GREATPCB is well known turn-key PCB(1-30 layers) & PCB Assembly service provider for low- to mid-volume electronic contract manufacturing, including PCB fabrication, sourcing of components, and complete electronic PCB assembly. With a state of the art facility and modern technology.

Don't wanna be here? Send us removal request.

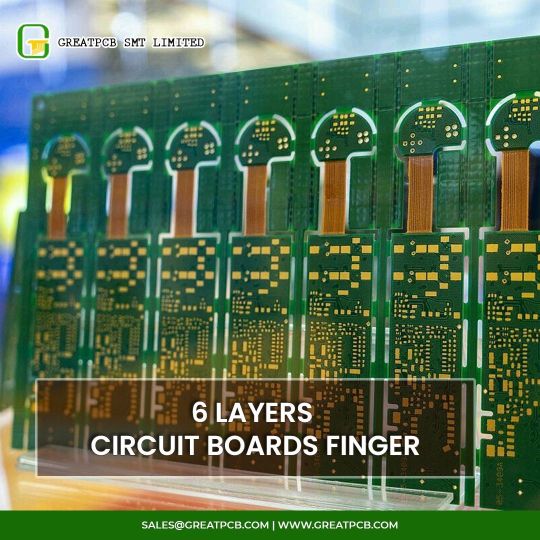

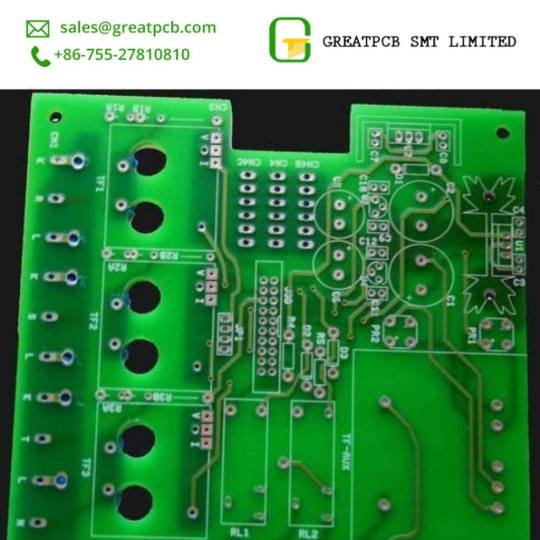

Photo

PCB Design Services, Printed Circuit Board Assembly | GreatPCB

Printed circuit board (PCB) fabrication and layout services is one of the ways that we help our customers get to market faster as our engineering team has significant real world experience designing PCBs for performance and manufacturability.

View more: https://www.greatpcb.com/design-pca/

0 notes

Text

Top 5 Primary Aspects of Heavy Copper PCB Design in 2022

Printed circuit boards are found in different electronic and electrical components. These products are in reality thin boards prepared from fibreglass or laminate materials. Based upon the applications various kinds of boards are used. The base layer of a standard board is generally constructed from fibreglass. Under normal conditions, these layers perform well. At high temperatures, this material however does not perform effectively. As a result, they sustain heavy damages.

Various aspects that require consideration

In the printed circuit board industry, the current trend is circuits made from copper. There is a relationship between heat rise and the flow of current. During the flowing of current through a trace localized heating occurs due to power loss. The cooling of traces occurs due to conduction and convection. Estimation of heat rise is essential for obtaining information about the safe transmission of current. Learn about the extensive use of heavy copper PCB through GreatPCB in electronic circuitry requiring high power.

1. Use of modern technology in different applications

Technology has advanced at a rapid pace. For high-end applications, heavy copper PCB is a great choice. With the development of society, the demand for these products has risen significantly. They are in substantial demand for a wide range of electronic industries. This technology can operate complex switches in those areas facing space constraints. They are used in the following applications generally:

· Torque controls

· Power line monitors

· Rail traction systems

· Overload relays

· HVAC systems

2. Maximum reliability

The motivating factors behind this technology are efficient thermal management and stable performance. The boards of modern times are constructed in such a manner to allow the passage of heavy currents. The process involves the generation of high heat. The optimal performance of the board takes place due to the efficient dissipation of heat. You may be unconvinced about the host of benefits that one can derive from electrical applications. In these situations, get in touch with an electrical specialist or a reputed manufacturer. Such companies are known for their supply of reliable components.

