on health and wellness, Indian consumers are seeking products that offer superior nutritional value and quality. Freeze-dried foods align with these preferences, offering a premium option that preserves natural goodness.

Expansion of Export Markets: India is a significant player in the global food market, exporting a variety of food products. Freeze-drying enhances the shelf life and quality of products, making them more competitive in international markets.

Growth of the Convenience Food Sector: The demand for ready-to-eat and convenience foods is increasing in India. Freeze-drying provides a solution for producing high-quality, shelf-stable products that cater to busy lifestyles.

Advancements in Technology: The development of advanced freeze-drying technology has made the equipment more accessible and efficient, encouraging adoption by Indian food manufacturers and processors.

Key Players in the Indian Food Freeze Dryer Market

Lyo Group : At LSI, we are dedicated to providing high-quality, high-performance freeze dryers for the research, and pharmaceutical industries. Our roots can be traced back to New York in 1996, where we first began our journey to become a leading provider of freeze drying solutions. Today, we are proud to have a global reach with multiple locations and representatives serving customers all around the world.

We believe that our success lies in our commitment to excellence in every aspect of our business. From the materials and components used in our equipment, to the testing and validation processes, we aim to provide our customers with freeze dryers that are reliable, easy to use, and easy to maintain.

Challenges and Opportunities

While the adoption of food freeze dryers in India is on the rise, there are several challenges and opportunities to consider:

Cost Considerations: The initial investment in freeze-drying technology can be substantial. However, the long-term benefits, including reduced wastage and extended shelf life, often justify the cost.

Technological Advancements: Keeping up with the latest technological advancements is essential for manufacturers to stay competitive. Continuous innovation in freeze-drying technology can enhance efficiency and product quality.

Training and Support: Proper training and support are crucial for effective use and maintenance of freeze-drying equipment. Providing comprehensive training and technical support can enhance the adoption and utilization of these systems.

Customization Needs: Different food products require specific freeze-drying conditions. Offering customizable solutions that cater to the diverse needs of the food industry can provide a competitive edge.

Conclusion

Food freeze dryers are revolutionizing the Indian food industry by offering a superior method for preserving the quality, flavor, and nutritional value of food products. As consumer preferences shift towards healthier and more convenient options, the demand for freeze-dried foods is set to grow. Key players in the market are driving innovation and providing high-quality equipment to meet this demand, paving the way for a new era in food preservation. With continued advancements and a focus on addressing challenges, food freeze dryers are poised to make a significant impact on India’s culinary landscape and beyond.

0 notes

Text

Pharmaceutical Ultrasonic Cleaners, Manufacturer, Supplier, India

Pharmaceutical Ultrasonic Cleaners, Pharmaceutical Ultrasonic Cleaners Manufacturer, Pharmaceutical Ultrasonic Cleaners Supplier, Mumbai, India.

Water Bath, Multi Stage Cleaning Systems, Ultrasonic Immersible Transducers, Ultrasonic Cleaner With Dryer, Ultrasonic Cleaning Systems, Ultrasonic Cleaners, Ultrasonic Equipment, Table Top Sonicator With Inbuilt Chiller Unit, Refrigeration Products, Water Cooler, Ice Cube Machine, Single Door Deep Freezer, Hard Top Deep Freezer, Glass Top Deep Freezer, Utrasonic Cleaners For Medical Instruments, Ultrasonic Cleaner For Industrial Filter Cleaning, Ultrasonic Cleaner For Automobile Industries, Ultrasonic Cleaner For Medical Industry, Ultrasonic Cleaner For Electronic Industry, Ultrasonic Cleaner For Hotel Industry, Ultrasonic Cleaner With Mechanical Timer, Mumbai, India.

#Water Bath#Multi Stage Cleaning Systems#Ultrasonic Immersible Transducers#Ultrasonic Cleaner With Dryer#Ultrasonic Cleaning Systems#Ultrasonic Cleaners#Ultrasonic Equipment#Table Top Sonicator With Inbuilt Chiller Unit#Refrigeration Products#Water Cooler#Ice Cube Machine#Single Door Deep Freezer#Hard Top Deep Freezer#Glass Top Deep Freezer#Utrasonic Cleaners For Medical Instruments#Ultrasonic Cleaner For Industrial Filter Cleaning#Ultrasonic Cleaner For Automobile Industries#Ultrasonic Cleaner For Medical Industry#Ultrasonic Cleaner For Electronic Industry#Ultrasonic Cleaner For Hotel Industry#Ultrasonic Cleaner With Mechanical Timer#Mumbai#India

0 notes

Text

#ovens manufacturers#industrial oven manufacturers in india#hot air oven manufacturers in india#hot air chamber manufacturers in india

0 notes

Text

Exporter of Flash Dryer in Tunisia

Drytech Engineering Systems is a leading Exporter of Flash Dryer in Tunisia.

