#4x8 cnc machine

Explore tagged Tumblr posts

Text

Mastering Woodworking with the Router Table 4x8: Elevate Your Craft with Precision and Versatility

In the world of woodworking, achieving professional-grade results relies heavily on having the right tools at your disposal. Among these tools, the router table 4x8 stands out as an essential piece of equipment for both novice and experienced woodworkers. This article explores the features, benefits, and applications of a router table while also comparing it to the increasingly popular desktop CNC machine.

What is a Router Table 4x8?

A router table 4x8 is a large woodworking device designed to support a router, enabling it to make precise cuts and shapes in various materials. The "4x8" designation refers to the dimensions of the tabletop, providing ample space for handling large workpieces. This expansive surface allows for increased stability and control, essential for executing detailed woodworking tasks.

Benefits of Using a Router Table 4x8

Enhanced Stability and Control: The larger size of a router table provides a stable working environment, which helps minimize vibrations and errors during the routing process. This stability is particularly beneficial when working with intricate designs or larger boards.

Versatile Applications: Router tables are incredibly versatile and can perform numerous tasks, such as shaping edges, creating grooves, and making joinery cuts. With adjustable speeds and heights, you can tailor your routing operations to suit various woodworking projects.

Improved Safety: Operating a router table significantly reduces the risk of injury compared to using a handheld router. The secure positioning of the workpiece minimizes kickback and enhances user safety, allowing for a more focused and productive work environment.

Compatibility with Different Router Bits: A router table 4x8 is designed to accommodate a wide range of router bits. This flexibility enables woodworkers to explore diverse techniques and styles, facilitating the creation of unique designs and finishes.

Comparing Router Tables and Desktop CNC Machines

Both the router table 4x8 and desktop CNC machines have their merits, and understanding their differences can help you choose the right tool for your needs.

Precision and Automation

Desktop CNC machines excel in precision and automation, making them ideal for detailed and repetitive tasks. These machines use computer-controlled settings to execute intricate designs with high accuracy, which can be especially beneficial for commercial woodworking applications. However, they often require significant upfront investment and time to master the software.

Hands-On Flexibility

In contrast, a router table 4x8 offers a more hands-on approach, allowing for immediate adjustments and manual control over the routing process. This hands-on experience fosters creativity, enabling woodworkers to experiment with different techniques and designs. The tactile nature of routing can enhance the enjoyment of woodworking and lead to innovative results.

Selecting the Right Router Table 4x8

When choosing a router table, keep these considerations in mind:

Build Quality: Select a router table with a sturdy construction that can handle regular use. A solid base will contribute to the table's durability and stability during operations.

Ease of Use: Look for features like adjustable heights, clear measurements, and intuitive controls that simplify your workflow. A user-friendly design is crucial for maximizing efficiency and effectiveness in your woodworking projects.

Included Accessories: Many router tables come with valuable accessories such as fences, dust collection ports, and miter gauges. These tools can enhance your routing capabilities and improve the accuracy of your cuts.

Conclusion

A router table 4x8 is an invaluable addition to any woodworking shop, providing a perfect blend of stability, versatility, and safety. While desktop CNC machine offer advanced precision and automation, the hands-on experience of using a router table can inspire creativity and innovation in your projects. By understanding the benefits and features of a router table, you can elevate your woodworking skills and bring your creative visions to life. Embrace the possibilities that a router table 4x8 offers, and take your woodworking craft to new heights.

2 notes

·

View notes

Text

Easy financing and no hidden fee on 4x8 CNC router tables

Every CNC router table is designed, assembled, and tested here in the USA with a relentless focus on quality and long-term durability. There aren’t any shortcuts or gimmicks. Just solid engineering, straightforward pricing, and genuine appreciation for those who serve. Because building better tools starts with supporting the people who build better communities. Get this CNC machine for sale from here: https://premierplasmacnc.com/

1 note

·

View note

Text

Working with ABS? Here’s What You Should Know

You can tell a lot about a material based on how people actually use it, not just what brochures say. ABS plastic sheets, for example, aren’t new. But ask any workshop guy, prototyping engineer, or serious DIY builder—they’ve all got a sheet or two tucked away, ready for action.

There’s a reason for that. ABS (Acrylonitrile Butadiene Styrene) is strong, relatively lightweight, and ridiculously easy to work with. Doesn’t matter if you’re cutting it, drilling it, or heating it to shape—it responds well and forgives small mistakes. It’s one of those materials that sort of disappears once it’s in place. That’s how you know it’s doing its job.

One format I’ve come across often in both hobby and professional work is the 1x8 Abs plastic sheet 4x8. Not too large, not too small—kind of the “just right” option for quick builds or mid-sized projects. Let’s dive into the basics of these sheets and why so many people prefer them.

Why ABS Is the Go-To Plastic for Builders and Makers

ABS isn’t glamorous. You’re not buying it to impress anyone. What you’re getting is reliability. It won’t crack under stress, it doesn’t absorb moisture like wood, and it doesn’t warp out of shape randomly like some thin plastics. Whether you’re doing automotive interiors or building a quick jig for your tools, ABS just works.

The sheet surface is also a big plus. Some come textured, some smooth—you pick what suits your job. The matte finish doesn’t reflect light harshly, which makes it great for signage or visible applications. And for folks who like to paint, it takes color nicely with just a bit of sanding and the right primer.

