Don't wanna be here? Send us removal request.

Text

A strategy with multiple channels, which could be achieved by a Digital Marketing Company in Coimbatore, would include content marketing, social media marketing, email marketing, etc. Building community driven brand allows you to acquire a rare edge in competition.

0 notes

Text

Here’s How To Build a Community-Driven Brand

Brands are now based on people and shared values rather than just items in today’s digital environment. In addition to selling, a community-driven business interacts, listens, and fosters loyalty. Consumers want to feel like they belong, not that they are just numbers.

Here are some tips for creating a brand that unites people and encourages repeat business.

Start with a Clear Purpose :

Your brand must have a purpose beyond making money. Consumers prefer to support companies that represent something significant. Your purpose should be in line with what your audience genuinely cares about, whether that be empowerment, wellness, or sustainability. Your entire creation and communication process is built around this goal.

Understand Your Audience Deeply :

You need to know your people in order to create a solid community. Find out what drives them, what issues they deal with, and what they cherish most. To get information, use comment sections, feedback forms, and social media surveys. Your ability to interact and serve them will improve as you gain a deeper understanding of them.

Create Spaces for Real Interaction :

Give your audience a place to connect—with you and with each other. This could be a Facebook group, Discord server, or even a branded hashtag on Instagram. These spaces allow for conversations, content sharing, and deeper relationships. It turns followers into participants in your brand journey.

Involve Your Community in Decisions :

Ask your audience to help you develop your brand by testing new features, offering suggestions, or providing comments. People become emotionally invested when they feel like they are contributing. This fosters a sense of ownership and increases trust. A community-built brand is more powerful than one that is created alone.

Recognize and Celebrate Your Community :

People love to be seen and appreciated. Highlight customer stories, share user-generated content, or run contests that reward engagement. Even a simple shoutout can make a big impact. Recognition builds emotional connection and inspires others to join the community as well.

Be Human and Authentic :

Be genuine, truthful, and personable instead of using a businesslike tone. Talk like a person, not a brand, and share your story and behind-the-scenes content. Answer messages, express gratitude to your audience, and own up to your errors when necessary. Authenticity increases brand credibility and fosters loyalty.

Conclusions :

It takes effort, empathy, and persistence to develop a brand that is driven by the community. However, the outcomes are worthwhile. You build a devoted following that supports you at every stage and believes in your cause. Customers ultimately become part of your brand’s narrative rather than merely purchasing your goods.

A strategy with multiple channels, which could be achieved by a Digital Marketing Company in Coimbatore, would include content marketing, social media marketing, email marketing, etc. Building community driven brand allows you to acquire a rare edge in competition.

#web development company#digital marketing company#digital marketing#digital marketing company in coimbatore

0 notes

Text

Brands are now based on people and shared values rather than just items in today’s digital environment. In addition to selling, a community-driven business interacts, listens, and fosters loyalty. Consumers want to feel like they belong, not that they are just numbers.

0 notes

Text

Double Flanged Type Butterfly Valves- Various Industrial Applications

Double flanged type butterfly valves are indispensable components in various industrial processes, offering exceptional durability and versatility. Designed to manage the flow of fluids, these valves are widely employed in industries such as water treatment, oil and gas, power generation, and chemical processing. Their unique structure and functionality make them a preferred choice among European valve manufacturers and global suppliers.

Key Features of Double Flanged Butterfly Valves

Double-flanged butterfly valves consist of a disc mounted on a rotating shaft. The valve operates by rotating the disc to control or halt the fluid flow. Their robust flanged design ensures secure installation between two pipe flanges, making them ideal for high-pressure applications.

These valves are known for:

Compact Design: They require less space compared to traditional gate or globe valves.

Ease of Operation: Their simple mechanism allows for quick opening and closing.

Cost-Effectiveness: With fewer moving parts, maintenance costs are significantly reduced.

Industrial Applications

Water Treatment Plants

In water treatment, managing large volumes of water efficiently is critical. Double-flanged butterfly valves are commonly supplied by water valve suppliers for controlling water flow in pipelines, especially in desalination plants and wastewater treatment facilities. Their ability to handle varying pressures and resist corrosion makes them ideal for this sector.

