Don't wanna be here? Send us removal request.

Text

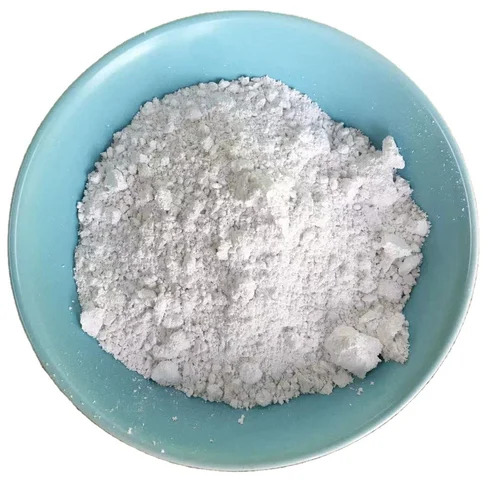

Everything You Need to Know About Calcium Carbonate

Calcium carbonate is one of the most widely used minerals in the world. Found naturally in limestone, marble, and chalk, it serves as a key ingredient in a variety of industries—from construction to pharmaceuticals. Its versatility, abundance, and eco-friendliness make it a vital component in manufacturing, agriculture, health, and environmental sectors.

In recent years, India has emerged as a global hub for calcium carbonate production. The rise of the Calcium Carbonate Manufacturer in India has made high-purity, competitively priced calcium carbonate available both domestically and internationally. In this article, we’ll explore everything you need to know about calcium carbonate—its forms, uses, benefits, and why India is a leading supplier.

What is Calcium Carbonate?

Calcium carbonate (chemical formula: CaCO₃) is a white, odorless powder or crystal that occurs naturally in rocks and shells. It is composed of calcium, carbon, and oxygen and is known for its alkalinity, chemical stability, and non-toxicity.

It exists in three main forms:

Calcite: The most common crystalline form

Aragonite: Less stable and often found in marine organisms

Vaterite: Rare and the least stable form

Calcium carbonate is either mined (known as ground calcium carbonate or GCC) or synthetically produced through a precipitation process (known as precipitated calcium carbonate or PCC).

Types of Calcium Carbonate

1. Ground Calcium Carbonate (GCC)

Extracted directly from natural limestone or marble and ground into a fine powder. Used in paints, plastics, paper, and construction.

2. Precipitated Calcium Carbonate (PCC)

Produced through a chemical reaction involving calcium hydroxide and carbon dioxide. Known for controlled particle size and high purity. Often used in pharmaceuticals, food, and high-end paper products.

Key Industrial Applications of Calcium Carbonate

1. Paper Industry

Calcium carbonate is used as a filler and coating pigment. It improves paper brightness, opacity, and surface smoothness while reducing production costs.

2. Plastic and Rubber

Acts as a reinforcing agent, increasing strength and durability. It also reduces polymer content, thus lowering manufacturing costs.

3. Paints and Coatings

Used as a white pigment and filler that enhances brightness, hiding power, and weather resistance of paints.

4. Construction Materials

Essential in the production of cement, concrete, and asphalt. It improves compressive strength and workability.

5. Pharmaceutical and Food Industry

Used as a calcium supplement and antacid. It also serves as a food additive (E170) for color and firmness in products like toothpaste, gum, and dairy.

6. Agriculture

Works as a soil conditioner and pH regulator. It improves nutrient availability and crop yield.

7. Environmental Applications

Used in flue gas desulfurization, water treatment, and acid neutralization processes due to its alkaline nature.

Benefits of Using Calcium Carbonate

Abundant and Inexpensive: Found naturally and easy to process, making it affordable

Eco-Friendly: Biodegradable and safe for human and environmental exposure

Multifunctional: Offers mechanical, optical, and chemical advantages in products

Food & Pharma Safe: Non-toxic and FDA-approved for consumption in regulated quantities

Customizable: Available in various particle sizes, brightness levels, and surface treatments

India’s Role in the Global Calcium Carbonate Market

India is rich in high-purity limestone deposits, which form the raw material for calcium carbonate production. With increasing industrial demand, especially in paper, plastics, and construction, Indian manufacturers have ramped up their capabilities.

Today, the Calcium Carbonate Manufacturer in India is recognized for producing a wide range of grades—coated, uncoated, ultra-fine, and specialty PCC—tailored to meet specific industry standards.

Why Choose a Calcium Carbonate Manufacturer in India?

Raw Material Abundance

India has large reserves of high-quality limestone in Rajasthan, Gujarat, and Madhya Pradesh.

Advanced Technology

Modern grinding and precipitation facilities ensure consistent quality, purity, and controlled particle sizes.

Competitive Pricing

Lower operational and labor costs allow Indian manufacturers to offer affordable pricing globally.

Customization

Indian suppliers can deliver customized grades (mesh sizes, coating levels, brightness) for diverse applications.

Export-Ready Infrastructure

Manufacturers have reliable supply chains and logistics for prompt domestic and international delivery.

Quality Parameters to Consider When Choosing a Supplier

When selecting a calcium carbonate manufacturer, consider the following parameters:

Purity (Low iron, silica, and heavy metals)

Whiteness (High brightness levels >95%)

Particle Size Distribution (Customizable microns/mesh)

Moisture Content

pH and Specific Gravity

Surface Treatment (Stearic acid coating for plastics)

A trustworthy Calcium Carbonate Manufacturer in India will provide technical data sheets, COAs (Certificates of Analysis), and samples for evaluation.

Growing Industries Relying on Indian Calcium Carbonate

Indian calcium carbonate is increasingly being used in:

Middle East and Africa: For construction and water treatment

Southeast Asia: In plastics and packaging

Europe and North America: For pharmaceutical and food-grade applications

With a reputation for reliability and quality, Indian suppliers are expanding their footprint globally.

Sustainability in Calcium Carbonate Manufacturing

Top manufacturers in India are adopting eco-friendly practices:

Dust control systems

Energy-efficient machinery

Wastewater recycling

Low-emission processing units

These steps help reduce the environmental impact and ensure regulatory compliance.

Final Thoughts

Calcium carbonate is an indispensable industrial mineral used across a broad spectrum of sectors. Whether you're in manufacturing, agriculture, pharmaceuticals, or construction, its versatility and functionality make it an ideal choice for product enhancement.

With abundant natural resources, advanced processing technology, and a strong global presence, the Calcium Carbonate Manufacturer in India offers consistent quality, reliability, and affordability. Whether you need GCC or PCC, India is well-positioned to meet your calcium carbonate needs with precision and efficiency.

0 notes

Text

What Is Calcium Carbonate and Why Is It Important?

Calcium carbonate is one of the most abundant and versatile minerals on Earth. Found in rocks, shells, pearls, and even in the human body, this compound is essential across a wide range of industries — from construction and agriculture to pharmaceuticals and food production.

In this article, we’ll explore what calcium carbonate is, its many uses, and why partnering with a reliable Calcium Carbonate Manufacturer in India is crucial for businesses that depend on this essential mineral.

What Is Calcium Carbonate?

Chemically known as CaCO₃, calcium carbonate is a naturally occurring compound composed of calcium, carbon, and oxygen. It appears as a white, odorless powder or crystal and is found in several natural forms:

Limestone: A sedimentary rock primarily composed of calcium carbonate.

Marble: A metamorphic rock that originates from limestone.

Chalk: A soft, white form of limestone.

Calcite and Aragonite: Two mineral forms of calcium carbonate.

It is also present in shells, coral reefs, eggshells, and the skeletons of marine organisms.

Key Physical and Chemical Properties

Color: White or colorless

Solubility: Slightly soluble in water; reacts with acids

Stability: Chemically stable under normal conditions

Hardness: Medium soft (Mohs hardness 3)

Non-toxicity: Safe for use in food, pharmaceuticals, and cosmetics

These properties make calcium carbonate a widely preferred raw material for industrial and commercial use.

Industrial Applications of Calcium Carbonate

1. Construction Industry

One of the most common uses of calcium carbonate is in the construction sector. It serves as a primary ingredient in cement and concrete and is used as a building material in the form of marble and limestone.

