#plastic mold company

Text

Are you searching for Plastic injection molding companies in china? Then here you are at the right place. Order any kind of mold for all industries with them now. Top quality and cost-effective guarantee. Order now!

#Injection Mold#Machining#Manufacturers#Mold Parts#Plastic Molds#industry#plastic injection molding companies in china

2 notes

·

View notes

Text

They're so ugly I love themmmmmm

#kaiba has a button on his back implying some sort of kung fu grip action#but i can't get it to work 😔#joey also has a button on his back and a battery stopper strip thingy slot#but also a little lightbulb on his chest?????#🤔🤔🤔#is it supposed to be a metaphor for the heart of the cards or something#or did every toy in the 2000s just have to have some sort of electrical component to it#and so they said 'fuck it lightbulb joey wheeler'#it is a mystery#the marik one is obviously from a toy line released much later than the other 3#the duel disk has a little button on top that lets it spin open lmao#god i wanna see the production behind these things#like who was in charge of designing these what poor artist was tasked w trying to interpret the ygo hair in a 3d space#which heads of their departments looked at these foul beasts and said#'yeah these look totally fine. slap the company logo on the packaging and ship these out'#they're all hard plastic save for kaiba's coattails which are more like a rubber mold#i kno VERY LITTLE about the toy design/manufacturing process and pipeline from one of my old teachers#but he didn't really talk about it much cause it was a sketching class geared more towards animators and illustrators#god i should've asked him more questions about it i loooooove toy productionnnnnn#he always scared me tho 😔😔😔

5 notes

·

View notes

Text

Precision Plastic Injection Mold & Molding Company | Keiteq

Keiteq is a precision plastic injection molding company specializing in high-quality plastic injection molding services. Contact us today for a free quote!

0 notes

Text

Two-shot injection molding china

Hsmolds.net offers the best two-shot injection molding services in China, providing precision and efficiency. With cutting-edge technology and skilled professionals, they deliver high-quality, dual-material components for various industries. From automotive to electronics, their expertise ensures impeccable results, meeting diverse project requirements. Experience excellence in two-shot molding with Hsmolds.net – your trusted partner for innovative solutions and superior products.

0 notes

Text

Precision and Quality in Plastic Molding: Best Precision Tools

In the heart of Coimbatore, Best Precision Tools has established itself as a leading plastic molds manufacturer, offering a wide range of services tailored to various industries, including engineering, electronics, automotive, and healthcare. With a focus on plastic injection molding, the company provides high-quality, precise, and accurate molded components.

Expertise and Innovation

Best Precision Tools prides itself on its expertise in plastic conversion projects. By transforming metal casting components into plastic ones, the company addresses the need for cost reduction, weight management, and rust prevention. This innovation is particularly beneficial for industries like pumps, home appliances, and textile machinery, which are crucial to Coimbatore's industrial landscape.

Comprehensive Services

The company’s services span from initial concept design to final production. Their capabilities include prototype development, tool designing, and manufacturing. This end-to-end approach ensures that every product meets stringent quality standards, suitable for both domestic and international markets.

Technological Advancements

Staying ahead in the competitive market, Best Precision Tools continually upgrades its technological infrastructure. The use of advanced machinery and a team of skilled professionals allows the company to deliver innovative solutions that meet the evolving demands of their clients.

Industry Applications

Best Precision Tools caters to diverse sectors, including telecommunications, consumer products, healthcare, and packaging. Their plastic injection moulding process is integral in producing complex and detailed plastic parts efficiently, which are then assembled into larger products.

Commitment to Quality

The company's philosophy centers around matching their output to customer expectations. This commitment to quality is evident in their meticulous attention to detail and consistent delivery of superior products.

Benefits of Plastic Injection Moulding

Cost-Effective Production: Plastic injection moulding reduces production costs significantly compared to traditional metal casting.

High Precision and Accuracy: The process allows for the creation of intricate designs with minimal deviation.

Efficiency: Rapid production cycles and the ability to produce large volumes make this method ideal for mass production.

Versatility: Suitable for a wide range of materials, including various polymers and elastomers.

Enhanced Product Performance: Plastic components offer advantages such as lower weight, rust resistance, and improved aesthetics.

Conclusion

Best Precision Tools exemplifies excellence in plastic molding through its innovative techniques, quality focus, and comprehensive service offerings. Their ability to convert metal components to plastic not only meets the demands of modern engineering but also contributes to sustainable and cost-effective manufacturing solutions. For businesses seeking reliable and precise plastic components, Best Precision Tools stands out as a premier partner.

