ChemAnalyst is a subscription based Digital Platform covering in depth data and analysis on 200+ Chemicals. Petrochemicals, Polymer and Resin, Elastomer and Rubber, Bulk Chemicals and Fertilizer, Feedstock and Intermediates, Specialty Chemicals. ChemAnalyst is provide latest chemical price, weekly and monthly prices report of chemicals news and market analysis

Don't wanna be here? Send us removal request.

Text

Endless Possibilities of Polypropylene: Manufacturing Details to Practical Applications

In this blog, we explore one of the most common plastics in use today in industries all over the world. Polypropylene or PP is a highly popular plastic thanks to its unique production process and versatility. This polymer is produced through the polymerization of propylene gas and is a thermoplastic polymer with high chemical and thermal resistance as well as durability.

Welcome to our world of Polypropylene manufacturing where the magic of science and technology turns raw materials into the products that we use in our everyday lives. This article will explore the manufacturing of PP to its latest production technologies and processes. However, our investigation doesn’t stop here. We will also explore the extensive uses of Polypropylene from packaging to textile to automotive and medical devices.

From a regular customer to the aspiring engineer to the experienced professional – our Polypropylene story will inform and engage you. So, let’s get started and see what Polypropylene has to offer!

Introduction

Polypropylene (PP), a polyolefin with a chemical formula of (C3H6)n, stands out as a versatile thermoplastic polymer slightly tougher than Polyethylene. Its low density coupled with remarkable heat resistance makes it indispensable across various industries. From packaging food, beverages, and consumer goods to manufacturing automotive components like bumpers and interior trim, PP demonstrates its reliability. It's also a trusted material in the medical field for its sterilization compatibility, non-reactive nature, and in consumer goods for its strength. Moreover, in specialized applications such as cast films, Polypropylene's moldability and extrudability enable intricate designs, further solidifying its status as a cornerstone material in modern manufacturing.

Some of the interesting properties includes:

Melting Point: PP melts at different temperatures depending on its type (homopolymer or copolymer).

Lightweight: PP is one of the lightest plastics, making it ideal for applications where weight reduction matters.

Chemical Resistance: PP handles a wide range of chemicals well, but is not suitable for strong solvents or oxidizing agents.

Heat and Water Performance: PP maintains its properties even in hot, humid, or wet environments.

Stress Cracking: PP resists cracking under pressure from the environment.

Microbial Resistance: While good for some sterilization methods, PP can be susceptible to mold and bacteria growth.

Manufacturing Process

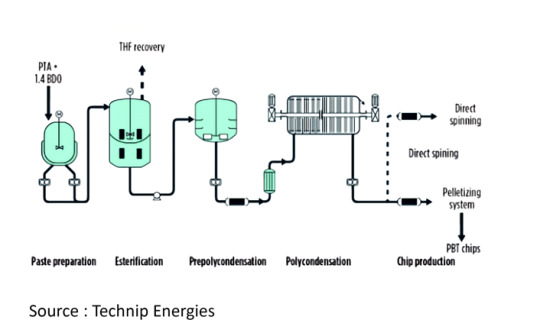

Polypropylene is derived from propene, which is abundantly produced from gas oil, naphtha, ethane, and propane. Concurrently, various methods are under development to generate bio-based Polypropylene, also known as bio-based Polypropylene, utilizing bio-based propene.

(a) Using a Ziegler-Natta catalyst

In the polymerization process, Ziegler-Natta catalysts play a crucial role, formed through the interaction between Titanium(IV) Chloride and an Aluminum Alkyl like Triethyl Aluminum. While the slurry method is occasionally employed, the primary methods for polymer production utilizing these catalysts are two.

(i) The bulk process

Polymerization occurs within liquid propene, conducted without a solvent at temperatures ranging from 340 to 360 Kelvin and pressures between 30 to 40 atmospheres to maintain propene in its liquid state. Following polymerization, solid polymer particles are isolated from the liquid propene, which is subsequently recycled. Utilizing liquid propene as a solvent during polymer formation eliminates the necessity for hydrocarbons like C4-C8 alkanes, commonly employed in the concurrent production of polyethylene.

(ii) The gas phase process

Propene and hydrogen blend is directed over a bed housing the Ziegler-Natta catalyst at temperatures ranging from 320 to 360 Kelvin and pressures varying between 8 to 35 atmospheres.

The polymer is isolated from the gaseous propene and hydrogen through cyclones, while the unused gas is reclaimed for reuse. Both processes can be conducted continuously and employ 'stereospecific' Ziegler-Natta catalysts to catalyze polymerization. These catalysts persist in the product and must be deactivated using water or alcohols before the polymer is transformed into pellets.

Bulk and gas phase techniques have substantially reduced gaseous and aqueous byproducts by utilizing highly active catalysts, leading to minimal residues in the final polymer.

(b) Using a metallocene as catalyst

Metallocenes, originally defined as molecules with a transition metal atom sandwiched between two parallel cyclopentadienyl ligands, with ferrocene being a notable example, now encompass a broader range of ligands related to cyclopentadienyl. Among these, zirconium-based metallocenes stand out as the sole commercial method for producing syndiotactic poly(propene). Similar to Ziegler-Natta catalysts, metallocenes facilitate polymerization through bulk or gas phase methods, as described earlier, or through the slurry process.

Poly(propenes) manufactured using metallocenes, known as mPP, find specific applications in producing non-woven fibers and heat-seal films. Additionally, metallocenes catalyze the production of copolymers comprising propene and ethene.

Technologies used by Major Polypropylene Manufacturers

Process Name : Spheripol process

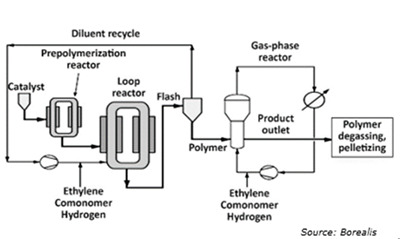

LyondellBasell has been at the forefront of innovation with the introduction of the Spheripol Polypropylene process. Through the development of a third-generation high-yield, high-selectivity catalyst, LyondellBasell has streamlined the Spheripol process, simplifying its steps and enhancing product quality to a remarkable extent. The Spheripol process consists of three main units:

Catalyst feeding

Polymerization

Finishing section

At the core of all polymerization facilities lies the bulk polymerization segment, which is responsible for generating homo and random copolymers.

This method entails tubular loop reactors filled with liquid propylene, continuously supplied with catalyst and hydrogen to regulate molecular weight.

For random copolymers, an additional comonomer like ethylene is introduced. The resulting polymer is consistently discharged from the reactor, with any unreacted propylene recycled back into the loop reactor.

To manufacture impact copolymers, a vital gas phase reactor comes into play. Polymer from the loop reactor is transferred to this reactor, where an elastomer, derived from the polymerization of ethylene and propylene, interacts with the homopolymer matrix produced in the initial reactor.

Applications of Polypropylene

Packaging

Polypropylene's impressive combination of strength, good looks, and affordability makes it a dominant player in the packaging industry. This versatile material can be shaped into both rigid and flexible forms, catering to a wide range of product protection needs. In the realm of flexible packaging, PP's crystal-clear clarity and ability to effectively block moisture vapor make it ideal for food packaging, personal care products, and various other applications. It's a familiar sight in shrink wrap that keeps products bundled together, and its thin, flexible films find uses in the electronics industry, graphic arts, and even the closures on disposable diapers. Shifting to rigid applications, Polypropylene excels in blow molding, a technique that transforms it into sturdy crates, bottles, and containers. From housing delicate medical equipment to holding your favorite yogurt, PP's diverse capabilities make it a packaging material you'll likely encounter on a daily basis.

2. Consumer Goods & Items

Polypropylene isn't just for packaging! This versatile plastic pops up all around your house in a variety of applications. From see-through containers to sturdy furniture, housewares, appliances, luggage, and even toys, PP's durability and lightweight properties make it a popular choice for many consumer goods.

3. Automotive

Polypropylene (PP) emerges as a preferred choice for automotive parts owing to its trifecta of affordability, exceptional mechanical attributes, and moldability. Its extensive use spans across battery cases, trays, bumpers, fender liners, interior trim, instrumental panels, and door trims, reflecting its versatility in various applications within the automotive sector. Noteworthy characteristics such as a low coefficient of linear thermal expansion and specific gravity, alongside high chemical resistance and excellent weatherability, further elevate PP's appeal. Its superior processability and a finely tuned balance between impact resistance and stiffness add to its allure, making Polypropylene a stalwart material in the automotive industry, meeting stringent performance requirements while offering cost-effective solutions.