Oil and Gas Industry

The oil and gas industry requires robust valve solutions to manage high-pressure and high-temperature environments. These valves are integral to controlling the flow of crude oil, natural gas, and other fluids. Control valves suppliers and ball valves suppliers often include double-flanged butterfly valves in their inventory to cater to these demanding applications.

Power Generation

In power plants, efficiency and reliability are paramount. Double flanged butterfly valves regulate the flow of steam and cooling water, playing a vital role in thermal and hydroelectric power plants. Their ability to operate seamlessly under extreme conditions ensures uninterrupted energy production.

Chemical Processing

The chemical industry deals with corrosive and hazardous substances, necessitating valves that can withstand aggressive environments. Gate valves suppliers and globe valves suppliers often recommend double flanged butterfly valves for handling chemicals safely. Their precision and durability ensure optimal performance.

HVAC Systems

Heating, ventilation, and air conditioning (HVAC) systems rely on these valves to regulate airflow and maintain temperature consistency. Their compact size and easy installation make them ideal for modern HVAC setups.

Why Choose European Valve Manufacturers?

European valve manufacturers are renowned for their commitment to quality and innovation. They offer a comprehensive range of products, including stock valves and custom solutions, ensuring compatibility with diverse industrial requirements. By sourcing from reputable suppliers, industries gain access to valves that meet stringent international standards.

Conclusion

Double flanged type butterfly valves are a critical component across numerous industries. Their versatility, cost-effectiveness, and robust design make them a popular choice among water valve suppliers, ball valves suppliers, and control valves suppliers alike. Whether you’re looking for precision control in chemical processing or reliable performance in water treatment, these valves deliver unmatched value. Partnering with established European valve manufacturers ensures access to high-quality solutions that stand the test of time. Valvulasfevisa, is one of the leading butterfly valves suppliers and valve stockist in USA. They ensures optimal performance and long-term value.

0 notes

Text

Double flanged type butterfly valves are a critical component across numerous industries. Their versatility, cost-effectiveness, and robust design make them a popular choice among water valve suppliers, ball valves suppliers, and control valves suppliers alike. Whether you’re looking for precision control in chemical processing or reliable performance in water treatment, these valves deliver unmatched value. Partnering with established European valve manufacturers ensures access to high-quality solutions that stand the test of time. Valvulasfevisa, is one of the leading butterfly valves suppliers and valve stockist in USA. They ensures optimal performance and long-term value.

0 notes

Text

EVERYTHING YOU NEED TO KNOW ABOUT VALVE TYPES: A COMPREHENSIVE GUIDE

Valves play a pivotal role in controlling the flow of liquids, gases, and slurries within various industrial systems, including oil and gas, petrochemicals, water treatment, and power generation. Understanding the different types of valves and their respective applications is vital for selecting the most appropriate solution for specific operational requirements. This content delves into the various valve types, their functionalities, and how European Valve Manufacturers, Valve Suppliers, and Valve Stockists contribute to ensuring the supply of reliable, high-performance valves across industries.

Ball Valves

Ball valves are quarter-turn valves that use a spherical ball with a hole through the center to control the flow of materials. When the ball’s hole aligns with the pipe, the fluid flows freely, while turning the valve 90 degrees moves the ball, shutting off the flow. Ball Valves Suppliers typically offer these valves in various configurations, including full-port, reduced-port, and V-port designs, making them ideal for on/off and throttling applications. Due to their tight shut-off capability and resistance to corrosion, ball valves are widely used in applications with high-pressure or high-temperature fluids, such as natural gas transmission and chemical processes. They are favored for their durability, low-maintenance design, and ease of operation.

Gate Valves

Gate valves are primarily used for isolating or shutting off fluid flow in a pipeline. The valve operates by raising or lowering a wedge-shaped gate to allow or block flow. Typically, Gate Valves Suppliers recommend these valves for applications where the valve is either fully open or fully closed, and throttling control is unnecessary. They are well-suited for high-flow, low-pressure applications, such as in water distribution networks and HVAC systems. Their primary advantage lies in their ability to offer minimal flow resistance when fully open, though they are not ideal for applications requiring precise flow regulation. Moreover, gate valves can experience wear over time due to their design, especially when used for throttling or in systems that require frequent operation.

