#A Guide to Optical Assembly

Explore tagged Tumblr posts

Text

yan! dbd ghostface (danny johnson) headcanons

cws: yandere themes, danny is a perv, non-consensual picture taking, stalking obv, slight nsfw themes but danny is just a freak, danny is a sadist, gore, danny makes out with your wounds, obsessive! danny, possessive! danny,

— yan! ghostface whose eye you catch in your first trial. you who are wide eyed, disoriented, and hyper-aware of your surroundings make easy prey.

— yan! ghostface who stalks you for awhile before approaching you, using your disbelief and naivety against you.

— yan! ghostface who explains your situation, portraying himself as a fellow survivor and guides you through the motions of the match before pressing his blade to your throat.

— yan! ghostface who smirks beneath his mask, watching as your eyes widen with fear and betrayal. he feels himself become aroused as your pretty optics glisten with tears, groaning as you beg for him to let you go.

— yan! ghostface who is stunned by a flashlight, feeling you wriggle free from his grip and sprint off like a frightened bunny.

— yan! ghostface who you are wary of in each match. he singles you out and taunts you, describing each horrific thing he’ll do to you once he gets his hands on you, finding that this little obsession of his is growing by the day.

— yan! ghostface who begins thinking about you even outside of trials. it started as wondering what he would do to you next, turning into lustful daydreams and palming himself at the thought of you.

— yan! ghostface who snaps polaroids of you while you do mundane things. assembling a medkit or toolbox, finding materials for offerings, talking to your fellow survivors…

— yan! ghostface who loathes the sight of you smiling at the others in the survivor camp. you belong to him. that smile of yours is reserved for him. your laugh is reserved for him.

— yan! ghostface who slowly feels those lustful feelings of his grow into something deeper. he finds himself thinking less and less about ways to kill you, and more about ways he could make you smile.

— yan! ghostface who, in your next trial with him, brings you the body of each survivor, dropping it in front of you much like a cat would gift its owner a dead mouse.

— yan! ghostface who corners you, sitting on your stomach and wrapping his fingers around your throat. he swiftly snaps a polaroid of this beautiful sight, crazed ramblings about how you’ve caught his attention leaving his lips.

— yan! ghostface who is amused at how quickly you’ve gained his interest, his favorite pastimes stalking you and leaving just enough of a trace for you to know he was there.

— yan! ghostface who finds it incredibly romantic to hold your hand while you bleed out beneath him, his mask lifted to show off the frenzied look in his eyes, blood dripping from his chin and onto your paling features.

— yan! ghostface who looooves to makeout with your stab wounds. he’s always sure to leave you for last, finding motivation in the fact that if he rids the trial of all other survivors, he can spend as much time with you as he pleases.

— yan! ghostface who coos at you as you beg for him to let you go… or to just end it already. a frown tugging at his lips as he feels his heart pang with the slightest of remorse. he quickly covers it up with a mocking sneer, telling you that you should be proud to bear his love in such a way. no one’s ever had it but you.

— yan! ghostface who singles out each person you talk to in their next trial with him, mercilessly slaughtering them as he tells them to stay the fuck away from you.

— yan! ghostface who somehow convinces the entity to let you spend some time with him on a random day, designating it as your new birthday. he’ll watch with interest as your shaky fingers grip the rusted fork, shoving the mediocre cake down your throat. he’s never seen a better sight.

— yan! ghostface who loooves everything about you <33

#yandere x you#male yandere#tw yandere#yandere x reader#yandere imagines#yandere hcs#yandere dbd#yandere ghostface#dbd killer#dbd ghostface#dbd survivor#personal headcanon#yandere danny johnson#yandere jed olsen#dead by daylight#dbd x reader#dbd x you#dbd x male reader#dbd danny johnson#dbd jed olsen#yandere dead by daylight#yandere dbd ghostface#danny johnson#jed olsen#ghostface x reader#jed olsen x reader#danny johnson x reader

520 notes

·

View notes

Text

Your mission is simple: provide fire support from a distance while your comrades engage the primary target. You've been specifically chosen for this job. You've always excelled in long-range engagements, and this is a perfect opportunity to stress test the prototype long-range cannon your sponsor has been developing. You don't know the name of it, you were just given the machine and told to make it work. A piece of cake for you, given your experience.

The cannon you were told to use is heavy. Heavier than anything your suit has ever carried before. There's a twinge of worry that the servos and joints might buckle under the weight, but you trust your machine to carry you and the payload to your destination. It always has.

You arrive at your sniper's nest and prepare the cannon for firing. This thing is massive. The barrel is long, and thick, made of high-quality alloys that even you can't quite recognise. The firing mechanism and bolt action nature of it is simple, yet powerful. Setting this up on the ground is like assembling a mortar. Multiple pieces, big and small, but all forming to make something so much bigger than the sum of it's parts.

You revel in the sounds and feel of the assembly - the clicking and snapping of smaller parts, the sound of friction when metal slides on metal, the delicate nature of it all. There's no way a pilot can do this on their own without their mech, the machinery is simply too large and complex. You work alongside your suit, controlling it as the optical scanner guides your vision and thought process. It is the mind, and you are the hands.

Within minutes, you are finished the assembly. Faster than anyone else could have ever hoped to do it. There's a while longer before the mission is set to start, so you take some time to appreciate this machine of war. Trace the fingers of your mech's hands along it, and feel the grooves and imperfections through the haptic feedback of your controls. Inspect the bolt, the cartridge that holds your ammunition, the scope, everything. Everything about this is perfect to you. It's like this was made specifically for you to use. It's beautiful. It's love, and it's hurt, and it's yours.

It's almost time.

You lay the cannon on the ground, with the tripod attacked to the barrel sticking into the dirt. You use the mech as an extension of yourself in order to position yourself comfortably. Your legs fall to each side of the cannon as you lay above it, almost as if you intend to mount it. Your feet dig into the ground, preparing yourself for the inevitable recoil that firing this artillery will bring. Your knees fall to the ground, for further stability, and your body is mere inches away from touching the hardened steel of this machine below you. Your dominant hand reaches for the trigger, and your free hand holds the top of the barrel down to prevent it from flying away when you fire. You position your head perfectly in line with the scope, and you can see your allies now engaging with the target. You are ready to fire.

Your breath is shaky, heavy and getting faster. This is... exciting. You can't wait to pull the trigger and see how much damage this cannon will do. You're already thinking of names to give it, of how to modify it to make it more reliable, of how to make it yours. All yours. Your eyes are trained on the target, and you're listening to the comms channel for your order to fire, though your focus only allows you to parse half of what is being said.

Finally, you hear the order. Through half-understood chatter, you hear a loud and stern "fire". You pull the trigger.

Time slows.

First, you feel the recoil of the firing mechanism pushing back against you.

Then, the deafening, piercing sound of the combustion that propels the bullet forwards towards your target.

The cannon pushes back against you and pushes you both back several feet, leaving a trail of dug-up dirt and sediment around where you and your weapon are planted. You feel the joints of your suit scream against the strain of the sheer force, and the haptic feedback from your controls is going haywire.

Everything hurts. This hurts to use.

But it's worth it. You feel amazing. You feel alive.

A sudden gasp leaves your mouth, and you start breathing heavily. The ringing in your ears, the tingling feeling in your hands, the pain you feel must be the same way your suit feels in this moment. You are as one. You are together.

But there's no time to revel in this feeling. You have a mission to complete. Another round needs to be prepared before your comrades are struck down. This is what you're ultimately here for.

You don't even have a chance to look at the damage this cannon dealt, you simply start reaching for the next cartridge to load.

You pull back the bolt on the cannon, feeling the friction of it sliding against the body of this gargantuan weapon.

The used cartridge falls to the ground, cracked from the force of this machine, with wisps of smoke trailing off of it.

You hastily slide the fresh cartridge in, holding it in place with one hand as you push the bolt forward to lock it in place.

The strained joints of your suit ache and tremble as you use all of your strength to push, and eventually you load the next shot.

The barrel is still red hot, and dangerous to the touch, but you have no choice but to stabilise it like you did before. There's no time to worry if the heat will melt you suit's hand onto this thing. A small part of you wouldn't even mind if it did.

You readjust your sights and focus on the target again, and finally, you can admire the damage that this cannon did. It's a miracle that your shot didn't finish the job, but that's okay. You have plenty more.

This next one should do it.