Used in: Road construction, roofing, cement production, and as aggregate in concrete

2. Plastic and Polymer Industry

Calcium carbonate acts as a cost-effective filler that improves rigidity and impact strength in plastics. It also enhances the surface finish and processing speed of thermoplastics.

Used in: PVC pipes, films, masterbatches, and molded plastic items

3. Paper Industry

As a coating and filler material, calcium carbonate enhances the brightness, smoothness, and opacity of paper. It also improves ink absorbency and print quality.

Used in: Writing paper, coated boards, packaging materials

4. Paints and Coatings

Calcium carbonate is used as a pigment extender and rheology modifier. It improves the durability, weather resistance, and brightness of paints.

Used in: Emulsion paints, industrial coatings, primers

5. Pharmaceuticals

Thanks to its high calcium content and non-toxic nature, calcium carbonate is widely used as a dietary supplement and antacid. It helps in treating calcium deficiencies and acid indigestion.

Used in: Tablets, chewables, powders, and capsules

6. Food and Beverage Industry

Food-grade calcium carbonate serves as a food additive (E170), a calcium fortifier, and an acidity regulator. It is especially useful in baking and dairy products.

Used in: Calcium-enriched drinks, baking powder, cereals

7. Agriculture

In agriculture, calcium carbonate neutralizes acidic soils and improves nutrient availability for crops. It also strengthens cell walls in plants and improves overall soil structure.

Used in: Soil conditioners, animal feed additives, fertilizers

8. Water Treatment

Calcium carbonate is used in water treatment facilities to adjust pH levels and remove impurities. It helps in softening hard water and in reducing corrosion in pipelines.

Benefits of Using Calcium Carbonate

Natural and Abundant: Readily available and sustainable

Cost-Effective: A low-cost alternative to synthetic fillers

Environmentally Friendly: Non-toxic and biodegradable

Versatile: Can be used in a wide range of industries

High Purity: Especially when processed by reputable manufacturers

Why Choose a Calcium Carbonate Manufacturer in India?

India is one of the leading producers and exporters of calcium carbonate in the world. The country’s rich deposits of limestone and advanced mining technologies make it a preferred sourcing destination for global industries.

Here’s why selecting a trusted Calcium Carbonate Manufacturer in India is vital for your business:

1. High-Quality Raw Material

Indian manufacturers have access to high-grade limestone sources, ensuring superior quality calcium carbonate with high purity and consistency.

2. Advanced Processing Facilities

Leading manufacturers use state-of-the-art technology to produce finely ground, surface-treated, and customized grades of calcium carbonate for diverse industrial needs.

3. Competitive Pricing

Due to cost-effective production methods and abundant resources, calcium carbonate from India is competitively priced without compromising on quality.

4. Wide Range of Grades

Whether you need precipitated calcium carbonate (PCC), ground calcium carbonate (GCC), or coated variants, Indian manufacturers offer a wide spectrum of options.

5. Sustainable and Compliant

Top Indian suppliers follow eco-friendly mining practices and comply with international standards like ISO, GMP, and REACH. This ensures that you receive safe and responsibly sourced materials.

Final Thoughts

Calcium carbonate is much more than a common mineral — it's a vital ingredient that supports key industries around the globe. From strengthening buildings to enriching food, and from improving medical products to enhancing industrial output, its importance is undeniable.

India has firmly established itself as a leading global supplier of high-quality calcium carbonate. By choosing a reputable Calcium Carbonate Manufacturer in India, businesses gain access to reliable supply, consistent quality, and industry-leading expertise.

0 notes

Text

Why Dolomite Powder Is Important in Construction and Industry

Dolomite powder, derived from the mineral dolomite (CaMg(CO₃)₂), has become an essential material in modern construction and various industrial applications. With its chemical stability, strength-enhancing properties, and cost-effectiveness, dolomite powder is now widely used across sectors such as cement production, steel, glass, ceramics, and agriculture.

India, known for its rich dolomite reserves, has emerged as a leading supplier of high-purity dolomite powder. Today, businesses seek dependable Dolomite Powder Manufacturer in India to meet the growing demand for quality mineral solutions. But what makes dolomite powder so indispensable? Let's explore its key roles in construction and industry.

What Is Dolomite Powder?

Dolomite is a double carbonate of calcium and magnesium. When this mineral is ground into a fine powder, it becomes suitable for a wide range of applications. Dolomite powder typically appears as a white or off-white powder with excellent purity and consistent particle size, making it ideal for use as a filler, stabilizer, or mineral additive.

Key Properties of Dolomite Powder

Before diving into its applications, here are some essential properties that make dolomite powder valuable:

High density and hardness

Good whiteness and brightness

Neutral pH and chemical stability

Low moisture content

High content of calcium and magnesium carbonate

These properties allow dolomite powder to improve durability, reduce costs, and enhance the physical characteristics of a wide variety of end products.

Role of Dolomite Powder in Construction

1. Cement Manufacturing

One of the most important uses of dolomite powder in construction is in the production of cement. It acts as a source of magnesium oxide (MgO), which enhances the strength and setting time of cement. Additionally, dolomite helps in reducing the shrinkage and cracking of concrete, leading to more durable structures.

2. Concrete and Mortar Mixes

Dolomite powder is added to concrete and mortar as a filler material. It improves the density and compressive strength of the mixture while maintaining workability. Moreover, it helps in reducing thermal cracking due to its low heat of hydration.

3. Asphalt and Road Construction

In road construction, dolomite powder is mixed with asphalt to enhance its binding and wear resistance. It also helps reduce the cost of road surfacing materials while extending their life.

4. Plaster and Wall Putty

Dolomite powder is a common ingredient in wall putty and plaster formulations. It adds smoothness, prevents cracking, and ensures better coverage and adhesion on walls and ceilings.

Industrial Applications of Dolomite Powder

Beyond construction, dolomite powder plays an important role in various industries due to its chemical and physical characteristics.

✅ Steel and Iron Industry

Dolomite is used as a fluxing material in steel manufacturing. It removes impurities like sulfur and phosphorus from molten metal and improves the durability and heat resistance of refractory linings in furnaces.

✅ Glass and Ceramics

In the glass industry, dolomite powder improves the chemical resistance and durability of glass. It acts as a stabilizer and enhances transparency and brightness. Similarly, in ceramics, it increases the strength and smooth finish of ceramic tiles and sanitary ware.

✅ Paints and Coatings

As a white mineral filler, dolomite powder adds opacity, brightness, and chemical resistance to paints and coatings. It also improves the weather resistance of the final product.

✅ Plastic and Rubber Industry

Dolomite powder is used as a filler in plastic and rubber manufacturing. It enhances stiffness, impact strength, and processability while reducing the cost of raw materials.

✅ Agriculture

Dolomite is also applied in agriculture as a soil conditioner and pH regulator. Its high magnesium content improves soil fertility, especially in acidic soils, and promotes plant growth.

Why Choose a Trusted Dolomite Powder Manufacturer in India?

With India being one of the world’s leading sources of dolomite, it is crucial for companies to work with a reputable Dolomite Powder Manufacturer in India to ensure consistency, purity, and cost-efficiency.

What to Look For in a Supplier:

Consistent particle size distribution

High brightness and chemical purity

Customized grades for specific industrial needs

Reliable supply chain and prompt delivery

Certifications such as ISO or BIS compliance

Technical assistance and quality testing support

Choosing a trustworthy supplier not only guarantees product performance but also helps maintain production efficiency and end-product quality.

Sustainability and Economic Benefits

Dolomite powder is not only a high-performance material but also an eco-friendly and cost-effective option. Its abundance in nature, combined with low mining and processing costs, makes it a sustainable choice for mass-scale industrial applications. Using dolomite helps reduce dependency on more expensive materials without compromising quality.

In many cases, it also improves the recyclability of products, particularly in plastics and construction materials, aligning well with global sustainability goals.

Conclusion

Dolomite powder is an indispensable material across construction and industry, prized for its versatility, chemical stability, and affordability. From improving the strength of cement and concrete to serving as a critical flux in steelmaking, its applications are broad and impactful.

