#3DLaserScanning

Explore tagged Tumblr posts

Text

3D Laser Scanning – Types | Benefits | Applications

3D Laser Scanning

3D laser scanning techniques have been developed since the end of 1990s for 3D digital measurement, documentation and visualization in several fields including 3D design in processing industry, documentation and surveying in architecture and infrastructure. By using a 3D laser scanner, a tunnel or underground construction can be digitized in 3D with a fast-scanning speed and high resolution up to “mm” level.

The scanning data consists of not only XY-Z co-ordinates but also high-resolution images, either gray-scale (with reflex intensity data) or color (with RGB data), and then can be transformed into a global co-ordinate system by control survey. Therefore, any rock engineering objects with its as-built situation can be quickly recorded as the 3D digital and visual format in a real co-ordinate system and provides a potential application for 3D measurement, documentation and visualization with high resolution and accuracy.

In modern engineering the term ‘laser scanning’ meaning is the controlled steering of laser beams followed by a distance measurement at every direction. This method, often called 3D object scanning or 3D laser scanning, is used to rapidly capture shapes of objects, buildings, and landscapes.

What is 3D Laser Scanning?

3D laser scanning is a non-destructive, non-contact method of capturing data that can be used for rapid and accurate creation of three-dimensional files, for archiving and digital manipulation. A 3D laser scanner emits a narrow laser beam that hits a target object, gathering millions of closely spaced measurements in a matter of minutes. These scanned measurements are put together and grouped into compressed point cloud databases, which can be processed to generate a 3D dense representation of the object.

3D Scanners Bridging Physical and Digital Worlds

3D scanners are tri-dimensional measurement devices used to capture real-world objects or environments so that they can be remodeled or analyzed in the digital world. The latest generation of 3D scanners do not require contact with the physical object being captured.

3D scanners can be used to get complete or partial 3D measurements of any physical object. The majority of these devices generate points or measures of extremely high density when compared to traditional “point-by-point” measurement devices.

How 3D Scanning Works?

Scanning results are represented using free-form, unstructured three-dimensional data, usually in the form of a point cloud or a triangle mesh. Certain types of scanners also acquire color information for applications where this is important. Images/scans are brought into a common reference system, where data is merged into a complete model. This process — called alignment or registration — can be performed during the scan itself or as a post-processing step.

Computer software can be used to clean up the scan data, filling holes, correcting errors and improving data quality. The resulting triangle mesh is typically exported as an STL (STereoLithography or Standard Tessellation Language) file or converted to Non-uniform Rational B-Spline (NURBS) surfaces for CAD and BIM modeling.

Types of Laser Scanning

1. Airborne Laser Scanning (LiDAR)

Airborne laser scanning (LiDAR = acronym for ‘Light detection and Ranging’, also LIDAR) is a scanning technique for capturing data on the features of, and objects on, the surface of the earth. It is an important data source in environmental studies, since it is capable of mapping topographic height and the height of objects on the surface to a significant vertical and horizontal accuracy, and over large areas. Airborne laser scanning is an active remote sensing technology able to rapidly collect data from vast areas.

2. Terrestrial Laser Scanning

Terrestrial Laser Scanners (TLS) are positioned directly on the ground, or on a platform placed on the ground, and are normally mounted on a tripod. TLS is, in its essence, an improved version of the laser tachometric measurement toolkit (the so-called total station) that is based on the combination of distances and angles measured from a fixed point. Tachometric laser scanners digitize objects of interest with a frequency of 1000 Hz or higher. Each point is measured per one oblique distance and, additionally, two orthogonal angles are measured. Most TLS are long-range devices. Nowadays, a great variety of TLS is available with different range and pulse frequencies.

3. Handheld (portable) Laser Scanning

There has recently been an increase in the application of handheld scanners. Their basic advantage is their portability. Scanners that are attached to light portable stands fall in this category as well, even though they are not ‘handheld’ in the true sense of the word. Primary used in reverse engineering, nowadays they are very often employed in digital documentation of moveable cultural heritage objects.

