#labtechnology

Explore tagged Tumblr posts

Text

Laboratory Instruments Suppliers in Bloemfontein – FinelabUK

FinelabUK is one of the top laboratory instruments suppliers in Bloemfontein, offering high-quality, precision-engineered lab tools for medical, research, and industrial applications. Our instruments are built for accuracy, durability, and performance. FinelabUK supports laboratories in Bloemfontein with innovative solutions tailored to their specific scientific needs

#LaboratoryInstrumentsSuppliersBloemfontein#FinelabUK#LabEquipmentBloemfontein#ScientificInstruments#MedicalLabSupplies#ResearchTools#BloemfonteinLabs#LabTechnology#PrecisionLabInstruments#TrustedLabPartner

0 notes

Text

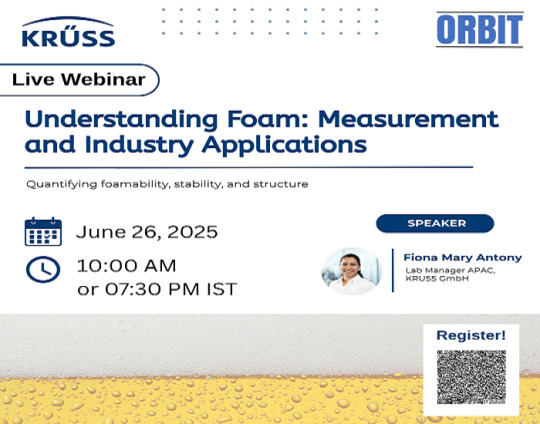

Unlocking Foam Science: Measurement Techniques and Industry Insights

💡 Webinar Alert! Join us for a FREE educational session on understanding and measuring foam across industries.

🗓️ Date: June 26, 2025 ⏰ Time Slots: 10:00 AM IST or 7:30 PM IST 👩🔬 Speaker: Dr. Fiona Mary Antony (KRÜSS)

What you’ll learn: ✅ Foamability & Stability Testing ✅ Foam Structure Analysis ✅ Industry Applications in R&D, QA, and more

📌 Save your spot now: 👉 Register Here

0 notes

Text

Colorimeter Market Drivers: Key Technological and Industrial Factors Shaping Global Market Growth

The colorimeter market is experiencing notable growth, driven by a combination of technological advancements, increased quality control standards, and the growing need for accurate color measurement across multiple industries. These drivers are shaping a competitive and innovation-driven landscape, with companies investing heavily in more precise, efficient, and user-friendly colorimetry solutions. From manufacturing to pharmaceuticals, and from textiles to petroleum, colorimeters have become essential tools for ensuring product consistency and meeting regulatory compliance.

Rising Industrial Demand for Accurate Color Measurement

One of the primary drivers for the growth of the colorimeter market is the increasing demand for accurate and efficient color measurement across a broad spectrum of industries. Sectors such as food and beverage, pharmaceuticals, paints and coatings, textiles, and chemicals rely heavily on colorimeters to maintain product uniformity and quality. In industries where color plays a critical role in consumer perception and regulatory compliance, these devices are indispensable. For example, in the food industry, consistent color can indicate product freshness or quality, while in pharmaceuticals, it ensures the consistency and stability of formulations.

Technological Advancements Fueling Market Expansion

Technology is a significant catalyst in propelling the colorimeter market forward. Modern colorimeters are now more compact, user-friendly, and capable of high-precision measurements. Integration with digital platforms, wireless connectivity, and cloud-based data storage are transforming how industries collect, analyze, and share color data. These features not only improve accuracy but also increase efficiency, reduce human error, and streamline workflow processes. Portable and handheld colorimeters are becoming particularly popular due to their convenience in field applications, allowing on-site quality checks without the need for lab setups.

Regulatory Compliance and Quality Control Requirements

The growing emphasis on meeting international quality standards is another key driver. Regulatory bodies across industries are setting stricter guidelines for color consistency, particularly in products such as medicines, food items, and industrial coatings. Businesses are investing in high-performance colorimeters to ensure their products meet these standards and avoid costly recalls or regulatory penalties. The increasing adoption of standardized testing and reporting procedures further strengthens the need for advanced color measurement technologies, bolstering market growth.

