#supply chain management consultancy

Text

NAV stands for Navigation (or to navigate). We steer our customers to success through the rough route of complex processes and IT landscapes.

We provide Process consulting and Solution development services, enabling clients to discover the benefits of SAP’s Digital Supply Chain Platforms and Microsoft Power Platform.

#it consulting services#sap consulting#technology consultant#management consulting#supply chain management consulting#Microsoft Power Platform#Supply Chain#SAP S/4HANA#SAP GTT#SAP S/4 Hana#Transportation Management Consulting Services#Business Network for Logistics

2 notes

·

View notes

Text

Customized Solutions: Tailoring Supply Chain Strategies to Industry Needs

Supply chain management has become a crucial determinant of a company's performance in the ever-changing commercial environment of today. With the increasing specialisation and diversity of industries, it is evident that the conventional one-size-fits-all approach to supply chain strategy has been ineffective. In recent times, there has been a notable increase in the significance of tailored solutions, as enterprises acknowledge the importance of adapting their supply chain strategies to align with the distinct requirements of their respective sectors. This blog article aims to explore the significance of tailored supply chain solutions and their role in enhancing operational efficiency, minimising expenses, and facilitating industry-specific expansion. Smarter solutions for stronger supply chains. Partner with VNC Global - for top-class Supply chain management consulting in Australia to drive growth!

Understanding the Need for Customization:

Each sector functions inside its own specific environment, which is defined by particular obstacles, rules, and market forces. Therefore, it can be argued that a standardised supply chain approach is insufficient in addressing the intricacies specific to each sector. Customised solutions consider these variables, providing a personalised approach that is in line with the specific requirements of the industry.

Optimizing Operations for Efficiency:

The possibility for operational optimisation is a fundamental advantage of customising supply chain strategies to align with industry requirements. The utilisation of generic methodologies frequently leads to operational inefficiencies, manifesting in the form of surplus inventories, delays in processes, and bottlenecks. In contrast, customised solutions optimise operational efficiency by matching processes with the specific demands of the industry.

Industries characterised by significant fluctuations in demand may derive advantages from using agile supply chain methods that provide swift adaptations in production and distribution processes. Conversely, industries characterised by consistent and predictable demand patterns should prioritise the implementation of lean supply chain methods as a means to mitigate inefficiencies and achieve cost reductions. By optimising the supply chain in this manner, organisations can improve operational efficiency and responsiveness.

Reducing Costs and Enhancing ROI:

The issue of cost containment continues to be a persistent worry for firms operating in various sectors. Customised supply chain solutions are of paramount importance in effectively addressing this challenge. Tailoring tactics to the specific needs of an industry leads to the minimization of wastage, more efficient allocation of resources, and optimisation of costs. Experience real-time visibility, control, and savings. Invest in the best Supply chain management software in Australia offered by VNC Global!

Industries characterised by rigorous compliance requirements might derive advantages from supply chain strategies that prioritise the principles of traceability and transparency. By incorporating technology such as blockchain, enterprises can effectively verify regulatory adherence while concurrently mitigating the potential financial repercussions associated with product recalls. This technique not only results in cost savings but also serves to protect the reputation of the brand.

Fostering Industry-Specific Growth:

Customised supply chain solutions encompass more than just enhancing operational efficiency; they also play a significant role in fostering growth within certain industries. Industries undergo a natural progression, characterised by the impact of technology breakthroughs, market dynamics, and consumer preferences. The use of supply chain strategies customised to these elements facilitates the ability of firms to maintain agility and adaptability.

Consider the pharmaceutical business as an illustrative case. The emergence of personalised medication and the requirement for temperature-sensitive distribution may render conventional supply chain models inadequate. The implementation of a tailored approach that integrates cold chain logistics and real-time tracking systems guarantees the secure and effective transportation of delicate pharmaceuticals. The ability to adapt enables firms to effectively capitalise on emerging opportunities and navigate industry shifts.

