#industrial water filtration system in Telangana

Text

India’s giant lift irrigation project using some of the largest water pumps ever built with special shaft seals

Kaleshwaram Lift Irrigation Scheme

Canada’s Thordon Bearings is playing a vital role in providing water to arid regions, with the installation of axial shaft seals and filtration systems to the world’s largest irrigation project, in south central India. The Kaleshwaram Lift Irrigation Scheme (KLIS) in Telangana, India, has been constructed in a region characterized by water scarcity, aiming to efficiently utilise available water resources for agriculture.

As the world's largest multi-stage lift irrigation project, it runs for about 500 km (310 miles) through 13 districts and is connected to a 1770 km (1100 mile) canal network incorporating 20 reservoirs and extensive underground tunnels. It features some of the largest water pumps ever built.

SXL Axial shaft seal assemblies installed

A crucial component of the large pumps used in projects like this is the shaft seal, which prevents water leakage from lift pump shafts and flooding of the plant. The Francis-type inward-flow turbine pumps at Kaleshwaram work using a combination of radial and axial flow, requiring a reliable and robust seal design.

Thordon and its authorized distributor in India, Soneji Engineering Pvt. Ltd (SEPL), won a tender to supply 24 large diameter axial shaft seal assemblies, along with a water filtration system, for the project’s turbine pumps. The Thordon SXL Segmented Shaft Seal assembly was chosen for the project based on the product’s superior sealing capabilities, wear life, and extensive use across multiple markets.

“The agreement is for the supply of all components,” said Axel Swanson, Business Development Manager, Hydro & Industrial, Thordon Bearings. “This includes complete assembly, testing, installation, and commissioning on site.”

Thordon has designed the seal assembly and supplied its proprietary SXL material to SEPL, which was responsible for manufacturing all other components, as well as testing, installation, and commissioning on site. The work undertaken by SEPL was commissioned by Bharat Heavy Electrical Limited (BHEL).

www.thordonbearings.com

Read the full article

0 notes

Text

Puddle Flanges Supplier in India

Puddle Flanges Supplier in India:

Meghmani Metal Industries:

Meghmani Metal Industries primarily supplies puddle flanges independently in India. For the petrochemical, oil, gas, and associated industries, we have a great deal of expertise offering Puddle Flange in a range of sizes and materials.

Applications of Puddle Flanges

Basement Walls: Preventing water ingress through pipe penetrations and other openings.

Below-Grade Structures: Ensuring water tightness around sewage pipes, utilities, and other service penetrations.

Swimming Pools: Maintaining watertight integrity around inlets, outlets, and filtration systems.

Foundations: Protecting against water seepage through wall penetrations.

Advantages of Using Puddle Flanges

The use of puddle flanges offers several advantages, including:

Water Tightness: Puddle flanges effectively prevent water penetration and seepage.

Structural Integrity: Protecting foundations and structures from potential water damage.

Longevity: Durable materials and effective sealing mechanisms contribute to long-term reliability.

Simplicity: Installation is relatively straightforward, even for non-specialized personnel.

Versatility: Puddle flanges can be used in various construction and infrastructure applications.

Meghmani Metal is prominent of Puddle Flanges Supplier in India, serving various locations, including Mehsana, Surat, Rajkot Gandhidham, Silvassa, Daman, Ankleshwar, Bhavnagar, Surendranagar, Bhuj, Dahej, Vadodara, Surat, Vapi, Valsad, Kheda, Anand, Nadiad, Naroda, Odhav, Kathwada, Sanand, Sarkhej, Satej, Kheda, Kadi, Kalol, Vatva, Kathwada, Rakhial, Naroda, Jamnagar, Junagarh, Amreli, Modasa, Himmatnagar, Deesa, Palanpur, Gandhinagar, Bhalla, Rajkot, Morbi, Mumbai, Maharashtra, Madhya Pradesh, Gujarat, Bihar, Chhatisgarh, Jharkhand, Tamilnadu, Rajasthan, Uttar Pradesh, Odisha, Andhra Pradesh, Telangana, Kerala, Karnataka, Assam, Arunachal Pradesh, Delhi, Bangalore, Kolkata, Chennai, Pune, Nagpur, Haridwar, Dadra Nagar Haveli, Bharuch, Bhachau, Etc.