4. Fibre

Polypropylene fibers find their way into a variety of applications, including ropes, straps, and different fabric types. These fibers are especially strong and handle moisture well, making them ideal for uses in marine environments like ropes and twines.

Market Outlook

The packaging industry remains the dominant consumer of Polypropylene (PP) , particularly within food applications. However, the automotive sector is expected to be also contribute to the PP market growth in the coming years. Polypropylene's cost-effectiveness and robust mechanical properties make it ideal for automotive components like bumpers, dashboards, and door trims, contributing to over half of its total plastic usage. The burgeoning demand for electric and hybrid electric vehicles (EV/HEVs) further bolsters Polypropylene's appeal, promising to significantly augment market expansion. Additionally, the building & construction and electrical & electronics industries are projected to accelerate Polypropylene market growth due to its exceptional insulating properties. This surge in demand across diverse sectors suggests a robust future for the Polypropylene market.

Polypropylene Major Global Producers

Major companies in the Global Polypropylene market are Braskem, Reliance Industries Limited, ExxonMobil Chemical, LyondellBasell, Borouge, Shenhua Ningxia Coal Industry, Total Petrochemicals, Prime Polymer Co., Ltd., Indian Oil Corporation Limited, SABIC Europe, Zhejiang Petrochemical, Sinopec KPC PC JV, INEOS, Japan Polypropylene Corporation, Saudi Polyolefins, and Petrochina Dushanzi Petrochemical, and Others.

Conclusion:

Polypropylene (PP) is one of the most important plastic materials in modern industry because of its unique properties and wide range of applications. PP has been able to gain popularity in the world of polymers due to its cost-effectiveness, superior mechanical properties, and ease of molding. It is used in all automotive parts like battery cases and interior trims and ropes and twines for marine uses to prove its versatility. Polypropylene is likely to continue to be used in everyday items and various advances in the future of technology and industry because of its ability to contribute to our society in significant ways.

#Polypropylene#Polypropyleneprices#Polypropylenemarket#Polypropylenenews#Polypropylenepricetrend#Polypropylenepriceforecast#Polypropylenemarketprice#priceofPolypropylene

1 note

·

View note

Text

Unlocking the Power of Ethylene Oxide: From Production to Practical Applications

Hello and welcome to our blog about Ethylene Oxide – a unique and indispensable substance in different areas of our life. Ethylene Oxide is one of the most important organic compounds as it has many uses and chemical properties. In this blog, we explore the use of Ethylene Oxide in various industries ranging from pharmaceuticals to agriculture and textiles among others. So, lets drive into it!

Introduction

Ethylene Oxide serves as a versatile chemical primarily utilized as an intermediate in the production of various industrial chemicals, notably Ethylene Glycol. Additionally, it functions as a surface disinfectant, particularly prevalent in the healthcare and medical equipment sectors, where it substitutes steam in sterilizing heat-sensitive tools such as disposable plastic syringes. Moreover, Ethylene Oxide finds extensive application in diverse sectors, including non-contact infrared thermometers, thermal imaging systems, liquid chemical sterilization, patient lifts, surgical staplers, household and industrial cleaners, cosmetics, shampoos, polyurethanes, heat transfer liquids, plasticizers, ointments, and various fabric applications.

Manufacturing Process

This blog unveils a process for manufacturing Ethylene Oxide which has several steps. The operations fall into four main stages:

Stage 1 involves EO reaction, EO recovery, and carbon dioxide removal

Stage 2 focuses on removing non-condensables and purifying EO

Stage 3 centers on glycols reaction and dewatering

Stage 4 deals with glycols purification.

Stage 1: EO Reaction, EO Recovery, and Carbon Dioxide Removal

Feedstock ethylene is commonly delivered via pipeline from a steam cracker. While air can supply oxygen in an air-based process, modern methods rely on pure oxygen from an air separation unit.

The reaction between ethylene and oxygen occurs in a fixed-bed reactor with a silver catalyst in the tubes and a coolant on the shell side. Heat from the exothermic reactions is managed by the coolant, which produces steam for heating various parts of the plant.

A substantial gas flow continuously circulates through the EO reactors. Reaction byproducts (EO, carbon dioxide, and water) are removed, while unreacted oxygen and ethylene are recycled. To mitigate fire and explosion risks, a diluent is added to the recycle gas, typically methane, enabling safe operation with higher oxygen levels.

A small amount of organic chlorinated compound is introduced to control catalyst performance, with resulting chlorine distributed across product and effluent streams. A vent stream, known as inerts purge, reduces the accumulation of inerts and impurities in the recycle gas. This vent gas is often used as fuel.

Additional ethylene, oxygen, and diluent are introduced into the recycle gas loop as needed.

To manage the significant influx of inert nitrogen from the air feed, a portion of the recycle gas was redirected to a secondary EO reactor, referred to as the purge-reactor, where the majority of the ethylene was converted. EO was extracted from the purge-reactor product gas through absorption in water, while the remaining gases (such as unreacted ethylene, nitrogen, and carbon dioxide) were released into the atmosphere.

EO mixes completely with water. At normal temperatures and without catalysts, EO's reactivity with H2O (leading to glycol formation) remains minimal across a broad pH spectrum, making water an effective medium for scrubbing EO for removal or recovery. The gas exiting the reactor is treated to recover EO by absorbing it into water. The resulting aqueous EO solution undergoes concentration in a stripper. From the top of the stripper, a concentrated EO-water mixture is directed to a stage for removing non-condensable substances and purifying EO (Stage 2). The bottom stream of the stripper consists of EO-free water, which is cooled and returned to the EO absorber.

Typically, one or more bleed streams are extracted from the EO recovery process to prevent the buildup of glycols and/or salts. These substances undergo further processing to reclaim EO and/or glycols.

A portion of the recycle gas exiting the EO absorber is directed through a column where carbon dioxide, produced during the oxidation process, is absorbed under pressure. It forms hydrogen carbonate in a heated potassium carbonate solution.

The carbon dioxide is then separated from the carbonate solution in an atmospheric stripper through a reverse reaction. The carbon dioxide released from the top of the stripper can be released into the atmosphere or reclaimed for other purposes, such as in carbonated drinks, following treatment to eliminate volatile organic compounds (VOCs). The regenerated carbonate solution from the bottom of the stripper is cooled and reused in the carbon dioxide absorber. The overhead stream from the absorber, now depleted of carbon dioxide, is combined again with the recycle gas stream and directed back to the EO reactor(s).

Step 2: Non-condensables removal and EO purification

After the initial separation process, the Ethylene Oxide (EO) and steam mixture is cleaned up. This purification step removes unwanted elements like carbon dioxide and excess ethylene. The unusable gases get sent back for recycling, while the cleaned-up EO-water mix gets separated. In most European plants, this mix gets distilled to extract high-purity EO. Leftover water might be reused or sent for further processing. The final EO product is chilled and stored. Since EO is a gas at normal temperatures, special storage methods are needed. It's typically kept under nitrogen and cooled, though pressurized storage is also an option. Any leftover EO gas from storage or other processes gets captured and recycled back into the system. Finally, for transport, EO is loaded onto pressurized railcars under a nitrogen blanket.

Step 3: Glycols reaction and dewatering

Glycols are produced by introducing a mixture of EO and water into a reactor operating at elevated temperatures, usually ranging between 150 and 250 °C. Under these conditions, reactions occur rapidly, requiring no catalyst. Sufficient residence time is provided to ensure complete conversion of EO. A reactor pressure typically between 10 and 40 barg is maintained to prevent EO vaporization. The feed to the reactor contains an excess of water to control the adiabatic temperature rise and enhance MEG selectivity. Generally, glycol products consist of 75 to 92 wt-% MEG, with the remaining portion comprising DEG and some TEG. All of the EO feed is converted into glycols, including MEG, DEG, TEG, or heavier glycols.

The output from the glycols reactor comprises different glycol products along with surplus water. This excess water is eliminated through multiple-effect evaporation followed by vacuum distillation. After heat exchange, the purified water is returned to the glycols reactor for reuse. A portion of the recycled water is extracted to prevent impurity buildup. Low-pressure steam produced in this process serves as a heat source in various sections of the plant.