4. Long- and Short-Range Laser Scanning

Long-range laser scanning is tailored for surveying and monitoring expansive areas or structures. Using high-powered lasers and advanced optics, it covers distances from yards to miles/meters to kilometers. Employing time-of-flight or phase-based technologies, it finds applications in geological surveys, urban planning, infrastructure monitoring, and archaeological site mapping. Short-range laser scanning focuses on high-precision tasks within confined spaces. Covering distances from centimeters to meters/ feet to yards, it utilizes structured light or laser triangulation. Widely used in industrial metrology, 3D scanning, quality control, and cultural heritage preservation, it excels in capturing fine details with accuracy.

3D Scanning File Formats

TZF: This format is a Trimble scan files in a zipper format. The software exports the current project as a folder with:

• One TZF format file per station • One TCF format file per station if the station has been acquired with images

E57: This format is a file format specified by the ASTM (American Society of Testing and Materials), an international standards organization. The E57 format supports two types of data: Gridded Data and Non-Gridded Data. Gridded Data is a data which aligned in regular arrays.

E57 Gridded Files: The software exports the current project as one LAS 1.2 format file.

E57 Non-Gridded Files: The software exports the current project as one LAS 1.2 format file.

PTX: This format is an ASCII based for scan file format. The software exports the current project as one LAS 1.2 format file.

LAS, Non-Gridded: The format is public file format for interchanging 3-dimensional point cloud data between users. It is binary-based and has several versions: 1.0, 1.1, 1.2, 1.3 and 1.4. The application exports the current project as one LAS 1.2 format files.

POD, Non-Gridded: The POD (Point Database) file format is Bently Pointools’ native point cloud format. The software exports the current project as one POD format file. Points, color, intensity and normal (if available) information are exported.

RCP: This format file is a project file for Recap from Autodesk. The software exports the current project as one RCP format file.

TDX: TDX is Trimble Data eXchange file format, commonly used in some Trimble software applications like TBC (Trimble Business Center) or RealWorks. The software exports the information listed below:

• Stations with registration sets • Created panorama(s) • Measured points • Leveling information

Benefits of 3D Laser Scanning

3D laser scanning has become an indispensable tool across many industries due to its ability to capture highly detailed and more accurate 3D data. Here are some of the key benefits of 3D laser scanning:

High Accuracy

Laser scanning provides extremely accurate measurements, making it effective for applications where precision is critical, such as engineering, construction, and product manufacturing.

Rapid Data Capture

Laser scanners can quickly collect a large amount of data, reducing the risk associated with scanning high buildings and improving field staff safety.

Non-contact Technology

Laser scanning is noninvasive and doesn’t require physical contact with the object or environment being scanned, making it ideal for fragile, hazardous, or hard-to-reach locations.

Comprehensive Documentation

Laser scanning creates detailed and comprehensive digital records of objects, buildings, or landscapes, which are invaluable for preservation and historical archiving.

Visualization

Data from 3D laser scans can be used to create highly realistic visualizations, aiding in the design, analysis, and communication of complex structures and spaces.

Clash Detection

When integrated with building information modeling (BIM), laser scanning helps identify clashes between design plans and existing structures, reducing costly construction errors.

Applications of 3D Laser Scanning

3D Laser Scanning is used in numerous applications: Industrial, architectural, civil surveying, urban topography, reverse engineering, and mechanical dimensional inspection are just a few of the versatile applications. 3D laser scanning technology allows for high resolution and dramatically faster 3D digitizing over other conventional metrology technologies and techniques. Some very exciting applications are animation and virtual reality applications.

1. Construction Industry and Civil Engineering

a. As-built drawings of bridges, industrial plants and monuments b. Documentation of historical sites c. Site modelling and lay outing d. Quality control e. Quantity surveys f. Freeway redesign g. Establishing a benchmark of prre-existing shape/state in order to detect structural changes resulting from exposure to extreme loadings such as earthquake, vessel/truck impact or fire. h. Create GIS (Geographic Information System) maps and Geomatics

2. Reverse Engineering

Reverse Engineering refers to the ability to reproduce the shape of an existing object. It is based on creating a digitized version of objects or surfaces, which can later be turned into molds or dies. It is a very common procedure, which has diverse applications in various industries. Non- contact 3D laser scanning allows even malleable objects to be scanned in a matter of minutes without compression, which could change their dimensions or damage to their surfaces. Parts and models of all sizes and shapes can be quickly and accurately captured. 3D laser scanning for reverse engineering provides excellent accuracies and helps to get products to market quicker and with less development and engineering costs. 3D Laser scanning provides the fast, accurate, and automated way to acquire 3D digital data and a CAD and BIM model of part’s geometry for reverse engineering when none is available. Also, new features and updates can be integrated into old parts once the modeling is accomplished. A practical mechanical and civil engineering application would be to assist in the production of "as built" data and documentation. Currently, many manufacturing or construction activities are documented after the actual assembly of a machine or civil project by a designer or engineering professional. 3D laser scanners could expedite this activity to reduce man-hours required to fully document an installation for legacy.

