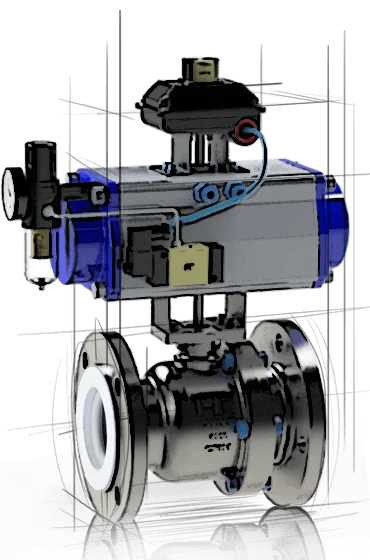

We are manufacturer of high quality Industrial Valve, Bellow Seal Valve, Ball Valve, Butterfly Valve, Lined Valve, and Pipe fitting accessories, Flange etc

Don't wanna be here? Send us removal request.

Text

PTFE Lined Tanks: Construction Methods, Maintenance, and Industrial Relevance

PTFE lined tanks are essential components in industries that operate under chemically aggressive conditions. Their reliability and resistance to corrosion make them indispensable for critical storage and processing tasks. This article focuses on the construction methods, maintenance protocols, and industrial importance of PTFE lined tanks.

Construction Techniques

The construction of PTFE lined tanks involves the integration of mechanical strength and chemical protection. The outer shell is usually constructed from carbon steel or stainless steel to provide structural integrity. The inner surface is lined with PTFE through several established methods:

Paste Extrusion: PTFE is extruded into sheets and then molded to the tank's inner surface.

Isostatic Molding: A high-pressure process that forms a uniform PTFE lining over complex geometries.

Fusion Bonding: PTFE powder is bonded to the tank surface and then sintered at high temperature.

Each method offers specific advantages in terms of adhesion, thickness control, and suitability for different tank shapes and sizes.

Maintenance Best Practices

PTFE lined tanks are known for their low maintenance needs, but regular checks can extend their lifespan:

Visual Inspection: Periodic checks for physical damage or detachment of the lining.

Leak Testing: Ensures the integrity of the lining under operational conditions.

Cleaning Protocols: Use of non-abrasive, chemical-compatible cleaning agents to maintain the non-stick properties.

Proper documentation and scheduled maintenance ensure continued compliance with safety and quality standards.

Industrial Applications

Petrochemical Industry: Safe containment of acids and reactive compounds.

Battery Manufacturing: Storage of strong alkalis and electrolytes.

Agrochemical Sector: Handling of fertilizers, pesticides, and solvents.

Textile Processing: Management of dyes and bleaching agents.

Environmental and Safety Benefits

By preventing leaks and corrosion, PTFE lined tanks contribute to environmental protection and worker safety. Their use reduces the risk of accidental spills, contamination, and equipment failures.

Closing Note

The durability and chemical resistance of PTFE lined tanks make them a vital component in modern industrial setups. Their strategic role in ensuring operational safety, regulatory compliance, and cost-effectiveness cannot be overstated. Investing in PTFE lined equipment is not just a choice for performance but a commitment to safety and sustainability.

0 notes

Text

PTFE Lined Tanks: Construction Methods, Maintenance, and Industrial Relevance

PTFE lined tanks are essential components in industries that operate under chemically aggressive conditions. Their reliability and resistance to corrosion make them indispensable for critical storage and processing tasks. This article focuses on the construction methods, maintenance protocols, and industrial importance of PTFE lined tanks.

Construction Techniques

The construction of PTFE lined tanks involves the integration of mechanical strength and chemical protection. The outer shell is usually constructed from carbon steel or stainless steel to provide structural integrity. The inner surface is lined with PTFE through several established methods:

Paste Extrusion: PTFE is extruded into sheets and then molded to the tank's inner surface.

Isostatic Molding: A high-pressure process that forms a uniform PTFE lining over complex geometries.

Fusion Bonding: PTFE powder is bonded to the tank surface and then sintered at high temperature.

Each method offers specific advantages in terms of adhesion, thickness control, and suitability for different tank shapes and sizes.

Maintenance Best Practices

PTFE lined tanks are known for their low maintenance needs, but regular checks can extend their lifespan:

Visual Inspection: Periodic checks for physical damage or detachment of the lining.

Leak Testing: Ensures the integrity of the lining under operational conditions.

Cleaning Protocols: Use of non-abrasive, chemical-compatible cleaning agents to maintain the non-stick properties.

Proper documentation and scheduled maintenance ensure continued compliance with safety and quality standards.

Industrial Applications

Petrochemical Industry: Safe containment of acids and reactive compounds.

Battery Manufacturing: Storage of strong alkalis and electrolytes.

Agrochemical Sector: Handling of fertilizers, pesticides, and solvents.

Textile Processing: Management of dyes and bleaching agents.

Environmental and Safety Benefits

By preventing leaks and corrosion, PTFE lined tanks contribute to environmental protection and worker safety. Their use reduces the risk of accidental spills, contamination, and equipment failures.

Closing Note

The durability and chemical resistance of PTFE lined tanks make them a vital component in modern industrial setups. Their strategic role in ensuring operational safety, regulatory compliance, and cost-effectiveness cannot be overstated. Investing in PTFE lined equipment is not just a choice for performance but a commitment to safety and sustainability.

0 notes

Text

Double Block and Bleed Valves: Engineered for Isolation, Designed for Safety

In the demanding world of industrial process control, system integrity and operator safety are top priorities. Double Block and Bleed Valves (DBB valves) have emerged as a critical solution for achieving complete shutoff and verifying isolation, especially in high-pressure, high-risk applications. These valves combine safety, performance, and efficiency in a single, compact design.

Let’s explore how DBB valves work, their advantages, and why they are essential across industries like oil & gas, chemicals, power, and marine.

What is a Double Block and Bleed Valve?

A Double Block and Bleed Valve is a valve assembly that provides positive isolation by incorporating two independent shut-off mechanisms (block valves) and a third outlet (bleed valve) between them. This configuration ensures that any fluid trapped between the two closed block valves can be safely vented, drained, or monitored for leaks.

This valve design enhances the system’s reliability by:

Preventing leakage across the isolation point,

Allowing for pressure release,

Verifying complete system isolation before maintenance begins.

Core Design and Functionality

DBB valves are available in two main configurations:

Single-Body Design: Combines two block valves and a bleed valve into a single, compact housing. This reduces installation time, weight, and space requirements — especially useful in offshore and modular systems.

Split-Body or Modular Configuration: Utilizes two individual isolation valves with a bleed valve in between. Though larger in footprint, it offers flexibility in part replacement and maintenance.

The bleed function plays a vital role. It allows trapped pressure between the two block valves to be released or monitored. If pressure is detected during isolation, it’s an immediate indicator of valve seat failure, allowing preventive actions before a full breakdown occurs.