Step 4 - Glycols purification

The glycol stream, now depleted of water, undergoes fractionation in several vacuum columns to separate and recover the different glycol products at high purity. The co-products in the MEG manufacturing process, in decreasing quantities, are diethylene glycol (DEG), triethylene glycol (TEG), and heavier glycols. These individual glycol products are then further purified through subsequent fractionation. After cooling, the glycol products are directed to storage. The residual stream from the final vacuum column contains the heavier glycols, which can either be sold for additional glycol recovery or disposed of, such as through incineration.

Step 5 - Crystallization Step

The crystallization step follows the barium removal process to precipitate Ethylene Oxide from the solution, yielding pure Ethylene Oxide. This ensures the removal of impurities, particularly barium ions, resulting in high-purity Ethylene Oxide suitable for various applications.

Crystallization techniques such as heat concentration or vacuum distillation are employed to precipitate Ethylene Oxide. Higher temperatures during crystallization expedite the process; however, subsequent drying at temperatures below 60°C prevents the release of water of crystallization, maintaining the product as hydrated Ethylene Oxide, which is easier to handle. Additional treatments like pulverization may be performed to adjust the physical properties of Ethylene Oxide as needed.

Applications of Ethylene Oxide

Chemical Industry

Ethylene Oxide is used majorly for the production of Ethylene Glycol. Ethylene Glycol is a multi-functional chemical. It serves as an antifreeze which is used in automotive coolant systems to prevent freezing and protect the engines from cold. It also plays a vital role as a raw material for the synthesis of polyester fibers and resins in the textile and plastic industries. Ethylene Glycol is used as a deicing fluid for planes and runways to enable them to operate even during the winter season. It is also a humectant in cosmetics, a heat transfer medium in industrial processes, and a solvent for paints and coatings. It is used as a chemical intermediate for the manufacture of several industrial chemicals that are essential in various industries hence can be considered as the most important industrial chemical. Additional derivatives of Ethylene Oxide find application in household cleaning products and personal care items like cosmetics and shampoos. These derivatives are also utilized in industrial cleaning solutions, heat transfer fluids, polyurethanes, and plasticizers.

2. Medical

Ethylene Oxide sterilization processes can sanitize medical and pharmaceutical products that cannot support conventional, high-temperature steam sterilization procedures. Medical devices that require Ethylene Oxide sterilization include heart valves, pacemakers, surgical kits, gowns, drapes, ventilators, syringes, and catheters.

3. Agriculture

Ethylene Oxide and its derivatives play a crucial role in producing a wide array of active and inactive components utilized in insecticides, pesticides, and herbicides, tailored to meet the specific needs of the agricultural sector, thereby safeguarding crops and enhancing agricultural productivity. In agricultural crop processing, Ethylene Oxide-based demulsifiers enhance the separation of oil from water, particularly in corn oil extraction within the bioethanol production process. The extracted oil finds applications in the food industry, animal feed production, or biodiesel manufacturing. Ethylene Oxide is also instrumental in producing industrial starches from agricultural sources, known as hydroxyethyl starches, which serve as versatile inputs in various industries such as adhesives, papermaking, and laundry starch. Additionally, in veterinary and animal surgical settings, Ethylene Oxide is utilized to sterilize medical equipment, surgical instruments, and procedure kits, ensuring optimal hygiene and safety standards.

4. Oil & Gas

Ethylene Oxide derivatives play a surprising role in making oil and gas production cleaner and more efficient. These compounds help purify natural gas, prevent pipeline corrosion, and even capture carbon emissions. They also speed up oil well operations and extend equipment life, ultimately lowering the cost of petroleum products. A key family of these derivatives – ethanolamines – even contributes to cleaner burning fuels by removing impurities.

Market Outlook

The primary use of Ethylene Oxide lies in its role as a chemical intermediate for synthesizing glycol ethers, acrylonitrile, ethoxylates, ethylene glycol, and polyether polyols, all of which find extensive applications across various downstream industries. The escalating demand for these derivatives from end-user sectors is a key driver propelling the global market forward. Among these derivatives, the Ethylene Glycol segment holds dominance globally, particularly due to its widespread utilization in automotive, packaging, and pharmaceutical industries. Ethylene Glycol serves as a crucial component in the production of polyester fibers, polyethylene terephthalate (PET) resins, and automotive antifreeze. Furthermore, the increasing global population, particularly in emerging economies, is fueling demand for personal and healthcare products, further augmenting the need for Ethylene Oxide.

Ethylene Oxide Major Global Producers

Major companies in the Global Ethylene Oxide market are Sinopec, BASF, Shell, Dow Chemical, Ningbo Henyuan, Nippon Shokubai Co., Ltd., Reliance Industries Limited, SINOPEC SABIC (TIANJIN) Petrochemical Company Limited, Maruzen Petrochemical Co., Ltd., PTT Global Chemical, Sasol Limited, Saudi Kayan Petrochemical Company, Nizhnekamskneftekhim, Indorama Ventures Public Company Limited, and Others.

Conclusion:

Ethylene Oxide serves primarily as a chemical precursor for the synthesis of glycol ethers, acrylonitrile, ethoxylates, ethylene glycol, and polyether polyols, essential components utilized across diverse industries. The rising demand from the chemical sector, particularly for chemicals like Ethylene Glycol is expected to propel the global Ethylene Oxide market in the foreseeable future. Furthermore, the increasing need within the medical industry for Ethylene Oxide to sterilize medical instruments and equipment is also contributing to the growth of the Ethylene Oxide market.

#ethyleneoxide#ethyleneoxideprices#ethyleneoxidemarket#ethyleneoxidenews#ethyleneoxidepricetrend#ethyleneoxidepriceforecast#ethyleneoxidedemand#ethyleneoxidesupply#ethyleneoxidemarketprice#priceofethyleneoxide

1 note

·

View note

Text

Propylene’s Manufacturing Techniques and Multiple Applications

Propylene is a vital chemical in the field of chemical engineering as it is considered as one of the most important basic chemicals that are used for the production of a number of other compounds. From Propylene oxide to acrylonitrile, cumene and acrylic acid, the derivatives derived from Propylene are a crucial factor in the production of a diverse range of products that we use in our everyday life. These chemicals are used in the production of films, fibers, containers, packaging materials and caps and closures to demonstrate the significance and usefulness of Propylene in modern industry. Let us explore the role of Propylene in various industries and the new solutions it inspires.

Introduction

Propene, also referred to as Propylene, serves as a crucial building block akin to ethene, particularly in the production of poly(propene) or Polypropylene. Unlike ethene, propene readily participates in substitution reactions, yielding a diverse array of significant chemicals. Its primary applications include the production of Polypropylene, acrolein, acrylonitrile, cumene, Propylene oxide, and butanal. These derivatives are instrumental in the manufacturing of acrylic polymers, phenol, acetone, polyurethanes, and surface coating solvents, showcasing propene's pivotal role in various industrial processes and product formulations.

Manufacturing Process

The production of Propylene is not direct, but indirectly through various other major industrial processes. Here are the two main ways Propylene is produced:

Steam Cracking: This is one of the largest processes accountings for the bulk of Propylene in the world today. Steam cracking is a process in which heavier hydrocarbons such as naphtha or natural gas liquids are cracked in a cracking furnace at high temperatures and with the use of steam. This process produces a mixture of several hydrocarbons with different chain lengths – the main product is ethylene and Propylene as a by-product.

Fluid Catalytic Cracking (FCC): This process is carried out in FCC units in refineries. FCC is mainly used to upgrade heavier gas oil from crude oil into gasoline. This process also produces a lighter stream of byproducts consisting of Propylene and other hydrocarbons. The significance of FCC as a Propylene source is expanding because it can process different feedstocks and likely to meet the growing Propylene demand.

Steam Cracking Units

The steam cracking process plays a pivotal role in the petrochemical sector, serving as the primary method for producing light olefins like ethylene and Propylene. It involves thermal cracking, utilizing either gas or naphtha, to generate these olefins. This review focuses on the naphtha steam cracking process, which primarily involves straight run naphtha sourced from crude oil distillation units. To qualify as petrochemical naphtha, the stream typically requires a high paraffin content, exceeding 66%.

Cracking reactions take place within the furnace tubes, and a significant concern and constraint for the operational lifespan of steam cracking units is the formation of coke deposits in these tubes. These reactions occur at elevated temperatures, typically ranging from 500°C to 700°C, depending on the feedstock's properties. For heavier feeds like gas oil, lower temperatures are employed to minimize coke formation.