Environmental Awareness and Sustainability Initiatives

Sustainability has emerged as a core focus in product manufacturing, influencing the materials, methods, and monitoring systems used in production. As industries move toward eco-friendly practices, the role of colorimeters in monitoring natural dyes, eco-friendly coatings, and biodegradable packaging materials becomes more critical. Accurate color measurement helps companies develop sustainable alternatives without compromising on visual appeal or quality, reinforcing the value of colorimeters in environmentally conscious production.

Growth in Research and Development Activities

Investment in research and development is pushing the boundaries of what colorimeters can do. Innovations in sensor technology, software development, and material science are giving rise to more sophisticated instruments capable of multi-angle measurements, complex data analysis, and integration with automated systems. These advancements are not only improving performance but also expanding the application scope of colorimeters, from traditional sectors like textiles to emerging fields like biotechnology and nanomaterials.

Expanding Applications in Emerging Markets

Emerging markets, especially in Asia-Pacific, Latin America, and parts of Africa, are seeing increased demand for color measurement tools due to rapid industrialization and urbanization. Growing manufacturing sectors, improved infrastructure, and rising consumer expectations are encouraging local businesses to adopt advanced quality control instruments like colorimeters. Additionally, government initiatives supporting industrial modernization are further boosting market penetration in these regions.

Increased Adoption in the Petroleum and Chemical Sectors

The petroleum and chemical industries are increasingly using colorimeters for product testing and quality analysis. In the petroleum sector, colorimeters help determine the quality and composition of fuels and lubricants. Variations in color can indicate contamination, aging, or blending issues, which are critical factors for operational safety and regulatory compliance. In chemicals, colorimeters assist in maintaining consistency in dyes, pigments, and intermediate products, playing a vital role in production accuracy and safety.

Conclusion

The colorimeter market is set to continue its upward trajectory, fueled by a blend of industrial demand, regulatory pressure, technological innovation, and expanding global applications. As companies strive for quality, sustainability, and competitiveness, the role of advanced color measurement tools becomes even more essential. With ongoing developments in smart technologies and digital integration, the future of the colorimeter market looks promising, offering new opportunities for manufacturers and end-users alike.

0 notes

Text

Benefits and Uses of Convection oven

In a laboratory setting, convection ovens serve essential functions in various scientific processes, providing controlled heat treatment for precise, consistent results. Here are the main benefits and uses of laboratory convection ovens:

Benefits of a Convection Oven in Labs

Uniform Heat Distribution:

The built-in fan circulates hot air evenly, ensuring consistent temperatures throughout the chamber, which is critical for applications requiring precise, uniform heating.

Reduced Drying Time:

Convection ovens allow for faster drying times by moving heated air across samples. This benefit makes them efficient for drying, curing, and dehydration processes in labs.

Temperature Stability and Control:

Laboratory convection ovens are designed with precise temperature controls, allowing for stable, consistent heating. This is essential for repeatable results and minimizes errors in sensitive applications.

Energy Efficiency:

By reaching and maintaining desired temperatures quickly and consistently, convection ovens in labs are more energy-efficient than conventional ovens, saving time and resources.

Enhanced Safety Features:

Many lab-grade convection ovens include safety features such as over-temperature alarms, automatic shut-off, and heat-resistant doors, which help reduce the risk of accidents in laboratory environments.

Uses of Convection Ovens in Labs

Drying and Dehydration:

Convection ovens are widely used to dry samples, glassware, or equipment by evaporating moisture quickly and evenly, essential in preparing samples for weighing or further analysis.

Curing and Polymerization:

In material science and chemistry labs, convection ovens are used to cure polymers, adhesives, and coatings, which requires precise, consistent heat to achieve optimal material properties.

Baking and Aging:

Convection ovens help simulate aging by exposing materials to specific temperatures over time, useful in testing the durability and longevity of products such as rubber, plastics, and coatings.

Sterilization:

Used to sterilize non-flammable equipment, tools, and glassware by heating to temperatures that destroy microorganisms. Convection ovens are an alternative to autoclaves for items sensitive to moisture.

Annealing and Heat Treatment:

Metals, ceramics, and alloys undergo annealing in convection ovens to relieve internal stress, enhance ductility, and alter mechanical properties, crucial for applications in metallurgy and materials research.

Evaporation of Solvents:

Labs use convection ovens to evaporate solvents safely from chemical mixtures. This is especially beneficial in preparing samples for qualitative and quantitative analysis.

Moisture Content Analysis:

Convection ovens are commonly used to measure moisture content in various materials. Samples are dried at controlled temperatures to constant weight, allowing accurate measurement of residual moisture.