Read the full article

#AandhraPradesh#Ahmedabad#Amreli#Anand#Ankleshwar#ArunachalPradesh#Assam#Bangalore#Bhachau#Bhalla#Bharuch#Bhavnagar#Bhuj#Bihar#Chennai#Chhatisgarh#DadraNagarHaveli#Dahej#Daman#Deesa#Delhi#Gandhinagar#Gujarat#Haridwar#Himmatnagar#India#Jamnagar#Jharkhand#Junagarh#Kadi

0 notes

Text

Kangen Water Machine Price

Kangen Water Machine Price

Do you want to find Kangen Machine Price India?

KANGEN WATER ENAGIC MACHINE PRODUCTS TYPE AND PRICING

If you take good care, a Kangen Water machine can work better up to 25 years. This machine is made in Japan, is very strong and reliable in producing a high-quality antioxidant alkaline water for you and your family. We provide you below with details of different kinds of machines. Kangen Machine Price India

LEVELUK SD501

The Ultimate Home Use Model (Global BEST SELLER! Very RECOMMENDED to BUY!)

Price Rs 277000/-

The SD501 is the finest machine in its class, with the highest quality built-in electrolysis chamber on the market. This Kangen Water® filtration machine generates a continuous stream of 5 types of water for countless household needs. You can easily operate the SD501 thanks to a large LCD panel and clear voice prompts. When you need enough delicious, healthy alkaline water to hydrate your whole family, the SD501 is the product you’ve been searching for!

Warranty 5 (five) years.

Click the tab below to see more detail about LeveLuk SD501

LeveLuk SD501 Product Details

LEVELUK SD501 PLATINUM

Introducing the BRAND NEW 5-Language SD501 Platinum!

Price Rs 297000/-

The new LeveLuk SD501 PLATINUM features a revamped modern design geared to match today’s more stylish kitchens. Same power and performance as the SD501 in an all-new package! The industry-leading continuous ionized electrolysis water generator system, the SD501 PLATINUM is the finest machine in its class. With the strongest electrolysis chamber available, fully-equipped with a built-in electrolysis chamber, and featuring a large LCD panel and clear voice prompts, the SD501 PLATINUM is the leader of the pack.

The Multi-Language SD501 Platinum expertly “speaks” in 5 languages: English, German, French, Italian and Spanish!

Warranty 5 (five) years.

Click the tab below to see more detail about LeveLuk SD501 Platinum

LeveLuk SD501 Platinum Product Details

width=”228″ height=”234″

LEVELUK K8 (KANGEN 8)

The Mighty 8 Plate Anti-Oxidizer!

Price Rs 343000/-

The Kangen 8 is Enagic’s most powerful antioxidant machine – featuring 8 platinum-dipped titanium plates for improved water ionization and increased antioxidant production potential. Enjoy this Kangen Water K8 machine in virtually any country, thanks to its worldwide multi-voltage power supply and interchangeable plug capability (sold separately). If you’re looking for a powerful, versatile, feature-loaded machine, the Kangen 8 is for you.

Warranty 5 (five) years.

Click the tab below to see more detail about LeveLuk K8

LeveLuk k8 Product Details

LEVELUK JRII

Basic Product and Energy Saver

Price Rs 155000/-

The JRII has three solid electrode plates which reduce the energy consumption. Due to the solid platinum-coated titanium plates, this unit can still produce the strong acid and strong Kangen waters. Due to the lower power consumption and fewer plates, this machine is only recommended for singles or couples. Families should consider one of the more robust models above due to the amount of output required.

Warranty 3 (three) years. Kangen Machine Price India

Click the tab below to see more detail about LeveLuk JRII

LeveLuk JRII Product Details

LEVELUK SUPER501

The Large Family Unit

Price Rs 397000/-

The Super501 is the highest quality water ionizer for heavy home use, featuring a built-in electrolysis enhancer tank and 7 and 5 electrode plates. If you need safe, clean alkaline water to hydrate your growing family or business, the Super501 is the perfect solution! This highly productive machine also generates 5 different types of water for numerous uses around your home or business. With an easy to use LCD screen and clear voice prompts, the Super501 is accessible and simple to operate.

Warranty 3 (three) years.

Click the tab below to see more detail about LeveLuk SUPER501

LeveLuk SUPER501 Product Details

ANESPA DX

The NEW exclusive ANESPA DX Home Spa System transforms your ordinary bathroom into a natural hot spring resort.

Price Rs 200000/-

ANESPA DX produces a continuous stream of healthy ionized mineral water. With a new, larger ceramic cartridge that removes almost 100% of chlorine and other harmful substances in your tap water, and adds safe, moisturizing minerals that are healthy for your skin and hair. Enjoy a lovely shower or bath in ANESPA DX hot spring water.