Strengthening Industry Collaboration:

The implementation of tailored supply chain solutions frequently necessitates industry-wide collaboration and strategic collaborations. The act of exchanging best practices, insights, and resources is of utmost importance in order to collectively enhance operational efficiency. The cooperative efforts between entities not only yield advantages for individual enterprises but also contribute to the overall enhancement of the industry.

businesses characterised by intricate regulatory obligations have the potential to engage in collaborative efforts aimed at addressing compliance challenges. By pooling their resources, these businesses can collectively work towards the development of innovative technologies that facilitate the process of adhering to regulatory standards. Collaborative endeavours not only alleviate operational difficulties but also cultivate a sense of brotherhood among participants within the sector.

Final Thoughts:

In the contemporary landscape characterised by a wide range of industries and their corresponding complexities, the adoption of customization has emerged as a crucial strategy in the realm of supply chain management. Customising tactics to cater to the unique requirements of the sector allows organisations to enhance operational efficiency, minimise expenditures, and facilitate industry-specific expansion.

In a contemporary context where the ability to adapt and be agile is of utmost importance for achieving success, the adoption of tailored supply chain solutions is not only a choice but rather a strategic need. In the context of ongoing industrial development, enterprises that place emphasis on customised supply chain strategies establish themselves as frontrunners, equipped to effectively address the distinctive requirements of their specific environments. Supply chain excellence made attainable. Connect with VNC Global for tailored Supply chain management consulting in Australia!

#Supply chain management consulting in Australia#Supply chain management software in Australia#vncglobal

2 notes

·

View notes

Text

youtube

What Is MRO Procurement Strategy And How Can You Benefit?

Paragon Results can help to increase the productivity of a factory or manufacturing plant, decrease overall costs and minimize downtime when equipment breaks or needs updating. We can provide your organization with the expertise to develop and implement a carefully crafted MRO procurement strategy that will help you gain control of costs, maintain compliance and standardize your purchasing procedures. By facilitating transparency, our MRO sourcing consultants can increase indirect spend visibility, identify areas of waste and remove weak links in your supply chain. Contact us to learn more about our strategy: https://paragonresults.com/

#Supplier Diversity Consultants#executive coaching services#mro procurement strategy#procurement and supply chain management#strategic sourcing solution#Youtube

2 notes

·

View notes

Text

Demand Planning With True Demand

For the following scenario which of the following historical orders data stream you would consider from a demand planning perspective?

1. All order streams A to E should be considered.

2. Only relevant order streams coming from customers — B and E should be considered.

3. Only the Orders placed on plant (A and C) should be considered.

Which would be an appropriate choice? Should we be only looking at POS data for order streams originating from customers (B and E) placed on distributor and warehouse? Would other order streams cloud the demand plan

Now another debate — ‘Hey, should we consider orders or shipments for this analysis? For this read more here at ‘How do you define True demand for forecasting? details here — https://demandplanning.net/DemandDownload.htm

So, in that case what will happen to order streams from distributor to plant, warehouse and from warehouse to plant? Should we consider those for planning demand? Why?

Do third party distributors keep its inventory adjustments isolated from the plant? Keeping the plant guessing about next batch of orders. Where and how do we draw the fine line to differentiate demand and replenishment planning?

In your job experience have you put on multiple hats of a buyer and of a demand planner?

#demand planning#forecasting#supply chain management#new blog#demand#supply chain#consulting#services

2 notes

·

View notes

Text

Manage your forecast modeling process by Exception:

Review major forecast changes from a previous cycle.

Review items with major forecast errors.

Review high growth or high decline forecasts compared to previous year.

Review major over-rides through Sales Collaboration.

#ForecastPro#Forecasting Tool#Demand Modeling#statistical forecasting techniques#planning process#statistical forecast#Tools for Forecasting#Demand Planning tools#Supply Planning solution#sales and operations planning workshop#S&OP#demand forecasting process#Valtitude#Demand Planning#S&OP Forecasting Consulting#Supply Chain Management Software#IBP#Supply Chain Optimization

0 notes

Text

“80% of your supply chain errors derive from 20% of your products”

Design, Analysis, and implementation of an exception management approach have helped companies to

Streamline the planning process

Improve forecast accuracy significantly and

Focus on the major supply chain drivers that improve the bottom line

Exception management leverages the 80/20 rule.

