#AI automation in car factories

Explore tagged Tumblr posts

Text

AI in Automotive Manufacturing 2025: Driving the Future of Smart Production

Introduction

The automotive industry is undergoing a paradigm shift, with artificial intelligence (AI) playing a crucial role in transforming manufacturing processes. AI in automotive manufacturing 2025 is set to revolutionize production efficiency, quality control, and supply chain optimization. From predictive maintenance to autonomous quality inspection, AI is enhancing every aspect of car production, making factories smarter and more efficient. In this article, we explore how AI is reshaping the automotive manufacturing landscape, its benefits, and the future it holds.

The Role of AI in Automotive Manufacturing

AI is bringing unprecedented efficiency and precision to car manufacturing by enabling automation, predictive analytics, and intelligent decision-making. Key areas where AI is making a significant impact include:

1. Smart Robotics & Automation

AI-driven robotic arms are streamlining manufacturing processes by executing tasks such as welding, painting, and assembly with extreme accuracy. Unlike traditional robots, AI-powered machines adapt to new tasks through machine learning algorithms, reducing downtime and improving productivity.

2. Predictive Maintenance

Predictive maintenance powered by AI helps automotive manufacturers prevent unexpected equipment failures. By analyzing data from IoT sensors, AI can predict machinery breakdowns and recommend timely maintenance, reducing downtime and costs.

3. AI-Powered Quality Control

Traditional quality control methods are being replaced by AI-driven vision inspection systems that detect even the smallest defects in car components. AI ensures consistency and precision, minimizing recalls and warranty claims.

4. Supply Chain Optimization

AI is optimizing the automotive supply chain by predicting demand, managing inventory, and identifying disruptions before they occur. This helps manufacturers maintain a steady production flow while reducing costs and improving efficiency.

5. Autonomous Vehicles in Manufacturing Plants

Automakers are integrating AI-powered autonomous vehicles within factories to transport materials, enhancing efficiency and reducing human intervention in logistics.

Benefits of AI in Automotive Manufacturing

The integration of AI in car manufacturing offers numerous advantages, including:

• Enhanced Efficiency: AI automates repetitive tasks, reducing manual labor and increasing production speed.

• Cost Savings: Predictive analytics minimize operational costs by preventing breakdowns and optimizing resource allocation.

• Improved Product Quality: AI-driven quality control ensures defect-free components, leading to higher customer satisfaction.

• Sustainability: AI helps reduce waste and energy consumption, making manufacturing more environmentally friendly.

• Workforce Safety: AI-powered robots take over hazardous tasks, improving workplace safety for employees.

Challenges in Implementing AI in Automotive Manufacturing

Despite its benefits, AI adoption in automotive manufacturing faces several challenges:

• High Initial Investment: Implementing AI-driven systems requires significant investment in technology and infrastructure.

• Skilled Workforce: Companies need trained professionals who can manage AI systems effectively.

• Data Privacy & Security: Protecting sensitive manufacturing data from cyber threats remains a critical concern.

• Integration Complexity: AI systems must be seamlessly integrated into existing manufacturing processes, requiring careful planning.

The Future of AI in Automotive Manufacturing

By 2025, AI is expected to become an integral part of every automotive production process. Key future trends include:

• Fully Automated Factories: AI will lead to the development of smart factories with minimal human intervention.

• AI-Driven Customization: Personalized car manufacturing will be possible, allowing customers to customize vehicle features in real time.

• Sustainable Manufacturing: AI will enhance sustainability by optimizing resource usage and reducing emissions.

• Collaboration Between AI & Humans: AI will complement human workers, enabling them to focus on high-value tasks while AI handles repetitive processes.

Conclusion

The AI in automotive manufacturing 2025 revolution is transforming the industry by improving efficiency, quality, and sustainability. As automakers embrace AI-driven technologies, they will unlock new opportunities for growth and innovation. While challenges exist, the benefits of AI far outweigh the hurdles, making it a game-changer for the future of car manufacturing.

#tagbin#writers on tumblr#artificial intelligence#technology#ai trends 2025#AI in automotive manufacturing 2025#AI in car production#artificial intelligence in auto industry#AI-driven vehicle manufacturing#smart factories in automotive#AI-powered car assembly#robotics in automobile production#future of AI in automotive#AI automation in car factories#machine learning in automotive industry