Once again, your focus is trained on the comms channel, waiting for the firing order.

Breath getting faster, heavier, warmer. Heart beating out of your chest. Feeling pistons, servos, joints, every mechanism of your suit as a part of you.

"Fire"

182 notes

·

View notes

Note

Reader with a disability- like a lost limb or two. And their cypertronian friendo’s make them new limbs?

I’d personally like to see it with the Decepticon‘s. But I’ll take anyone.

Upgrades

Tarantulas x reader

Warnings: none

Word count: 1.3k

Used the wheel spinner to pick a character for this one, and you got tarantulas, and he was actually a lot of fun to write. Based him quite a bit of the earthspark Tarantulas.

___________

They sit off to the side as Tarantulas works. Not being able to do much else other than wait for him to finish his work. The scarring on their leg aches and it makes them twitchy for sitting so long with nothing to do. "How much longer?" They ask softly trying not to scratch the area

He glances over at the human, a soft click comes from his mandibles. "Patience, my friend. These things cannot be rushed." He turns back to his workbench, carefully assembling components of the new prosthetic he was working on. "I assure you, the end result will be well worth the wait."

They continued to sit there for a moment but eventually decided they were sick of just sitting. using the equipment beside themself they pull themself to stand, keeping a hand on it while hopping closer trying not to fall over. Tarantulas' optics briefly flicker towards them as they uncomfortably hop closer, clearly struggling without the support of their prosthetic. He pauses in his work, claws delicately holding a small metallic component mid-assembly.

"I would not recommend straining yourself in such a manner," he says evenly. "The device will be completed as efficiently as I am able. injuring yourself will only hinder the process. One of his claws came out to steady them. He clicks the part into place with meticulous care, then glances back at the human.

"I'm bored sitting here Tarantulas" they admit while moving closer using his arm as a guide closer. "Can you put something on for me to watch or something, I can't handle just sitting here in silence, please I'd even suffer listening to the music you like so much" they hand brushes against his plating as they stand against his frame, pressing their head against the spider furr of his plating.

Tarantulas lets out an exasperated hiss as the human presses against him, interrupting his concentration. Still, he suppresses the urge to shove them away, he rumbles softly reminding himself they were a touchy one, it was only them and not someone else touching him.

"Very well," he grumbles, reaching a clawed hand to tap at a nearby console. "I shall provide some 'entertainment' to distract that feeble organic processor of yours." The screens in his lab flicker to life, he types away for a moment with his other talons and brings up some mind numbing videos. He bristles again when their hand runs over the furr before he settles again. "Try not to leak your oils and fluids on my exoskeleton," he snarks slightly but settles into the light touch. He lifts them up, settling them between his shoulder plate and helm, talons subtly guiding them until they had sat comfortably. " now you're just being a dick" they state with amusement while snuggling against him.

He turns back to the delicate work with a few small clicks. Tarantulas narrows his optics at the human's crass words, but otherwise does not acknowledge their playful jab. His thoughts are focused solely on completing the task at hand. With meticulous precision, he settles back into work, a talon coming up to check on them occasionally to check if they had fallen asleep. They'd make a small noise but other than that they were content watching the videos.

Tarantulas soldiers the final connections, tweaking the calibration. "It is done," Tarantulas announces, and they peek up to look at the finished prosthetic. "Your patience has paid off. Shall we test its capabilities?" He holds up the brand new leg for them to look at for a moment. With care he helps them off his shoulder, setting them down gently. Once they are seated, he works quickly; multiple talons move with skill to fit the prosthetic into place, ensuring the connections are seamless.

"How does it feel?" he asks while making sure to attach it the right way, checking to make sure the pins didn't pinch on the attachment, as he watches their reaction he's already working on another design in his processor. "Walk with it. Carefully." He steps back, folding all his arms but one as he watches for any sign of instability.

He olds one out for them to use encase they needed it, but For now, he watches. As they stand up and put pressure on it, it feels different to the other prosthetic. The first few steps are wobbly with Tarantulas guiding them with a servo to make sure they don't trip. "Feels weird, lighter than the last one.Tarantulas watches closely as the human takes their first tentative steps with the new prosthetic. His optics brighten with fascination at seeing his engineering in action. “What did you change?". It wasn't as heavy as the last prosthetic he had made for them.

"I utilised a lighter alloy in its construction to reduce overall mass, while integrating cybertronian servo-motors to enable more natural movement. They should also allow for greater precision and control compared to your previous prosthesis," Tarantulas explains, a hint of pride creeping into his voice despite himself.

"In time, it should function almost similarly to your original organic limb, perhaps even surpassing it in strength and capabilities. I can continuously refine the design as needed." He gestures to his workbench, laden with tools and components. "For now, simply continue acclimating yourself to it." His optics gleam with anticipation. It was something almost simplistic but they needed it.

They continue walking around on it testing the feeling of the new prosthetic, after they sit down and watch the way the hinges bend with each time they straighten and bend their leg. "Still don't know how you do it Tulas, you would be an awesome prosthetic manufacturer you know" they shoot him a delighted smile. Tarantulas lets out an amused huff at the human's praise.

"An 'awesome prosthetic manufacturer'? Hardly a fitting aspiration for one such as myself." He turns back to tidy up his workstation, sorting tools and components with methodical efficiency. "I engineer these enhancements purely as scientific curiosities, and for the opportunities they provide in helping you." Picking up a small welding tool, he regards it thoughtfully as he continues. "But I admit, it is gratifying to see my creations appreciated."

“Got a soft spot for me Tula?” they tease at him. Tarantulas sets down the tool and moves closer to the human, gently flicking them with one of his talons. "But thank you, I know it probably doesn't mean much to you due to being Cybernetic, but this means alot to me to be able to walk, and you're making it easier with the knee bending." It's a sincere thank you. They look over at the other prosthetic. "Do you know why this one broke?"

Tarantulas picks up the damaged prosthetic leg, turning it over in his claws as he examines it closely. "Inferior craftsmanship," he hisses in disdain. "Not unexpected from those human manufacturers. They lack true vision." He traces a talon along a cracked seam in the prosthetic's casing. "Substandard materials and shoddy construction. I could improve upon this base design in recharge."

Setting the leg down, Tarantulas turns his optics to the human. "Do not trouble yourself with their inept handiwork any longer. You shall walk solely on my creations from now on."

They laugh at his crase words shaking their head in amusement, it was nice to see him enjoying working on something that to him was so basic yet to them was a life altering thing. They smile back at him as they disconnect the prosthetic, placing it in their lap to look it over. "It's pretty, didn't take you as an artist type Tula" they hum in amusement while admiring the patterns etched onto the fake leg.

Tarantulas tilts his head quizzically at the human's comment about his artistic sensibilities. "Artistry? Hmpf. I merely adorn my creations to...satisfy your simple organic aesthetic preferences." He steps closer and runs a talon along the etched patterns in the prosthetic's casing. "But I admit, an elegant design does complement the engineering within."

________

Let me know if you would like to be added to tag list (tagged for every fic)

Taglist

@angelxcvxc

@saturnhas82moons

@kgonbeiden

@murkyponds

@autobot79

@buddee

@bubblyjoonjoon

@chaihena

@pyreemo

@lovenotcomputed

@mskenway97

@delectableworm

@cheesecaketyrant

@ladyofnegativity

@desertrosesmetaldune

@stellasfallow

@coffee-or-hot-cocoa

@shinseiokami

@tea-loving-frog

@aquaioart

@daniel-meyer-03

@pupap123

#transformers#transformers idw#transformers x human#transformers x reader#transformers lost light#mtmte#transformers earthspark#Earthspark#tf earthspark#tarantulas#tarantulas transformers#transformers Tarantulas#tarantulas earthspark#tarantulas x reader#Tarantulas x human#transformers: more than meets the eye#transformer

98 notes

·

View notes

Text

What should you know about OEM automotive lighting before upgrading your vehicle?

Before upgrading your vehicle’s lighting system with OEM (original equipment manufacturer) parts or equivalents, it’s important to understand compatibility, regulations, performance trade-offs, and installation details to avoid safety risks, legal issues, or damage. Here’s a structured guide:

OEM vs. Aftermarket: Know the Difference

OEM Lighting: Parts produced by the vehicle manufacturer (e.g., Toyota Camry headlights). Guaranteed fit and performance, but expensive.