As demand continues to rise, partnering with a reliable Dolomite Powder Manufacturer in India is essential for businesses seeking high-quality raw materials at competitive prices. Whether you are in infrastructure development, steel production, or the plastics industry, dolomite powder will remain a key ingredient in your growth and success.

0 notes

Text

A Simple Guide to Dolomite Powder and Its Benefits

Dolomite powder is a naturally occurring mineral product that plays a crucial role in various industrial applications. Known for its composition of calcium magnesium carbonate (CaMg(CO₃)₂), dolomite powder is valued for its strength, whiteness, and versatility. From construction to agriculture, and from steel to ceramics, dolomite continues to prove its utility across diverse sectors.

In this guide, we’ll explore what dolomite powder is, how it’s manufactured, and the many benefits it offers. We’ll also highlight why sourcing from a reliable Dolomite Powder Manufacturer in India can be a smart business decision.

What Is Dolomite Powder?

Dolomite is a sedimentary rock that contains a high percentage of calcium and magnesium carbonates. When this rock is finely ground, it becomes dolomite powder — a versatile mineral filler and additive.

Key Characteristics of Dolomite Powder:

High purity (rich in CaCO₃ and MgCO₃)

Excellent whiteness

Low moisture content

High specific gravity

Non-toxic and eco-friendly

Insoluble in water, but reacts with strong acids

These properties make it suitable for multiple industrial uses, especially where consistency, strength, and chemical stability are required.

How Is Dolomite Powder Manufactured?

The production process of dolomite powder involves:

Mining: Dolomite rocks are extracted from quarries.

Crushing: The rocks are broken down into smaller chunks.

Grinding: These pieces are ground into fine powder using ball mills or pulverizers.

Screening and Classification: The powder is sorted into different mesh sizes based on application.

Packaging: Finally, it is packed in bags or bulk containers for distribution.

A quality-focused dolomite powder manufacturer in India will ensure consistent particle size, high brightness, and purity during production, often using automated systems and lab testing to maintain standards.

Common Applications of Dolomite Powder

Dolomite powder is used across a wide range of industries due to its chemical and physical characteristics. Below are some of its major applications:

1. Construction Industry

One of the largest consumers of dolomite powder is the construction sector.

Used in cement manufacturing as an additive

Mixed with concrete to enhance strength and durability

Acts as a filler in asphalt and road construction

Used in making ceramic tiles and marble slabs

It enhances compressive strength and provides a smooth finish to construction materials.

2. Steel and Iron Industry

Dolomite is used as a fluxing agent in the production of iron and steel. It helps in removing impurities like sulfur and phosphorus during the smelting process.

Protects furnace linings from wear

Promotes efficient melting and slag formation

Maintains chemical balance in blast furnaces

Its refractory properties make it ideal for high-temperature operations.

3. Agriculture and Soil Conditioning

Agricultural-grade dolomite powder is often used as a soil conditioner and a source of magnesium and calcium for plants.

Neutralizes acidic soils (raises pH)

Improves nutrient absorption

Enhances root development and crop yield

Used in organic farming as a natural mineral fertilizer

It is especially useful in acidic regions where soil pH is too low for optimal plant growth.

4. Glass and Ceramics

In glass manufacturing, dolomite is used to increase strength and resistance to chemical corrosion.

Helps in producing clear and colored glass

Improves melt homogeneity

Enhances durability in ceramics and sanitaryware

In ceramics, it enhances the hardness and shine of the final product.

5. Detergents and Soaps

Dolomite powder is often used as a filler in detergents, soaps, and cleaning products.

Enhances texture and consistency

Acts as a mild abrasive in scouring powders

Cost-effective bulk filler

Its non-toxic and inert nature makes it safe for household use.

6. Paints, Plastics, and Rubber

Dolomite serves as a functional filler and pigment extender in the paints, plastics, and rubber industries.

Enhances opacity and whiteness in paints

Improves durability and elasticity in rubber

Reduces cost while maintaining quality in plastic products

It’s commonly found in wall paints, PVC pipes, and synthetic rubber products.

Benefits of Using Dolomite Powder

Dolomite powder offers several advantages depending on the industry and application:

High Strength: Improves structural integrity in construction materials.

Eco-Friendly: Naturally occurring and non-toxic.

Cost-Effective: Reduces production costs as a bulk filler.

Versatile: Suitable for multiple industries with custom mesh sizes.

Enhances Productivity: Optimizes process efficiency in smelting, farming, or manufacturing.

Why Choose a Dolomite Powder Manufacturer in India?

India is one of the world’s leading producers and exporters of industrial minerals, including dolomite. Working with a reputable dolomite powder manufacturer in India offers a range of benefits:

1. Abundant Resources

India has rich reserves of high-grade dolomite in states like Rajasthan, Gujarat, and Chhattisgarh, ensuring a steady supply of raw material.

2. Advanced Processing Facilities

Leading manufacturers use state-of-the-art machinery for grinding, classification, and packaging to meet global standards.

3. Custom Specifications

Indian manufacturers often provide customized grades and particle sizes based on the unique requirements of different industries.

4. Competitive Pricing

Due to lower production and labor costs, Indian suppliers offer high-quality dolomite powder at globally competitive prices.

5. Global Export Capabilities

With a well-established supply chain, many Indian manufacturers export dolomite powder to the Middle East, Africa, Southeast Asia, and Europe.

Conclusion

Dolomite powder may seem like a simple mineral, but its applications and benefits are far-reaching. Whether you're building infrastructure, manufacturing steel, improving soil health, or producing consumer goods, dolomite powder plays a crucial role in enhancing quality, efficiency, and sustainability.

Partnering with a reliable Dolomite Powder Manufacturer in India ensures not just product quality, but also access to cost-effective, customizable, and environmentally responsible solutions. As global industries move toward more sustainable practices, the demand for this versatile mineral will continue to grow.

0 notes

Text

How Ground Calcium Carbonate Is Used in Daily Life

When we think of minerals, we often imagine construction sites, mines, or industrial settings. Yet, minerals like Ground Calcium Carbonate (GCC) are not limited to these environments—they are an essential part of our daily lives. From the paper we write on to the toothpaste we use every morning, GCC plays a quiet but critical role in improving product performance, lowering costs, and supporting sustainability. With India's growing manufacturing capacity, choosing a trusted Ground Calcium Carbonate Manufacturer in India has become increasingly important for businesses across sectors.

What is Ground Calcium Carbonate?

Ground Calcium Carbonate is derived from natural limestone or marble and processed into a fine white powder through crushing and grinding. Chemically, it is composed of calcium carbonate (CaCO₃) and is known for its high purity, brightness, and fine particle size. It is non-toxic, environmentally friendly, and available in a range of grades suited for industrial, commercial, and domestic applications.

Unlike synthetic fillers, GCC is naturally occurring and has been used for centuries in various forms. Today, it remains a versatile, cost-effective, and sustainable solution across a wide range of industries.

Common Daily Uses of Ground Calcium Carbonate

While you might not see it, you come into contact with GCC multiple times a day. Its functional properties make it indispensable in the production of materials and products that people rely on every day.

1. Paper and Printing Industry

One of the most common uses of GCC is as a filler and coating pigment in paper manufacturing.

It improves the brightness, smoothness, and opacity of paper.

Enhances print quality and reduces ink absorption.

Allows paper manufacturers to reduce costs by replacing more expensive wood pulp.

High-quality writing, printing, and packaging papers often owe their look and feel to ground calcium carbonate.

2. Plastic and Polymer Industry

GCC acts as a functional filler in plastics to improve mechanical properties and reduce costs.

Increases strength, rigidity, and thermal stability of plastic products.

Enhances the surface finish and reduces warping or shrinkage.

Used in films, pipes, containers, automotive parts, and household products.

Its excellent dispersion and compatibility with resins make it a preferred choice in the plastic industry.

3. Paints and Coatings

In the world of paints and coatings, GCC serves both aesthetic and performance-enhancing roles.

Improves whiteness, gloss, and opacity of paints.

Acts as an extender for titanium dioxide, reducing overall cost.

