Don't wanna be here? Send us removal request.

Text

How Can MST Fiber Distribution Terminal Assembly Transform Your FTTH Network Deployment

Fiber to the Home (FTTH) networks expand rapidly worldwide, with labor shortages and rising costs challenging operators. The MST Fiber Distribution Terminal Assembly, featuring a black plastic MST terminal enclosure for fiber cab and weatherproof MST fiber distribution box for FTTH n, streamlines deployment.

Factor Details Labor Costs Labor forms 60-80% of deployment costs. Installation Complex permitting and varied strategies increase timelines. The outdoor fiber optic MST terminal assembly with 8 p supports efficient, scalable rollouts in diverse environments.

Key Takeaways

The MST Fiber Distribution Terminal Assembly cuts labor needs by arriving pre-connectorized, allowing quick plug-and-play installation without complex splicing or special skills. Its modular design and factory-sealed enclosure lower costs by reducing installation time, maintenance, and the need for expensive equipment, helping operators scale networks efficiently. With flexible mounting options and strong environmental protection, the MST assembly ensures reliable, fast FTTH deployment in diverse settings, from cities to rural areas.

MST Fiber Distribution Terminal Assembly: Solving FTTH Deployment Challenges

Addressing Labor Shortages with MST Fiber Distribution Terminal Assembly Telecommunications industry surveys highlight several common FTTH deployment challenges: Cost constraints Technical expertise shortages Service disruption mitigation Quality assurance Community collaboration Labor shortages, especially the lack of skilled fiber splicing technicians, often slow FTTH rollouts. The MST Fiber Distribution Terminal Assembly, developed by Dowell, directly addresses this issue. The terminal arrives pre-connectorized and factory-sealed, eliminating the need for on-site splicing. Installers do not need to open the enclosure or perform complex fiber work in the field. This approach reduces the demand for specialized labor and minimizes training requirements. The MST Fiber Distribution Terminal Assembly features plug-and-play installation, allowing teams to connect drop cables quickly and securely. No terminal re-entry is required, which further reduces maintenance visits and labor hours. Multiple port and splitter options enable a single technician to serve many subscribers in one visit, streamlining the deployment process. Dowell’s user-friendly packaging and universal mounting bracket support rapid installation in diverse environments, from urban poles to rural handholes. These features collectively help operators overcome workforce shortages and accelerate network expansion. Reducing High Costs Using MST Fiber Distribution Terminal Assembly Cost remains one of the most significant barriers to FTTH deployment. Operators face high expenses related to labor, materials, and ongoing maintenance. The MST Fiber Distribution Terminal Assembly helps control these costs in several ways: Pre-terminated Design: The terminal arrives ready for installation, reducing the need for expensive field splicing equipment and skilled labor. Scalable Modular Options: Multiple port configurations (2, 4, 6, 8, or 12 ports) and internal splitters allow operators to match current needs and scale up as demand grows, avoiding unnecessary upfront investment. Reduced Maintenance: The factory-sealed, environmentally protected enclosure minimizes the risk of damage and service interruptions, lowering long-term maintenance costs. Efficient Deployment: Plug-and-play installation and flexible mounting options reduce installation time, which translates to lower labor costs and faster time-to-market. Feature MST Fiber Distribution Terminal Assembly Details Connector Technology Hardened connectors, factory-terminated, environmentally sealed Ingress Protection Rating IP68 (water and dust resistant) Operating Temperature Range -40°C to +85°C Cable Tensile Strength Up to 1200N long term Installation Options Wall-mounting, aerial, pole installation Dowell’s MST Fiber Distribution Terminal Assembly meets or exceeds industry standards for environmental protection and durability, ensuring a long service life and protecting the operator’s investment. Simplifying Installation Complexity with MST Fiber Distribution Terminal Assembly Traditional FTTH installations often involve complex splicing, multiple enclosure entries, and specialized tools. These factors increase the risk of errors and slow down deployment. The MST Fiber Distribution Terminal Assembly simplifies this process through its modular, pre-terminated design. Plug-and-play connections eliminate the need for field splicing. Hardened adapters and factory-sealed enclosures protect fiber connections from dust, moisture, and temperature extremes. Multiple mounting options (pole, pedestal, handhole, strand) provide flexibility for any deployment scenario. User-friendly packaging allows for easy cable management and unspooling during installation. Operators can deploy the MST Fiber Distribution Terminal Assembly in a wide range of environments, from dense urban areas to remote rural locations, with minimal disruption to existing services. Dowell’s solution supports rapid network upgrades and expansions, enabling operators to respond quickly to growing broadband demand. The modular design allows for incremental network growth without major infrastructure changes, making it easier to future-proof FTTH networks for emerging technologies.

MST Fiber Distribution Terminal Assembly: Accelerating and Enhancing FTTH Rollouts

Enabling Rapid Network Expansion with MST Fiber Distribution Terminal Assembly Network operators need solutions that support fast, scalable growth in both urban and rural areas. The MST Fiber Distribution Terminal Assembly enables rapid expansion through several key features: Pre-connected with hardened adapters, eliminating the need for fiber splicing and reducing installation complexity. Available in configurations from 2 to 12 ports, supporting customized network requirements and easy scalability. Robust IP67 waterproof rating and high mechanical strength ensure reliable operation in harsh environments. Flexible installation options, including wall, pole, aerial, and pedestal mounting, adapt to diverse deployment scenarios. Factory-sealed or field-assembled options provide project flexibility. Plug-and-play design and centralized connection points simplify deployment and maintenance, saving up to 40% in installation time. These advantages allow operators to expand FTTH networks efficiently, meeting the demands of both dense cities and remote communities. Improving Reliability and Service Quality through MST Fiber Distribution Terminal Assembly Service providers prioritize reliability and high-quality connections. The MST Fiber Distribution Terminal Assembly supports these goals by: Offering multiple output ports for distributing signals to many destinations, which enhances scalability and flexibility. Maintaining minimal signal loss through efficient signal management, preserving network performance. Supporting advanced features such as signal amplification and wavelength management, which help reduce downtime. Utilizing a rugged, weatherproof design that protects fiber connections from environmental hazards, ensuring consistent service even in extreme weather. These features help operators deliver dependable broadband with fewer interruptions and higher customer satisfaction. MST Fiber Distribution Terminal Assembly vs. Traditional Fiber Distribution Methods Aspect MST Fiber Distribution Terminal Assembly Traditional Fiber Distribution Methods Installation Efficiency Plug-and-play, pre-connectorized; reduces installation time by ~40% Requires field splicing; more complex and time-consuming Scalability Supports high-density connectors and splitters; customizable port counts Limited scalability; less flexible Environmental Durability IP67/IP68 rated; robust against weather and physical damage Often less robust; may lack high IP ratings Deployment Flexibility Multiple mounting options; supports FTTH, FTTA, 5G Fewer mounting options; less adaptable Signal Attenuation Reduced by factory pre-termination and fewer connection points Higher due to multiple splices Service Provisioning Enhanced by 15–30% due to simplified design Lower efficiency; manual splicing required The MST Fiber Distribution Terminal Assembly stands out for its efficiency, scalability, and durability, making it a superior choice for modern FTTH deployments. Operators gain a powerful tool for efficient FTTH deployment. In Anacortes, Washington, city staff maintained fiber rollout momentum during the pandemic by using MST terminals for no-contact installations. This approach supported community resilience and economic growth. MST solutions help networks adapt quickly to changing demands. By: Eric Tel: +86 574 27877377 Mb: +86 13857874858 E-mail: [email protected] Youtube: DOWELL Pinterest: DOWELL Facebook: DOWELL Linkedin: DOWELL Read the full article

0 notes

Text

How Can MST Fiber Distribution Terminal Assembly Transform Your FTTH Network Deployment

Fiber to the Home (FTTH) networks expand rapidly worldwide, with labor shortages and rising costs challenging operators. The MST Fiber Distribution Terminal Assembly, featuring a black plastic MST terminal enclosure for fiber cab and weatherproof MST fiber distribution box for FTTH n, streamlines deployment.

Factor Details Labor Costs Labor forms 60-80% of deployment costs. Installation Complex permitting and varied strategies increase timelines. The outdoor fiber optic MST terminal assembly with 8 p supports efficient, scalable rollouts in diverse environments.