0 notes

Text

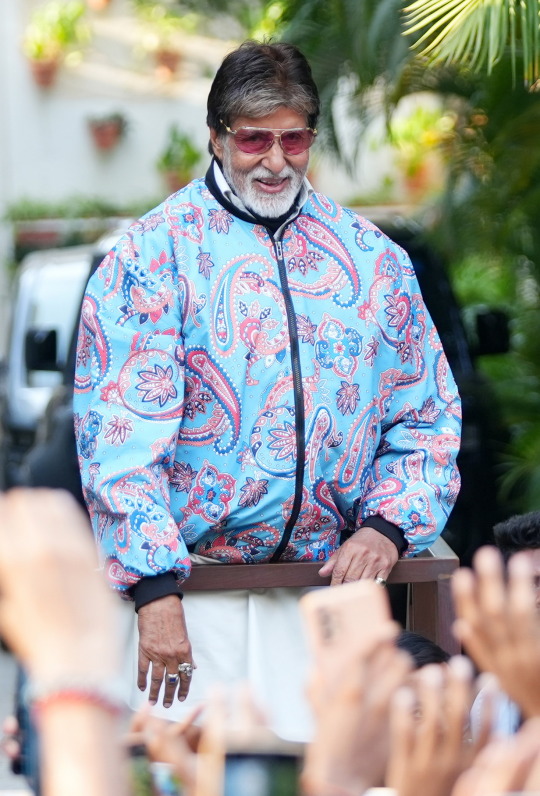

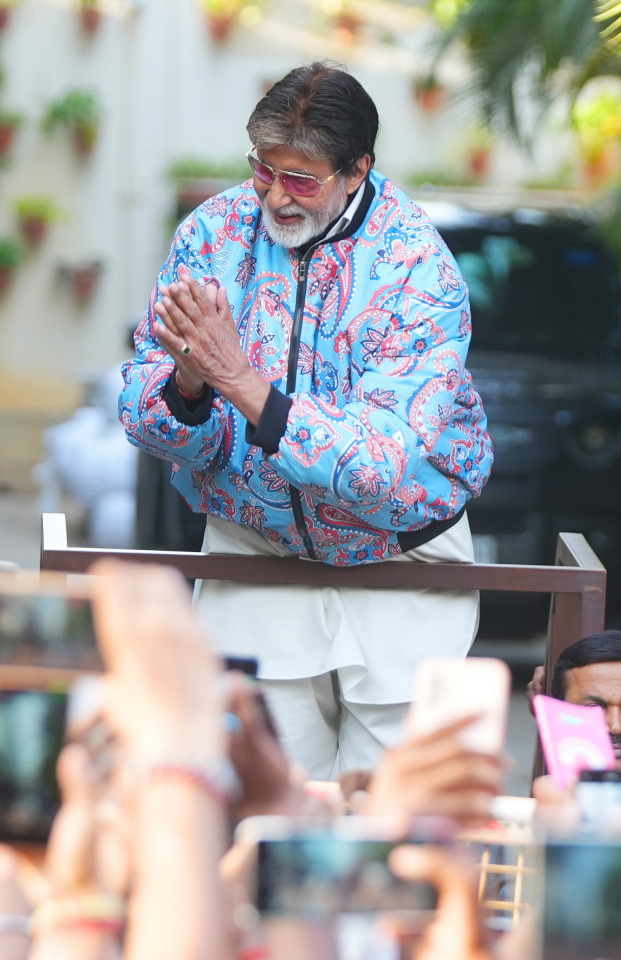

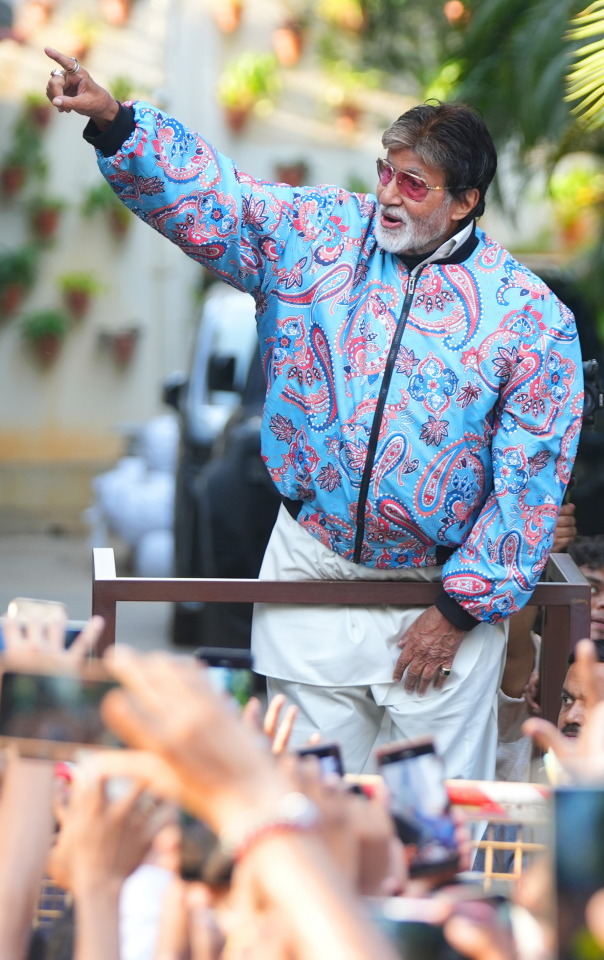

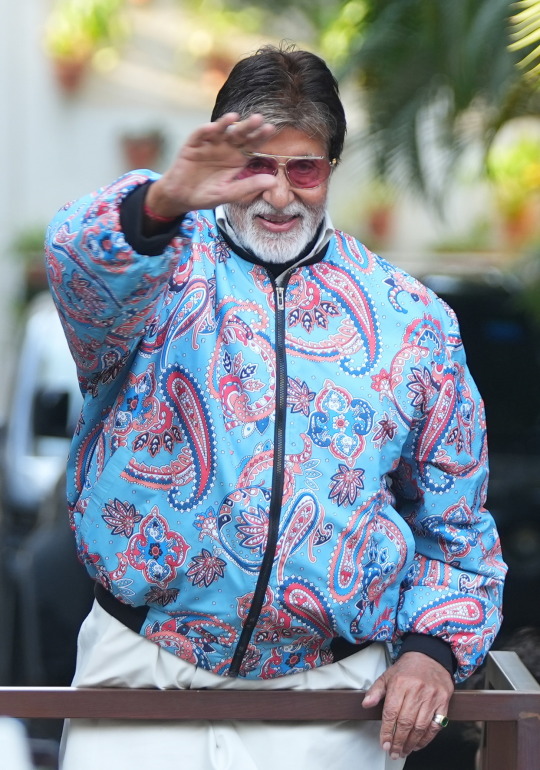

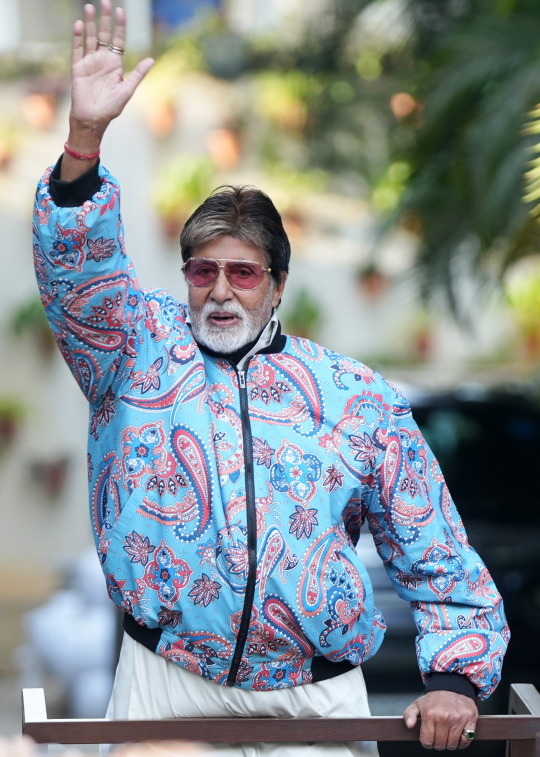

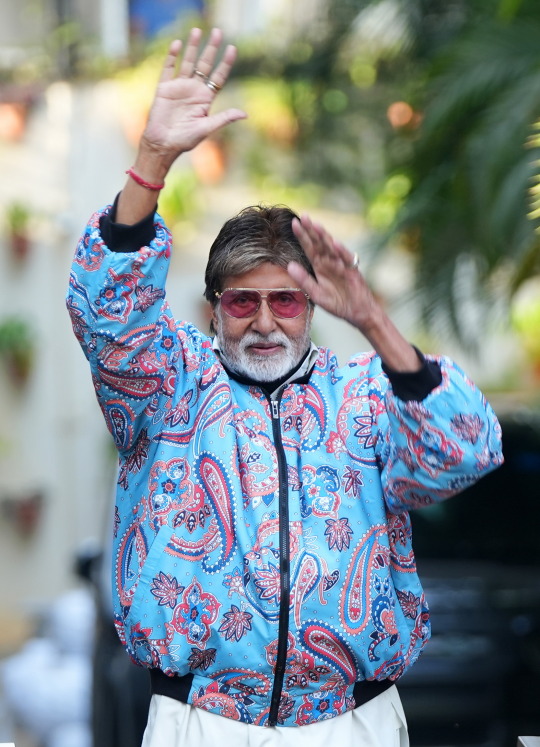

DAY 6274

Jalsa, Mumbai Aopr 20, 2025 Sun 11:17 pm

🪔 ,

April 21 .. birthday greetings and happiness to Ef Mousumi Biswas .. and Ef Arijit Bhattacharya from Kolkata .. 🙏🏽❤️🚩.. the wishes from the Ef family continue with warmth .. and love 🌺

The AI debate became the topic of discussion on the dining table ad there were many potent points raised - bith positive and a little indifferent ..

The young acknowledged it with reason and able argument .. some of the mid elders disagreed mildly .. and the end was kind of neutral ..

Blessed be they of the next GEN .. their minds are sorted out well in advance .. and why not .. we shall not be around till time in advance , but they and their progeny shall .. as has been the norm through generations ...

The IPL is now the greatest attraction throughout the day .. particularly on the Sunday, for the two on the day .. and there is never a debate on that ..