Globe Valves

Globe valves are designed for flow regulation, providing excellent throttling capabilities due to their precise internal components. The valve’s body is shaped like a globe, and it utilizes a plug or disc to control the flow of fluids. Globe Valves Suppliers typically recommend these valves for applications where flow control is critical, such as in steam, gas, and water distribution systems. Their key advantage is their ability to handle both high pressures and temperatures while maintaining accurate flow regulation. Globe valves are often preferred in scenarios where system adjustments need to be frequent and precise, such as in heating, ventilation, and air conditioning (HVAC) systems, power plants, and industrial cooling systems.

Control Valves

Control valves are an integral part of automated process systems, providing precise control over parameters such as pressure, temperature, and flow rate. These valves work in conjunction with control systems, where they adjust their position to maintain a desired setpoint within a closed-loop system. Control Valves Suppliers often offer valves with actuators and positioners to ensure optimal performance, even in complex systems. These valves are used extensively in industries such as chemical processing, oil refineries, and power generation, where real-time control of fluid dynamics is essential to maintain system stability and efficiency. The accuracy and responsiveness of control valves make them indispensable for applications that require continuous modulation.

Water Valves

Water valves are engineered specifically for applications within potable water systems, wastewater treatment, and industrial water handling. These valves are designed to withstand corrosion and wear from harsh water environments. As a Water Valve Supplier, selecting valves based on factors such as pressure, temperature, and the type of water (e.g., clean or dirty water) is essential for ensuring optimal performance. Ball, gate, and globe valves are commonly used in water systems, but more specialized valves like check valves and pressure-reducing valves are often employed to ensure proper water flow and pressure management. Water valves are fundamental in preventing contamination, controlling pressure fluctuations, and maintaining consistent water flow in municipal and industrial systems.

Conclusion

Selecting the right valve for a specific application requires a deep understanding of its operating principles, material compatibility, and functional performance. European Valve Manufacturers, along with Valve Suppliers and Valve Stockists, offer a vast array of high-quality valve solutions tailored to meet the rigorous demands of diverse industries. we are specialized for stock valves, whether you’re dealing with high-pressure fluid systems, water treatment, or intricate process controls, working with reputable valve suppliers ensures access to the latest valve technologies and reliable products. Understanding the distinct functions and advantages of valve types such as ball valves, gate valves, globe valves, control valves, and water valves allows you to make informed decisions, ensuring long-term efficiency and safety in industrial operations.

0 notes

Text

One Valve, Multiple Applications: Floating Ball Valves from Fevisa

In the dynamic world of industrial processes, valves play a pivotal role in regulating, directing, and controlling the flow of various mediums, from liquids to gases. Among the vast array of valves available, floating ball valves have emerged as a versatile solution for multiple applications.

Fevisa, one of the leading valve manufacturers in Spain, stands out for its expertise in designing and producing high-quality floating ball valves. Their innovative designs cater to a diverse range of industries, including oil and gas, water treatment, and chemical processing.

The Power of Floating Ball Valves:

Floating ball valves are characterized by a freely moving ball inside the valve body, which creates a reliable seal when pressed against the valve seat. This design ensures efficient flow control, leak-proof operation, and enhanced durability, making it a popular choice for industries worldwide.

As a trusted ball valves suppliers, Fevisa offers a wide range of floating ball valves designed to meet the unique needs of its clients. Whether it’s high-pressure environments or demanding chemical applications, these valves deliver exceptional performance.

Diverse Applications Across Industries:

Fevisa’s floating ball valves find applications in numerous industries due to their adaptability and reliability:

1. Oil and Gas Sector: The ability to handle high-pressure and high-temperature environments makes floating ball valves an ideal choice for upstream and downstream operations. 2. Water Treatment : As a renowned water valves supplier, Fevisa’s products are instrumental in ensuring smooth water distribution and waste management processes. 3. Chemical and Petrochemical Industries : Floating ball valves can handle corrosive fluids, providing durability and safety in critical environments. 4. Power Generation : With precision and reliability, these valves contribute significantly to power plant operations, ensuring efficient flow control.

A Comprehensive Valve Portfolio:

In addition to floating ball valves, Fevisa is recognized as a leading valve stockist with a comprehensive range of products to meet every industrial need. Their portfolio includes:

Gate Valves: As a gate valves suppliers, Fevisa ensures optimal shut-off capabilities, perfect for isolation purposes.