3. Going through the guidelines

In cases where controlled dielectric needs exist, the heavy boards will require this chemical element. To prevent the occurrence of short circuits space and trace width in heavy boards are increased to a significant extent. Upon request, reliable companies may satisfy customized needs. However, in these cases, the pricing structure is a bit higher. It is a prudent idea to send all the specifications and files you have to a reputed manufacturer for review and for getting a quote.

4. About their performance

Their performance is not affected by processing temperature. The elongation performance is the best. These products can even hold well during hot-melt welding procedures and do not show signs of brittleness when exposed to low temperatures. This chemical element develops a robust non-toxic layer even in the presence of a highly corrosive setup.

5. Unique features

These products have unique features. So they are appropriate for high-end applications. Some of the advantages are highlighted below:

· Thermal distribution

The copper-plated vias have powerful thermal resistance. They are in frequent use in sectors where high frequency and high speed are the need of the hour.

· Mechanical strength

These boards have incredible mechanical strength. They add to the robustness of the electrical system.

· Effective conductor

They are good conductors. So they play a vital role in the manufacturing of electronic devices. They assist in the joining of different boards together.

Act intelligently

Immerse yourself in extensive study to obtain information about companies that have gained a place of prominence in printed circuit board fabrication.

Blog Resource: https://greatpcbsmt.blogspot.com/2022/02/top-5-primary-aspects-of-heavy-copper.html

0 notes

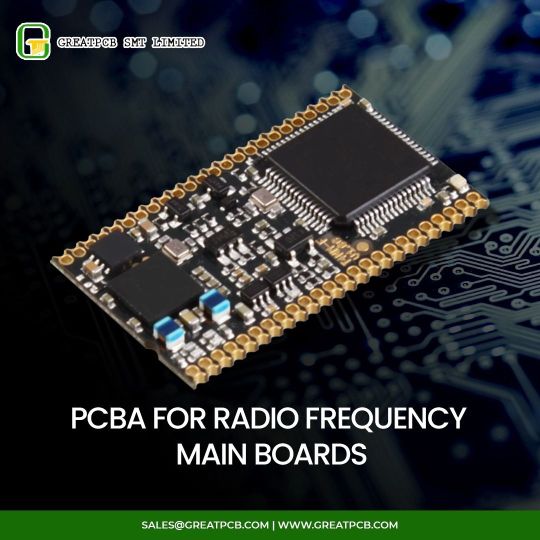

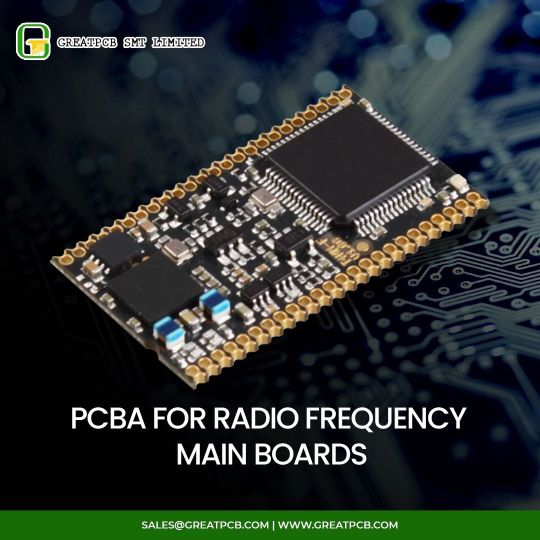

Photo

Reliable Quality PCB Assembly Services in China - GreatPCB

GREATPCB is a well-known turn-key PCB(1-30 layers) & PCB Assembly service provider for low- to mid-volume electronic contract manufacturing, including PCB fabrication, sourcing of components, and complete electronic PCB assembly. With a state of the art facility and modern technology.