Sample Pre-Treatment:

In analytical labs, convection ovens pre-treat samples by removing moisture, and stabilizing them for testing in procedures like chromatography, mass spectrometry, and elemental analysis.

When Not to Use Convection Ovens in Labs

Convection ovens may not be suitable for highly volatile materials or samples sensitive to oxidation due to the circulating air, which can encourage reactions. In such cases, vacuum ovens or inert gas purged systems are preferable.

In summary, laboratory convection ovens provide reliable, even heat for drying, curing, sterilizing, and other applications that require precise temperature control, making them indispensable for research, quality control, and analytical laboratories.

M-Kube Enterprise is an Indian company catering customized laboratory products, laboratory consumables, and laboratory solutions in India, Australia, the USA, New Zealand, Singapore, Malaysia, South Korea, Dubai, the Philippines, Indonesia, and Vietnam.

#LaboratoryConvectionOvens#LabEquipment#ScientificProcesses#HeatTreatment#ThermalProcessing#MaterialScience#LabTechnology#ResearchTools#QualityControl#AnalyticalLabs#UniformHeatDistribution#DryingAndDehydration#CuringAndPolymerization#SterilizationOvens#SamplePreTreatment#MoistureContentAnalysis#HeatTreatmentEquipment#AnnealingOvens#ConvectionVsVacuumOvens#LabSafetyFeatures#MKubeEnterprise#CustomLabProducts#LabConsumables#GlobalLabSolutions#LaboratorySuppliesIndia#LaboratoryEquipmentAustralia#LabProductsUSA#ScientificSolutionsAsia#LabEquipmentSuppliers#CustomLabSolutions

1 note

·

View note

Text

Why Choose an Explosion-Proof Rotary Evaporator?

If you're a lab researcher, especially in the fields of chemistry or pharmaceuticals, you know how crucial the right equipment is to the success of your experiments. When dealing with high temperatures or volatile liquids, safety and efficiency must always come first.

That's why the Explosion-Proof Rotary Evaporator has become an essential tool in our lab. Not only does it efficiently separate solvents, but it also ensures safety during operation. After all, a small mistake could lead to unforeseen consequences, right?

Why an Explosion-Proof Rotary Evaporator?

In many experiments, a rotary evaporator is a must-have, especially when extracting, concentrating, or purifying chemicals. One of its biggest advantages is its ability to evaporate solvents at low pressure, reducing heat loss during the process. But an Explosion-Proof Rotary Evaporator takes it a step further by eliminating the risk of explosions, making it the safest choice for hazardous environments.

I know choosing the right equipment can be confusing, especially when you need both safety and efficiency. You might be asking, “How do I find the one that’s right for me?” Well, the AKR-1020 Explosion-Proof Rotary Evaporator might just be the answer.

Advantages of the Explosion-Proof Rotary Evaporator

Enhanced Safety: Unlike regular rotary evaporators, the explosion-proof design ensures stable operation even in high-temperature, flammable gas environments.

Efficient Operation: The rotating motion of the evaporator accelerates solvent evaporation while maintaining solvent purity and concentration.

Smart Control System: With precise temperature and pressure control, it greatly enhances repeatability and reliability in your experiments.

How to Choose the Right Equipment

Choosing the right equipment isn't just about ensuring the success of your experiments; it’s also about keeping your lab safe. The Explosion-Proof Rotary Evaporator we offer at Equilrxnlab, like the AKR-1020, delivers exceptional performance without compromising on safety.

See It in Action!

Don’t just take my word for it! Check out this video to see how the AKR-1020 improves lab efficiency and safety in real-time. You'll see it’s not just a machine—it’s a smart lab assistant.

Why the Explosion-Proof Rotary Evaporator is Essential

Every successful experiment relies on the right tools, and safety and efficiency are factors that cannot be ignored. The Explosion-Proof Rotary Evaporator makes your experiments safer and more efficient. Choose the AKR-1020 Explosion-Proof Rotary Evaporator to add an extra layer of protection to your lab.

#ExplosionProofRotaryEvaporator#LabSafety#ChemicalResearch#RotaryEvaporator#LabEquipment#LabTechnology#ScientificResearch#Equilrxnlab#ChemicalInstruments#SolventEvaporation#InnovationInLab#LabEfficiency#SafetyInTheLab#ResearchTools#LaboratorySolutions

0 notes

Text

Revolutionizing Agriculture with Our Tissue Culture Lab!