🤣

.. and I am most appreciative to read the comments from the Ef on the topic of the day - AI .. appreciative because some of the reactions and texts are valid and interesting to know .. the aspect expressed in all has a legitimate argument and that is most healthy ..

I am happy that we could all react to the Blog contents in the manner they have done .. my gratitude .. such a joy to get different views , valid and meaningful ..

And it is not the end of the day or the debate .. some impressions of the Gen X and some from the just passed Gen .. and some that were never ever the Gen are interesting as well :

The Printing Press (15th Century)

Fear: Scribes, monks, and elites thought it would destroy the value of knowledge, lead to mass misinformation, and eliminate jobs. Reality: It democratized knowledge, spurred the Renaissance and Reformation, and created entirely new industries—publishing, journalism, and education.

⸻

Industrial Revolution (18th–19th Century)

Fear: Machines would replace all human labor. The Luddites famously destroyed machinery in protest. Reality: Some manual labor jobs were displaced, but the economy exploded with new roles in manufacturing, logistics, engineering, and management. Overall employment and productivity soared.

⸻

Automobiles (Early 20th Century)

Fear: People feared job losses for carriage makers, stable hands, and horseshoe smiths. Cities worried about traffic, accidents, and social decay. Reality: The car industry became one of the largest employers in the world. It reshaped economies, enabled suburbia, and created new sectors like travel, road infrastructure, and auto repair.

⸻

Personal Computers (1980s)

Fear: Office workers would be replaced by machines; people worried about becoming obsolete. Reality: Computers made work faster and created entire industries: IT, software development, cybersecurity, and tech support. It transformed how we live and work.

⸻

The Internet (1990s)

Fear: It would destroy jobs in retail, publishing, and communication. Some thought it would unravel social order. Reality: E-commerce, digital marketing, remote work, and the creator economy now thrive. It connected the world and opened new opportunities.

⸻

ATMs (1970s–80s)

Fear: Bank tellers would lose their jobs en masse. Reality: ATMs handled routine tasks, but banks actually hired more tellers for customer service roles as they opened more branches thanks to reduced transaction costs.

⸻

Robotics & Automation (Factory work, 20th century–today)

Fear: Mass unemployment in factories. Reality: While some jobs shifted or ended, others evolved—robot maintenance, programming, design. Productivity gains created new jobs elsewhere.

The fear is not for losing jobs. It is the compromise of intellectual property and use without compensation. This case is slightly different.

I think AI will only make humans smarter. If we use it to our advantage.

That’s been happening for the last 10 years anyway

Not something new

You can’t control that in this day and age

YouTube & User-Generated Content (mid-2000s onward)

Initial Fear: When YouTube exploded, many in the entertainment industry panicked. The fear was that copyrighted material—music, TV clips, movies—would be shared freely without compensation. Creators and rights holders worried their content would be pirated, devalued, and that they’d lose control over distribution.

What Actually Happened: YouTube evolved to protect IP and monetize it through systems like Content ID, which allows rights holders to:

Automatically detect when their content is used

Choose to block, track, or monetize that usage

Earn revenue from ads run on videos using their IP (even when others post it)

Instead of wiping out creators or studios, it became a massive revenue stream—especially for musicians, media companies, and creators. Entire business models emerged around fair use, remixes, and reactions—with compensation built in.

Key Shift: The system went from “piracy risk” to “profit partner,” by embracing tech that recognized and enforced IP rights at scale.

This lead to higher profits and more money for owners and content btw

You just have to restructure the compensation laws and rewrite contracts

It’s only going to benefit artists in the long run

Yes

They can IP it

That is the hope

It’s the spread of your content and material without you putting a penny towards it

Cannot blindly sign off everything in contracts anymore. Has to be a lot more specific.

Yes that’s for sure

“Automation hasn’t erased jobs—it’s changed where human effort goes.”

Another good one is “hard work beats talent when talent stops working hard”

Which has absolutely nothing to with AI right now but 🤣

These ladies and Gentlemen of the Ef jury are various conversational opinions on AI .. I am merely pasting them for a view and an opinion ..

And among all the brouhaha about AI .. we simply forgot the Sunday well wishers .. and so ..

my love and the length be of immense .. pardon

Amitabh Bachchan

107 notes

·

View notes

Note

i guess what i don't understand about the whole generative AI thing is … yes, a lot of what's wrong is a function of capitalism, and absent capitalism the value of the tool could be assessed differently. but what we have, in the real world right now, is a tool created and funded and employed by capitalists with specific intent, to automate creative functions in order to avoid having to compensate creative labor. we have game studios doing full AI voices so they don't have to pay actors. we have film executives talking about how within a few years, if all goes as it should, storyboarding will be replaced completely with AI. it doesn't feel like a hypothetical future value-neutral appreciation of AI makes sense to give any weight, when the actual real-world applications, right now, are the farthest thing from value-neutral. and i don't think that putting up a website with a public frontend for the tool absolves anything, when we know what these tools are built specifically to achieve, and being actively used to achieve right now. maybe a lot of people are putting up bad arguments against AI, sure, but that doesn't mean AI somehow isn't making so many things so much worse.

did we defeat machine translation / self checkouts / fast food order kiosks / car factory machines / digital photography / elevator buttons / the spinning jenny? like, sounds like that's a whole bunch of bad stuff employers are planning on doing but no amount of shouting about how the technology is Soulless or at random people who use it is going to stop them. you know what will stop them? unionizing and striking.

205 notes

·

View notes

Text

It used to be that when BMW would refit a factory to build a new car, the only way the automaker could check if the chassis would fit through the production line was to fly a team out and physically push the body through the process, making note of any snags.

Now, process engineers can simply run a simulation, sending a 3D model of the car through a near-identical digital twin of the factory. Any mistakes are spotted before the production line is built, saving time and money.

Such is the power of the industrial metaverse. Forget sending your avatar to virtual meetings with remote colleagues or poker nights with distant friends, as Mark Zuckerberg envisioned in 2021 when he changed Facebook’s name to Meta; the metaverse idea has found its killer app in manufacturing.

While the consumer version of the metaverse has stumbled, the industrial metaverse is expected to be worth $100 billion globally by 2030, according to a World Economic Forum report. In this context, the concept of the metaverse refers to a convergence of technologies including simulations, sensors, augmented reality, and 3D standards. Varvn Aryacetas, Deloitte’s AI strategy and innovation practice leader for the UK, prefers to describe it as spatial computing. “It’s about bridging the physical world with the digital world,” he says. This can include training in virtual reality, digital product design, and virtual simulations of physical spaces such as factories.

In 2022, Nvidia—the games graphics company that now powers AI with its GPUs—unveiled Omniverse, a set of tools for building simulations, running digital twins, and powering automation. It acts as a platform for the industrial metaverse. “This is a general technology—it can be used for all kinds of things,” says Rev Lebaredian, vice president of Omniverse and simulation technology at Nvidia. “I mean, representing the real world inside a computer simulation is just very useful for a lot of things—but it’s absolutely essential for building any system that has autonomy in it.”

Home improvement chain Lowe’s uses the platform to test new layouts in digital twins before building them in its physical stores. Zaha Hadid Architects creates virtual models of its projects for remote collaboration. Amazon simulates warehouses to train virtual robots before letting real ones join the floor. And BMW has built virtual models for all its sites, including its newest factory in Debrecen, Hungary, which was planned and tested virtually before construction.