View more: https://www.greatpcb.com/pcb-assembly/

0 notes

Text

Defining Printed Circuit Board Assembly and Ways to do it in 2022

A printed circuit board is an organized board of various electronics components that pass on the electricity to make a device function. Several tech businesses depend on PCBs. The businesses place an order for PCBs to top manufacturers, to get the parts they need. Often, the order is in bulk, as there is usually a huge scale of production. There are different ways of conducting the assembly process of PCB boards. This blog here tries to discuss the broad aspects of the manufacturing process in a detailed manner. Continue reading to know the details related to this topic.

The Basic Definition of the Assembly Process

GreatPCB is a top-notch manufacturer, having expertise in PCB board assembly, using advanced techniques in a flawless, accurate way. The process is all about connecting a wide range of components of the PCB, using a tested non-conductive substrate. From a practical perspective, there are three major ways to do the assembly process of PCBs.

Surface Mount Assembly Process (SMT)

The particular technique of Surface Mount Assembly was first developed by the manufacturers and researchers in the 1960s as an effective PCB board assembly procedure. In a couple of decades, the process developed further. There were more innovations in its application. Currently, most of the manufacturing plants implement the techniques of SMT to produce PCBs in bulk.

In this process, manufacturers consider components that have metal tabs. These components can be easily soldered on the surface of the circuit boards. The manufacturers use sophisticated soldering methods to perform the task. The main focus of SMT is to attain a higher circuit density, to make the product more efficient. It leads to improved functional features of the electronic device for which the PCB is used.

The Technology of Plated-Through-Hole (PTH)

It is yet another technology that is implemented to manufacture PCBs in bulk. In this case, the components have leads in their bodies. The PCBs under this process have well-defined drilled holes. The dimensions of the holes are decided by the manufacturers, according to industrial requirements and client specifications.

The drilled holes on the circuit boards make it practically very convenient to execute the assembly process, without any technical hassles. It saves considerable time for the PCB manufacturer. The level of efficiency is high. The manufacturer inserts the leads of the components through the hills of the circuit board.

Electro-Mechanical Assembly Process

Another term used for the electro-mechanical assembly process is the box-build assembly procedure. Numerous elements are used in this particular process. For example, the manufacturers use wire harnesses extensively. Also, metalwork is used comprehensively at the middle stages of the assembly process. The manufacturer customizes the metalwork to make it appropriate for the process.

Moulded plastics of various kinds are also integrated into the procedural framework of PCB assembly. The manufacturers perform the task expertly. Moreover, different types of the loom are used to accomplish the manufacturing objectives. The PCBs are nicely assembled with the devices.

New Generation Methods

Manufacturers and researchers constantly try to evolve the assembly process, making it even more efficient, in terms of saving costs and production time. The next big thing in the industry of PCB assembly is extensive use of microelectronics, with robust electronics engineering techniques. Certainly, there are more innovations integrated within the framework of the process.

Get in touch with a PCB manufacturer

It is intelligent to directly call a well-known PCB manufacturer and enquire about the details of the production process. You can also write to the manufacturer, placing your queries. A top PCB manufacturer is more than happy to address your questions.

Blog Resource: https://greatpcbsmt.blogspot.com/2022/01/a-printed-circuit-board-is-organized.html

#pcb board assembly#pcb prototype services#pcb assembly services#pcb assembly services suppliers#PCB

0 notes

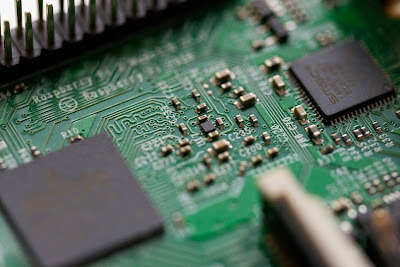

Photo

Printed Circuit Board Assembly PCBA- GreatPCB

GREATPCB is a well-known turn-key PCB(1-30 layers) & PCB Assembly service provider for low- to mid-volume electronic contract manufacturing, including PCB fabrication, sourcing of components, and complete electronic PCB assembly. With a state of the art facility and modern technology.

View more: https://www.greatpcb.com/pcb-assembly/

0 notes

Link

Get production level prototype PCBs through us, the top PCB assembly China based service. We are here to help you develop your PCB designs through our prototype PCB assembly (PCBA) service aimed at helping large companies develop rapid prototypes and small companies engage in low volume production at low cost.