Globe Valves: Known for precision throttling and flow control, Fevisa’s globe valves are trusted across industries.

Butterfly Valves: Compact and efficient, Fevisa, as a top butterfly valve suppliers, offers reliable solutions for large flow systems.

Control Valves: These valves ensure accurate modulation of flow, pressure, and temperature, catering to complex process requirements.

Why Choose Fevisa?

Fevisa’s reputation as one of the leading valve manufacturers in Spain is built on decades of innovation, quality, and customer satisfaction. Their dedication to delivering premium products makes them a trusted name among control valves suppliers globally. Their robust distribution network ensures prompt delivery, and their experienced team provides unmatched technical support, reinforcing their position as a preferred ball valves supplier.

Conclusion:

Floating ball valves from Fevisa demonstrate the potential of a single valve design to cater to multiple applications. With its comprehensive product range and commitment to excellence, Fevisa continues to lead as a reliable partner for industries worldwide. Fevisa offers the ideal combination of quality, innovation, and service for businesses seeking a trustworthy valve stockist.

****Fevisa: Your ultimate destination for high-performance valves.***

0 notes

Text

How Actuator Valves Enhance Control and Efficiency in Fluid Flow Systems: Maximize ROI with Valvulasfevisa

Introduction:

Efficient fluid flow management is essential across various industries, from oil and gas to water treatment. Control valves and actuator systems have become vital in regulating flow, optimizing processes, and boosting overall system efficiency. Choosing the right valve stockist or valve manufacturers can make all the difference. This blog explores how actuator valves enhance control, improve efficiency, and maximize ROI (Return on Investment) in fluid systems, and why Valvasfevisa is a leader in this field.

Importance of Control and Efficiency in Fluid Flow Systems:

Fluid systems rely on valves to control flow rates, pressure, and direction. However, in complex systems, manual control often leads to inaccuracies, inefficiencies, and, ultimately, higher operational costs. This is where actuator valves come into play. By automating valve functions, actuator valves ensure precise flow control, reduced energy consumption, and optimized system performance. Valvasfevisa, a top Valve Stockist, has emerged as a preferred supplier for industries seeking to improve efficiency with advanced valve solutions. Known for its range of high-quality products, Valvasfevisa is also recognized as a trusted Valve Stockist globally, providing superior actuator valve solutions that enhance fluid flow systems.

How Actuator Valves Improve System Control and Efficiency:

1. Precision Control :

Actuator valves offer precise control over fluid flow by using mechanical or pneumatic forces to adjust valve positioning. This results in improved accuracy, making them indispensable in industries requiring precise fluid handling, such as pharmaceuticals and food processing. Valvasfevisa’s collection includes options from prominent Valve Manufacturers in Spain, meeting diverse industry requirements.

2. Enhanced System Efficiency :

By maintaining accurate flow and pressure control, actuator valves reduce wastage and optimize resource utilization. This results in significant cost savings over time. The automation provided by actuator valves also minimizes the risk of human error, boosting both safety and efficiency in the process.

3. Reduced Maintenance :

With actuator valves, systems require less frequent manual intervention, lowering maintenance costs. Valvasfevisa, as a trusted Ball Valves Supplier, Gate Valves Supplier, and Butterfly Valve Supplier, offers durable products that meet rigorous industrial standards, ensuring reliability and longevity.

4. Remote Operation and Monitoring :

One of the key benefits of actuator valves is remote operability. Through centralized control systems, operators can adjust valve settings across multiple locations, allowing for streamlined monitoring. This capability not only enhances safety but also supports real-time system adjustments, helping operators avoid costly downtimes.

Choosing Valvasfevisa as Your Preferred Valve Supplier:

Valvasfevisa is dedicated to providing the best solutions in actuator valves. Their product range includes Globe Valves Supplier, Water Valves Supplier, and Control Valves Supplier, covering all essential valve types for various fluid systems. Each product is crafted for optimal performance, helping industries achieve superior efficiency and ROI. By choosing Valvasfevisa, industries benefit from access to high-quality components that enhance system integrity and operational productivity.