Enhances scrub resistance and paint durability.

From home wall paints to industrial coatings, GCC ensures consistent quality and appearance.

4. Rubber Industry

In rubber formulations, GCC is used as a reinforcing filler.

Enhances hardness, tensile strength, and abrasion resistance.

Improves aging and weather resistance.

Common in products like tires, hoses, footwear, and belts.

It helps manufacturers achieve a balance between performance and cost-efficiency.

5. Pharmaceuticals and Personal Care Products

High-purity GCC grades are used in health and beauty applications.

Acts as a calcium supplement in tablets and syrups.

Used as a mild abrasive in toothpaste.

Functions as a pH adjuster and bulking agent in cosmetics.

Because it is safe, non-reactive, and naturally sourced, it is ideal for direct use in consumable products.

6. Food Industry

Food-grade calcium carbonate is used as a dietary supplement and food additive.

Provides a natural source of calcium in fortified foods.

Used as a stabilizer and anticaking agent in baking products and snacks.

Ensures product consistency and extended shelf life.

7. Construction and Building Materials

In the construction sector, GCC is used in:

Cement and concrete as a performance-enhancing additive.

Floor tiles, adhesives, sealants, and wall panels.

Enhancing workability and finish of construction materials.

Its chemical stability and availability make it a staple in the building industry.

Why Work with a Trusted Ground Calcium Carbonate Manufacturer in India?

India is a global hub for mineral processing, and the demand for high-quality GCC continues to rise across domestic and international markets. Choosing a reliable Ground Calcium Carbonate Manufacturer in India offers several key benefits:

1. High Purity and Consistent Quality

Top Indian manufacturers use advanced technology to ensure:

Uniform particle size

Optimal brightness

Controlled moisture and impurity levels

This consistency ensures reliability in manufacturing and better product outcomes.

2. Custom Grades for Industry-Specific Needs

Each application demands a specific particle size, brightness level, and chemical purity. Leading Indian producers can deliver:

Coarse and fine mesh powders

Coated and uncoated variants

Custom formulations based on client requirements

3. Cost-Effective Production and Supply

With abundant limestone reserves and efficient manufacturing processes, India offers competitive pricing without compromising quality.

4. Sustainability and Compliance

Reputable manufacturers adopt eco-friendly mining and processing practices. Many are ISO-certified and comply with both domestic and international regulations, ensuring safety and sustainability.

5. Reliable Export and Logistics Network

India’s well-developed infrastructure and global trade partnerships make it easy for manufacturers to supply high-quality GCC to clients around the world in a timely manner.

Final Thoughts

Ground Calcium Carbonate may seem like just another white powder, but its role in our daily lives is anything but ordinary. It enhances the performance, appearance, and sustainability of countless products we use every day—from paper and plastic to paint, food, and cosmetics.

As demand continues to grow, choosing the right Ground Calcium Carbonate Manufacturer in India can give businesses a competitive edge by providing consistent quality, customized solutions, and economic benefits.

0 notes

Text

Everyday Uses of Dolomite Powder You Should Know

Dolomite powder may not be something you think about every day — but it plays a quiet, essential role in many parts of your daily life. From the buildings you walk through to the toothpaste you use in the morning, dolomite powder is a multi-functional mineral used across various industries and products.

In this article, we’ll break down what dolomite powder is, explore its everyday applications, and explain why choosing a reliable Dolomite Powder Manufacturer in India is crucial for quality and performance.

What Is Dolomite Powder?

Dolomite is a naturally occurring mineral composed of calcium magnesium carbonate (CaMg(CO₃)₂). It’s found in sedimentary rock formations and is typically white, grey, or pink in color.

Dolomite powder is produced by crushing, grinding, and processing dolomite rock into fine particles. This powder is prized for its chemical stability, whiteness, hardness, and low moisture content — qualities that make it valuable across a wide range of industries.

Everyday Uses of Dolomite Powder

1. Construction and Building Materials

One of the most widespread uses of dolomite powder is in the construction industry. It is used as a key ingredient in the production of cement, concrete, and asphalt. Dolomite serves both as a filler and a strengthening agent in construction materials.

Cement & Concrete: Dolomite adds hardness and resistance to weathering.

Road Base & Asphalt: Its crushed form is used for roadbeds and surface layers.

Builders and engineers often source high-purity dolomite from a reputable Dolomite Powder Manufacturer in India to ensure the quality of their projects.

2. Plastics and Rubber

In plastics and rubber manufacturing, dolomite powder is used as a filler to improve strength, opacity, and thermal resistance. It also helps reduce production costs by partially replacing more expensive raw materials.

PVC Pipes: Enhances durability and reduces shrinkage.

Rubber Products: Increases resistance to wear and compression.

The particle size and purity offered by Indian manufacturers make dolomite ideal for precise formulations in polymer industries.

3. Paints and Coatings

Dolomite powder is used as an extender in paint manufacturing. Its white color, smooth texture, and chemical inertness make it an excellent filler material.

Wall Paints: Adds brightness and smooth finish.

Industrial Coatings: Enhances anti-corrosion properties.

Paint manufacturers rely on consistent quality from a trusted Dolomite Powder Manufacturer in India to maintain product standards and customer satisfaction.

4. Soaps and Detergents

In the detergent and soap industry, dolomite powder is used as a filler to add bulk and improve consistency. Its fine particle size also helps in cleaning performance without damaging surfaces.

Soaps: Enhances lather and texture.

Powdered Detergents: Improves flowability and reduces caking.

Its affordability and eco-friendly nature make dolomite a sustainable choice in cleaning product formulations.

5. Agriculture and Soil Treatment

Dolomite powder plays a key role in agriculture as a soil conditioner and pH regulator. Its high magnesium content benefits crops and plant health.

Soil Amendment: Neutralizes acidic soils.

Fertilizer Additive: Supplies calcium and magnesium for crop growth.

Indian farmers and agricultural suppliers commonly source dolomite from local manufacturers to reduce costs and support regional supply chains.

6. Pharmaceuticals and Health Supplements

Dolomite’s natural calcium and magnesium content makes it valuable in health-related applications. In its purified form, dolomite powder is used in dietary supplements and pharmaceutical formulations.

Calcium-Magnesium Supplements: Supports bone health and metabolism.

Tablet Fillers: Used as an excipient in medicine manufacturing.

Only high-purity, food-grade dolomite powder from certified Dolomite Powder Manufacturers in India is suitable for such sensitive uses.

7. Personal Care Products

In personal care, dolomite is used in products like toothpaste, face powders, and cosmetics due to its non-toxic nature, mild abrasiveness, and smooth texture.

Toothpaste: Acts as a gentle abrasive for cleaning teeth.

Cosmetics: Adds smoothness and absorbency in face powders and masks.

The consistent particle size and chemical safety of Indian-manufactured dolomite powder make it a trusted choice for global cosmetic brands.

Why Choose a Dolomite Powder Manufacturer in India?

India is home to some of the world’s largest dolomite reserves and has become a hub for dolomite powder production. Choosing a reliable Dolomite Powder Manufacturer in India ensures:

High Purity and Consistency: Indian manufacturers offer dolomite with minimal silica and iron content, meeting global standards.

Customization: Whether you need coarse, micronized, or coated powder, Indian suppliers can tailor products to your needs.

Cost Efficiency: Due to abundant natural resources and competitive pricing, Indian dolomite offers excellent value.

Global Reach: With improved logistics and export capabilities, many Indian manufacturers supply dolomite powder to international markets across Asia, the Middle East, Europe, and Africa.

Conclusion

From roads and buildings to toothpaste and food supplements, dolomite powder is part of your everyday life in more ways than you might expect. Its versatility, chemical properties, and affordability make it an essential ingredient across industries.

Choosing the right Dolomite Powder Manufacturer in India is not just about price — it's about quality, consistency, and the ability to meet your specific application needs. Whether you're a builder, a product developer, or an agricultural supplier, dolomite powder is a mineral worth knowing — and sourcing wisely.

