Text

Experiment with ways to hold your yarn. I picked one from the first video I saw, kept powering through until my hand stopped cramping, now the way I hold my yarn to keep tension is mildly concerning and basically impossible for anyone else to replicate.

I also have aphantasia but it has literally never been a problem for me when crocheting because I know what the stitches feel like. You should become familiar with the types of stitches, what each motion/part of crocheting creates, and then how to tell the different stitches apart based on that.

Also I’m sure a million other people have also said this, but never be afraid to undo your own work if you’re unhappy with it. On the flip side, don’t strive for perfection 100% of the time either, because then you’ll never finish anything. You need to find the middle ground of “this may have issues, but I’m happy enough to finish it”

Hey crocheting tumblr, I picked up the basic-bitch “I taught myself to crochet” kit last night. My friend taught me some basics two weeks ago but I’ve basically forgotten it all because I can’t visualize shit (hell yeah aphantasia, or damn close to it at least), but I have a book now, so it’s cool. My fiber art of choice is cross-stitch, but I figure it might be worth expanding my gayness into other forms of handicrafts and seeing if they’re fun. Might end up making some little vidja-game dolls or something if this works out.

what do you wish you’d known when you started crocheting?

#crochet#crochet is all muscle memory and feeling so aphantasia shouldn’t affect you too much#(fun fact is I can actually crochet with my eyes closed)#and yeah my yarn grip is all weird#I can post pictures if anyone is interest but basically I do funky things with my ring and pinky finger#I started doing specific stretches to make it easier and now I have 180 degrees of motion in all of my knuckles

65 notes

·

View notes

Text

I don't know who needs to hear this, but

YOU DO NOT NEED TO START A NEW HOBBY!

STEP AWAY FROM THE TEXTILES!

YOU DON'T NEED MORE YARN!

THAT FABRIC IS NOT CALLING TO YOU! LEAVE IT ALONE!

#currently side eyeing the sewing machine I was given last weekend#I’m going to learn a new skill soon#and it’s either hemming my own clothes or cables in knitting#haven’t decided yet

149K notes

·

View notes

Text

I felt like making a doily

168 notes

·

View notes

Text

Throwback to the time when a group of us were trying to troubleshoot why one of my friend’s hexagon cardigan wasn’t coming out like the pictures. It wasn’t until the FOURTH person looked at it, that they counted that there were actually 8 sides, not 6 like everyone else counted

Math is really tiring, im so glad i finally get to relax and do some knitting and crochet and i oh god oh my what the fuck

#so no I cannot count#it’s a running joke now that only one of us can count to 6#and ironically it was the art major#I can do advanced calculus but single digit counting is my weakness

105K notes

·

View notes

Text

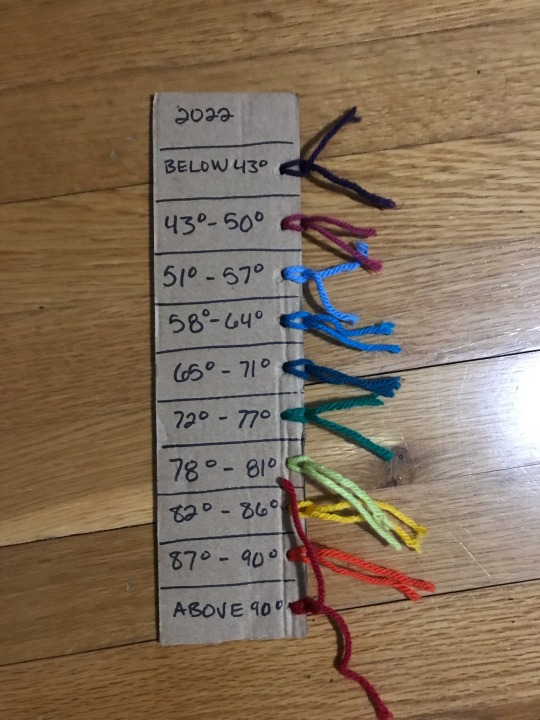

How to crochet a temperature blanket in eight easy steps (with pictures) :

Step 1: choose your colors and set the ranges

Step 2: get started crocheting!