We are based in Ahmedabad, Gujarat, India.

Drytech Engineering Systems is a Manufacturer, Supplier, and Exporter of Spray Dryers, Flash Dryers, Spin Flash Dryers, and Multi Effect Evaporators.

Flash Dryer Manufacturer specializes in designing and producing flash dryers, which are industrial machines used for rapidly drying materials.

These manufacturers focus on creating equipment that utilizes high-velocity hot air to evaporate moisture from various substances, including powders, granules, and slurries.

Why Choose Our Flash Dryer?

Reliability: Built with high-quality materials for durability and longevity.

Customization: Tailored solutions to meet specific production needs.

Expert Support: Our team provides comprehensive support from installation to maintenance.

Features:

Fast Drying Process: Utilizes high-velocity hot air to quickly evaporate moisture, significantly reducing drying time.

Versatility: Suitable for a wide range of materials, including powders, granules, and slurries.

Energy Efficiency: Optimized design minimizes energy consumption, lowering operational costs.

Compact Design: Space-saving structure allows for easy integration into existing production lines.

Control Systems: Advanced automation and monitoring ensure precise temperature and airflow control, enhancing product quality.

Applications:

Food Industry

Chemical Processing

Pharmaceuticals

Drytech Engineering Systems is an Exporter of Flash Dryer in Tunisia locations in Tunis, Sfax, Sousse, Bizerte, Aryanah, Gafsa, and El Mourouj.

Contact Us For detailed information and inquiries, please feel free to contact us.

View Product: Click Here

Read the full article

0 notes

Text

Magnesium Sulfide Manufacturing Plant Project Report 2024: Setup and Cost

The Magnesium Sulfide Manufacturing Plant Project Report offers a detailed blueprint for establishing a facility dedicated to producing magnesium sulfide (MgS), a versatile compound with applications spanning agriculture, environmental remediation, and material science. Magnesium sulfide is valued for its role in improving soil fertility, treating contaminated environments, and contributing to advanced materials. This comprehensive report outlines the essential steps and considerations for setting up a magnesium sulfide manufacturing plant, including market analysis, technological requirements, regulatory compliance, and financial planning. Designed for investors and industry professionals, the report provides crucial insights into the complexities of magnesium sulfide production and highlights the potential opportunities in this growing sector.

Understanding Magnesium Sulfide

Magnesium sulfide is an inorganic compound that is primarily used in the following applications:

Agriculture: As a soil amendment to improve soil fertility and provide essential magnesium nutrients.

Environmental Remediation: In the treatment of wastewater and soil contaminated with heavy metals.

Material Science: In the production of certain types of ceramics and as a precursor for various magnesium compounds.

Benefits of Magnesium Sulfide:

Nutrient Supply: Provides magnesium, a crucial nutrient for plant growth.

Pollution Control: Effective in removing contaminants from water and soil.

Material Enhancement: Used in advanced materials with specific properties.

Get a Free Sample Report with Table of Contents @ https://www.expertmarketresearch.com/prefeasibility-reports/magnesium-sulfide-manufacturing-plant-project-report/requestsample

Key Considerations for Setting Up a Magnesium Sulfide Manufacturing Plant

Market Research and Feasibility Study Conducting thorough market research is essential for understanding the demand for magnesium sulfide and identifying potential customers. Assess the needs of industries such as agriculture, environmental services, and material science. A feasibility study will help determine the economic viability of the project, including investment requirements, market size, and revenue projections.

Location and Infrastructure Choosing the right location is crucial for the success of the manufacturing plant. Consider the following factors:

Proximity to Raw Materials: Ensure access to raw materials such as magnesium ore and sulfur.

Logistics: Select a location with efficient transportation networks for both raw material supply and product distribution.

Infrastructure: The facility should be equipped with necessary utilities like electricity, water, and waste management systems. Adequate space for production, storage, and administrative functions is also important.

Technology and EquipmentThe production of magnesium sulfide requires specialized technology and equipment. Key components include:

Reactors: For the chemical reaction that produces magnesium sulfide from magnesium and sulfur.