Industrial Applications That Depend on DBB Valves

The use of DBB valves spans across several mission-critical sectors:

Oil & Gas: Used in manifolds, flow metering stations, and pig launchers to isolate sections of the pipeline while maintaining safety standards.

Refineries & Petrochemicals: Isolate hazardous chemicals or reactive fluids during inspection or replacement of instrumentation and safety systems.

Power Plants: Ensure reliable shutoff of feedwater, steam, and auxiliary systems during equipment overhauls or emergency stops.

Offshore Platforms: Space-saving single-body DBB valves are installed in tight, high-pressure environments to ensure maximum safety with minimal weight.

Pharmaceuticals and Clean Process Industries: Prevent cross-contamination between fluids and ensure sterile maintenance conditions.

Benefits of Using Double Block and Bleed Valves

Adopting DBB valves offers multiple operational and safety advantages:

Enhanced Safety for Operators and Equipment: Leakage detection through the bleed function protects maintenance personnel and system components.

Operational Efficiency: Maintenance can be carried out on isolated sections without shutting down the entire system.

Reduced Leak Paths: Integrated single-body designs minimize potential failure points.

Regulatory Compliance: Supports emission control and leakage prevention in accordance with global safety and environmental standards.

Space and Weight Optimization: Particularly important in offshore and skid-mounted systems.

Available Materials and Standards

DBB valves are engineered in a range of materials based on process media and environmental conditions:

Standard Materials: Stainless Steel (SS 304, SS 316), Carbon Steel

Specialty Alloys: Monel, Inconel, Duplex, Super Duplex, and Hastelloy for corrosive or high-temperature applications

Commonly adhere to:

API 6D, API 607 (Fire Safe)

ASME B16.34

ISO 15848 (Fugitive Emissions)

NACE MR0175 for sour service applications

Choosing the Right DBB Valve Manufacturer

The effectiveness of a DBB valve depends on more than design — precision manufacturing, quality control, and adherence to industry standards are essential. When selecting a DBB valve supplier, consider their engineering capabilities, material traceability, pressure testing protocols, and customization options.

Freture Techno Pvt. Ltd., a leading Double Block and Bleed Valve manufacturer based in Mumbai, India, delivers robust, precision-engineered valve solutions for global industries. With a focus on innovation and quality, their DBB valves are trusted across oil & gas, petrochemical, and heavy industrial sectors.

Conclusion

When safety, performance, and system integrity are non-negotiable, Double Block and Bleed Valves offer the most reliable isolation solution. They protect operations, people, and equipment — while allowing essential maintenance with confidence. Investing in high-quality DBB valves from trusted manufacturers like Freture Techno Pvt. Ltd. ensures long-term reliability and operational excellence in your fluid handling systems.

1 note

·

View note

Text

PFA Lined Plug Valves in Pharma and Biotech – Designed for Purity and Precision

In the pharmaceutical and biotech sectors, where product purity and equipment cleanliness are non-negotiable, PFA lined plug valves play an integral role. Their chemically inert, smooth, and non-porous surfaces make them ideal for handling high-purity fluids, buffer solutions, and cleaning agents without risking contamination.

These valves meet the stringent hygiene standards required for Good Manufacturing Practices (GMP) and are built to withstand clean-in-place (CIP) and sterilize-in-place (SIP) procedures.

Why PFA is Preferred in Pharma Environments

PFA’s ultra-smooth interior eliminates micro-crevices where bacteria can hide, making it an ideal lining for pharma valves.

Excellent Chemical Compatibility: Works with strong acids, alcohols, cleaning agents, and saline solutions.

High-Temperature Resistance: Withstands SIP cycles up to 200°C.

Non-Adhesive Surface: Prevents material sticking or clogging.

FDA-Compliant Materials: Suitable for contact with active ingredients.

Low Leachability: Ensures product purity remains intact.

Typical Pharma and Biotech Applications

WFI (Water for Injection) systems

Cleanroom chemical dosing

Bioreactor flow control

Buffer preparation tanks

Sterile filtration units

These valves support both batch and continuous production environments, ensuring repeatability and regulatory compliance.

Unique Features

Mirror-polished internals for hygienic design

Compact layout ideal for skid-mounted units

Compatible with automated SCADA or BMS systems

ASME BPE and ISO certifications available

Long-Tail Keywords

PFA lined plug valve for pharmaceutical industry

hygienic lined plug valve manufacturers in India

CIP/SIP compatible plug valves for biotech

Conclusion

PFA lined plug valves are the gold standard for pharmaceutical and biotech applications. Their inertness, temperature resistance, and hygienic design make them essential for maintaining production integrity and regulatory compliance.

Freture Techno Pvt. Ltd., a trusted PFA lined plug valve supplier, offers precision-engineered solutions that meet global pharma standards, ensuring safe and sterile fluid control in sensitive manufacturing environments.

#pfa plug valve#ptfe plug valve#lined plug valve#plug valve#manufacturer#suppliers#exporters#freture techno#India

0 notes

Text

Enhancing Water Network Efficiency in Municipal Supply Systems Using Pressure Reducing Stations

Urban and semi-urban areas rely on extensive water distribution networks to deliver consistent water supply across residential, commercial, and industrial zones. One of the biggest challenges in these networks is managing fluctuating water pressure caused by elevation changes, demand variations, and pumping dynamics. To combat these inconsistencies, Pressure Reducing Valves (PRVs) and complete Pressure Reducing Stations (PRS) have become vital tools for municipalities aiming to enhance network performance, minimize leakage, and optimize supply.

The Problem of High and Unstable Pressure

In municipal water distribution, water is often pumped at high pressure to overcome long distances and elevation gradients. However, this high upstream pressure, if left unregulated, can cause burst pipelines, excessive leakage, and water hammer effects. The situation worsens in low-lying areas or during periods of reduced consumption, when pressure naturally spikes.

Without proper pressure control mechanisms, municipal utilities face higher operating costs, frequent maintenance needs, and increased non-revenue water (NRW)—a significant problem in aging water infrastructures.

Role of Pressure Reducing Stations in Water Distribution

A Pressure Reducing Station (PRS) is a specialized setup designed to control and stabilize water pressure before it enters distribution zones or supply branches. It typically includes:

Pressure Reducing Valves (PRVs)

Bypass lines for maintenance or emergencies

Isolation valves

Strainers and filters

Instrumentation (gauges, transmitters, flow meters)

Flow control or surge protection equipment

These stations are strategically placed across the pipeline network, especially near elevation drops, zone boundaries, or critical supply junctions. By dividing the system into pressure-managed zones, PRSs allow for better control, fewer system failures, and optimized water usage.

Maintaining Consistent Flow and Supply

One of the biggest advantages of PRVs is their ability to maintain a constant downstream pressure, regardless of fluctuations in upstream pressure. This means consumers at various elevations receive consistent water pressure, improving service quality while reducing the risk of pipeline fatigue or bursts.

For instance, in a hilly municipality, PRVs prevent excess pressure from building up in low-lying areas while ensuring adequate flow to elevated neighborhoods. The result is a balanced and equitable water supply that supports both residential and commercial usage.

Reducing Non-Revenue Water (NRW)

Non-Revenue Water—water lost through leaks, theft, or unmetered usage—is a serious concern for municipalities. High-pressure zones are more prone to leakage, as old pipes and joints are not designed for prolonged overpressure. By reducing pressure to optimal levels, PRVs decrease leakage volumes and extend pipeline lifespan.

Studies have shown that even a 10% pressure reduction can result in over 30% reduction in leakage rates. Over time, this leads to cost savings, improved water accountability, and a more sustainable water supply model.

Automation and Remote Monitoring

Modern PRV stations can be equipped with smart controllers and actuators that allow dynamic pressure adjustments based on time of day, demand, or remote operator input. Integration with SCADA (Supervisory Control and Data Acquisition) systems offers real-time monitoring of pressure trends, flow rates, and valve performance.

In case of emergency conditions such as pipeline ruptures or backflow risks, automated stations can respond instantly—closing valves or reducing pressure to protect the system. These automated responses eliminate delays and reduce the risk of large-scale water losses.

Long-Term Reliability and Easy Maintenance

PRVs designed for municipal systems are often pilot-operated, providing precise regulation and smooth operation even under variable flow conditions. Their robust construction, corrosion-resistant bodies, and easily serviceable components ensure years of reliable operation with minimal maintenance.

Periodic inspections, calibration, and flushing keep the stations in top condition—ensuring that the city’s water infrastructure performs optimally despite growing demand and aging assets.

Conclusion

Pressure Reducing Stations are indispensable for modern water supply networks. They do more than manage pressure—they protect infrastructure, reduce water losses, improve service quality, and lay the foundation for smarter, more resilient cities.

By investing in well-designed, automated PRV systems, municipalities not only enhance operational efficiency but also move closer to the goal of sustainable, equitable, and accountable water distribution.

0 notes

Text

Industrial Applications of Ball Valves: Why Industries Rely on Trusted Manufacturers for Flow Control

Across multiple industries, reliable fluid handling is essential to maintain operational efficiency and safety. At the heart of these systems are ball valves, known for their tight shut-off capabilities, ease of operation, and long service life. Choosing a trusted ball valve manufacturer plays a vital role in ensuring performance under demanding conditions.

Let’s explore the significance of ball valves in various industrial settings and how a reliable valve manufacturer adds value beyond the product.

The Role of Ball Valves in Industrial Operations

Ball valves are quarter-turn devices featuring a spherical closure unit that regulates fluid flow. When aligned with the pipeline, the hole in the ball allows fluid to pass through freely. When turned 90 degrees, it blocks the flow entirely. This simple mechanism enables quick isolation and ensures minimal pressure drop across the system.

Key advantages include:

Leak-tight performance

Quick actuation

Low maintenance requirements

Long service life

Compatibility with automation systems

These properties make ball valves ideal for both critical and utility applications in process systems.

Types of Ball Valves for Industrial Use

A trusted industrial ball valve manufacturer typically offers a wide range of designs tailored to various process conditions:

Floating Ball Valve – Suitable for low- to medium-pressure applications, offering bidirectional sealing.

Trunnion Mounted Ball Valve – Designed for high-pressure and large-diameter pipelines, providing stability and reduced operating torque.

Full Bore and Reduced Bore Valves – Full bore minimizes flow resistance, while reduced bore offers a compact, economical alternative.

Three-Piece Design – Facilitates easy maintenance, cleaning, or part replacement without removing the valve from the pipeline.

Fire-Safe Valves – Equipped with secondary sealing systems that remain operational during fire emergencies.

Stainless Steel Ball Valve – Offers corrosion resistance for aggressive chemicals or high-purity applications.

Each type can be further customized with manual, pneumatic, or electric actuators, depending on operational requirements.

Ball Valve Applications Across Industries

Industrial systems require ball valves in a range of processes where control, safety, and efficiency are non-negotiable. Here are some examples of where these valves are applied:

Oil & Gas Sector: Used in storage tanks, pipelines, and gas distribution systems for safe and reliable isolation.

Chemical Processing: Essential for handling aggressive fluids, acids, and solvents under varying pressures.

Pharmaceutical Manufacturing: Hygienic designs are used in purified water systems, clean-in-place (CIP), and water for injection (WFI) lines.

Water & Wastewater Treatment: Employed in inflow/outflow regulation, filtration systems, and sludge management.

Power Generation: Utilized for steam and condensate line isolation in high-pressure applications.

Food & Beverage Industry: Sanitary-grade valves support hygienic fluid handling with minimal contamination risk.

The broad versatility of ball valves has made them indispensable in fluid control systems worldwide.

What to Look for in a Reliable Ball Valve Manufacturer

Not all valve suppliers offer the same level of reliability. A precision ball valve supplier should possess the expertise and capacity to meet both standard and complex requirements.

Key factors to evaluate:

Product Range: Ability to supply a variety of valve types and materials

Design Capability: Customization options for end connections, materials, and actuation

Compliance Standards: Conformance with API, ASME, ISO, and other relevant specifications

Quality Testing: In-house testing facilities for pressure, sealing, and fire safety performance

Documentation: Complete support with test certificates, material traceability, and third-party inspection reports

Value Beyond the Product

A dependable manufacturer provides more than just a valve—they deliver performance assurance. From initial specification to after-sales support, a trusted partner ensures that valves integrate seamlessly into the system and continue to perform over time.

One such trusted name in the valve industry is Freture Techno Pvt. Ltd. The company offers a full range of high-performance ball valves, known for engineering precision, reliability, and customization. Their valves are designed and tested to meet the demands of modern process industries.

#ball valves manufacturers#ball valve suppliers#ball valve types#ball valve exporters#freture techno

0 notes

Text

At Freture Techno Pvt. Ltd., we take pride in being a leading manufacturer and supplier of Bellow Seal Valves in India.

Freture Bellow Sealed Valves incorporate a formed multi-ply bellow that is welded to the stem and bottom of the bonnet, forming a hermetic seal or impermeable barrier.

Bellow are available in a wide variety of materials and can be used in practically any corrosive chemical application, reliable and high-quality Bellow Sealed Valves. With a strong commitment to customer satisfaction and product excellence, Freture Techno has established itself as a trusted provider in the industry. In this blog post, we will explore the key features and benefits of Freture Techno's Bellow Sealed Valves, highlighting why they are the ideal choice for your fluid control needs.

0 notes

Text

Bellow Sealed Valves in Power Generation Ensuring Leak-Proof Performance for Safer, Cleaner Operations

Power generation facilities operate under demanding conditions, where safety, reliability, and efficiency are non-negotiable. In these environments, the risk of leakage or emissions from critical systems poses serious concerns. This is where bellow sealed valves play a vital role. Designed to deliver zero-leakage performance, these valves help power plants meet strict operational and environmental requirements.

Across thermal, nuclear, and renewable power plants, bellow sealed valves ensure that steam, condensate, and cooling systems function without compromise. This article explores their design, benefits, and applications in the power generation sector, and offers guidance on selecting the right valve for these challenging environments.

The Design Behind Bellow Sealed Valves

Bellow sealed valves feature a unique construction that eliminates stem leakage. A flexible metallic bellows surrounds the valve stem, creating a hermetic seal. This bellows expands or contracts as the valve operates, allowing the stem to move without providing a path for fluid or gas to escape.

The bellows is welded securely at both ends, forming a pressure-tight barrier. As a result, emissions at the stem—one of the most common leak points in conventional valves—are entirely prevented. The robust design ensures long-term leak-tight performance, even under the high pressures and temperatures found in power plants.

Materials of Construction for Demanding Conditions

In power generation, systems often handle superheated steam, high-temperature water, or aggressive chemicals. Bellow sealed valves must withstand these challenges. Therefore, manufacturers select premium materials such as SS316, SS316L, alloy steels, and Hastelloy. The bellows itself is typically fabricated from multi-ply stainless steel or other high-strength alloys to balance flexibility and durability.

These materials resist corrosion, fatigue, and thermal stress. Internal surfaces may receive special treatments, such as electropolishing or hard-facing, depending on the application. This ensures that valves remain reliable over long service intervals.

Key Advantages in Power Generation Systems

Bellow sealed valves provide several critical benefits in power plants:

✅ Zero stem leakage – The hermetic seal ensures that steam or fluids remain contained, reducing environmental impact and improving plant safety.

✅ Extended service life – High-quality materials and precision engineering provide durability in high-pressure, high-temperature applications.

✅ Reduced maintenance requirements – The absence of gland packing eliminates wear points, minimizing the need for adjustments or replacements.

✅ Improved operator safety – With no leakage at the stem, operators face lower risks from hot fluids or hazardous vapors.

✅ Support for regulatory compliance – Bellow sealed valves help meet emissions and safety standards, including those from OSHA, ASME, and local environmental agencies.

These advantages contribute to more reliable, efficient, and sustainable power generation operations.

Applications in Power Plants

Bellow sealed valves find use across a wide range of critical systems in power generation facilities. Common applications include:

Steam isolation systems – Prevent leakage of high-pressure steam in boilers and turbines.

Condensate return lines – Ensure the integrity of condensate recovery systems, helping conserve water and energy.

Feedwater systems – Maintain leak-tight control of water supplied to boilers.

Chemical dosing lines – Provide safe handling of conditioning chemicals used to protect boilers and heat exchangers.

Cooling water circuits – Prevent loss of cooling media and protect heat exchange equipment.

Whether in fossil-fuel, nuclear, or concentrated solar power plants, bellow sealed valves help safeguard plant reliability and efficiency.

Integration with Automation

Modern power plants depend on automation to enhance safety and performance. Bellow sealed valves are designed for seamless integration with automated control systems. They can be equipped with pneumatic, hydraulic, or electric actuators to enable remote operation.

Feedback devices, position indicators, and proximity switches can also be added. These accessories allow precise monitoring of valve status, improving system diagnostics and enabling predictive maintenance. Integration with SCADA and DCS platforms helps operators ensure data integrity and regulatory compliance.

Supporting Environmental Goals

Power generation facilities face increasing pressure to reduce emissions and environmental impact. Bellow sealed valves support these goals by eliminating fugitive emissions from valve stems. This helps plants comply with regulations governing air quality and greenhouse gas emissions.

Their long service life and low maintenance requirements further reduce resource consumption and waste generation. By minimizing leakage and extending equipment longevity, bellow sealed valves contribute to cleaner, more sustainable power generation.

Maintenance and Lifecycle Management

While bellow sealed valves are built for durability, proactive maintenance ensures reliable performance over time. Regular inspections check for signs of bellows fatigue, seat wear, or stem misalignment. Preventive maintenance programs may include scheduled replacements of wear components to avoid unplanned downtime.

Documentation of maintenance activities supports compliance with safety and quality standards. Many valve manufacturers provide maintenance kits, training, and support services to help plant operators manage valve performance throughout its lifecycle.

Clean and Safe Plant Environments

In power plants, leaks can pose risks not only to equipment efficiency but also to workplace safety. Bellow sealed valves help protect workers by containing hot, pressurized fluids and preventing the release of harmful substances. Their tight sealing supports clean plant environments, helping prevent corrosion of surrounding structures and equipment caused by leaks.

In nuclear power plants, the role of bellow sealed valves becomes even more critical. These valves help ensure that systems handling radioactive steam or fluids remain securely sealed, protecting personnel and the environment.

Selecting the Right Bellow Sealed Valve

Choosing the appropriate bellow sealed valve for power generation involves careful consideration of several factors:

Material compatibility – Ensure that the valve materials suit the media handled and operating conditions.

Pressure and temperature ratings – Select valves rated for the system’s maximum operating conditions.

Automation requirements – Determine actuator type and integration needs for the plant’s control systems.

Maintenance accessibility – Choose designs that simplify inspection and servicing.

Certifications – Verify that the valve complies with relevant standards and plant specifications.

Working with a trusted manufacturer ensures that the right valve is chosen for each application.

Conclusion

Bellow sealed valves provide essential leak-tight flow control in the power generation industry. Their advanced design, robust materials, and reliable performance help power plants operate safely, efficiently, and sustainably. From steam isolation to cooling circuits, these valves play a key role in protecting plant integrity and supporting environmental compliance.

Freture Techno Pvt. Ltd., a leading Bellow sealed valve manufacturer in Mumbai, India, offers high-performance valves tailored to the rigorous demands of power generation. Their products deliver proven durability, precision, and safety for critical applications across the energy sector.

#Bellow valves#bellow sealed valves#bellow sealed globe valve#bellow sealed gate valve#eurochlore bellow valves#extesntion stem bellow valves#freture techno

0 notes

Text

Reliable PTFE Lined Column Manufacturers for Corrosion-Resistant Process Equipment

In industries where aggressive chemicals and high temperatures are routine, equipment durability is non-negotiable. PTFE lined columns have emerged as a trusted solution for safely handling corrosive media in chemical processing and pharmaceutical manufacturing. Sourcing these components from reliable PTFE lined column manufacturers ensures performance, safety, and long-term value.

What is a PTFE Lined Column?

A PTFE lined column is a vertical process vessel internally coated with Polytetrafluoroethylene (PTFE), a high-performance fluoropolymer known for its outstanding chemical resistance and thermal stability. These columns are essential in applications where direct contact between harsh chemicals and metal surfaces can lead to corrosion, contamination, or failure.

The PTFE lining acts as a protective barrier, isolating the internal media from the metal body—usually made of mild steel or stainless steel. These lined columns are extensively used in gas absorption, distillation, and chemical reaction processes across various industries.

Key Benefits of Choosing PTFE Lined Columns

PTFE lined columns offer a range of advantages that make them ideal for demanding environments:

Exceptional Corrosion Resistance: PTFE is virtually inert to most acids, alkalis, and solvents, even at elevated temperatures.

Temperature and Pressure Tolerance: These columns can operate reliably across wide temperature ranges without degrading or warping.

Low Maintenance: The non-stick, smooth surface of PTFE prevents scale buildup and allows for easier cleaning.

Extended Lifespan: Because they resist chemical attack, PTFE lined columns often outlast unlined metal equipment in aggressive service conditions.

Leak-Proof Sealing: High-quality PTFE linings offer excellent sealing properties, reducing the risk of leaks and operational hazards.

These benefits translate into safer operations, reduced downtime, and better return on investment.

Qualities of Reliable PTFE Lined Column Manufacturers

Not all PTFE lined column suppliers are created equal. When choosing a manufacturer, several key attributes should be considered:

Use of Virgin PTFE Material: High-quality manufacturers use virgin, chemically pure PTFE that meets or exceeds industry standards for durability and resistance.

Advanced Lining Techniques: Precision techniques such as isostatic molding, paste extrusion, and seamless welding are crucial for a uniform, bubble-free lining.

Compliance with Standards: Reliable manufacturers conform to standards like ASME, ASTM, or DIN to ensure dimensional and operational integrity.

Custom Fabrication Capabilities: The ability to fabricate PTFE lined columns in various sizes, diameters, and pressure classes is essential for diverse industrial needs.

In-House Testing and Quality Checks: Trusted suppliers conduct spark testing, hydro testing, and visual inspections to guarantee the integrity of the PTFE lining.

Engineering Support: Technical teams capable of offering design consultation, installation guidance, and post-sales service add significant value.

Industries Served by PTFE Lined Columns

PTFE lined columns are critical to many sectors that deal with aggressive chemical processes. These include:

Pharmaceuticals: For handling highly pure or corrosive chemicals without contamination.

Specialty Chemicals: To ensure safe and consistent processing of aggressive intermediates.

Agrochemicals: Where reaction vessels need to withstand strong acids or caustic solutions.

Water and Waste Treatment: In systems treating wastewater with chemical reagents or oxidizing agents.

In each of these applications, the use of PTFE lined process columns reduces the risk of corrosion-related failures, helping companies maintain operational continuity and compliance.

How to Choose the Right PTFE Lined Column Manufacturer

When selecting a PTFE lined column manufacturer, the following considerations can guide your decision:

Reputation and Experience: Look for manufacturers with proven expertise and a strong track record in delivering lined equipment.

Customization Options: Ensure the supplier can accommodate unique process requirements with tailor-made solutions.

Certifications and Documentation: Demand material test certificates, QA/QC reports, and spark test records to verify quality.

Responsive Support: Reliable after-sales service and technical troubleshooting reflect a manufacturer’s commitment to client success.

Global Reach or Local Presence: Depending on your location, choose a partner who can deliver promptly and offer support without delays.

Conclusion

Investing in high-quality PTFE lined columns is vital for ensuring chemical process safety, efficiency, and regulatory compliance. Manufacturers that use genuine PTFE materials, follow rigorous fabrication protocols, and offer engineering support can make a significant difference in plant performance.

For those seeking corrosion-resistant column solutions, Freture Techno Pvt. Ltd. is a leading PTFE lined column manufacturer in India, known for delivering precision-engineered, long-lasting equipment to industries worldwide.

0 notes

Text

Comparing Inlet Vane Dampers vs. Variable Frequency Drives in Airflow Management

In the debate between inlet vane dampers vs. variable frequency drives (VFDs), it’s important to understand the distinct advantages each offers in industrial airflow management. While VFDs adjust motor speed, inlet vane dampers regulate airflow at the source—before it enters the fan.

Energy-efficient inlet vane damper solutions reduce energy by lowering the air pressure the fan needs to manage. They offer a cost-effective method for airflow control in existing systems without significant retrofitting. This makes them a viable choice for facilities with tight upgrade budgets.

On the other hand, VFDs may offer more granular motor control but often come with higher initial and maintenance costs. Additionally, VFDs can cause harmonic distortion in electrical systems, requiring additional filters or correction equipment, further increasing costs.

Inlet vane dampers, in contrast, present a mechanical solution that’s easy to integrate into existing ductwork and fan systems. They’re ideal for dynamic environments where fast, responsive airflow control is necessary. Examples include chemical processing, pharmaceutical plants, and food production units.

These dampers are also easier to maintain, with fewer electrical components that could fail under harsh operating conditions. In many cases, inlet vane dampers serve as an excellent first step toward airflow optimization, especially when combined with basic automation controls.

Freture Techno Pvt. Ltd. is a leading manufacturer of inlet vane dampers in Mumbai, India, providing energy-saving solutions with low operational costs.

0 notes

Text

Earth Day 2025: Engineering a Sustainable Future with Emission-Free Valve Solutions

Every year on April 22, Earth Day serves as a global reminder of the need to protect the planet and pursue more sustainable practices in every aspect of human life. For the industrial sector, especially in high-stakes environments such as oil & gas, pharmaceuticals, and food processing, this translates to reducing emissions, preventing leakages, and improving operational efficiency. Freture Techno Pvt. Ltd., a leading industrial valve manufacturer in India, stands at the forefront of this green transformation.

Sustainability at the Core of Valve Engineering

Freture Techno Pvt. Ltd. has redefined what it means to be environmentally responsible in the field of flow control. With a deep understanding of the challenges faced by complex industrial applications, the company designs and manufactures high-performance valves that not only meet technical demands but also contribute to environmental protection.

Specializing in advanced solutions such as bellow sealed valves, double block and bleed (DBB) valves, lined valves, and rotary actuators, Freture ensures each product is engineered with leak-proof precision. These valves help industries curb fugitive emissions, reduce process losses, and maintain safe operations, thereby aligning daily industrial functions with long-term sustainability goals.

Precision That Protects

In sectors like oil and gas, valve failure or leakage can result in catastrophic environmental and financial consequences. Freture Techno’s Bellow sealed valves are engineered for zero leakage, ensuring containment of hazardous fluids under high-pressure conditions. This technology prevents volatile organic compounds (VOCs) from escaping into the atmosphere, aligning with both international environmental standards and the broader Earth Day mission.

For the pharmaceutical industry, contamination-free processing is a necessity. Freture’s sanitary-grade, emission-free valves support cleanroom operations by eliminating the risk of leakage and ensuring high-purity water systems and sterile product lines.