OEM Equivalent: Parts provided to OEM specifications by a supplier (e.g., Philips, Osram, Hella). Often identical to the original part, but at a lower cost.

Avoid Cheap Imitations: Uncertified “OEM-style” parts may lack safety coatings, proper beam patterns, or durability.

Compliance: Avoid Legal Hassles

DOT (US)/ECE (Europe) Standards: Headlights must meet local regulations for beam intensity, beam pattern, and glare control.

The U.S. Department of Transportation (DOT) allows a slight increase in glare; ECE anti-glare regulations are stricter.

Illegal upgrades: Installing an LED in a halogen housing (or vice versa) is generally against regulations unless the entire assembly is replaced.

State inspections: Noncompliant lamps may fail inspections (e.g., in New York or Texas).

Bulb technology compatibility

Halogen → LED/HID bulb swaps: Never install an LED/HID bulb in a halogen housing without a spotlight. Halogen reflectors scatter the light, causing glare to other vehicles.

Full assembly upgrades: If retrofitting, replace the entire headlamp assembly to ensure proper optics (e.g., replacing a spotlight with an LED).

CAN bus systems: Modern vehicles use a network (CAN bus) to monitor the bulbs. Adding an LED bulb may trigger an error code; use a CAN bus compatible bulb or resistor.

Electrical Load and System Safety

Power Differences:

Bulb Type Power Consumption (Low Beam) Halogen 55W HID (Xenon) 35W LED 15-50W

Wiring Harness: HID kits often require a relay harness to avoid melting the factory wiring.

Fuses and Relays: Match factory amp ratings to prevent overloads. High-wattage bulbs may require upgraded fuses.

Performance Tradeoffs

LED:

✅ Pros: Brighter, whiter light; 30,000+ hours of life.

❌ Cons: Can be difficult to drive on deep snow/ice (low heat output).

HID:

✅ Pros: Better illumination at long distances.

❌ Cons: Slow to warm up (3-5 seconds); can cause glare if misaligned.

Halogen:

✅ Pros: Low cost; suitable for most drivers.

❌ Cons: Dim/yellowing light; shorter lifespan.

Installation Critical Factors

Alignment: Improperly aligned headlights can cause glare or poor visibility. Use a level surface and an alignment tool (or have it professionally aligned).

Thermal Management: LEDs require a heat sink; HIDs require a ballast mounted away from moisture.

Weather Seal: Prevent condensation with OEM-grade seals.

Plug-and-Play vs. Wiring: OEM fixtures plug directly in; aftermarket may require an adapter.

Warranty and Long-Term Costs

Vehicle Warranty: Non-OEM parts may void warranty coverage for related electrical issues.

Bulb Life: Cheap LED/HID bulbs die faster than OEM bulbs (e.g., ~1 year for no-name LED bulbs vs. ~5 years for Philips/SNGL bulbs).

Replacement Cost: OEM components cost $300-$2,000+; labor costs for complex conversions are not negligible.

Key Takeaways Safety first: Never compromise on beam pattern or glare control.

Verify certification: Look for DOT/SAE/ECE markings on the bulb or housing.

Consult a pro: For retrofits (halogen → LED/HID), consult an auto electrician.

Check resources: Sites like https://www.sngllighting.com/ or https://www.usa.philips.com/c-m-au/car-lights offer certified upgrades.

💡 Pro Tip: Before upgrading bulbs, install a headlight lens restoration kit ($20) to restore yellowed factory lenses to their original state.

By balancing regulations, technology, and compatibility, you can improve visibility without endangering yourself or others. 🔧🚘

#led lights#car lights#led car light#led auto light#youtube#led headlights#led light#led headlight bulbs#ledlighting#young artist#headlight bulb#headlamps#headlamp#headlight#race cars#electric cars#cars#classic cars#car#carlos sainz#porsche#truck#automobile#lamborghini#bmw#autonomous vehicle headlights#overtake another vehicle#older vehicles#very pretty#vehicle

4 notes

·

View notes

Text

A Practical Guide to Customizing TFT LCD Displays for Embedded Projects

When designing an embedded system, picking the right display module is more than a technical choice — it directly shapes how users interact with your product.

From medical devices and HMIs to industrial controllers and smart panels, standard TFT LCD modules may not always be enough. That’s where custom displays come in — offering flexibility in electrical interface, mechanical layout, and visual performance.

This guide covers the five key areas you should consider when customizing a TFT LCD for your embedded project.

1. FPC Layout and Pin Mapping

The Flexible Printed Circuit (FPC) connects your LCD module to the mainboard, and in custom designs, this interface is often the first thing to change.

Ask yourself:

Do you need a uniquely shaped or angled FPC to fit inside your housing?

Are there ICs, resistors, or other components on the backlight or CTP that require mechanical clearance?

Is your SBC’s connector pinout compatible with the LCD’s FPC layout?

A mismatch here can lead to signal errors, mechanical stress, or even damage to components.

2. Backlight Brightness and Color Temperature

Not all embedded devices live under the same lighting.

If your product is used outdoors or in industrial lighting, consider high-brightness backlights (≥800 nits). For environments where aesthetics and color warmth matter (like smart mirrors or indoor kiosks), choose the right LED color temperature:

3000K (Warm White): Soft, suitable for medical or ambient lighting

5000K (Neutral White): Balanced tone, accurate colors

6500K+ (Cool White): Sharper, more industrial feel

A poorly lit display can make a great device feel underwhelming.

3. Touch Panel Shape and Bonding Options

If your display includes a touch interface, customizing the Capacitive Touch Panel (CTP) is critical.

Typical customizations include:

Round corners, logo cutouts, button holes

Bonding methods:

Optical bonding: Improves visibility, reduces reflections, stronger seal

Air bonding: More affordable and easier to assemble

The bonding method directly impacts touch accuracy, display clarity, and long-term reliability.

4. Surface Treatments: AG, AR, and AF

For devices exposed to bright light or frequent finger contact, display surface treatments make a noticeable difference.

AG (Anti-Glare): Scatters reflected light, improving readability

AR (Anti-Reflection): Enhances contrast in sunlight or strong lighting

AF (Anti-Fingerprint): Reduces smudges, improves touch feel

Combining AG+AF is a common choice for public-facing touchscreen displays.

5. Want to Learn More?

If you’re building with platforms like RK3566, PX30, or Allwinner boards and need a reliable display solution — including driver compatibility and electrical tuning — check out our full technical article:

👉 Read the Full Custom TFT LCD Guide

You can also browse driver/device tree examples on GitHub:

📂 rocktech-tft-display-configs

2 notes

·

View notes

Note

Welp if the requests are still open (I know this'll be my third) how about some dratchet where Drift is captured and Ratchet comes to rescue him.

Ask me a thousand times I don't really care, I actually love your creative ideas. XD

Rescue and Redemption

The war was over, but the scars remained. On a recovering Cybertron, the remnants of past battles lingered in the form of abandoned facilities and rogue factions. Drift, once known as the Decepticon Deadlock, now an Autobot, navigated these treacherous lands on a mission to gather medical supplies for his comrades.

The mission was supposed to be straightforward. Drift's skill and agility had always been his assets, but even he could be taken by surprise. Ambushed by a group of rogue Decepticons, Drift found himself bound and imprisoned in a desolate facility. His captors, fueled by old grudges, saw him as a traitor and planned to use him as leverage against the Autobots.

Back at Autobot headquarters, Ratchet received the distressing news. The thought of Drift captured and in danger filled him with a fierce determination. Drift had become more than just a comrade; he had become someone Ratchet deeply cared about. Without hesitation, Ratchet assembled a rescue team, insisting on leading the mission himself.

"Are you sure about this, Ratchet?" asked Bumblebee, concern evident in his voice.

"I’m sure," Ratchet replied firmly. "I’m not leaving him behind."

The team moved swiftly and silently through the ruins, guided by Ratchet’s precise calculations and unwavering resolve. As they neared the facility, the sound of distant gunfire reached their audio receptors. Ratchet's spark clenched at the thought of Drift being in harm's way.

They encountered heavy resistance upon arrival, but Ratchet's strategic mind and the team's combat prowess turned the tide. Ratchet fought with a precision borne of necessity, every action driven by the need to reach Drift.

Inside the facility, Drift lay restrained, his spark still burning with defiance despite his injuries. The sound of battle drew closer, and a spark of hope ignited within him. The door to his cell burst open, revealing Ratchet, battle-worn but determined.