The steam cracking process is characterized by high temperatures and short residence times. While the primary focus of a naphtha steam cracking unit is typically ethylene production, the yield of Propylene in such units can reach up to 15%.

Fluid Catalytic Cracking (FCC)

Presently, a significant portion of the Propylene market relies on steam cracking units for supply. However, a considerable share of the global Propylene demand stems from the separation of LPG generated in Fluid Catalytic Cracking Units (FCC).

Typically, LPG generated in FCC units contains approximately 30% Propylene, and the added value of Propylene is nearly 2.5 times that of LPG. In local markets, the installation of Propylene separation units proves to be a financially rewarding investment. However, a drawback of separating Propylene from LPG is that it results in a heavier fuel, causing specification issues, particularly in colder regions. In such cases, alternatives include segregating the butanes and redirecting them to the gasoline pool, adding propane to the LPG, or supplementing LPG with natural gas. It's important to note that some of these alternatives may decrease the availability of LPG, which could pose a significant constraint based on market demand.

A challenge in Propylene production lies in the separation of propane and Propylene, a task complicated by their close relative volatility of approximately 1.1. Traditional distillation methods struggle due to this narrow gap, necessitating distillation columns with numerous equilibrium stages and high internal reflux flow rates.

Two primary technologies employed for Propylene-propane separation are Heat-Pump and High Pressure configurations. The High Pressure approach relies on conventional separation methods, requiring sufficient pressure to condense products at ambient temperature, with a reboiler utilizing steam or another heat source. However, this method's reliance on low-pressure steam availability in refining hardware can be limiting. Alternatively, the Heat-Pump technology utilizes the heat from condensing top products in the reboiler, effectively combining the reboiler and condenser into a single unit. To address non-idealities, an auxiliary condenser with cooling water may be installed.

Implementing Heat-Pump technology enables a reduction in operating pressure from approximately 20 bar to 10 bar, thereby increasing the relative volatility of Propylene-propane and simplifying the separation process. Typically, Heat-Pump technology proves more attractive when distillation becomes challenging, particularly when relative volatilities are below 1.5.

Several variables must be considered when selecting the optimal technology for Propylene separation, including utility availability, temperature differentials in the column, and installation costs.

Propylene produced in refineries typically adheres to specific grades: Polymer grade, with a minimum purity of 99.5%, is directed towards the Polypropylene market, while Chemical grade, with purities ranging from 90 to 95%, is allocated for other applications. A comprehensive process flow diagram for a standard Propylene separation unit utilizing Heat-Pump configuration is illustrated in the following Figure.

The LPG extracted from the FCC unit undergoes a series of separation processes to isolate the light fraction, primarily comprising propane and Propylene. This fraction is then directed to a deethanizer column, while the heavier fraction, containing butanes, is either routed to the LPG or gasoline pool, depending on refinery configuration. The lighter fraction from the deethanizer column is often recycled back to the FCC unit for incorporation into the refinery fuel gas pool. Alternatively, it may be directed to petrochemical plants for the recovery of light olefins, particularly ethylene. The bottom fraction from the deethanizer column undergoes further separation in the C3 splitter column to separate propane and Propylene. Propane is recovered from the bottom of the C3 splitter and sent to the LPG pool, while Propylene is directed to the Propylene storage park. Before processing, the feed stream undergoes a caustic wash treatment to remove contaminants, such as carbonyl sulfide (COS), which can adversely affect petrochemical processes and may be produced in the FCC unit through the reaction between carbon monoxide and sulfur in the Riser.

Major Technologies Used for Producing Propylene

Process: OCT Process

Lummus Technology, one of the leading technology providers, presents two deliberate pathways to Propylene: Olefins Conversion Technology (OCT), which employs olefins metathesis, and CATOFIN propane dehydrogenation.

Traditionally, commercial on-purpose Propylene production methods have contributed to less than 5% of the global Propylene output, with the majority sourced as a by-product of steam crackers and fluid catalytic cracking (FCC) units.

Through the OCT process, low- value butylenes are subjected to reaction with ethylene to yield Propylene. The ethylene feedstock can range from diluted ethylene, typical of an FCC unit, to polymer-grade ethylene. Potential C4 feedstocks encompass mixed C4s generated in steam cracking, raffinate C4s from MTBE or butadiene extraction, and C4s produced within an FCC unit.

The ultra-high purity Propylene yielded by the OCT process surpasses polymer-grade specifications and promises potential cost savings in downstream Polypropylene facilities.

The mixture of ethylene feed and recycled ethylene is combined with the C4/C5 feed and recycled butenes/pentenes, and then heated before entering the fixed-bed metathesis reactor. Within the reactor, the catalyst facilitates the reaction of ethylene with butene-2 to produce Propylene, and the conversion of ethylene and pentenes to Propylene and butenes, while also isomerizing butene-1 to butene-2. Some coke buildup occurs on the catalyst, necessitating periodic regeneration of the beds using nitrogen-diluted air. The process is engineered for high utilization of olefins, typically ranging from 90 to 97%, with a Propylene selectivity of around 94 to 95%. After cooling and fractionation to remove ethylene for recycling, a portion of the recycle stream is purged to eliminate methane, ethane, and other light impurities. The bottoms from the ethylene column are directed to the Propylene column, where butenes/pentenes are separated for recycling to the reactor, and some are purged to eliminate unreacted butenes, isobutenes, butanes, unreacted pentenes, isopentenes, pentanes, and heavier compounds from the process. The overhead product from the Propylene column constitutes high-purity, polymer-grade Propylene.

Applications of Propylene

Polypropylene

The vast majority of Propylene, a key industrial ingredient, goes into making Polypropylene. This versatile plastic is used in everything from clothes and water bottles to patio furniture and countless other items. The most prominent among Propylene’s stars is Polypropylene (PP). This is a strong plastic that is used in packaging and is significantly lightweight. PP dominates the food container and beverage bottle market as well as the textile bag and carpet industry. It is resistant to moisture, chemicals, and heat that makes it ideal for food packaging and protecting some items when being transported. And its price makes it the first choice of the manufacturers.

Cumene

Cumene, a crucial intermediate compound, is predominantly synthesized through the Friedel-Crafts alkylation process involving Propylene and Benzene. This organic chemical holds significant value and finds widespread application in various products including plastics, pharmaceuticals, and adhesives. Moreover, cumene's exceptional solvency properties make it a preferred solvent in formulations for paints, inks, and cleaners. Its derivatives play a pivotal role in the production of polymers such as PET and polycarbonates, essential materials utilized in packaging, electronics, and construction industries. Additionally, cumene serves as an effective octane booster in gasoline, enhancing combustion efficiency and engine performance while reducing exhaust emissions.

Oxo Alcohol

Oxo alcohols form an important class of chemical intermediates that are used to produce plasticizers, coatings, and detergents. Oxo alcohols are used in a wide variety of industries from plastics and coatings to pharmaceuticals and cosmetics industries thus emphasizing their significance in various industrial processes.

Isopropanol

In the indirect-hydration method, Propylene undergoes a reaction with sulfuric acid to generate mono- and diisopropyl sulfates, which are subsequently hydrolyzed to produce isopropanol. This versatile compound is commonly diluted with water and employed as a rubbing-alcohol antiseptic, and it also serves as a key ingredient in aftershave lotions, hand lotions, and various cosmetic products. In industrial applications, isopropanol functions as a cost-effective solvent for cosmetics, medications, shellacs, and gums, in addition to its role in denaturing ethanol (ethyl alcohol).

Market Outlook

The majority of globally produced Propylene is utilized in the manufacturing of Polypropylene through polymerization. Propylene and its derivatives play crucial roles in various industries, including packaging, electronics, automotive, textiles, cosmetics, food and beverage, pharmaceuticals, construction, and others. Polypropylene stands as the predominant thermoplastic polymer, serving as a pivotal material for plastic components across a multitude of industries such as packaging, electronics, automotive, textiles, and beyond. Furthermore, various derivatives of Propylene are utilized across an array of sectors including cosmetics, personal care, food and beverage, pharmaceuticals, construction, automotive, and others, encompassing textiles, paper, pulp, electronics, consumer goods, and chemicals. As these sectors expand, the demand for Propylene is expected to increase.