At Shivchhaya Bio-Tech, we specialize in plant tissue culture to create high-quality, disease-free, and genetically uniform plants. Our cutting-edge lab provides sustainable solutions for plant propagation, genetic research, and conservation.

Why Choose Us?

🌿 High-Quality Plants: Disease-free and genetically consistent. 🌍 Sustainable Practices: Eco-friendly and efficient plant production. 🔬 Innovative Research: Advancing plant biotechnology and genetic improvement. 💡 Custom Solutions: Tailored for nurseries, researchers, and businesses.

Transform your agricultural practices with the future of biotechnology. Contact us today to learn more!

For more information visit: https://shivchhayabiotech.com/ Contact us on: +91 77790 21916

#TissueCulture#PlantScience#Biotechnology#SustainableAgriculture#PlantPropagation#GeneticResearch#EcoFriendlyFarming#AgricultureInnovation#BiotechSolutions#FutureOfFarming#Micropropagation#PlantBreeding#AgriculturalResearch#DiseaseFreePlants#LabTechnology#PlantConservation#AgriculturalTechnology#PlantBiotechnology#CropImprovement#ResearchExcellence#SustainableFarming#GeneticImprovement#PlantGenetics#InnovationInAgriculture#BiotechResearch#AgricultureLab#AgriculturalScience#AgTech#PlantGenomics

0 notes

Text

Labtron Anaerobic Jar is a hermetic container featuring a transparent lid, O-ring seal, and side tube for gas management. It holds 3 stacks of 8 petri dishes (9-10 cm) with optional racks for easy anaerobic operation, ensuring efficient lab performance.

0 notes

Text

Fully Automated Slide Stainer 135 ml

Labmate Slide Stainer is a compact tabletop unit with 20 stations, each holding 135ml. It ensures efficient staining with adjustable times and allows sample addition anytime. The end station offers automatic cleaning and water flow control for convenience.

0 notes

Text

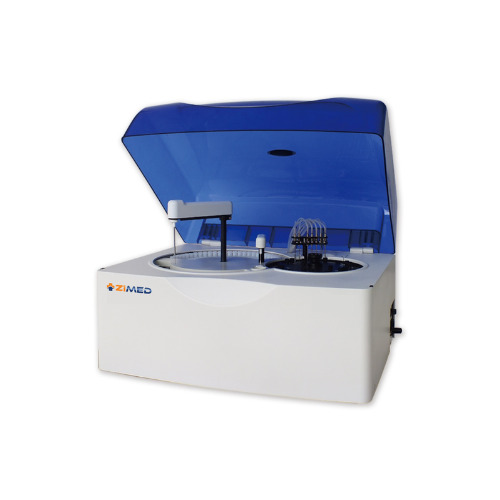

Automatic Biochemistry Analyzer

zimed automatic bio chemistry analyzer with systems for loading, washing, cooling, and calibration. It retests samples after dilution if they are insufficient or results are out of range.

0 notes

Text

Rotary Evaporator 250 W

Labnic Rotary Evaporator is a top-quality, essential tool for cost-effective evaporation, with a 10L rotary flask, a 5L receiving flask, and a 21L water bath. It provides a 20–130 rpm speed range, an RT to 99°C temperature range and ensures quick heating with smooth, jolt-free operation.

0 notes

Text

Laboratory Equipment List in Captain – FinelabUK

Explore FinelabUK’s comprehensive laboratory equipment list in Captain, featuring essential tools like microscopes, centrifuges, autoclaves, incubators, and spectrophotometers. Designed for accuracy and durability, our equipment meets the needs of research labs, medical facilities, and academic institutions. FinelabUK ensures quality and innovation in every piece of lab equipment.

#LaboratoryEquipmentListInCaptain#FinelabUK#LabEquipment#ScientificTools#MedicalLabSupplies#ResearchInstruments#CaptainLabSolutions#EducationalLabTools#PrecisionEquipment#LabTechnology

0 notes

Text

🛠️ Orbit Research Associates to Exhibit at IOGCA 2025

📅 Date: 18–19 September 2025 📍 Venue: Radisson Blu Hotel, Dwarka, New Delhi 🔗 Website: www.orbitind.com

Orbit Research Associates is excited to announce our participation in the 8th International Oil, Gas & Chemical Conference and Exhibition (IOGCA 2025), taking place at the Radisson Blu Hotel, Dwarka, New Delhi.