Key Takeaways

The MST Fiber Distribution Terminal Assembly cuts labor needs by arriving pre-connectorized, allowing quick plug-and-play installation without complex splicing or special skills. Its modular design and factory-sealed enclosure lower costs by reducing installation time, maintenance, and the need for expensive equipment, helping operators scale networks efficiently. With flexible mounting options and strong environmental protection, the MST assembly ensures reliable, fast FTTH deployment in diverse settings, from cities to rural areas.

MST Fiber Distribution Terminal Assembly: Solving FTTH Deployment Challenges

Addressing Labor Shortages with MST Fiber Distribution Terminal Assembly Telecommunications industry surveys highlight several common FTTH deployment challenges: Cost constraints Technical expertise shortages Service disruption mitigation Quality assurance Community collaboration Labor shortages, especially the lack of skilled fiber splicing technicians, often slow FTTH rollouts. The MST Fiber Distribution Terminal Assembly, developed by Dowell, directly addresses this issue. The terminal arrives pre-connectorized and factory-sealed, eliminating the need for on-site splicing. Installers do not need to open the enclosure or perform complex fiber work in the field. This approach reduces the demand for specialized labor and minimizes training requirements. The MST Fiber Distribution Terminal Assembly features plug-and-play installation, allowing teams to connect drop cables quickly and securely. No terminal re-entry is required, which further reduces maintenance visits and labor hours. Multiple port and splitter options enable a single technician to serve many subscribers in one visit, streamlining the deployment process. Dowell’s user-friendly packaging and universal mounting bracket support rapid installation in diverse environments, from urban poles to rural handholes. These features collectively help operators overcome workforce shortages and accelerate network expansion. Reducing High Costs Using MST Fiber Distribution Terminal Assembly Cost remains one of the most significant barriers to FTTH deployment. Operators face high expenses related to labor, materials, and ongoing maintenance. The MST Fiber Distribution Terminal Assembly helps control these costs in several ways: Pre-terminated Design: The terminal arrives ready for installation, reducing the need for expensive field splicing equipment and skilled labor. Scalable Modular Options: Multiple port configurations (2, 4, 6, 8, or 12 ports) and internal splitters allow operators to match current needs and scale up as demand grows, avoiding unnecessary upfront investment. Reduced Maintenance: The factory-sealed, environmentally protected enclosure minimizes the risk of damage and service interruptions, lowering long-term maintenance costs. Efficient Deployment: Plug-and-play installation and flexible mounting options reduce installation time, which translates to lower labor costs and faster time-to-market. Feature MST Fiber Distribution Terminal Assembly Details Connector Technology Hardened connectors, factory-terminated, environmentally sealed Ingress Protection Rating IP68 (water and dust resistant) Operating Temperature Range -40°C to +85°C Cable Tensile Strength Up to 1200N long term Installation Options Wall-mounting, aerial, pole installation Dowell’s MST Fiber Distribution Terminal Assembly meets or exceeds industry standards for environmental protection and durability, ensuring a long service life and protecting the operator’s investment. Simplifying Installation Complexity with MST Fiber Distribution Terminal Assembly Traditional FTTH installations often involve complex splicing, multiple enclosure entries, and specialized tools. These factors increase the risk of errors and slow down deployment. The MST Fiber Distribution Terminal Assembly simplifies this process through its modular, pre-terminated design. Plug-and-play connections eliminate the need for field splicing. Hardened adapters and factory-sealed enclosures protect fiber connections from dust, moisture, and temperature extremes. Multiple mounting options (pole, pedestal, handhole, strand) provide flexibility for any deployment scenario. User-friendly packaging allows for easy cable management and unspooling during installation. Operators can deploy the MST Fiber Distribution Terminal Assembly in a wide range of environments, from dense urban areas to remote rural locations, with minimal disruption to existing services. Dowell’s solution supports rapid network upgrades and expansions, enabling operators to respond quickly to growing broadband demand. The modular design allows for incremental network growth without major infrastructure changes, making it easier to future-proof FTTH networks for emerging technologies.

MST Fiber Distribution Terminal Assembly: Accelerating and Enhancing FTTH Rollouts

Enabling Rapid Network Expansion with MST Fiber Distribution Terminal Assembly Network operators need solutions that support fast, scalable growth in both urban and rural areas. The MST Fiber Distribution Terminal Assembly enables rapid expansion through several key features: Pre-connected with hardened adapters, eliminating the need for fiber splicing and reducing installation complexity. Available in configurations from 2 to 12 ports, supporting customized network requirements and easy scalability. Robust IP67 waterproof rating and high mechanical strength ensure reliable operation in harsh environments. Flexible installation options, including wall, pole, aerial, and pedestal mounting, adapt to diverse deployment scenarios. Factory-sealed or field-assembled options provide project flexibility. Plug-and-play design and centralized connection points simplify deployment and maintenance, saving up to 40% in installation time. These advantages allow operators to expand FTTH networks efficiently, meeting the demands of both dense cities and remote communities. Improving Reliability and Service Quality through MST Fiber Distribution Terminal Assembly Service providers prioritize reliability and high-quality connections. The MST Fiber Distribution Terminal Assembly supports these goals by: Offering multiple output ports for distributing signals to many destinations, which enhances scalability and flexibility. Maintaining minimal signal loss through efficient signal management, preserving network performance. Supporting advanced features such as signal amplification and wavelength management, which help reduce downtime. Utilizing a rugged, weatherproof design that protects fiber connections from environmental hazards, ensuring consistent service even in extreme weather. These features help operators deliver dependable broadband with fewer interruptions and higher customer satisfaction. MST Fiber Distribution Terminal Assembly vs. Traditional Fiber Distribution Methods Aspect MST Fiber Distribution Terminal Assembly Traditional Fiber Distribution Methods Installation Efficiency Plug-and-play, pre-connectorized; reduces installation time by ~40% Requires field splicing; more complex and time-consuming Scalability Supports high-density connectors and splitters; customizable port counts Limited scalability; less flexible Environmental Durability IP67/IP68 rated; robust against weather and physical damage Often less robust; may lack high IP ratings Deployment Flexibility Multiple mounting options; supports FTTH, FTTA, 5G Fewer mounting options; less adaptable Signal Attenuation Reduced by factory pre-termination and fewer connection points Higher due to multiple splices Service Provisioning Enhanced by 15–30% due to simplified design Lower efficiency; manual splicing required The MST Fiber Distribution Terminal Assembly stands out for its efficiency, scalability, and durability, making it a superior choice for modern FTTH deployments. Operators gain a powerful tool for efficient FTTH deployment. In Anacortes, Washington, city staff maintained fiber rollout momentum during the pandemic by using MST terminals for no-contact installations. This approach supported community resilience and economic growth. MST solutions help networks adapt quickly to changing demands. By: Eric Tel: +86 574 27877377 Mb: +86 13857874858 E-mail: [email protected] Youtube: DOWELL Pinterest: DOWELL Facebook: DOWELL Linkedin: DOWELL Read the full article

0 notes

Text

How the FTTA 8 Port Waterproof Terminal Box Solves Outdoor Fiber Connectivity Challenges

The outdoor fiber cable market has surged, driven by the need for robust broadband and 5G infrastructure. Dowell’s FTTA 8 Port Waterproof Terminal Box stands out as an IP65 rated 8 port fiber optic cable termination bo. This outdoor 8 port fiber distribution box waterproof design ensures network reliability. Users trust this waterproof fiber optic terminal box with 8 ports for demanding environments.

Key Takeaways

The FTTA 8 Port Waterproof Terminal Box offers strong protection against water, dust, and harsh weather, ensuring fiber connections stay safe and reliable outdoors. Its simple, flexible design makes installation easier and faster, reducing costs and the need for specialized skills or tools. Easy access and organized cable management help technicians perform quick maintenance, minimizing network downtime and supporting long-term performance.