Explore more about their services and expertise on their website

#plastic moulding company#Plastic components manufacturer#Plastic injection moulding#Molds manufacturer#Injection molds manufacturer#Plastic molds manufacturer

0 notes

Text

Four Strategies For Choosing The Best Plastic Embellishment Organization

Choosing the best plastic molding companies in Ohio requires cautious thought to guarantee that you work with a trustworthy and competent maker. The following are four viable ways of distinguishing and selecting the top plastic molding companies in Ohio:

Research and Reviews: Start by conducting thorough research online. Look at Ohio-based plastic molding organizations' sites, client audits, and online evaluations. Consider what previous customers have to say about the company's dependability, communication, service quality, and overall level of satisfaction.

Mastery and involvement with the business: Contemplate the expertise and experience of the plastic molding associations you are surveying. Search for organizations that have a demonstrated history in plastic trim and explicit mastery in the sort of embellishment cycles or materials you require. Organizations with a great deal of involvement are bound to oversee complex undertakings well and produce excellent outcomes.

Quality Standards and Certificates: Ensure the plastic molding organizations you're thinking about employing have the proper affirmations and fulfill severe quality guidelines. Keeping up with industry standards ensures that the company will consistently meet your quality requirements and demonstrates a dedication to excellence.

Customized Counsel and Correspondence: Orchestrate meetings with forthcoming plastic embellishment organizations to talk about your venture necessities exhaustively. Pay attention to the company's communication, question-answering, and solution-tailored approach. Throughout the molding process, a company that values open lines of communication and provides individualized guidance is likely to be a trustworthy partner.

You can find the best plastic molding companies in Ohio that meet your project goals and quality expectations by combing thorough research. Feel free to get some information about costs, tests, references, and timetables before going with a choice. Your manufacturing project's success depends on choosing the right partner for plastic molding.

0 notes

Text

Why PTMS? Precision and Innovation in Plastic Injection Molding Solutions

PTMS as a partner, companies can trust in the expertise, innovation, and dedication to quality that drive success in the plastic injection molding companies. Whether it's producing precision injection components for automotive applications, electronic devices, medical devices, or consumer products, PTMS delivers solutions that meet the most demanding requirements and exceed customer expectations. With a focus on precision, innovation, and sustainability, PTMS is poised to continue leading the way in plastic injection molding manufacturing for years to come.

1 note

·

View note

Text

Looking for top-notch plastic injection molding services? Look no further! Our company in China specializes in precision molding for diverse industries. With cutting-edge technology and expert craftsmanship, we deliver high-quality products tailored to your specifications. Visit our website to learn more. https://www.rchplastic.com/injection-molding/

0 notes

Text

#plastic-parts-manufacturing-companies#plastic-components-manufacturers#Best-Plastic-Mold-Companies-in-Canada

0 notes

Text

How to Build Plastic Containers?

Plastic containers are everywhere in our daily lives. They are essential tools for storing, transporting, and organizing products. From kitchen cabinets to industrial cabinets, versatility knows no bounds. While they are easy to pick up, making these pots requires a mix of science, technology, and craftsmanship. In this article, we will explore the intricacies of plastic container manufacturing by the best injection molding company and the materials, processes, and concepts involved in the process.

Understanding Plastic Materials:

Plastic molds are generally made from various polymers, each with unique properties and applications. Common plastics include:

Polyethylene (PE): Known for its flexibility and chemical resistance, PE is widely used in containers for food, beverage and household products

Polypropylene (PP): PP provides excellent heat resistance and is commonly used in microwave-resistant containers, as well as packaging and industrial applications

Polyvinyl chloride (PVC): PVC is prized for its durability and versatility, making it suitable for a wide range of containers including pipes, bottles and packaging

Polystyrene (PS): PS is lightweight and insulated, making it ideal for disposable food containers, packaging and insulation.

Every plastic has unique properties, it is important to choose the right material to ensure the product works smoothly and efficiently

The Manufacturing Process:

The manufacture of plastic containers usually involves a series of manufacturing steps, e.g.

Design: The process begins with the design of the container, considering factors such as size, shape, functionality, and intended use. Computer-aided design (CAD) software is often used to create a detailed container drawing.

Material Selection: Once the design is complete, suitable plastic materials are selected based on their characteristics and suitability for the application

Injection Molding: Injection molding is one of the most common methods used to manufacture plastic containers. In this process, plastic shells are molded and placed in the molds under high pressure. The molded plastic molds harden into the desired shape when cooled.