3. Mechanical Applications

Reverse engineering of a mechanical component requires a precise digital model of the objects to be reproduced. Rather than a set of points a precise digital model can be represented by a polygon mesh, a set of flat or curved NURBS surfaces, or ideally for mechanical components, a CAD solid model. A 3D scanner can be used to digitize free-form or gradually changing shaped components as well as prismatic geometries whereas a coordinate measuring machine is usually used only to determine simple dimensions of a highly prismatic model. These data points are then processed to create a usable digital model, usually using specialized reverse engineering software.

4. Civil Applications

Civil activities could be for a roadway periodic inspection. The digitized roadway data could be contrasted to previous roadway 3D scans to predict rate of deterioration. This data could be very helpful in estimating roadway repair or replacement costing information. When personnel accessibility and/or safety concerns prevent a standard survey, 3D laser scanning could provide an excellent alternative. 3D Laser scanning has been used to perform accurate and efficient as-built surveys and before-and after construction and leveling survey.

5. Design Process

Design process including: a. Increasing accuracy working with complex parts and shapes b. Coordinating product design using parts from multiple sources c. Updating old CD scans with those from more current technology d. Replacing missing or older parts e. Creating cost savings by allowing as-built design services, for example: automotive manufacturing plants. f. “Bringing the plant to the engineers” with web shared scan and saving travel costs.

Conclusion

3D laser scanning equipment senses the shape of an object and collects data that defines the location of the object’s outer surface. This distinct technology has found applications in many industries including discrete and process manufacturing, utilities, construction. Laser scanning technology has matured and developed in the past two decades to become a leading surveying technology for the acquisition of spatial information.

The high-quality data produced by laser scanners are now used in many of surveying’s specialty fields, including topographic, environmental, and industrial. These data include raw, processed, and edited dense point clouds; digital terrain and surface models; 3D city models; railroad and power line models; and 3D documentation of cultural and historical landmarks. 3D laser scanners have a wide range of applications which applicable to very small object to a wide range area.

#3DLaserScanning#ScantoBIMservices#BIMModelingServices#AirborneLaserScanning#TerrestrialLaserScanning#LongRangeLaserScanning#ShortRangeLaserScanning#BIMServices#Benefitsof3DLaserScanning#Applicationsof3DLaserScanning

1 note

·

View note

Text

As-Built Services capture every detail, ensuring your project documentation is a true reflection of excellence.

Surveying and documentation activities are conducted after the completion of a construction project. The primary goal is to accurately capture and record the final built environment, ensuring that the project documentation reflects the as-built conditions with precision.

Elevate your construction journey with the precision you can trust. Ready to redefine accuracy? Let's build together. 🏗️

2 notes

·

View notes

Text

Top Benefits of 3D Laser Scanning Services for Accurate As-Built Documentation & Reality Capture

Tejjy Inc. is a trusted 3D laser scanning company in the USA, offering high-resolution reality capture and accurate as-built data for various industries. Our skilled professionals deliver precise 3D scanning services, providing point cloud data, 3D models, CAD drawings, and digital twins. With an accuracy of 4-6 mm, we cater to diverse sectors, including renovation, surveying, facility management, and heritage preservation. Serving over 150 million square feet, our solutions support general contractors, architects, engineers, asset managers, and more. Whether you need building scanning, lidar services, or 3D scanning, Tejjy Inc. is your go-to for accurate, reliable results.