Outdoor Fiber Connectivity Challenges and the FTTA 8 Port Waterproof Terminal Box

Weather and Environmental Hazards Outdoor fiber optic installations face a range of environmental threats. Flooding, urban runoff, and natural disasters such as earthquakes, tornadoes, and wildfires can disrupt network infrastructure. Polluted floodwaters and toxic fumes from burning cable materials present additional hazards during recovery. UV radiation and temperature extremes also impact the longevity of fiber components. UV rays cause cable jackets to crack or become brittle, while temperature fluctuations can compromise seals and lead to material degradation. Outdoor fiber solutions must withstand these conditions to ensure reliable performance. Common environmental hazards include: Flooding and urban runoff carrying chemicals and debris Natural disasters with unpredictable impacts Polluted water and electrical hazards during recovery UV exposure and temperature extremes causing material fatigue Installation and Deployment Difficulties Deploying fiber optic terminal boxes outdoors introduces several challenges. Improper installation can result in broken cables, signal loss, and increased vulnerability to environmental damage. Excessive bending, defective connectors, and inadequate transmitting power often lead to network failures. High installation costs and a shortage of skilled professionals further complicate deployment, especially in remote areas. Durable, weatherproof enclosures like the FTTA 8 Port Waterproof Terminal Box help address these issues by simplifying installation and reducing the need for specialized tools. Maintenance and Accessibility Issues Maintenance of outdoor fiber terminal boxes often encounters obstacles such as moisture ingress, corrosion, and cable damage from poor management. Degraded seals allow water inside, leading to signal loss. Corrosion from salt and pollution damages metal parts, while overcrowding limits future upgrades. User-friendly access to internal components enables quicker repairs and reduces network downtime. Features like modular design and robust construction, as found in the FTTA 8 Port Waterproof Terminal Box, support efficient maintenance and long-term reliability. Network Reliability and Performance Network reliability depends on both environmental resilience and proper installation. Wired fiber connections offer higher stability and lower latency compared to wireless alternatives. However, outdoor conditions such as extreme weather, temperature swings, and physical impacts can degrade connectors and equipment, causing signal loss or interruptions. Protective measures, including weatherproof enclosures and regular maintenance, are essential. The FTTA 8 Port Waterproof Terminal Box provides a rugged solution that maintains signal integrity and supports stable network performance in challenging environments.

How the FTTA 8 Port Waterproof Terminal Box Overcomes Outdoor Fiber Issues

Superior Waterproof and Dustproof Protection Dowell’s FTTA 8 Port Waterproof Terminal Box delivers exceptional protection against water and dust, making it ideal for harsh outdoor environments. The enclosure meets the IP65 and IP68 standards, ensuring that fiber connections remain secure even during heavy rain or dust storms. The box’s construction from high-quality PC+ABS material provides resistance to aging and environmental wear, extending the lifespan of network infrastructure. The product’s compliance with ISO9001 demonstrates adherence to international quality management standards. These certifications confirm the terminal box’s suitability for demanding outdoor applications. The fully enclosed structure, sealed cable entries, and reinforced adapters work together to prevent moisture and dust ingress, safeguarding critical fiber connections. Note: The FTTA 8 Port Waterproof Terminal Box stands out by meeting both IP65 and IP68 ratings, offering higher protection than many competing products. Design Feature Description Material PC+ABS, anti-aging, wet-proof material for environmental resistance. Protection Rating IP65 and IP68 rated for high-level waterproof and dustproof protection. Cable Entry Diameter Sealed entries from 8-14mm to prevent ingress of dust and moisture. Flip-Up Distribution Panel Allows easy access for maintenance without compromising waterproof seal. Integrated Cable Management Organizes cables to prevent dust and moisture ingress and maintain performance. Simplified and Flexible Installation Features Dowell designed the FTTA 8 Port Waterproof Terminal Box for straightforward installation in various outdoor scenarios. The box includes wall mounting kits, screws, cable ties, and heat shrink protective sleeves, making deployment convenient and efficient. Technicians can mount the box on walls, poles, or strands, adapting to different site requirements. The simplified design allows non-expert technicians to install the terminal box with up to 40% higher efficiency compared to traditional enclosures. Features such as anti-torsion cable glands and internal strain relief protect cables during installation, reducing the risk of damage. The plug-and-play design eliminates the need for specialized splicing tools, lowering labor costs and minimizing installation errors. Installation accessories provided: Wall mounting kits Screws and cable ties Heat shrink protective sleeves Flexible mounting options: Wall-mounted Pole-mounted Strand-mounted Tip: The FTTA 8 Port Waterproof Terminal Box supports both armored and non-armored cables, accommodating a range of cable diameters for versatile deployment. Easy Maintenance and Serviceability The FTTA 8 Port Waterproof Terminal Box features a flip-up distribution panel, allowing technicians to access internal components quickly for repairs or upgrades. This design eliminates the need to detach the entire box from the network, reducing operational downtime. Clearly labeled ports simplify identification, making troubleshooting and maintenance more efficient. Dowell’s all-in-one design integrates fiber clamping, splicing, fixing, storage, and distribution. Dedicated channels keep cables, pigtails, and patch cords organized and independent, streamlining maintenance and minimizing the risk of accidental damage. The robust PC+ABS enclosure and IP65-rated structure ensure durability, supporting reliable long-term use in outdoor environments. Callout: Versatile mounting options and a scalable design allow seamless integration and future-proofing, enabling hassle-free upgrades and repairs. Enhanced Network Stability and Performance Network stability remains a top priority for outdoor fiber deployments. The FTTA 8 Port Waterproof Terminal Box achieves this through a combination of mechanical strength, ingress protection, and advanced cable management. The enclosure withstands pulling forces up to 1200N, thanks to armored cable and strength member fixation. Torsion-proof cable glands relieve mechanical stress, preventing fiber breakage during installation and operation. The box’s design minimizes the number of connecting nodes, reducing signal loss and enhancing overall network stability. High-strength materials and an arc interface design provide shock resistance, maintaining normal operation in harsh conditions. The terminal box supports both 4G and 5G networks, ensuring compatibility with high-speed data transmission requirements. Performance Metric Description Ingress Protection IP68 rating ensures waterproofing and dust resistance, protecting internal components. Mechanical Strength Withstands pulling force of 1200N, ensuring durability under stress. Signal Integrity Reduces signal loss by minimizing connecting nodes, supporting stable network performance. Installation Efficiency Increases efficiency by 40%, reducing human error and downtime. Additional features supporting performance: Bending radius of 20D reduces cable stress and prevents fiber damage. Pre-assembled waterproof cable assemblies minimize signal attenuation. Splice protection sleeves and PLC splitters can be securely mounted inside for flexible network configurations. Dowell’s FTTA 8 Port Waterproof Terminal Box provides a comprehensive solution for outdoor fiber connectivity, combining robust protection, easy installation, and reliable performance. The FTTA 8 Port Waterproof Terminal Box stands out as a practical choice for outdoor fiber connectivity. Operators benefit from a warranty of up to 10 years and 24/7 technical support. Key features include IP65-rated protection, versatile mounting, and low insertion loss. This solution ensures reliable performance in any environment. By: Eric Tel: +86 574 27877377 Mb: +86 13857874858 E-mail: [email protected] Youtube: DOWELL Pinterest: DOWELL Facebook: DOWELL Linkedin: DOWELL Read the full article

0 notes

Text

Fiber Optic Splice Closures: A Utility Company’s Secret to Rapid Repairs

Utility companies rely on Fiber Optic Splice Closures to deliver fast repairs and maintain stable service. These closures protect sensitive fiber connections from harsh environments. Their robust design supports swift, secure restoration of network function. Quick deployment reduces costly downtime, ensuring reliable communication for customers and critical infrastructure.

Key Takeaways

Fiber optic splice closures protect delicate fiber connections from harsh weather and damage, ensuring stable and reliable network service. Their smart design allows quick access and easy repairs, helping utility companies reduce costly downtime and restore service fast. Using modular, weatherproof closures and following best practices like proper sealing and testing leads to longer-lasting networks and lower maintenance costs.