Warranty 3 (three) years.

Click the tab below to see more detail about ANESPA DX

ANESPA DX Product Details

KANGEN MACHINE PRICE INDIA

Andhra Pradesh Adoni Amaravati Anantapur Chandragiri Chittoor Dowlaiswaram Eluru Guntur Kadapa Kakinada Kurnool Machilipatnam Nagarjunakoṇḍa Rajahmundry Srikakulam Tirupati Vijayawada Visakhapatnam Vizianagaram Yemmiganur Arunachal Pradesh Itanagar Assam Dhuburi Dibrugarh Dispur Guwahati Jorhat Nagaon Sibsagar Silchar Tezpur Tinsukia Bihar Ara Baruni Begusarai Bettiah Bhagalpur Bihar Sharif Bodh Gaya Buxar Chapra Darbhanga Dehri Dinapur Nizamat Gaya Hajipur Jamalpur Katihar Madhubani Motihari Munger Muzaffarpur Patna Purnia Pusa Saharsa Samastipur Sasaram Sitamarhi Siwan Chandigarh (Union Territory) Chandigarh Chhattisgarh Ambikapur Bhilai Bilaspur Dhamtari Durg Jagdalpur Raipur Rajnandgaon Dadra And Nagar Haveli (Union Territory) Silvassa Daman And Diu (Union Territory) Daman Diu Delhi (National Capital Territory) Delhi New Delhi Goa Madgaon Panaji Gujarat Ahmadabad Amreli Bharuch Bhavnagar Bhuj Dwarka Gandhinagar Godhra Jamnagar Junagadh Kandla Khambhat Kheda Mahesana Morvi Nadiad Navsari Okha Palanpur Patan Porbandar Rajkot Surat Surendranagar Valsad Veraval Haryana Ambala Bhiwani Chandigarh Faridabad Firozpur Jhirka Gurgaon Hansi Hisar Jind Kaithal Karnal Kurukshetra Panipat Pehowa Rewari Rohtak Sirsa Sonipat Himachal Pradesh Bilaspur Chamba Dalhousie Dharmshala Hamirpur Kangra Kullu Mandi Nahan Shimla Una Jammu And Kashmir Anantnag Baramula Doda Gulmarg Jammu Kathua Leh Punch Rajauri Srinagar Udhampur Jharkhand Bokaro Chaibasa Deoghar Dhanbad Dumka Giridih Hazaribag Jamshedpur Jharia Rajmahal Ranchi Saraikela Karnataka Badami Ballari Bangalore Belgavi Bhadravati Bidar Chikkamagaluru Chitradurga Davangere Halebid Hassan Hubballi-Dharwad Kalaburagi Kolar Madikeri Mandya Mangaluru Mysuru Raichur Shivamogga Shravanabelagola Shrirangapattana Tumkuru Kerala Alappuzha Badagara Idukki Kannur Kochi Kollam Kottayam Kozhikode Mattancheri Palakkad Thalassery Thiruvananthapuram Thrissur Madhya Pradesh Balaghat Barwani Betul Bharhut Bhind Bhojpur Bhopal Burhanpur Chhatarpur Chhindwara Damoh Datia Dewas Dhar Guna Gwalior Hoshangabad Indore Itarsi Jabalpur Jhabua Khajuraho Khandwa Khargon Maheshwar Mandla Mandsaur Mhow Morena Murwara Narsimhapur Narsinghgarh Narwar Neemuch Nowgong Orchha Panna Raisen Rajgarh Ratlam Rewa Sagar Sarangpur Satna Sehore Seoni Shahdol Shajapur Sheopur Shivpuri Ujjain Vidisha Maharashtra Ahmadnagar Akola Amravati Aurangabad Bhandara Bhusawal Bid Buldana Chandrapur Daulatabad Dhule Jalgaon Kalyan Karli Kolhapur Mahabaleshwar Malegaon Matheran Mumbai Nagpur Nanded Nashik Osmanabad Pandharpur Parbhani Pune Ratnagiri Sangli Satara Sevagram Solapur Thane Ulhasnagar Vasai-Virar Wardha Yavatmal Manipur Imphal Meghalaya Cherrapunji Shillong Mizoram Aizawl Lunglei Nagaland Kohima Mon Phek Wokha Zunheboto Odisha Balangir Baleshwar Baripada Bhubaneshwar Brahmapur Cuttack Dhenkanal Keonjhar Konark Koraput Paradip Phulabani Puri Sambalpur Udayagiri Puducherry (Union Territory) Karaikal Mahe Puducherry Yanam Punjab Amritsar Batala Chandigarh Faridkot Firozpur Gurdaspur Hoshiarpur Jalandhar Kapurthala Ludhiana Nabha Patiala Rupnagar Sangrur Rajasthan Abu Ajmer Alwar Amer Barmer Beawar Bharatpur Bhilwara Bikaner Bundi Chittaurgarh Churu Dhaulpur Dungarpur Ganganagar Hanumangarh Jaipur Jaisalmer Jalor Jhalawar Jhunjhunu Jodhpur Kishangarh Kota Merta Nagaur Nathdwara Pali Phalodi Pushkar Sawai Madhopur Shahpura Sikar Sirohi Tonk Udaipur Sikkim Gangtok Gyalsing Lachung Mangan Tamil Nadu Arcot Chengalpattu Chennai Chidambaram Coimbatore Cuddalore Dharmapuri Dindigul Erode Kanchipuram Kanniyakumari Kodaikanal Kumbakonam Madurai Mamallapuram Nagappattinam Nagercoil Palayankottai Pudukkottai Rajapalaiyam Ramanathapuram Salem Thanjavur Tiruchchirappalli Tirunelveli Tiruppur Tuticorin Udhagamandalam Vellore Telangana Hyderabad Karimnagar Khammam Mahbubnagar Nizamabad Sangareddi Warangal Tripura Agartala Uttar Pradesh Agra Aligarh Allahabad Amroha Ayodhya Azamgarh Bahraich Ballia Banda Bara Banki Bareilly Basti Bijnor Bithur Budaun Bulandshahr Deoria Etah Etawah Faizabad Farrukhabad-cum-Fatehgarh Fatehpur Fatehpur Sikri Ghaziabad Ghazipur Gonda Gorakhpur Hamirpur Hardoi Hathras Jalaun Jaunpur Jhansi Kannauj Kanpur Lakhimpur Lalitpur Lucknow Mainpuri Mathura Meerut Mirzapur-Vindhyachal Moradabad Muzaffarnagar Partapgarh Pilibhit Rae Bareli Rampur Saharanpur Sambhal Shahjahanpur Sitapur Sultanpur Tehri Varanasi Uttarakhand Almora Dehra Dun Haridwar Mussoorie Nainital Pithoragarh West Bengal Alipore Alipur Duar Asansol Baharampur Bally Balurghat Bankura Baranagar Barasat Barrackpore Basirhat Bhatpara Bishnupur Budge Budge Burdwan Chandernagore Darjiling Diamond Harbour Dum Dum Durgapur Halisahar Haora Hugli Ingraj Bazar Jalpaiguri Kalimpong Kamarhati Kanchrapara Kharagpur Koch Bihar Kolkata Krishnanagar Malda Midnapore Murshidabad Navadwip Palashi Panihati Purulia Raiganj Santipur Shantiniketan Shrirampur Siliguri Siuri Tamluk Titagarh