0 notes

Text

Dolomite Powder: A Useful Mineral for Many Industries

In the landscape of industrial minerals, dolomite powder holds a unique and highly valuable position. This naturally occurring mineral, composed of calcium magnesium carbonate (CaMg(CO₃)₂), offers a wide range of physical and chemical properties that make it indispensable across various industries. From steel and glass manufacturing to agriculture and construction, dolomite powder plays a vital role in enhancing product performance, reducing costs, and supporting sustainable practices.

With increasing global demand, choosing the right Dolomite Powder Manufacturer in India has become a key factor in ensuring consistent supply, high purity, and tailored solutions for industrial applications.

What Is Dolomite Powder?

Dolomite is a sedimentary rock formed through the post-depositional alteration of limestone and is rich in calcium and magnesium carbonate. When it is crushed and finely ground, it becomes dolomite powder, a versatile material used either as a raw ingredient or as a functional filler across numerous industries.

Dolomite powder is appreciated for its whiteness, purity, and uniform particle size. It is non-toxic, chemically stable, and can be used in applications that require hardness, durability, and pH regulation.

Key Properties of Dolomite Powder

High Purity and Brightness

Good Wettability

High Bulk Density

Low Moisture Content

Excellent Compatibility with Polymers

Resistance to Weathering

These properties make dolomite powder suitable for use in everything from construction materials to agricultural soil treatments.

Industrial Applications of Dolomite Powder

1. Steel and Metallurgy

Dolomite powder plays a crucial role in the steel industry. It is used as a fluxing material in the production of iron and steel, helping to remove impurities such as silica and phosphorus. The magnesium in dolomite helps improve the durability and corrosion resistance of steel products.

Calcined dolomite is also used in refractory linings for steel furnaces, increasing heat resistance and structural integrity.

2. Glass Manufacturing

Dolomite powder is a key ingredient in the glass industry. It acts as a stabilizer and enhances the melting behavior of the glass. The presence of magnesium carbonate in dolomite improves the strength, transparency, and chemical resistance of glass products like bottles, windows, and fiberglass.

3. Paints and Coatings

In the paints and coatings sector, dolomite powder serves as a cost-effective filler that improves the opacity, weather resistance, and surface finish of paints. It contributes to the durability and washability of both interior and exterior paints.

Its high whiteness and consistent particle size help maintain color accuracy and reduce the need for expensive pigments.

4. Plastics and Polymers

Dolomite is widely used in the plastic industry as a filler and reinforcing agent. It enhances rigidity, impact resistance, and dimensional stability in plastic products. Dolomite powder is often used in manufacturing pipes, cables, plastic films, and household items.

Its natural whiteness also reduces the need for artificial colorants, making the product more cost-effective.

5. Agriculture

In agriculture, dolomite powder is used to neutralize acidic soil and provide essential nutrients like calcium and magnesium. It improves soil structure, promotes better water retention, and enhances nutrient absorption by plants. As a natural soil conditioner, dolomite supports sustainable farming practices.

6. Ceramics

Dolomite powder improves the thermal and mechanical properties of ceramic products, making it ideal for use in tiles, sanitary ware, and pottery. It helps increase the vitrification point, improves glaze adherence, and enhances the overall strength of ceramic materials.

7. Construction and Road Building

In construction, dolomite powder is used as a filler in concrete, asphalt, and mortar. It increases compressive strength, improves workability, and provides a smoother finish. Dolomite also contributes to the production of dry mixes, adhesives, and sealants used in modern construction projects.

Why Partner with a Dolomite Powder Manufacturer in India?

India is one of the leading producers and exporters of dolomite powder in the world. Working with a reputed Dolomite Powder Manufacturer in India offers several benefits:

– Rich Mineral Reserves

India is home to vast and high-quality dolomite deposits, ensuring a consistent supply of pure raw materials.

– Advanced Processing Technology

Indian manufacturers utilize modern crushing, grinding, and micronizing equipment to produce dolomite powder with uniform particle size, controlled moisture, and high brightness.

– Customization and Technical Support

Many Indian manufacturers offer product customization based on specific industry needs, including coated dolomite, micronized powder, and different mesh sizes. Technical teams often assist in application development and formulation optimization.

– Competitive Pricing

Thanks to local raw materials, skilled labor, and efficient logistics, Indian manufacturers offer dolomite powder at highly competitive rates, making them attractive suppliers for both domestic and global markets.

– Quality Certifications

Leading Indian dolomite manufacturers follow international quality standards such as ISO, ensuring consistent performance and customer satisfaction.

Growing Demand Across the Globe

The increasing need for cost-effective, eco-friendly materials in industries like plastics, construction, and agriculture has driven global demand for dolomite powder. As companies shift toward sustainable practices, natural minerals like dolomite will play an even more critical role.

With this rising demand, the importance of choosing a reliable Dolomite Powder Manufacturer in India becomes paramount. Indian manufacturers continue to expand their capabilities, invest in technology, and strengthen their global supply chains to meet evolving industrial needs.

Conclusion

Dolomite powder is more than just a filler—it's a performance-enhancing, cost-saving mineral that serves a wide range of industries. Whether strengthening steel, enhancing paints, improving soil health, or supporting construction, dolomite offers unmatched versatility and value.

As industries evolve and sustainability becomes a top priority, partnering with a trusted Dolomite Powder Manufacturer in India ensures access to high-quality material, technical expertise, and long-term reliability. From raw strength to refined beauty, dolomite continues to shape the products we use every day.

0 notes

Text

Ground Calcium Carbonate in Industry: A Key Ingredient in Many Products

Ground Calcium Carbonate (GCC) is a widely used industrial mineral that plays a vital role in the performance, appearance, and cost-efficiency of numerous products across sectors. Derived from high-purity limestone or marble, GCC is valued for its whiteness, chemical stability, particle shape, and non-toxic nature.

From plastics and paints to paper, rubber, adhesives, and even food and pharmaceuticals, GCC serves as a multifunctional ingredient that improves mechanical properties, enhances appearance, and reduces production costs. With India's abundant limestone reserves and advanced processing facilities, the country has emerged as a leading source of quality GCC. A trusted Ground Calcium Carbonate Manufacturer in India offers consistent, customized grades tailored to meet the needs of both domestic and international industries.

This article explores what GCC is, how it is processed, and why it is such a crucial ingredient in so many industrial applications.

What Is Ground Calcium Carbonate (GCC)?

Ground Calcium Carbonate is produced by mechanically crushing and grinding naturally occurring calcium carbonate rocks—typically limestone or marble—into fine powder. Unlike Precipitated Calcium Carbonate (PCC), which is chemically synthesized, GCC is purely physical in origin and retains the crystalline structure of its natural source.

Key Properties of GCC:

High whiteness and brightness

Inert chemical nature

Low oil and moisture absorption

Controlled particle size distribution

Non-abrasive and easy to disperse

Environmentally safe and non-toxic

How Is GCC Processed?

The production process of GCC involves the following steps:

1. Extraction

High-purity limestone or marble is mined from quarries, typically in regions with significant mineral deposits such as Rajasthan and Gujarat in India.

2. Crushing and Grinding

The raw material is crushed into smaller pieces and then ground using roller mills, ball mills, or jet mills to achieve the desired fineness—ranging from coarse particles to ultra-fine powders below 10 microns.

3. Classification

Advanced air classifiers are used to ensure a consistent particle size distribution suitable for each application.

4. Surface Treatment (Optional)

In certain applications (e.g., plastics and polymers), GCC is surface-treated with fatty acids or silanes to enhance compatibility with hydrophobic materials.

5. Packaging and Quality Control

Final products are packaged in bags or bulk and subjected to rigorous quality checks for brightness, purity, fineness, moisture content, and chemical composition.

A high-quality Ground Calcium Carbonate Manufacturer in India ensures end-to-end quality control and technical customization to suit varied industry requirements.

Industrial Applications of Ground Calcium Carbonate

GCC finds widespread application in industries due to its unique physical and chemical properties. Let’s look at the top sectors where GCC is indispensable:

1. Plastics and Polymers

GCC is used as a cost-effective filler in thermoplastics like PVC, polyethylene, and polypropylene. It enhances:

Dimensional stability

Stiffness and hardness

Surface finish

Heat resistance

It also reduces shrinkage and overall material costs, especially in injection-molded and extruded parts like pipes, profiles, containers, and automotive components.