Fiber Optic Splice Closures: Function, Features, and Importance

What Are Fiber Optic Splice Closures? Fiber optic splice closures serve as protective enclosures for fiber optic cable splices. Utility companies use these closures to shield sensitive fiber connections from environmental hazards such as moisture, dust, and extreme temperatures. Manufacturers construct these closures from high-strength plastics or stainless steel, ensuring durability and waterproof performance. Each closure contains a main body, splice trays for organizing fibers, sealing elements to keep out contaminants, cable glands for secure entry, and mounting brackets for installation. Sealing mechanisms like gels, gaskets, and pull-and-shrink tubing maintain the integrity of the internal splices. This robust construction allows for installation in aerial, underground, and indoor environments, making fiber optic splice closures a versatile solution for network protection. Core Functions: Protection and Organization Fiber optic splice closures play two critical roles in utility networks: protection and organization. They enclose fiber splices in a rugged, sealed housing, preventing damage from water, dust, and mechanical stress. Splice trays inside the closure keep fibers neatly organized, reducing the risk of tangling or breakage. Strain relief hardware secures cables, minimizing stress on the fibers during installation and maintenance. Service loops of excess fiber are stored inside or near the closure, allowing for easier future repairs or upgrades. Different closure types—such as dome, in-line, aerial, and pedestal—support various installation environments and cable entry needs. Proper cable preparation, grounding, and sealing ensure long-term network integrity. Tip: Neat fiber management inside closures, especially dome types, simplifies re-entry and reduces the risk of fiber damage during network modifications. Dowell, a leading provider in the industry, designs fiber optic splice closures that integrate advanced organization features. Their closures often include modular splice trays and patch panel adapters, enhancing both protection and cable management for utility networks. Key Features for Rapid Repairs: Accessibility, Weatherproofing, and Modularity Rapid repairs depend on the accessibility and design of fiber optic splice closures. Compression seal technology and O-ring sealing allow for easy assembly and watertight protection. Many closures require no specialized tools for installation or access, enabling technicians to work efficiently in the field. Mid-access designs let installers add closures over existing cables with minimal disturbance. Hinged splice trays, unibody storage baskets, and removable components improve access to spliced fibers, reducing repair time. Weatherproofing stands as a crucial feature. Closures use durable outer shells, elastic rubber rings, and dome-shaped designs to protect against rain, snow, UV radiation, and physical damage. These features ensure that fiber connections remain intact and functional, even in harsh conditions. Industry standards such as IEC 61753 and IP68 ratings confirm their ability to withstand water, dust, and temperature extremes. Modularity further accelerates repairs and upgrades. Modular closures support a wide range of fiber capacities and allow independent work on individual components. This design simplifies installation, maintenance, and network expansion. Dowell’s modular closures, for example, enable easy assembly, scalability, and compatibility with existing systems, making them a preferred choice for utility companies seeking efficient network management. Why Speed Matters: Impact of Downtime and Need for Fast Response Network downtime can have a severe financial impact on utility companies. According to the ITIC 2024 Hourly Cost of Downtime survey, large enterprises in the utilities sector face average downtime costs exceeding $5 million per hour. This high cost highlights the importance of rapid response and efficient repairs. Fiber optic splice closures help minimize downtime by enabling quick access and streamlined repairs. Accessibility features—such as re-enterable housings, numbered port layouts, and easy-to-use connectors—reduce the complexity and duration of fieldwork. These closures also support fast troubleshooting and maintenance, even in challenging environments like aerial or underground installations. Note: Fast, reliable repairs not only save money but also ensure continuous service for critical infrastructure and customers. By choosing advanced fiber optic splice closures from trusted suppliers like Dowell, utility companies can maintain high network reliability, reduce repair times, and protect their bottom line.

Fiber Optic Splice Closures in Utility Operations

Real-World Scenarios: Emergency Repairs and Outage Response Utility companies often face emergencies that threaten network stability. The Matanuska Telephone Association (MTA) in Alaska provides a notable example. After a 7.1 magnitude earthquake, MTA used fiber optic splice closures as part of its emergency restoration plan. These closures enabled rapid repairs for both aerial and underground cables. Proper sealing prevented water ingress and fiber stress, while OTDR testing verified restoration quality. This approach minimized network damage and restored service quickly. Compared to alternatives, breathable closures offer fast installation—typically within 45 minutes—and cost-effective protection for fusion splices. Their design reduces labor and speeds up outage response, making them ideal for urgent repairs. Choosing the Right Fiber Optic Splice Closure: Durability, Capacity, and Compatibility Selecting the right closure ensures long-term network reliability. Utility companies evaluate durability by choosing closures made from engineering plastics like ABS or PC, or high-strength aluminum alloy for outdoor use. These materials resist corrosion, aging, and impact. Sealing materials such as rubber and silicone provide waterproof and dustproof protection. Compliance with GR-771-CORE standards confirms environmental durability. Capacity and compatibility also matter. Closures must accommodate the required number of fibers and support various cable types and splicing methods. The table below compares two common closure types: Closure Type Fiber Capacity Ideal Applications Advantages Limitations Horizontal (In-Line) Up to 576 Aerial, underground High density, linear layout Needs more space Vertical (Dome) Up to 288 Pole-mounted, subsurface Compact, water-deflecting design Lower capacity than in-line Dowell offers closures that meet these criteria, ensuring compatibility and durability for diverse utility networks. Best Practices for Fast Deployment and Maintenance Efficient deployment starts with careful planning and site surveys. Technicians prepare cables, perform fusion splicing, and organize fibers in trays. Proper sealing with heat-shrink tubing or gel technology ensures environmental protection. OTDR testing verifies splice quality. Regular inspections and cleaning prevent contamination and maintain performance. Technician training, such as hands-on emergency restoration courses, reduces errors and speeds up repairs. Dowell supports these best practices by providing modular, user-friendly closures that simplify installation and maintenance. Fiber Optic Splice Closures help utility companies minimize downtime and maintain reliable service. These closures feature modular designs, advanced weatherproofing, and high splice capacity, which support rapid, effective repairs. Advanced Feature Benefit for Utilities Modular Design Faster repairs and easier upgrades Improved Sealing Fewer outages from environmental damage Utility companies that follow best practices report lower maintenance costs and longer closure lifespans.

FAQ

What is the typical lifespan of a fiber optic splice closure? Most closures last 20 years or more. Manufacturers design them to withstand harsh weather, UV exposure, and physical stress. Can technicians re-enter a closure for future repairs or upgrades? Yes. Many closures feature re-enterable designs. Technicians can open them for maintenance, upgrades, or troubleshooting without damaging the internal fibers. How do utility companies test the integrity of a splice closure after installation? Technicians use OTDR (Optical Time Domain Reflectometer) testing. This tool checks for signal loss, confirming proper splicing and sealing. By: Eric Tel: +86 574 27877377 Mb: +86 13857874858 E-mail: [email protected] Youtube: DOWELL Pinterest: DOWELL Facebook: DOWELL Linkedin: DOWELL Read the full article

0 notes

Text

Why Fiber Optic Splitters Are the Backbone of Modern FTTH Networks

A fiber optic splitter distributes optical signals from a single source to many users. This device supports point-to-multipoint connections in FTTH networks. The fiber optic splitter 1x2, fiber optic splitter 1x8, multimode fiber optic splitter, and plc fiber optic splitter all provide reliable, passive signal delivery.

Key Takeaways

Fiber optic splitters share one high-speed internet signal with many users, making networks efficient and reliable. Using splitters lowers costs by reducing cables, installation time, and power needs, simplifying network setup and maintenance. Splitters allow easy network growth by adding more users without major changes, supporting both small and large deployments.

Fiber Optic Splitter Fundamentals

What Is a Fiber Optic Splitter? A fiber optic splitter is a passive device that divides a single optical signal into multiple signals. Network engineers use this device to connect one input fiber to several output fibers. This process allows many homes or businesses to share the same high-speed internet connection. The fiber optic splitter does not require power to operate. It works well in both indoor and outdoor environments. How Fiber Optic Splitters Work The fiber optic splitter uses a special material to split light signals. When light enters the device, it travels through the splitter and exits through several output fibers. Each output receives a portion of the original signal. This process ensures that every user gets a reliable connection. The splitter maintains signal quality, even as it divides the light. Note: The efficiency of a fiber optic splitter depends on its design and the number of outputs. Types of Fiber Optic Splitters Network designers can choose from several types of fiber optic splitters. The two main types are Fused Biconical Taper (FBT) splitters and Planar Lightwave Circuit (PLC) splitters. FBT splitters use fused fibers to split the signal. PLC splitters use a chip to divide the light. The table below compares these two types: Type Technology Typical Use FBT Fused fibers Small split ratios PLC Chip-based Large split ratios Each type offers unique benefits for different FTTH network needs.

