#3D Printing Design

Explore tagged Tumblr posts

Text

Reducing Construction Waste through 3D Printing in Architecture

In the global shift toward sustainable construction, the fusion of technology and eco-conscious design is no longer an ideal—it’s a necessity. Among the technologies leading this transformation is 3D printing. Once a niche tool for prototypes and industrial parts, it is now a powerful force in sustainable architecture. By reimagining how buildings are conceptualized, constructed, and maintained, 3D printing in sustainable architectural practice is revolutionizing the way we think about green spaces, urban resilience, and environmental impact.

The Role of 3D Printing in Sustainable Construction Sustainability in architecture now demands more than eco-certifications or solar panels. It calls for a shift in the construction process itself. 3D printing offers a way to build structures using additive manufacturing, where materials are layered precisely to form intricate forms. This method dramatically reduces excess material use and lowers emissions related to traditional building techniques, aligning construction with carbon-reduction goals.

Material Efficiency and Waste Reduction Conventional construction often leads to significant waste through offcuts, formwork, and overordering. With 3D printing, architects can program precision from the start. Structures are printed using only the exact amount of material needed, whether it's concrete, bioplastics, or composites made from recycled materials. This precision minimizes landfill contribution and supports circular economy models.

Design Freedom and Green Aesthetic Possibilities Architectural 3D printing removes many design constraints imposed by conventional tools. Organic curves, porous façades, or integrated passive ventilation channels are now feasible and cost-effective. This opens the door to not only creative expression but also functionally sustainable elements like daylight maximization, energy flow optimization, and natural insulation layering that would be prohibitively expensive using standard methods.

Speed, Scalability, and Labor Impact In sustainable architecture, time matters. Long construction phases lead to extended emissions, resource consumption, and urban disruption. 3D printing shortens the build timeline by automating labor-intensive stages, allowing for faster project completion and reduced energy use onsite. This also addresses labor shortages and supports safer, controlled building environments.

Localized Production and Environmental Benefits Transporting construction materials across long distances adds to a project's carbon footprint. 3D printing allows for localized production using nearby raw materials or even waste-derived substrates. Onsite printing reduces transportation emissions and supports regional economies by adapting building components to local environmental and cultural needs, making green design truly context-sensitive.

Smart Integration with Eco-Materials The integration of 3D printing with bio-based or low-impact materials marks a new era in sustainable design. Innovations in mycelium-based composites, hempcrete, and recycled plastics mean structures can be both high-performance and biodegradable. 3D printing enables seamless layering and mixing of these materials, allowing architects to embed sustainability into the structural DNA of their projects rather than adding it as a feature.

Urban Regeneration and Adaptive Reuse Cities facing infrastructure decay or housing shortages are turning to 3D printing to revitalize underused land sustainably. Whether through modular housing units or urban green walls that regulate microclimates, this technology enables adaptive reuse strategies that preserve space, reduce energy use, and create livable, green urban environments. The flexibility and affordability of 3D printing also promote equity by making sustainable design accessible to a broader population.

For more info https://bi-journal.com/3d-printing-in-sustainable-architectural-practice/

Conclusion 3D printing in sustainable architectural practice is not a futuristic concept—it is a present-day solution to some of the industry's most pressing challenges. It brings together innovation, material responsibility, and design versatility in a way few technologies can. As more architects embrace its potential, we’ll witness not just greener buildings, but a smarter, faster, and more inclusive approach to shaping the spaces we live and work in. The road to sustainability is no longer paved in concrete alone—it’s being printed layer by layer.

#Sustainable Architecture#3D Printing Design#Eco Construction#BI Journal#BI Journal news#Business Insights articles

0 notes

Text

Engineering DNA offers custom engineering solutions including 3D printing, reverse engineering, drafting, and simulations. Specializing in production engineering, product design, and CFD simulation, we deliver accuracy and excellence. Contact us today for innovative mechanical design and FEA Analysis services.

#3D Printing Design#Reverse Engineering Services#Drafting Services#3D Simulation#Interior design 3D Modeling#CFD Simulation#Product Design Engineering#3D Modeling for 3D Printing#Manufacturing Engineering#Finite Element Analysis Services#Design and Drafting Services#3D CAD Services#Manufacturing Engineering Services#3D Modeling Services#3D Design Services

0 notes

Text

You know those fanfics where Zidian evolves into a magic snake? That's the idea but it's the fuzzy worm thing.

#behold! Zidian's true form!#mdzs#jiang cheng#i'm intrigued by merch and was thinking of designing one without actually making them and this came to mind#3d print him and wrap him in the funny fuzzy worm thing#inspired by those fics where zidian became a magical snake#i never owned one so I'm just gonna assume that it's soft enough to be comforting

5K notes

·

View notes

Photo

3D printed skeletons, designed by ValravenFR

This artist on Instagram

#art#sculpture#3d art#3d printing#dark art#horror#fantasy#macabre#skeleton#creature design#mermaid#loch ness monster

3K notes

·

View notes

Text

Councilor cosplay!?

We’re thrilled to officially announce that Councillor Viktor’s 3D printable props will be available for download soon! Follow us for updates and more exciting content! 👀🙏 2D character design: @nightshadowcat_drawings 3D modelling: @valebragato Fanfic: @kantou_qed

#3d printing#arcane#arcane AU#arcane season 2#character design#cosplay#councilor viktor#fanart#jayce talis#jaycexviktor#jayvik#originaldesign#viktor arcane#viktor cosplay

246 notes

·

View notes

Text

I started posting some of my shoe designs for G3 Monster High, Rainbow High, and Shadow High over on Cults3D. I felt like locking the designs to physical prints only over on my Ko-Fi was almost like gatekeeping? Especially with 3D Printers getting more accessible every day. It also opens up things internationally as well since shipping is cost-prohibitive for such small items. I have seven designs listed so far with more to come! I listed some of the doll heads I've designed as well!

