Elma Electronic specializes in delivering advanced embedded computing solutions that include integrated chassis systems, modular enclosures, board products, and precision hardware components.

Don't wanna be here? Send us removal request.

Text

CMOSS | SOSA | Elma Electronic

Used by the US Army MORA is the U.S. Army DEVCOM C5ISR Center’s architecture for open radio frequency interfaces for ground vehicles. Its purpose is to offer new capabilities, including reducing size, weight, and power (SWaP) and improving interoperability functions within the platform. This 3U OpenVPX development platform provides a 6-slot backplane that supports plug-in card profiles aligned with the SOSA Standard. It supports the latest profiles used to develop systems that follow the hardware requirements of both SOSA and CMOSS

#SOSAAligned#SensorOpenSystemsArchitecture#OpenStandards#ModularOpenSystems#MOSA#CMOSS#OpenVPX#VITA65#InteroperableSystems#EmbeddedDefense#RuggedMissionSystems#C5ISR#MilitaryElectronics#TacticalComputing#DefenseInnovation#ElmaSOSA#SOSACompliance#SOSAPlatform#MissionCritical#ElmaElectronic

0 notes

Text

SOSA Aligned | SOSA Systems

Elma’s SOSA and CMOSS Aligned 12-Slot 3U Development Platform served as the heart of joint efforts by five SOSA Consortium member companies to build and test a fully functioning system aligned to SOSA. These industry partners, that participated in the demo using Elma’s development platforms included Behlman Power, Concurrent Technologies, Crossfield Technology, Curtiss Wright, Interface Concept and Spectranetix (a Pacific Defense company).

#SOSA#SOSAAligned#SOSAStandard#SOSAReady#SOSACompliant#SOSAPlatform#SOSAConsortium#OpenArchitecture#ModularOpenSystems#SOSAIntegration#ElmaSOSA#ElmaOpenVPX#ElmaDefenseSolutions#ElmaMissionSystems#ElmaRuggedPlatforms#ElmaBackplanes#ElmaModularDesign#SOSAByElma#DefenseTechnology#AerospaceComputing#RuggedEmbeddedComputing#TacticalSystems#CMOSS#VPXSystems

0 notes

Text

Rotary Encoders | Elma Electronic

Our famous "Swiss Click Indexing System" featured on all our rotary encoders epitomizes great switching feel. Elma’s engineering services can also customize our standard offerings to suite your individual requirements, even in small quantities.

#embedded software#embedded#electronicssolution#california#hardware#electronics#IncrementalEncoder#DefenseElectronics#EncoderTechnology#CompactEncoders#AbsoluteEncoder#backplanes#embedded systems

0 notes

Text

How Connectivity is Changing in the Face of SOSA

As the SOSA Technical Standard progresses, the recent herculean efforts undertaken by the technical working groups have elevated the standard even further. The additions to Snapshot 3 further define system realizations in accordance with the MOSA directive from the DoD and other government agencies.

Although several factors in systems design, network speeds and power supply requirements have been examined and defined as the SOSA initiative nears its first release, one of the areas most impacted is connectivity. With SOSA Release 1.0 slated for mid-2021, it’s important to take a look at the evolution of the connectivity through Snapshots 1, 2 and 3, paying special attention to the accommodations made for speed increases and data throughput to meet the growing bandwidth needs of applications.

Network Needs in Systems Aligned to SOSA

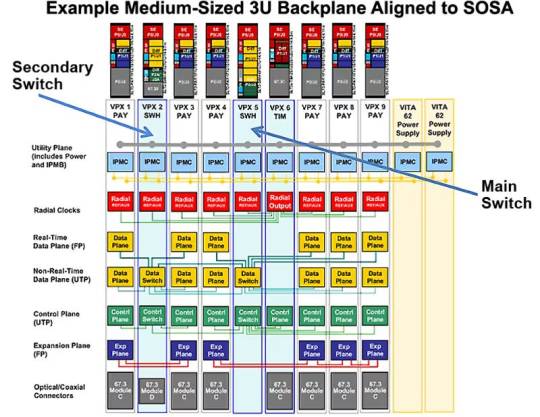

Figure 1: Example of a 3U Backplane Profile with Network Slot Profiles

In fact, SOSA relies extensively on Ethernet networks to pass information between SOSA modules, and currently supports high speed 1/10/40 Gb Ethernet (with 100 Gb in development) as well as low latency and deterministic transfer of data. High speed switches are used to implement Ethernet plug-in card switches.