Conclusion:

Actuator valves have revolutionized fluid flow systems by providing unmatched control, precision, and efficiency. Industries across the globe rely on trusted suppliers like Valvasfevisa for access to reliable actuator valve solutions that maximize ROI. Whether you need a Gate Valves Supplier, Ball Valves Supplier, or Valve Manufacturers in Spain, Valvasfevisa’s extensive inventory and technical expertise make them a top choice. For industries aiming to upgrade their fluid flow systems, Valvasfevisa ensures optimal performance and long-term value.

0 notes

Text

As technology advances, the role of CFD in tunnel safety will continue to grow, ensuring that these critical infrastructures can withstand the challenges posed by fire emergencies.

Reach out Graphler technology for a CFD Consulting Services .We are also specialized in Stress Analysis Services , Structural Design Services and more.

0 notes

Text

Inorder to reduce higher cooling demands for buildings or industries, passive cooling by night-time flushing can be seen as a promising option.CFD simulations is performed for 24 hours in a peak summer day. During the day time operation, the internal loads coupled with solar heat gain is simulated. Choose the best CFD consulting services providers for high standard quality works.

0 notes

Text

Unveiling the Strength: A Comprehensive Finite Element Analysis of the Strap U-Frame

In the realm of engineering, structural integrity and performance are paramount. At Graphler Technology Solutions, our commitment to delivering cutting-edge analyses ensures that every project achieves its full potential. Recently, we undertook an extensive finite element analysis (FEA) of a Strap U-Frame. This blog delves into the highlights and insights from the study.

Objective of the Study:

The primary goal of the FEA was to evaluate the structural behavior of the Strap U-Frame under a variety of operational loads and conditions. This included assessing how the U-Frame responded to forces induced by tension in the strap, moments generated during operation, and reaction forces from components like the crank and pawl. By simulating these real-world conditions, the analysis aimed to:

Identify Critical Stress Points: Determine locations within the U-Frame where stress exceeded safe operational thresholds, particularly areas prone to potential cracking or fatigue failure.

Examine Deformation Patterns: Evaluate how the structure deforms under load to ensure that any displacements remain within acceptable limits to maintain functionality.

Validate Material Performance: Analyze whether the materials selected for the U-Frame and its components could withstand the applied loads without permanent damage or failure.

Guide Design Improvements: Provide actionable insights for optimizing the design and material usage to enhance durability, safety, and cost-effectiveness.

This holistic approach ensured that the U-Frame design met stringent performance standards while aligning with the operational demands and longevity expectations of the client.

Analysis Setup

The analysis focused on multiple load cases, including:

Belt Tension: Simulated at 26688 N, generating a significant moment of 1334400 N-mm.

Force Transmission: Evaluated through the crank lever requiring a force of 3587.10 N for operation.

Boundary conditions, material properties, and operational loads were meticulously configured to replicate real-world scenarios.

Key Findings

1. Deformation Analysis

Maximum deformation observed: 2.93 mm.

Despite localized deformation, the overall structure maintained functional integrity.

2. Stress Distribution

U-Frame: Maximum principal stress reached 1032 MPa, exceeding the material’s ultimate tensile strength. However, the stress concentration was confined to the surface peel layer, indicating potential for localized cracking without immediate failure.

Pawl: Maximum stress of 858.23 MPa surpassed yield strength at contact points. The compressive nature of stress ensured no catastrophic failure.

Shaft: Surface stress exceeded yield strength but remained within acceptable limits at the core, highlighting resilience against major deformation or breakage.

3. Reaction Forces

4. Engineering Inferences

Localized Cracking: Stress concentrations in the U-Frame and Pawl necessitate enhanced surface treatments or reinforcements to mitigate fatigue risks.

Material Performance: While the materials demonstrated high resilience, exceeding yield thresholds in localized regions requires design refinements.

Optimized Design: Potential adjustments in geometry or material distribution can enhance load-bearing capacity without significant weight increases.

Graphler Technology is one of the leading product design companies in India. We have experts in FEA services and also we are specialized in CFD consulting services, structural design services, 2D to 3D Conversion services, stress analysis services etc.

0 notes

Text

Understanding CFD in Heat Exchanger Design: A Case Study

In modern engineering, Computational Fluid Dynamics (CFD) is vital for optimizing thermal systems. This blog explores a recent CFD thermal analysis performed by Graphler Technology Solutions to evaluate a heat exchanger’s efficiency in transferring heat from a hot fluid (MSW slurry) to a cold fluid (DM water). Here’s what the study uncovered:

The Study Setup

The analysis simulated the heat transfer dynamics between two fluids using steady-state Conjugate Heat Transfer (CHT) analysis. Key parameters included:

Hot fluid (MSW Slurry): Initial temperature of 400°C, flow rate of 0.5 LPM, and inlet pressure of 300 Bar.