Made with the new Google Sites, an effortless way to create beautiful sites.Report abuse

#Kangen Water Hyderabad#Kangen Water Secunderabad#Kangen Water Machine Price#Kangen Water#kangen water machine

1 note

·

View note

Text

Juniper Publishers-Open Access Journal of Environmental Sciences & Natural Resources

Treatment of Highly Concentrated Effluent Generated from Intermediate Chemical and Bulk Drug Industries Renovated with Tertiary Removal

Authored by Atun Roy Choudhury

Abstract

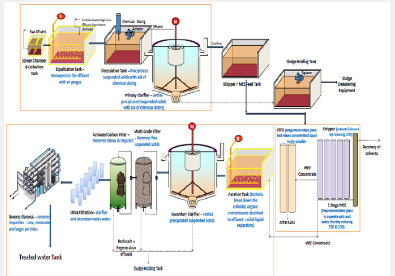

Effluent generated from the bulk drug industries is attributed with potential risk to the biotic and abiotic environment. The safe disposal of the same requires multiple stages of standard operation and stringent purification. In order to get rid of the ill impacts associated with the unscientific disposal of the bulk drug industry wastewater common effluent treatment plant (CETP) can be installed as a safe, inexpensive, and wholesome treatment unit. The present study, paid minute attention from the primary collection of the potentially hazardous wastewater to the reuse of the tertiary treated reverse osmosis (RO) process permeate. Initially, the collected effluent was stored in a bottom lined collection tank facilitate with a scrubber system and top enclosure to suppress the odour nuisance. Then effluent was immediately taken to the equalization tank and once homogenization got achieved the same was sent to the flocculation unit, where chemical coagulants were added with the effluent and forwarded to the primary clarifiers to remove the flocculants in the form of solid sludge.