Sheet Thickness and What It Means for You

Not every project calls for the same thickness. That’s where knowing your specs pays off. A thinner sheet might save weight and cut easily, but you don’t want it buckling under load.

For more demanding work, the 10MM Abs plastic sheet really stands out. It’s thick enough to handle structural loads, support bolts, and hold its shape even when you’re using it in outdoor or rugged setups. I’ve used this thickness for shelving inside a van conversion and it didn’t budge—even with tools stored on top during long trips.

This thickness also gives you the flexibility to do advanced machining if needed. Want to route a groove or make a slot? You’ve got room to play with 10MM. That’s something thinner sheets just can’t handle without snapping or flexing.

Some Smart Ways People Use ABS Sheets

There’s a pretty long list, honestly. But here are some of the real-world uses I’ve seen or done myself:

Custom enclosures for electronics—keeps things safe and doesn’t interfere with signals.

Tool drawer liners—cut it to fit, drop it in, no more clanking tools.

RC and hobby builds—especially when you want lightweight and strong materials.

Wall paneling—interior cladding that’s easy to clean and doesn’t rot.

Protective guards—cover moving parts, hot surfaces, or electrical components.

What’s great is that most of these uses don’t require industrial-grade tools. A decent jigsaw, drill, and some sandpaper will get you through most jobs.

Working with ABS: Not as Hard as It Sounds

If you’ve never worked with ABS, don’t stress—it’s surprisingly user-friendly. Just clamp it down properly before cutting, because it can chatter a bit if it’s loose. A fine-tooth saw or a Dremel works wonders. And if you ever want to bend it, warm it up gently with a heat gun and use gloves to avoid burns.

One time I cut a 125 Abs plastic sheet for a machine cover—it was thick and took a while to cut, but the results were clean. The important thing was taking my time and making sure I wasn’t rushing the blade. You don’t need a CNC to get great results, just patience and sharp tools.

Wrapping Up the ABS Advantage

So, what’s the verdict? ABS sheets are the definition of dependable. Whether you’re tackling a one-off garage fix or assembling parts for an actual product launch, this plastic pulls its weight.

From the handy 1x8 Abs plastic sheet 4x8 for medium-sized builds, to the beefier 10MM Abs plastic sheet for structure and load, to the thicker and more industrial 125 Abs plastic sheet, there’s something for everyone. You don’t need to be a pro to get results—just a little know-how and the right sheet.

FAQs

1. Who is the largest manufacturer of ABS plastic sheets?

If you're serious about quality and reliable supply, Singhal Industries Pvt Ltd is one of the most trusted names in the business. They’ve been leading the ABS plastic sheet game in India for years, offering a wide range of sizes, finishes, and thicknesses, all backed by dependable service and fast delivery.

2. Can ABS plastic sheets be recycled?

Yes, ABS plastic is recyclable. Most industrial recycling facilities can handle it. Just make sure you’re not mixing it with other plastics or coated materials that could interfere with the process.

3. What’s the best way to clean ABS plastic?

Keep it simple: a mild soap solution and a soft cloth will do. Avoid harsh cleaners or abrasive sponges—they can scratch or dull the surface. If it's got oil or grime on it, a little isopropyl alcohol works well too.

0 notes

Text

4x8 CNC Plasma Table Setup Tips for Precision Cuts

A 4x8 CNC Plasma Table is a powerful tool for metalworkers, fabricators, and industrial shops looking to achieve accurate and efficient cuts. However, to get the most out of your machine, proper setup is crucial. In this guide, we’ll walk through essential setup tips to help you get clean, precise cuts every time.

1. Choose a Stable and Level Surface

Before you begin any cutting work, make sure your 4x8 CNC Plasma Table is installed on a solid, level surface. Uneven flooring can lead to table vibrations, affecting cut quality and accuracy. Use a spirit level to adjust and align the table legs properly.

2. Calibrate Your Table Accurately

One of the most important steps in setup is calibration. Take time to:

Square the gantry

Check for backlash in the drive system

Ensure the torch is perpendicular to the table

Calibration errors can lead to poor cuts and wasted material. Most CNC plasma table software includes a calibration tool—use it regularly to maintain precision.

3. Optimize Torch Height Control (THC)

Torch Height Control is vital for clean and consistent cuts. Make sure your THC system is:

Enabled and active

Properly set to the material thickness

Responsive to surface variations

On a 4x8 CNC Plasma Table, maintaining the ideal torch-to-material distance helps reduce slag and ensures even cutting across the full sheet size.

4. Secure and Ground the Material

Improper grounding or loose material can lead to poor cut quality and even safety hazards. Use clamps or magnetic holders to keep your metal sheet flat and firmly in place. Additionally, double-check that your grounding clamp is properly attached to the workpiece for a steady arc.

5. Use High-Quality Consumables

Precision cutting isn’t just about setup—it also depends on the quality of your consumables. Always use clean, compatible tips, electrodes, and shields for your 4x8 CNC Plasma Table. Worn parts can lead to rough edges, excessive dross, and inconsistent cuts.

6. Fine-Tune Your Cutting Parameters

The cut quality depends on your feed rate, amperage, and air pressure. Here’s a quick guideline:

Too fast = Incomplete cuts

Too slow = Excessive slag and melting

Low pressure = Rough, jagged cuts

Too much amperage = Wider kerf and reduced detail

Test your settings on a scrap piece before committing to the final workpiece.

7. Keep the Table Clean

Debris, dust, and metal slag can build up over time, interfering with the movement of your machine. Regularly clean the slats and remove any leftover material after each job. A clean table supports smoother gantry movement and reduces chances of cut errors.