Propylene Major Global Producers

Notable players in the Global Propylene market are Reliance Industries Limited, Indian Oil Corporation Limited, HPCL-Mittal Energy Limited, Haldia Petrochemicals Limited, Mangalore Refinery & Petrochemicals Ltd, Brahmaputra Cracker and Polymers Limited, Shenhua Ningxia Coal Group Corporation Limited, Bharat Petroleum Corporation Limited, Hindustan Petroleum Corporation Limited, GAIL (India) Limited, Nayara Energy Limited, Fujian Refining & Petrochemical Co Ltd, Zhong Tian He Chuang Energy, Sinopec Sabic Tianjin Petrochemical Co., Ltd., Wanhua Chemical Group Co., Ltd, and Others.

Conclusion:

In summary, Propylene can be considered as a highly important, versatile and indispensable chemical compound that is used as an input for various industries around the globe. Its importance as a major producer of Polypropylene, an important thermoplastic material used in packaging and automobile industries, among others, attests to its significance in the economy. Furthermore, Propylene and other derivatives are used in various chemical industries such as cosmetics, pharmaceuticals, and construction industries. The anticipated growth of the Polypropylene industry is expected to significantly propel the market in the coming years. Additionally, various derivatives of Propylene, including Propylene oxide, acrylic acid, acetone, IPA, Polypropylene glycol, and cumene, find extensive applications across numerous industries, further driving demand for Propylene in the forecast period. Moreover, the rapidly expanding construction, automotive, and packaging industries present promising growth prospects in the global Propylene market.

#propylene#propyleneprices#propylenemarket#propylenenews#propylenepricetrend#propylenepriceforecast#propylenedemand#propylenesupply#propylenemarketprice#priceofpropylene

1 note

·

View note

Text

Benzene’s Brilliance: Unveiling the Manufacturing Magic and Endless Applications!

Thank you for joining us in the next part of our blog. Now, we will try to figure out some interesting facts about Benzene. Although it might be a new name to you, this chemical is widely used in different spheres in day-to-day life. Benzene is an organic compound that is a colorless and sweet-smelling liquid and is not only interesting from a chemical perspective but also finds an application in various industries.

Benzene is a natural petrochemical that is obtained from natural gas, crude oil, or coal and is used as a basic raw material for the manufacture of various other chemicals. Its uses are endless as it is used in the production of plastics, rubbers, detergents, drugs, and many other products. However, this is not all – Benzene is also useful in other aspects besides chemical synthesis.

Here we will look at how Benzene was discovered, its applications in different industries and how it is an essential solvent in both chemical and pharmaceutical industries. So, let’s fasten our seat belts and begin our quest to demystify Benzene and appreciate its magic!

Introduction

Benzene, a clear and pleasantly scented compound, serves as both a solvent in chemical and pharmaceutical sectors and a pivotal component in numerous manufacturing processes. By combining with various substances, it forms a spectrum of compounds crucial for producing a diverse range of consumer goods. Furthermore, Benzene acts as a precursor for key chemicals like Ethylbenzene, Cumene, and Cyclohexane, which in turn contribute to the creation of plastics and assorted materials.

Manufacturing Process

Benzene can be generated through various methods, one of which is catalytic reforming. This process involves several steps including the dehydrogenation of cycloparaffins, the dehydroisomerization of alkyl cyclopentanes, and the cyclization followed by dehydrogenation of paraffins. In catalytic reforming, the feedstock for Benzene production typically consists of thermally cracked naphtha cut within the temperature range of 71–104 °C. The catalytic reformer utilizes a catalyst comprising platinum-rhenium on an alumina support with a high surface area. Subsequently, the Benzene product is commonly separated from the reformate using solvent extraction techniques.

Benzene can alternatively be produced through a method called cracking, which involves a series of steps. Initially, crude oil is heated, and steam is introduced into the mixture. Subsequently, the resulting gaseous mixture is briefly passed through a furnace at temperatures ranging from 700 to 900 °C. During this process, the dissolved compounds undergo fractional distillation, allowing for the separation of various components, among which Benzene is included.

Another method for Benzene production involves the hydrodealkylation of Toluene. This process utilizes a catalyst, typically containing chromium, molybdenum, and/or platinum. Toluene and hydrogen are combined under pressures ranging from 20 to 60 atmospheres and heated to temperatures between 500 and 660 °C. This reaction results in the conversion of the mixture into Benzene and methane, with Benzene subsequently separated through distillation.

Processes used by Major Companies

Process: Pyrolysis Gasoline Process

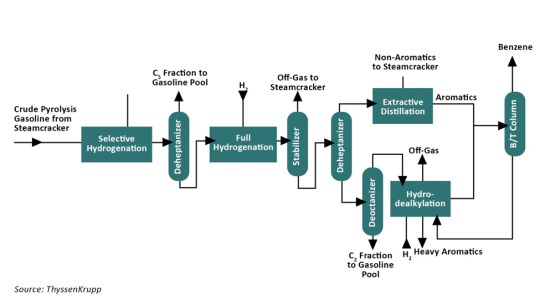

ThyssenKrupp AG is a German conglomerate specializing in industrial engineering and steel manufacturing. Formed in 1999 through the merger of Thyssen AG and Krupp, the company's operational headquarters are situated in Duisburg and Essen. Benzene from Pyrolysis Gasoline Process is used by this Group to produce Benzene.

The standard procedure for extracting Benzene and toluene from raw pyrolysis gasoline comprises several essential phases. Initially, a selective hydrogenation process is utilized to saturate diolefins at a lower temperature, thus preventing polymerization. Following this, the selectively hydrogenated pyrolysis gasoline undergoes depentanization to isolate the C fraction, which is incorporated into the gasoline blend as an octane-boosting component. This approach helps in minimizing hydrogen usage and scaling down the full hydrogenation unit.

If the C fraction is rerouted back to the steam cracker for use as feedstock, it undergoes full hydrogenation and is then separated alongside non-aromatic compounds either through a combined depentanizer/stabilizer or through extractive distillation, eliminating the necessity for a complete depentanizer setup. The full hydrogenation unit ensures the complete saturation of olefins and the removal of contaminants such as nitrogen and sulfur. The resultant off gas, containing hydrogen sulfide, is separated in the stabilizer and reintroduced into the steam cracker.

To isolate aromatics, a distinct aromatic fraction is separated from the pre-treated pyrolysis gasoline. For Benzene extraction, a C fraction is isolated, whereas for both Benzene and toluene retrieval, a C fraction is obtained and directed to extractive distillation. Subsequently, the C or C fraction is channeled into the gasoline blend as feedstock.

The following figure demonstrates the entire process:

Applications of Benzene

Styrene:

The biggest application of Benzene is that it is the precursor of styrene. This is the raw material used to make polystyrene (PS) a type of plastic. PS ends up being used in millions of objects people use every day, from disposable cups to food packaging to toys. It is a light material and transparent in nature and thus used for many purposes.

Cumene:

Cumene is a key intermediate product majorly produced through the Friedel-Crafts alkylation process of Benzene with propylene. Firstly, it is a raw material for the production of acetone and phenol – valuable organic chemicals widely used in such goods as plastic, medicines, and glue. Cumene also finds use as a solvent in formulations for paints, inks, and cleaners due to its superior solvency properties. Its derivatives are used in the production of polymers such as PET and polycarbonates used in packaging, electronics, and construction, respectively. In addition, as an octane booster in gasoline, cumene helps to increase the octane number and improve combustion of the fuel, which leads to enhanced engine power and lower exhaust fumes. In general, cumene is an essential and diverse compound that is crucial for the operation of different industrial systems and technologies.

Synthetic Rubber:

Benzene is a key intermediate in the manufacture of synthetic rubber such as styrene butadiene rubber and nitrile butadiene rubber. SBR is the main component of tires for most cars which offer good gripping and durability. NBR is a tough material used in hoses, gaskets, and seals, which are all important parts that help to keep machinery functioning.

Nylon:

The conversion of Benzene to caprolactam opens up the door to the world of nylon fibers. These fibers are spun into clothing fabrics, carpets, and other technical textiles. Nylon is strong, elastic, and resistant to wrinkles and thus suitable for clothes, particularly for sportswear and carpets that require frequent use.

Dyes and Resins:

Benzene has played a great role in the world of color. It is a basis for different dyes applied in textile industry, paints and plastics. These dyes add brightness to our clothing, our houses, and other personal possessions. Further, Benzene finds application in epoxy resins for tough adhesives, coatings, and the core composite materials – crucial for construction and other industrial purposes.