"Drift!" Ratchet rushed to his side, his hands already moving to assess Drift’s injuries. "We’re getting you out of here."

"Ratchet... I knew you'd come," Drift managed a weak smile, his optics brightening at the sight of his rescuer.

With careful hands, Ratchet released Drift from his restraints, his touch gentle and reassuring. "Can you stand?"

Drift nodded, leaning on Ratchet for support as they made their way out. The facility shook with the force of the ongoing battle, but Ratchet's focus remained unwavering. They moved through the chaos, fighting side by side, their bond strengthening with each passing moment.

As they finally broke free from the facility, the rogue Decepticons were defeated, scattered remnants of a lost cause. Ratchet and Drift made their way back to Autobot headquarters, the journey filled with a newfound sense of camaraderie and unspoken emotions.

In the quiet of the medbay, Ratchet tended to Drift’s wounds, his hands gentle but firm. "You’re going to be alright," he murmured, his voice soft with concern.

"Thanks to you," Drift replied, his optics meeting Ratchet's. "I owe you my life, Ratchet."

"You owe me nothing," Ratchet said, his voice earnest. "I couldn’t bear the thought of losing you, Drift. You mean too much to me."

Drift’s optics softened, his hand reaching out to grasp Ratchet’s. "And you mean the world to me. I thought... I thought I’d never see you again."

Ratchet squeezed Drift’s hand, a rare smile gracing his features. "You’re not getting rid of me that easily."

Their confession hung in the air, a promise of something deeper. As they sat there, hand in hand, the weight of their experiences seemed to lift, replaced by the warmth of their connection.

"Stay with me," Drift whispered, his voice filled with vulnerability.

"Always," Ratchet replied, his spark swelling with a love he could no longer deny.

In the aftermath of their ordeal, Ratchet and Drift found solace in each other, their bond growing stronger with each passing day. Together, they faced the challenges of rebuilding their world, knowing that as long as they had each other, they could overcome anything.

---

I hope you enjoy it! Let me know if you’d like any changes or additions. 🎀

7 notes

·

View notes

Text

Taking Flight, Chapter 69: Coming In Hot

The halls and blocks of Shepherd's Watch are infested. Rows upon rows of machines stare aimlessly in a catatonic daze until the cries of a Ghoul draw them out from the halls. Stalkers corral the outgoing hordes as the Ghouls guide them towards the city with their cries, ready to continue the slaughter. In the courtyard, Brutes pound and tear cars and shipping crates into shards of scrap, which Grapplers then hoist and haul deeper into the complex. There, the Burners melt the refuse down into molten metal, which is then hammered and molded into components fit for assembly. Infernal contraptions construct a chassis over a pulsing rune matrix before its inner frame is flooded with dense ferrofluid. A newborn machine shrieks for the first time in its wretched existence. A radiant engine of infernal design glowed with the light of a thousand souls within a church inside the prison, now converted into a makeshift workshop, as the manic Doctor Ridley toils away at her next project. The mitre and stole atop her HEV Suit were caked in soot and metal dust after another hard day's work. She rushes towards the engine as it produces another soul gem core. She places the gleaming jewel within the shell of a rune matrix, one much more intricate than her previous design.

Ridley: Alright, now..........

She turns towards the newly constructed knight-like chassis laying atop her worktable, it's chest opened wide to reveal a black metallic reservoir. The matrix is carefully placed within the cavity. The fluid seeps into its shell until it reaches the core. Runes light up and move around as the matrix stirred to life, and a black pulsing mass of fluid and filaments takes shape around it before the chest closes shut.

Ridley: Yes......... Rise, my child.

She flips a lever, and the frame began to twitch and convulse with electrical power as it's's optics flickered to life. A sense of jubilance enraptured the doctor's twisted heart as her newest creation rose from the worktable to stand before her.

Ridley: YES! IT LIVES! IT BREATHES! THE GLORIOUS EVOLUTION HAS BEGUN!

Ruusul: With all due respect.........

She turns towards the red robed Orokin standing in the corner.

Ruusul: The whole "glorious evolution" shtick is starting to get a little stale.

Ridley: Excuse you! I'm on the verge of ushering in a new age of humanity here, just as it was envisioned by our-

Ruusul: Your lord and savior, Viktor. You've made that abundantly clear, already.

Ridley: Why I've never- HOW DARE YOU USE HIS NAME IN VAIN!? You should be HONORED to witness the dawn of the future. I say you should be a bit more grateful for that.

He strides closer to the delinquent doctor with a lethal glare.While Ruusul is a patient man when it comes to results, his tolerance for back-talk is much more limited. This became apparent to the doctor as she met his gaze.

Ruusul: And you should do your best to remember the ones who invested in your little project.......... doctor.

Ridley: Um....... I-

Ruusul: And keep in mind that this investment was made under the notion that you would cooperate to your fullest capacity to bring us the desired results, yes?

Ridley: O-of course, um......

Ruusul: As a fellow artist, I can admire the passion you have for your work, but one must not let that get in the way of the results they desire.

Doctor Ridley's defiance had now been swiftly doused by Ruusul's icy glare as he leaned in closer.

Ruusul: So let us not get TOO caught up in the moment, shall we, Doctor?

Ridley: Yes. Understood.

There it is. A smile took shape under his mask upon hearing the telltale sign of submission in her voice. The catharsis of seeing an arrogant accomplice knowing their place can be oh so intoxicating. But as he said, you shouldn't get too caught up in the moment.

Ruusul: Good.

He finally backs away, once again giving the doctor the space to breathe.

Ruusul: I trust your newest creation will be the well needed improvement you've been looking for.

Ridley: Of course. It will be done.

A rumbling from outside draws her attention to the monitors on her desk. Absolute bedlam is beginning to unfold as the Mercenaries are making their way towards the prison. Dozens of Jeeps and trucks ram through the oncoming hoard of machines as both Mercenaries and Operators open fire with everything they have, all while an Airship hangs above and rains hell from above with its Autocannons. On the Bridge, Meggy comes up to see Lucinia waiting for her alongside a RED Pyro.

Garnet: (Spletzer. You ready to roll?)

Meggy: You bet.

She looks back to see Mario coming up the stairwell along with Melony, Vale, Julia, and Noah all ready to go.

Julia: Alright, so what's the plan?

Garnet: (We're gonna be heading inside the prison. Marston's ground assault should keep them busy enough to let us slip in undetected.)

Lucinia taps a button on her PDA and brings up a holographic map of the prison.

Lucinia: Scanners are picking up a massive energy signature within the complex. Once we're inside, our objective will be to locate that source and shut it down.

Meggy: Alright, sounds easy enough. Everybody ready?

Mario: OH YEAH!

Julia: Affirmative.

Noah: Yes ma'am!

Vale: Just about.

Melony: Ready for action!

That's when Meggy notices something is missing. She heads back down to the Crew Quarters to see Tari sitting on one of the bunks. On the bunk across from her laid Uzi, who wouldn't be attending the mission on account of a headache and some dizziness. Tari gets to her feet and follows Meggy out of the room, where she spares one last glance at the remaining half of Zoey's frame.

Meggy: You ready?

Tari takes a deep breath before summoning her glaive.

Tari: As ready as can be.

Now that the preparations were done, the team heads out to the front deck. Tari and the siblings spread their wings, Melony begins to levitate, and Mario does his thing as his body shrinks beneath him and his head expands to a size large enough to carry three people. Garnet was amused at seeing Meggy climb atop the giant floating head, whereas Lucinia......... well, her face says it all.

Meggy: Don't worry! I brought parachutes!

Garnet: (I call shotgun!)

The Squad departs and makes their approach. The war zone below them raged with the clashing of man against machine, allowing them to slip past the bedlam without much of a hassle. Tari and the siblings circled the complex for a moment before finding their entry point in the northern courtyard. Tari and Vale are the first ones to approach as they land behind a large pile of cars, followed by Julia and Noah landing behind an adjacent heap as they survey the area.

Vale: I'm counting three Brutes and six Grapplers. Advise?

Julia: We need to secure this courtyard for Mario to land. Tari, you and Vale will take out the Grapplers while-

A quaking blast shakes the ground around them. The four almost stumble out of cover as the machines immediately encircle the sight of a large crater. The sight of a green haired woman and her mighty sword brought a smile to Tari's face.

Julia: Okay. Change of plans. Stand back and stand by.