Step 3: hmm. This is only a month and it’s pretty long.

Step 4: maybe a double crochet was the wrong stitch for this

Step 5: haha yeah it’s a little big

Step 6: stop looking at the blanket as a whole.

Step 7: keep crocheting. Ignore the fact that you can no longer easily lift the project. Stop taking pictures of your progress entirely. Keep the finished parts folded so you never really see it all at once.

Step 8: finish and gaze upon the titan you have created.

4K notes

·

View notes

Text

The crochet version of writers block that is Wanting to Crochet, Having Time To Crochet, Having the Yarn You Want To Use, but every single pattern seems wrong

407 notes

·

View notes

Text

Want to learn something new in 2022??

Absolute beginner adult ballet series (fabulous beginning teacher)

40 piano lessons for beginners (some of the best explanations for piano I’ve ever seen)

Excellent basic crochet video series

Basic knitting (probably the best how to knit video out there)

Pre-Free Figure Skate Levels A-D guides and practice activities (each video builds up with exercises to the actual moves!)

How to draw character faces video (very funny, surprisingly instructive?)

Another drawing character faces video

Literally my favorite art pose hack

Tutorial of how to make a whole ass Stardew Valley esque farming game in Gamemaker Studios 2??

Introduction to flying small aircrafts

French/Dutch/Fishtail braiding

Playing the guitar for beginners (well paced and excellent instructor)

Playing the violin for beginners (really good practical tips mixed in)

Color theory in digital art (not of the children’s hospital variety)

Retake classes you hated but now there’s zero stakes:

Calculus 1 (full semester class)

Learn basic statistics (free textbook)

Introduction to college physics (free textbook)

Introduction to accounting (free textbook)

Learn a language:

Ancient Greek

Latin

Spanish

German

Japanese (grammar guide) (for dummies)

French

Russian (pretty good cyrillic guide!)

336K notes

·

View notes

Text

Happy National Bird Day! Here are 4 Crochet Bird Amigurumi Patterns Designed By Tanya Zhylyayeva to mark the day ... get the patterns: 👉 https://buff.ly/35c54cY 🐦

685 notes

·

View notes

Text

I actually figured out how to do this! The trick was that I was so tired that my brain just did both the knitting and reading on autopilot!

I do need to be a certain level of tired or mentally checked out to be able to do this unfortunately

It's so fucked up that I can't easily knit and read at the same time

#I reach new levels or productivity when my brain shuts itself off apparently#I would not recommend this for complex patterns#or just in general honestly

673 notes

·

View notes

Text

"It takes 35,000 stitches to make a pair of socks, so that's 35,000 actions you're doing to produce this item that will hopefully take care of somebody, it's kind of like magic." 🔮✨🐇🧶❤️

I love this project - they complete UFOs left behind by loved ones.

9K notes

·

View notes

Text

The dreidel is done and it can actually spin!!! I’ll get the pattern up soon

690 notes

·

View notes

Photo

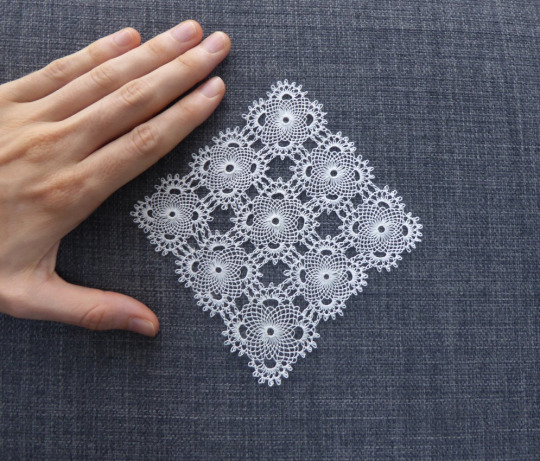

needle lace

881 notes

·

View notes

Text

Knit a Hat That Looks Like a Bob Ross Painting ... 👉 https://buff.ly/3pZYcbx

#knitting#hat#knitting patterns#I feel like I need a tag specifically for all of the weird stuff knithacker posts