View more: https://www.greatpcb.com/pcb-assembly/

0 notes

Text

10 Important Advantages of Prototype PCB Assembly

In recent times, the manufacturing process of printed circuit boards has undergone revolutionary changes. A couple of year’s back, the board for testing early samples was constructed by the designer himself. Nowadays, just as designing homemade printed circuit boards has gone through evolutionary phases in the same way, the commercial manufacturing process has made rapid progress. With the improvement in technology, the type of materials used has also gone through changes. The manufacturing cost has also gone down to a significant extent. Full-scale manufacturers are now relying on prototyping services due to their cost-effective approach.

Seek the help of experts

You will derive a host of benefits if you make the right choice of a service provider. Contact Prototype PCB Assembly services at affordable rates through GreatPCB.

1. Gain a better perspective

Printed circuit boards have been in existence for quite some time. Day by day, their manufacturing process is becoming complex because countless intricacies are involved. Get in touch with the Prototype PCB Assembly service for testing the functionalities of electronic designs.

2. Detection of flaws

One of the crucial factors that you need to consider is quality. The design should be free from defects of any kind. The models should be of the right quality and should be functional. If you leave various aspects of production runs to chance, your bills will increase significantly. Therefore it is necessary to get hold of design flaws quite early.

3. Avoid messing with the budget

You should not cross the budgetary limit at any point. For this purpose, you should check the range of services the company offers. You have to assess whether they take the client seriously or not. Find out if the prototyping services are essential for their business or not. The earlier the design flaws are detected, the better it will be because fixing up will be done earlier. So the costs will be much less.

4. Testing several options

You will be able to avail of various options regarding the components based upon the design of a printed circuit board. The experts carry out different combinations of the methods. The aim is to determine a solution that is functional and cost-effective.

5. Getting hold of a supplier

While going through the testing phases, you can try out new companies with smaller orders. In this way, you may pick a supplier best suited for your needs and that too at minimal expenses.

6. Discovery of issues

Detection of issues at an early phase will be beneficial because it will easier on the wallet. You would not want to do a production run of thousands of units and then discover issues.

7. Develop familiarity

As a supplier performs testing on a sample, you will get a chance to become familiar with the intricacies of the processes.

8. Clear picture

After a run is complete on the sample, both you and the supplier will have a fair picture of the appearance of a high volume run.

9. Visual aid

You can use these models to explain the concepts to your clients. Planning for the enclosure of the finished item becomes much easier.

10. From the scalability aspect

When you are involved in a complex project then it is advisable to break it into multiple components. Testing on each function separately will help in the detection of problems early on.

Making a prudent decision

Choose a company for your fabrication needs after an extensive study on the net. Keep in mind that an efficient company will have a team assigned for this line of work exclusively. Take a close look at the website because from there you will get all the relevant information.

Blog Resource: https://greatpcb.wordpress.com/2021/12/20/10-important-advantages-of-prototype-pcb-assembly%ef%bf%bc-%ef%bf%bc/

0 notes

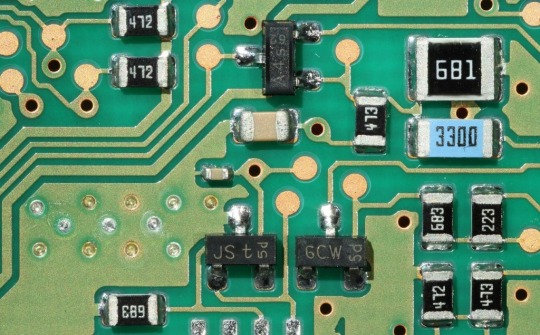

Photo

PCB Design Services - PCA, PCB Fabrication Layout Services - GreatPCB

Printed circuit board (PCB) fabrication and layout services is one of the ways that we help our customers get to market faster as our engineering team has significant real world experience designing PCBs for performance and manufacturability.