As a trusted provider of high-precision analytical instrumentation, we continue to meet the growing needs of the oil, gas, and chemical industries through cutting-edge solutions and expert support.

🤝 In Collaboration with PSL Systemtechnik GmbH (Germany)

We’re proud to exhibit alongside our principal manufacturer, PSL Systemtechnik GmbH, a global leader in process simulation and testing equipment for applications like flow assurance, hydrate formation, and wax deposition studies.

🧪 What You’ll Discover at Our Booth

✅ Live demos of advanced instruments for: — Surface chemistry — Interfacial analysis — Process optimization

✅ One-on-one consultations with our expert team ✅ Insights into improving data accuracy and compliance ✅ Global technologies customized for Indian industries

Whether you’re in R&D, QA/QC, or production, our solutions are engineered to optimize your workflows.

🔍 Explore Our Product Catalog

Preview the technologies we’ll showcase: 👉 www.orbitind.com/products

📞 Schedule a Meeting or Get in Touch

💻 www.orbitind.com | www.orbitresearch.co.in 📧 [email protected] 📱 011 – 42420858 | 45578977

📣 Join Us at IOGCA 2025

Visit us at the event and discover how Orbit Research Associates, in collaboration with PSL Systemtechnik, is helping reshape the future of analytical instrumentation in the oil, gas, and chemical sectors.

#IOGCA2025#OrbitResearch#OilAndGas#ChemicalIndustry#LabTechnology#PSLSystemtechnik#EngineeringInnovation#ScientificInstruments#TradeShows2025#ProcessOptimization

1 note

·

View note

Text

Horizontal Autoclave 200L

Labmate horizontal autoclave is a powerful sterilization machine for high-volume use in medical, lab, and industrial settings. Its horizontal design allows easy loading of larger items. It operates within a temperature range of 50°C to 134°C, has a weight of 230 kg, and a time range of 0 to 99 hours.

#HorizontalAutoclave#Sterilization#MedicalEquipment#LabTechnology#IndustrialSterilization#SteamSterilization#HealthcareSafety#LabSafety#AutoclaveSterilization#InfectionControl

0 notes

Text

Distinguish Between Industrial Furnaces and Lab Furnaces

Industrial Furnaces

Industrial furnaces are designed for large-scale applications and typically operate at higher temperatures to process metals, glass, ceramics, and other materials. They are robust, high-capacity, and optimized for continuous, high-demand production environments.

Types of Industrial Furnaces

Blast Furnace

Application: Primarily used in the steel industry for smelting iron ore into molten iron.

Size and Capacity: Capacities can exceed 1,000 tons of molten iron per day.

Temperature Range: Up to 2,200°C (3,992°F).

Benefits: Efficient for large-scale metal production.

Limitations: High energy consumption, environmental impact due to carbon emissions.

Induction Furnace

Application: Melting and refining metals like steel, copper, and aluminum.

Temperature Range: 1,200°C to 1,600°C (2,192°F to 2,912°F).

Size and Capacity: Typically ranges from 1 to 100 tons per batch, with larger systems for high-volume operations.

Benefits: Precise temperature control, high efficiency, minimal emissions.

Limitations: Requires specialized setup and significant electrical power.

Rotary Kiln Furnace

Application: Used in cement, lime, and refractory manufacturing industries.

Temperature Range: 1,000°C to 1,450°C (1,832°F to 2,642°F).

Size and Capacity: Lengths can exceed 100 meters with capacities ranging from 50 to 1,000 tons per day.

Benefits: Continuous processing, large capacity.

Limitations: High fuel consumption, requires extensive maintenance.

Electric Arc Furnace

Application: Melting scrap metal, primarily in the steel recycling industry.

Temperature Range: 1,300°C to 1,800°C (2,372°F to 3,272°F).

Size and Capacity: Can range from 5 to 400 tons per charge, depending on the size of the furnace.

Benefits: Efficient for recycling, can reach high temperatures quickly.

Limitations: High electricity consumption, potential for noise and dust pollution.

Annealing Furnace

Application: Softening metals or glass through heat treatment to improve workability.

Temperature Range: 200°C to 1,100°C (392°F to 2,012°F).

Size and Capacity: Often ranges from a few hundred to several tons, depending on the design.

Benefits: Enhances material properties, prevents metal cracking.

Limitations: Requires precise temperature control; often a slow process.