We evaluate the end-to-end chain to capture valuable information clusters that drive the underlying business process.

Through our unique methodology and solution, we help clients institutionalize an exception management mentality to improve focus and create value through the planning process. Through this exception management approach, we have achieved impressive results with major corporate supply chains.

#Tools for Forecasting#Demand Planning tools#Supply Planning solution#Demand Planning LLC#Sales and Operations Planning#Supply Chain Optimization#Valtitude#Demand Planning#S&OP Forecasting Consulting#Supply Chain Management Software#IBP#forecasting#supplychainvisibility#realtimeplanning#sapdigitalcore#inventoryoptimization#advancedplanning#supplychainmanagement#digitalsupplychain#sapcloud#demandplanning

0 notes

Text

Planning is a critical function in any business. Banks need a business plan outlining your plan for profitability before lending capital.

So do venture capitalists when they seed new start-ups. Business planning is not just a one-off process; it needs to be done annually.

The business plan derives from a market plan, an understanding of the market you are in and your position in that market. The profitability and the feasibility of your business largely depend on the following things:

The size of the market and its rate of growth

Your share of the market

The effectiveness of your marketing plan to keep or grow your share

The efficiency of operations to generate a healthy margin on your sales.

Market Planning vs. Marketing Plan

Market Planning is the process of sizing up your market and calculating your share versus your competitors. A Marketing Plan is the tool used to increase your share of the market through marketing activities such as advertising, branding, and promotions.

A key component of Market Planning is market share forecasting. In the manufacturer to retailer to consumer model, what matters most is the shelf take-away or sales at retail. Marketing Strategies aim to maximize shelf consumption (and usage) and thus increase your share of that consumption.

The first step is calculating the total market potential for your products. The second step is to estimate your retail sales and derive your share of the total market. The third step is to forecast your base case market share as well as target market share given your advertising budget and your marketing plan. Let us use the case of an infant car seat manufacturer to illustrate this process.

Estimating the Total Market

If you are a baby seat manufacturer, you need to understand the total market potential of infant car seats in both units and dollars. In this case, the entire population of infants is your market. If two million babies are expected in a year, the market for infant seats is 2m units. However, some of the households may be two car households and decide to buy two seats. If 50% of the households buy two seats, then the market is really 3m units.

Now what is the market potential for infant car seats in dollars? It depends on the price segments of car seats. There may be different types of car seats with different features commanding varying prices. Let us assume that there are two kinds of seats one being a simple no-frills car seat and the other a fancier seat with additional features like a cup holder, sun shade, diaper holder, etc. Different consumer segments may demand these car seats at different price ranges.

We can apply several market analysis techniques to understand price points and calculate the average price of these two market segments. Let us say our studies show the average prices to be $40 for the basic seat and $50 for the fancy seat.

The total market potential in dollars is the sum of the basic seat segment and the fancy seat segment. Suppose the basic seat segment is 2m units. At a price of $40, this potential is $80m. The fancy seat has 1m units at a price of $50 and a market potential of $50m. The total dollar market potential is then $130m.

Estimating Market Share

In simple terms, your market share equals total retail take-away of your products divided by the total market potential. This is just a calculation of your share of the total retail sales.

Your total retail sales depend on which segment you participate in and who the other players are in that segment. Retaining and growing your share depends on a number of marketing factors including product differentiation, advertising, brand value, etc. The size and the marketing budget of your competitors also are key determinants of your market share.

In the infant car seat manufacturer example, let us say, you compete in the basic seat segment of the market. If you own 50% of the basic seat market, which is 2m units, then your total annual retail sales is 1m units compared to a total market of 3m units. Your share of the infant car seat market is then 33.3%.

We can calculate the dollar share using the following steps:

Your retail dollars equal your retail unit sales x your average price. In this case your dollar retail sales is given by (1m units x $40) which gives $40m

The total dollar market potential is $130m (calculated above)

Your dollar market share is then $40m over $130m which is 31%

Although your unit share is 33.3%, the dollar share is 31% because you play in the low-price segment of the market.