Pharmaceuticals:

Benzene’s derivatives are used in crucial roles in the pharmaceutical sector. Phenol, aniline, and other derivatives are used as synthetic precursors to drugs. Also, Benzene-derived solvents such as toluene and xylene are essential in formulating active pharmaceutical ingredients. They also serve as starting materials for manufacturing the active substances in such drugs as antibiotics and analgesics.

Market Outlook

The increasing demand for Cumene, a vital derivative crucial for acetone production, particularly in the paints and coatings sectors, carries notable significance. This surge in Cumene requirement significantly contributes to the overall growth of the global Benzene market. Additionally, the rising necessity for Benzene derivatives in downstream sectors is captivating, fueled by the increasing demand for chemicals used in rubber processing, nylon resins, and synthetic fibers. EthylBenzene, a prominent derivative of Benzene, finds its primary application in styrene production. The escalating demand for styrene-based polymers such as polystyrene, styrene-acrylonitrile resins, and acrylonitrile butadiene styrene rubber, particularly in disposable medical devices and consumer electronics, further drives the global Benzene market. Essentially, Benzene, serving as a versatile and indispensable chemical, remains at the forefront of various industrial processes, propelled by its derivatives that cater to diverse sectors. The trajectory of the Benzene market intricately intertwines with the expanding horizons of downstream industries, positioning it as a cornerstone in the domain of organic compounds and chemical intermediates.

Benzene Major Global Producers

Significant players in the Global Benzene market are Reliance Industries Limited, Haldia Petrochemicals Limited, Formosa Chemicals & Fiber Corporation, Hanwha TotalEnergies Petrochemical Co., Ltd, GS Caltex, LG Chemical, S-OIL, SK Geo Centric (SKGC), Hengli Petrochemical Refinery, Exxon Mobil Corporation, Sinopec Shanghai Petrochemical Company Limited, Thai Oil Public Company Limited, Petrochina Dalian Chemical, Borealis AG, SABIC, AP Feyzin (Total And Ineos), Versalis S.p.A., and Others.

Conclusion:

As the final thought, Benzene is an essential entity in the organic compounds and chemical intermediates with the help of which numerous processes and applications are possible. Benzene is used as a solvent in chemical and pharmaceutical industries, as a raw material to produce various consumer products and in the production of other goods. In addition, its significance in the production of Benzene derivatives such as Cumene and Styrene, which are used in the production of plastic, synthetic fibers, and pharmaceuticals, is a plus. With the expansion of industries and their downstream industries, the Benzene market will also develop significantly, which means Benzene will continue to have a significant impact on global production and development. In conclusion, Benzene’s utility, necessity, and future are a testament to its importance as a primary building block in the world of chemistry and industry.

#benzene#benzeneprices#benzenemarket#benzenepricetrend#benzenepriceforecast#benzenenews#benzenemarketprice#pricefbenzene

1 note

·

View note

Text

Lithium Hydroxide’s Manufacturing Process & Tomorrow's Innovations

The Lithium Hydroxide might sound complicated, but it is in reality an amazing and valuable compound. This white, sometimes sparkling solid, which is an essential element in various industries, surprisingly has some unique applications.

Lithium Hydroxide is a widely used chemical compound, and in this article, we will take a look at its various aspects. We'll be looking into its properties, how it is made (which involves some interesting chemistry, too!), and some of the amazing things it is used for. Lithium Hydroxide, which is used in both air freshening systems on spaceships and in special greases, has a range of unexpected uses. Therefore, please fasten your seatbelt and let us dive into the discussion of this essential chemical!

Introduction

Lithium Hydroxide (LiOH) is a white, solid compound that comes in two forms (hydrated and anhydrous) and is made by reacting lithium carbonate with calcium hydroxide. It is used to create lithium greases, which are valuable lubricants due to their resistance to heat, water, and pressure. In batteries, Lithium Hydroxide is gaining traction as a replacement for lithium carbonate because it allows for bigger batteries with more power, better safety, and longer life. It's already used by Tesla and is likely to be adopted by other electric vehicle makers. Lithium Hydroxide also finds use in alkaline batteries and air scrubbers.

Manufacturing Process

This blog unveils a process for manufacturing Lithium Hydroxide, involving several steps. Initially, lithium sulfate reacts with barium hydroxide in a liquid medium, yielding a Lithium Hydroxide solution through hydroxylation. Subsequently, barium ions in the Lithium Hydroxide solution are eliminated via a barium removal process utilizing a cation exchange resin and/or a chelate resin. Finally, Lithium Hydroxide is precipitated from the treated solution in a crystallization step.

Step-1 Lithium Concentration

The extraction process involves bringing the lithium dissolved solution (aqueous phase) into contact with a solvent (organic phase) and mixing them with agitation using a mixer to transfer lithium ions and similar substances from the dissolved solution to the solvent. Following this, the organic phase and the aqueous phase are separated using a settler based on their differing specific gravities. Depending on factors such as lithium ion concentration, an O/A ratio (organic phase to aqueous phase volume ratio) exceeding 1.5/1.0 may be utilized. To enhance the extraction efficiency of lithium ions, the O/A ratio can be adjusted, and the number of extraction stages can be increased. For the lithium dissolved solution, a phosphonate ester extracting agent, a phosphate ester extracting agent, or a combination of both may be employed as extracting agents. Optionally, the extracting agent could be thinned with a hydrocarbon-based organic solvent, including aromatic, paraffinic, or naphthenic solvents. Ideally, the equilibrium pH range during extraction falls between 7 and 8.

Scrubbing the solvent with the lithium solution effectively eliminates sodium ions that have been extracted into the solvent. By modifying the lithium ion concentration within the lithium solution, lithium ions within the solution can replace the sodium ions present in the solvent, thereby facilitating the efficient removal of sodium ions from the solvent.

The lithium ions present in the scrubbed solvent are subsequently extracted from the solvent through a back-extraction process. This involves stirring and mixing the solvent with a pre-back extraction liquid, typically an acidic aqueous solution, using a mixer or similar equipment. This facilitates the transfer of lithium ions from the solvent to the aqueous phase. The pre-back extraction solution utilized for this process may comprise various inorganic acids such as sulfuric acid, hydrochloric acid, or nitric acid. Among these options, sulfuric acid is favored because it yields a back-extracted liquid containing lithium sulfate, a valuable raw material for Lithium Hydroxide production.

The back-extracted liquid obtained from the back extraction step can undergo additional back extraction cycles, serving as a pre-back extraction liquid. This process further elevates the lithium ion concentration. Moreover, the back-extracted liquid can also be employed in the scrubbing step as a lithium solution. This cyclical approach optimizes the extraction process, enhancing lithium ion concentration and maximizing the utilization of resources.

Step 2 - Hydroxylation Step

In the hydroxylation step, lithium sulfate, obtained from the back-extraction process or similar sources, undergoes a reaction with barium hydroxide in a liquid medium to yield a Lithium Hydroxide solution. This chemical transformation can be represented as follows:

Li2SO4 + Ba(OH)2 → 2LiOH + BaSO4

Consequently, a solution containing dissolved Lithium Hydroxide is generated, while barium sulfate precipitates. The utilization of barium hydroxide proves effective as it facilitates the chemical conversion reaction with lithium sulfate, enabling the production of a Lithium Hydroxide solution.

Step 4 - Barium Removal Step

In the barium removal step following hydroxylation, the Lithium Hydroxide solution undergoes contact with either a cation exchange resin or a chelate resin to eliminate impurities, particularly barium ions. The resin adsorbs these ions from the solution, enhancing the purity of Lithium Hydroxide obtained after subsequent crystallization.

It's crucial to meticulously select the resin and operating conditions during barium removal to ensure efficient extraction of barium ions from the Lithium Hydroxide solution. Resins like weakly acidic cation exchange resins with carboxyl groups or aminophosphoric acid type chelate resins exhibit high selectivity for barium ions while minimizing adsorption of lithium ions.

Moreover, maintaining an alkaline pH (preferably 9 or higher) in the Lithium Hydroxide solution during resin contact optimizes the barium removal efficiency.

Step 5 - Crystallization Step

The crystallization step follows the barium removal process to precipitate Lithium Hydroxide from the solution, yielding pure Lithium Hydroxide. This ensures the removal of impurities, particularly barium ions, resulting in high-purity Lithium Hydroxide suitable for various applications.