178 notes

·

View notes

Text

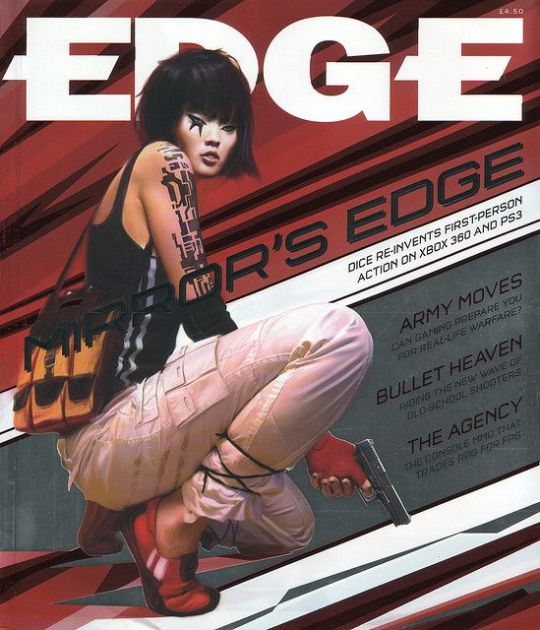

Edge 178

#3d#art#cgi#cybercore#cyber y2k#design#edge magazine#electronic#fashion#games#gaming#graphic art#graphic design#graphics#kaybug#magazine covers#microsoft#mirror's edge#print#ps3#scans#sony#tech#technology#video games#y2kcore#y2kore#y2k aesthetic#y2k art#y2k blog

535 notes

·

View notes

Text

#art#artwork#drawing#dramatic lighting#board games#3d printing#abstract games#ttrpg#gaming#board game design#board game geek#tabletop games#card games#gamedev#games#猫#cat#cats#dogs#cute#cute animals#funny#meme#funny memes#tcg#trading cards#trading card games#tabletop#ttrpg community

294 notes

·

View notes

Text

"Dune" Chess by Rory Noble-Turner,

3D Printed Quartz Sand,

380 x 380 x 140mm

#art#design#sculpture#minimal#forms#abstract#chess#chessboard#dune#sand#3d printing#3d#rory noble-turner#quartz sand#organic#desert#landscape

168 notes

·

View notes

Text

Pulled from the depths, these 5 “Neptune’s Purse specimens" are but one example of future Creature Compendium Collection specimens.

At 10x8 inches they are quite the statement piece to any menagerie.

Each mermaid comes with a numbered and wax sealed print(4.25x6inch). They will come unpainted to allow their owner the ability to paint them however they see fit. This model kit requires some minimal building skills(glueing, painting etc) Tail is unattached for safer shipping but is keyed to fit and can be attached with glue to the body. See photo for reference.

Material: Resin You will be receiving the mermaid figurine and wax sealed print only.

#garage kit#statue#sculpture#mermay#mermaid art#mermaid#creature concept#concept design#monster#fantasy art#3d art#3d printing

244 notes

·

View notes

Text

Making an ice cream truck yarn bowl to go with my ice cream cone hooks and I *love* it. I’m changing some things (longer cab, bigger wheels, overall roundness), but it actually printed!

192 notes

·

View notes

Text

I'm extremely proud of this Articulated Ankylosaurus model and now she can be printed in full colour. This print took 33 hours but boy was it worth it. She looks beautiful 🤩. Printed using 4 different Filament colours with the use of my Bambu Lab AMS and P1S. once I've set up my Etsy Shop she will be available to purchase, she would make the perfect gift for a kid! Let me know what you think 🤔 I'll be updating this file on my Cults3D store soon to include full colour AMS compatibility 👍🏼. Please let me know what you think.

#my art#sculpture#3d art#3d printing#dinosaur#blender#my artwork#dinosaur art#cute#ankylosaurus#articulated#3d printer#3d model#3d design

151 notes

·

View notes

Text

"Cadenza staircase"

NEST building’s STEP2 unit in Dübendorf, Switzerland,

Created by ETH Zurich and ROK Architects,

It reimagines concrete construction with 3D-printed formwork and dry-joint assembly, this helical staircase comprises 16 prefabricated steps, each connected without permanent binding materials, allowing for easy disassembly and reuse.

Reinforced with post-tensioned memory steel, the design minimizes material use while ensuring durability, embodying NEST’s commitment to sustainable and experimental building techniques.

#art#design#stairwell#stairway#architecture#staircase#stairs#interiors#staircases#spiral staircase#cadenza#ETH Zurich#ROK Architects#3d printing#3D-printed#forms#dubendorf#helical#prefabricated#prefab#sustainability#sustainable architecture#steel#switzerland

88 notes

·

View notes

Text

Still printing out the one for the right hand then I'll spray primer and paint on the hands and arm cones

Got the pin backings on the pilot pin, using locking backs so they'll stay on the hat

Got the bulbs in for the headband

Then I painted and varnished a pair of docs

#max's posts#art#murder drones#serial designation n#cosplay#work in progress#3d printing#anime los angeles

66 notes

·

View notes