Setting up your 4x8 CNC Plasma Table correctly is the key to achieving professional-level precision in your metalworking projects. With attention to detail and regular maintenance, your table can deliver clean, accurate cuts for years to come. Always refer to your machine’s manual and safety guidelines before starting.

0 notes

Text

ABS Plastic Sheets: A Durable and Versatile Solution for Industrial and Commercial Use

Understanding ABS Plastic Sheets

Acrylonitrile Butadiene Styrene, commonly known as ABS, is a thermoplastic polymer that has gained immense popularity across industries due to its strength, durability, and adaptability. ABS plastic sheets are particularly renowned for their tough physical properties and excellent resistance to impact, chemicals, and heat. These sheets are widely used in applications ranging from automotive parts and electronic enclosures to signage and protective panels. In cities like Ahmedabad, which has become a major manufacturing hub, there’s a growing demand for ABS plastic sheet exporters in Ahmedabad to cater to both domestic and international markets.

Key Features That Make ABS Sheets Stand Out

What sets ABS plastic sheets apart from other materials is their unique combination of rigidity and flexibility. They are easy to machine, form, and bond, making them ideal for both prototyping and mass production. With a smooth finish that can be painted or printed on, ABS sheets are commonly used in industrial design and interior aesthetics. Furthermore, they are non-toxic, recyclable, and perform well in a wide range of temperatures, which enhances their usability in outdoor and high-impact environments. These features contribute to the rising popularity of Abs plastic sheet 4x8 manufacturers in Gujarat, where large-scale production allows for competitive pricing and customization.

Wide-Ranging Industrial Applications

ABS plastic sheets are found in a surprisingly diverse number of industries. In the automotive sector, they are used to make dashboards, door panels, and trim components due to their resistance to vibration and wear. In construction, they are utilized for wall coverings, cladding, and piping systems. In the electrical and electronics industry, ABS is favored for its insulating properties and ease of molding into various shapes. With so many sectors relying on ABS, manufacturers in Gujarat have positioned themselves as a go-to source for high-quality products, especially the standard 4x8 size sheets that are widely used in modular systems.

The Manufacturing Strength of Gujarat

Gujarat has emerged as one of India’s top manufacturing states, especially in the field of plastics. With its advanced infrastructure, skilled workforce, and robust supply chains, Gujarat hosts numerous ABS plastic sheet 4x8 manufacturers that produce export-grade material. Ahmedabad, in particular, is home to several well-established manufacturers and exporters who ship ABS sheets across the globe. These companies adhere to international standards, offering flame-retardant, UV-resistant, and customized textured finishes. As a result, the Abs plastic sheet price in Ahmedabad remains competitive while maintaining top-notch quality.

Customization and Finishing Options

One of the standout advantages of ABS plastic sheets is the variety of customization options available. Manufacturers can produce sheets in different colors, finishes (like matte, gloss, or embossed), and thicknesses to meet specific industry needs. Whether it's a furniture manufacturer needing textured panels or a car company requiring custom-dyed interiors, ABS sheets deliver both aesthetics and performance. With advanced thermoforming and CNC machining techniques, ABS plastic sheet exporters in Ahmedabad can provide tailor-made solutions that fit seamlessly into any production line or end-use application.

Market Demand and Global Export Trends

The global demand for ABS plastic sheets is steadily increasing, driven by industries that are looking for lighter, more durable, and cost-effective alternatives to metal and wood. Indian manufacturers, especially those based in Ahmedabad and other parts of Gujarat, have become key players in the international market. Thanks to competitive production costs, reliable logistics, and the ability to scale, these manufacturers are exporting to countries across Asia, Europe, and Africa. The rising export activity also helps in stabilizing the ABS plastic sheet price in Ahmedabad, making it an attractive sourcing destination for both bulk buyers and OEMs.

Quality, Compliance, and Sustainability

Today’s manufacturers are not just focused on quantity—they are equally invested in quality and environmental responsibility. Leading ABS plastic sheet 4x8 manufacturers in Gujarat ensure compliance with international safety and quality norms such as RoHS, REACH, and ISO certifications. Many producers are also moving toward more sustainable production methods, incorporating recycled materials and reducing waste in their processes. This commitment to quality and green practices makes them reliable partners in long-term supply chains, especially for environmentally conscious clients.

Conclusion: The Future is ABS

ABS plastic sheets are proving to be a material of the future, combining functionality with form in ways that few other materials can. Their durability, flexibility, and adaptability make them an essential component in a wide variety of industries. With Gujarat—and especially Ahmedabad—leading the way in production and export, businesses have a reliable and cost-effective source for high-quality ABS products. Whether you’re looking to buy in bulk, customize for a specific use, or find the best Abs plastic sheet exporters in Ahmedabad, there’s never been a better time to tap into this thriving market.

Frequently Asked Questions (FAQs)

1. What is the standard size of ABS plastic sheets available in Gujarat?

Most manufacturers in Gujarat offer ABS plastic sheets in the standard 4x8 feet size, although custom sizes are also available based on project requirements.

2. How can I verify the quality of ABS plastic sheets from Ahmedabad exporters?

Look for certifications like ISO and RoHS, request product samples, and check customer reviews or testimonials. Reputed ABS plastic sheet exporters in Ahmedabad are transparent about their quality standards.