#3DLaserScanning#LaserScanning#ScanToBIM#3DScanning#RealityCapture#PointCloud#DigitalTwin#Surveying#Architecture#USA

0 notes

Text

Voyage Repair in Ship Repair: Ensuring Safe and Efficient Maritime Operations

Voyage repair is an important part of ship maintenance. It helps keep vessels safe, efficient, and aligned with international standards during their journeys. These repairs happen while a vessel is still on a voyage or transiting via channels/straits. These repairs help technical managers to reduce the idle time for repairs.

Unlike conventional dry dock-based repairs, voyage repairs can rectify defects without interrupting the shipping schedule, preserving the vessel's operational integrity and meeting critical delivery deadlines.

Importance of Voyage Repair

Voyage repair plays a vital role in maintaining a vessel's integrity and performance. By addressing issues promptly during a voyage, ship operators can prevent minor problems from escalating into major faults that could jeopardize safety and lead to costly repairs.

This approach ensures that ships remain operational and can continue their voyages without significant interruptions.

Reduced Downtime: Time spent at sea can be long. Going back to port for small repairs can be costly and wasteful. Voyage repairs allow for operational continuity.

Cost Efficiency: Fixing the ship while still working can reduce docking fees. It also lowers labor costs in big ports and lessens the financial impact of delays.

Improved Safety: Fixing problems quickly while at sea makes it safer. This helps protect the crew, the cargo, and the environment. This helps reduce risks linked to operational failure.

Key Components of Voyage Repair

Periodic Inspections: Regular inspections are essential to monitor the condition of critical ship components such as the hull, engines, and electrical systems. Non-Destructive Testing (NDT) techniques, including Ultrasonic Testing (UT) and Magnetic Particle Inspection (MPI), are employed to detect hidden flaws without dismantling parts of the ship.

Troubleshooting and Repairs: When malfunctions occur, voyage repair teams quickly identify and rectify the issues. This may involve repairing engine parts, fixing leaks, or addressing electrical failures to ensure the ship's systems operate smoothly.

Condition Monitoring: Continuous monitoring of ship components helps track their performance over time. Technologies like vibration analysis and ultrasonic testing predict potential failures, allowing maintenance personnel to schedule repairs before problems become severe.

Predictive Maintenance: By analyzing data from condition monitoring, predictive maintenance strategies anticipate when components will need repairs or replacements. This foresight reduces unexpected breakdowns and optimizes maintenance schedules.

Best Practices for Effective Voyage Repair

Effective Planning and Scheduling: Detailed planning ensures that repair activities are well-coordinated and do not disrupt the ship’s operations. Flexible scheduling accommodates unexpected changes in repair scope, ensuring timely completion.

Skilled Workforce: A highly trained and experienced crew is essential for successful voyage repairs. Continuous training programs keep technicians updated with the latest repair techniques and technologies.

Compliance with Regulations: Adhering to international maritime regulations and standards ensures that repairs meet safety and performance criteria. This compliance is crucial for avoiding legal issues and maintaining the ship’s certification.

Voyage Repair in Ship Repair: A Comprehensive Guide

Voyage repair is an essential practice in the maritime industry, allowing repairs to be conducted while a vessel is still at sea. This method helps reduce downtime and keep ships operational, avoiding costly delays. The ability to perform repairs while the vessel continues its journey is crucial for maintaining a competitive shipping schedule, minimizing risks, and controlling costs. In this article, we’ll explore the technical aspects of voyage repair, its advantages, challenges, and future trends.

1. Importance of Voyage Repair

Shipping companies face high demands for efficiency and reliability. Any breakdown at sea can lead to delays, penalties, and even cargo loss. Voyage repair offers a solution to address problems without returning to port, making it a critical strategy for modern shipping operations. The key benefits include:

Operational Continuity: Repairs can be made while the vessel is still underway, ensuring that schedules remain intact.

Cost Efficiency: Avoiding port calls for minor repairs saves money on docking fees and labor costs.

Safety: Fixing issues as soon as they arise ensures the safety of the crew, cargo, and vessel.

2. Types of Repairs Conducted During Voyages

Several types of repairs are common during voyages, each serving a critical function in maintaining the vessel’s operation:

Mechanical Repairs: Engines, pumps, and compressors often require adjustments or part replacements. Common tasks include engine repairs, shaft realignment, and pump maintenance.

Electrical Repairs: Electrical systems, including power distribution and navigation equipment, can malfunction during a voyage. Repairs may include fixing wiring, circuit breakers, and key navigational tools like radar and GPS.