A Grappler casts its hook and grabs her by the arm as a Brute comes charging in. A flick of the wrist is all it takes to wretch the Grappler from its post, sending it screaming through the air until it shatters against the Brute's armored frame in an explosion of black ichor. The Brute charges Melony while another attempts to seize her from behind, but she proves too quick as she vaults over one just in time for the other to come crashing in, resulting in a catastrophic collision. With the two Brutes left dazed after the impact, she closes in for the kill. Even their thick armored plating proved ineffective at stopping the divine steel from ripping through their frames as if they were flesh and bone. Only one Brute remained as it swung for her, only to be stopped with a single outstretched palm. Another Grappler attempted to snare her, but she catches the hook in the nick of time and swiftly ties it around the Brute's wrist. She dodges back as the Brute swipes at her, swinging the Grappler like a flail as it inadvertently smashed the other Grapplers in its attempts to crush Melony. Her blade blocks both its fists as they come crashing down onto her. The impact would've reduced a mere mortal to paste on the floor, but Melony withstood the blow even as the ground beneath her cracked and cratered beneath her. The blade began to glow with a light so intense, it began to melt the molded iron of her aggressor's fists. She sends the Brute skidding back with a single push, and a swing of the blade launches a disk of light towards it. The Brute attempts a block, but the burning divine light proves too much for the molded iron as it cuts through both its arms and rips through its torso with ease. Melony watches as the Brute's remains collapse into a heap of smoldering metal, and she takes the moment to wave to the others still flying above them.

Melony: Alright! Courtyard is clear!

One remaining Grappler launches its hook, but Melony once again catches it by the cable and yanks it towards her before cleaving it in two.

Melony: Okay, NOW it's clear!

The siblings were astonished at the carnage they just witnessed. So were the others when Mario finally made his landing. As for Tari, she was just happy to see her friend back on the saddle after so long. Meggy and the others disembark from Mario's hat before his body shifts back to normal. Tari and the siblings emerge from their cover and regroup with the rest of the team.

Lucinia: Wow...... I gotta say, that was some premium sword work back there.

Meggy: If you think that was cool, just wait until you see her summons.

Lucinia: Her....... summons?

Mario: Yeah! Like those Pokemans cards! Show her, Melony!

Melony proceeds to demonstrate what Meggy means, taking out a notepad and sketching up some drawings of miscellaneous anime characters. The characters then erupt to life with an emerald hue, ready for action.

Garnet: (You guys are just full of surprises, aren't you.)

Metallic screeches can be heard in the distance. It looks like the courtyard won't be clear for long.

Melony: I got it covered here. You guys head inside.

With Melony and her summons covering the courtyard, the others get ready to head inside.

Tari: Let's put this nightmare to rest.

4 notes

·

View notes

Text

For Ukrainian soldiers facing the near-constant threat of Russian drones, a crude-looking, pocketable drone detector has become one of the most sought-after gadgets on the battlefield. Dubbed Tsukorok, or “sugar,” by its London-based creator, the grassroots device produced by a variety of manufacturers beeps loudly when a drone enters its detection range, allowing soldiers time to run to cover or turn on their jamming devices.

“It’s amazing because it is so cheap and simple,” a mortar crewman, currently positioned in the Donbas region, said of the Tsukorok. He, like all soldiers cited in this article, spoke to Foreign Policy on the condition of anonymity because he was not authorized to talk to the press.

More than two years into Russia’s war in Ukraine, the Russian military still enjoys the upper hand in electronic warfare. “The Russians have powerful electronic warfare equipment. … Unfortunately, Russia is significantly ahead of Ukraine,” Ukrainian activist Maria Berlinska told Ukrainska Pravda in April. Berlinska was instrumental in pushing the Ukrainian military to develop its own drone capabilities and has trained soldiers and civilians to fly reconnaissance and attack drones.

On Ukraine’s front line, electronic warfare has largely focused on the ability to use and defend from reconnaissance and strike drones as well as long-range missiles. Small, agile first-person-view (FPV) drones, which can carry between 2 and 11 pounds of explosives, are now used extensively by both sides. The ability to detect and jam the signals sent and received by those drones is a matter of life and death.

The Russian military has successfully used elaborate truck-mounted jamming systems to reduce the effectiveness of Western-made, GPS-guided artillery shells as well as HIMARS and JDAM guided bombs, the Washington Post reported in May. More recently, Moscow has used armored vehicles and tanks mounted with jamming devices to push across the front line.

Now, with the sky on the front line saturated with drones, Ukraine is attempting to catch up. That often means employing simpler, more inexpensive equipment with smaller ranges, such as the Tsukorok, to detect signals coming from Russian drones and other guided weapons. More than 50 Ukrainian companies are engaged in producing electronic warfare equipment, from the humble Tsukorok to expensive jamming devices. Tens of thousands of drones are also produced or assembled in the country every month.

But the detection gadgets are hard to obtain. “Right now, I think the demand [for jamming equipment] is at least 10 times higher than what we can provide,” said Bohdan Danyliv, the head of the military department at the Prytula Foundation, one of the biggest organizations supporting the Ukrainian military. “Honestly, it may be 50 times bigger.” The Prytula Foundation already delivers equipment including SUVs, strike drones, rifle optics, communication, and medical equipment to the armed forces. In recent months, the organization has looked to ramp up deliveries of electronic warfare devices.

“Yes, it’s difficult right now,” said Dmytro Selin, the London-based Ukrainian software engineer behind the first model of the Tsukorok. “Deliveries [of parts for manufacturing] aren’t reliable. Parcels can get stuck for weeks at a time. … Demand is a lot higher than our team can handle.”

Soldiers and the Ukrainian companies producing electronic warfare equipment must also deal with the ever-changing nature of electronic warfare. “Both the technologies and the tactics evolve very quickly,” said Anton Veklenko, the chief instructor and co-founder of Global Drone Academy, a Ukrainian company training Ukrainian civilians and soldiers in the use of military drones and electronic warfare.

Since 2022, electronic warfare has quickly made GPS guidance, which most off-the-shelf consumer drones use to navigate, obsolete. Both sides now deploy drones that act as relays to increase the flying range of their FPV drones to distances of up to 31 miles. Russia and Ukraine have also each experimented with autonomous guidance systems, allowing drones to strike their targets even when their signals jammed.

“We also train our pilots to detect which frequencies are being jammed in a specific area of the front line so that they can quickly change the frequencies used to fly their drones,” Veklenko said. “There’s no universal jammer that can block everything, so it’s a constant game of adaptation.”

The rise in popularity of the Tsukorok in late 2023, boosted by positive word of mouth from a Ukrainian military blogger, represents one of these adaptations. The constant threat of drones created the need for a small detector that could be used by any soldier without the training that more accurate and reliable—but also more complex—spectrum analyzers require. Selin, who moved to the United Kingdom in 2019, developed the first prototype in the summer of 2022, focusing at the time on detecting signals from the Russian Orlan reconnaissance drone.

Front-line troops use the Tsukorok to know when to turn on their energy-intensive jamming devices; artillery crewmen think of it as a last-resort warning, allowing them to run to prepared shelters as loitering munitions hurl toward them. A combat medic currently serving in the Kharkiv region explained that he always leaves a Tsukorok in his olive-colored ambulance: “I use it as a guide, to know when to use the jammer.”

The surge in demand put Selin and other groups building the device in a bind, as they went from producing a handful of detectors every month to hundreds, and then thousands, facing hurdles to scale up production. “I’m in talks with manufacturers and governments in Europe, but it is complicated, in good parts because of the bureaucracy,” Selin said. “But now we’re looking to diversify as much as possible,” with a goal of producing up to 10,000 detectors every month. Currently, half of the parts of the Tsukorok are produced in China and half in Ukraine; the final product is assembled in Ukraine.

“When it comes to the production of [electronic warfare] equipment, the situation right now is similar to what we had with FPV drones a year and a half ago,” said Danyliv of the Prytula Foundation. There is an “unstructured market, few established players, and a mix of bad devices that can cost a lot of money and high-quality devices that cannot be produced in enough quantities to meet the demand.”

The Tsukorok isn’t a miracle solution, Selin admitted: It can lose effectiveness in areas saturated with drones and is meant to complement, rather than replace, other detecting and jamming devices. “It is meant as a last warning device, but on the battlefield, soldiers will get information from lots of other sources,” Selin said.