3. Are ABS sheets suitable for outdoor use?

Yes, ABS sheets with UV stabilization and weather-resistant coatings are well-suited for outdoor applications such as signage, kiosks, and construction barriers.

4. How is the ABS plastic sheet price in Ahmedabad compared to other regions?

Due to local manufacturing and efficient supply chains, the ABS plastic sheet price in Ahmedabad is generally lower than in many other cities, without compromising on quality.

0 notes

Text

CNC Plasma Table for Professionals – Maverick Series

The Maverick Series CNC Plasma Table is your go-to plasma cutting machine for accuracy, reliability, and seamless CNC performance.

0 notes

Text

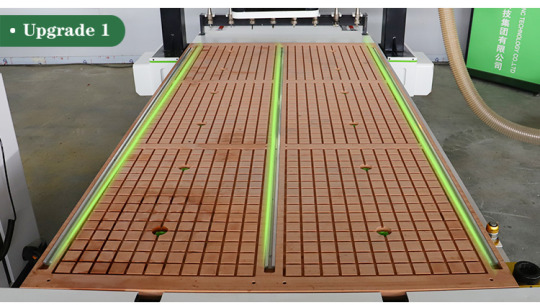

1325 CNC Wood Cutting Machine 4×8

The CNC wood cutting machine is also known as cnc wood cutting machine,CNC nesting machine, cnc router machine for wood, cnc machine for wood cutting, cnc machine wood cutting , CNC machine for cabinet making, cabinet door cutting machine for sale, etc.CNC wood cutting machines have revolutionized woodworking by automating and streamlining the cutting process. They are widely used in various woodworking applications, including furniture manufacturing, cabinetry, woodworking workshops, and architectural millwork.

Our 1325 CNC machine is one of our popular and best-selling machines. It is good at cutting, carving, engraving, drilling, routing, grooving, and pocketing of wood, MDF, acrylic, PVC, plastic, foam, stone, soft metal, and other materials.

CNC Wood Cutting Machine 4×8

This 1325 cnc wood cutting machine can change 12 different tools automatically. It is very suitable for the people who do complex work and change different tools frequently. This machine is provided with a push device and can push materials after cutting or engraving.

High Precision Cutting Best Selling CNC Machine For 4×8 Small CNC Machine

The 4×8 CNC machine XYZ axis Taiwan Hiwin square rail makes the gantry and spindle moving at high speed with high precision. CNC kit 4×8 adopts Hiwin square rail with high rigidity and very durable. XY axis German Helical rack and pinion are directly coupled to the stepper motor and pinion. This 4×8 CNC router cheap configuration ensures that the accuracy is less than ±0.03mm when the max 4×8 work table speed is 20,000mm/min.

Stable, Stronger And More Durable Structural Design Of CNC Machine Table 4×8

The Heavy structure adopts thicken steel square which improves the stability of wood CNC 4×8. This Stronger structure is necessary for cutting solid materials such as hardwood. During the 4×8 wood CNC machine cutting and carving process, the XYZ axis remains stationary against external cutting forces.

Long Time Operation With High-Power Stepper Motor Of Cheap CNC Router

Stepper motor and driver do not require regular maintenance. This not only reduces maintenance downtime but also spindle is able to run normally for a long time. Coupled with the fast working speed, the CNC machine 4×8 efficiency is greatly improved.

Compatible With Any Advanced Software For 4×8 CNC Wood Router

Software including Vectric Aspire, Type3, Ucancam, Artcam, AlphaCam, Powermill, Solidworks is run on the system of CNC table 4×8. You can use the CNC wood router 4×8 quickly without wasting the cost of training labor. This is simple and efficient for you.

Features CNC Wood Cutting Machine

1. Heavy duty frame. The frame is longer and much stronger than normal CNC routers.

2.Taiwan 1000w SYNTEC servo motor with Japan SHIMPO reducer. It adopts full closed loop and has brake function on Z axis. It provides constant position feedback, bigger power and smooth contentious motion.

3. Linear type tool change magazine under gantry. It can change 12 different tools fast.

4. Y axis adopts #30 Taiwan square linear guide. While X and Z axis adopt #25 square linear guide. 2M helical rack is used to ensure the high-speed and stable operation of the machine, and also ensure a higher processing accuracy.

5. ATC air cooling spindle. Max. speed can be 24000RPM. With ISO30 tool holder, it can use 20mm bits at max.

What can a 4X8 CNC Router do?

A 4X8 CNC Router is the ideal wood cutting and carving machine that imparts excellent efficacy in manufacturing doors, furniture designs, etc.

It runs on the CAD software that enables a user to cut detailed designs with utmost precision on a preferred material. The process of producing complex designs manually demands a lot of time and other resources. Just opposite, this wonder machine can perform carving and cutting in three axes to come up with the design you want.

Usually, it is cumbersome for manual processes to offer such precision and they incur huge material loss as well. With the aid of the driving software, you can convert complicated designs into a reality with the aid of 4X8 CNC Router.

Heavy duty CNC router is good for complex processes and long time work, such as:

Wood door, furniture making; MDF, Poly wood cutting;

Hardwood engraving & carving;

Big scale woodworking;

Soft metal, plastic, acrylic, foam engraving & cutting, etc.;

Automatic Wood CNC Router Cutting & Engraving Machine

A CNC wood router is an automatic machine tool for wood cutting, relief carving, drilling & slotting, which works with 2D/3D designed files by CAD/CAM software. A CNC wood router machine is composed of bed frames, spindles, T-slot table or vacuum table, vacuum pump, CNC controller, motor driver, guide rail, rack and pinion, ball screw, power supply, limit switch, collets, tools & bits, and other parts & accessories. The most common types of wood routers include 3 axis, 4th axis, 4 axis, 5 axis CNC woodworking machines.