1K notes

·

View notes

Note

explain to me how gears are machined!

wohaohowhao. gears are impossibly difficult to fabricate. way, way beyond what people might expect looking at them. “oh, it is just a shape, it is simple” - imbeciles. morons

this will be VERY LONG and i am doing most of you idiots a favor by putting this here:

i’m not going to go over what a gear is or what it does, but i will be making some assumptions:

pinions are not gears

gears are made out of metal (steel)

hobs don’t exist (they’re cheating and rob you of a nuanced understanding of what goes into a proper gear)

if you tried to machine some gears “freehand” you would never actually end up creating something that can truthfully called a gear -- the best you could do is a spoked wheel with maybe 5-7% efficiency

gears are complicated to machine for 3 primary reasons

geometrical limits -- gears are circles (squat cylinders if we’re being precise) with a finite number of equally-spaced teeth at their peripheries. in order for two gears to mate (mesh, “come together”, etc) they must have exactly the same tooth geometry (e.g. exactly the same size) and exactly the same spacing between the teeth

it’s not apparent at first, but this is a pretty limiting set of requirements. remember, two identical meshed gears are not very useful; a 1:1 gear ratio just sort of transfers power from over here to over there. you usually want a big gear driving a small gear, or vice versa. since your gear tooth size and spacing is fixed, you have a greatly reduced set of gear diameters you can work with, since in order to fit one extra tooth on a gear, you have to jump up a corresponding diameter increment, and can’t use any diameters in-between. you are also restricted by a tooth/diameter minimum, i.e., you can’t have a 1 or 2 tooth gear, which is something that a computer scientists might not realize at first glance

so, this isn’t too bad altogether, you just have to do your homework before cutting some gears. don’t worry, it gets worse

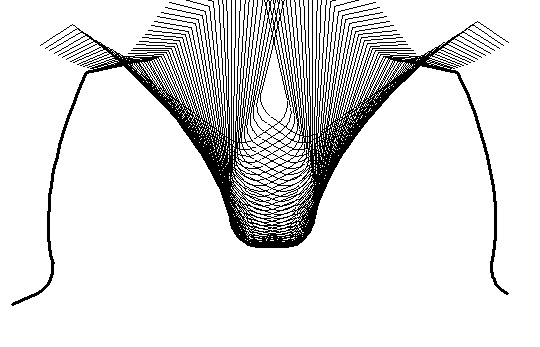

tooth geometry - you might think that there are all sorts of different tooth shapes you can employ to get all sorts of results, but you’d be wrong (idiot), there is only one tooth shape:

the involute of a circle, two pictured above. don’t worry about what that means. yes i know what this shape resembles.

if you don’t cut your teeth to exactly this shape (which, btw, changes according to the diameter of the gear they’re cut into) you will not evenly transmit power between gears, which is to say your gears won’t spin at a steady RPM. this is because your fucked up wrongteeth will be slamming into each other & knocking each other into free space that should be filled by goodteeth. look:

the blue dot and red dot (respectively) in the above images represent the point of contact (thus the point of power transmission) between the two gears at any given point in time. remember, gears are metal, metal is hard, the total area of surface contact between two pieces of metal is usually hilarious small (because metal does not “give” or “soften” to normalize a traveling path of contact, and due to all of this, the point of contact between two meshed gear teeth has to travel evenly and without interruption -- just as the blue and red dots above. why? i need to digress for a second.