2. Paints and Coatings

In the paints industry, GCC acts as an extender and rheology modifier:

Improves opacity and brightness

Enhances dispersion of pigments

Increases scrub and weather resistance

Controls gloss and viscosity

It is used in emulsion paints, decorative coatings, primers, and textured finishes.

3. Paper Industry

One of the largest consumers of GCC is the paper and pulp industry. GCC is used as a filler and coating pigment to:

Increase brightness and opacity

Improve surface smoothness

Enhance printability

Reduce ink absorption

It replaces more expensive fibers and improves the overall economics of paper manufacturing.

4. Rubber Industry

GCC acts as a reinforcing filler in rubber compounds, especially in tires, hoses, footwear, and conveyor belts. It:

Improves tensile strength

Enhances processing characteristics

Reduces compound cost

5. Adhesives and Sealants

In adhesives, GCC:

Acts as a rheological agent

Improves spreadability and consistency

Increases bulk and reduces formulation cost

6. Construction Materials

In cement, mortar, concrete, and plasters, GCC:

Enhances workability and strength

Provides whiteness and smooth texture

Reduces shrinkage and cracking

7. Pharmaceuticals and Food

Pharma and food-grade GCC is used as:

An active ingredient in calcium supplements and antacids

A carrier or bulking agent

A food additive (E170) for acidity control and texture improvement

Why Choose a Ground Calcium Carbonate Manufacturer in India?

India is home to vast reserves of limestone and marble, making it one of the most cost-effective and quality-conscious producers of GCC globally.

Key Advantages of Indian Manufacturers:

Rich natural deposits ensure steady supply of raw materials.

Customized grades: From coarse mesh to ultra-fine particles, tailored to industry needs.

Surface-coated variants for polymer and plastic applications.

Competitive pricing: Cost-efficient production without compromising quality.

Global export capabilities: Many Indian manufacturers export GCC to the Middle East, Southeast Asia, Africa, and Europe.

A leading Ground Calcium Carbonate Manufacturer in India often supports industries not just with product supply, but also with technical expertise and formulation assistance.

Choosing the Right Supplier

When selecting a GCC supplier, consider the following:

Product consistency and purity

Customization options (particle size, coating, etc.)

Delivery capabilities and logistics

Certifications (ISO, GMP, FDA for food/pharma grades)

Technical support and industry reputation

Conclusion

Ground Calcium Carbonate is far more than just a filler—it's a multifunctional material that adds value to a wide range of industrial products. Its role in enhancing performance, improving aesthetics, and reducing costs makes it an essential component in plastics, paints, paper, construction, and beyond.

With India’s mineral wealth and processing expertise, partnering with a reputable Ground Calcium Carbonate Manufacturer in India ensures reliable supply, tailored solutions, and consistent quality — giving manufacturers a competitive edge in today’s global market.

0 notes

Text

How Calcium Carbonate Is Used in Paper, Paint, and Plastic

In today’s fast-paced manufacturing industries, raw materials that offer versatility, performance enhancement, and cost-effectiveness are essential. Calcium carbonate is one such widely used mineral that plays a vital role in various industrial applications. Among its many uses, it holds a significant position in the paper, paint, and plastic sectors.

From improving brightness and durability to reducing production costs, calcium carbonate has become a staple ingredient for manufacturers around the world. As demand rises, sourcing high-quality material is critical—making the role of a trusted Calcium Carbonate Manufacturer in India increasingly important.

What is Calcium Carbonate?

Calcium carbonate (CaCO₃) is a naturally occurring mineral found in rocks like limestone, chalk, and marble. It is processed into fine powder form for use as a filler, coating agent, or additive in industrial production. Known for its whiteness, low abrasiveness, and chemical stability, calcium carbonate is essential for enhancing product characteristics and reducing manufacturing costs.

Why Calcium Carbonate is a Preferred Material

Industries prefer calcium carbonate for its unique properties:

High brightness and whiteness

Controlled particle size

Low oil absorption

Good dispersion in polymers and liquids

Non-toxic and eco-friendly

These features make it an ideal filler and functional additive in many industrial applications, especially in paper, paint, and plastic manufacturing.

1. Calcium Carbonate in the Paper Industry

As a Filler and Coating Agent

In paper production, calcium carbonate serves as both a filler in the paper pulp and a coating pigment on the paper surface. Its primary function is to improve the quality and reduce the cost of production.

Benefits:

Brightness and Opacity: Calcium carbonate increases the brightness and opacity of paper, making it more suitable for printing and publishing.

Improved Printability: The smooth surface created by calcium carbonate coatings enhances ink adhesion and print quality.

Reduced Use of Expensive Pulp: As a filler, it replaces part of the costly wood pulp, reducing raw material costs.

This makes calcium carbonate an indispensable material in the production of writing paper, printing paper, packaging boards, and coated papers.

2. Calcium Carbonate in the Paint Industry

As an Extender and Rheology Modifier

In paints and coatings, calcium carbonate is widely used as a filler or extender. It helps improve product consistency, increase opacity, and reduce the need for costly pigments like titanium dioxide.

Benefits:

Better Coverage: Calcium carbonate enhances hiding power, allowing paint to cover surfaces more effectively.

Enhanced Durability: It contributes to the overall hardness and weather resistance of the coating.

Improved Flow and Workability: It modifies the paint's rheological properties, providing a smoother finish and easier application.

Cost Savings: Replacing a portion of titanium dioxide with calcium carbonate reduces raw material costs without sacrificing quality.

Both decorative and industrial paints benefit from its use, especially water-based, solvent-based, and powder coatings.

3. Calcium Carbonate in the Plastic Industry

As a Filler and Reinforcing Agent

In plastics, calcium carbonate is added to thermoplastics, thermosets, and elastomers to improve physical properties and reduce the cost of polymer resins.

Benefits:

Increased Stiffness and Strength: It reinforces the plastic matrix, making products more rigid and dimensionally stable.

Improved Surface Finish: Calcium carbonate helps produce a smoother and glossier surface in plastic products.

Better Processability: It aids in faster molding cycles and lower energy consumption during production.

Cost Reduction: Substituting a portion of expensive resins with calcium carbonate significantly lowers production costs.

Common plastic applications include PVC pipes, sheets, films, injection-molded products, and cables.

Why Choose a Calcium Carbonate Manufacturer in India?

India has become a global hub for the production and export of high-quality calcium carbonate. Choosing the right Calcium Carbonate Manufacturer in India offers several strategic advantages:

1. Abundant Natural Resources

India is home to vast reserves of limestone and marble, which are primary sources of high-purity calcium carbonate. This ensures a reliable supply of raw materials.

2. Advanced Manufacturing Facilities

Leading Indian manufacturers employ cutting-edge grinding, classification, and coating technologies to deliver calcium carbonate with precise particle sizes, high brightness, and low moisture content.

3. Cost Efficiency

Manufacturing costs in India are lower compared to many Western countries. As a result, Indian calcium carbonate is competitively priced without compromising on quality.

4. Customized Grades for Specific Industries

A reputable Calcium Carbonate Manufacturer in India can provide customized grades to meet the exact requirements of different applications—whether it's fine-ground uncoated powder for paper, coated grades for plastics, or specialty formulations for high-performance paints.

5. Global Supply Capabilities

Many Indian manufacturers have a robust export network and adhere to international quality standards such as ISO, REACH, and ROHS. They serve clients across Asia, the Middle East, Europe, and Africa with consistent quality and timely delivery.

Things to Look for in a Supplier

When sourcing calcium carbonate, ensure your supplier offers:

Technical Data Sheets and Lab Reports

Consistency in Particle Size and Whiteness

Packaging Options (Bulk, Jumbo Bags, etc.)

On-time Delivery and Export Documentation

Responsive Technical Support

Partnering with a reliable Indian manufacturer ensures long-term benefits and peace of mind for your production processes.