SOSA systems are comprised of SOSA modules that must communicate. This means that SOSA module interconnects provide facilities to pass information between SOSA modules and physical network interconnects are defined to pass the information between SOSA plug-in cards.

Because the SOSA standard defines plug-in card hardware by OpenVPX VITA 65.0 and VITA 65.1, OpenVPX backplanes implement slots to accept plug-in cards and allow for interconnection between SOSA hardware entities to implement the necessary networks required in SOSA systems.

Network connections are implemented over the in the interconnected pipes found in the backplane, and the pipes are logically organized into various planes in OpenVPX. These connections may be physically implemented in copper in the backplane or externally via fiber optics.

System Requirements Defined by Industry Parameters

Figure 2: Increasing networks speeds have influenced performance attributes in SOSA aligned systems.

The need for this increased performance has influenced several connectivity design factors

A new VPX connector (TE’s RT3) was developed to support speeds of 25+ Gb/s

Module profiles were added to SOSA and OpenVPX to describe the required protocols

VITA 67.3 I/O connectors were updated to support RF contacts and fiber optic MT ferrules

Shift were made in slot profiles for payload & I/O-intensive SBCs as well as for switches and timing slots

Ensuring Connectivity as the SOSA Ecosystem Builds

Given the nature of SOSA, designed to foster interoperability across manufacturers and product technologies, ensuring connectivity within a system is critical.

One notable industry event that clearly demonstrated the strength of the SOSA ecosystem as well as helped validate the interoperability of the SOSA aligned components was the first Tri-Service Open Architecture Interoperability Demonstration (TSOA-ID) event for the media, acquisition community and industry influencers, hosted in January 2020 by the Georgia Tech Research Institute in Atlanta, Georgia.

Elma’s SOSA and CMOSS Aligned 12-Slot 3U Development Platform served as the heart of joint efforts by five SOSA Consortium member companies to build and test a fully functioning system aligned to SOSA. These industry partners, that participated in the demo using Elma’s development platforms included Behlman Power, Concurrent Technologies, Crossfield Technology, Curtiss Wright, Interface Concept and Spectranetix (a Pacific Defense company).

Connectivity needs in systems aligned to SOSA have kept pace with changing market demands, even during the initial stages of the standard’s development. Ensuring reliable throughput for high network speeds creates a path for continued strengthening of SOSA across all branches of the DoD.

Learn more in this informative webinar “How the SOSA Technical Standard Implements Highly Standardized, Configurable and Interoperable Network Communications Protocols”, hosted by Military & Aerospace Electronics, and experts from Elma Electronic, Interface Concept and Pentek.

#embedded systems#embedded software#california#electronicssolution#backplanes#hardware#embedded#SOSAAligned#switches#electronics#fremont#sosa#sosastandard#sosachassis

0 notes

Text

3U VPX Backplane

The winning product is Elma Electronic’s high speed 3U VPX backplane that supports multiple functions including mixed payload modules, single board computers, switches and RF payloads for use by the DoD’s Hardware/Software Convergence Initiative A unique aspect to this backplane is its support of high speed signals on all the data paths as well as leading edge VITA 67.3 connectors compatible with legacy VITA 67.1 and VITA 66.4 RF and optical I/O connectors. According to Elma, this was also the first VPX backplane with a radial slot card for timing and synchronization.

#embedded software#embedded#embedded systems#backplanes#electronicssolution#california#switches#hardware#3u vpx backplane#vpx backplane#vpxchassis#electronics#fremont#vme solutions

0 notes

Text

Upgrades and Enhancements for Legacy VME and CPCI Ethernet Switches

In the past few years, several end-of-life (EOL) announcements in the embedded computing market have both caused angst and opportunity. Making the shift away from a tried-and-true solution always brings with it the need to review not only the mechanical elements of an embedded system, but the integration and networking elements as well. And when that review is forced upon a designer, as in the case of an EOL announcement, it may mean forced choices of not-as-optimum alternatives. Or it could be something different altogether.