Thereafter, the effluent was taken to the MEE feed tank and the bottom sludge was sent to the dewatering unit. The permeate was sent to the stripping column and the volatile organics were remove. In order to ensure optimal recovery the effluent of the stripper column was fed to the 5 stage multiple effect evaporator (MEE) system and successively followed by agitated thin film dryer (ATFD) set-up. Ultimately, the condensate was sent to the secondary treatment unit incorporated aeration facility and microbial digestion. The supernatant was conveyed to the secondary clarifier and successively to the tertiary treatment facility which comprises pressure sand filter, ultra filtration (UF), and RO. The end product was explicitly analysed to meet the prescribed standards and found to be feasible for reuse in the boiler. Both the primary and secondary sludge was safely discarded into the secured landfill. Thus, an absolute treatment system was delineated above which ensured optimal environmental safety

Keywords:CETP; COD; High TDS treatment; Pharmaceutical wastewater; Tertiary removal

Introduction

Two states located in the southern peninsula of Indian subcontinent namely, Telangana and Andhra Pradesh are considered to be the medicinal drug capital of the country which yields approximately 42% of the annual gross pharmaceutical production. Recently, these two states acting as a pioneer in the above delineated sector and showed a promising potential by having a continuous reciprocation with the market demand, technology up gradation, and modernized synthesis mechanisms. Its steady emergence in the pharmaceutical field has given it an international acclamation and plethora of foreign reputed pharma companies started capitalizing their investment into it [1,2]. Though drugs are often treated as life saving elements and trusted partner in health care industry, the production of it is always attributed to generation of highly toxic and complex wastewater. This aspect found to be contradictory to the progress pathway of the industry and thus, seeks a separate attention. Due to the complexity of the generated effluent it requires extensive treatment to bring down to the disposal or reusable limits. A single system consisting of a singular purification approach can not satisfy the prescribe figures due to high TDS and COD values (i.e. often ranging 1,00,000 mg/l and 45,000 mg/l respectively) [3-6]. Therefore a wholesome treatment system comprising multidimensional treatment facility is of utmost importance in order to treat the bulk drug industry wastewater. Furthermore centralization of the entire facilities under a single platform ensures the minimal environmental intervention with minimization of the land requirement. Hence, common effluent treatment plant is the ultimate solution to optimize the treatment expenditure attributed to waste treatment [7-10]. The treatment with the help of CETP requires similarity of the generated effluent. This is a feasible solution for those small scale industries, clustered together who can’t afford to install a separate individual treatment units at their disposal. It prevents them from any additional burden and extends opportunity to focus on the desired output without posing much additional cost to the stack holders [11,12].

The CETP capable of treating pharmaceutical wastewater should comprise the units such as equalization unit, flocculation unit, biological treatment unit, high TDS treatment unit, and tertiary treatment unit [13-17]. The polished effluent can be further reused into the system as a boiler feed or also for greenbelt development. Each facility play a significant role in reduction of a certain parameter and the malfunction of any unit can successively upset the performance of the further units and thus, the plant operation is a delicate issue which needs to be performed under extreme supervision [18]. Despite all those facts execution of CETP can face significant protest from the nearby residents due to the obnoxious smell generation during the ATFD operation and powder precipitation. Therefore, keeping all the social constraints in mind successful operation of the CETP is a challenging task [19,20]. A study conducted by Popuri [21] reported an ultimate contaminant removal of 98% or above can be achieved by a complete CETP. But, contradictorily, a study carried by Salunke et al. [22] reported the inefficiency of such plants under certain circumstances. Thus, in limelight of the above delineated context the primary objective of this study was to explore the feasibility of the industrial CETP towards the treatment of the bulk drug industry wastewater and application of the same to minimize the environmental hazard.