gear teeth can’t just whack into each other. this isn’t carpentry. gears are used to transmit power up to the order thousands of tons per revolution. they’re made out of extremely hard martensitic steel that doesn’t handle large impluse shocks very well. if you slam martensite around hard enough, it will shatter (not “bend”, or more precisely deform elastically/plastically) and if slammed around under load, it will fucking explode. again, consider the colossal amount of power being transmitted, divided by the minimal area of surface contact between two gear teeth, and you get pressures sometimes several times what exists in the core of the earth. when the tooth that is holding this pressure suddenly shatters, all that energy is released into bits of broken gear tooth that’ll cut through you like a knife through butter, that will cut through a cast iron chassis like a knife through butter, not even noticing it

but not only that -- even with indestructible handwavium gears your teeth can’t slam into each other because that scenario requires there to be uneven empty space between gear teeth, allowing unmitigated travel in, possibly, the wrong fricken direction. this kills your efficiency incredibly quickly: sudden changes in a gear’s rotational speed oppose that gear’s nominal momentum, i.e., gears that don’t spin at a constant RPM require energy to slow down/speed up as they deviate. that energy comes from your input power, which should be transferred to the driven gear, but instead is powering zero-sum deviations in spin rate. additionally, incidences of tooth contact following a period of no contact between two gears (e.g. tooth contact beginning at any point in time other than the last moment the previous two gear teeth were in contact) (e.g. two teeth slamming into each other) see a massive reduction in power transfer as most of that energy goes into friction between the teeth instead of transmitting power mechanically -- instead of the two teeth coming together steadily, you have the driving gear tooth speed up during the period of no contact only to slam into the driven gear tooth, spalling off metal from the tooth surface and heating it from the friction (sparks). these two things will drop your efficiency to less than 10%, usually on the lower side of that, but that doesn’t matter, because if your gear teeth are slamming together they’re about to explode anyway

but ok, first we solved the issue of “how do i even design working gears considering the geometrical limits”, and now we’ve solved the issue of “what extremely weird and specific shape do i make the gear teeth so my gear train does anything other than explode spectacularly/immediately” and now we can move on to

rotational compounding error, machining precision, offset -- this is the real killer, what makes machining gears truly difficult.

let’s digress again

gears are made out of metal, and people who make things out of metal are machinists, and do so using machines. when you’re machining metal, and you’re in america, you operate using two units: the mil (1/1000th of an inch which is about the smallest discrete movement a professional [piano player, diemaker, anything that requires precise small hand movements] can make with their hands consciously. the tip of a needle is around 100 mils) and the tenth (one tenth of one mil, or 1/10,000th of an inch). these are inconceivably & imperceptibly small units.

the first step to machining a gear involves cutting a perfect circle. you start with barstock, that is, a rod of metal whose diameter is a bit above what the final gear diameter should be. stock that comes out of the steel mill may look round, but it’s not, remember, we’re working in thousands of an inch here, just appearing round won’t cut it.

we stick the stock in the lathe and turn it concentric (into a perfect circle) and cut off a “slice” with a thickness as close to the design as possible without going under. we now have a squat cylinder whose edges are perfectly circular but whose faces aren’t flat enough nor square enough with the round edges. easy -- we stick it face down onto the surface grinder, grind a side flat, flip it over, grind the other side flat and then until its the right thickness. now, we have a perfectly circular, perfectly square cylinder of the right dimensions. now to cut the teeth!

here is where things get tricky and you need special hardware. you cut involute teeth using a special mill tool which you move the workpiece through axially at it’s periphery as to machine the void between two teeth -- on your second pass, you will have machined two voids leaving a perfect tooth between them. but, once you’ve made your first pass, you have to rotate the workpiece, and holy shit. you cannot be off by even 1/100th of a degree. these are perhaps the most sensitive and crucial cuts you’ll be doing, because your error adds up and if it’s too high, you’ll go to cut that last tooth and realize you still have extra surface space, or go to cut the last tooth and realize you don’t have enough space. either of these will result in a totally useless gear that won’t complete a single rotation before exploding. the solution is to mount the gear in a dividing head which allows for extremely precise, but more importantly, extremely repeatable rotations in the workpiece