Fiber Optic Splitter Roles and Benefits in FTTH Networks

Efficient Signal Distribution A fiber optic splitter enables a single optical signal to reach many users. This device divides the light from one fiber into several outputs. Each output delivers a stable and high-quality signal. Service providers can connect multiple homes or businesses without installing separate fibers for each location. This approach ensures efficient use of network resources. Tip: Efficient signal distribution reduces the need for extra cables and equipment, making network management easier. Cost Savings and Simplified Infrastructure Network operators often choose a fiber optic splitter to lower costs. By sharing one fiber among many users, companies save on both material and labor expenses. Fewer cables mean less digging and less time spent on installation. Maintenance becomes simpler because the network has fewer points of failure. The passive nature of the splitter also eliminates the need for electrical power, which further reduces operational costs. Key cost-saving benefits include: Lower installation expenses Reduced maintenance needs No power requirements Scalability and Flexibility for Network Growth Fiber optic splitters support network growth with ease. Providers can add new users by connecting more output fibers to the splitter. This flexibility allows networks to expand as demand increases. The modular design of splitters fits both small and large deployments. Service providers can upgrade or reconfigure the network without major changes to the existing infrastructure. Technical Features for Modern Deployments Modern fiber optic splitters offer advanced features that meet today’s network demands. These devices maintain signal quality even when splitting the light into many outputs. They resist environmental changes such as temperature and humidity. Splitters come in different sizes and configurations, including rack-mounted and outdoor models. This variety allows engineers to select the best option for each project. Feature Benefit Passive operation No external power needed Compact design Easy installation High reliability Consistent performance Wide compatibility Works with many network types Real-World FTTH Application Scenarios Many cities and towns use fiber optic splitters in their FTTH networks. For example, a service provider may install a 1x8 splitter in a neighborhood. This device connects one central office fiber to eight homes. In apartment buildings, splitters distribute internet to each unit from a single main line. Rural areas also benefit, as splitters help reach distant homes without extra cables. Note: Fiber optic splitters play a key role in delivering fast and reliable internet to both urban and rural communities. A fiber optic splitter helps deliver fast, reliable internet to many homes. Network providers trust this device for its efficiency and cost savings. As more people need high-speed connections, this technology remains a key part of modern FTTH networks. Reliable networks depend on smart solutions like fiber optic splitters.

FAQ

What is the typical lifespan of a fiber optic splitter? Most fiber optic splitters last over 20 years. They use durable materials and require little maintenance in both indoor and outdoor environments. Can fiber optic splitters affect internet speed? A splitter divides the signal among users. Each user receives a portion of the bandwidth. Proper network design ensures everyone gets fast, reliable internet. Are fiber optic splitters difficult to install? Technicians find splitters easy to install. Most models use simple plug-and-play connections. No special tools or power sources are needed. By: Eric Tel: +86 574 27877377 Mb: +86 13857874858 E-mail: [email protected] Youtube: DOWELL Pinterest: DOWELL Facebook: DOWELL Linkedin: DOWELL Read the full article

0 notes

Text

Fire-Rated Fiber Optic Enclosures: Compliance for Commercial Buildings

Fire-Rated Fiber Optic Enclosures help commercial buildings meet strict fire safety codes. These enclosures, including Fiber Optic Splice Closure and Vertical Splice Closure, block fire from spreading through cable routes. A 3 Way Fiber Optic Enclosure or Vertical Heat-Shrink Joint Closure also protects network equipment and keeps fire barriers strong.

Key Takeaways

Fire-rated fiber optic enclosures protect buildings by blocking fire, smoke, and heat from spreading through cable routes, helping meet strict fire safety codes. Choosing the right enclosure means matching fire resistance ratings, certifications, and materials to the building’s environment and code requirements. Proper installation, labeling, and regular maintenance ensure long-term safety, compliance, and protection of critical network infrastructure.

Fire-Rated Fiber Optic Enclosures: Definition and Role

What Are Fire-Rated Fiber Optic Enclosures Fire-Rated Fiber Optic Enclosures serve as protective housings for fiber optic cables in commercial buildings. Manufacturers design these enclosures to withstand high temperatures and block the passage of flames, heat, and smoke. By sealing cable penetrations in fire-resistance rated walls, floors, and ceilings, these enclosures help maintain the integrity of fire-rated barriers. Specialized products, such as intumescent blocks and fire protection plugs, address irregular or hard-to-reach cable pathways. These solutions reinforce compromised drywall or concrete, keeping fire and smoke contained within designated compartments. This containment extends evacuation time and limits fire spread, which is critical for occupant safety. Importance for Commercial Building Compliance Commercial buildings must comply with strict fire safety codes. Fire-Rated Fiber Optic Enclosures play a vital role in meeting these requirements. Non-compliance can result in serious consequences: Denied insurance claims for fire-related losses Increased insurance premiums after inspections Coverage limitations or exclusions Potential policy cancellation for severe violations Fines and citations from regulatory agencies or fire marshals Correction orders that may restrict business operations Emergency repair costs that exceed planned budgets Reputational damage that can last beyond the repair period Non-compliant fire doors and barriers can increase average fire damage costs by about 37% in commercial settings, according to NFPA data. Regulatory authorities may impose fines, citations, or legal actions. Insurance providers often view compliance favorably, which can reduce premiums and liability risks. Fire-Rated Fiber Optic Enclosures help building owners avoid these risks and protect both people and property.

Fire-Rated Fiber Optic Enclosures: Fire Safety Standards and Certifications

NEC Article 770 and NFPA 70 Requirements The National Electrical Code (NEC) Article 770 and NFPA 70 set the foundation for fire safety in fiber optic installations. These codes require that Fire-Rated Fiber Optic Enclosures and cables do not increase the risk of fire or smoke spread within a building. Installers must firestop all penetrations through fire-rated walls, floors, and ceilings using approved methods. This preserves the fire resistance rating of each barrier. Cables must be installed securely, using hardware that avoids damage. In air-handling spaces, nonmetallic cable ties must have low smoke and heat release properties. A key aspect of compliance involves selecting the correct cable type for each building environment. The NEC classifies optical fiber cables by their fire resistance and smoke characteristics. The table below summarizes which cable types are permitted in specific spaces: Cable Type Plenum Riser General Use Ducts/Raceways Shafts OFNP/OFCP Y* Y* Y* Y* Y* OFNR/OFCR N Y* Y* Y* Y* OFNG/OFCG N N Y* N N OFN/OFC N N Y* N N Y indicates permitted use, subject to limitations in NEC sections 770.110 and 770.113. Circuit integrity (CI) cables used for critical systems must meet a minimum two-hour fire rating, tested according to ANSI/UL 2196. These requirements align with additional fire test standards, such as NFPA 262 and UL 1685. Dowell provides Fire-Rated Fiber Optic Enclosures that meet these rigorous standards, supporting safe and compliant installations in commercial buildings. UL, IEC, and ANSI Certifications Certifications from organizations such as UL (Underwriters Laboratories), IEC (International Electrotechnical Commission), and ANSI (American National Standards Institute) validate the fire performance of fiber optic enclosures. UL certification, for example, confirms that enclosures and cables have passed standardized fire resistance and smoke emission tests. IEC standards, including IEC 60332 and IEC 61034, address flame propagation and smoke density for optical fiber cables. ANSI standards, such as ANSI/UL 2196, set benchmarks for circuit integrity during fire exposure. Manufacturers like Dowell design and test their Fire-Rated Fiber Optic Enclosures to meet or exceed these certifications. Building owners and contractors should always verify that products carry the appropriate listings and markings. This ensures that the selected enclosures will perform as required during a fire event and satisfy inspection requirements. Practical Meaning of Compliance Compliance with fire safety standards and certifications delivers real-world benefits for commercial buildings. Properly installed and certified Fire-Rated Fiber Optic Enclosures help maintain the integrity of fire barriers, limit the spread of flames and smoke, and protect critical network infrastructure. Insurers often require documented compliance before issuing or renewing policies. Regulatory agencies may conduct inspections to verify that all cable penetrations and enclosures meet code requirements. Recent changes in the NEC reflect ongoing efforts to streamline and clarify fire safety rules. The 2026 NEC update moves the content of Article 770 into new articles within the limited-energy systems section. This organizational change does not alter the core requirements for fire-rated enclosures but highlights the importance of staying current with evolving codes. Dowell remains committed to providing up-to-date solutions that help clients achieve and maintain compliance. Tip: Regularly review code updates and product certifications to ensure ongoing compliance and avoid costly retrofits or penalties.