How can you retain or increase your market share?

The Marketing Plan is an outline of your strategy to increase your market share. It may cover a number of marketing and brand building techniques as well as the budget dollars allocated to each activity. Generally, the following tools are used to retain/gain market share:

Advertising and Sales programs to increase unit share while keeping prices constant

Building Brand Value to move to the high-end segment of the market. This will result in higher selling prices without hurting unit sales. (In our example, you may be able to sell the same basic seat for $45 because consumers are willing to pay a premium price for your brand)

Sales Promotions through discounts and coupons will increase unit share but may compromise the dollar share

Aggressive Price cutting may also be used as a strategy to capture a higher market share from your competitors

The last and perhaps the most often used strategy in the Consumer Packaged Goods sector is to capture market share through new product introductions

Practical Steps to Forecasting Your Market Share

Depending on the industry, forecasting the total market for a particular product may be as easy as obtaining the market potential from externally syndicated sources. And it may be complex to the point of estimating the market by extrapolation based on your own point-of-sale data

We can forecast our retail sales independently and derive the market share as a ratio of our own retail sales forecast over the forecasted market potential. This is the base case share forecast. For example, if we observe the share to be 25% over the last few years, we can assume a stable forecast of 25% for the next year

We can then come up with an objective or a target market share estimate based on the promotional plans and budgets. If we estimate additional advertising investment can produce a 3% gain in share, our forecast will be a 28% share

When the total market potential is increasing, our retail sales forecast may be growing even with constant market shares.

Market share forecasts are important in order to understand the return on investment of advertising dollars and the budget needed to retain versus grow market share. But truly, market share forecasts tell us the long-term demand for our products. They are early warnings of what and how much to produce and distribute to be successful in the marketplace.

#sales and operations planning workshop#S&OP#demand forecasting process#sales and operations planning#S&OP process#Operations Planning Process#Valtitude#Demand Planning#S&OP Forecasting Consulting#Supply Chain Management Software#IBP#Supply Chain Optimization#Tools for Forecasting#Demand Planning tools#Supply Planning solution#Demand Planning LLC#Sales and Operations Planning#forecasting#advancedplanning#inventoryoptimization#realtimeplanning#supplychainvisibility#sapdigitalcore

0 notes

Text

This Sales and Operations Planning Workshop is a practical guide to designing and implementing an internal collaboration process that would improve your value chain planning and integrate it into business management.

Sales and Operations Planning Process brings together all elements of Sales, Marketing, Finance, and Operations into one integrated set of plans. This integrated planning forum greatly enhances communication of key market and customer intelligence into the supply chain.

Sales and Operations Planning is the best practice planning solution that starts with creating an unbiased demand forecast, reviews the feasibility of the demand plan in the face of supply constraints, and arrives at a constrained operational plan to drive the supply chain operations in the immediate planning horizon. In this training workshop, we will explain the design and mechanics of this internal collaboration process which brings together all stakeholders. We will discuss the key components of the S&OP process – the mechanics, reports, consensus, and hand-offs as well as the metrics. No other training program provides as much practical information and insight to all aspects of S&OP, as this.

– Available in the following formats:

– Web Workshop, on-site workshop at your location, or as a public training course.

Topics Covered:

S&OP Overview- Key components

Demand Forecasting Process

Integrating the Sales Force to Achieve Consensus

Supply Review of Demand

Implementation Methodology

S&OP Templates and Reports

S&OP Score-card

New Product Planning

Preparing for the Executive S&OP

Exception Management in S&OP

#sales and operations planning workshop#S&OP#demand forecasting process#sales and operations planning#S&OP process#Operations Planning Process#Valtitude#Demand Planning#S&OP Forecasting Consulting#Supply Chain Management Software#IBP#Supply Chain Optimization#Demand Planning LLC#Sales and Operations Planning#supplychainvisibility#forecasting#realtimeplanning#sapdigitalcore#inventoryoptimization#advancedplanning#supplychainmanagement#digitalsupplychain#sapcloud

0 notes

Text

The sales and Operations Planning Process thrives on collaboration and honest communication between key organizational players. This is a unique process embodying several information-sharing sessions and decision forums, with the final intent to generate an organizational Plan and key Sales and Operations issues for the top organizational manager to decide on.