Study Area

The entire research work was carried out within the premises of the Common Effluent Treatment Plant (CETP) designed and maintained by IL&FS Environment in Fab City. The plant is located in an isolated industrial estate and ensures minimal human and environmental interventions. The influence topography and the geological location optimized the safety with constant progress and changes. The approximate coordinates of the plant include, North West Corner (17°12’5.70”N, 78°30’18.54”E); North East (17°12’5.64”N, 78°30’24.08”E); South West (17°12’1.99”N, 78°30’17.87”E); South East (17°12’1.65”N, 78°30’23.85”E).

Materials and Methods

Collection of Effluent from Industries

Process effluent from the pharmaceutical industries is transported to the designed location by means of 10m3 capacity GPS mounted closed tankers. The collection chamber was constructed with a design capacity of 150m3 connected to scrubber for control of odour pollution Thus, the collection tank can withhold approx. 15 truck unloading on regular basis.

Equalization of the Influent

Uniformity of the influent is the prime objective for the efficient working and thus, in order to maintain the minimal variation in the characteristics of the influent equalization tank was introduced. The influent mass was withheld in equalization tank over a period of 20 to 30 min and the tank has a capacity of 400m3. The influent in the tank gets homogenized due to air purges located at the bottom of the tank.

Flocculation

Flocculation tank is the set-up which serves as the platform for mixing. It is attributed with an agitator and has a volume holding capacity of 50m3. The agitator has a maximum working speed of 98 RPM, but 60 RPM was generally used for field application. Polyelectrolyte was used as a chemical coagulant and its efficacy was analysed against total solid removal.

Primary Settling

Once the agitation begins, the wastewater was brought into complete rest to ensure optimal precipitation. Settling of the particles with higher specific gravity often ensured in the primary clarifier, which indirectly released the burden of the high TDS treatment units. The facility comprises one primary clarifier with a volumetric capacity of 150m3 and the effluent from the primary clarifier use to be directly sent to the MEE feed tank for further purification (Tables 1-3).

Sludge Dewatering

The process sludge generated from both the clarifiers found to be highly humid in nature and thus, a moisture removal operation was quite mandatory. Excessive moisture was removed in sludge dewatering unit and the slurry got converted into bulky solid mass. The same was discarded in the secure landfill and environmental safety was ensured.

Removal of Volatile Compounds

The supernatant effluent from the MEE feed tank was directly conveyed to the stripping column via pumping station for further removal of volatile organic compounds (VOC). Contaminated water flows downward by gravity action and the air was forced through it. Thereafter, the contaminated air was purified by passing it through a demister before releasing it to the open atmosphere.

Effluent Densification

The end product of stripper column was further sent to the MEE unit for densification and volume reduction. The installed MEE setup has 5 nos. of calandrias and works in a forward flow mode. The raw juice from stripper column was introduced to the first calandria from the bottom and brought in contact with steam. Heat exchange, gasification, and condensation were few of the operation that was performed simultaneously. The condensate from the facility was sent to the tertiary filtration units; whereas, the concentrate was forwarded to the agitated thin film dryer for further solidification.

Secondary Treatment

The condensate from the high TDS treatment system was conveyed to the biological treatment unit for further polishing and removal of the organic contaminants. This facility incorporates aeration and aerobic microbial digestion. An optimum air supply rate of can be achieved in this system which is subjected to the influent BOD concentrations. A mixed consortium of microbial culture was used in the system by mixing the cow dung into the HTDS condensate with a ratio of 10:90.

Secondary Settling

The effluent from the biological treatment unit was retained in the secondary clarifier over a period of 1 hr to remove the settable solids from the stream before sending it to the advanced treatment unit. Once, the retention time got completed supernatant was sent to the tertiary treatment unit whereas, bottom sludge was conveyed to the sludge dewatering facility and discarded in a similar fashion.

Tertiary Treatment

The semi-polished effluent from the physicochemical treatment unit was supplied to the tertiary unit as an influent. The same was initially introduced to the pressure sand filter and successively followed by Ultra Filtration (UF) and reverse osmosis process. The permeate of RO yielded a satisfactory quality of effluent fit for reuse/recycle in the plant and industries for utilities and RO rejects is again sent back to the MEE. The process flowchart of the plant operations has been portrayed in Figures 1-4.

To know more about Juniper Publishers please click on: https://juniperpublishers.com/manuscript-guidelines.php

For more articles in Open Access Journal of Environmental Sciences & Natural Resources please click on: https://juniperpublishers.com/ijesnr/index.php

#Juniper Publishers PubMed Indexed Journals#Juniper Publishers Review#Environmental Biology#Geo Morphology#Oceanology#Soil Science

0 notes