Fire-Rated Fiber Optic Enclosures: Materials and Construction

Fire-Resistant Materials (Plenum, PVC/Riser, LSZH) Manufacturers select materials for fiber optic enclosures based on fire resistance and safety requirements. Plenum, PVC/riser, and LSZH (Low Smoke Zero Halogen) materials each offer distinct fire ratings. Plenum-rated cables, marked as OFNP, provide the highest flame retardancy and are essential in air handling spaces. These cables use materials like fluorinated ethylene polymer (FEP) or specialized PVC, which limit flame spread and produce minimal smoke. LSZH cables contain no halogens, so they emit very little smoke and no toxic gases during combustion. This feature makes LSZH ideal for confined or public spaces where smoke inhalation poses a significant risk. PVC/riser cables, labeled OFNR, are suitable for vertical runs between floors but have lower fire resistance and higher toxicity due to halogen content. Feature PVC/Riser Cable Plenum Cable LSZH Cable Flame Resistance Average Very Good Good Self-Extinguish Poor Very Good Good Halogen Content Contains Halogens Contains Halogens* Halogen-Free Smoke Production Higher Very Low Very Low Toxicity Higher Lower Lowest *Note: Some plenum cables are halogen-free but generally contain halogens. Construction Methods for Fire Rating Engineers design enclosures to meet strict fire resistance standards. Tests such as UL 94 and PH120 evaluate how materials behave under fire conditions. A V-0 rating under UL 94 means the material self-extinguishes quickly and does not drip flaming particles. PH120 certification ensures the enclosure protects internal hardware for up to 120 minutes during a fire. Manufacturers use vertical and horizontal burn tests, mechanical shock, and water spray simulations to verify performance. These methods ensure that enclosures maintain their integrity and protect network components during fire exposure. Comparison of Enclosure Options Selecting the right enclosure involves balancing durability, fire resistance, installation ease, and cost. Plenum cables offer the highest fire rating and durability, making them suitable for air handling spaces but at a higher price. Riser cables provide moderate fire resistance and are easier to install in vertical shafts. LSZH cables excel in low smoke and toxicity, ideal for sensitive environments, though they are not direct substitutes for plenum cables. Outdoor cables, such as PE, resist weather but lack indoor fire ratings. Cable Type Durability Fire Resistance Ease of Installation Cost Considerations Plenum High Highest Requires compliance More expensive Riser Durable Moderate Easier in risers Less expensive LSZH Durable Good Specialized areas More expensive PE (Outdoor) High Not suitable Outdoor only Varies

Tip: Always match enclosure materials and ratings to the building’s fire safety requirements and installation environment for optimal protection and compliance.

Fire-Rated Fiber Optic Enclosures: Selection Criteria

Building Code and Regulatory Considerations Every commercial building must follow local, state, and national fire safety codes. Authorities such as the National Fire Protection Association (NFPA) and the International Building Code (IBC) set strict rules for cable management and fire barrier integrity. Inspectors often check if Fire-Rated Fiber Optic Enclosures meet these standards. Building owners should review the following before selecting an enclosure: Fire Resistance Rating: The enclosure must match or exceed the fire rating of the wall, floor, or ceiling it penetrates. Certification Requirements: Products should carry recognized certifications, such as UL or IEC, to ensure compliance. Documentation: Proper records of installation and product specifications help during inspections and insurance reviews. Note: Local codes may have unique requirements. Always consult with a licensed fire protection engineer or code official before finalizing product selection. Environmental and Application Factors The environment where the enclosure will be installed plays a major role in product selection. Different spaces in a commercial building present unique challenges. For example, air handling spaces require plenum-rated materials, while riser shafts need riser-rated products. Moisture, temperature, and exposure to chemicals can also affect performance. Key environmental and application factors include: Location: Indoor, outdoor, plenum, riser, or general use areas Temperature Range: Some enclosures must withstand extreme heat or cold Moisture and Corrosion Resistance: Wet or humid environments require enclosures with special seals or coatings Mechanical Protection: High-traffic or industrial areas may need reinforced enclosures A table can help compare environmental needs: Application Area Required Rating Environmental Challenge Recommended Feature Plenum Spaces Plenum (OFNP) Airflow, smoke control Low smoke, flame retardant Riser Shafts Riser (OFNR) Vertical fire spread Self-extinguishing Outdoor Areas UV/Weather Resistant Sun, rain, temperature Sealed, UV-stable Industrial Zones Impact Resistant Vibration, dust, chemicals Reinforced, gasketed Matching Features to Project Needs Selecting the right Fire-Rated Fiber Optic Enclosures involves more than just code compliance. Project managers must balance safety, performance, and budget. The following checklist can guide the decision-making process: Assess the Building Layout: Identify all fire-rated barriers and cable pathways. Determine Required Ratings: Match enclosure ratings to the fire resistance of each barrier. Evaluate Cable Types: Choose enclosures compatible with plenum, riser, or LSZH cables as needed. Consider Future Expansion: Select enclosures with extra capacity for future cable additions. Review Installation Requirements: Some enclosures offer tool-less entry or modular designs for faster installation. Check Maintenance Needs: Easy-access panels and clear labeling simplify inspections and repairs. Tip: Involve IT, facilities, and safety teams early in the planning process. Their input ensures the selected enclosures meet both technical and regulatory needs. A well-chosen enclosure protects network infrastructure, supports code compliance, and reduces long-term costs. Fire-Rated Fiber Optic Enclosures provide peace of mind for building owners and occupants by combining safety with reliable performance.

Fire-Rated Fiber Optic Enclosures: Installation and Maintenance

Installation Best Practices Proper installation ensures both safety and code compliance. Installers should follow these best practices: Select cables and raceways that meet NEC Article 770 requirements. Firestop every penetration of fire-rated walls, partitions, floors, or ceilings. Always follow manufacturer instructions and NEC 300.21. Restore the integrity of any fire barrier after making penetrations for fiber optic installations. Use plenum-rated cables and raceways in environmental air spaces, such as above suspended ceilings or below raised floors. Support cables with the building’s structural components and approved fittings. Avoid using ceiling grids or ceiling-support wires. Arrange cables neatly and in a workmanlike manner to comply with NEC 770.24. This also ensures easy access for future maintenance. Position above-ceiling cables so that suspended ceiling panels can be moved without obstruction, preventing code violations. Tip: Careful planning before installation reduces the risk of costly corrections and ensures long-term reliability. Labeling and Documentation Requirements Accurate labeling and thorough documentation help maintain compliance and simplify future inspections. Each enclosure and cable should display clear, durable labels that indicate fire rating, installation date, and cable type. Installers should maintain detailed records, including product certifications, installation diagrams, and fire barrier restoration details. Organized documentation supports smooth inspections and insurance claims. Inspection and Ongoing Maintenance Routine inspections keep systems safe and compliant. Facility teams should check enclosures for physical damage, label legibility, and barrier integrity. Maintenance schedules should include periodic testing of firestopping materials and prompt repair of any deficiencies. Regular reviews ensure that all components continue to meet evolving code requirements. Fire-Rated Fiber Optic Enclosures support compliance and protect vital infrastructure in commercial buildings. These enclosures prevent fire and toxic gas spread, offer durable protection against environmental hazards, and help reduce insurance costs. Their use enhances operational continuity and risk management for building owners. Protects critical components for up to four hours Reduces maintenance needs Supports installation in diverse environments By: Eric Tel: +86 574 27877377 Mb: +86 13857874858 E-mail: [email protected] Youtube: DOWELL Pinterest: DOWELL Facebook: DOWELL Linkedin: DOWELL Read the full article

0 notes

Text

Exploring What Sets OptiTap Waterproof Fiber Optic Adapter Apart for Outdoor Applications

The OptiTap waterproof fiber optic adapter from Corning sets a new standard for outdoor connectivity. This Waterproof Optic Adapter features robust engineering. The Corning Optitap SC waterproof fiber optic adapter delivers reliable performance in harsh environments. Hardened Corning Optitap adapter for outdoor fiber installations ensures network stability. Waterproof single-mode Corning Optitap connector a supports diverse network needs.

Key Takeaways

The OptiTap adapter offers superior protection with an IP68 rating, making it fully dustproof and waterproof for reliable outdoor use in harsh conditions. Its durable, corrosion-resistant, and UV-stable design ensures long-lasting performance even under extreme weather and sunlight exposure. The adapter supports quick, tool-free installation and broad compatibility with various fiber types and connectors, saving time and reducing costs.