We kick off the S&OP implementation with an on-site workshop to be attended by your sponsors and stakeholders. For many companies on the wall about taking the plunge, this workshop will be a key input and bring to fore many company-specific drivers. Our on-site workshop addresses the following key steps in developing and implementing an effective S&OP process.

#sales and operations planning#S&OP process#Operations Planning Process#Tools for Forecasting#Demand Planning tools#Supply Planning solution#Software and Tools for Forecasting#Supply Chain and Business Management#Valtitude#Demand Planning#S&OP Forecasting Consulting#Supply Chain Management Software#IBP#Supply Chain Optimization#forecasting#supplychainvisibility#realtimeplanning#inventoryoptimization#sapdigitalcore#supplychainmanagement#advancedplanning#digitalsupplychain#sapcloud

0 notes

Text

Here is a list of key Software and Tools for Forecasting along with a brief summary of the functionality and applications. This is compiled without any specific endorsement of its usefulness or appropriateness for a specific situation. Please contact us if you want a more detailed report on each of the below software

Oracle Demantra – Oracle’s own Demand Planning tool that integrates into the rest of the Oracle ERP applications. Demantra also include a Trade Promotions Management package to optimize promotions spend.

i2 – Rhythm Demand Planner, Supply Planner and Factory Planner along with several web-based trade matrix solutions.

Manugistics – The pioneering Demand Planning solution in the manufacturing space, particularly CPG and High Tech.

SAS – The Statistical Analysis System is a powerful data analytic and reporting tool. SAS is also trying to market industry specific applications and solutions for Demand Planning, Market Research

Forecast Pro – Software for Statistical Forecasting that is easy to implement as an off-the-shelf solution. This software is available as a single user as well as shared multi-user environment.

Logility – Traditional Demand and Supply Planning solution along with a solution for Collaborative Planning.

SAP Demand Planning – APO demand planning that integrates neatly into the SAP ERP applications. SAP also provides Business Warehouse which is a warehouse and reporting repository.

Steel wedge – Solution for Sales and Operations planning aimed at engaging the entire Value chain holistically in this process. This has an Excel GUI to view and manipulate the enterprise data.

Demand Forecasting and Inventory Planning – SCP’s Demand Forecasting and Inventory Planning, Demand and Supply Planning module is a time-phased Forecasting, Demand and Supply Planning, & Demand Supply Planning Master Production Scheduling and Distribution Requirements Planning (DRP) tool

Autobox was first launched in 1975 and automatically builds customized Univariate and Multivariate models for time series data with automatic intervention detection for outliers, seasonal pulses, level shifts and local time trends.

#Tools for Forecasting#Demand Planning tools#Supply Planning solution#Demand Planning LLC#Sales and Operations Planning#Supply Chain Optimization#Valtitude#Demand Planning#S&OP Forecasting Consulting#Supply Chain Management Software#IBP#forecasting#supplychainvisibility#realtimeplanning#inventoryoptimization#advancedplanning#supplychainmanagement#sapdigitalcore#digitalsupplychain#sapcloud

0 notes

Text

1. DEMAND ANALYTICS

Under the six-sigma DMAIC approach, measurement of your current state is a key requirement for diagnostic, design and implementation of the process. Even for on-going process stability, measurement is critical.

The Demand Analytics module provides key insights on your planning performance and provides an insightful view of demand volatility, demand visibility and product mix analysis. It also provides additional insights on comparisons to the budget and annual plan.

Our Clients have reported improved Demand visibility, forecast accuracy and higher adoption of the S&OP process throughout the organization.

2. SCM ANALYTICS

With Planvida, the Supply Chain Scorecard process can be completed in minutes.

Every month, you get all the KPIs for your S&OP in a few minutes - ready to go on Day 2 morning.