Dryers and Kilns: To process and convert raw materials into the final product.

Quality Control Instruments: To test the purity and quality of the magnesium sulfide produced.

Material Handling Systems: For efficient management of raw materials and finished products.Investing in advanced technology and maintaining high standards of equipment maintenance are crucial for efficient and consistent production.

Raw Materials and Supply ChainThe primary raw materials for magnesium sulfide production include:

Magnesium Ore: The source of magnesium for the compound.

Sulfur: Required to react with magnesium to produce magnesium sulfide.Establishing reliable relationships with suppliers to ensure a steady and high-quality supply of raw materials is essential. Efficient supply chain management will help maintain production schedules and control costs.

Regulations and ComplianceOperating a magnesium sulfide manufacturing plant involves adherence to various regulations and standards. Key compliance areas include:

Environmental Regulations: Implement measures to manage emissions, waste, and resource usage. Ensure proper disposal of by-products and adherence to environmental protection standards.

Safety Regulations: Develop and enforce safety protocols to protect workers and prevent accidents. This includes proper training, protective equipment, and emergency response plans.

Quality Standards: Comply with industry standards for product quality and safety. This may include certifications such as ISO for quality management.Regular audits and inspections will help ensure ongoing compliance with regulatory requirements.

Production ProcessThe production process for magnesium sulfide generally involves the following stages:

Preparation: Raw materials are prepared and measured for the reaction process.

Reaction: Magnesium and sulfur are reacted under controlled conditions to produce magnesium sulfide.

Processing: The magnesium sulfide is processed and converted into the desired form, such as powder or granules.

Quality Control: The finished product is tested to ensure it meets quality and performance standards.Implementing robust quality control measures throughout the production process is crucial for producing high-quality magnesium sulfide.

Marketing and Sales StrategyDeveloping an effective marketing and sales strategy is essential for the success of your magnesium sulfide manufacturing plant. Consider the following:

Target Markets: Identify potential customers in industries such as agriculture, environmental services, and material science.

Promotion: Utilize marketing channels such as industry trade shows, online platforms, and direct sales to showcase your products.

Customer Relationships: Build strong relationships with clients through reliable delivery, high-quality products, and excellent customer service.Understanding customer needs and providing tailored solutions can help enhance your market presence and drive sales.

Financial PlanningA detailed financial plan is crucial for managing your plant's budget and ensuring profitability. Key components include:

Initial Investment Costs: Expenses related to plant setup, equipment purchase, and raw materials.

Operational Expenses: Costs for labor, maintenance, utilities, and ongoing raw material procurement.

Revenue Projections: Forecasted sales based on market research and pricing strategies.

Profit Margins: Analysis of potential profit margins and return on investment.Securing funding through loans, investors, or grants may be necessary to support the initial setup and ongoing operations.

Frequently Asked Questions (FAQ)

What are the primary uses of magnesium sulfide?

Magnesium sulfide is used in various applications, including as a soil amendment in agriculture, for environmental remediation of wastewater and contaminated soil, and as a precursor in the production of advanced materials.

What are the main challenges in setting up a magnesium sulfide manufacturing plant?

Key challenges include managing the complex chemical processes involved, ensuring consistent product quality, and adhering to environmental and safety regulations. Additionally, maintaining an efficient supply chain and managing raw material costs can be challenging.

How can I ensure the quality of magnesium sulfide production?

Ensuring quality involves implementing rigorous quality control measures, including testing raw materials, monitoring the production process, and conducting final product inspections. Investing in advanced technology and adhering to industry standards are also essential.

What are the environmental impacts of magnesium sulfide manufacturing?

Magnesium sulfide manufacturing can have environmental impacts, such as emissions and waste. To mitigate these effects, adopt sustainable practices such as controlling emissions, recycling waste materials, and complying with environmental regulations.

How much does it cost to set up a magnesium sulfide manufacturing plant?

The cost of setting up a magnesium sulfide manufacturing plant can vary widely based on factors such as plant size, technology, location, and scale of production. Initial investments can range from several million to tens of millions of dollars. A detailed feasibility study will provide a more accurate estimate.

Media Contact:

Company Name: Claight Corporation

Contact Person: Lewis Fernandas, Corporate Sales Specialist — U.S.A.

Email: [email protected]

Toll Free Number: +1–415–325–5166 | +44–702–402–5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Website: www.expertmarketresearch.com

Aus Site: https://www.expertmarketresearch.com.au/

0 notes