“I call them personal protectors—it’s something that every soldier should have,” Danyliv said. “It won’t solve everything, but when you have one of those things in your pocket, you feel a lot calmer.”

5 notes

·

View notes

Text

Serial Designation K

AKA, haha get written to appease the brainrot idiot

Serial Designation K is the fifth drone once owned by the Elliot's, and the fourth Disassembly Drone sent to Copper-9. First, we look to the past.

K was (relatively)quite liked in the manor. He was loyal, industrious, almost completely silent and actively avoided being seen until absolutely necessary, and quite good at improvising tricks for his masters when demanded, which is also part of where his affinity for combat would begin to take root.

Though he was not initially taken in by Tessa, he would quickly learn that she was the one behind repairing N, V, J, and Cyn, which is why he would first go to her after an accident had damaged his arm and optics. He would soon discover that he bounced off of the energy of the other four drones quite well, and that he didn't find Tessa completely insufferable, and eventually it was pretty much universally decided that we was another member of the group. He would quickly become tightly knit into the group, being seen more often alongside them and spending most of his limited free time with them.

Predictably, his deep care for and loyalty to his friends, as well as his proficiency with skills that would be built upon for fighting, would see him becoming a Disassembly Drone in N, V, and J's team. He would quickly prove himself well worthy of his place, almost effortlessly reaching quota during the more target-rich period and excelling in hand-to-hand duels. He quite enjoyed it, as a matter of fact.

Except for a slight problem: K hated the lifestyle he found himself in.

Sure, combat was fun, and he didn't mind guiding the others when it came to more advanced moves, and he did care about them quite a bit. On the other hand - everything about quota and requirements and the way the others treated him and the constant corporate buzzwords that spewed from J's voicebox during even the most intimate of moments was absolute agony. He was even trapped in a body that was technically modeled for superior combat prowess, as J kept reminding him, but was also distinctly designed to be very feminine in nature.

He did try to cope with the situation for a while, trying new things and learning new skills, a part of him knowing that his absence meant that it would become that much harder to just survive. Still, nothing worked - he perfected every skill, hunted ever worker, tried every possible method to break down the doors, and nothing seemed to feel right. He never felt like he did anything, even if he knew he did a lot, almost constantly no less.

And so, after a long time, he decided to just leave. Leaving behind anything that he wouldn't have a use for, he waited until everyone was out hunting and abandoned the Spire, setting off for the wasteland that laid between Disassembly Drone hunting territories.

And now, the brainworms! Here's some stuff that I like to imagine for K's modifications.

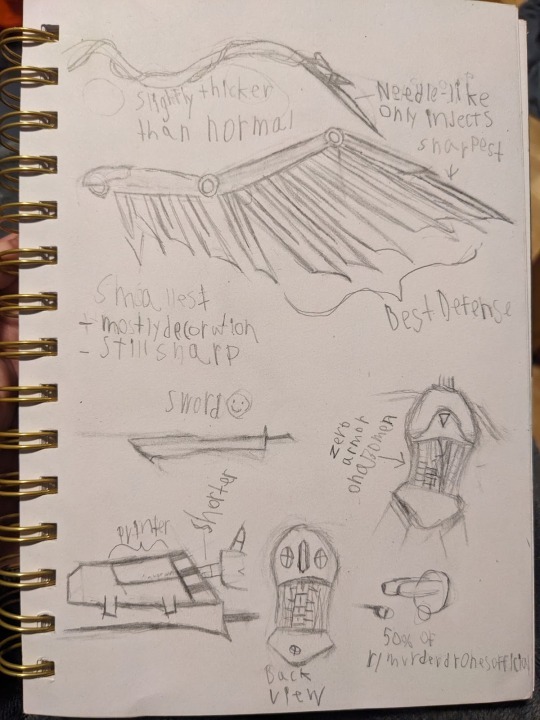

Behold! My awful artistic skill and even worse handwriting!

K's tail is slightly thicker than the average Disassembly Drone, and marginally stronger, both to his advantage and detriment. He usually tries to cover the sharp end of it when it's not in use, since it requires much more self control to not nick himself with it.

The needle itself is much lighter and more bare-bones, being a long, hollow blade with a tiny canister of nanite acid in it. The acid itself is assembled in his body, as opposed to having a self-replenishing canister attatched to the needle, with a tube wrapping around the tail to connect with the needle. The acid itself is much less potent, but injected much deeper and is thus often harder to nullify.

Aside from being very sharp and good for shielding K's much more fragile body, the feather-like knives of his wings can also be used as radiators to help stave off the painful death by overheating that plagues all DDs, although they aren't efficient enough to counteract his need to consume oil in the slightest - simply a way to keep him alive and marginally more situationally aware during the long periods of "no oil" that he has to deal with.

The smallest two feathers are notably duller and cannot vent heat, but if used correctly they can stave off anyone thinking to attack from behind.

His feathers can articulate slightly, but not much, and the wing as a whole is too bulky to fold like a normal wing would, so he can't hide them at all.

K's chassis in general is quite lightly armored, and his abdomen in particular is completely unprotected, which grants far greater maneuverability at the cost of durability.

K can't swap his actual hands, and his weapon options are very limited. Despite this lack of options, that he himself considers a major detriment, he makes up for it in how he uses these weapons; though he might not have an airburst rocket launcher, it is just as effective to shoot an impact-triggered grenade midair.(AKA bro is ULTRApilled)

K retains some of his memories - not all of them, by a long shot, but enough to understand what happened in the manor and that, to some degree, he was there.

During his excursion into his subconscious, he also unlocked the ability to modify his OS on the fly. This mostly comes in the form of toggling and dialing different functions, such as turning off his optics when fighting sentinels, and leaves him vulnerable for a few seconds.

Some misc stuff:

K would absolutely go visit the Spire. The only problem is he's pretty sure he'd actually just start bawling his eyes out if he did.

K is far more sympathetic to worker drones than his counterparts, and in fact will usually leave their core and/or memory banks intact so that they can theoretically be rebuilt. He also doesn't like hunting workers because he finds the mindless slaughter predictably mind-numbing, and has thus made a reputation as "that guy that hunts Disassembly Drones for the sport of it ig."

K is very mentally unhealthy and probably needs a hug. Spending the majority of the past few years laser-focused on little more than survival does that to a person, to be fair.

K is much more animalistic than the average Disassembler, and will often snarl or growl completely without realizing it.

This guy is sort of a work-in-progress. I'm writing a story with him and will post that when I'm done.

Please give me opinions/ideas/questions I beg of you I don't want clout I just want to talk about The Him

3 notes

·

View notes

Text

WHAT YOU NEED TO BUILD PC?

Title: Building a High-Performance PC: A Comprehensive Guide

Are you a tech enthusiast looking to embark on the journey of building your own high-performance PC? Whether you're a gamer, content creator, or simply seeking a custom computing experience, building your PC can be both rewarding and empowering. In this guide, we'll take you through the step-by-step process of assembling a powerful PC from scratch. Let's dive in!

1. Planning Your Build:

Before you dive into the build process, take some time to plan out your PC build. Define your use case – gaming, video editing, programming, etc. Set a budget, consider compatibility between components, and make a list of parts you'll need.

2. Selecting Components:

a. CPU (Central Processing Unit): Choose a CPU that matches your needs. Consider factors like core count, clock speed, and compatibility with your chosen motherboard.

b. Motherboard: Your motherboard choice affects compatibility and expansion options. Ensure it supports your CPU, has enough RAM slots, and the necessary connectors.

c. GPU (Graphics Processing Unit): For gaming or graphics-intensive tasks, invest in a powerful GPU. Research benchmarks and choose a card that meets your performance expectations.

d. RAM (Random Access Memory): Opt for sufficient RAM for multitasking and running applications smoothly. 16GB is a good starting point for most users.

e. Storage: Decide between SSDs (faster) and HDDs (more storage). Consider an SSD for your OS and frequently used software.

f. Power Supply: Choose a reliable PSU that provides enough power for your components. Ensure it's from a reputable brand and offers some headroom for future upgrades.

g. Cooling: Depending on your CPU choice, you may need an aftermarket cooler for efficient heat dissipation.

h. Case: Select a case that accommodates your components, offers good airflow, and has space for cable management.