Here is our collection of most popular CNC machines for woodworking, from single-spindle to multi-spindle kits, from small footprint to large format tables, from desktop to gantry styles, from hobby to industrial models, from primary 3 axis to professional 5 axis, from entry-level for beginners to high-end ATC series for experts, all types of CNC wood routers are available.Just discover what you need, plan your budget, compare features and costs, find and buy the best one to start or upgrade your woodworking business.

0 notes

Text

Top Reasons Why ABS Plastic Sheets Are Perfect for Industrial Use

ABS (Acrylonitrile Butadiene Styrene) plastic sheets have become a popular material choice in various industries due to their durability, versatility, and ease of fabrication. These sheets are widely used across multiple sectors, 3/8 abs plastic sheet 4x8 automotive, construction, electronics, and more, for their impressive performance characteristics. In this blog, we will explore the top reasons why ABS plastic sheets are perfect for industrial use and how they add value to various applications.

1. High Impact Resistance

One of the primary reasons ABS plastic sheets are favored in industrial settings is their high impact resistance. The combination of acrylonitrile, butadiene, and styrene gives ABS its toughness, making it highly resistant to physical impacts and damage. This property is essential in industries where materials are exposed to rough handling, shocks, or stress. 1/4 abs plastic sheet 4x8 can absorb and distribute impact energy, which reduces the risk of cracks, breaks, or fractures.

In sectors such as automotive and construction, where equipment and components are subject to harsh conditions, the impact resistance of ABS plastic sheets ensures durability and long-lasting performance. This makes them an ideal choice for fabricating parts that need to withstand wear and tear over time.

2. Lightweight and Strong

Despite their strength, ABS plastic sheets are lightweight compared to many other materials used in industrial applications. This unique combination of strength and lightness makes them an ideal alternative to heavier materials like metals. Using lightweight materials helps reduce the overall weight of products or machinery, improving efficiency and performance.

In industries like automotive manufacturing, lightweight materials contribute to fuel efficiency by reducing the weight of vehicles. In construction, the reduced weight of ABS sheets simplifies transportation, handling, and installation, ultimately lowering costs and improving project timelines.

3. Excellent Heat Resistance

ABS plastic sheets are known for their excellent heat resistance, which makes them suitable for applications where temperature fluctuations are common. They can maintain their structural integrity and performance under high-temperature environments, which is why they are often used in the automotive, electronics, and manufacturing sectors.

For example, in the automotive industry, ABS sheets are used to create dashboard components and other interior parts that may be exposed to the sun’s heat. Their ability to retain shape and function without warping or deforming is a crucial factor in these applications.

4. Chemical Resistance

Industries that deal with harsh chemicals require materials that can withstand exposure without degrading. ABS plastic sheets offer good resistance to many chemicals, including acids, alkalis, and oils. This makes them suitable for use in industrial environments where contact with chemicals is frequent, such as in chemical processing plants or laboratories.

In addition, ABS plastic sheets are used to fabricate storage containers, piping systems, and other components that require a high level of chemical resistance. This property ensures that products made from ABS remain reliable and durable even when exposed to potentially corrosive substances.

5. Ease of Fabrication

One of the most significant advantages of ABS plastic sheets is their ease of fabrication. They can be easily cut, shaped, drilled, and molded into various forms, which allows for customization to meet specific industrial requirements. ABS plastic sheets are also compatible with a wide range of fabrication processes, including thermoforming, CNC machining, and 3D printing.

This versatility in fabrication makes ABS plastic sheets a preferred choice for manufacturers and engineers who need a flexible material that can be tailored to suit their needs. Whether it’s producing intricate parts for machinery or creating custom components for specialized applications, ABS plastic sheets offer the flexibility required for diverse projects.

6. Cost-Effective Material

Cost is always a crucial factor when selecting materials for industrial use. ABS plastic sheets offer an excellent balance between performance and affordability. They are generally more cost-effective than metals and other high-performance plastics, making them an attractive option for industries that need durable materials without breaking the bank.

Because of their affordability, ABS plastic sheets are used in mass production and prototyping, allowing manufacturers to produce high-quality products while keeping costs manageable. The cost-effectiveness of ABS also extends to its long lifespan and minimal maintenance requirements, further reducing expenses over time.

7. Aesthetic Appeal

In addition to their functional properties, ABS plastic sheets also have a high-quality finish that enhances the aesthetic appeal of industrial products. They are available in various colors, textures, and finishes, making them suitable for both functional and decorative purposes.

For example, ABS plastic sheets are often used in the production of appliance housings, consumer electronics, and automotive interior components, where appearance is just as important as functionality. The material's smooth surface can be easily painted or textured to achieve a desired look, further enhancing its versatility in industrial design.

8. Weather Resistance

Many industrial applications require materials that can withstand exposure to the elements, including sunlight, rain, wind, and temperature changes. ABS plastic sheets are known for their weather resistance, making them suitable for outdoor applications. They do not easily degrade when exposed to UV rays or moisture, which helps maintain their structural integrity over time.

In industries such as construction, ABS plastic sheets are used to create outdoor signage, protective covers, and other components that need to endure the elements. Their weather resistance ensures that they continue to perform reliably even in challenging outdoor environments.