To simulate its entire manufacturing process, BMW filled its virtual factories with 3D models of its cars, equipment, and even people. It created these elements in an open-source file format originated by Pixar called Universal Scene Description (OpenUSD), with Omniverse providing the technical foundation for the virtual models and BMW creating its own software layers on top, explains Matthias Mayr, virtual factory specialist at BMW.

“If you imagine a factory that would take half an hour to walk from one side to the other side, you can imagine it’s also quite a large model,” Mayr says. Hence turning to a gaming company for the technology—they know how to render scenes you can run through. Early versions of the virtual factory even had gaming-style WASD keyboard navigation, but this was dropped in favor of a click-based interface akin to exploring Google Street View in a browser, so anyone could easily find their way.

BMW also uses Omniverse for collaboration on car design and customization visualizations for customers, but a key benefit is being able to model production lines. New cars mean a new assembly process, but refitting a factory is a daunting process. Previously, key information was held in silos—production crews understood details of the assembly process, external suppliers had specs of new parts or machinery, architects had detailed building plans—and costs would pile up for every delay or mistake. “The later you find a problem, the worse it is,” says Lebaredian.

Now, problems are worked out virtually, with a central location for standardized data to be held. There’s still a critical human element: Mapping a facility requires sending a laser scanner strapped to a person running through a factory to capture point cloud data about how everything is arranged. Design engineers also need to create a 3D model of every stage of a car as it’s assembled. This level of detail allows BMW to virtually test the assembly process, complete with simulations of robotics, machines, and even human workers, as BMW has data tracking how long it takes employees to assemble a part.

The main idea is to avoid errors—does that machine even fit there?—but the system also enables optimization, such as moving a rack of components closer to a particular station to save steps for human assemblers. “You can optimize first and gain a lot of efficiency in the first production, and in the construction phase, you have fewer mistakes,” Mayr says. “It’s less error prone.”

Omniverse being a Nvidia platform, AI is naturally next. BMW is already layering in generative AI to help with navigation of its virtual models—they’re so massive that finding a particular point in the digital factory can still require asking a human expert for directions. But the aim is to use AI to optimize production lines too. “Because you have the whole data available, not just for one plant, it will be able to make good suggestions,” says Mayr—lessons learned in one factory could more easily be applied to others.

And then there’s robotics and other autonomous systems. Here, Omniverse can offer a digital space for testing before deploying in the real world, but it can also generate synthetic training data by running simulations, just as driverless car systems are trained with virtual video footage generated by AI. “Real-world experience isn’t going to come mostly from the real world—it comes from simulation,” says Lebaredian.

Aryacetas predicts that the biggest impact from the industrial metaverse will be embodied or physical AI—in other words, robots. “Robots aren’t fully there yet, but they’re rapidly training up to understand the physical world around them—and that’s being done because of these underlying spatial computing technologies,” he says.

The future of the metaverse isn’t avatars in a virtual world; it’s digital twins teaching industrial robots how to step out into the physical one.

2 notes

·

View notes

Text

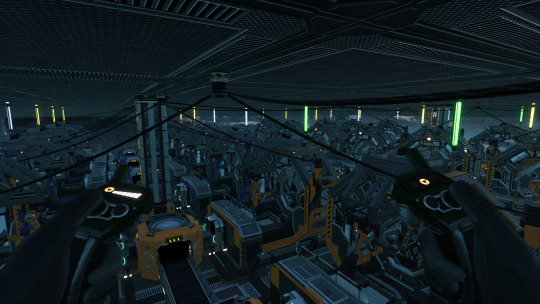

The Great Satisfactory State of Play April 2025 #3

Rocky Desert Phase 4 Factories

So we went to the Dune Desert to pay one last visit to Factory Town before it gets destroyed; we popped into the Northern Forest to visit the Phase 2 factories; and now we're about to zip into the Rocky Desert to have a gander at the Phase 3 rigmarole.

And here we are on the natural bridge that connects Northern Forest to Rocky Desert. In the distance, we can see several factories, two of which feed the reactor on the opposite side of the big rock tower. So we travel west, then up the slope...

And here we have an open air silica and quickwire factory. The golden wire is crapped out in the foreground; silica is made down the back.

And where does the raw quartz come from to feed the machine? Well...

It comes from the bottom floor of the steelworks immediately below us, since the reactor doesn't use all that much silica, and I have more than enough being belted from deep within the immense cave that spans the entire width of this biome. It was a cinch to add a splitter and get that sorted!

Iron plate, silica, steel beams go out past the encased industrial beam factory in the distance, which adds much needed EIBs to the feed. Without these, the reactor stops hard.

An early WIP shot of the reactor. Obviously it's an uranium reactor, that also makes plutonium fuel rods for recycling. This was before I added the assemblers and manufacturers needed to finish that job. But that was then...

...this is now. The quickwire and silica are trained down this line to the far distant factory on the shoreline. But there's a factory closer, and newer, and it's the best example of my idea of the Stack. Shall we have a closer look?

That box in the foreground is from a mod, that allows you to tap power from train lines without needing a station. The modernist thing on the left is the caterium smeltery. That's all it does. So we skip that and hover along the power line to the skeletal one behind it. That's the Stack for electromagnetic control rods.

The idea of the Stack is simple. Each floor is dedicated to a single step in the manufacturing process. I tend to forget that because compactness. In the distant left, foundries and smelters feed copper and iron into the Stack.

Ground floor, iron and copper ingot arrival, copper sheet making. Please mind your step as getting bowled from stepping on the belts may offend (they're sent to one corner.) Going up.

Belt bridge porn. Where was I? Oh yes.

Second floor, copper wire. Note that my prefabs for 8 constructors are actually 4x4 rather than 5x5, which I use for the assemblers further up. Step to the rear of the car please.

Third floor, quickwire extrusion. This setup with the mesh flooring (from a mod) actually works quite well as it offers plenty of space for in- and output belting. Everybody up!

Fourth floor, iron pipe manufacture. With this half-floor we see one flaw of the Stack concept, if you consider empty floor space a flaw. And now we have to step outside the concrete pillar framework to look into the next floor up.

Fifth floor, AI limiters and stators. Yes, on the same floor, because it occurred to me that there was no logical reason to put them on separate floors. But now I wonder if another half-floor would have been so bad. Stators in back, AI limiters in front.

The prefabs include built-in logistics floors, and conveyor supports for the inputs, assuming everything, er, enters the same way. And those go up to...

Top floor, ECR final join and dispatch. I have kluged up two drone ports at the reactor to receive these, and also supply said drones with fuel rods for plenty of power.

So that's my first true Stack! So what came before?

This is what came before: This damnable thick square building that makes parts for and does final join on modular engines and adaptive control units. On top are five drone ports. One receives fuel for the others. The two we can see receive smart plating and automated wiring. And there's that train station at the bottom of a rather entertaining ramp. Let's look inside.

Cool! We have a satellite HUB terminal (from a mod), and all other mod cons! Not to mention well-lit, at least in these lower floors, I skipped lighting as I went up and got impatient.

So many foundries and coated iron plate assemblers. Oh, and steel beam constructors.

I can't wait for the day when 1.1 is made mod friendly. This form of compact vertical transport is... well, it's not the going-up, it's the going-down. A 20m drop is hair-raising.

Silicon circuit boards and so, so many screws. There's about eight belts of them going up the south wall.