Crystallization techniques such as heat concentration or vacuum distillation are employed to precipitate Lithium Hydroxide. Higher temperatures during crystallization expedite the process; however, subsequent drying at temperatures below 60°C prevents the release of water of crystallization, maintaining the product as hydrated Lithium Hydroxide, which is easier to handle. Additional treatments like pulverization may be performed to adjust the physical properties of Lithium Hydroxide as needed.

Applications of Lithium Hydroxide

1. Batteries

Lithium Hydroxide (LiOH) found in batteries, specifically lithium-ion batteries, is a significant contributor to the high electrochemical potential and lightweight characteristic of lithium, which in turn leads to high energy density. Its inherent property of staying stable at the high temperatures in the charging cycles guarantees the batteries' safety. Lithium-ion batteries with LiOH have low discharge rates, and they hold charges over a long time. They are rechargeable, thanks to the lithium ions that are moving back and forth between electrodes that are facilitated by LiOH. This mixture thus leads to lightweight, power-efficient energy storages that are suitable for use in electric vehicles, portable gadgets, and other devices which require high-performance long-lasting power sources.

2. Grease and Lubricants

Lithium Hydroxide finds application in lubricating greases, commonly referred to as lithium grease, enhancing their resistance to water and oxidation. These greases maintain their lubricating efficacy across a broad temperature spectrum, enabling them to endure high-pressure conditions. Their insolubility ensures longevity, making them suitable for humid environments where water exposure is frequent without losing their lubricating properties.

3. Glass & Ceramics

Multiple advantages of Lithium Hydroxide make it applicable in the glass and ceramics industries. Besides the fact that it allows for more accurate dimensional tolerances, it also helps to reduce thermal expansion, which in turn prevents cracks and fractures during production and use. Furthermore, it provides clarity that makes the glass transparent by getting rid of any imperfections that may cause cloudiness. Through the reduction of the melting point of the glass mixtures, Lithium Hydroxide helps energy-efficient manufacturing processes and gives molten glass a better flow. In ceramics, it enhances properties like the strength and thermal shock resistance when it functions as a flux or a filler. Additionally, lithium compounds are capable of coloring glass and ceramics that give them particular colors, which makes them more attractive and appealing.

Market Outlook

The Lithium Hydroxide market is driven by the increasing demand for electric vehicles and consumer electronics. Lithium Hydroxide is a critical component in lithium-ion batteries, which are used in these electric vehicles and consumer electronics. Because of this, the demand for lithium-ion batteries is a major driver of the Lithium Hydroxide market. Additionally, the dominance of lithium-ion batteries in the Lithium Hydroxide market is expected to continue due to ongoing research and development efforts to improve battery performance.

Lithium Hydroxide Major Global Producers

Top companies in the Global Lithium Hydroxide market are Albemarle Corporation, Sociedad Química y Minera de Chile (SQM), Tianqi Lithium Corporation, Ganfeng Lithium Co., Ltd., Livent Corporation, Jiangxi Ganfeng Lithium Co., Ltd., FMC Corporation, Galaxy Resources Limited, Nemaska Lithium Inc., Altura Mining Limited, and Others.

Lithium Hydroxide Market Opportunities

The Lithium Hydroxide market, which is used as the basic material in batteries, ceramics, and other industrial applications, has been growing at a fast rate over the years. Here are some potential opportunities within this market::

Electric Vehicles (EVs) and Energy Storage: The growing demand for electric vehicles and lithium-ion batteries for renewable energy storage necessitates Lithium Hydroxide which has been identified as a crucial component in lithium-ion batteries. Governments across the globe have started enforcing stringent measures on carbon emission and providing incentives for the use of electric vehicles. As a result, the demand for Lithium Hydroxide is highly likely to undergo a sharp increase.

Energy Sector: The transformation of energy sources to include wind turbines and solar panels as the new sources of energy requires energy storage systems that are efficient to avoid intermittent issues. The lithium-ion battery technology, based on Lithium Hydroxide, is the most popular in energy storage solutions for grid stabilization and backup power. As the renewable energy industry is expanding, Lithium Hydroxide, the main component in lithium-ion batteries, is also in high demand.

Consumer Electronics: The development of smartphones, tablets, laptops, and many other portable electronic devices that are driven by lithium-ion batteries has accelerated the demand for this type of batteries. With the ever-growing demand for devices with longer battery life and faster charging capabilities, manufacturers are obliged to use Lithium Hydroxide-based batteries as the majority of consumers are in search of these features.

Conclusion:

In the end, Lithium Hydroxide is the pioneer in the field of innovation and different industries such as battery technology and glass and ceramics production. The diversity and the irreplaceable role of lithium in the production of lithium-ion batteries guarantee its staying power in a techno-evolutionary world which is ever changing. As we are witnessing more and more development of renewable energy and the growth of electric vehicles, the need for Lithium Hydroxide is projected to have a significant increase. No doubt, this technology will play a critical role in the renewable energy storage solutions of the future. Lithium Hydroxide is a chemical that will help us build a greener and more efficient future, and it will be widely used in many fields.

#lithiumhydroxide#lithiumhydroxideprices#lithiumhydroxidemarket#lithiumhydroxidepricetrend#lithiumhydroxidepriceforecast#lithiumhydroxidenews#lithiumhydroxidedemand#lithiumhydroxidesupply#lithiumhydroxidemarketprice#priceoflithiumhydroxide

1 note

·

View note

Text

Unlocking the Power of Phosphoric Acid: From Production Methods to Practical Applications

H3PO4, often referred to as Orthophosphoric acid or Phosphoric acid, is a silent hero in our daily routines that might not be well known but plays a vital role. This acid, which is very useful, finds uses in fertilizers that feed our crops, carbonated beverages we love, and many more! It is the same question that follows: how is this acid being manufactured and what are the places where we find it?

In this blog, we are going to take a glance at the really interesting world of phosphoric acid. We shall look at the two processes which are adopted for the production of it, i.e., wet and thermal processes. Following that, we will unravel the mystery behind its diverse uses, including its involvement in agriculture and the fact that it is surprisingly a component of our cosmetics and food!

We’ll explore handful of its many applications such as:

Food science: It gives a fresh and strong kick to processed foods and drinks, while also working as a preservative.

Plant power: Phosphoric acid, which is a main constituent of fertilizers, supplies the associated phosphorus which is required to sustain healthy plants.

Beyond the surface: Phosphoric acid is one of the key ingredients in personal care products to keep the right balance of the pH level.

In short, this is the time to fasten your seatbelt as you are going to unveil the power of H3PO4.

Introduction

Phosphoric Acid (H3PO4) is a versatile acid with a presence in countless industries. But before we delve into its uses, understanding its structure and properties is key. These characteristics, essentially its makeup and behavior, are what make phosphoric acid so valuable in fields like agriculture, personal care, and even beverages.

These are:

Rust removal: Phosphoric acid can convert the iron oxide layer (rust) on metal surfaces into a phosphate layer. This phosphate layer acts as a protective barrier, preventing further rust formation.

Food and Beverage: Food-grade phosphoric acid adds a tangy flavor and acts as a preservative in colas, jams, and processed meats.

Agriculture: The biggest use of phosphoric acid is in fertilizers. It provides essential phosphorus for plant growth.

Personal care: Phosphoric acid helps adjust the pH level in cosmetics and skincare products.

Pharmaceuticals: Phosphoric acid finds use in some medications and as a starting material for drugs.

Manufacturing Process

There are two main ways to make phosphoric acid: the wet process and the thermal process. The wet process is more common and used for fertilizers, while the thermal process creates a much purer form of phosphoric acid used in high-quality products like medicine, detergents, food, and beverages.

Wet Process

Treating sulfuric acid (H2SO4) with naturally occurring phosphate rock involves drying and crushing the rock before continuously introducing it into a reactor alongside sulfuric acid. This reaction leads to the combination of calcium from the phosphate rock with sulfate, resulting in the formation of calcium sulfate (CaSO4), commonly known as gypsum.

Gypsum is separated from the reaction solution through filtration. Facilities typically employ a dihydrate process, yielding gypsum in the form of calcium sulfate with 2 molecules of water (CaSO4.2 H2O, or calcium sulfate dihydrate)

Some other facilities utilize a hemihydrate process, which yields calcium sulfate with half a molecule of water (CaSO4.½ H2O). The one-step hemihydrate process offers the advantage of producing wet process phosphoric acid with a higher concentration of P2O5 and fewer impurities compared to the dihydrate process.