Some clients want the SCM analytics implemented first as this gives you end-to-end insights into your entire supply chain. Our SCM anlaytics cloud gives you key insights into your customer service, inventory metrics, production adherence to plan, lead-time compliance and several control charts for tracking supply chain functional performance to plan.

3. PLANNING AND FORECASTING CLOUD

Our cloud-based planning and Forecasting engine is the most sophisticated among several offerings on the market. This engine provides a probabilistic forecast using an AI-driven modeling platform. Many organizations are suffering from the lack of good demand visibility. Our planning engine contains a diverse set of models and machine learning algorithms and the AI picks the best model for the demand profile.

Our Demand Forecasting models can run causal models, transfer functions, event-response models and a variety of other models for seasonal variations and complex higher order demand variability. The probabilistic forecast will help you with predictive planning so you can set accurate inventory targets.

Pricing starts at $1,795 month and up to five users can access the system. It can be seamlessly integrated with your ERP or BI system.

4. ON-GOING SUPPORT

Our support team is here to ensure things run smoothly for your organization.

Our Data Science team will review the models and the results of the AI engine so the ML algorithms will work on steroids combined with this intelligent human input.

#PlanVida#Planning#Analytics#SAP IBP#SAP IBP workshop in India#Statistical modeling and forecasting in SAP IBP#Valtitude#Demand Planning#S&OP Forecasting Consulting#Supply Chain Management Software#IBP#Supply Chain Optimization

0 notes

Text

STUDY AND ANALYZE YOUR PLANNING PROCESS IN THE CONTEXT OF YOUR BUSINESS MODEL AND BEST-IN-CLASS PRACTICES TO DEVELOP RECOMMENDATIONS AND IMPLEMENTATION STEPS:

Measure – Assess the process

Map – Identify process pain points with stakeholder interviews, and data analysis

Gaps – Highlight key areas of opportunity and value enhancing process solutions

Value – Provide recommendation with a facilitated one day workshop

OUR CONSULTING MODEL EMPLOYS THE SIX-SIGMA METHODOLOGY OF DMAIC:

Define

Measure

Analyze

Improve and Control

Because of the diverse experience of DemandPlanning.Net Consultants, we can design and deliver the process in almost half the time and resource costs required by some of the bigger consulting houses. We add value to your process design in two ways:

With our knowledge base of best practices and the benchmark industry process, we can analyze and recommend processes and benchmarks rather quickly

Our central philosophy is exception management grounded in the Six-Sigma principles. This helps design a very effective process that is time-efficient as well

A quick three week engagement to assess your organizational readiness for implementing IBP

#IBP#Planning#SAP IBP#APO#Valtitude#Integrated Business Planning Process#Demand Planning#S&OP Forecasting Consulting#Supply Chain Management Software#Supply Chain Optimization#forecasting#supplychainvisibility#realtimeplanning#sapdigitalcore#inventoryoptimization#supplychainmanagement#advancedplanning#digitalsupplychain#sapcloud

0 notes

Text

Customized Solutions: Tailoring Supply Chain Strategies to Industry Needs

Supply chain management has become a crucial determinant of a company's performance in the ever-changing commercial environment of today. With the increasing specialisation and diversity of industries, it is evident that the conventional one-size-fits-all approach to supply chain strategy has been ineffective. In recent times, there has been a notable increase in the significance of tailored solutions, as enterprises acknowledge the importance of adapting their supply chain strategies to align with the distinct requirements of their respective sectors. This blog article aims to explore the significance of tailored supply chain solutions and their role in enhancing operational efficiency, minimising expenses, and facilitating industry-specific expansion. Smarter solutions for stronger supply chains. Partner with VNC Global - for top-class Supply chain management consulting in Australia to drive growth!

Understanding the Need for Customization:

Each sector functions inside its own specific environment, which is defined by particular obstacles, rules, and market forces. Therefore, it can be argued that a standardised supply chain approach is insufficient in addressing the intricacies specific to each sector. Customised solutions consider these variables, providing a personalised approach that is in line with the specific requirements of the industry.