EOL is not the only option

One product segment particularly affected is high-performance embedded Ethernet switches in VME, CompactPCI, and VPX form factors. Component availability triggered board-level EOL notices, with some suppliers forced to reduce or eliminate product offerings in some of these form factors.

How Ethernet speeds have evolved

Created in the early 1970s, Ethernet has seen many improvements and enhancements over the past several decades, with the speed of data flow increasing again and again. Today, Gigabit is considered the low-end, with many embedded systems requiring Ethernet connectivity speeds of 10, 25, 40, and even 100 Gigabit. It can even be faster than that, but 10 and 25 Gigabit SERDES lanes, which can be combined in groups of four to form fat pipes supporting 40 GigKr4 and 100 GigKr4, are commonplace in today’s embedded systems market.

In addition, these embedded systems often utilize Ethernet switches when more than a single point-to-point connection is required. The ComEth family of Ethernet switches is a good example of a modern switch that provides the high performance switching and routing features most desired by system integrators. This includes a feature rich switch management application called Switchware that lets the user configure an extensive list of parameters and configuration settings using either a convenient browser interface or Command Line Interface (CLI). Once a switch configuration is created, the configuration file is saved, exported and then loaded onto other switches, facilitating easy configuration across each switch.

System enhancements for VME & CompactPCI

Interfaces such as to VME and CPCI backplanes remain at 1000BaseT speeds due to the limitations of the backplane connectors, although other interfaces, like front panel ports, have been updated to support faster uplink speeds. For example, some ports that supported 1000BaseT in the past now offer a wide range of speeds up to 10 Gig-BaseT capability. Such ports often support 10 and 100 Megabit, Gigabit, 2.5, 5 and 10 Gigabit speeds.

This facilitates overall system enhancements, where other equipment in the system may also need to accommodate bandwidth increases. It is interesting that sometimes Gigabit is not fast enough and 10 Gigabit is more than enough, so these intermediate speeds of 2.5 and 5 Gigabit may help solve the problem of matching the switch’s speed to the needed bandwidth. There is also more use of SFP, SFP+, and QSFP ports, allowing users to select — and even mix — a variety of media interfaces.

Some systems require both copper and fiber of different speeds and a modern commercial-off-the-shelf (COTS) Ethernet switch allows the system integrator great flexibility to be compatible with higher-level system requirements. In some cases, even the need for quite old 100 Megabit fiber interfaces is still supported with these new designs for applications that must have it.

In the VPX market, backplanes often utilize SERDES interfaces, which had been Gigabit or 10 Gigabit speeds for the past few years. With enhancements to VPX backplane designs and connector technology, new generation VPX form factor Ethernet switches now support speeds of Gigabit, 10 Gigabit and 25 Gigabit SERDES on a single lane and, when four lanes are combined into a fat-pipe,current products are supporting 40 GigKR4 and even 100 GigKr4 speeds, with more speed improvement on product roadmaps.

Enabling innovation instead of EOL shutdowns

Component availability is an issue we will be facing for a while, but by using this challenge as an innovation opportunity, embedded system designers can move towards new models of development to capitalize on computing technologies, like enhanced speeds in Ethernet switching, and improve system performance.

Browse the entire line of available Ethernet switches.

#embedded systems#switches#california#backplanes#electronics#fremont#modern switch#Switchware#RuggedSwitches#DefenseElectronics#SWManagement#EmbeddedEthernet#SystemLifecycle#embedded software#electronicssolution#VPX backplane#EOL#Ethernet switch#Ethernet switches#Elma Electronic#embedded Ethernet switches#embedded

0 notes

Text

Why Development Chassis are Critical to Implementing Systems Aligned to SOSA

Perhaps surprisingly, one of the many benefits that the SOSA™ Technical Standard offers involve development chassis.