Structural Repairs: These include minor fixes to the hull or deck, corrosion control, and even underwater repairs using specialized teams or ROVs (Remotely Operated Vehicles).

3. Methods of Performing Voyage Repairs

The execution of repairs during voyages involves a combination of onboard crew expertise, specialized technicians, and advanced technology:

Onboard Teams: Ship crews often include personnel trained to handle routine repairs. For more complex tasks, technicians can be flown to the ship at sea or meet the ship at its next port.

Mobile Workshops: Some companies provide mobile workshops, equipped with tools and spare parts, that can be deployed to the vessel’s location.

Condition Monitoring: Modern vessels use condition monitoring systems to detect issues before they become critical. This data allows repairs to be scheduled at the optimal time during a voyage.

Underwater ROVs and Divers: When structural or hull repairs are necessary, ROVs and divers can perform inspections and repairs in deep waters.

Benefits of Voyage Repair

Enhanced Safety: Regular and timely repairs reduce the risk of accidents and ensure that all ship systems function correctly.

Increased Reliability: Ships that undergo voyage repairs are less likely to experience unexpected breakdowns, ensuring smooth and uninterrupted voyages.

Cost Efficiency: Proactive maintenance and repairs prevent costly emergency fixes and extend the lifespan of ship components.

Regulatory Compliance: Maintaining compliance with maritime standards through regular repairs avoids penalties and ensures the ship remains certified for operation.

Conclusion

Voyage repair is indispensable for maintaining the safety, efficiency, and reliability of maritime operations. By integrating advanced technologies and adhering to best practices, ship operators can ensure their vessels remain in optimal condition throughout their voyages. This proactive maintenance approach improves the lifespan and performance of ships. It also helps the sustainability and competitiveness of the maritime industry.

#VoyageRepair#ShipMaintenance#MaritimeSafety#NDT#RoboticWelding#3DLaserScanning#PredictiveMaintenance#Shipbuilding#MaritimeIndustry#ShipEfficiency#weser maritim

0 notes

Text

Fast-Track Surveying with Rapid Scan-to-BIM: Unlock AI’s Potential

To develop a better understanding of the Scan to BIM conversion process and the advancements in the field, it is first necessary to understand the key aspects of surveying.

Surveying: A Consequential Stage for Architecture and Engineering Projects

Surveying is a conscious process of understanding the building characteristics with appropriate analysis, synthesis, and documentation of the architectural project. It helps the architects and engineers to develop a better understanding of the project specifications.

The process not only allows the creation of accurate technical construction drawings but also assesses the quantitative and qualitative attributes to make suitable design choices.

Success Story: 400,000 Sq.Ft. of Scan to BIM Conversion in Just 43 Days

Key Aspects of Surveying:

Explicit Data Extraction: The successful restoration and redevelopment of projects requires details about every nuance of the existing built form.

Steer Away from Errors and Oversights: Surveying identifies and records the nuances of any built form in the most accurate way possible, reflecting on the specific construction situations.

The possible reasons behind structural failure, and details about the degradation and erosion of materials, leaving no room for errors or oversights.

Compliance with Codes and Standards: The detailed site study allows the architects and designers to understand the codes that govern the existing structure and make amendments, ensuring compliance with the latest building codes and standards.

What is Scan to BIM?

Based on the tools and procedures used during the survey, there are various operational methodologies like photogrammetry, planimetric survey, and topographical survey, which can be employed to obtain site details. In addition to these techniques, the latest advancement in the industry is Scan to BIM: surveying with 3D laser scanners.

Read More :How is a Scan to BIM Reshaping the AEC Industry

Rapid Scan to BIM Conversion: A Preferable Choice for Surveyors and MEP Engineers

The Point cloud to BIM services are increasingly replacing the standard approach in various countries and hold enormous potential for automating the AEC sector. Here are the key factors driving the demand for rapid Scan to BIM services:

Companies are entitled to meet tight project deadlines to ensure client satisfaction.

Speed, Quality, and Affordability: Three Pillars for a successful Scan to BIM conversion

Speed, Quality, and Affordability are the three pillars in the AEC industry for a lucrative Scan to BIM conversion and smooth project delivery. Creating an equilibrium between these pillars results in meeting client expectations and maintaining a competitive edge in the industry.