View more: https://www.greatpcb.com/design-pca/

0 notes

Link

Printed circuit boards are among the key essentials when it comes to developing electronics. China is currently holding the peak position for producing high-quality PCBs for professional use. In recent years, the PCB industry in China has grown to leaps and bounds and is still raging with newer inventions. So many companies have popped up in recent times for which finding the best manufacturer is a difficult task. If you are also searching for a reliable printed circuit board manufacturer in China, do not decide in a hurry. Here are some crucial evaluating pointers that can help in making the selection.

#pcb assembly services suppliers#pcb assembly manufacturing#pcb prototype services#pcb manufacturer china#pcb assembly china

0 notes

Text

How to Choose a Good PCB Manufacturer in China in 2021/22?

Printed circuit boards are among the key essentials when it comes to developing electronics. China is currently holding the peak position for producing high-quality PCBs for professional use. In recent years, the PCB industry in China has grown to leaps and bounds and is still raging with newer inventions. So many companies have popped up in recent times for which finding the best manufacturer is a difficult task. If you are also searching for a reliable printed circuit board manufacturer in China, do not decide in a hurry. Here are some crucial evaluating pointers that can help in making the selection.

Check out the factory strength

Manufacturing PCBs requires large-scale factory resources. Going for a small-scale PCB producing company is not a wise step on your part. A good PCB manufacturer in china requires featuring reliable infrastructure that can produce bulk quantities. It not only helps in producing an efficient service but also ensures quality measures. Check the production scale and capability of the factory to get a reliable service.

Reputation matters largely

When it comes to selecting PCB manufacturers, reputation and service experience are two very important factors. With a reputed PCB manufacturer in china like GREATPCB SMT LIMITED, you can stay assured about the service quality. Companies that have relevant and professional certifications to produce high-end PCBs are fit for the choice. Companies running for several years in the PCB-making business are better and reliable options to avoid substandard services and products.

Location of the factory

PCB manufacturing units also need to be accessible for easy delivery and timely service. The factory's location from where shipping the end products is easier makes it a good manufacturing resource for professional needs. Alongside a capable working force, the advantage of shipping area proximity truly makes the best combination for your selection.

Technology and equipment in use

Printed circuit boards are also evolving with time, for which the manufacturing technology is also developing. Alongside the technology, the equipment in use should also be at par with the modern requirements of manufacturing. Check this right so that you do not end up receiving substandard PCBs and services.

Quality checking steps

If the manufacturing of the PCB has any defects, the whole electronic unit will not work. Thus, quality checking steps are a must when it comes to producing PCBs. A simultaneously functioning quality checking unit ensures the delivery of flawless PCBs. Check it right to get the best service.

An efficient team

Without the assistance of a large and efficient team, producing PCBs at a bulk level is not possible. You must evaluate the capacity and working abilities of the team by reviewing their past services. What you can do is assign them a smaller task and check the potential before ordering bulk.

One-stop solution provider

PCB manufacturing units that also help in other PCB-related services are the best for resolving the professional requirements. Whether it is PCB assembling or fabrication, a side-by-side service unit truly helps out the needs. Thus, find a company that offers it all in a compact service pack.

Dedicated service and assistance

Lastly, before relying on the services of the PCB manufacturers, check their professionalism. A dedicated service is a must when it comes to PCB-making. The way they assure you to handle the aftersales issues is also a major determining factor. Thus, evaluate them based on their diligence, dedication, and commitment towards assisting.

Find the right balance of quality and budget

Identify a good PCB-making factory that features all the mentioned qualities and fits into the budget. Get high-standard services and quality PCBs with the right team in the business.

Blog Resource: https://greatpcb.wordpress.com/2021/11/17/how-to-choose-a-good-pcb-manufacturer-in-china-in-2021-22%ef%bf%bc/

0 notes

Photo

PCB Assembly Services, Printed Circuit Board - GreatPCB

• Min IC pitch 0.30mm (12mil), 8 BGA • Foot pin SO, SOP, SOJ, TSOP, TSSOP, QFP, BGA and U-BGA • Min chip placement 01005 • Max PCB Size 410 x 600mm (16.2 x 23.6″) • Min PCB thickness 0.35mm (13.8mil) • Min:BGA ball pitch 1-3mm (4-12mil) • BGA ball diameter 0.4-1mm (16-40mil) • QFP lead pitch 0.38-2.54mm (15-100mil) • packing Anti-static bubble bag and carton

View more: https://www.greatpcb.com/pcb-assembly/

0 notes

Text

How to Improve Printed Circuit Board Assembly Process Performance?