OptiTap Waterproof Fiber Optic Adapter: Unmatched Protection and Durability

IP68 Waterproof and Dustproof Performance The OptiTap waterproof fiber optic adapter stands out with its IP68 rating, which exceeds the industry standard for outdoor fiber optic adapters. Many competing products, such as the Fiber Optic Mini SC Waterproof Adapter, only achieve an IP67 rating. The IP68 rating ensures complete protection against dust ingress and allows the adapter to withstand continuous immersion in water. This level of environmental sealing makes the OptiTap waterproof fiber optic adapter ideal for challenging outdoor conditions, where dust and moisture often threaten network reliability. Note: The IP68 rating of the OptiTap adapter provides a higher level of dustproof and waterproof protection compared to most outdoor adapters, ensuring stable performance even in the harshest environments. Feature Corning OptiTap SC Hardened Adapter IP Rating IP68 (higher dust and water protection) Durability Designed for harsh outdoor environments Environmental Sealing Meets highest environmental standards with sealed housing Dustproof Performance Superior to many other outdoor adapters rated IP67 Application Suitable for challenging outdoor conditions Dowell recognizes that environmental hazards can cause common failure modes in outdoor fiber optic adapters, such as water ingress and dust contamination. The robust sealing system of the OptiTap waterproof fiber optic adapter addresses these risks, ensuring long-term reliability for outdoor network deployments. Corrosion-Resistant and UV-Stable Construction Corning engineers the OptiTap waterproof fiber optic adapter with advanced materials that resist corrosion and UV degradation. The adapter features a hardened outdoor-grade plastic shell, which withstands acid, alkali, and chemical exposure. This construction ensures that the adapter maintains its mechanical integrity and optical performance over time, even when exposed to harsh outdoor elements. Material Type Description Hardened outdoor-grade plastic Provides corrosion resistance and durability in harsh outdoor environments IP68-rated sealing Ensures protection against water, dust, and environmental hazards including corrosion Rugged construction Designed to withstand extreme weather conditions, enhancing corrosion resistance The OptiTap waterproof fiber optic adapter also incorporates special plastic materials certified for UV resistance according to ISO 4892-3. This UV stability prevents material degradation from prolonged sunlight exposure, which is essential for outdoor installations such as FTTH and 5G networks. The adapter’s UV-resistant design ensures that it continues to deliver reliable connectivity, even after years of service in direct sunlight. Tip: UV stability and corrosion resistance are critical for outdoor fiber optic adapters. The OptiTap waterproof fiber optic adapter’s advanced materials help network operators like Dowell achieve long-lasting, maintenance-free performance. Engineered for Extreme Temperatures and Weather Outdoor fiber optic networks often face extreme temperature fluctuations and severe weather. The OptiTap waterproof fiber optic adapter operates reliably within a wide temperature range, from -40°C to +85°C. This capability ensures stable performance in both freezing winters and scorching summers. Source Operating Temperature Range Carefiber -40°C to +85°C Fiberroom -40°C to +85°C The adapter’s rugged design resists not only temperature extremes but also mechanical stress, humidity, and physical impacts. Corning’s engineering ensures that the adapter maintains low insertion loss and high return loss, preserving signal integrity in all weather conditions. Dowell leverages these features to support robust outdoor network deployments, minimizing the risk of signal degradation due to environmental factors. The adapter’s precise fiber end-face alignment maximizes optical energy coupling, reducing signal loss. The ceramic connection interface and auxiliary sealing components further enhance stability and environmental resistance. Network operators trust the OptiTap waterproof fiber optic adapter for its proven ability to withstand the toughest outdoor environments, ensuring uninterrupted connectivity for critical applications.

OptiTap Waterproof Fiber Optic Adapter: Installation, Compatibility, and Real-World Applications

Tool-Free, Plug-and-Play Installation Network operators demand fast, reliable installations, especially in outdoor environments where time and weather are critical factors. The OptiTap waterproof fiber optic adapter delivers a true plug-and-play experience. Technicians can complete installation in under two minutes, a significant improvement over traditional fiber splicing methods that often require 20 to 40 minutes per drop. This efficiency results from the factory-terminated design and tool-free connection process. Feature OptiTap Installation Time Traditional Fiber Splicing Installation Time Installation Time Under 2 minutes 20 to 40 minutes per drop Dowell leverages this rapid deployment capability to accelerate project timelines and reduce labor costs. The adapter’s compact form factor and intuitive design allow for easy integration into wall outlets, panels, and outdoor enclosures. Field technicians appreciate the reduction in specialized training and equipment, which further streamlines network expansion and maintenance. Tip: Quick, tool-free installation not only saves time but also minimizes the risk of installation errors, ensuring consistent network performance. Broad Compatibility with Fiber Types and Connectors The OptiTap waterproof fiber optic adapter supports a wide range of fiber types and connector standards, making it a versatile solution for diverse network architectures. It accommodates Mini SC/APC connectors and integrates seamlessly with Corning equipment. The adapter operates across a wavelength range of 1260–1650nm, which aligns with single-mode fiber applications commonly found in FTTH, FTTB, and FTTx networks. Dowell selects the OptiTap waterproof fiber optic adapter for its ability to support both hybrid and non-hybrid cables. The adapter fits round cables with outer diameters from 5.0mm to 14mm and flat cables with dimensions up to 4.6x8.9mm. This broad compatibility surpasses many traditional outdoor adapters, which often have more limited cable support. Feature/Specification OptiTap Waterproof Fiber Optic Adapter Traditional Outdoor Adapters Cable Types Supported Hybrid and non-hybrid Less flexible Round Cable OD 5.0mm to 14mm Narrower range Flat Cable Dimensions 4.0x7.0mm to 4.6x8.9mm Often not supported Connector Types SC/APC, MPO, LC Limited options Waterproof Rating IP68 Comparable or lower Operational Efficiency Saves 40% operating time Less efficient This flexibility allows Dowell to deploy the adapter in a variety of outdoor scenarios, from aerial and pole-mounted installations to underground and direct burial applications. The adapter’s compliance with IEC 61753-1 standards ensures high reliability and performance, even in the most demanding environments. Proven Performance in FTTH, 5G, and Harsh Outdoor Deployments The OptiTap waterproof fiber optic adapter has demonstrated outstanding performance in real-world deployments. In large-scale urban FTTH projects, Dowell has used the adapter to reduce installation times and project costs, leading to higher customer satisfaction. The adapter’s IP68 waterproof rating and rugged construction ensure durability and environmental adaptability, which are critical for outdoor fiber networks. FTTH (Fiber to the Home): Enables rapid, tool-free subscriber connections without the need for fusion splicing. This feature is ideal for last-mile deployments, where speed and reliability are essential. 5G and Small Cell Backhaul: Provides robust, weatherproof fiber links for antenna-to-network interfaces in 5G and small cell networks. Rural Fiber Networks: Offers scalable, cost-effective solutions for underserved areas, supporting both hybrid and non-hybrid cable types. Outdoor Distribution Boxes: Simplifies plug-and-play terminations in outdoor terminals, handholes, and distribution cabinets. Emergency Communications: Supports rapid deployment for disaster recovery and field operations in challenging environments. Telecom Towers and Municipal Broadband: Used in FTTA (Fiber to the Antenna) and municipal broadband networks, where weatherproof, hardened connections are required. Note: The OptiTap waterproof fiber optic adapter maintains low insertion loss (≤0.20 dB) and high return loss (≥60 dB), ensuring excellent signal integrity in both indoor and outdoor environments. Dowell’s field experience confirms the adapter’s ability to withstand mechanical stress, temperature extremes, and high humidity. The design supports up to 1000 mating cycles and endures repeated drops and cable tension, making it a reliable choice for mission-critical outdoor networks. Network operators choose this adapter for its proven durability, reliable signal transmission, and easy installation. Key Differentiator Description Durable and Resilient Design Hardened construction withstands harsh conditions, ensuring reliable outdoor performance. Optimized Signal Transmission Low insertion loss and high return loss support efficient data transfer. Compatibility with Fiber Types Supports single-mode and multimode fibers for versatile applications. Easy Installation and Maintenance User-friendly design reduces downtime and operational costs. The adapter’s certifications, robust warranty, and 24/7 support further ensure long-lasting, dependable outdoor connectivity. By: Eric Tel: +86 574 27877377 Mb: +86 13857874858 E-mail: [email protected] Youtube: DOWELL Pinterest: DOWELL Facebook: DOWELL Linkedin: DOWELL Read the full article

0 notes

Text

How the 16 Port Waterproof Terminal Box Improves Fiber Network Reliability in 2025

The 16 Port Waterproof Terminal Box delivers robust protection for fiber connections in demanding environments. Network operators rely on the high capacity 16 fiber FTTH distribution box for f to shield infrastructure from moisture and dust. The Easy install 16 port FTTH fiber terminal box with advanced sealing technology ensures stable performance. Many prefer the 16 port outdoor FTTH fiber optic access terminal b for critical deployments.