9. Recyclability and Environmental Benefits

With increasing environmental concerns, industries are moving towards more sustainable practices, and ABS plastic sheets offer a solution in this regard. ABS is a recyclable material, which means that products made from ABS sheets can be recycled at the end of their life cycle, reducing waste and contributing to sustainability efforts.

The recyclability of ABS plastic sheets is particularly beneficial in industries that prioritize eco-friendly materials and processes. By choosing ABS, companies can minimize their environmental footprint while still benefiting from a high-performance material.

10. Electrical Insulation Properties

In the electronics industry, materials with excellent electrical insulation properties are essential. ABS plastic sheets have good insulating properties, making them a suitable choice for applications that involve electrical components. They are commonly used to create enclosures, housings, and covers for electrical devices, ensuring safety and protection against electrical hazards.

ABS plastic sheets are also used in the production of circuit boards, switches, and other electronic components that require insulation from electrical currents. Their non-conductive nature makes them a reliable material for protecting sensitive electronic equipment.

Conclusion

ABS plastic sheets offer a unique combination of properties that make them perfect for industrial use. From their high impact resistance and lightweight strength to their heat, chemical, and weather resistance, Abs sheet manufacturer provide a durable and versatile solution for a wide range of applications. Their ease of fabrication, cost-effectiveness, and recyclability further enhance their appeal, making them a valuable material in industries such as automotive, construction, electronics, and beyond.

Whether you're looking for a material that can withstand tough industrial conditions or one that offers flexibility in design and fabrication, ABS plastic sheets are a smart choice. Their adaptability to various environments and applications ensures they remain a staple in industrial manufacturing for years to come.

Frequently Asked Questions (FAQs):

What makes ABS plastic sheets from Singhal Industries ideal for industrial use? ABS plastic sheets from Singhal Industries are highly durable, impact-resistant, and lightweight, making them perfect for a wide range of industrial applications. They offer excellent heat and chemical resistance, ensuring reliable performance even in harsh environments. Their ease of fabrication and cost-effectiveness further enhance their appeal, allowing industries to create custom components without compromising on quality.

Why should I choose Singhal Industries for ABS plastic sheets? Singhal Industries is known for producing top-quality ABS plastic sheets that combine strength, flexibility, and durability. Their sheets are designed to meet the specific needs of various industries, from automotive to construction and electronics. Additionally, Singhal Industries offers sheets that are recyclable, providing a more environmentally friendly option while maintaining the high performance required in industrial settings.

Are ABS plastic sheets from Singhal Industries suitable for outdoor use? Yes, ABS plastic sheets from Singhal Industries are highly weather-resistant, making them ideal for outdoor applications. They can withstand exposure to UV rays, moisture, and temperature changes, maintaining their structural integrity over time. This makes them suitable for outdoor signage, protective covers, and other products that need to endure tough outdoor conditions.

0 notes

Text

How ABS Plastic Sheets Revolutionize 3D Printing and Fabrication?

Introduction to ABS Plastic Sheets in 3D Printing and Fabrication

In recent years, ABS (Acrylonitrile Butadiene Styrene) plastic sheets have emerged as a game-changer in the world of 3D printing and fabrication. Their strength, versatility, and cost-effectiveness make them a preferred choice for hobbyists, engineers, and industrial manufacturers alike. Available in various sizes such as the popular 4x8 ABS plastic sheet and thicknesses like the 1/4 ABS sheet, ABS plastic has opened new doors for innovation in product design and manufacturing. In this article, we will explore how ABS plastic sheets are revolutionizing the 3D printing and fabrication industry and why they are the material of choice for many modern applications.

The Benefits of Using ABS Plastic Sheets in 3D Printing

One of the key reasons ABS plastic sheets are so popular in 3D printing is their balance between strength and flexibility. When printed, ABS creates robust yet lightweight objects, ideal for both prototypes and final products. The sheets are also cost-effective, especially in larger sizes like the 4x8 ABS plastic sheet, making them perfect for large-scale industrial projects. Furthermore, ABS plastic sheets are widely available in a variety of thicknesses, including the 1/4 plastic sheeting, giving manufacturers more control over the level of detail and strength required for their specific projects.

Another benefit is its chemical resistance, which makes ABS ideal for producing components exposed to harsh environments. ABS sheets are also easy to machine and post-process, offering additional customization possibilities. Whether you’re printing small gadgets or large mechanical parts, ABS plastic provides the durability and flexibility needed to bring designs to life.

Enhanced Fabrication Flexibility with ABS Plastic

ABS plastic sheets are not only useful in 3D printing but also in various forms of fabrication. Fabricators often choose ABS for projects requiring thermoforming, CNC machining, or laser cutting due to its excellent workability. The material’s inherent flexibility allows it to be easily shaped without cracking or breaking, especially in thicknesses like the 1/4 ABS sheet. This quality is particularly important in industries like automotive and aerospace, where precision and durability are crucial.

Furthermore, ABS sheets can be produced in different colors and finishes, enhancing their aesthetic appeal in consumer-facing applications. The combination of strength, machinability, and cosmetic versatility makes ABS plastic an excellent choice for both functional and decorative projects.

Thermoforming and Customization Potential with ABS Sheets

When it comes to thermoforming, ABS plastic sheets stand out due to their low melting point and ability to be easily molded. This allows manufacturers to create complex shapes with intricate details, essential for custom fabrication tasks. The 4x8 ABS plastic sheet size is especially popular in large thermoforming projects, as it provides ample material for substantial designs without the need for multiple smaller pieces.