Cold fluid (DM Water): Initial temperature of 10°C, flow rate of 38.61 LPM, and inlet pressure of 2 Bar.

The system comprised four heat exchange passes, designed to ensure progressive heat transfer and achieve target temperature levels.

Key Findings

Temperature Distribution

In Pass 1, the hot fluid’s temperature dropped significantly from 400°C to 29.86°C.

Subsequent passes refined the output temperature, with Pass 4 reaching equilibrium at ~10°C.

Heat Transfer Efficiency

The cold fluid flow rate was 77 times higher than the hot fluid’s, driving an aggressive temperature drop.

The heat exchanger required approximately 9–10 meters to align the hot fluid’s temperature with that of the cold fluid.

Material Effectiveness

Stainless steel (Grade 304) and rockwool insulation ensured thermal integrity, with average heat transfer coefficients of:

Cold fluid side: 1027 W/m²-K

Outer insulation: 454 W/m²-K

Energy Implications

The design successfully minimized thermal losses while maintaining the structural and thermal stability of the exchanger.

Material Selection: The use of rockwool insulation and stainless steel proved effective. For future designs, these materials should remain standard, especially for similar operational conditions.

Flow Rate Optimization: High cold fluid flow rates were critical to achieving rapid heat exchange. Depending on energy costs, optimization between flow rates and exchanger length can be explored.

Length Considerations: A total pipe length of 18 meters, with four sequential passes, was adequate for the temperature targets. This insight aids in reducing unnecessary material and space usage in similar designs.

Reach out Graphler technology for a CFD Consulting Services .We are also specialized in Stress Analysis Services , Structural Design Services and more.

0 notes

Text

0 notes

Text

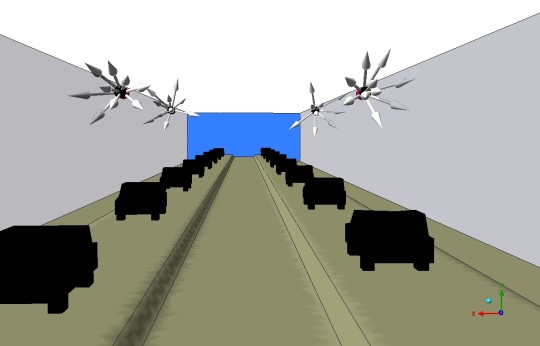

Understanding Aerodynamic Performance: A Study on Passenger Cars

The field of aerodynamics plays a critical role in the automotive industry, as it directly impacts a vehicle’s fuel efficiency, speed, stability, and overall performance. At Graphler Technology Solutions, we recently conducted an aerodynamic simulation of a passenger car to assess and optimize its aerodynamic performance. Here’s an overview of the key elements of this study and its outcomes.

1.Objective of the Study

The primary goal of this aerodynamic analysis was to evaluate the aerodynamic torsor, which includes both drag and lift forces acting on the car. Additionally, the study focused on the flow features around the vehicle, including the wake and bodywork. These analyses are essential for improving vehicle design by minimizing drag, enhancing stability, and increasing fuel efficiency.

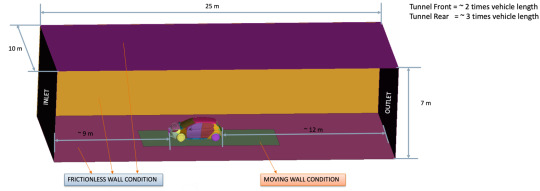

2.Methodology: Wind Tunnel Simulation

The study utilized a wind tunnel simulation setup, with specific boundary conditions replicating real-world scenarios. The tunnel design ensured that the aerodynamic features of the vehicle could be accurately observed:

Tunnel Front: ~2 times the vehicle length.

Tunnel Rear: ~3 times the vehicle length.

The boundary conditions included an inlet velocity, pressure outlet, frictionless walls, and a moving belt to simulate ground movement. Additionally, tires, rims, brakes, and air intake were modeled with realistic conditions such as angular velocities and mass flow.