A simplified reaction for the dihydrate process is outlined below:

To produce the strongest phosphoric acid and reduce evaporation costs, typically 93 percent sulfuric acid is utilized. Maintaining the precise ratio of acid to rock in the reactor is crucial, so advanced automatic process control equipment is employed to regulate these two feed streams.

During the reaction, gypsum crystals are formed and separated from the acid through filtration. These crystals undergo thorough washing to ensure at least a 99 percent recovery of the filtered phosphoric acid. After washing, the gypsum slurry is transferred to a gypsum pond for storage. Water is extracted and recycled through a surge cooling pond to aid in the phosphoric acid process.

Considerable heat is generated within the reactor. In older plants, this heat was dissipated by blowing air over the hot slurry surface. However, modern plants employ vacuum flash cooling to cool a portion of the slurry, which is then recycled back into the reactor.

Wet process phosphoric acid typically contains 26 – 30% of P2O5. To meet phosphate feed material specifications for fertilizer production, the acid often requires further concentration. Depending on the intended fertilizer types, phosphoric acid is concentrated to 40-55% of P2O5 using two or three vacuum evaporators.

Thermal Process

The production of phosphoric acid by thermal process requires elemental (yellow) phosphorus, air, and water as raw materials. This manufacturing process involves three main steps: Combustion, Hydration, and Demisting.

During combustion, liquid elemental phosphorus undergoes oxidation in a combustion chamber, typically at temperatures ranging from 1650 to 2760°C. This combustion reaction forms phosphorus pentoxide. It is depicted in the following reaction:

The produced phosphorus pentoxide is then hydrated either with dilute H3PO4 or water to generate strong phosphoric acid liquid. This is depicted in the following reaction:

The final step, demisting, involves the removal of phosphoric acid mist from the combustion gas stream before it is released into the atmosphere. This is typically achieved using high-pressure drop demistors.

The phosphoric acid concentration typically falls between 75 – 85% in the output from the thermal process. Such a high concentration is necessary for the production of high-grade chemicals and various non-fertilizer products.

Applications of Phosphoric Acid

Agriculture

The phosphoric acid is considered as a crucial chemical in modern agriculture as it performs diverse functions including production of fertilizers, amendment of soils, animal nutrition, and environmental preservation. The majority of the phosphoric acid is applied to fertilizer production, where it plays the fundamental role of forming the phosphate fertilizers, which are essential for the healthy growth of crops and maintaining the soil fertility. Furthermore, phosphoric acid helps in poultry feed as a source of dietary phosphorus. Among the widely used phosphatic fertilizers are diammonium phosphate (DAP), monoammonium phosphate (MAP), NPKs, and SSP. DAP stands out as a valuable provider of both phosphorus and nitrogen, essential for plant growth and development, particularly in cereal grains, fruits, and vegetables. By improving soil fertility, DAP contributes to enhanced crop production efficiency.

2. Food & Beverages

Phosphoric acid finds application as a food additive, serving as an acidity regulator in various food products such as jams, cereal bars, processed meats, and cheese. Within the beverage industry, it acts as an acidic agent, playing a crucial role in preventing the growth of fungi and bacteria while imparting a distinctive flavor to these drinks.

3. Rust Removal

Phosphoric acid is among the various acids commonly employed for rust removal from metals like iron and steel. When applied, it initiates a chemical reaction wherein the reddish-brown ferric oxide, commonly known as rust, undergoes transformation into a black-colored compound known as ferric phosphate. This reaction effectively breaks down and reacts with the rust present on the metal surface. Subsequently, the resulting black ferric phosphate compound can be easily extracted, leaving the metal surface free from rust and restored to its original state.

4. Personal Care & Cosmetics

Phosphoric acid plays a crucial role in the production of a diverse range of personal care items, cleaning products, bath formulations, fragrances, hair care solutions, dyes, nail treatments, lipsticks, and skincare preparations. Its function extends to regulating the pH levels of these materials, ensuring their effectiveness and stability. However, it is advisable to seek guidance from reputable phosphoric acid suppliers to gain comprehensive insights into its proper usage, applications, and characteristics.

Market Outlook

The main reason for the market of phosphoric acid development is the rise of the demand for DAP phosphate fertilizers. Being the most essential intermediate product in the course of the phosphate fertilizer manufacture, phosphoric acid is employed to make DAP, MAP, NPKs and SSP. DAP plays a major role in fulfilling the fertilizer demand of which is due to its rich nutrient content and ability to increase the soil fertility and crop production. The rise of world population and consumers’ buying power is likely to lead to more agricultural output. Thus, DAP fertilizers are utilized to balance the soil phosphate deficiency and improve crop production. This is likely to be the reason behind the rise of phosphoric acid consumption in the near future.

Phosphoric Acid Major Global Producers

Main players in the Global Phosphoric Acid market are Mosaic Company, IFFCO, Nutrien, Ma’aden, J.R. Simplot Company, ICL-YTH Group, OCP Group, Wengfu Group Co., Ltd., ICL(Rotem), Indorama (Industries Chimiques du Senegal), PhosAgro, Foskor Group, Rotem Amfert Negev Ltd., Yara, Coromandal International limited, JIFCO, and Indo Maroc Phosphore SA (IMACID), and Others.

Conclusion:

Phosphoric acid (H3PO4) has a range of uses which are reflected by the fact that it provides the sharp fizz of your favorite cola and the fertilizer that nourishes your crops. It fights rust, brings out the shine of metal surfaces, and lengthens their life. In food science, it can do the trick of adding flavor and preserving the food. The phosphorus it provides for plant growth is one of the main constituents of fertilizers. Besides food and agriculture, phosphoric acid is used for the maintenance of proper pH level in personal care products and also is in the list of vital components in dentistry and pharmaceuticals. Therefore, the next time you sip a beverage, marvel at a rust-free piece, or maintain your garden, remember the hidden ability of phosphoric acid to bring its magic to everyday life.

#phosphoricacid#phosphoricacidprices#phosphoricacidmarket#phosphoricacidnews#phosphoricacidpricetrend#phosphoricacidpriceforecast#phosphoricaciddemand#phosphoricacidsupply

1 note

·

View note

Text

From Quarry to Everyday: Calcium Carbonate's Journey and Utility

Have you ever stopped to think about the hidden ingredients that make up the world around you? From the sturdy walls of your house to the brightness of your favorite paint color, there's a good chance a common mineral called calcium carbonate plays a role. Today, we're diving deep into the fascinating world of calcium carbonate and exploring its surprising applications across various industries. From construction and papermaking to pharmaceuticals and plastics, get ready to discover how this versatile material silently shapes our everyday lives!

Introduction

Calcium carbonate (CaCO3) makes up a significant portion of the Earth's crust in the form of rocks like limestone, chalk, and marble. Limestone and chalk consist of calcium carbonate, while dolomite comprises a blend of calcium and magnesium carbonates. Though they contain impurities like clay, certain specimens are remarkably pure, surpassing 97%. Widely utilized in construction and for countering acidity, limestone and its derivatives serve various purposes across industries. It's a popular and versatile filler used in plastics because it improves both stiffness and impact resistance, making the final product tougher. It also helps maintain a consistent color and appearance. These calcium carbonate filled plastics are often used in construction and industrial applications where durability is key. Calcium carbonate has many other uses beyond plastics. It's found in paper, rubber, adhesives, and coatings. In paints, it acts as a filler, extender, and pH buffer. Concrete gets its strength and color stability from calcium carbonate fillers. It's even used in environmental cleanup, fertilizers, animal feed, and various cosmetic and hygiene products.

Interestingly, calcium carbonate exists in three different natural forms called polymorphs.

Calcite is the most common and stable form at normal temperatures and pressures.

Aragonite is less stable and slowly changes into calcite over millions of years.

Vaterite is the rarest and least stable form, quickly transforming into one of the other two polymorphs.

Each polymorph has a distinct crystal structure and appearance.

Manufacturing Process

The production process of Calcium Carbonate powder includes multiple stages, such as:

Raw Material Preparation:

The initial step in the production process of calcium carbonate comprises preparing the raw materials. The principal raw material utilized is limestone, a sedimentary rock primarily composed of calcium carbonate. Limestone is typically sourced from quarries or mines, after which it undergoes crushing and screening to achieve the desired particle size. The quality and attributes of the limestone utilized can significantly influence the properties of the resultant calcium carbonate product.

Calcination: