#FEP Lined Ball Valve

Explore tagged Tumblr posts

Text

How PTFE Lined Ball Valves Enhance Chemical Processing Efficiency

Industrial processes rely on durable, corrosion-resistant components to handle aggressive chemicals. PTFE lined ball valves play a vital role in ensuring chemical processing efficiency, offering leak-proof operation, minimal friction, and enhanced durability. These properties make them ideal for applications where chemical purity, longevity, and operational safety are key concerns.

How PTFE Lining Improves Performance

Exceptional Chemical Compatibility: Prevents chemical breakdown and degradation.

Reduced Friction & Clogging: Ensures smooth flow and minimizes blockages.

Extended Valve Lifespan: Resists wear, reducing replacement and maintenance costs.

Key Benefits for Chemical Plants

PTFE lined ball valves are indispensable in chemical plants, where exposure to corrosive fluids poses operational risks. The protective PTFE barrier prevents leaks and ensures safe, contamination-free processing.

Leak-Proof Design: Minimizes hazardous spills and improves workplace safety.

High Temperature & Pressure Tolerance: Ideal for extreme processing conditions.

Long-Term Cost Savings: Reduced downtime and maintenance enhance plant efficiency.

The FDA-approved PTFE lining further supports industries requiring strict hygiene compliance, including pharmaceutical and food processing sectors. With versatile end connections and configurations, PTFE lined ball valves cater to diverse industrial needs, ensuring seamless integration into processing systems.

Investing in PTFE lined ball valves guarantees long-term operational efficiency, safety, and cost savings. Their non-stick, non-reactive properties make them a superior choice over conventional ball valves, particularly for industries dealing with highly aggressive fluids. With the ability to maintain purity, prevent contamination, and withstand extreme conditions, these valves continue to set the standard for chemical processing applications.

Choosing a trusted PTFE Lined ball valve manufacturer ensures high-quality solutions tailored to specific industry requirements, enabling businesses to optimize their operations and enhance overall system reliability.

#PTFE Lined Ball Valve#FEP Lined Ball Valve#Lined Ball Valves#manufacturers#suppliers#india#freturetechno

0 notes

Text

Valve Manufacturing Companies in India Powering Oil & Gas Sectors

India's industrial sectors are growing rapidly, and the oil and gas industry stands at the forefront of this progress. At the heart of this critical sector lies an equally vital component—industrial valves. Today, valve manufacturing companies in India are playing a pivotal role in supporting the infrastructure and operations of the oil and gas domain. With precision engineering, innovative designs, and compliance with global standards, Indian valve manufacturers are not just meeting domestic demand but also expanding their global footprint.

Rising Demand for Industrial Valves in Oil & Gas

The oil and gas industry demands high-performance valves capable of withstanding extreme temperatures, pressures, and corrosive environments. Whether upstream in drilling, midstream in transportation, or downstream in refining, valves regulate and control the flow of liquids and gases, ensuring safe and efficient operations.

India’s increasing energy needs, driven by rapid urbanization and industrialization, have triggered a surge in infrastructure development. Pipelines, refineries, and LNG terminals all require robust valve systems. This demand has driven valve manufacturing companies in India to invest in R&D, innovation, and automation to deliver world-class solutions.

How Valve Manufacturing Companies in India Serve the Oil & Gas Industry

Indian valve manufacturers have evolved significantly in recent decades. Today, they cater to a wide range of oil and gas applications with products like gate valves, globe valves, ball valves, check valves, control valves, and pressure relief valves.

Precision Engineering by Valve Manufacturing Companies in India

Companies like MNC Valves are leveraging CNC machining, CAD/CAM software, and advanced testing equipment to ensure precision in every product. Valves are manufactured to meet API, ASME, and ISO standards, ensuring safety and performance in the harshest environments.

Customization and Material Expertise

Oil and gas operations often require valves made of special materials such as duplex stainless steel, Inconel, and Hastelloy. Indian manufacturers offer material customization, coating options (PFA, FEP, epoxy), and valve designs tailored to specific operational requirements. This flexibility makes them a trusted partner for complex projects in both onshore and offshore environments.

Global Competitiveness and Export Capabilities

Over the years, Indian valve manufacturers have built a reputation for quality, timely delivery, and cost competitiveness. With in-house design teams, advanced production lines, and skilled labor, they have earned certifications from international bodies such as CE, ATEX, and SIL.

Many valve manufacturing companies in India are now major exporters, supplying valves to oil and gas markets in the Middle East, Africa, Southeast Asia, and Europe. Their valves are used in refineries, petrochemical plants, LNG terminals, and offshore rigs across the globe.

MNC Valves – A Trusted Name in Oil & Gas Valve Solutions

As one of the leading valve manufacturing companies in India, MNC Valves stands out for its focus on innovation, quality, and customer service. The company offers a comprehensive range of industrial valves designed to meet the stringent requirements of the oil and gas sector.

From design to dispatch, MNC Valves ensures rigorous quality checks, third-party inspections, and traceability of materials. Their ability to deliver custom-engineered valves within tight timelines has earned them repeat clients from across India and abroad.

Future Outlook – Supporting India’s Energy Vision

India’s energy sector is poised for massive growth, with ambitious targets for refining capacity, pipeline expansion, and LNG infrastructure. This growth will further increase demand for high-performance valves. Government initiatives such as “Make in India” and investments in domestic oil exploration are expected to boost the local manufacturing ecosystem.

Valve manufacturing companies in India, like MNC Valves, are strategically positioned to meet this demand by continuously upgrading their technology and expanding their manufacturing capabilities. Their role in ensuring safety, efficiency, and reliability across the oil and gas value chain will only become more critical in the years ahead.

FAQs About Valve Manufacturing Companies in India

Q1: What types of valves are commonly used in the oil and gas industry? A: Common types include gate valves, globe valves, ball valves, butterfly valves, check valves, and control valves. These valves are essential for flow regulation, pressure control, and system safety.

Q2: Are Indian valve manufacturers globally certified? A: Yes. Many Indian valve companies, including MNC Valves, hold certifications like ISO, API, CE, and ATEX, ensuring they meet international quality and safety standards.

Q3: Can Indian valve manufacturers offer customized solutions? A: Absolutely. Leading valve manufacturers in India provide customized valves based on material, size, pressure class, and application requirements specific to the oil and gas industry.

Q4: What sets MNC Valves apart from other valve manufacturers? A: MNC Valves focuses on precision engineering, stringent quality control, and customer-centric customization, making it a preferred supplier in both domestic and international oil & gas markets.

In conclusion, valve manufacturing companies in India are integral to the development and success of the oil and gas industry. With their focus on quality, innovation, and customer satisfaction, firms like MNC Valves are powering critical energy infrastructure both at home and abroad.

#valve manufacturer in Ahmedabad#valve manufacturing companies in India#valves manufacturer in india

0 notes

Text

Gate Valve Exporter - Mayur Valves MVS

Mayur (Valves) System Private Limited is an ISO 9001 : 2015 Certified Company, Established in the year 1978, MVS Industrial Valves offers Diaphragm Valves, Ball Valves, Plug Valves, Butterfly Valves, Gate Valves, Globe Valves, Check Valves or Non Return Valves, Knife Gate Valves, Sight Flow Indicator or Sight Glass, Strainer or Filters, PTFE / FEP / PFA / PVDF Lined Valve, PTFE Lined Pipe, PTFE / FEP / PFA / PVDF Lined Pipe Fittings and Plastic / PP / PVDF Valves. Gate Valve Manufacturers Exporters in India MVS Industrial Valves have been exported to more than 40+ countries worldwide

Assurance of Quality: Mayur Valves MVS follows strict quality control procedures to guarantee that every gate valve satisfies global requirements. Every stage of the production process, from obtaining raw materials to inspecting the finished product, is cantered upon quality.

Wide Product Selection: To meet the needs of many applications and industries, Mayur Valves MVS provides a wide selection of gate valves. Mayur Valves MVS offers a solution for your needs, whether they are for industrial operations, oil and gas, or water supply valves.

Customization Options: Mayur Valves MVS offers customization options to fit gate valves to individual demands, acknowledging that every project has different requirements. Customers can request customized solutions, ranging from material selection to size and design alterations.

Reliable Performance: Mayur Valves MVS gate valves are built to provide constant performance even in the most demanding conditions, with a focus on durability and dependability. Thorough testing guarantees that every valve surpasses expectations and fulfils performance criteria.

Global Reach: Mayur Valves MVS reaches markets on all continents as an exporter, providing services to clients all over the world. Customers can count on prompt product delivery no matter where they are thanks to an efficient distribution system and effective logistics.

Conclusion

Go no further than Mayur Valves MVS for quality gate valves built for dependability and performance. Dedicated to quality and client satisfaction, Mayur Valves MVS is still a reliable partner for businesses worldwide. Get in touch with us right now to find out more about our offerings.

Contact Us: - +91 9898563969 [email protected]

Address: - Mayur (Valves) System Private Limited, SOBO Center, 421, Block B, 4th Floor, Gala Gymkhana Road, Near Sun City, South Bopal, Ahmedabad - 380058, Gujarat, India.

Visit for More Information: - https://mvsvalves.com/

#Gate Valve Exporter#Gate Valve Manufacturers Exporters in India#gate valve manufacturers exporters in gujarat#gate valve manufacturers exporters

0 notes

Text

#valve#valves#industrial valve#valves manufacturers#valves exporters#ball valves#fep/pfa lined valves

1 note

·

View note

Link

Fiksar Valve Mfg - Our wide range of Ball Valve, Plug Valve, Butterfly Valve, Knife Edge Gate Valve, Non Return Valve, Steam Trap, Ball Valve, Ball Valve API 6D, Plug Valve Teflon Sleeve, PTFE Lined Plug Valve, FEP Lined Plug Valve, PFA Lined Plug Valve, Ball Valve BS5351, SMS Ball Valve Manufacturer, Supplier, Gujarat, India

1 note

·

View note

Text

The Ultimate Guide to Pp Ball Valves With Electrical Actuators

An overview of PP ball valves with electrical actuators

PP (polypropylene) ball valves with electrical actuators are valves that use a ball to control the flow of fluids. The ball is rotated by an electric actuator, which can open or close the valve to allow or restrict the flow of the fluid. PP is a thermoplastic polymer that is commonly used in the manufacturing of valves due to its chemical resistance, durability, and low cost. These valves are commonly used in industrial and commercial applications such as water treatment, chemical processing, and HVAC systems. They are available in a variety of sizes and pressure ratings and can be controlled by a variety of electrical actuator types such as pneumatic, hydraulic, and electric.

The benefits of using PP ball valves with electrical actuators

There are several benefits to using PP ball valves with electrical actuators:

Durability: PP is a strong and durable material that is resistant to many chemicals, making it well suited for use in harsh industrial environments.

Chemical resistance: PP is resistant to a wide range of chemicals, including acids, bases, and organic solvents, making it ideal for use in chemical processing and other industrial applications.

Low cost: Compared to other types of valves, PP ball valves are relatively inexpensive, making them a cost-effective choice for many applications.

Easy to operate: Electrical actuators make it easy to open and close the valve remotely, allowing for precise control of fluid flow.

Low maintenance: PP ball valves with electrical actuators require minimal maintenance, making them a reliable choice for long-term use.

Variety of control options: The electrical actuator can be controlled by different systems such as PLC, DCS, SCADA and other control systems

High-temperature resistance: PP can withstand high temperatures and maintain its strength, making it suitable for high-temperature applications.

Lightweight: PP ball valves are lightweight and easy to handle, making them easy to install and maintain.

Suitable for both liquid and gas: PP ball valves are suitable for both liquid and gas applications and can be used in a wide range of industries such as HVAC, Water treatment, and chemical processing.

The different types of PP ball valves with electrical actuators

There are several types of PP ball valves with electrical actuators, including:

Full-port PP ball valves: These valves have a large flow passage and a full-size ball, allowing for minimal pressure drop and maximum flow through the valve.

Reduced-port PP ball valves: These valves have a smaller flow passage and a smaller ball, which can be useful for applications where flow control is more important than flow rate.

Three-way PP ball valves: These valves have three ports and are used to direct the flow of fluid between two different paths. They are commonly used in HVAC systems and other applications where the flow of fluid needs to be directed to multiple locations.

PTFE/FEP Lined PP ball valves: These valves have an inner lining made of PTFE or FEP, which provides excellent chemical resistance, making them suitable for use in harsh chemical environments.

Flanged PP ball valves: These valves have flanges on the ends, which allows for easy installation and secure connection to pipes and other fittings.

Threaded PP ball valves: These valves have threads on the ends, which allows for easy installation and secure connection to pipes and other fittings.

Actuator PP ball valves: These valves have an actuator attached to the valve stem, which is used to open and close the valve. Actuators can be pneumatic, electric, or hydraulic.

High-pressure PP ball valves: These valves are designed to handle high-pressure applications and are available in a variety of pressure ratings.

Cryogenic PP ball valves: These valves are designed to handle low temperatures and are suitable for use in cryogenic applications such as LNG storage and transportation.

The installation process of PP ball valves with electrical actuators

The installation process of PP ball valves with electrical actuators typically includes the following steps:

Planning: Before installing the valve, it is important to plan the location of the valve and ensure that it is easily accessible for maintenance and operation. It is also important to confirm that the valve is the correct size and type for the application and that the necessary connections and accessories are available.

Preparation: Before installing the valve, the pipe or fitting should be cleaned and checked for any damage or debris. The valve should also be checked to ensure that it is free from damage and that all parts are present and in good condition.

Installation: The valve should be installed in the pipe or fitting, making sure that it is properly aligned and that the gasket or sealing ring is in place. The valve should then be tightened using the appropriate tools, making sure not to overtighten.

Connection: The electrical actuator should be connected to the valve according to the manufacturer's instructions, making sure that the correct wiring and voltage are used.

Testing: The valve should be tested to ensure that it is functioning properly and that there are no leaks or other issues. This can be done by running water or other fluid through the valve and observing the flow.

Maintenance: Regular maintenance should be performed on the valve and actuator to ensure proper functioning and longevity. This may include cleaning, lubrication, and replacement of parts as needed.

It is important to follow the manufacturer's instructions and any local codes and regulations when installing a PP ball valve with electric actuator. It is also important to have trained personnel with relevant knowledge and experience to do the installation.

How to maintain PP ball valves with electrical actuators

Proper maintenance is crucial to ensure the longevity and proper functioning of PP ball valves with electrical actuators. Here are some steps for maintaining these valves:

Regular Inspection: Inspect the valve and actuator regularly for any signs of wear, damage, or leakage. This can be done by visually inspecting the valve and actuator, as well as by running fluid through the valve and observing the flow.

Cleaning: Keep the valve and actuator clean to prevent build-up of debris or corrosion. This can be done by wiping down the valve and actuator with a clean, dry cloth.

Lubrication: Lubricate the valve and actuator as needed to ensure smooth operation. This should be done according to the manufacturer's instructions, using the recommended lubricant.

Tightening: Check the valve and actuator connections for proper tightness and retighten if necessary. Overtightening can cause damage so it is important to use the appropriate tools and to follow the manufacturer's instructions.

Actuator maintenance: Check the actuator for proper operation and lubrication, as well as for proper voltage and amperage. Actuator's manual and instructions should be followed for proper maintenance.

Replace worn parts: Replace any worn or damaged parts, such as gaskets, seals, or O-rings, to ensure proper functioning and to prevent leaks.

Storing: If the valve is not in use for an extended period of time, it should be stored in a clean and dry place, protected from extreme temperatures and humidity.

It's important to follow the manufacturer's instructions for maintenance and to have trained personnel with relevant knowledge and experience to do the maintenance. It's also important to follow the safety guidelines and regulations while performing the maintenance.

0 notes

Text

Best PTFE Lined Ball Valves manufacturer | Nobleglassworks

Nobel Glass Works is the Best PTFE Lined Ball Valves manufacturer in India. We introduce ourselves as a reputed manufacturer of Industrial Glass equipment like borosilicate glass tube, PTFE , FEP, PFA products, sight glass, heat exchanger, flask, valves, solar tube, well glass & pipe line components etc.

If you are looking for the PTFE Lined Ball Valves manufacturer in India, Nobel Glass Works is a trusted name in the market.

0 notes

Text

FEP and UPVC Ball Valve

What is UPVC 3-Way Ball Valve? What is a Valve?

Taking a look at the humble pipe is a good place to start. It could be a pipe transporting water in your bathroom or a pipe carrying gas to your kitchen stove. A mechanism that controls how much liquid or gas flows through these liquid and gas pipes is required to function efficiently; this mechanism can be used to increase, decrease, or even stop the flow of fluid or gas. A valve is a mechanism that performs this function. They are mechanical switches that can turn pipes on and off as well as increase or decrease the flow of fluid/gas through them.

Now let's take a look at a few more examples from everyday life. To brush your teeth, you open a valve that lets pressurized water flow out of the pipe when you turn on the tap. Turning the tap more to one side typically reduces, stops, or increases the amount of water coming out (depending on the valve).

FEP Ball Valves:

The best type of ball valve to use for paper and pulp industries is the FEP-lined ball valve. At 10kg/cm2 pressure and 180°C operating temperature, it is capable of withstanding a pressure of 180°C. FEP-lined Ball Valves are ideal for slurries and viscous materials since they are non-sticky. Its unique properties make it superior to alloys.

In terms of its effects, FEP is similar to PTFE except for its soften-processed performance. Despite this, FEP can be quickly processed, welded, and re-molded into complex shapes. Welding and remodeling prospects, chemical and UV resistance, biocompatibility, and clear color are some of the unique properties of FEP.

PFA Ball Valve:

Many oil and gas industries utilize PFA-lined ball valves. PFA-lined valves can withstand temperatures up to 230°C at 10kg/cm2. PFA-lined valves have similar properties and qualities to FEP, but PFA is more temperature-resistant than FEP. In addition to their thermoplastic properties, PFA-lined valves offer a wide range of benefits. A thermoplastic material with the highest working temperature capacity is PFA. There is no fluoroplastic that can work continuously at a temperature higher than +260°C. It is possible to weld and re-mold it, with good permeability and outstanding chemical resistance. We are the PFA lined ball valve manufacturers in India.

What is UPVC 3-Way Ball Valve?

UPVC Ball Valve Manufacturers: The two ports of the PVC union ball valve are made up of two unions that can be disassembled and replaced at any time, making them easier to check and replace than common ball valves. An adjustable tightness, a low friction coefficient, ease of maintenance, and no leaks are some of the characteristics of a union ball valve. Furthermore, since the joints can be purchased separately, you can choose between threaded, socket, and standard joints. Although its single cost is higher than that of common ball valves, its replacement cost is lower.

Aira Euro Automation is the leading ball valve manufacturer in India. We offer various types of industrial valves like ball valves, butterfly valves, control valves, and many more.

0 notes

Link

Lined Ball Valves - We offer Lined Ball Valve at affordable rates ... 1" to 6" Flanged. Ball with Shaft. WCB / SS 304. Seals. PTFE. Temprature FEP.

0 notes

Photo

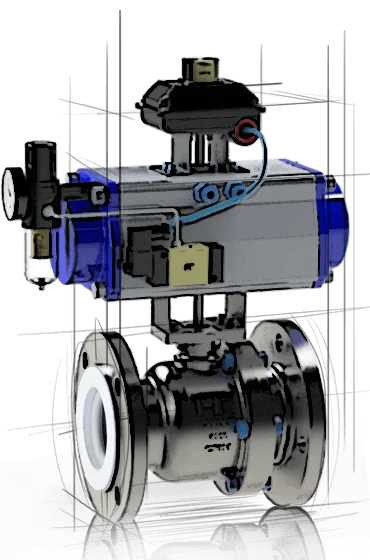

Live in the moment and enjoy your weekend.😀 The below is FEP fully lined ball valve.

0 notes

Text

Industrial Valve Suppliers | Ball Valve Manufacturers | Butterfly Valve Manufacturers in India

Valves are one of the important parts of machinery or instrument which delivers special purpose and specifically designed for the suitable operation. The operation quality of plant or instrument is depends on the work ability or functionality of valves. Therefore it is crucial to keep industrial valve’s functioning proper for the success of the operation.

Industrial valves have wide range of application area, mainly used for controlling or throttling applications. Industrial valves are used at so many places in a single process plants. The valves are used to keep the process variables stable or as requirement position within the suitable operation range and to keep flow of material in predefined manner. It is also used to keep required temperature of material in the process.

These variables are level and flow of fluid or gas as well as of required of material. It is obligatory to keep an industrial valve efficient because it is the device which is responsible to affect the operation.

Industrial valve suppliers in India offer wide range of industrial valves. These valves include ball valves, gate valves, butterfly valves and many more.

Ball valves are specifically designed to use in the applications like water, air and steam pipe line. Depending upon the application area, the material of construction is decided. Several materials like cast iron, carbon steel and stainless steel are used to build valve. FEP and PFA lined material is also used to build the valve for specific application.

Ball Valve is a device which is used to control the flow of medium. Ball Valve Manufacturers in India helps to select the best suitable choice of ball valve considering the application area of ball valve.

Butterfly Valve Manufacturers in India provide best quality butterfly valve with a reliable range. Butterfly valves used to control the flow of a medium but leave some material in the pipes. It is generally used in low temperature and low pressure flow system. It is light in weight and contain face to face dimension.

Butterfly valves are the quarter turn valves. Butterfly valves are designed to function well in different kinds of mediums. It is used for both the purposes, to regulate the flow of material as well as for the isolation purpose.

Yogi Plast Service is one of the best Indian manufacturers, manufacture and supply high quality ball valves and butterfly valves.

http://www.industrialproductssupplier.com/product-category/all-category/industrial-valve/

0 notes

Text

Industrial Valve Suppliers | Ball Valve Manufacturers | Butterfly Valve Manufacturers in India

Valves are one of the important parts of machinery or instrument which delivers special purpose and specifically designed for the suitable operation. The operation quality of plant or instrument is depends on the work ability or functionality of valves. Therefore it is crucial to keep industrial valve’s functioning proper for the success of the operation.

Industrial valves have wide range of application area, mainly used for controlling or throttling applications. Industrial valves are used at so many places in a single process plants. The valves are used to keep the process variables stable or as requirement position within the suitable operation range and to keep flow of material in predefined manner. It is also used to keep required temperature of material in the process.

These variables are level and flow of fluid or gas as well as of required of material. It is obligatory to keep an industrial valve efficient because it is the device which is responsible to affect the operation.

Industrial valve suppliers in India offer wide range of industrial valves. These valves include ball valves, gate valves, butterfly valves and many more.

Ball valves are specifically designed to use in the applications like water, air and steam pipe line. Depending upon the application area, the material of construction is decided. Several materials like cast iron, carbon steel and stainless steel are used to build valve. FEP and PFA lined material is also used to build the valve for specific application.

Ball Valve is a device which is used to control the flow of medium. Ball Valve Manufacturers in India helps to select the best suitable choice of ball valve considering the application area of ball valve.

Butterfly Valve Manufacturers in India provide best quality butterfly valve with a reliable range. Butterfly valves used to control the flow of a medium but leave some material in the pipes. It is generally used in low temperature and low pressure flow system. It is light in weight and contain face to face dimension.

Butterfly valves are the quarter turn valves. Butterfly valves are designed to function well in different kinds of mediums. It is used for both the purposes, to regulate the flow of material as well as for the isolation purpose.

Yogi Plast Service is one of the best Indian manufacturers, manufacture and supply high quality ball valves and butterfly valves.

http://www.industrialproductssupplier.com/product-category/all-category/industrial-valve/

0 notes

Text

Industrial Valve Suppliers | Ball Valve Manufacturers | Butterfly Valve Manufacturers in India

Valves are one of the important parts of machinery or instrument which delivers special purpose and specifically designed for the suitable operation. The operation quality of plant or instrument is depends on the work ability or functionality of valves. Therefore it is crucial to keep industrial valve’s functioning proper for the success of the operation.

Industrial valves have wide range of application area, mainly used for controlling or throttling applications. Industrial valves are used at so many places in a single process plants. The valves are used to keep the process variables stable or as requirement position within the suitable operation range and to keep flow of material in predefined manner. It is also used to keep required temperature of material in the process.

These variables are level and flow of fluid or gas as well as of required of material. It is obligatory to keep an industrial valve efficient because it is the device which is responsible to affect the operation.

Industrial valve suppliers in India offer wide range of industrial valves. These valves include ball valves, gate valves, butterfly valves and many more.

Ball valves are specifically designed to use in the applications like water, air and steam pipe line. Depending upon the application area, the material of construction is decided. Several materials like cast iron, carbon steel and stainless steel are used to build valve. FEP and PFA lined material is also used to build the valve for specific application.

Ball Valve is a device which is used to control the flow of medium. Ball Valve Manufacturers in India helps to select the best suitable choice of ball valve considering the application area of ball valve.

Butterfly Valve Manufacturers in India provide best quality butterfly valve with a reliable range. Butterfly valves used to control the flow of a medium but leave some material in the pipes. It is generally used in low temperature and low pressure flow system. It is light in weight and contain face to face dimension.

Butterfly valves are the quarter turn valves. Butterfly valves are designed to function well in different kinds of mediums. It is used for both the purposes, to regulate the flow of material as well as for the isolation purpose.

Yogi Plast Service is one of the best Indian manufacturers, manufacture and supply high quality ball valves and butterfly valves.

http://www.industrialproductssupplier.com/product-category/all-category/industrial-valve/

0 notes

Text

What is the difference between PTFE, FEP and PFA?

PTFE, FEP, and PFA are the most well-known and commonly utilised fluoroplastics. But what are the differences between them? Learn why fluoropolymers are unique and which fluoroplastic is suitable for your application.

The properties of fluoroplastics:

Fluoropolymers offer a number of unique characteristics that make them suited for a wide range of applications, including residential, medical, automotive as well as electrical.

Noble Glass Works is the most prominent and noted PTFE Lined Ball Valves manufacturer in India.

The properties:

● They can withstand extremely high temperatures,

● They have non-stick qualities,

● They are known to have a low friction surface,

● They have extreme resistance to solvents, chemicals, as well as electricity.

Different fluoroplastics have small differences, such as different working temperatures, and are suitable for different applications. When used effectively, fluoropolymers can give significant cost and performance benefits.

Noble Glass Works is a respected PTFE Lined Ball Valves manufacturer in Gujarat.

1. PTFE (Polytetrafluoroethylene):

The forefather of all fluoroplastics is polytetrafluoroethylene or PTFE. The most prevalent fluoropolymer is PTFE, which was discovered by chemist Roy J. Plunkett in 1938 and has the best temperature, chemical resistance, and non-stick properties.

Aside from the unique properties of fluoroplastics, PTFE stands out by providing the following benefits:

● It has the best price-performance ratio of any fluoroplastic, and it can work continuously at 260°C + temperature, which is the highest of any other fluoroplastic.

● It is chemically resistant, has strong non-stick characteristics, and is translucent in colour.

The fact that PTFE does not dissolve when heated is its primary disadvantage, making it difficult to process. Very uncommon methods are required to mould, extrude, and fuse this fluoropolymer.

PTFE is ideal for electronic component protection as well as electrical insulation due to its unique properties.

Noble Glass Works is one of the excellent as well as most reliable PTFE High Pressure Bellows manufacturers in India.

2. FEP (Fluoroethylenepropylene):

FEP is the melt-processable version of PTFE (Fluoroethylenepropylene). FEP is similar to PTFE in terms of properties, although it has a lower maximum operating temperature of +200°C. FEP, on the other hand, is easier to work with and can be welded and re-moulded into complex shapes.

In addition to the unique properties of fluoroplastics, FEP has the following advantages:

● It has a great potential for welding and re-moulding, and it can act without hesitation at temperatures ranging from -200°C to +200°C and cryogenic temperatures. FEP is highly resistant to chemicals and ultraviolet rays, and it is bio-compatible and clear in colour.

The low shrink temperature of FEP heat shrink allows it to be safely shrunk over objects that are temperature-sensitive without causing any kind of injury. As a result, FEP is a fantastic material for encasing sensitive electrical components and equipment.

If you are looking for the renowned and most prevalent PTFE Lined Ball valve manufacturer in India, Noble Glass Works is the right choice for you.

3. PFA (Perfluoralkoxy):

PFA, or perfluoralkoxy, is a high-temperature FEP derivative. PFA has similar properties to FEP, but because of its lower melt viscosity than PTFE, it can be used at temperatures up to +260°C and still be melt-processed.

In addition to the distinctive characteristics of fluoropolymers, PFA stands out by providing the following benefits:

● It has the same ability to work at 260°C+ as PTFE, and it has a high potential for welding and re-moulding.

● It has good permeability resistance, is chemically resistant even when working at high temperatures, is biocompatible, and has a clear colour.

The main disadvantage of PFA is that it is more costly than PTFE and FEP.

PFA is used in applications that require a higher purity grade, better chemical resistance, and a higher working temperature. Medical tubing, valve liners, pumps and fittings, semi-conductor baskets, as well as heat exchangers all use this fluoroplastic.

#PTFE Lined Ball Valves manufacturer in India#PTFE Lined Ball Valves manufacturer in Gujarat#PTFE High Pressure Bellows manufacturers in India#Nobleglasswork

1 note

·

View note

Text

Industrial Valve Suppliers | Ball Valve Manufacturers | Butterfly Valve Manufacturers in India

Valves are one of the important parts of machinery or instrument which delivers special purpose and specifically designed for the suitable operation. The operation quality of plant or instrument is depends on the work ability or functionality of valves. Therefore it is crucial to keep industrial valve’s functioning proper for the success of the operation.

Industrial valves have wide range of application area, mainly used for controlling or throttling applications. Industrial valves are used at so many places in a single process plants. The valves are used to keep the process variables stable or as requirement position within the suitable operation range and to keep flow of material in predefined manner. It is also used to keep required temperature of material in the process.

These variables are level and flow of fluid or gas as well as of required of material. It is obligatory to keep an industrial valve efficient because it is the device which is responsible to affect the operation.

Industrial valve suppliers in India offer wide range of industrial valves. These valves include ball valves, gate valves, butterfly valves and many more.

Ball valves are specifically designed to use in the applications like water, air and steam pipe line. Depending upon the application area, the material of construction is decided. Several materials like cast iron, carbon steel and stainless steel are used to build valve. FEP and PFA lined material is also used to build the valve for specific application.

Ball Valve is a device which is used to control the flow of medium. Ball Valve Manufacturers in India helps to select the best suitable choice of ball valve considering the application area of ball valve.

Butterfly Valve Manufacturers in India provide best quality butterfly valve with a reliable range. Butterfly valves used to control the flow of a medium but leave some material in the pipes. It is generally used in low temperature and low pressure flow system. It is light in weight and contain face to face dimension.

Butterfly valves are the quarter turn valves. Butterfly valves are designed to function well in different kinds of mediums. It is used for both the purposes, to regulate the flow of material as well as for the isolation purpose.

Yogi Plast Service is one of the best Indian manufacturers, manufacture and supply high quality ball valves and butterfly valves.

http://www.industrialproductssupplier.com/product-category/all-category/industrial-valve/

0 notes

Link

Teflon Lined Ball Valves - We offer Teflon Lined Ball Valve at affordable rates ... 1" to 6" Flanged. Ball with Shaft. WCB / SS 304. Seals. PTFE. Temprature FEP.

0 notes