Vehicle Parameters

The vehicle dimensions used in the study were as follows:

Length (X-axis): 4009.67 mm

Width (Y-axis): 1996.85 mm

Height (Z-axis): 1443.07 mm

These dimensions were crucial in determining the drag and lift forces experienced by the vehicle during the analysis.

3.Key Deliverables

The outputs of the study offered valuable insights into the vehicle’s aerodynamic performance:

Aerodynamic Torsor:

Global and Discretized Data: The analysis provided both global and specific measurements for the drag and lift forces on various parts of the vehicle.

Bodywork Analysis:

Parts Contribution to Drag and Lift: A detailed breakdown of the aerodynamic forces contributed by different regions of the vehicle, such as the superstructure, wheels, under the hood, and floor, helped pinpoint areas for potential improvements.

Flow Analysis:

Pressure Coefficient (CP) Distribution: This analysis was performed along the vehicle’s body to map pressure variations, which influence drag and lift.

Wake Analysis: The wake region, critical for vehicle stability, was analyzed using tomography. Velocity, pressure, and pathlines in the wake were studied to better understand airflow patterns behind the vehicle.

4.Practical Applications

Understanding how drag and lift forces impact a vehicle allows for more efficient design choices. For instance, reducing drag enhances fuel efficiency, while controlling lift improves vehicle stability at high speeds. Our comprehensive aerodynamic analysis provides the necessary data to make informed design adjustments, whether for mass production cars or specialized racing vehicles.

Conclusion

Through this simulation, Graphler Technology Solutions continues to demonstrate its commitment to providing innovative engineering solutions. By analyzing and refining aerodynamic performance.

Graphler Technology, one of the best Product Design Companies and CFD consulting services providers. We also specialize in stress analysis services, structural analysis services, and structural design services. For more information on night purging and how you can incorporate it into your next project, please feel free to contact us today.

0 notes

Text

Fire and Smoke CFD Analysis in Road Tunnels: Ensuring Safety and Preparedness

Introduction

Understanding CFD Analysis

CFD is a branch of fluid mechanics that uses numerical analysis and algorithms to solve and analyze problems involving fluid flows. In the context of road tunnels, CFD is used to simulate the behavior of fire and smoke, helping engineers predict their spread and impact under various scenarios.

Key Components of Fire and Smoke CFD Analysis

Fire Dynamics Simulation:

Heat Release Rate (HRR): This is a measure of the energy released by the fire. It is a critical input for CFD simulations as it influences the temperature and smoke production.

Fuel Characteristics: The type of materials involved in the fire affects the combustion process, influencing smoke production and toxicity.

Smoke Behavior and Dispersion:

Smoke Movement: CFD models predict how smoke travels through the tunnel, considering factors such as ventilation systems, tunnel geometry, and traffic conditions.

Visibility and Toxicity: The simulation assesses how smoke affects visibility and air quality, crucial for evacuation and rescue operations.

Ventilation Systems:

Natural Ventilation: Utilizes the tunnel’s design and natural airflow to manage smoke.

Mechanical Ventilation: Involves fans and other mechanical systems to control smoke spread and ensure clear escape routes.

Emergency Response:

Evacuation Modeling: CFD helps in planning and optimizing evacuation routes and procedures, ensuring that people can exit the tunnel safely and quickly.

Firefighting Strategies: Simulations can evaluate the effectiveness of different firefighting tactics and equipment placement.

Applications and Benefits of CFD Analysis

Design Optimization: Engineers use CFD to optimize tunnel design, ensuring that ventilation systems and safety measures are effective in controlling fire and smoke.

Risk Assessment: By simulating various fire scenarios, CFD helps in identifying potential risks and weak points in the tunnel design.

Regulatory Compliance: CFD analysis supports compliance with safety standards and regulations, providing evidence of the tunnel’s ability to handle fire emergencies.

Training and Preparedness: Emergency response teams can use CFD simulations for training, improving their readiness and effectiveness in real-world scenarios.

Challenges and Future Directions

While CFD analysis offers significant benefits, it also presents challenges. Accurate simulations require detailed input data and considerable computational resources. Additionally, real-world conditions can be complex and variable, making it difficult to account for all possible scenarios.