Additionally, ABS plastic’s durability ensures that the end product maintains its shape over time, even under stress. Many industries rely on thermoforming ABS plastic for products such as automotive interiors, protective covers, and even custom equipment housings. The ability to mold ABS sheets into precise and detailed forms expands the design possibilities far beyond what other materials can offer.

Cost-Effectiveness and Efficiency in Large-Scale Production

Cost is a major factor in any manufacturing or fabrication project, and this is where ABS plastic sheets truly shine. Available in larger dimensions like the 4x8 ABS plastic sheet, they offer a cost-effective solution for large-scale production without compromising quality. Moreover, the efficiency of working with ABS plastic, especially in thicknesses such as the 1/4 plastic sheeting, reduces the amount of time needed for machining, cutting, or thermoforming. This ultimately leads to savings in labor and material costs, making it a financially sound choice for businesses looking to streamline their production processes.

Additionally, ABS plastic’s recyclability makes it an eco-friendly option, further reducing long-term production costs. Many manufacturers are now adopting sustainable practices, and ABS plastic’s ability to be reused and recycled aligns perfectly with these goals. By minimizing waste and maximizing production efficiency, ABS plastic sheets provide a compelling solution for businesses striving for both profitability and sustainability.

ABS Plastic in Prototyping and Industrial Applications

Another exciting aspect of ABS plastic is its role in prototyping. Engineers and designers often use ABS sheets, such as the 1/4 ABS sheet, to create prototypes before committing to full-scale production. This allows for design testing, evaluation, and modifications without the need for expensive materials or tools. Prototypes made from ABS plastic can withstand rigorous testing, including physical and chemical stresses, making them ideal for iterative design processes.

In industrial applications, ABS plastic is commonly used in the production of durable parts that need to perform under high pressure or extreme temperatures. Whether it’s a functional component for a piece of machinery or a custom-fabricated part for an aerospace project, ABS plastic’s resilience makes it a valuable asset in these high-demand environments. Its superior mechanical properties ensure long-lasting performance, even under harsh operating conditions.

Advancements in ABS Sheet Technology

As technology in 3D printing and fabrication continues to evolve, so does the development of new ABS plastic sheets. Modern advances have led to the creation of specialized ABS variants with enhanced properties, such as higher impact resistance, improved UV stability, and even flame-retardant capabilities. These advancements allow ABS plastic sheets to be used in even more challenging environments and applications.

Manufacturers can now choose from a wide range of ABS options, depending on their project’s specific needs. For instance, a 1/4 ABS sheet may be selected for its rigidity in a structural application, while a thinner or more flexible variant could be chosen for a part that requires greater flexibility. The increasing versatility of ABS plastic sheets ensures that they remain a key material in the future of 3D printing and fabrication.

Conclusion: ABS Plastic as a Cornerstone of Modern Manufacturing

ABS plastic sheets, available in various sizes such as the 4x8 ABS plastic sheet and thicknesses like the 1/4 ABS sheet, have become essential in revolutionizing 3D printing and fabrication. Their unique combination of strength, flexibility, and cost-effectiveness makes them a go-to material for projects ranging from small-scale prototypes to large industrial applications. Furthermore, the ability to customize ABS sheets through processes like thermoforming and CNC machining adds a level of versatility that few other materials can match.

As the demand for efficient and sustainable production methods grows, ABS plastic will continue to play a critical role in shaping the future of manufacturing and fabrication. Whether you are a hobbyist experimenting with 3D printing at home or an industrial manufacturer looking for durable materials for large-scale production, ABS plastic sheets offer the perfect balance of performance and affordability.

FAQs about ABS Plastic Sheets

1. What is ABS plastic?

ABS (Acrylonitrile Butadiene Styrene) is a thermoplastic polymer known for its toughness, impact resistance, and ease of fabrication. It is widely used in various applications, including 3D printing, automotive parts, and consumer goods.

2. What are the advantages of using ABS plastic sheets?

ABS plastic sheets offer several advantages, including:

Strength and Durability: They provide excellent strength-to-weight ratios, making them suitable for both prototypes and final products.

Chemical Resistance: ABS resists many chemicals, making it ideal for various industrial applications.

Workability: The material is easy to machine, thermoform, and laser cut, providing flexibility in fabrication.

Cost-Effectiveness: Available in large sizes like the 4x8 ABS plastic sheet, they are economical for large-scale projects.

3. What sizes do ABS plastic sheets come in?

ABS plastic sheets are available in various sizes, including standard sheets like 4x8 feet. They can also be purchased in smaller dimensions to suit specific projects. Additionally, they come in different thicknesses, such as the commonly used 1/4 ABS sheet.

0 notes

Video

youtube

CNC Nesting Machine No-dust Working 4x8 / 4x9 /6x9/7x9 /5x10

The CNC Nesting Machine Center automatically labels on the sheet,

and then it will load a 4x8 / 4x9 /6x9/7x9 /5x10 sheets etc, from a pallet by way of a scissor lift located at the rear of the CNC Nesting

machine. A movable gantry system equipped with suction cups using retractable guide rails and stops on the table safely and accurately guides the material sheet onto the CNC platform. Once the sheet is placed, the vacuum hold down automatically and operator starts the cut cycle for the CNC to execute. At the same time, machine will start to label on next sheet. After the sheet is fully processed, it is then pushed off to a conveyor table at the front end while another finished labeling sheet is simultaneously loaded from the rear of the machine again. During this whole process the residual dust or chips that are not picked up from the dust collector are swept off the table and conveyor into various chutes keeping the work cell clear of dust and debris. Upon completion, the individual parts are labeled by the operator through an integrated bar code system. This facilitates clear identification of the finished parts for quick and easy assembly later on.