Likewise, in food and beverage plants, Freture’s lined valves play a critical role in maintaining hygienic flow, resisting corrosion, and preventing material degradation. The result is an eco-conscious production cycle that prioritizes both quality and safety.

Designing for Eco-Efficiency

Freture Techno doesn’t just manufacture valves—it engineers sustainability. Its modular valve designs allow for easy customization, repair, and longer product lifecycle, effectively reducing material waste. Each valve is crafted using durable materials that extend operational longevity, minimizing the frequency of replacements and contributing to lower resource consumption.

The company’s energy-efficient manufacturing processes and use of recyclable components reinforce its responsibility toward eco-friendly operations. Moreover, all valves undergo stringent testing for leakage, durability, and compliance with emission standards, guaranteeing that only the most sustainable solutions reach industrial pipelines.

A Partner in Sustainable Progress

Across industries, the shift toward sustainability is no longer optional—it is essential. Freture Techno Pvt. Ltd. partners with clients not just to meet compliance but to foster innovation that makes industrial operations cleaner, safer, and more responsible.

From supporting greenfield pharma projects to upgrading legacy oil & gas installations, Freture’s valves are trusted wherever precision and sustainability intersect. With expert consultation and customized solutions, the company helps clients navigate increasingly strict environmental norms without compromising on performance.

Earth Day Commitment: Today and Tomorrow

As the world observes Earth Day 2025, Freture Techno Pvt. Ltd. reiterates its ongoing commitment to sustainable engineering. Each valve designed is a pledge—to nature, to industry, and to future generations. The company believes that operational excellence should not come at the planet’s expense, and its innovations reflect that philosophy every day.

On this Earth Day and beyond, industries are encouraged to adopt zero-emission valve solutions, embrace green engineering, and invest in eco-efficient technologies that promote long-term planetary health. Freture Techno Pvt. Ltd. remains ready to lead that charge—one valve at a time.

0 notes

Text

Maintenance and Troubleshooting of Industrial Damper Valves

Industrial damper valves, like all mechanical components, require regular maintenance to ensure optimal performance and avoid system failures. A well-maintained damper not only extends equipment life but also contributes to process efficiency and safety.

Importance of Regular Maintenance

Scheduled maintenance helps identify and correct minor issues before they escalate into major problems. Maintenance practices vary based on the type of damper valve, operating conditions, and application. However, some universal tasks include cleaning, lubrication, alignment checks, and inspection of moving parts.

Common Maintenance Procedures

1. Visual Inspection: Check for any signs of wear, corrosion, or physical damage. Look for deformed blades, misalignment, and structural integrity of the housing.

2. Lubrication: Lubricate all moving parts including linkages, actuators, and bearings. Proper lubrication reduces friction and prevents premature wear.

3. Actuator and Control Check: Inspect actuators (manual or automated) for proper operation. Electrical connections, air supply (in pneumatic actuators), and hydraulic fluid levels should be verified.

4. Seal and Gasket Inspection: Examine seals and gaskets for cracks or leaks. Replace if they show signs of deterioration to prevent leakage.

5. Cleaning: Remove dust, soot, or other particulates that may impede movement or airflow. In exhaust or combustion systems, this is especially critical.

Troubleshooting Common Issues

1. Valve Sticking or Jamming: Often caused by debris buildup, inadequate lubrication, or misaligned components. Cleaning and realignment usually resolve the issue.

2. Leakage: Check for worn gaskets, seals, or damaged blades. In high-performance systems, ensure that the valve type meets the required leakage standards.

3. Inconsistent Actuation: This could stem from actuator malfunctions, low air pressure in pneumatic models, or signal loss in electrical units. Verify actuator settings and inputs.

4. Noise or Vibration: Loose components or imbalance can cause noise. Tighten hardware and check for uniform airflow.

Maintenance Frequency

Monthly: Visual inspections and light cleaning.

Quarterly: Full operational testing and lubrication.

Annually: Detailed inspection, part replacements if needed, and performance testing.

Documentation and Record Keeping

Maintain a detailed log of inspections, repairs, and replacements. Documentation helps track performance trends and schedule future maintenance more effectively.

Proper maintenance and timely troubleshooting of industrial damper valves ensure uninterrupted operation, reduce downtime, and prolong the life of both the valve and the entire system. A proactive approach to care and service is key to achieving long-term reliability and efficiency.

#Industrial damper hvac#Industrial damper working principle#Industrial damper types#Industrial damper manufacturers

0 notes

Text

Sanitary Valve Standards in the Dairy Industry: Meeting Regulatory and Safety Requirements

The dairy industry operates under some of the strictest hygiene and safety protocols due to the perishable nature of its products. As a result, every piece of equipment—especially valves used in milk and dairy processing systems—must comply with rigorous sanitary standards. These valves play a pivotal role in ensuring the safety, quality, and consistency of dairy products.

In this article, we will explore the key sanitary standards governing dairy valves, how these requirements impact valve design and manufacturing, and why compliance is essential for modern dairy operations.

The Importance of Sanitary Valves in Dairy Processing

Valves in dairy facilities regulate the flow of milk, cream, yogurt, whey, and other fluid ingredients. Since these products are prone to bacterial contamination, any component that comes into contact with them must be easy to clean, non-reactive, and designed to eliminate the risk of contamination.

Sanitary valves are distinguished by:

Hygienic internal surfaces with no dead zones

Use of FDA-approved materials

Compliance with global standards such as 3-A Sanitary Standards, EHEDG, and FDA CFR 21

Resistance to repeated CIP (Clean-In-Place) and SIP (Sterilize-In-Place) cycles

Key Regulatory and Industry Standards for Dairy Valves

1. 3-A Sanitary Standards

The 3-A Sanitary Standards Inc. (3-A SSI) sets specific requirements for the design and fabrication of dairy equipment in the U.S. market. Valves must have smooth, cleanable surfaces and be constructed from non-toxic materials such as 316L stainless steel. They must also be easy to disassemble for inspection or cleaning.

Why it matters: 3-A certification assures end users that the valve is safe for dairy use and will not harbor microbial growth.

2. EHEDG (European Hygienic Engineering & Design Group)

EHEDG promotes hygiene in the design and maintenance of food processing equipment, particularly in Europe. Its guidelines emphasize cleanability, hygienic construction, and validation testing to ensure that valves do not contribute to product contamination.

Why it matters: EHEDG compliance is essential for exporting to the European market and for global companies adhering to strict hygiene protocols.

3. FDA Compliance (CFR Title 21)

The U.S. Food and Drug Administration regulates food contact materials through CFR Title 21. All elastomers, gaskets, and seals used in dairy valves must be FDA-approved and certified for food contact.

Why it matters: FDA compliance ensures that materials used in valves will not leach harmful substances into dairy products.