Development chassis are nothing new in embedded computing; they date back to the earliest days of VME, and labs often have development chassis for board design testing and bring up, subsystem testing, or software development and integration. Like deployable systems, development chassis have evolved alongside new industry opens standards.

This is noteworthy because when designing with VPX, a chassis with a single-slot or multi-slot power-and-ground backplane — where all other signals are running straight through to rear transition module (RTM) connectors — can be handy for working with a single board, or multiple boards connected through the RTM boards. However, before the introduction of the SOSA Technical Standard, it was difficult to purchase a commercial off-the-shelf (COTS), multi-slot backplane for a development chassis that supported high-speed slot-to-slot links, due to the varied pin mappings that different vendors chose for their plug-in card products.

The SOSA Technical Standard changed that. By limiting the number of slot profiles and defining specific protocols supported on the various communications planes, companies can now offer COTS backplanes that align to the technical standard and can support similarly SOSA aligned plug-in cards from different suppliers. This means that developers can now purchase off-the-shelf development chassis that permit true multi-board subsystem, or even full system, development.

Open Standards Accelerate System Development

In addition to freeing developers and integrators from the limitations of RTMs and external cabling to link boards in a backplane as well as the need for custom backplanes, SOSA aligned COTS backplanes in development chassis provide several other interesting advantages:

• Subsystem or complete system development: In the past, one usually had to jump from a one- or two-board development platform with limited communications links directly to a target custom backplane, often in the target deployable chassis. Using development platforms based on SOSA, such as Elma’s CompacFrame chassis with SOSA backplanes, one can build up a system component-by-component and validate design elements prior to committing to a target deployable platform design. The fact that development hardware often includes VITA 46.11 chassis management hardware means that even the chassis management itself, which is a function distributed across multiple components in a system, can be brought up and debugged prior to moving to deployable hardware.

• Signal integrity testing: SOSA aligned COTS backplanes in a cost-effective development chassis provide an ideal environment for signal integrity testing of new board designs. By plugging a target-test board into various slots, one can measure the quality of high-speed signals nearer or farther from a board under development using a COTS backplane with known signal characteristics.

• Pre-deployment field testing: It’s now possible to obtain semi-deployable development chassis based on COTS components, such as Elma’s ATR-3600S that uses the same backplanes as lab-grade development chassis. These types of platforms allow for rapid field testing of subsystems or complete prototype systems prior to committing to a production-deployable design.

Development hardware can also be shared between projects, or inherited by subsequent projects, even though they may have different — and sometimes completely dissimilar — board-level content. This saves not only on lab budget, but the time to order and receive all new hardware for a new development project. Should a backplane from a previous project not fit the architectural needs of a new project, there is a good chance that another COTS backplane could, simplifying development platform upgrades to new architectures or slot counts.

Enhanced Design Outcomes in Chassis Development

Sometimes, the unintended consequences of our actions benefit us in ways that we never expected. The advantages of SOSA to deployed platforms, such as ease of integration, enabling future technology insertions and breaking vendor lock, were utmost on the minds of the framers of the technical standard.

However, looking back we can now see a shift in how development platforms are designed and offered by embedded manufacturers as well as how they are used by our integrator customer base. That shift is making it easier and less expensive to perform the development stages of a deployable system project and put solutions into the hands of the warfighter faster than ever before.

#embedded software#embedded#california#backplanes#electronicssolution#electronics#switches#embedded systems#SOSA#SOSAAligned#ModularOpenSystems#VITA65#CMOSS#DefenseElectronics#SOSAIntegration#SOSADevelopment#SOSAReady#SOSACompliance#SOSAPlatform#hardware#fremont

0 notes

Text

SOSA Architecture | SOSA Standard

With its focus on open, modular system design, the SOSA architecture enables flexible integration of plug-and-play embedded computing components. Elma supports this with robust hardware platforms that accelerate development timelines and reduce integration complexity for advanced defense and aerospace programs.