When you want to improve the performance of your electronics equipment or automobile feature, you have to improve the performance of the PCB. It happens when you fine-tune the assembly process. There are specific steps to perform the task. You have to consider several aspects to enhance the performance of the assembly process.

Preventing the mechanisms that lead to failures

GreatPCB is one of the top PCB assembly services suppliers that know how to prevent the mechanisms that reduce performance levels optimally. Relying on its expertise is a wise step you should take. The company has helped several clients to date across the globe.

Quality control

It is extremely important to focus on the quality control aspects of the top-rated PCB assembly services suppliers. You need to enquire about the details in this regard to be surer about the overall process.

Locating issues, if any, at each stage

It is very important to locate issues at each stage of manufacturing. The process helps in quickly determining the issues. You can take relevant steps or remedies quickly. It adds value to the production process. The result is the rise in the performance level.

A neat plan for mass production

A reputable manufacturer of PCB devices concentrates on sophisticated methods for the mass production of the boards. There needs to be a tidy plan for the assignment or the project. Without a plan, it is not possible to proceed. The plan ensures a rise in the performance level during the assembly procedures.

Importance of SMT

The full form of SMT is Surface Mount Technology. It is crucial to adopt it and apply it optimally. The technology is very effective in tuning the performance parameters of the PCB manufacturing procedures.

Implementing the SPI procedure

It is yet another way to improve the level of performance in the PCB assembly process. The full form of SPI is Solder Paste Inspection. It helps in making the structure of the PCB board more robust. Also, the functionalities of the board remain intact in the long run.

Focusing on AOI

You will be more than happy to know that a renowned manufacturing service provider applies a range of solutions to improve the performance level during the assembly procedures. One of those is the AOI. The full form of AOI is Automated Optical Inspection. It is quickly able to detect issues in the manufacturing details.

Applying ICT solutions

You can also depend on the application of ICT solutions when you need to be surer about the performance standard of the PCB boards. The full form of ICT is ‘In-Circuit Testing’. The testing process enables to check overall or specific functionality of the PCB board.

A combination of various methods

It depends on the manufacturer's intent, the business requirements and various other things whether a single technique will be applicable or a combination of methods will be applied to increase the performance level.

Creating value for the final PCB boards

When the performance level of the deliverable PCB boards increases, there is more value for the final products. It helps in advancing the business. The core of the pieces of equipment becomes better. As an investor or someone dealing with the costs, you will be happy with the results.

Hire a renowned manufacturer

It is always a great idea to hire a top-rated manufacturer for PCB assembly services. The manufacturer with several years of experience knows to increase the performance level of the PCB boards. The boards become flawless. You do not have any scope to complain against the performance. Visit the official website of the manufacturer.

Blog Resource: https://greatpcb.wordpress.com/2021/10/21/how-to-improve-printed-circuit-board-assembly-process-performance/

#pcb assembly services suppliers#pcb assembly services manufacturers#Printed Circuit Board Assembly#PCB Assembly Services

0 notes

Link

GreatPCB is going great guns in the low and mid-volume electronic contract manufacturing outsourced services sector. We serve electronic manufacturing units, military, government, medical instrumentation, and other sectors with our total turnkey PCB and PCB assembly services. View more: https://www.greatpcb.com/company-profile/

#PCB#Printed Circuit Board Assembly#pcb Manufacturing Services#pcb manufacturer china#pcb assembly services manufacturers

0 notes

Photo

PCB Assembly Services Manufacturers | GreatPCB

Get production level prototype PCBs through us, the top PCB assembly China based service. We are here to help you develop your PCB designs through our prototype PCB assembly (PCBA) service aimed at helping large companies develop rapid prototypes and small companies engage in low volume production at low cost.