Blow molding: Another popular method of manufacturing plastic molds is blow molding, which is particularly suitable for containers with holes, such as bottles and jars. In blow molding, a hollow plastic molding (called a parison) is created and then blown into the mold into the desired shape

Thermoforming: A plastic sheet is heated until it bends and then forms on molds under vacuum or pressure. This method is often used for trays, clamshells, and other shallow containers.

Assembly: Depending on the design, several items, such as covers, handles, or closures, may need to be assembled with some plastic containers.

Quality control: Strict quality control procedures are applied throughout the process to ensure that containers meet the required strength, durability, and dimensional accuracy standards.

Advantages of Utilizing Plastic Containers

Lightweight: Have you ever attempted to carry a glass container? You'll appreciate the ease of plastic's lightness.

Sturdy: Drop them, and they're likely to withstand the impact.

Economical: They won't strain your budget.

Potential Environmental Impact and Recycling

Nevertheless, the picture isn't entirely positive. Plastic pollution poses a significant concern. However, recycling efforts can alleviate some of these issues. Thus, it's important to recycle whenever possible.

Precautions and Safety Measures

Avoid exposing certain plastics to high temperatures.

Ensure that food containers are made of food-grade materials.

Recycle. This cannot be emphasized enough.

Materials Required for Building Plastic Containers

Building plastic containers requires several materials to ensure their efficient and effective production. The primary material, of course, is plastic resin, which serves as the base material for molding the containers. This resin can be sourced from various types of plastics, such as polyethylene (PE), polypropylene (PP), or polyethylene terephthalate (PET), depending on the desired properties of the containers.

Additionally, additives are often mixed with the resin to enhance specific characteristics of the containers. These additives may include colorants to give the containers their desired appearance, stabilizers to protect against degradation from UV exposure or heat, and reinforcements to increase strength and durability.

Furthermore, molds made of steel or aluminum are necessary for shaping the plastic resin into the desired container design. These molds must be precisely crafted to ensure consistency and accuracy in the final product.

Other materials required in the production process include machinery and equipment for melting, molding, and finishing the plastic containers. Overall, a combination of plastic resin, additives, molds, and machinery is essential for building plastic containers that meet quality standards and effectively serve their intended purposes.

Conclusion

Plastic container manufacturing is a multifaceted process that requires careful consideration of materials, design, and manufacturing processes. From injection frisbee to blow molding and thermoforming, various processes are used to produce molds that meet the needs of customers and industries. By understanding the key components of plastic mold manufacturing and the factors affecting their performance, we can appreciate the craftsmanship and innovation behind these daily things that matter. Whether storing leftovers in the kitchen or transporting goods worldwide, plastic containers are indispensable in our modern lives.

FAQs

1. What types of plastics are commonly used in molds?

Polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), and polystyrene (PS) are common mold plastics.

2. How can I recycle plastic containers?

Plastic containers can be recycled in a variety of ways, including mechanical recycling, which involves shredding, grinding and recycling plastics into new products, or chemical recycling recycling, which breaks down plastic into its composite for recycling

3. Are plastic containers safe for food storage?

Yes, plastic containers intended for food storage are generally made of plastic that has been tested for safety and meets regulatory standards. It is important to follow the plastic moulding manufacturer's instructions for consumption proper handling and storage back to ensure food safety.

4. Can plastic containers be made for specific products?

Yes, plastic containers can be customized in size, shape, color, and function to meet the specific needs of different applications, such as food packaging, industrial storage, or consumer goods.

#injection molding solutions#injection frisbee#plastic injection mold design#injection molding maker#best injection molding company#plastic chocolate molds

0 notes

Text

Plastic Injection Mold & Molding Parts Manufacturers in India since 1968

Looking for plastic injection mold and molding parts manufacturing Companies in India, Delhi, NCR. Then contact with General Plastic Industries in India. Leading since 1968.

#plastic injection molding companies#plastic mould manufacturers in delhi#injection moulding#contract manufacturing

0 notes

Text

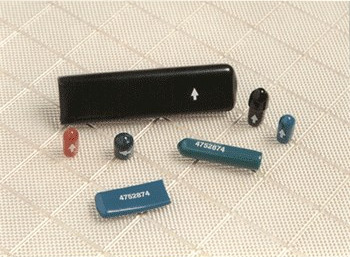

Kore Industries: Revolutionizing Automotive Manufacturing Through Precision and Innovation

Introduction:

In the ever-evolving landscape of automotive manufacturing, Kore Industries stands as a beacon of innovation, redefining industry standards with its expertise in precision plastic molding. This article delves into the core competencies of Kore Industries and elucidates how the company's cutting-edge solutions are reshaping the automotive industry.