Sanitary Design Considerations

To comply with these standards, dairy valve manufacturers incorporate several hygienic design features:

Polished internal surfaces (typically Ra < 0.8 µm) to prevent bacterial adhesion

Self-draining flow paths to avoid product pooling

Dead-leg-free construction to eliminate stagnant zones

Seals and seats made of EPDM, PTFE, or silicone—all FDA-approved

Tri-clamp ends or DIN connections for easy removal and reassembly

Inspection, Validation, and Documentation

Modern dairy facilities demand full traceability and documentation. Certified valves often come with:

Material Test Reports (MTRs)

Pressure and leak test results

Surface roughness certificates

Welding validation reports (where applicable)

These documents help meet both internal quality audits and external inspections from food safety authorities.

Impact on Dairy Operations

By using valves that meet global sanitary standards, dairy processors can:

Achieve faster cleaning cycles

Reduce downtime and maintenance

Extend product shelf life

Avoid costly product recalls due to contamination

Most importantly, compliant valves enable dairy plants to operate with confidence, knowing they are protecting public health and maintaining regulatory integrity.

Conclusion

Sanitary valve standards form the backbone of safe and efficient dairy processing. Whether it's 3-A, EHEDG, or FDA compliance, each requirement ensures that the valves used are designed to meet the highest levels of cleanliness, durability, and safety. Working with manufacturers who understand and implement these standards is crucial for dairy processors looking to stay competitive and compliant.

Freture Techno Pvt. Ltd. is a leading Dairy Industry Valves Manufacturer in Mumbai, India.

0 notes

Text

How PTFE Lined Ball Valves Enhance Chemical Processing Efficiency

Industrial processes rely on durable, corrosion-resistant components to handle aggressive chemicals. PTFE lined ball valves play a vital role in ensuring chemical processing efficiency, offering leak-proof operation, minimal friction, and enhanced durability. These properties make them ideal for applications where chemical purity, longevity, and operational safety are key concerns.

How PTFE Lining Improves Performance

Exceptional Chemical Compatibility: Prevents chemical breakdown and degradation.

Reduced Friction & Clogging: Ensures smooth flow and minimizes blockages.

Extended Valve Lifespan: Resists wear, reducing replacement and maintenance costs.

Key Benefits for Chemical Plants

PTFE lined ball valves are indispensable in chemical plants, where exposure to corrosive fluids poses operational risks. The protective PTFE barrier prevents leaks and ensures safe, contamination-free processing.

Leak-Proof Design: Minimizes hazardous spills and improves workplace safety.

High Temperature & Pressure Tolerance: Ideal for extreme processing conditions.

Long-Term Cost Savings: Reduced downtime and maintenance enhance plant efficiency.

The FDA-approved PTFE lining further supports industries requiring strict hygiene compliance, including pharmaceutical and food processing sectors. With versatile end connections and configurations, PTFE lined ball valves cater to diverse industrial needs, ensuring seamless integration into processing systems.

Investing in PTFE lined ball valves guarantees long-term operational efficiency, safety, and cost savings. Their non-stick, non-reactive properties make them a superior choice over conventional ball valves, particularly for industries dealing with highly aggressive fluids. With the ability to maintain purity, prevent contamination, and withstand extreme conditions, these valves continue to set the standard for chemical processing applications.

Choosing a trusted PTFE Lined ball valve manufacturer ensures high-quality solutions tailored to specific industry requirements, enabling businesses to optimize their operations and enhance overall system reliability.

#PTFE Lined Ball Valve#FEP Lined Ball Valve#Lined Ball Valves#manufacturers#suppliers#india#freturetechno

0 notes

Text

Why Indian Check Valve Manufacturers Are Gaining Global Recognition

The Indian industrial valve industry is rapidly expanding, positioning the country as a global leader in check valve production. With rising exports and increasing adoption of advanced manufacturing techniques, Indian check valve manufacturers are competing with global giants in the market.

Growth of the Indian Valve Industry

India’s industrial sector has witnessed significant growth, particularly in:

Oil & Gas – Indian manufacturers supply valves to refineries worldwide.

Pharmaceuticals – High-purity valves are in demand for sterile processes.

Water Treatment – The demand for reliable water treatment valves has surged.

Key Factors Behind India’s Success in Valve Manufacturing

1. Cost-Effective and High-Quality Production

India’s competitive manufacturing costs make its products more affordable while maintaining high quality.

2. Advanced Technology Adoption

CNC machining for precision manufacturing.

Automated quality control measures.

Compliance with global safety standards.

3. Expanding Export Capabilities

Indian manufacturers have established strong partnerships with international clients, exporting to markets in Europe, the Middle East, and North America.

Leading Indian Check Valve Manufacturers

Several Indian companies are now recognized globally for their expertise in manufacturing non-return valves and industrial check valves. Their ability to produce customized solutions while maintaining affordability gives them a competitive edge in the global market.

For businesses seeking high-performance, cost-effective solutions, partnering with a top check valve company in India ensures optimal results for industrial applications.

#check valve manufacturer#swing check valve#lift check valve#ptfe lined checked valve#NVR Valve#freture techno#India

0 notes

Text

PTFE Lined Gate Valves vs. Conventional Gate Valves: Which One is Right for Your Industry?

Selecting the right valve for industrial applications is critical to ensuring safety, reliability, and efficiency. PTFE (Polytetrafluoroethylene) lined gate valves and conventional metal-seated gate valves are two widely used options, each with its own set of advantages and limitations. PTFE lined gate valves are preferred in industries dealing with highly corrosive fluids, while conventional gate valves remain dominant in high-pressure and high-temperature applications.

This article provides a comprehensive comparison between PTFE lined gate valves and conventional gate valves, discussing their design, performance, maintenance requirements, cost-effectiveness, and suitability for different industries.

Design and Material Composition

PTFE Lined Gate Valves

Designed with an internal PTFE lining that protects the valve’s metallic body from corrosive fluids.

Typically constructed with materials like cast iron, ductile iron, or stainless steel to ensure structural integrity while benefiting from PTFE’s corrosion resistance.

The non-stick and low-friction properties of PTFE provide smooth valve operation and prevent buildup of deposits.

Conventional Gate Valves

Made entirely of metal, including stainless steel, carbon steel, or bronze.

Available in different designs such as wedge gate, slab gate, and parallel slide gate valves.

Require additional coatings or internal linings (like epoxy or rubber) for corrosion protection, which may degrade over time.

Performance & Durability

Corrosion Resistance

PTFE Lined Gate Valves: Offer excellent chemical resistance to acids, alkalis, and solvents, making them ideal for highly aggressive environments.

Conventional Gate Valves: More susceptible to corrosion, requiring special coatings or higher-grade alloys for resistance, which increases cost.

Temperature and Pressure Handling

PTFE Lined Gate Valves: Typically designed for moderate pressure applications (ANSI Class 150-300) and temperatures between -50°C to 200°C.