Optimizing Operations for Efficiency:

The possibility for operational optimisation is a fundamental advantage of customising supply chain strategies to align with industry requirements. The utilisation of generic methodologies frequently leads to operational inefficiencies, manifesting in the form of surplus inventories, delays in processes, and bottlenecks. In contrast, customised solutions optimise operational efficiency by matching processes with the specific demands of the industry.

Industries characterised by significant fluctuations in demand may derive advantages from using agile supply chain methods that provide swift adaptations in production and distribution processes. Conversely, industries characterised by consistent and predictable demand patterns should prioritise the implementation of lean supply chain methods as a means to mitigate inefficiencies and achieve cost reductions. By optimising the supply chain in this manner, organisations can improve operational efficiency and responsiveness.

Reducing Costs and Enhancing ROI:

The issue of cost containment continues to be a persistent worry for firms operating in various sectors. Customised supply chain solutions are of paramount importance in effectively addressing this challenge. Tailoring tactics to the specific needs of an industry leads to the minimization of wastage, more efficient allocation of resources, and optimisation of costs. Experience real-time visibility, control, and savings. Invest in the best Supply chain management software in Australia offered by VNC Global!

Industries characterised by rigorous compliance requirements might derive advantages from supply chain strategies that prioritise the principles of traceability and transparency. By incorporating technology such as blockchain, enterprises can effectively verify regulatory adherence while concurrently mitigating the potential financial repercussions associated with product recalls. This technique not only results in cost savings but also serves to protect the reputation of the brand.

Fostering Industry-Specific Growth:

Customised supply chain solutions encompass more than just enhancing operational efficiency; they also play a significant role in fostering growth within certain industries. Industries undergo a natural progression, characterised by the impact of technology breakthroughs, market dynamics, and consumer preferences. The use of supply chain strategies customised to these elements facilitates the ability of firms to maintain agility and adaptability.

Consider the pharmaceutical business as an illustrative case. The emergence of personalised medication and the requirement for temperature-sensitive distribution may render conventional supply chain models inadequate. The implementation of a tailored approach that integrates cold chain logistics and real-time tracking systems guarantees the secure and effective transportation of delicate pharmaceuticals. The ability to adapt enables firms to effectively capitalise on emerging opportunities and navigate industry shifts.

Strengthening Industry Collaboration:

The implementation of tailored supply chain solutions frequently necessitates industry-wide collaboration and strategic collaborations. The act of exchanging best practices, insights, and resources is of utmost importance in order to collectively enhance operational efficiency. The cooperative efforts between entities not only yield advantages for individual enterprises but also contribute to the overall enhancement of the industry.

businesses characterised by intricate regulatory obligations have the potential to engage in collaborative efforts aimed at addressing compliance challenges. By pooling their resources, these businesses can collectively work towards the development of innovative technologies that facilitate the process of adhering to regulatory standards. Collaborative endeavours not only alleviate operational difficulties but also cultivate a sense of brotherhood among participants within the sector.

Final Thoughts:

In the contemporary landscape characterised by a wide range of industries and their corresponding complexities, the adoption of customization has emerged as a crucial strategy in the realm of supply chain management. Customising tactics to cater to the unique requirements of the sector allows organisations to enhance operational efficiency, minimise expenditures, and facilitate industry-specific expansion.

In a contemporary context where the ability to adapt and be agile is of utmost importance for achieving success, the adoption of tailored supply chain solutions is not only a choice but rather a strategic need. In the context of ongoing industrial development, enterprises that place emphasis on customised supply chain strategies establish themselves as frontrunners, equipped to effectively address the distinctive requirements of their specific environments. Supply chain excellence made attainable. Connect with VNC Global for tailored Supply chain management consulting in Australia.