Speed:

Speed is a critical factor for meeting client demands and achieving desired results, leading to repetitive clientele.

Quick turnaround time can be a governing factor for a client while deciding on the service provider company.

Quality:

High-quality BIM models are crucial for accurate planning, design, and construction of projects. Poor quality might lead to errors, rework, and increased commercials.

Qualitative BIM models provide detailed site representations, inducing accuracy and precision to the results on site.

Read More : Convert Point Cloud Data to Revit Models: A Quick Guide

Integrating Advanced Technology to Scan to BIM Conversion

The AI-powered Scan to BIM conversion tool by ScantoBIM.Online can be a preferable approach for a 50% faster conversion process. Services offered by VBS can be tailored as per the needs and pain points of the Surveyors and MEP engineers, enhancing their overall experience.

Benefits of Adapting AI-powered Conversion Tool

Scan to BIM is becoming a more advanced and accessible tool for surveying due to technological breakthroughs and emerging trends that simplify the conversion process.

Minimum Human Intervention: The AI-powered approach reduces human intervention in the Scan to BIM conversion process and

Unparalleled Accuracy and Precision: The in-house plugins reduce the possibility of errors, providing unmatched accuracy and consistency to the Surveyors and MEP professionals. The BIM models are developed according to the industry standard to ensure precise results.

Rapid Conversion Success Story

Hale Tip- a company grounded in virtual design and construction, engaged AI-powered conversion tools for 750,000 sq ft of Scan to BIM projects.

The BIM model was delivered in 50 days which equates to successfully converting 22,000 sq ft area daily.

Conclusion

Architectural survey methods with 3D laser scanning are capable of registering every nuance of the building with a superior level of accuracy to conventional methods, reducing errors, and minimizing the fieldwork.

The current technological advancements in the industry and the emerging trends have increased the demand for the BIM models as the end product of the site surveys. Scan to BIM services is a new paradigm that still challenges professionals when dealing with old and heritage buildings

Original Source: Fast Track Surveying with Rapid Scan to BIM Conversion: Unlock the potential of AI

Insightful Article:

Scan to BIM Conversion Services for As-Built: Accelerate the Process by 50%

Walk-through of Point Cloud to BIM Modeling Services

0 notes

Text

Advanced Methods to Improve Building Scan Quality and Minimize Artifacts

Are you tired of dealing with incomplete or inaccurate building scans? 🏢🔍 It's time to take your scanning game to the next level! By implementing advanced scanning techniques and utilizing high-quality equipment, you can significantly Improve Scan Quality of Building projects. This ensures comprehensive data capture, reducing the chances of missing critical information and minimizing unwanted artifacts.

Discover the best practices for achieving flawless building scans. From optimizing your scan settings to regular equipment maintenance and employing advanced software solutions, there are numerous ways to enhance your scan quality. Let’s make sure every detail is captured with precision and accuracy! 🛠️📐

#ImproveScanQualityofBuilding#3DLaserScanning#3DLaserSurveying#BuildingScanMissingData#BuildingScanningChallenges#BuildingScans#ImprovedQuality#AccurateData

0 notes

Text

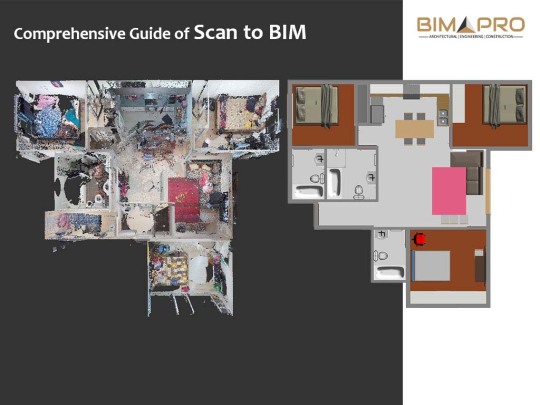

Scan to BIM is an innovative process that involves using 3D scanning technologies to capture precise measurements and data of physical structures, and then converting this data into detailed 3D Building Information Models (BIM). These digital models serve as accurate representations of the real-world environment and are essential tools for architects, engineers, and construction professionals.