Conclusion

Fire and smoke CFD analysis is an indispensable tool in the design and management of road tunnels. By providing detailed insights into fire dynamics and smoke behavior, it helps engineers create safer environments and develop effective emergency strategies. As technology advances, the role of CFD in tunnel safety will continue to grow, ensuring that these critical infrastructures can withstand the challenges posed by fire emergencies.

Reach out Graphler technology for a CFD Consulting Services .We are also specialized in Stress Analysis Services , Structural Design Services and more.

0 notes

Text

A Guide to Choosing the Perfect Industrial Valves.

Industrial valves are essential components that regulate the flow of liquids, gases, and slurries in pipelines across numerous industries. Selecting the right valve for your application is crucial for maintaining operational efficiency, safety, and durability. As one of the leading European valve manufacturers, Valvulas Fevisa offers a wide range of high-quality valves, including stock valves, to meet the needs of industries like oil and gas, chemical processing, water treatment, and manufacturing. This guide will help you select the ideal valve solution for your specific application by considering factors such as valve types, materials, and performance.

Understand Your Application

The first step in selecting the appropriate industrial valve is to understand the specific requirements of your system. Several factors should guide your valve selection:

Fluid Type: Whether the medium is liquid, gas, or slurry, the valve must be suited to the fluid’s properties, such as chemical composition and viscosity.

Pressure and Temperature: Ensure the valve can withstand the system’s pressure and temperature without compromising performance.

Flow Control: Do you need full shutoff, throttling, or automated flow regulation? Different valve types provide various levels of control based on your operational requirements.

Types of Valves and Their Applications

There are numerous types of industrial valves, each suited to specific tasks. Understanding the purpose and strengths of each valve type will help you make the best choice for your system.

2.1 Gate Valves

As a gate valves supplier, we offer valves designed for complete shutoff in fluid systems. Gate valves are commonly used in water distribution and oil pipelines for applications that require either full open or full close positions.

Advantages: Minimal pressure drop when fully open; effective for on/off control.

Disadvantages: Not ideal for throttling, as partial opening can cause wear and leaks.

2.2 Ball Valves

As a leading ball valves supplier, we provide ball valves that offer quick, reliable shutoff with minimal pressure drop, making them ideal for use in industries such as chemical processing, oil and gas, and water treatment.

Advantages: Quick and easy operation with superior sealing.

Disadvantages: Not recommended for precise flow regulation.

2.3 Globe Valves

As a trusted globe valves supplier, we offer globe valves that excel in throttling and flow control applications. These valves are ideal for high-pressure environments like steam systems and cooling systems.

Advantages: Excellent for throttling and regulating flow.

Disadvantages: Higher pressure drop when fully open compared to other valves.

2.4 Butterfly Valves

Our butterfly valves are perfect for large-volume flow control in systems where space is limited. They are commonly used in water treatment plants, HVAC systems, and chemical processing facilities.

Advantages: Lightweight, cost-effective, and easy to install.

Disadvantages: May not provide complete shutoff in high-pressure applications.

Material Considerations for Industrial Valves

Choosing the right material for your valve is essential to ensure durability and optimal performance. Common valve materials include:

Stainless Steel: Highly resistant to corrosion, ideal for use in chemical processing and food industries.

Carbon Steel: Often used in high-pressure applications in the oil and gas industry due to its strength.

Cast Iron: Common in lower-pressure systems like water distribution, favored for its cost-effectiveness.

Special Alloys: Best suited for extreme environments, including offshore oil rigs and chemical plants, where corrosion resistance is critical.

Maintenance and Lifecycle Costs

Some valves, such as ball valves, are low-maintenance, while others, like control valves, may need frequent inspections and calibration. When selecting a valve, it’s important to consider not just the initial cost but also the total lifecycle cost, including maintenance, operational efficiency, and potential downtime.

Conclusion

Choosing the right valve for the right job is key to ensuring safety, operational efficiency, and cost-effectiveness. As one of the leading European valve manufacturers and water valve suppliers, VALVULAS FEVISA offers a wide selection of stock valves, including gate valves, ball valves, globe valves, butterfly valves, and control valves to meet the specific needs of your industry.

Contact us today for expert assistance in selecting the right valve solution tailored to your operational requirements, and let our expertise as a leading gate valves supplier, ball valves supplier, and control valves supplier help drive your system’s success.

0 notes