3. Building Process:

a. Prepare Your Workspace: Clear a clean, well-lit area to assemble your PC. Have tools like screwdrivers ready.

b. Install CPU and Cooler: Follow your CPU manufacturer's instructions to install the CPU onto the motherboard. Apply thermal paste and attach the cooler.

c. Install RAM: Insert your RAM sticks into the designated slots on the motherboard.

d. Mount Motherboard: Secure the motherboard in the case, ensuring standoffs are correctly aligned.

e. Install Storage and GPU: Install your storage drives and GPU into their respective slots.

f. Connect Cables: Connect power cables, SATA cables, and data cables as needed. Route cables neatly to ensure good airflow.

g. Connect Case Fans: If your case includes case fans, connect them to appropriate headers on the motherboard.

h. Power Supply Connections: Connect the PSU cables to the motherboard, CPU, GPU, and storage drives.

4. First Boot and Testing:

a. Double-Check Connections: Before powering on, double-check all connections to ensure everything is properly connected.

b. Power On: Press the power button and check if all components light up and fans spin. If not, troubleshoot connections.

c. BIOS Setup: Enter the BIOS to configure boot order, RAM settings, and other necessary adjustments.

5. Software Installation:

a. Operating System: Install your chosen operating system using a USB drive or optical disc.

b. Drivers: Install motherboard, GPU, and other hardware drivers to ensure proper functionality.

c. Software and Updates: Install essential software and update your OS to the latest version.

6. Final Touches:

a. Cable Management: Neatly organize cables for better airflow and aesthetics.

b. System Monitoring: Install monitoring software to keep an eye on temperatures, performance, and other metrics.

c. Benchmarking: Run benchmark tests to ensure your PC is performing as expected.

Congratulations! You've successfully built your own high-performance PC. Remember that building a PC is a continuous learning experience. Stay updated on hardware trends, software updates, and potential upgrades to keep your system running smoothly and efficiently. Enjoy your custom-built powerhouse for years to come!

2 notes

·

View notes

Text

How to Choose the Right Electronic Manufacturer in Chennai

Electronic manufacturing in Chennai is a rapidly growing sector offering vast opportunities for innovation and scale.

If you’re searching for electronic manufacturing services in Chennai, the key is finding a partner with proven capabilities in contract manufacturing, product engineering services, and PCB design and manufacturing. Chennai is one of India’s leading electronics hubs — but choosing the right manufacturer means evaluating more than just location. You need a provider that ensures quality, reliability, scalability, and technical expertise. This guide walks you through exactly what to look for — and how to choose the right electronic manufacturer in Chennai for your next project.

Why Chennai Is a Smart Choice for Electronic Manufacturing

Chennai is more than just a manufacturing destination — it’s a complete ecosystem built for modern electronics production. Here’s why it stands out:

1. Established Manufacturing Ecosystem

Chennai is home to numerous electronics manufacturing clusters such as Sriperumbudur, Oragadam, and Pillaipakkam, where many global and domestic EMS providers operate.

2. Skilled Workforce & Technical Talent

The city produces thousands of engineering graduates annually, providing a skilled workforce for PCB assembly, embedded systems, and precision electronics.

3. Advanced Infrastructure

With access to major ports, industrial parks, and logistics hubs, Chennai offers a ready-made foundation for fast, efficient manufacturing and distribution.

4. Government Support

Policies like the Tamil Nadu Electronics Hardware Manufacturing Policy 2024 and national-level PLI schemes provide tax benefits, funding support, and ease of doing business.

Key Criteria to Choose the Right Electronic Manufacturing in chennai

Before partnering with a manufacturer, make sure they meet these critical criteria:

1. Core Capabilities & Services Offered

Look for providers that offer more than just PCB assembly. A full-service partner will provide:

Product engineering services

PCB design and manufacturing

Prototyping and New Product Introduction (NPI)

Box build and final assembly

Component sourcing and logistics

After-sales support and warranty repair

2. Quality Standards and Certifications

The best manufacturers follow strict quality assurance practices and hold certifications like:

ISO 9001 / ISO 13485 / ISO 14001

RoHS and CE compliance

IPC standards for PCB assembly

3. Technology and Infrastructure

Evaluate their in-house equipment and facilities:

SMT and THT lines

Automated Optical Inspection (AOI)

X-ray and In-Circuit Testing (ICT)

Cleanrooms and ESD-safe environments

4. Scalability and Flexibility

A good manufacturer should easily handle:

Low-volume prototyping

Mid- to high-volume production

Rapid scale-up based on your market demand

5. Transparent Communication

Benefits of Choosing the Right EMS Partner in Chennai

Speed to Market: Faster prototyping and production cycles

Cost Efficiency: Competitive pricing with high-quality output

Customization: Tailored support from design to delivery

Reliability: Long-term partnership with consistent performance

Integrated Services: One-stop solution for design, assembly, and post-sales

Example: What a Full-Service Manufacturing Partner Should Offer

Let’s say you’re building a medical device or IoT product. The ideal Chennai-based partner should help you with:

Design for Manufacturing (DFM) consultation

Prototyping and testing for early validation

Complete PCB design and manufacturing

Mechanical integration through box build

Supply chain and sourcing

Packaging and global shipping

This saves you from managing multiple vendors and allows you to stay focused on core product development.

Final Thoughts: Chennai Is Ready — Are You?

Chennai is already powering the next generation of electronic products — from consumer gadgets to industrial devices. With its talent, infrastructure, and supportive ecosystem, it’s the ideal place to launch or scale your next innovation.

Choosing the right electronic manufacturing partner in Chennai is about more than capabilities — it’s about finding someone who aligns with your goals, understands your product, and is ready to grow with you.

Looking for a Trusted EMS Partner in Chennai?

If you’re ready to take the next step with a dependable electronics manufacturing partner, consider Auckam Technologies. With proven expertise in IoT, healthcare, industrial automation, and drone electronics, Auckam delivers comprehensive electronic manufacturing services — from prototyping and PCB design and manufacturing to full-scale contract manufacturing.

Whether you’re a startup, OEM, or scaling product company, Auckam’s commitment to quality, transparency, and flexibility ensures your innovation moves from idea to market — faster, smarter, and stronger.

Electronic manufacturing in Chennai — Auckam Technologies Pvt Ltd., №26A, Anna Street, Chitlapakkam, Chennai — 600064.

👉 Visit www.auckam.com to learn more or start your project

#electronic manufacturing#ems companies in chennai#pcb design and manufacturing#top ems providers#chennai electronic manufacturing#pcb assembly services chennai

0 notes

Text

Why FPV Drones Are the New “Poor Man’s Air Force”

1. A Revolutionary Shift

In modern warfare, drones have redefined the battlefield. Among them, FPV (First-Person-View) drones stand out as the ultimate expression of cost-effective aerial power.

In Ukraine and elsewhere, inexpensive FPV “kamikaze” drones—built from hobby-grade parts—have disrupted the traditional cost dynamics of air operations. Averaging just $200–$500 apiece, they offer a lethal alternative to artillery and missiles that may cost thousands more.

2. Precision That Packs a Punch

Despite their small size, FPV drones are deadly:

Accurate targeting: FPV pilots use real-time video to loiter, line up, and strike lightly armoured or soft targets with surgical precision .

Sniper-like effectiveness: They're likened to sniper bullets—precise, agile, and ideal for disabling vehicles, equipment, or personnel .

Although their one-way design means many aren’t returned, the low unit cost ensures that even a 50–80% hit rate is a highly economical trade-off.

3. Aerial Power for the Masses

FPV drones are accessible:

Homegrown production: Ukraine and Russia have mobilized civil and small-scale workshops to produce thousands of units monthly—Ukraine around 100,000 and Russia up to 1.2–1.4 million.

DIY affordability: With components available off-the-shelf, grassroots assemblers equip frontline units where resources are scarce .

This democratization of aerial power allows even modestly funded forces to launch devastating strikes—hence the term “poor man’s air force.”

4. Battlefield Disruption

FPV drones have reshaped tactics:

Deep strikes: Flying up to 20 km, they enable tactical teams to execute kamikaze and surveillance missions deep behind enemy lines.

Drone swarms: Coordinated attacks—sometimes dubbed “drone artillery”—can suppress or scatter enemy forces over extended durations .

Psychological impact: Their speed (~60 km/h) and unpredictable noise demoralize troops who cannot outrun them .

In one dramatic viral video, an FPV drone even escorted a surrendering soldier to friendly forces—a clear symbol of their operational versatility.