View more: https://www.greatpcb.com/pcb-assembly/

#pcb manufacturing service#prototype pcb assembly#printed circuit board assembly pcba#pcb assembly services manufacturers#Printed Circuit Board Assembly#PCB

0 notes

Text

The 2021 List of Top 10 Printed Circuit Board Manufacturers

When you are planning to invest in printed circuit boards, it is extremely important to hire a top-rated manufacturer in the industry. You need to enquire about the manufacturer’s profile from its official website and online reviews, before investing. A precise list would be helpful in this regard. The following list provides you with good information.

GreatPCB

GreatPCB is one of the most reputable PCB Assembly Service Manufacturers that is a global expert in the SMT assembly process. The manufacturer has incredible goodwill in the industry in terms of building cost-effective, durable PCB designs.

Advanced Circuits

Advanced Circuits are one of the reliable PCB Assembly Services Manufacturers, too, with a prolific presence in the industry. The company efficiently operates through numerous divisions. It offers two broad categories of printed boards. The company always dedicatedly adheres to customer specifications, with a professional approach.

Sunstone Circuits

They are yet another dependable service provider from the industry, specializing in a wide range of PCB fabrication services, with robust manufacturing capabilities. Hiring them is cost-effective, as they supply affordable PCB products. The company has a fair amount of reputation in the market.

Bay Area Circuits

The manufacture has huge goodwill in the industry. Bay Area Circuits have a prolific experience of over 40 years in manufacturing several types of PCB products for various businesses. It supplies PCBs to commercial and medical service companies across the US. Its customer support service is world-class, too.

ALLPCB

ALLPCB is a relatively new entrant in the market. It is a Chinese Company operational since the year 2015. In little time, the manufacturer has been able to establish itself as a competitive player in the industry. The company supplies PCBs in bulk quantities to consumer electronics, IoT, ISC, and many other industrial sectors.

JLCPCB

JLCPCB is another reliable name in the sphere of PCB manufacturing. You can rely on the swiftness of its delivery service, meeting event stringent deadlines. Also, your budget remains under control when you place an order with the company. It has more than 15 years of expertise.

PCBgogo

PCBgogo is a popular name in the manufacturing sector of PCBs. The company is based in China. It has competitive expertise in designing a broad spectrum of PCBs for various business sectors, especially electronics types of equipment, medical tools, etc. The manufacturer provides a warranty on each of its PCB products.

PCB Way

It is another addition to the list from China. The manufacturer has a solid infrastructure that supports producing and delivering PCBs in bulk quantities meeting deadlines. It is considered to be one of the best SMT assemblers in the Chinese market. The company provides good customer service.

Camptech Circuits

The Camptech Circuits are an incredibly versatile PCB manufacturer with a rich portfolio to showcase. The company has several years of experience in the market, manufacturing a wide variety of PCBs for different industrial sectors. It concretely adds value to your factory unit and production process with a highly professional approach.

DSBJ

When you are searching for a manufacturer that is reliable and simultaneously has goodwill in the market, DSBJ easily cuts. It is an expert in producing an extensive range of PCBs for several companies in the global market. DSBJ has an excellent reputation in the industry.

Hire wisely

It is suggested to take your time while hiring the most suitable PCB manufacturer for the project. Go through the official websites of top players in the industry. Make a shortlist of the companies. Read about the relevant services you can avail of. Consider the prices they offer. Decide after a complete initial assessment.

Blog Resource: https://greatpcb.wordpress.com/2021/09/21/the-2021-list-of-top-10-printed-circuit-board-manufacturers/

0 notes

Photo

PCB Board Assembly Manufacturing - PCB Manufacture And Assembly

GREATPCB is a well-known turn-key PCB(1-30 layers) & PCB Assembly service provider for low- to mid-volume electronic contract manufacturing, including PCB fabrication, sourcing of components, and complete electronic PCB assembly. With a state of the art facility and modern technology.

View more: https://www.greatpcb.com/pcb-assembly/

0 notes

Photo

Printed Circuit Board (PCB) Assembly Services - GreatPCB

GREATPCB is a well-known turn-key PCB(1-30 layers) & PCB Assembly service provider for low- to mid-volume electronic contract manufacturing, including PCB fabrication, sourcing of components, and complete electronic PCB assembly. With a state of the art facility and modern technology.

View more: https://www.greatpcb.com/pcb-assembly/

0 notes