#SOSA#SOSAAligned#OpenStandards#ModularOpenSystems#MOSA#CMOSS#OpenVPX#VITA65#DefenseElectronics#C5ISR#EWSystems#SIGINT#ElmaSOSA#ElmaElectronic#ElmaFremont#RuggedSystems#EmbeddedComputing#SOSAConformance#SOSAIntegration#SOSADevelopment#SOSAChassis#SOSAReady#SOSAStandard#SOSAPlatform#SOSACompliance

0 notes

Text

19 Inch Rack Cabinet | 19 Inch Rack Mount

Elma’s 19 inch rack cabinet solutions provide secure, high-capacity enclosures for advanced electronics. Built with scalable configurations, they support thermal management, EMI shielding, and integration of multiple system architectures — making them perfect for mission-critical computing across various industries.

#19InchRackmount#RackmountChassis#RackmountSystems#RackmountEnclosure#IndustrialRackmount#DefenseRackmount#RuggedEnclosures#ModularRackmount#CustomRackmountSolutions#RackmountElectronics#RackmountPC#ElectronicEnclosures#19InchChassis#RackmountHardware#ElmaRackmount#ElmaSolutions#ElmaElectronic#ElmaFremont#FremontDefenseTech#RackMountComputing#RackmountIntegration#DataCenterHardware#RackMountAssembly#MilitaryGradeRackmount#RackmountDesign#HighPerformanceRackmount

0 notes

Text

VPX vs. OpenVPX: Key Differences and Why They Matter

As embedded systems evolve to meet modern performance and interoperability demands, the terms VPX and OpenVPX are becoming more prevalent. While often used interchangeably, they represent distinct concepts in the world of rugged embedded computing. Understanding the differences between VPX and OpenVPX is crucial when selecting the right architecture for your application, whether it's defense, aerospace, or industrial automation.

What is VPX?

VPX is a computing standard developed by VITA (VMEbus International Trade Association) that extends the legacy of VME by incorporating high-speed serial interconnects like PCI Express, RapidIO, and Ethernet. It introduces enhanced signal integrity, higher data throughput, and better thermal management. A VPX backplane supports advanced communication between modules in rugged environments, commonly found in military and aerospace systems.

What is OpenVPX?

OpenVPX builds upon the VPX standard by defining a system-level framework that specifies interoperability requirements between VPX modules. While VPX outlines the mechanical and electrical interface, OpenVPX ensures that modules from different vendors can work seamlessly together.

OpenVPX standardizes elements like:

Slot profiles

Module profiles

Payload and switch module types

OpenVPX backplane routing topologies

This added layer of definition is essential for defense integrators seeking to build plug-and-play systems with multi-vendor components.

Key Differences Between VPX and OpenVPX

1. Standard Scope

VPX: Focuses on individual module-level definitions.

OpenVPX: Defines system-level interoperability between modules.

2. Vendor Interoperability

VPX: Lacks standardization across systems, which can lead to compatibility issues.

OpenVPX: Promotes multi-vendor integration and long-term support through standardized system profiles.

3. System Integration

VPX: Ideal for custom system builds.

OpenVPX: Better suited for scalable, modular architectures that evolve over time.

4. Backplane Architecture

VPX backplane: Offers flexibility but can vary widely between implementations.

OpenVPX backplane: Uses predefined topologies and profiles, ensuring consistent performance and interoperability.

5. Form Factors

Both standards support different form factors, with 3U VPX and 3U OpenVPX being widely adopted for compact, high-performance applications.

Choosing Between VPX and OpenVPX

When to choose VPX:

Custom, single-vendor systems

Applications with tightly controlled hardware environments

When to choose OpenVPX:

Multi-vendor, interoperable systems

Programs requiring scalability, rapid integration, and long-term support

Elma Electronic: Your Source for VPX and OpenVPX Solutions

Elma Electronic offers a wide range of VPX products, including 3U VPX and 3U OpenVPX modules, rugged VPX chassis, and both VPX backplane and OpenVPX backplane configurations. Whether you're building a custom solution or looking for SOSA-aligned, interoperable systems, Elma provides expert guidance and reliable hardware.