#Supply chain management consulting in Australia#Supply chain management software in Australia#VNC Global

2 notes

·

View notes

Text

Introduction to IBP and forecast profiles

Demand Planning and Forecasting

Model Settings in IBP DP

Illustration of Forecast Profiles in IBP DP

IBP DP Master Profile

Uni-variate Profile

IBP DP Terminology and Statistical Modeling

IBP DP Terminology

Data Shifts

Historical Horizon Settings

Forecast Horizon Settings

Ex-post Forecasting in IBP DP

IBP Modeling phases

Modeling Mechanics

Statistical Modeling continued

Holt-Winters Models

Simple Moving Average Models

Exponential Smoothing Family: Simple, Double and Triple Exponential Smoothing

Multiple Linear Regression

Croston's Model - when to use and when not to use

Forecast adjustments using IBP DP

Monitoring model performance and re-specification for improved results

Model Diagnostics

Testing and measuring forecasting models in IBP

Definition of Demand Forecast Errors

Errors Across SKU’S vs. Errors Across Time

Model Errors defined in IBP DP

Definition of WMAPE, MAD, MASE, MPE, MAPE and RMSE

Model Diagnostics through Forecast Error

#SAP IBP#SAP IBP workshop in India#Statistical modeling and forecasting in SAP IBP#Valtitude#Demand Planning#S&OP Forecasting Consulting#Supply Chain Management Software#IBP#Supply Chain Optimization#forecasting#supplychainvisibility#realtimeplanning#inventoryoptimization#supplychainmanagement#digitalsupplychain#advancedplanning#sapcloud#sapdigitalcore

0 notes

Text

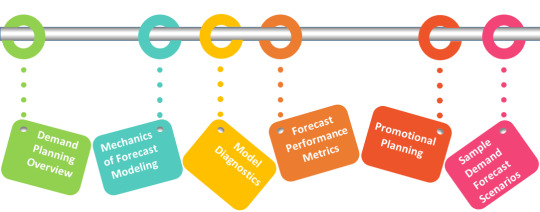

Demand Planning Overview:

Demand Planning Basics

Mechanics of the Forecasting Process

Organizational Structure

Role of a Demand Planner

Consensus Demand Plan:

Dollarizing the Demand Plan

Category Forecasting & top-down Demand Plan

Financial Plan and the “Gap” Process

Reconciling the bottom up & the top-down forecasts

Mechanics of Forecast Modeling:

Forecast Modeling

Time Series Methodology

Baseline versus event forecasting

Unconstrained vs. Constrained Demand Plan

Forecast Performance Metrics:

Mean Absolute Percent Error

Forecast Bias

What do we learn from forecast error?

Introduction to Exceptions Management

Collaborative Demand Planning:

Setting up a Consensus Process

Gathering Promotional and event intelligence

Evaluating promotional lifts

Achieving consensus with Sales Group

Customer Collaboration

#Demand Planning & Forecasting Workshop#demand planning workshop in India#Forecasting Workshop in India#Valtitude#Demand Planning#S&OP Forecasting Consulting#Supply Chain Management Software#IBP#Supply Chain Optimization#forecasting#supplychainvisibility#realtimeplanning#sapdigitalcore#inventoryoptimization#advancedplanning#supplychainmanagement#digitalsupplychain#sapcloud

0 notes

Text

How we can help you with a Forecast Pro Process?

• We help you refine the forecasting process – inputs, methodology,

hand-offs etc.

From Data analysis, to process refinement to modeling and

reporting, we will guide you with a process that leverages the full

power of TRAC.

Develop the statistical models in Forecast Pro TRAC for a sample of

your products and customers

Work with you to develop key reports – TRAC and Excel

Train you on the TRAC features, navigation techniques, statistical

modeling and forecast reporting in the context of your monthly

demand planning cycle!

#forecastpro#forecast pro trac#forecasting#ForecastPro#Forecasting Tool#Demand Modeling#statistical forecasting techniques#planning process#statistical forecast#Tools for Forecasting#Demand Planning tools#Supply Planning solution#Valtitude#Demand Planning#S&OP Forecasting Consulting#Supply Chain Management Software#IBP#Supply Chain Optimization#supplychainvisibility#realtimeplanning#sapdigitalcore#inventoryoptimization#advancedplanning#supplychainmanagement#sapcloud#demandplanning#digitalsupplychain

0 notes