Key Takeaways

The 16 Port Waterproof Terminal Box protects fiber networks from water, dust, and physical damage with its IP65-rated, durable PC+ABS enclosure, ensuring reliable outdoor performance. Advanced cable management and easy maintenance features speed up installation and reduce downtime, making network upkeep simpler and more cost-effective. Its robust design and flexible installation options help network operators maintain stable, future-ready fiber connections in harsh environments.

Outdoor Fiber Challenges and the Role of the 16 Port Waterproof Terminal Box

Outdoor fiber networks in 2025 face a range of environmental and operational threats. Dowell’s 16 Port Waterproof Terminal Box provides a robust solution, engineered to overcome these challenges and ensure reliable fiber connectivity in the most demanding conditions. Moisture and Water Ingress Protection Moisture ingress remains one of the most significant threats to outdoor fiber networks. When seals degrade, water can penetrate the enclosure, causing signal loss, corrosion, and even complete network outages. According to industry standards, fiber optic terminal boxes must use high-impact plastics like ABS or polycarbonate and achieve a high IP rating to resist water and dust. The IP65 rating, defined by IEC 60529, ensures the enclosure is dust-tight and protected against low-pressure water jets, making it suitable for outdoor use. IP Rating Protection Level Typical Application IP54 Limited dust, splashing water Indoor use IP65 Dust-tight, low-pressure water jets Outdoor use IP66 Heavy water jets Harsh outdoor IP67 Temporary immersion Flood-prone areas IP68 Continuous submersion Underground/underwater Dowell’s 16 Port Waterproof Terminal Box meets and exceeds these requirements, providing a secure barrier against water ingress. Its robust sealing and high-quality PC+ABS construction ensure long-term protection, even in extreme weather conditions. This level of defense is critical for FTTH and 5G deployments, where network reliability is non-negotiable.

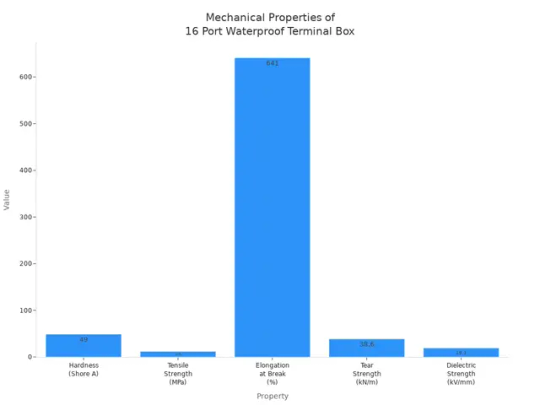

Defense Against Dust and Particle Contamination Dust and particle contamination can degrade fiber performance by settling on connector endfaces, causing signal attenuation and increased maintenance. Outdoor installations face multiple contamination sources: Airborne dust and debris from the environment Static electricity attracting particles Oils and lint from human contact Residues from dust caps and packaging Migration of contaminants during connector mating The 16 Port Waterproof Terminal Box achieves an IP65 dustproof rating, aligning with industry benchmarks for outdoor fiber distribution. This rating ensures complete protection against dust ingress, maintaining clean internal conditions and reducing the risk of signal loss. Dowell’s design also incorporates sealing gaskets and UV-stabilized materials, further minimizing contamination risks during installation and operation. Resistance to Physical Damage and Environmental Stress Outdoor fiber terminal boxes must withstand a variety of physical and environmental stresses. Common threats include: Humidity and salt corrosion, especially in coastal regions UV radiation and temperature fluctuations, which can weaken materials Ice formation inside cables during cold weather Wildlife interference and accidental damage from construction Acts of God, such as severe storms or accidental cuts from external activities Type of Damage / Environmental Stress Impact Dowell’s Design Features Humidity and Salt Corrosion Corrosion of metal parts Corrosion-resistant metals, PC+ABS housing UV Radiation and Temperature Fluctuations Material degradation UV-resistant plastics Cold Weather and Ice Formation Fiber bending, water freezing Waterproof seals, moisture barriers Wildlife and Construction Damage Mechanical damage Reinforced enclosure, robust mounting Moisture and Dust Signal degradation Seals, gaskets, IP65 rating Dowell’s 16 Port Waterproof Terminal Box demonstrates high resilience in standardized impact and stress tests. With a tensile strength of 11.8 MPa and elongation at break of 641%, the enclosure resists puncture, wear, and fatigue. The product’s certifications (ISO9001:2015, ISO14001, OHSAS18001) further validate its durability and manufacturing quality.

Power Integration and Advanced Cable Management Modern outdoor fiber deployments often require integrated power management to support active equipment. Key benefits include: Support for AC & DC power, breakers, battery storage, and surge protection Reliable operation of remote outdoor cabinets Enhanced resilience against power interruptions Simplified maintenance with organized power and fiber components in one enclosure Dowell’s 16 Port Waterproof Terminal Box also features advanced cable management. The flip-up distribution panel and multi-layer splicing trays separate feeder and drop cables, reducing the risk of kinks and bends. Quick-release designs and tool-free access speed up installation and maintenance. Proper cable alignment improves airflow and system reliability, while unique interlocking grooves prevent tangling and damage. These features can reduce cable management time by up to 60%, lowering maintenance costs and ensuring future-ready scalability. Tip: Efficient cable management not only speeds up installation but also minimizes long-term maintenance, making the network more reliable and cost-effective.

Key Features of the 16 Port Waterproof Terminal Box in 2025

IP65 Waterproof and Dustproof Enclosure The 16 Port Waterproof Terminal Box from Dowell features an IP65-rated enclosure that delivers robust protection for fiber optic connections. The enclosure is dust-tight and shields internal components from water jets, making it ideal for outdoor and industrial environments. The fully enclosed structure prevents dust and water ingress, supporting reliable operation in both indoor and outdoor settings. The box operates within a wide temperature range from -40°C to +85°C and tolerates humidity up to 85%. This level of protection ensures stable performance in FTTH networks, commercial buildings, and outdoor fiber deployments. Durable PC+ABS Construction for Longevity Dowell engineers the 16 Port Waterproof Terminal Box with high-quality PC+ABS material. This construction provides: Resistance to moisture, dust, and aging Impact resistance and antirust properties Stable performance and a long lifespan, even in harsh outdoor environments The PC+ABS material meets RoHS and REACH standards, reducing environmental impact while ensuring mechanical protection. Integrated Cable Management and Flexible Installation Efficient cable management is essential for network reliability. The terminal box supports: Multiple installation methods, including wall, pole, and aerial mounting Organized cable routing with 2 inlet ports and 16 outlet ports Multi-layer trays for selective access during installation and maintenance Storage for up to 2 meters of loose tube per port These features simplify installation, reduce labor costs, and support future network expansion. Proper cable management in the 16 Port Waterproof Terminal Box accelerates troubleshooting by up to 30%, minimizes downtime, and extends equipment life. Enhanced Sealing and Easy Maintenance Access Dowell incorporates advanced sealing technology in the terminal box. The design uses waterproof adapters and mechanical seals to prevent dust and water ingress. Fast insertion methods allow cable fixing and sealing outside the box, enabling quick installation without opening the enclosure. Easy access supports routine inspections, cleaning, and repairs without disrupting network service. Maintenance teams can check connectors, replace seals, and organize fibers efficiently, which helps maintain high network uptime and service reliability. Real-World Application: Outdoor Fiber Deployment Success Network operators deploy the 16 Port Waterproof Terminal Box in diverse environments, from urban FTTH rollouts to rural 5G infrastructure. Its robust construction and flexible installation options ensure reliable performance in challenging conditions. Dowell’s commitment to quality and innovation makes this terminal box a trusted solution for future-ready fiber networks. The 16 Port Waterproof Terminal Box stands out for its robust PC+ABS construction, IP65 protection, and versatile installation options. Network operators benefit from reduced maintenance, stable performance, and future-ready scalability. Industry certifications and advanced cable management ensure reliable operation in harsh outdoor environments. By: Eric Tel: +86 574 27877377 Mb: +86 13857874858 E-mail: [email protected] Youtube: DOWELL Pinterest: DOWELL Facebook: DOWELL Linkedin: DOWELL Read the full article