Conclusion

Calcium carbonate is more than just a filler — it's a performance-enhancing material used extensively in paper, paint, and plastic industries. Its ability to improve product properties, reduce costs, and support sustainable manufacturing makes it one of the most important industrial minerals today.

Working with an experienced and trusted Calcium Carbonate Manufacturer in India ensures access to world-class quality, custom solutions, and reliable supply for your specific needs. Whether you're looking to enhance product performance or optimize your production costs, calcium carbonate is the smart choice for manufacturers worldwide.

0 notes

Text

Industrial Uses of Dolomite Powder: Enhancing Strength, Reducing Costs

Dolomite powder, derived from the sedimentary rock dolostone (CaMg(CO₃)₂), has become a staple in numerous industrial processes. Known for its double carbonate composition of calcium and magnesium, dolomite powder possesses physical and chemical properties that make it valuable in applications ranging from construction and steel production to agriculture and plastics.

In recent years, the role of the Dolomite Powder Manufacturer in India has expanded significantly as global industries seek cost-effective, high-performance materials. This article explores how dolomite powder enhances industrial strength and efficiency while keeping production costs low.

What is Dolomite Powder?

Dolomite powder is a fine white or off-white mineral powder obtained by crushing and grinding naturally occurring dolomite rocks. With a typical chemical composition of around 30% CaO, 21% MgO, and the remainder as CO₂, dolomite offers benefits such as thermal resistance, low solubility in water, and moderate hardness.

Due to its unique structure and dual carbonate content, dolomite is more than just a filler — it's a performance enhancer that contributes to the strength, durability, and efficiency of industrial products and processes.

Key Industrial Applications of Dolomite Powder

1. Steel and Iron Manufacturing

Dolomite is a key ingredient in the iron and steel industry. It is used as a fluxing material in the production of steel and pig iron to remove impurities such as silica and alumina from the ore.

As a refractory lining in converters, blast furnaces, and ladles.

In sintering to improve the physical properties of the sintered ore.

Reduces consumption of costly raw materials like limestone and magnesium oxide.

By using dolomite, steel manufacturers achieve better thermal resistance and cost efficiency in metallurgical processes.

2. Construction Industry

Dolomite powder is widely used in concrete, asphalt, and cement for its strength-enhancing properties.

Improves the compressive strength and durability of concrete.

Acts as a filler in ready mix concrete, providing volume at a lower cost.

Enhances workability and reduces shrinkage in cementitious mixtures.

Its cost-effectiveness makes dolomite powder a practical choice for infrastructure, roads, and urban development projects — especially in emerging markets like India.

3. Glass and Ceramics

Dolomite is used as a fluxing agent in the manufacture of glass and ceramic products. It helps in:

Reducing the melting temperature of raw materials.

Increasing the durability and transparency of glass.

Improving the whiteness and strength of ceramic tiles and sanitary ware.

The high magnesium content in dolomite enhances thermal stability and surface finish in fired ceramic products.

4. Plastic, Paint, and Rubber Industries

As a functional filler, dolomite powder plays a significant role in polymer-based industries:

In plastics, it improves dimensional stability, impact resistance, and reduces cost.

In paints, dolomite enhances opacity, acts as a white pigment extender, and contributes to anti-cracking properties.

In rubber, it boosts elasticity and tensile strength while providing processing advantages.

The smooth texture, fine particle size, and chemical purity offered by leading Dolomite Powder Manufacturers in India make it a preferred choice for compound formulations.

5. Agriculture and Soil Conditioning

Dolomite powder serves as a soil conditioner and magnesium-calcium fertilizer, particularly beneficial in acidic soils.

Helps neutralize acidity and improve soil pH.

Supplies essential nutrients (Mg and Ca) for plant growth.

Enhances the absorption of phosphorus and other minerals.

In livestock farming, dolomite is also used as a feed additive to maintain bone health and metabolic function in animals.

6. Water Treatment

Dolomite powder is increasingly being used in water purification and wastewater treatment due to its neutralization and buffering capabilities.

Helps adjust pH levels in acidic waters.

Binds with heavy metals and phosphates, reducing contamination.

The Role of Indian Manufacturers

India holds extensive dolomite reserves, particularly in states like Rajasthan, Chhattisgarh, Odisha, and Andhra Pradesh. The mining, processing, and refinement of dolomite powder have become highly advanced in the country.

A modern Dolomite Powder Manufacturer in India typically offers:

High-purity grades with low silica and iron content.

Custom mesh sizes, from coarse to micronized powder, suitable for diverse applications.

Surface-treated variants for better compatibility with polymers.

Consistent supply chains for both domestic and international markets.

Indian manufacturers have also adopted eco-friendly practices, ensuring responsible sourcing and minimal environmental impact during extraction and processing.

Economic and Performance Benefits

The use of dolomite powder across industries provides multiple advantages:

Cost Reduction: It replaces more expensive raw materials without compromising performance.

Improved Product Life: Offers better resistance to wear, moisture, and heat.

Enhanced Strength: Contributes to structural and mechanical improvements in composites and concrete.

Versatility: Applicable in diverse sectors including manufacturing, agriculture, and healthcare.

This balance of affordability and utility makes dolomite powder an indispensable mineral in modern industry.

Conclusion

Dolomite powder is more than a mineral filler — it is a strategic material that enhances product performance while keeping costs in check. Its applications span across core industries that form the backbone of infrastructure, manufacturing, and agriculture.

As demand rises globally for reliable and cost-efficient materials, the importance of a reliable Dolomite Powder Manufacturer in India grows stronger. With abundant natural resources, advanced technology, and a commitment to quality, Indian manufacturers are well-positioned to meet the world’s growing appetite for high-grade dolomite powder.

0 notes

Text

What Is Coated Calcite? Properties, Processing, and Applications Explained

Calcite is a widely known and used mineral, primarily composed of calcium carbonate (CaCO₃). When calcite is treated with a coating—most often with stearic acid—it is transformed into coated calcite, a value-added product with enhanced functionality in various industrial applications. From plastics to paints and beyond, coated calcite plays a critical role in modern manufacturing. In this article, we’ll explore what coated calcite is, its key properties, how it’s processed, and where it’s commonly used, along with why sourcing from a reliable Coated Calcite Manufacturer in India is essential for industrial success.

What Is Coated Calcite?

Coated calcite is a form of calcium carbonate in which the surface of the particles is treated—typically with fatty acids like stearic acid—to improve dispersion, compatibility with polymers, and performance in specific applications. The coating process reduces the surface energy of calcite particles, making them more hydrophobic (water-repelling) and oleophilic (oil-attracting).

This modification significantly improves the material’s effectiveness in polymer-based systems, where natural calcite may otherwise cause processing difficulties or lead to inconsistent product performance.

Chemical and Physical Properties

Coated calcite retains most of the physical characteristics of natural or precipitated calcite but has enhanced surface properties. Here are the key features:

Chemical Formula:

CaCO₃ (Calcium Carbonate)

Physical Properties:

Particle Size: Typically ranges from 1 to 20 microns (can be customized)

Whiteness: 95% or higher

Specific Gravity: Around 2.7 g/cm³

Moisture Content: Low (typically < 0.2%)

Surface Treatment: Usually 1–3% stearic acid

Modified Properties:

Improved dispersibility in polymers and oils

Hydrophobic surface for better moisture resistance

Reduced agglomeration in composite systems

These enhanced properties make coated calcite highly valuable in thermoplastics, paints, adhesives, and sealants.

How Is Coated Calcite Processed?

The production of coated calcite involves several key steps:

1. Raw Material Selection

High-purity natural calcite or ground calcium carbonate (GCC) is selected. The raw material must be free from impurities like silica, iron oxide, and heavy metals.

2. Grinding and Classification

The calcite is finely ground using advanced grinding mills. The particle size is precisely controlled depending on the target application.

3. Surface Treatment

The ground calcite particles are mixed with stearic acid or another surface modifier. This is done in a coating machine or heated mixer, ensuring even distribution of the coating agent on the particle surfaces.

4. Cooling and Packaging

Once coated, the material is cooled, dried (if needed), and then packaged in moisture-proof bags for storage and shipment.