Laboratory Furnaces

Laboratory furnaces are designed for small-scale testing, research, and material development in labs. They offer precise temperature control, safety features, and are compact for benchtop or small-space applications.

Types of Laboratory Furnaces

Muffle Furnace

Application: Heating samples in ceramics, chemical, and metallurgical research.

Size and Capacity: Typically has a volume of 1 to 5 liters, suitable for small sample sizes.

Temperature Range: Up to 1,200°C (2,192°F).

Benefits: Clean heat source, ideal for ashing and incineration.

Limitations: Limited sample size, cannot be used for large-scale production.

Tube Furnace

Application: Conducting thermal processing in a controlled atmosphere, often for material synthesis and oxidation.

Temperature Range: 1,100°C to 1,800°C (2,012°F to 3,272°F).

Size and Capacity: Usually has a tube length of 60 to 150 cm, with diameters ranging from 2 to 10 cm.

Benefits: Excellent for creating precise, controlled environments.

Limitations: Small capacity; requires careful handling of gases.

Ashing Furnace

Application: Determining the mineral content in food, fuel, and other organic materials by combusting the organic matter.

Temperature Range: 600°C to 1,100°C (1,112°F to 2,012°F).

Size and Capacity: Generally ranges from 1 to 3 liters, suitable for small sample analysis.

Benefits: Accurately measures ash content, compact design for lab work.

Limitations: Limited to small samples; only suitable for specific applications.

Vacuum Furnace

Application: Heat treatment in a vacuum environment, commonly used in metallurgy and material science research.

Temperature Range: Up to 1,600°C (2,912°F).

Size and Capacity: Typically designed for small batches, with chamber sizes from 10 to 100 liters.

Benefits: Eliminates oxidation, ideal for sensitive materials.

Limitations: Expensive, requires maintenance and special equipment to handle the vacuum.

Chamber Furnace

Application: General-purpose lab furnace for heating, aging, or sterilizing samples.

Temperature Range: 100°C to 1,200°C (212°F to 2,192°F).

Size and Capacity: Usually has a capacity of 20 to 100 liters, allowing multiple samples.

Benefits: Versatile; can handle multiple samples at once.

Limitations: Limited to lower temperature ranges compared to other lab furnaces.

#IndustrialFurnaces#LaboratoryFurnaces#FurnaceTechnology#ThermalProcessing#MaterialScience#HeatTreatment#AdvancedMaterials#HighTempApplications#IndustrialEquipment#EngineeringSolutions#BlastFurnace#InductionFurnace#RotaryKilnFurnace#ElectricArcFurnace#AnnealingFurnace#MetalProcessing#CementIndustry#SteelRecycling#FurnaceDesign#HighTemperatureFurnaces#MuffleFurnace#TubeFurnace#AshingFurnace#VacuumFurnace#ChamberFurnace#LabEquipment#ThermalAnalysis#MaterialTesting#ControlledAtmosphere#LabTechnology

1 note

·

View note

Text

youtube

Meet the AKR-1010 New Rotary Evaporator: Efficiency & Precision for Your Lab

Ever wondered how labs handle large volumes of solvent evaporation efficiently? 🤔 Meet the AKR-1010 New Rotary Evaporator, a tool designed for researchers and scientists who need to get the job done with precision and speed.

🔬 Key Features:

20L evaporation capacity – Handle big volumes.

Temperature control from room temp to 180°C with ±1°C accuracy.

Vacuum pressure of 0.095Mpa for gentle solvent removal.

Adjustable rotational speed (0-120 rpm) for different sample needs.

The AKR-1010 is used across industries—from chemical research to pharmaceutical development, making it an essential tool in labs that prioritize accuracy and efficiency. Whether you’re concentrating a chemical or recovering solvents, this instrument ensures consistent results every time.

#RotaryEvaporator#AKR1010#LabEquipment#ChemicalResearch#PharmaceuticalResearch#LabInnovation#LaboratoryEfficiency#ScienceTools#PrecisionInstruments#LabTechnology#ResearchAndDevelopment#SolventRecovery#ChemicalSynthesis#EnvironmentalTesting#LabSolutions#ScienceMatters#Youtube

0 notes

Text

Labtron Medical Autoclave Class B, with a 14L capacity, offers fractionated sterilization with cycles ranging from 4 to 18 minutes. It features automatic water feeding/draining and an automated drying function, ensuring efficient, hands-free operation. Ideal for medical and laboratory use.

0 notes