And this is where everything ends up: the roof. That building in the centre is where all the spaghet for dispatching the Phase 3 goods and receiving Phase 2 is. And dispensing fuel. And feeding the sink. While we're up here, let's look around:

So many miners! Copper, iron, limestone, it's all here and all getting exploited a mile into the ground.

In back of the tower are the wet concrete refineries on the left, and the steamed copper sheet works. These were difficult to make, since I was, apparently, right on the edge of where I could place water extractors.

The mighty metal-roofed motor factory system! In the back, the double A-frame houses the solid steel ingot foundries; each different roofline indicates a separate stage of motor production. Copper ingots are belted in to a wire factory in the foreground.

The ground floor is marked with a coloured floor and path patterns, to highlight where you can walk from one end of Rocky Desert Motors to the other.

All of these constructors are making screws. All 64 of them. So. Many. Screws. If I didn't know any better, I'd think I was running Satisfactory+.

And here we have a distant shot of the abominations I made on the West Coast. There's a basic aluminium ingot factory, spagged to a hastily made heat sink factory and fuel packing plant, and also a massive refinery for making residual rubber and plastic to feed the tower. Coke, rubber and plastic are supplied by train, obviously. There's also a little fuel power plant that I really need to either redo or replace.

Actually this whole shebang desperately needs reworking. If I can rework the plant to make recycled rubber and plastic, that should improve output immensely.

Aaand that's where I am right now. In my pad of Warwick 14J5 I have a plan for a grid system that I can use to rebuild Factory Town... but first I have some more damned mining to do. I promised my passengers I'd have them in the North America Nebula by Easter.

Also, over Easter and possibly starting Wednesday, I'm going to reset Windows and see if that fixes the stability issues I've been having while streaming. Which means ensuring all my documents are backed up. So excuse me, I have to take my Type 8 Ye Olde Rock Thudder out to do just that...

2 notes

·

View notes

Text

Getting Started with Industrial Robotics Programming

Industrial robotics is a field where software engineering meets automation to drive manufacturing, assembly, and inspection processes. With the rise of Industry 4.0, the demand for skilled robotics programmers is rapidly increasing. This post introduces you to the fundamentals of industrial robotics programming and how you can get started in this exciting tech space.

What is Industrial Robotics Programming?

Industrial robotics programming involves creating software instructions for robots to perform tasks such as welding, picking and placing objects, painting, or quality inspection. These robots are typically used in factories and warehouses, and are often programmed using proprietary or standard languages tailored for automation tasks.

Popular Robotics Programming Languages

RAPID – Used for ABB robots.

KRL (KUKA Robot Language) – For KUKA industrial robots.

URScript – Used by Universal Robots.

Fanuc KAREL / Teach Pendant Programming

ROS (Robot Operating System) – Widely used open-source middleware for robotics.

Python and C++ – Common languages for simulation and integration with sensors and AI.

Key Components in Robotics Programming

Motion Control: Programming the path, speed, and precision of robot arms.

Sensor Integration: Use of cameras, force sensors, and proximity detectors for adaptive control.

PLC Communication: Integrating robots with Programmable Logic Controllers for factory automation.

Safety Protocols: Programming emergency stops, limit switches, and safe zones.

Human-Machine Interface (HMI): Designing interfaces for operators to control and monitor robots.

Sample URScript Code (Universal Robots)

# Move to position movej([1.0, -1.57, 1.57, -1.57, -1.57, 0.0], a=1.4, v=1.05) # Gripper control (example function call) set_digital_out(8, True) # Close gripper sleep(1) set_digital_out(8, False) # Open gripper

Software Tools You Can Use

RoboDK – Offline programming and simulation.

ROS + Gazebo – Open-source tools for simulation and robotic control.

ABB RobotStudio

Fanuc ROBOGUIDE

Siemens TIA Portal – For integration with industrial control systems.

Steps to Start Your Journey

Learn the basics of industrial robotics and automation.

Familiarize yourself with at least one brand of industrial robot (ABB, KUKA, UR, Fanuc).

Get comfortable with control systems and communication protocols (EtherCAT, PROFINET).

Practice with simulations before handling real robots.

Study safety standards (ISO 10218, ANSI/RIA R15.06).

Real-World Applications

Automated welding in car manufacturing.

High-speed pick and place in packaging.

Precision assembly of electronics.

Material handling and palletizing in warehouses.

Conclusion

Industrial robotics programming is a specialized yet rewarding field that bridges software with real-world mechanics. Whether you’re interested in working with physical robots or developing smart systems for factories, gaining skills in robotics programming can open up incredible career paths in manufacturing, automation, and AI-driven industries.

2 notes

·

View notes

Text

Week 10 Blog Post

Will automated infrastructure take away freedom under the need for safety?

The rise of AI and robotics has prompted the creation of self-driving cars and a greater push towards automated functions in factories and in society that require less human input. These advancements have also been used in attempts to increase public safety such as through facial recognition software and automatic braking technology. While this can be beneficial in preventing deaths and accidents, it has the potential to strip the public of their freedom to privacy and the freedoms to travel without AI due to automated cars potentially being safer and due to gps and camera surveillance.

2. If humans use robots as a proxy, will gender and race still play a role?

Race and gender will still likely play a role in robot technology if humans were to use upcoming robotics technology as a proxy for them to use, with humans relaxing at home while piloting robots remotely similar to a video game avatar. This is due to the desire of people to customize their avatars to represent their beliefs, such as through the creation of chatbots designed to connect with users through mimicking a sexual relationship. Due to this, it is likely that race and gender will still apply to robot proxies through customization and names.

3. Are there any benefits to trolling?

Trolling can be beneficial in situations where it can be used to bring joy to people or as a form of protest. Page 4 of Kelly Bergstrom’s article, “Don’t Feed the Trolls” describes the relationship between the reddit user, Grandpa Wiggly, and the community that built up around him. While Grandpa Wiggly’s identity, and some of his stories may have been fake, he was able to supply great joy to many readers as they could look forward to listening to his tall tales. Trolling can also be used as a form to disagree with individuals, such as by poking fun at those who create problematic policies for innocent people.

4. When should trolling become illegal?

Trolling should become illegal when it begins to bring undue harm or effects to undeserving people on the internet. In Anna Silman’s article, “A Timeline of Leslie Jones’s Horrific Online Abuse”, she describes the abuse Leslie Jones faced from online perpetrators such as the leakage of nude photos, passport, and driver’s license information. When this type of online abuse occurs, abuse that could harm innocent people, should be investigated to try and find the person who perpetrated such a crime.

References:

Bergstrom, Kelly. 2011. Don’t Feed the Trolls.

Silman, Anna. 2016. A Timeline of Leslie Jones’s Horrific Online Abuse.

5 notes

·

View notes

Text

AI & IT'S IMPACT

Unleashing the Power: The Impact of AI Across Industries and Future Frontiers

Artificial Intelligence (AI), once confined to the realm of science fiction, has rapidly become a transformative force across diverse industries. Its influence is reshaping the landscape of how businesses operate, innovate, and interact with their stakeholders. As we navigate the current impact of AI and peer into the future, it's evident that the capabilities of this technology are poised to reach unprecedented heights.

1. Healthcare:

In the healthcare sector, AI is a game-changer, revolutionizing diagnostics, treatment plans, and patient care. Machine learning algorithms analyze vast datasets to identify patterns, aiding in early disease detection. AI-driven robotic surgery is enhancing precision, reducing recovery times, and minimizing risks. Personalized medicine, powered by AI, tailors treatments based on an individual's genetic makeup, optimizing therapeutic outcomes.