A leading Coated Calcite Manufacturer in India typically adheres to strict quality control protocols at each step to ensure consistency, purity, and desired performance metrics.

Applications of Coated Calcite

1. Plastic and Polymer Industry

One of the largest consumers of coated calcite is the plastic industry. It is used in:

PVC pipes and cables

Polypropylene (PP) and polyethylene (PE) films

Masterbatches

Automotive plastics

Benefits include improved dimensional stability, better flow characteristics, reduced shrinkage, and cost-effectiveness.

2. Paints and Coatings

In the paints industry, coated calcite acts as a functional filler:

Enhances brightness and opacity

Improves dispersion of pigments

Provides anti-settling properties

Increases durability and scrub resistance

Its hydrophobic nature makes it particularly useful in water-resistant and outdoor coatings.

3. Rubber Industry

Coated calcite serves as a reinforcing agent in rubber compounds. It increases volume, improves hardness, and reduces production costs while maintaining elasticity.

4. Adhesives and Sealants

In formulations like hot-melt adhesives and sealants, coated calcite contributes to viscosity control, improved bonding, and thermal stability.

5. Paper Industry

Though less common than uncoated calcium carbonate, coated variants are used in specialty papers for improved smoothness, brightness, and printability.

Why Choose a Coated Calcite Manufacturer in India?

India has become a global hub for high-quality mineral processing, including coated calcite production. A reputable Coated Calcite Manufacturer in India offers:

Wide range of particle sizes and coatings tailored to industry-specific needs

Consistent product quality, with low moisture and high brightness

Competitive pricing and bulk supply capabilities

Eco-friendly manufacturing practices

Global export support with customized logistics

Indian manufacturers source calcite from rich mineral reserves in Rajasthan and Gujarat, ensuring steady availability and scalability.

Environmental and Safety Considerations

Environmentally Safe:

Coated calcite is non-toxic and environmentally friendly, especially when manufactured with low-VOC and lead-free processing agents. It poses minimal environmental risk in production or application.

Workplace Safety:

While the material is not hazardous, fine powders may cause respiratory irritation if inhaled in large amounts. Proper ventilation and protective gear are recommended during handling.

Choosing the Right Manufacturer

When selecting a Coated Calcite Manufacturer in India, consider the following:

Certifications such as ISO 9001, REACH compliance, and ROHS

Quality control labs with testing for brightness, moisture, and coating efficiency

Experience in your specific industry

Supply chain reliability for both domestic and international markets

Partnering with an experienced and quality-conscious supplier ensures your end product meets both functional and regulatory standards.

Conclusion

Coated calcite is more than just a mineral filler—it is a performance-enhancing material that adds real value across industries such as plastics, paints, rubber, and adhesives. Its hydrophobic nature, fine particle size, and compatibility with polymers make it a must-have for modern manufacturing processes.

As demand continues to rise globally, sourcing from a dependable Coated Calcite Manufacturer in India ensures consistent quality, cost savings, and product innovation. Understanding its properties and applications allows businesses to leverage coated calcite for superior performance and market competitiveness.

0 notes

Text

How Dolomite Powder Is Processed and Graded for Commercial Use

Dolomite powder is a valuable mineral product derived from dolomite rock, a naturally occurring double carbonate composed of calcium and magnesium (CaMg(CO₃)₂). It plays a crucial role across numerous industries such as construction, agriculture, ceramics, glass, steel manufacturing, paints, and plastics. However, before it reaches its final application, dolomite undergoes a detailed and carefully controlled process of extraction, processing, and grading.

India is one of the leading producers and exporters of high-quality dolomite powder. A reputed Dolomite Powder Manufacturer in India follows standardized procedures to ensure consistent particle size, chemical composition, and purity levels to meet diverse commercial demands.

In this article, we will explore how dolomite powder is processed and graded for various industrial uses, highlighting why Indian manufacturers are trusted globally.

What Is Dolomite and Why Is It Important?

Dolomite is a sedimentary carbonate rock composed primarily of calcium magnesium carbonate. It is similar in appearance to limestone but has a slightly different chemical structure and a range of distinct physical properties. When processed into powder form, dolomite offers excellent hardness, whiteness, and weather-resistance — qualities that make it highly useful in commercial applications.

Dolomite powder is commonly used as:

A filler in paints, plastics, and rubber

A fluxing material in steel production

A soil conditioner in agriculture

A component in ceramics and glass

A whitening agent in detergents and cosmetics

Step-by-Step: How Dolomite Powder Is Processed

The journey of dolomite from raw mineral to fine powder involves several crucial steps:

1. Mining and Extraction

The process begins with the identification and extraction of dolomite rock deposits, usually through open-pit mining. Dolomite quarries in India are rich in high-quality reserves with consistent chemical composition, especially in states like Rajasthan, Madhya Pradesh, and Gujarat.

Blasting or mechanical excavation is used to extract large dolomite boulders, which are then transported to processing plants for further treatment.

2. Crushing and Primary Screening

Once extracted, the dolomite rocks are crushed using jaw crushers or impact crushers to reduce their size to manageable fragments. The crushed rock is then screened to remove oversized particles and prepare it for further grinding.

3. Grinding and Milling

This is a critical stage where dolomite is ground into fine powder. Different types of grinding mills are used, depending on the target application:

Raymond mills

Ball mills

Hammer mills

Vertical roller mills

The particle size can vary from coarse (300 mesh) to ultra-fine (up to 10 microns), based on the industrial requirement. A reliable Dolomite Powder Manufacturer in India can customize particle sizes for various clients.

4. Air Classification and Grading

To ensure consistency and purity, the ground dolomite powder is passed through air classifiers. These machines separate the powder by particle size, removing impurities and oversized particles.

This step ensures that the dolomite powder meets the industry-specific grading requirements for:

Fineness

Whiteness

Chemical composition

Moisture content

For example:

Ceramics and glass industries require high-whiteness, fine-grade dolomite.

Steel manufacturers need low-silica, high-purity dolomite as flux.

Agriculture uses coarser dolomite for soil treatment.

Types of Dolomite Powder Based on Grading

Grading is essential for aligning dolomite powder with the specific needs of various industries. Here are the most common grades:

1. Industrial Grade

Used in construction materials, rubber, and paint industries. It focuses on brightness, fineness, and chemical neutrality.

2. Agricultural Grade

Slightly coarser and used for neutralizing acidic soils. It improves soil fertility and increases crop yield.

3. Pharmaceutical and Food Grade

Requires extremely high purity and is processed under strict hygiene standards. This grade is used in antacids, dietary supplements, and food additives.

4. Steel Grade

Demands high calcium and magnesium content with minimal silica. This is used in iron and steel industries for desulfurization.

Quality Control Measures

A professional Dolomite Powder Manufacturer in India conducts rigorous quality control during every step of processing. Key parameters tested include:

Calcium and magnesium content

Silica and iron impurities

Whiteness (reflectance value)

Moisture level

Particle size distribution (PSD)

Manufacturers also ensure compliance with industry standards like ISI, ISO 9001, and export regulations for international shipping.

Packaging and Logistics

After grading, the dolomite powder is carefully packed in:

HDPE bags (25–50 kg)

Jumbo bags (500–1000 kg)

Customized packaging for bulk shipments

Proper packaging prevents moisture absorption and contamination during transit. Indian manufacturers often provide efficient logistics and export services to deliver to clients across the globe.

Why Choose a Dolomite Powder Manufacturer in India?

India is home to some of the most advanced mineral processing facilities and abundant reserves of dolomite. Here’s why sourcing from a reputed Indian manufacturer makes sense:

High-grade raw material availability

Customized processing and grading

Advanced milling and classification technology

Competitive pricing

Strong domestic and international logistics

Adherence to global quality standards

A dependable Dolomite Powder Manufacturer in India will not only supply consistent quality but also support clients with technical advice, documentation, and tailored solutions.

Conclusion

Dolomite powder is a highly adaptable mineral product that supports a wide variety of commercial applications. Its functionality largely depends on how well it is processed and graded. From mining to milling, grading to quality testing — each step contributes to the powder’s performance and value in the final application.