0 notes

Link

This 4x8 CNC router machine has received a warm welcome from buyers with its suitable price, strong cutting ability and extremely low failure rate. As the most popular 4x8 CNC router machine, we will provide you with a 2-year warranty And perfect after-sales service. Of course, the price is very favorable. If you want to know the information of this machine, please contact us directly or visit our website.

1 note

·

View note

Text

Applications of 4x8 CNC router in the woodworking world

If you’re looking for a CNC machine for sale, consider one that grows with you. Because in the world of CNC machine wood, one table can do the job of ten tools. Premier Plasma CNC offers the best ones as per your needs. Visit this link to order: https://premierplasmacnc.com/.

0 notes

Video

youtube

Interesting! Processing acrylic fan with STM1325 4x8 CNC router machine

#cnc router#cnc machine#cnc woodworking machine#cnc wood carving machine#cnc router for wood#cnc machine for wood#cnc acrylic machine#cnc machine for acrylic#cnc router for acrylic#acrylic#4x8 cnc machine#4x8 cnc router#1325 cnc router machine#1325 cnc machine#1325 cnc router

0 notes

Text

Know About Yard Barns and More

The yard structures, and this is just the beginning the barn structure, if well explained, is enormous because it's elegant and also because it's practical. In case your house and chalet is full of redundant particulars that you can not find enough space for? A protean ceiling might be just what you really need. When planning to buy a cover, pay attention to a many important points

1. Capacity

2. Reduce clutter

3. Security

4. Update your home

5. Space to work and play"

Georgia Yard Barns may be a well- known company that yard barns and more theater sheds grounded primarily in central Georgia. they need further new designs and styles and have erected some shanties to help buyers make the home they've for the rudiments. At Georgia Yard Barns, you will get trendy theater sheds that fit your budget. For evaluation, individual selection and position of dealers.

All of our wood architecture is cut on our state-of-the-art CNC machines in our,000 square bottom plant, allowing us to offer the most authentic, precise and intricate mortise and tenon joinery available at the moment.

We use larger 8x8 superstuds, 8x12 shafts, 4x8 braces, and heavy wood shafts. The larger wood combined with authentic mortise and tenon joinery creates a stronger structure. We make real barns with posts and shafts, from the rustic stave to the top of the heavy rustic roof shafts.

All staff contrivers, certified structural masterminds and our platoon of timber framing experts. From the foundation to the finishing traces, we do everything ourselves. For more visit https://georgiayardbarns.com/

0 notes

Text

ELIHU-S CNC Plasma Cutting Machine for Efficiency

Optimize your metalwork with the ELIHU-S CNC Plasma Cutting Table. A premium CNC machine for efficient and precise plasma cutting.

0 notes

Text

4 X 8 Linear Atc CNC Router with Automatic Tool Changer

This is the 2022 latest linear ATC CNC router machine, this machine has CNC router tool changer, so its tool change time is very short, which can save a lot of tool change time and improve machine processing efficiency. It has built-in eject pins and a controllable dust cover with built-in machine lubrication system for accurate material loading every time. So this machine can process wood, MDF, particleboard, plywood, OSB, melamine board, etc. It is widely used in cabinet manufacturing industry. It can also process acrylic, plastic, soft metals and many other different materials.

4x8 cnc router with vacuum table

CNC linear cutting machines is used for decorations, musical instruments, wood crafts, wood furniture, wood door making, cabinet making, windows, and tables. Now the best linear ATC wood CNC machine for sale at affordable price.

The ATC CNC router machine is equipped with a 9.0kw air-cooled spindle, and two tool change methods are available: linear tool change and disc tool change. Usually used in conjunction with labelling machines and automatic loading and unloading platforms.

This 4x8 CNC machine has a rotary device equipped on the one side of working table. When users need to process cylindrical materials, they can clamp the cylindrical piece onto the rotary device. Then rotary device rotates and at the same time the spindle engraves on the surface of the work piece. This machine with rotary device is suitable to process cylindrical materials. Users can design and make beautiful cylindrical sculpture crafts with it.

This is the professional linear ATC CNC router, this ATC CNC router with tool changer, so this machine has very high machining speed and cutting precision, and this 4x8 CNC router is equipped with a 9KW(12HP) air-cooled spindle and a 12 High-speed tool changers, these can be used to perform complex and diverse machining tasks. If you would like to own a linear ATC CNC router, then please contact us.

Hot applications of Industrial CNC Router With Auto Tool Changer:

>Wooden furniture industry: solid wood and composite doors, cabinet doors, sliding doors, paint-free doors, lacquered doors, soft-packed doors, flat panel carving, solid wood carving, panel furniture processing, antique mahogany furniture processing, solid wood mural carving and other industries;

>Wooden crafts industry: clock and watch frames, craft photo frames, calligraphic cards, electrical counter-tops, sporting equipment, thin aluminum plate engraving and carving;

>Advertising industry: acrylic, PVC, MDF, artificial stone, plexiglass, plastic, copper, aluminum and other soft metal plates.

0 notes