2. Finance:

AI is reshaping the financial industry by enhancing efficiency, risk management, and customer experiences. Algorithms analyze market trends, enabling quicker and more accurate investment decisions. Chatbots and virtual assistants powered by AI streamline customer interactions, providing real-time assistance. Fraud detection algorithms work tirelessly to identify suspicious activities, bolstering security measures in online transactions.

3. Manufacturing:

In manufacturing, AI is optimizing production processes through predictive maintenance and quality control. Smart factories leverage AI to monitor equipment health, reducing downtime by predicting potential failures. Robots and autonomous systems, guided by AI, enhance precision and efficiency in tasks ranging from assembly lines to logistics. This not only increases productivity but also contributes to safer working environments.

4. Education:

AI is reshaping the educational landscape by personalizing learning experiences. Adaptive learning platforms use AI algorithms to tailor educational content to individual student needs, fostering better comprehension and engagement. AI-driven tools also assist educators in grading, administrative tasks, and provide insights into student performance, allowing for more effective teaching strategies.

5. Retail:

In the retail sector, AI is transforming customer experiences through personalized recommendations and efficient supply chain management. Recommendation engines analyze customer preferences, providing targeted product suggestions. AI-powered chatbots handle customer queries, offering real-time assistance. Inventory management is optimized through predictive analytics, reducing waste and ensuring products are readily available.

6. Future Frontiers:

A. Autonomous Vehicles: The future of transportation lies in AI-driven autonomous vehicles. From self-driving cars to automated drones, AI algorithms navigate and respond to dynamic environments, ensuring safer and more efficient transportation. This technology holds the promise of reducing accidents, alleviating traffic congestion, and redefining mobility.

B. Quantum Computing: As AI algorithms become more complex, the need for advanced computing capabilities grows. Quantucm omputing, with its ability to process vast amounts of data at unprecedented speeds, holds the potential to revolutionize AI. This synergy could unlock new possibilities in solving complex problems, ranging from drug discovery to climate modeling.

C. AI in Creativity: AI is not limited to data-driven tasks; it's also making inroads into the realm of creativity. AI-generated art, music, and content are gaining recognition. Future developments may see AI collaborating with human creators, pushing the boundaries of what is possible in fields traditionally associated with human ingenuity.

In conclusion, the impact of AI across industries is profound and multifaceted. From enhancing efficiency and precision to revolutionizing how we approach complex challenges, AI is at the forefront of innovation. The future capabilities of AI hold the promise of even greater advancements, ushering in an era where the boundaries of what is achievable continue to expand. As businesses and industries continue to embrace and adapt to these transformative technologies, the synergy between human intelligence and artificial intelligence will undoubtedly shape a future defined by unprecedented possibilities.

20 notes

·

View notes

Text

How 5g Technology Change The World

The world is getting ready to a technological revolution, and on the coronary heart of this alteration is 5G era. As the 5th generation of mobile networks, 5G guarantees extremely-speedy speeds, low latency, and extraordinary connectivity. This advancement is ready to reshape industries, improve every day existence, and create new opportunities across more than one sectors. From healthcare and transportation to entertainment and clever towns, 5G isn't always simply an upgrade; it's miles a catalyst for a brand new virtual generation.

what is 5g and how it works

The Fundamentals of 5G Technology

5G era is designed to provide extensively faster information speeds than its predecessor, 4G LTE. It operates on three special spectrum bands:

Low-band spectrum – Provides broad coverage however with highly slower speeds.

Mid-band spectrum – Offers a balance between pace and insurance.

High-band spectrum (millimeter-wave) – Delivers extremely fast speeds but has confined range.

With information speeds attaining up to 10 Gbps, 5G networks will enable seamless connectivity, permitting gadgets to communicate in actual-time with minimum delay (latency as little as one millisecond). This bounce in community functionality will pave the manner for improvements that had been previously impossible.

Transforming Industries

1. Healthcare

5G technology is revolutionizing the healthcare industry through allowing faraway surgical procedures, telemedicine, and real-time affected person tracking. With ultra-low latency and high-speed connectivity, surgeons can perform robotic surgical procedures from different elements of the world, expanding get admission to to existence-saving techniques. Additionally, 5G allows for stepped forward records transfer between clinical devices, ensuring timely prognosis and higher affected person care.

2. Smart Cities and Infrastructure

5G is a key aspect inside the improvement of smart towns. By connecting billions of gadgets through the Internet of Things (IoT), 5G lets in for efficient visitors management, smart lighting, and waste management structures. Autonomous motors will gain from actual-time verbal exchange with traffic indicators and different cars, reducing injuries and improving traffic waft. Cities will become more sustainable, energy-green, and safer for citizens.

Three. Manufacturing and Automation

The manufacturing quarter is undergoing a transformation with the appearance of 5G. Smart factories prepared with AI-powered robots and IoT gadgets will operate with minimum human intervention. Predictive renovation powered by means of real-time records will reduce downtime and decorate productiveness. Augmented fact (AR) and virtual reality (VR) packages will streamline employee education and improve efficiency on manufacturing unit flooring.

4. Entertainment and Media

The enjoyment industry is also experiencing a shift with 5G generation. High-definition streaming, cloud gaming, and immersive AR/VR reviews becomes the norm. With minimal buffering and high-speed connectivity, customers can enjoy seamless content intake. Additionally, 5G allows real-time interaction in stay events and esports, offering a more engaging experience for audiences worldwide.

5. Education and Remote Work

5G is gambling a crucial function inside the evolution of schooling and far off work. Virtual lecture rooms, interactive gaining knowledge of modules, and terrific video conferencing are becoming greater accessible. Students in faraway regions can advantage from advanced internet connectivity, bridging the virtual divide. Businesses, however, can put into effect flexible paintings models with uninterrupted video calls and faster cloud get entry to, boosting productivity and performance.

The Impact of 5G on Everyday Life

Beyond industries, 5G will significantly enhance normal reviews. Smart houses prepared with 5G-enabled IoT devices will provide better safety, energy management, and comfort. Personal assistants, consisting of AI-powered voice assistants, will become extra responsive and intuitive. Augmented fact packages will remodel purchasing experiences with the aid of allowing consumers to visualise products earlier than buying.

Moreover, the gaming industry will see a shift in the direction of cloud gaming platforms, wherein high-cease gaming reports are handy with out the need for steeply-priced hardware. With decreased latency, multiplayer gaming will become smoother, allowing gamers to compete in real time with minimal disruptions.

Challenges and Concerns

While the advantages of 5G are plain, there also are demanding situations that need to be addressed. Some of the key concerns consist of:

Infrastructure Development – The deployment of 5G calls for a big funding in new infrastructure, including small cell towers and fiber-optic networks.

Security and Privacy – With accelerated connectivity comes the hazard of cyber threats. Ensuring sturdy safety features is essential to shield user statistics and prevent cyberattacks.

Health Concerns – There have been debates regarding the capability fitness risks associated with 5G radiation. However, clinical research have now not observed conclusive proof linking 5G to health troubles.

Digital Divide – While urban areas may enjoy fast 5G adoption, rural and underserved areas may additionally face delays in deployment, probably widening the virtual divide.

The Future of 5G

The destiny of 5G era seems promising as countries and agencies continue to invest in its improvement. With advancements in artificial intelligence, side computing, and quantum computing, 5G will release even more opportunities. The transition to 6G in the coming years will in addition push the limits of connectivity, making futuristic concepts consisting of holographic verbal exchange and brain-computer interfaces a fact.