Explore VPX and OpenVPX offerings here: Elma Electronic

Final Thoughts

While VPX and OpenVPX share the same foundational architecture, OpenVPX enhances interoperability and scalability, making it a preferred standard for modern embedded systems. Knowing the distinctions ensures that your system is not only powerful but also future-ready.

Leverage Elma Electronic's expertise and robust catalog of VPX chassis, VPX products, and standardized OpenVPX backplanes to stay ahead in mission-critical embedded computing.

#embedded software#embedded systems#backplanes#switches#electronicssolution#VPX#OpenVPX#HighPerformanceEmbeddedComputing#HPEC#VPXComputing#VPXSystems#RuggedVPX#VPXArchitecture#VPXSolutions#EmbeddedVPX#VPXInHighPerformanceComputing#WhatIsOpenVPX#BenefitsOfVPXArchitecture#VPXForDefenseComputing#HighSpeedDataVPX#OpenStandardsForHPEC#WhyUseVPXInEmbeddedSystems#NextGenEmbeddedComputing#ElmaSBC#ElmaComputing#ElmaAI#ElmaEmbedded#ElmaEdgeComputing#ElmaTech

0 notes

Text

VME Chassis: The Backbone of Rugged Embedded Computing

In the world of embedded computing, VME chassis remains a leading standard for rugged, high-performance applications. Designed for reliability, scalability, and real-time processing, VME chassis solutions continue to be widely used in aerospace, defense, industrial automation, and telecommunications. If you are looking for a dependable computing platform that can withstand harsh environments while delivering optimal performance, VME chassis is the ideal choice.

What is a VME Chassis?

A VME chassis is an enclosure that houses VMEbus-based computing modules, providing the necessary infrastructure for seamless communication between multiple boards. Developed in the 1980s, the VMEbus architecture has proven its reliability for mission-critical applications, offering high-speed data transfer, modular expansion, and superior system durability.

Key Benefits of VME Chassis

High Reliability & Rugged DesignBuilt for extreme environments, VME chassis are widely used in military, aerospace, and industrial applications where durability is essential.

Scalability & Modular ArchitectureVME systems allow for easy expansion, enabling users to add or upgrade processing, I/O, and storage modules as needed.

Real-Time Processing CapabilitiesWith its parallel processing support, VME architecture ensures fast and efficient real-time data handling, crucial for applications like avionics and industrial automation.

Multi-Vendor CompatibilityThe standardized VMEbus architecture allows seamless interoperability between different manufacturers, ensuring flexibility in system design.

Long-Term Availability & SupportUnlike newer computing standards that may become obsolete quickly, VME technology offers extended product lifecycles, making it a reliable investment for long-term projects.

Applications of VME Chassis

Aerospace & Defense

VME chassis solutions power mission-critical military systems, avionics, radar processing, and defense applications, ensuring secure and reliable operations.

Industrial Automation

Manufacturing and automation industries rely on VME chassis for real-time control and monitoring of machinery, improving operational efficiency and productivity.

Telecommunications

With high-speed data handling capabilities, VME chassis support network infrastructure, signal processing, and telecom switching applications.

Scientific Research & Medical Imaging

VME-based computing systems are used in high-performance data acquisition and medical imaging devices, ensuring accuracy and precision in research and healthcare.

Why Choose Elma Electronic for VME Chassis Solutions?

Elma Electronic is a global leader in embedded computing, offering custom and standard VME chassis solutions tailored to meet industry demands. With decades of expertise in high-performance computing, Elma provides durable, scalable, and mission-ready VME systems designed for the most demanding applications.

Explore our VME solutions here: Elma Electronic - VME Chassis

Final Thoughts

VME chassis technology continues to be a trusted choice for industries requiring rugged, high-performance computing solutions. Whether you're upgrading existing systems or deploying new applications, VME chassis ensures long-term reliability, scalability, and efficiency.

Stay ahead in embedded computing with Elma Electronic cutting-edge VME chassis solutions. Contact us today to learn more!