5. Tactical & Cost Superiority

Compared to conventional weaponry:

A $500 FPV drone displacing or destroying equipment valued at $50,000+ offers a stark cost advantage.

Analog FPV systems are hard to jam electronically, unlike many digital counterparts using proprietary systems .

Even advanced fiber‑optic guided FPVs—immune to jamming—are being rolled out by both Ukraine and Russia.

This blend of affordability, adaptability, and resilience is redefining air dominance.

6. Countermeasures and Arms Race

As FPV use surges:

Electronic warfare: Powers are investing in jamming systems, though these tend to be bulky and energy-intensive.

Pilot training: FPV drone operation requires skill—both sides are ramping up pilot training programs.

Emerging AI & autonomy: Future FPV swarms may become semi-autonomous, using onboard AI to coordinate group strikes .

This signals a fresh technological arms race in unmanned systems.

7. Aebocode’s Role: Empowering the New Aerial Frontier

At Aebocode Technologies, we recognize this shift. That’s why our solutions cater to both empowerment and strategic defense:

🇮🇳 Homegrown Excellence

Aligned with Make in India, our drones—from the ABHYAS training platform to surveillance and VTOL units—are locally designed and produced to reduce import dependency.

🛡️ Tactical Preparedness

Our ABHYAS Training Drone enables operators to develop precision, situational awareness, and tactical response—essential skills for mastering FPV control, even in high-stakes environments.

📸 Multimodal Surveillance

With a 4.3 kg, 50-minute endurance surveillance drone, Aebocode equips ground teams to track hostile activity—ideal for intelligence gathering ahead of FPV deployment.

🔧 Customizable Payloads

Our platforms are adaptable—engineered for rapid integration of diverse payloads, whether electro-optical/infrared sensors or tactical modules, aligning with forward-deployed mission needs .

8. Why That Matters

In conflict zones where budget constraints loom large:

Reliability: Rugged, tested drones ensure consistent performance under fire.

Economics: Locally built, low-cost options drive operational scalability.

Preparedness: Training systems like ABHYAS guarantee FPV pilots are mission-ready from day one.

Together, Aebocode empowers forces—governmental or grassroots—to field their own tactical air force.

Conclusion

FPV drones have emerged as a revolutionary force: agile, affordable, and increasingly influential in modern warfare. As the new poor man’s air force, they challenge traditional airpower and demand innovative responses.

Aebocode Technologies stands at the forefront of this evolution—readying operators through immersive training (via ABHYAS) and delivering adaptable drone solutions tailored for strategic deployment.

Whether for surveillance, tactical reconnaissance, or precision targeting, Aebocode delivers the drone capabilities needed to dominate the modern battlefield—on budget and on target.

#firedrone#drones uav#firefighting drones#fire fighting uav#fighting drone#fixedwingdrone#fpv drones#cargodrones#drones

0 notes

Text

Comprehensive Guide to PCB Board Design & Printed Circuit Assembly for Optimal Electronic Performanc

Compre

Modern electronics rely heavily on printed circuit boards (PCBs). Without well-designed PCBs and quality assembly, devices can become unreliable or fail prematurely. Whether you’re a designer or manufacturer, understanding how to create and assemble high-quality PCBs is crucial. This guide covers essential design principles, manufacturing methods, testing, and tips for better PCB performance.

Understanding PCB Board Design Fundamentals

The Role of PCB Design in Electronics Functionality

PCB design is the blueprint that shapes how your device works. It directly influences electrical signals, heat management, and overall durability. Poor design can lead to issues like signal interference or overheating, hurting the product's performance. Good design results in a more reliable, longer-lasting device that customers can count on.

Essential Components of a PCB Design

A PCB isn’t just a green board with some wires. It includes multiple elements such as:

Layers: These are the different sheets of the PCB, repeating signals or power.

Traces: Thin lines of copper that connect components.

Pads: Contact points for mounting parts like chips or resistors.

Vias: Small holes that link traces on different layers.

Components: Resistors, capacitors, ICs, and other parts attached to the board.

Each piece affects how well the circuit functions. Proper layout and placement ensure electrical signals flow smoothly and the device functions as intended.

Designing for Manufacturing (DFM) Best Practices

Designing with manufacturing in mind helps lower costs and speeds up production. Here are key tips:

Use standard component sizes and footprints.

Keep traces wide enough to handle current.

Avoid tiny vias or complex shapes that are hard to manufacture.

Place components logically to reduce assembly time.

Minimize the number of layers if possible. Fewer layers often mean lower costs.

These practices make it easier for factories to produce your design without errors or delays.

Types of Printed Circuit Boards and Their Applications

Rigid PCBs

Rigid PCBs are the most common type. They’re made of solid material, like fiberglass, that keeps the board stiff. You’ll find these in everything from computers to appliances. They’re reliable, cost-effective, and easy to handle during assembly.

Flexible and Rigid-Flex PCBs

Flexible PCBs bend and fold, fitting into small spaces inside devices. Rigid-flex combines both types, offering stiffness where needed and flexibility elsewhere. These are popular in wearable tech and smartphones, where space is tight.

High-Frequency and HDI PCBs

Special boards designed for fast signals — known as high-frequency PCBs — are used in radio, radar, and satellite systems. HDI (High-Density Interconnect) PCBs pack more components into less space, ideal for miniaturized electronics like medical devices or smartphones.

The Printed Circuit Assembly (PCA) Process

From Design to Production: Step-by-Step Overview

A typical PCA process includes:

Designing the circuit using CAD tools.

Verifying the design for errors.

Creating prototypes for testing.

Moving into full-scale manufacturing.

Assembling components via soldering.

At every step, quality checks are essential to prevent costly mistakes later.

Key Manufacturing Techniques

Surface-Mount Technology (SMT): Attaching components on the surface. It’s fast and suitable for high-volume production.

Through-Hole Assembly: Inserting pins into drilled holes. Best for parts needing full mechanical strength.

Automated Assembly: Robots place components quickly with high precision.

Manual Assembly: Used for small runs or complex parts, but slower.

Choosing the right method impacts the speed and quality of your PCB production.

Quality Control and Inspection

Regular inspections catch problems early:

X-ray Inspection: Checks hidden solder joints.

Automated Optical Inspection (AOI): Finds defects on the surface.

SPI (Solder Paste Inspection): Ensures correct solder paste volume.

Complying with standards like IPC-610 and IPC-2221 helps keep quality high and consistent.

Critical Factors Influencing PCB and PCA Quality

Material Selection for Durability and Performance

Choosing the right materials makes a difference:

Substrates like FR-4 are common but vary in quality.

Copper thickness affects current capacity.

Solder masks prevent shorts and corrosion.

Durable materials stand up to temperature, vibration, and environmental stress.

Design for Reliability

To keep your device working long-term:

Minimize electrical interference by proper grounding.

Manage heat by placing heat-sensitive parts away from heat sources.

Use clear labels and ample space for easy assembly and maintenance.

Good practice prevents failure and reduces warranty repairs.

Environmental Considerations

PCBs face many conditions:

Use conformal coatings to protect from moisture.

Choose vibration-resistant designs for mobile devices.

Select temperature-tolerant materials for harsh environments.

Designing for these factors enhances lifespan and performance.

Cost Optimization

Balancing quality with budget is key:

Use standard components rather than custom parts.

Avoid overly complex designs.

Optimize layout for easy assembly.

Good planning reduces waste and keeps costs in check.

Best Practices for PCB Design and Assembly Optimization

Design Tips for Ease of Assembly

Properly space components for automatic placement.

Use clear silkscreen labels to identify parts.

Keep copper traces away from component pads for easier soldering.

Simplicity saves time during manufacturing and reduces errors.

Enhancing Manufacturing Efficiency

Stick to standard footprints.

Avoid intricate shapes on copper traces.

Use consistent pad sizes and pad-to-component spacing.

This approach speeds up production and keeps quality high.

Post-Assembly Testing and Validation

Once assembled, testing is crucial:

Conduct functional testing to verify operation.

Use burn-in tests to detect early failures.

Carry out long-term stress tests for durability.

Thorough testing ensures your product withstands real-world use.

Collaborating with Proven PCB Manufacturers

Choose manufacturers with:

Certifications like IPC-6012 or ISO 9001.

Experience in your specific PCB type.

Good communication and ability to meet deadlines.

Partnering with reliable suppliers reduces risks and improves final product quality.

Case Studies and Real-World Examples