machining gears requires precision on the level of mils & tenths described above, and this is due to how error compounds in a unidirectionally rotating system -- gears. normal gears rotate in one direction, clockwise or counterclockwise, continuously, without reversing. during one rotation, any error, any deviation from the design model incurred during machining translates to some positive or negative “extra” rotation. that is to say, as the first rotation of the gear occurs there is some “extra” force that causes the gear to “want” to rotate a little more or a little less than one full rotation. but here’s the kicker:

upon the beginning of the second rotation, that erroneous “extra” force remains. upon the completion of the second rotation, that “extra” force has now doubled. the error forces accrue, constructively because the gear is always spinning in the same direction, never reversing, and the error (geometric deviations from design model) is unchanging. gear trains that explode after maybe a dozen or so rotations aren’t very useful,

so what do we do ? hell, why does it even matter that we fabricate the gears to such tight tolerances if any deviation/error whatsoever leads to a functionally useless, doomed gear ?

the answer is simply to machine perfectly with no error wait no that is impossible. we need some slip space to allow accrued error force vectors to dissipate, but this is extremely precarious, as slip space both causes gear teeth to slam into each other as the point of contact between teeth doesn’t move evenly and also reduces the total tooth-contact travel distance meaning that all the force that is transferred now occurs over a shorter distance, multiplying the pressure between the teeth accordingly

“but wait ian you said that the teeth can’t slam into each other ever” -- yes, you’re right. how do we provide empty slip space between teeth without disrupting a continuous & even power transmission surface? the answer is fricken extremely calculated error analysis & gear offset

imagine you have two compatible gears and you mesh them together as hard as possible such that the teeth engage with each other as deeply as possible -- no empty space whatsoever -- this is zero gear offset. now lets say you pull them apart, to some arbitrarily large degree, but not so much that the teeth no longer engage with each other -- this is too much gear offset -- the teeth slam together and explode. but what if we very arduously and scientifically analyze and test our machining equipment as to accurately quantify the error they will impart to gears they machine and use that figure to calculate a gear offset that perfectly opposes erroneous forces ?

something beautiful happens

your slip space is perfectly large enough to dissipate all the error-borne forces, not a hair too big and not a hair too small. the gear teeth stay in contact evenly, they don’t slam into each other, and no error forces compound and cause the gears to explode. finally, a working gear: a monumental achievement that can only be properly appreciated when looked at through an engineer’s lens. proper gear trains can achieve up to like 99% efficiency (!!!) which is unheard of -- wings on a 747 commercial passenger jet are like 10% efficient, your car’s internal combustion engine is about 37% efficient.

7K notes

·

View notes

Text

"Knitted chair set #4604", taken from Chair Backs by the American Thread Company, 1947. These kind of lacy decorations (either knitted, tatted, or crocheted) were used to cover worn out spots on the chair arms, and to prevent sweat/oil from the sitter's neck and scalp from staining the back.

The book can be read for free in entirety here, courtesy of Project Gutenberg.

22 notes

·

View notes

Text

You may have heard of pilk (pepsi milk) but have you heard of evermilk? It’s a concoction my friends created that’s everclear mixed with milk. Surprisingly, it was described as “not as bad as you’d expect, but still not good”

#one of my friends walked in and said give me the worst thing you have#and then proceeded to drink a glass of evermilk#I didn’t try it because fuck that#but a bunch of people did and all but one said it wasn’t gross#pilk#evermilk#the joys of college

3 notes

·

View notes

Text

I've heard fiber art communities can be fucking nuts, but I just had one person I ordered yarn from local send me an email apologizing profusely about the fact my order would be a day late because she had to take her father to the hospital ( he's fine, thankfully), and earlier had another yarn seller worried I'd be upset the yarn I'd ordered from her was from two different animals, grown two different years.

The fuck did I get myself into?

14K notes

·

View notes