Affordable smartphones with best camera reviews

2 notes

·

View notes

Text

Vehicle Design and Manufacturing Processes

Introduction: Vehicle design and manufacturing processes have evolved dramatically over the years. From manual assembly lines to high-tech automation, the automotive industry has witnessed numerous advancements that enhance vehicle performance, safety, and sustainability. This blog explores the latest trends in vehicle design and the manufacturing processes that are transforming the industry.

Design Considerations: Designing a vehicle is a complex and multi-disciplinary process that involves engineering, aerodynamics, ergonomics, safety, and aesthetics. Engineers must consider factors like fuel efficiency, performance, and environmental impact, all while ensuring the vehicle’s safety for occupants and pedestrians.

For example, modern car designs prioritize aerodynamics to reduce fuel consumption, with sleek shapes and specialized components that minimize air resistance. Additionally, the safety of the vehicle is ensured by incorporating advanced safety systems, such as collision avoidance technologies, airbags, and crumple zones.

Manufacturing Technologies: The rise of automation has revolutionized vehicle manufacturing. Robotic arms, AI, and 3D printing are now integral to automotive production. Robotics allows for faster and more precise assembly, while AI systems help in predicting maintenance needs and optimizing production schedules.

One significant advancement is the use of 3D printing for creating prototype parts and even some vehicle components. This technology enables manufacturers to design and produce intricate parts with reduced material waste and lower costs. Additionally, automation has sped up assembly lines, allowing for mass production while maintaining consistent quality.

Sustainability: As the world becomes more eco-conscious, the automotive industry has shifted toward more sustainable practices. Electric vehicles (EVs) are at the forefront of this revolution, offering a cleaner alternative to traditional gasoline-powered cars. In addition to EVs, car manufacturers are adopting environmentally friendly materials, such as recycled plastics and plant-based composites, to reduce the carbon footprint of their vehicles.

Furthermore, energy-efficient manufacturing practices, such as using renewable energy to power factories and reducing waste, are helping the industry move toward a more sustainable future.

Future Trends: The future of vehicle design and manufacturing is exciting. One of the biggest trends is the development of autonomous vehicles, which use sensors, AI, and machine learning to navigate roads without human intervention. These vehicles promise to increase safety, reduce traffic, and improve transportation efficiency.

Modular vehicle design is also gaining traction. This approach allows manufacturers to produce customizable vehicles with interchangeable components, which can be tailored to meet different customer needs.

Conclusion: The automotive industry is undergoing a revolution, driven by innovative design principles and advanced manufacturing technologies. As sustainability becomes increasingly important and new technologies such as autonomous driving and electric vehicles take center stage, the future of vehicle design looks promising. By continuing to prioritize safety, efficiency, and environmental responsibility, the industry will continue to transform how we think about transportation.

For comprehensive information and resources on engineering topics, please visit the Engineer's Heaven website.

2 notes

·

View notes

Text

The Future is Now: How AI and Automation Are Revolutionizing 2024

Find out how AI and automation are reprogramming industries and people’s lives in the year 2024. Our text covers the most pressing issues, brand new concepts, and implications for the human resources field in this context. H1: Introduction:

Introduction to AI and automation Appreciating the changes and how not keeping up would be futile. H2: Growing Use of AI in 2024: On the growth in adoption of AI within sectors Artificial intelligence-derived technological interventions

H3: Automation within the Constraints of a Busy Schedule; The background of the issue of doing day-to-day activities faster and easier The era of smart homes and personal assistants is here, and society is embracing it. H3: Employment of the AI and the Automation: Effect of AI and Automation on The Enrichment of Jobs The Emergence of New Types of Occupations. H2: Top 5 Industries Revolutionized by AI at Present: 1. Healthcare 2. Manufacturing 3. Finance 4. Retail 5. Education H3: Use of AI for Enhancing Health Systems: AI that predicts and develops recommendations and plans for treatment Roles played by robots when it comes to surgery processes

H3: AI in the Manufacturing Industry: The Future of Manufacturing: Smart Factories Preferably with Robotism, Automated Warehouses, etc. Conclusion: Other aspects eased by modern technologies H3: AI’s Impact on Finance: This Part Demonstrates the Influence of AI on Financial Activities Facilitated by Artificial Instrumental Advantages. For instance, telemarketing correspondent inquiries. H3: AI in Retail: The configuration of retail strategy and value chain strategy is reflected in the adjusted supply chain architecture. In Conclusion. H3: AI in Education: Extends to current applications of AI in education..

Be informed, Be ahead! Click here join World News Update and always be informed of the progress in... AI.

Benefits and Costs: Current Challenges: Possibilities of Job Losses and the Skills Required H2: AI and Automation in the Near Future: Prospects and Possibilities for the Next Five Years Improving firms in incorporation of these concepts in the industry. The SWOT

H2: Conclusion:

Summarizes the impact of AI and automation within the context of ‘2024’. What should be done and what is to be done next? H2: FAQs: What about the question regarding automation—how it is changing the employment sector? Can technology ever fully eradicate the need for human workers?

What are the common functions that, however, are these days being performed by automated labor? What are the opportunities that technology offers, especially for independent enterprises? What skills do people should acquire or develop to have a chance of being effective at work? Introduction.

Everyone has been and is hearing a lot of talk about self-driving cars and robots taking over people's work for a few years now. However, as crazy as the idea of them is, in 2024 it is no longer just things we hear; they are actually happening. Everything from turning around businesses to finding a place to sleep at night, there is no doubt about it that these advancements are changing everything we know about the world. Therefore, changes like this are very important.

For this paper, we will expound on the revolutionary ways through which artificial intelligence as well as automation is taking a grip of the year 2024, the sectors most hit, and what features the future will bring. Shall we begin?

Do Not Let the AI Wave Get You Thin! Subscribe with World News Update for a more comprehensive cover on ai.

The Evolution of AI in 2024: Considering the way artificial intelligence has grown, its impact in 2024 is. Not even at the present could these industries and the advancement in AI afford to be separated. Important Breakthroughs in AI: Artificial intelligence is now not a thing of the past, for it is advancing right in 2024 from the point of sophistication and attention. AI assistive technology has revolutionized many a task. Automation of Everyday Businesses: Not only our economic perspective alters with the present progression toward automation but also other aspects of our lives. It’s true even for children’s toys. The Emergence of High-Tech Homes and Robo-Manservant: Think of being back in your house all day only to find out that your house knows all that stuff and even knows the choice of the music that you love playing. With smart houses, it is no longer a figure of speech. It is social reality. Alexa and Google Assistant are ever-present smart helpers in our habits and routines, allowing us to organize our day-to-day routine in a more efficient way.