Read more: https://www.bimprous.com/guide-of-scan-to-bim/

#BIMPRO#BIM#ScanToBIM#PointCloud#3DLaserScanning#AEC#Architectural#Engineering#Construction#Texas#USA

0 notes

Text

🌐 Embrace Precision with iScano Toronto's 3D Laser Scanning Services in Toronto!

Discover the power of 3D construction scanners and experience the excellence of laser scanning. Elevate your projects to new heights. Connect with us today for a complimentary consultation! 📏🔍 Explore the world of #3DLaserScanning, #TorontoConstruction, and #LaserScanners. 🏗️

Read more : https://posts.gle/Vz9pjY

Contact us: iScano Toronto 126 Simcoe Street, Unit 2204, Toronto, Ontario M5H 4E6 (647) 773-1341 https://iscano.com/3d-laser-scanning-toronto/

Visit our online listings: https://bit.ly/3WMJYM2 https://bit.ly/43p0DHW https://bit.ly/3LNhZYc

#3d scanning services#laser scanning#laser scan#3d laser#3d laser scanning services toronto#scanning services#3d laser scanning services#3d construction scanner#laser scanners#youtube

0 notes

Text

3d Scanning Reverse Engineering

3D scanning is a technique for collecting high-density spatial imaging with millions of coordinates quickly and accurately for your aircraft, vehicle and other large objects. SixD Engineering Solutions Pvt. Ltd. Visit this Link:- http://bit.ly/2n41v5J Phone No : +(91)-(120)-4542274 / 75 Email Id : info[@]sixdindia.com

#3dlaserscanning#3d laser scanning survey#3d laser scanning services#Reverse Engineering Services in India

1 note

·

View note

Text

Construction industry is currently responsible for 50% of the solid waste that is generated worldwide. This is a staggering number which has long lasting environmental impact and has created considerable concern in the recent decades. Green building methods have been adopted around the globe as a strategy to curtail construction waste. The application of BIM provides significant value at different stages of the building’s lifecycle in terms of waste management.

To know in detail how can BIM help reduce waste in construction click on the given link,

#constructionindustry#greenbuildingmethods#bimservices#wastemanagement#buildingwastemanagement#constructionwastereduction#bim#3dvisualization#clashdetection#bimcoordinationservices#bimmodel#hvac#building#construction#shopdrawings#scantobim#3dlaserscanning#scantobimservices

1 note

·

View note

Text

0 notes

Text

Silicon Engineering Consultants Limited specializes in providing As-Built BIM Services, which is widely recognized as one of the most essential services in the AEC Industries.

#Auckland #Newzealand

bit.ly/45OkEcB

#AsBuiltBIMModeling#LaserScanningServices#AsBuiltToBIMServices#AsBuiltToBIMSolutions#CADDrawing#AECIndustries#CADDesigning#3DLaserScanning#AsBuiltModellingService#AsBuiltBIMOutsourcingServices

1 note

·

View note

Text

Construction Laser Scanning Services

Starting from the planning stages through the final construction and maintenance phases, construction 3D laser scanning is employed throughout the project lifespan.

Improve project efficiency & safety with 3D laser scanning in construction to get analysis and site survey, design and planning, inspection and quality control, project management, upkeep & renovation.

0 notes

Text

3D Laser Scanning Company Philadelphia, PA

Our expert architects & engineers ensure quality-assured BIM models for the smooth and streamlined construction and management of residential, commercial, and industrial buildings. We offer the following BIM services such as MEP BIM, 3D Laser Scanning, Scan to BIM, Architectural BIM, Structural BIM, Revit Family Creation, 4D BIM scheduling, 5D BIM cost estimation & Shop Drawings Services in Pennsylvania.

0 notes

Text

Revolutionize your construction projects with 3D laser scanning! 🏗️ Get the complete guide to unlock its potential.

0 notes

Text

Fast Track Architectural Surveying with AI-Powered Scan to BIM

Transform architectural surveying with AI-powered Scan to BIM technology. Convert 3D laser scans into precise BIM models for faster project turnaround, reduced costs, and unmatched accuracy. Ideal for surveyors, MEP engineers, and AEC professionals seeking efficiency and a competitive edge in complex projects.

Read More:

0 notes