Conventional Gate Valves: Can withstand extreme high-pressure (ANSI Class 600-2500) and high-temperature conditions (up to 600°C), making them suitable for steam and power plants.

Sealing Efficiency

PTFE Lined Gate Valves: Provide superior zero-leakage sealing, ensuring tight shutoff and preventing fluid loss.

Conventional Gate Valves: Offer effective sealing but may experience wear over time, leading to potential leakage if not maintained properly.

Cost & Maintenance Considerations

Initial Investment

PTFE Lined Gate Valves: Higher upfront cost due to PTFE lining and specialized construction.

Conventional Gate Valves: Lower initial cost, but potential expenses arise due to frequent maintenance in corrosive applications.

Maintenance and Service Life

PTFE Lined Gate Valves: Require minimal maintenance since PTFE lining prevents scaling, deposits, and corrosion.

Conventional Gate Valves: More prone to corrosion, erosion, and mechanical wear, requiring frequent servicing and part replacements.

Industry Suitability

PTFE Lined Gate Valves: Best for Corrosive Environments

Chemical Processing: Handles strong acids and corrosive fluids safely.

Pharmaceutical Industry: Maintains sterility and prevents contamination.

Water & Wastewater Treatment: Resistant to scaling and harsh treatment chemicals.

Food & Beverage: Hygienic and resistant to cleaning agents.

Conventional Gate Valves: Best for High-Pressure and High-Temperature Applications

Oil & Gas Industry: Withstands extreme pressure in refineries and pipelines.

Power Plants: Handles steam at high temperatures and pressures.

Mining & Metallurgy: Robust design for handling abrasive slurries and solids.

Long-Term Cost Analysis

Although PTFE lined gate valves have a higher initial investment, their low maintenance costs and extended lifespan make them more cost-effective in corrosive industries. Conventional gate valves, while more affordable upfront, may lead to higher operational costs due to frequent repairs and material degradation in chemical environments.

Final Verdict: Which One Should You Choose?

Choose PTFE Lined Gate Valves if: You require excellent corrosion resistance, low maintenance, and contamination-free operation in industries like chemical processing and pharmaceuticals.

Choose Conventional Gate Valves if: You need to handle high-pressure and high-temperature conditions in power plants, steam applications, or the oil & gas industry.

Both PTFE lined gate valves and conventional gate valves serve critical roles in industrial applications. The choice depends on operational conditions, fluid compatibility, and long-term maintenance considerations. Investing in the right valve ensures safety, efficiency, and cost savings, making it essential to evaluate your industry’s specific requirements before making a selection.

0 notes

Text

The Role of Double Block and Bleed Valves in Chemical Processing: A Comprehensive Guide

Chemical processing facilities demand the highest standards of safety and operational efficiency due to the handling of reactive and potentially dangerous substances. One critical component that supports these standards is the Double Block and Bleed Valve. In this comprehensive guide, we examine the role of these valves in chemical processing, discussing their design, operational benefits, and the specific challenges they help overcome in maintaining a safe and efficient production environment.

What Are Double Block and Bleed Valves? At their core, Double Block and Bleed Valves are designed with two independent sealing mechanisms and an intervening bleed port. This configuration creates a redundant barrier that is crucial for isolating process lines, especially in scenarios where any leakage could have severe consequences. In chemical processing, where the purity and containment of chemicals are critical, these valves play an indispensable role.

Key Features and Operational Principles

Dual Sealing Mechanism: The valve employs two seals—an upstream and a downstream seal—to ensure that even if one seal fails, the other will maintain isolation.

Bleed Port Functionality: The bleed port, located between the two seals, allows for the controlled release of pressure and provides a means to test the integrity of the seals. This is especially important during routine maintenance or emergency shutdowns.

Material and Construction: Chemical processing environments can be extremely harsh. Therefore, these valves are often made from high-grade stainless steel, carbon steel, or specialized alloys to resist corrosion, high temperatures, and aggressive chemicals.

Advantages in Chemical Processing The deployment of Double Block and Bleed Valves in chemical processing offers several advantages:

Improved Safety: With dual seals, the risk of inadvertent chemical releases is greatly reduced, ensuring the safety of both personnel and equipment.

Enhanced Process Control: The ability to depressurize and monitor the interspace between seals allows operators to verify complete isolation before undertaking maintenance tasks.

Operational Flexibility: These valves enable selective isolation of process segments. This means that routine servicing or emergency interventions can be carried out without halting the entire production line.

Regulatory Compliance: Chemical processing plants are subject to strict safety and environmental regulations. The use of Double Block and Bleed Valves helps ensure compliance with industry standards, such as those set by API, ASME, and ISO.

Industry Applications and Use Cases Double Block and Bleed Valves are utilized in various chemical processing applications:

Batch Processing Systems: Where precise control over chemical reactions is required, these valves help isolate specific sections of the process, ensuring that reactions proceed safely.

Continuous Processing Plants: In continuous flow operations, they allow for the safe diversion of process streams during routine maintenance or emergency shutdowns.

Storage and Transfer Operations: When chemicals are transferred between storage tanks or processing units, these valves ensure that accidental mixing or contamination does not occur.

Installation and Maintenance Best Practices Ensuring the long-term reliability of Double Block and Bleed Valves in a chemical processing environment involves:

Professional Installation: Correct installation by trained technicians is essential. Proper alignment and secure connections are critical for maintaining the integrity of the dual seals.

Routine Inspections: Regular maintenance checks should be performed to assess seal wear, verify the functionality of the bleed port, and confirm overall valve performance.

Documentation and Compliance: Keeping detailed maintenance records and ensuring adherence to industry standards not only enhances safety but also facilitates regulatory compliance and audits.

Emerging Trends in Valve Technology The field of valve technology is rapidly evolving. Innovations such as the integration of digital monitoring systems and advanced materials are enhancing the performance of Double Block and Bleed Valves. These trends are particularly significant in chemical processing, where the ability to predict and prevent failures can lead to improved safety and operational efficiency. Smart sensors now offer real-time insights into valve performance, enabling predictive maintenance and reducing the likelihood of unexpected downtime.

Conclusion Double Block and Bleed Valves have become an essential component in chemical processing facilities, providing unmatched safety and operational benefits. Their robust design, featuring dual seals and a functional bleed port, ensures reliable isolation of process lines and helps maintain the integrity of sensitive chemical processes. As the Chemical industry continues to advance, the adoption of cutting-edge valve technologies will further improve safety standards, operational efficiency, and regulatory compliance. For chemical processing plants, investing in these advanced valves is not just a matter of regulatory necessity—it is a strategic move towards ensuring long-term process safety and operational excellence.

#Double Block and Bleed Valve#DBB Valve#Chemical and Fertilzer Industry#Isolation valves#Manufacturers#suppliers#freture techno#Mumbai#India

1 note

·

View note