#embedded software#switches#hardware#california#embedded systems#embedded#backplanes#electronics#fremont#electronicssolution#vmechassis#vpxchassis#chassisystems#aerospace#defense#vme solutions#industrial automation#industrial equipment

0 notes

Text

Modular Open Systems Architecture (MOSA) Addresses Trends in Modular Systems for Defense

Joint efforts between the DoD, government agencies and industry over the past two years have resulted in a collaborative effort to adopt a common platform through the development of an open standard. The flow of this new initiative starts with the government expressing what they need from embedded systems companies and all parties involved working together to achieve those goals. The top objectives are to specify base system architectures for common systems, such as selecting a hardware standard—in this case, the existing OpenVPX standard—and system interoperability. Known as The Open Group Sensor Open Systems Architecture™ or SOSA™, this effort has enabled collaboration across different industry boundaries that were not achievable before. But the question of interoperability across modules remained. Restricting the use and making specific use of OpenVPX slot profiles has helped move that effort forward Click Here : https://www.elma.com/en/news-events/blog/mosa-addresses-modular-systems-trends-for-defense

#embedded software#california#hardware#switches#electronics#backplanes#electronicssolution#embedded systems#embedded#fremont#MOSA#openvpx#sosastandard#sosaaligned#technology#computing#tech#security

0 notes

Text

CMOSS: Revolutionizing Modular Open Standards for Defense Systems

CMOSS (C5ISR/EW Modular Open Suite of Standards) is a framework developed by the U.S. Army to promote interoperability and reduce development costs across C5ISR (Command, Control, Communications, Computers, Cyber, Intelligence, Surveillance, and Reconnaissance) systems. By adopting CMOSS, organizations can integrate modular solutions that work seamlessly with existing and future systems. Elma's expertise aligns with CMOSS standards, delivering modular and flexible solutions that accelerate deployment in military operations.

#embedded software#california#embedded systems#backplanes#switches#electronics#hardware#electronicssolution#embedded#cmoss#sosastandard#sosaelectronics#sosa aligned#sosa compliant#vpx#openvpx#chassis

0 notes

Text

SOSA Standard: Modular System Excellence

The SOSA standard (Sensor Open Systems Architecture) is transforming modular system design with enhanced interoperability and flexibility for defense and aerospace applications. At Elma Electronic, we provide SOSA-compliant products, including rugged backplanes and chassis, to meet the most stringent industry demands. By leveraging the SOSA standard, Elma ensures superior compatibility, scalability, and cost efficiency, making it the preferred choice for mission-critical projects in military and aerospace sectors.

#embedded software#hardware#switches#electronics#backplanes#electronicssolution#embedded systems#embedded#california#fremont

0 notes

Text

CMOSS | Elma Electronic

CMOSS is a cutting-edge modular open system architecture standard enabling interoperability and scalability. It enhances system flexibility while reducing costs for defense and aerospace projects. Learn how Elma supports CMOSS-compliant solutions.

#embedded software#embedded systems#california#backplanes#switches#hardware#embedded#electronics#electronicssolution#cmoss#fremont#elmaelectronic#opensystems#elmax#californianews#los angeles#enginerring solutions#rugged platforms#integratedplatforms

0 notes

Text

Reliable Selector Switch Range at Elma

A selector switch is essential for switching between different electrical circuits with ease. Widely used in automation and control systems, it offers dependable performance and durability. Elma delivers high-quality selector switches, ensuring optimal functionality for your equipment while enhancing user convenience.

#embedded#embedded systems#embedded software#hardware#switches#california#electronicssolution#electronics#fremont#selectorswitch#reliability#efficiency#industrial#manufacturing#equipments#advanced technologies#medical product design

0 notes

Text

Transform Your Designs with Cutting-Edge SOSA Electronics

SOSA electronics enhance your system's adaptability and performance with open standards that prioritize efficiency and scalability. From rugged designs to advanced signal processing capabilities, these solutions are perfect for high-demand applications in aerospace and defense industries. Explore top-quality SOSA-compliant products with Elma Electronics.

#embedded#embedded systems#embedded software#california#hardware#electronics#electronicssolution#fremont#switches#systemstandard#sosaarchitecture#sosa#opensystems#backplanes#sensory

0 notes