Kore Industries: Precision at its Core:

At the heart of Kore Industries' success is its mastery of precision plastic molding, a technique that has become integral to the automotive sector's pursuit of excellence. The company's commitment to precision is not merely a practice but a philosophy embedded in every aspect of its operations, from design conception to final production.

Precision Plastic Molding Techniques:

1. Precision Plastic Gears: Kore's expertise in crafting precise plastic gears ensures the seamless operation of intricate automotive mechanisms, contributing to the overall efficiency and reliability of vehicles.

2. Multi-Shot Molding: Kore's proficiency in multi-shot molding allows for the creation of complex components with multiple materials in a single molding cycle. This not only streamlines the production process but also enhances the functionality and aesthetics of automotive parts.

3. Overmolding and Insert Molding: Kore excels in overmolding and insert molding, reinforcing the durability of automotive components. This precision technique is crucial for parts that require a combination of materials for optimal performance.

4. Tandem Molding: Addressing the challenges of complex molding requirements, Kore offers tandem molding solutions, showcasing adaptability and providing bespoke manufacturing processes for the automotive sector.

Engineering Excellence and Collaborative Innovation:

Kore Industries sets itself apart through a collaborative approach to problem-solving. The company actively engages with automotive manufacturers, leveraging its engineering know-how to address challenges proactively. Kore's commitment to experimentation with new methodologies and meticulous execution positions it as a trusted partner for automotive clients seeking innovative solutions

youtube

Top-of-the-Line Equipment and Technology:

Kore Industries takes pride in its molding facilities equipped with top-of-the-line, fully electric, and robotic technology. This commitment to technological precision ensures consistency and accuracy throughout the manufacturing process, meeting the demanding requirements of the automotive sector.

Kore's Impact on the Automotive Industry:

Kore's Precision in Action:

Automotive components demand precision to function seamlessly. Kore's precision plastic molding techniques contribute to the production of critical parts such as gears, interior trim components, buttons, handles, and various other components that define a vehicle's performance and aesthetics.

Efficiency and Cost Reduction:

By offering multi-shot molding capabilities, Kore enables automotive manufacturers to consolidate multiple parts into a single component. This not only reduces assembly costs but also streamlines production cycles, contributing to overall cost reduction and increased efficiency.

Enhanced Aesthetics and Functionality:

The automotive industry places a premium on both the visual appeal and functionality of vehicle components. Kore's expertise in overmolding and insert molding allows for the integration of different materials, creating parts that not only look aesthetically pleasing but also perform optimally.

Looking Ahead: Kore Industries' Continued Innovation:

As automotive technology evolves, so does Kore Industries. The company remains at the forefront of innovation, adapting its precision plastic molding techniques to meet the evolving needs of the automotive industry. Whether it's developing components for electric vehicles, autonomous driving systems, or next-generation interiors, Kore Industries stands ready to contribute to the future of automotive manufacturing.

Conclusion: Driving Precision Forward with Kore Industries:

In a sector where precision is paramount, Kore Industries emerges as a key player, driving the automotive industry forward with its commitment to excellence. Through precision plastic molding techniques, engineering know-how, and collaborative problem-solving, Kore continues to leave an indelible mark on the automotive landscape. As automotive manufacturers strive for greater efficiency, enhanced aesthetics, and reliability, Kore Industries stands as a steadfast partner, delivering solutions that redefine automotive precision.

0 notes

Text

Looking for precision mechanical components in China? Look no further than Hsmolds.net. With a reputation for quality and reliability, Hsmolds offers a wide range of precision mechanical components to suit your needs. From CNC machining to injection molding, they have the expertise to deliver top-notch products at competitive prices. Explore their catalog today for your manufacturing needs.

0 notes

Text

Plastic Injection Molding Companies in China

Are you searching for plastic injection molding companies in china? Then here you are at the right place. Order any kind of mold for all industries with them now. Top quality and cost-effective guarantee. Order now!

0 notes

Text

Plastic injection molding companies in china

Discover top plastic injection molding companies in China for cost-effective and high-quality manufacturing. Our expertise and cutting-edge technology ensure the precise production of plastic parts for diverse industries.

#Plastic injection molding companies in china#Mold manufacturers in china#Injection Molding Service China#Injection mold suppliers’ china#China Mold Manufacturer#Injection Mold Company China

1 note

·

View note