Partake in the Age of Artificial Intelligence! click and join Health Tips by 90s Mantor0 and literary be at the edge of the sea in terms of AI and automation. The Future of Employment: There is no doubt that the ways in which work is done have been dramatically changed due to technology. Therefore, what was being done by hand in the past is today done by machines. Current and emerging trends on AI and its impacts on the job market; Robots are being used more and more for routine activities, which humans can then stop doing and start on other tasks that are more stimulating or more strategic. For such employees, they should not only be open to such opportunities and paths but should offset the tremendous technological advances that continue to require people to seek new skills and competencies to remain employable. The Top 5 Sectors That Are About to Experience a Revolution As a Result of AI Now it is time to consider the use of AI and automation in specific sectors: 1. Medication Industry: The field of medicine is currently being revolutionized by AI, which aims at creating backing for the work of doctors and also to benefit patients. AI-Driven Diagnostics and Treatment Schemes: AI has the ability to diagnose patients better and more accurately in a fraction of human performance time. Therefore, it can be used to deliver diagnostics and treatment plans to the place where the patients are in real-time. The Role of Robots in Surgery:

The practice of robotic surgery has gained popularity as it assists in making accurate cuts and reduces the recovery period and healing process. 2. Production: Artificial intelligence has also been introduced in industries to make the manufacturing process faster. Smart factories and automated robots. The factories have the artificial intelligence-programmed robots doing works such as quality inspection and assembling and also carrying out predictive maintenance strategies that ensure all the machines are up all day long. 3. Finance: The financial sector has made a step in the integration of artificial intelligence, ranging from auto-trading to fraud detection and even risk management. AI-driven trading platforms: These computer programs can process a lot of data much faster than the human brain and make decisions in split seconds for quite profitable trades in the financial markets while reducing the chances of human intervention errors. 4. Retail: It's no mystery that AI is having a massive influence on modern-day retail by enhancing consumer pleasure and hands-free inventory approaches. Personalized Shopper Experience Retailers are leveraging AI to make hyper-personal product suggestions; this ensures that customers always enjoy unique buying encounters based on the details available about them. 5. Education: AI is used to provide tailored learning experiences in education by assisting students and educators in the process of implementing education according to the specifics of students’ individual abilities and needs. AI: A Crucial Component in the Learning Process: Gone are the days when a teacher would have to explain first, then organize tasks and correct, then/or thereafter feed students information. Thanks to AI, a teacher can tell where all the students are stuck and, without struggling, give each student a lesson tailored to address what problem he or she may be having at that particular time. Advantages and disadvantages of AI and automation: Nevertheless, AI and automation have some weaknesses as well. Operating Cost Effectiveness and Time Savings By using AI, companies can get busy with scaled activities while still doing repetitive work of the staff. At the same time, it offers the improvement of the company’s operations as well as considerably lower inputs. Future Work and Age-Related Job Loss Occurred along with the Skills Lost One of the negative consequences of this is also the fear that dynamic changes in the area of AI quite often result in job understating. AI with Automation in the Near Future: The following question pertains to the future of AI and how long people will learn and actually utilize it. What will happen in the next few years? If more capabilities of AI technology are used—this one even more in such areas as health, industry, and finance. We may also experience autonomous vehicles, smart cities, and AI-driven infrastructure components working at the core of everyday life. Trends and Technologies on the Rise: Most of the up-and-coming fads revolve around the more advanced development of quantum computing and the concepts of ethics surrounding the applications of AI to adjust it in a way that is of significant advantage to everyone’s wellbeing. In conclusion.

Read more>>>>>>>>>>

#AI in 2024#automation trends#artificial intelligence#future of work#smart technology#impact of AI#automation in industry.

3 notes

·

View notes

Text

Agilex 3 FPGAs: Next-Gen Edge-To-Cloud Technology At Altera

Agilex 3 FPGA

Today, Altera, an Intel company, launched a line of FPGA hardware, software, and development tools to expand the market and use cases for its programmable solutions. Altera unveiled new development kits and software support for its Agilex 5 FPGAs at its annual developer’s conference, along with fresh information on its next-generation, cost-and power-optimized Agilex 3 FPGA.

Altera

Why It Matters

Altera is the sole independent provider of FPGAs, offering complete stack solutions designed for next-generation communications infrastructure, intelligent edge applications, and high-performance accelerated computing systems. Customers can get adaptable hardware from the company that quickly adjusts to shifting market demands brought about by the era of intelligent computing thanks to its extensive FPGA range. With Agilex FPGAs loaded with AI Tensor Blocks and the Altera FPGA AI Suite, which speeds up FPGA development for AI inference using well-liked frameworks like TensorFlow, PyTorch, and OpenVINO toolkit and tested FPGA development flows, Altera is leading the industry in the use of FPGAs in AI inference workload

Intel Agilex 3

What Agilex 3 FPGAs Offer

Designed to satisfy the power, performance, and size needs of embedded and intelligent edge applications, Altera today revealed additional product details for its Agilex 3 FPGA. Agilex 3 FPGAs, with densities ranging from 25K-135K logic elements, offer faster performance, improved security, and higher degrees of integration in a smaller box than its predecessors.

An on-chip twin Cortex A55 ARM hard processor subsystem with a programmable fabric enhanced with artificial intelligence capabilities is a feature of the FPGA family. Real-time computation for time-sensitive applications such as industrial Internet of Things (IoT) and driverless cars is made possible by the FPGA for intelligent edge applications. Agilex 3 FPGAs give sensors, drivers, actuators, and machine learning algorithms a smooth integration for smart factory automation technologies including robotics and machine vision.

Agilex 3 FPGAs provide numerous major security advancements over the previous generation, such as bitstream encryption, authentication, and physical anti-tamper detection, to fulfill the needs of both defense and commercial projects. Critical applications in industrial automation and other fields benefit from these capabilities, which guarantee dependable and secure performance.

Agilex 3 FPGAs offer a 1.9×1 boost in performance over the previous generation by utilizing Altera’s HyperFlex architecture. By extending the HyperFlex design to Agilex 3 FPGAs, high clock frequencies can be achieved in an FPGA that is optimized for both cost and power. Added support for LPDDR4X Memory and integrated high-speed transceivers capable of up to 12.5 Gbps allow for increased system performance.

Agilex 3 FPGA software support is scheduled to begin in Q1 2025, with development kits and production shipments following in the middle of the year.

How FPGA Software Tools Speed Market Entry

Quartus Prime Pro

The Latest Features of Altera’s Quartus Prime Pro software, which gives developers industry-leading compilation times, enhanced designer productivity, and expedited time-to-market, are another way that FPGA software tools accelerate time-to-market. With the impending Quartus Prime Pro 24.3 release, enhanced support for embedded applications and access to additional Agilex devices are made possible.

Agilex 5 FPGA D-series, which targets an even wider range of use cases than Agilex 5 FPGA E-series, which are optimized to enable efficient computing in edge applications, can be designed by customers using this forthcoming release. In order to help lower entry barriers for its mid-range FPGA family, Altera provides software support for its Agilex 5 FPGA E-series through a free license in the Quartus Prime Software.

Support for embedded applications that use Altera’s RISC-V solution, the Nios V soft-core processor that may be instantiated in the FPGA fabric, or an integrated hard-processor subsystem is also included in this software release. Agilex 5 FPGA design examples that highlight Nios V features like lockstep, complete ECC, and branch prediction are now available to customers. The most recent versions of Linux, VxWorks, and Zephyr provide new OS and RTOS support for the Agilex 5 SoC FPGA-based hard processor subsystem.

How to Begin for Developers

In addition to the extensive range of Agilex 5 and Agilex 7 FPGAs-based solutions available to assist developers in getting started, Altera and its ecosystem partners announced the release of 11 additional Agilex 5 FPGA-based development kits and system-on-modules (SoMs).

Developers may quickly transition to full-volume production, gain firsthand knowledge of the features and advantages Agilex FPGAs can offer, and easily and affordably access Altera hardware with FPGA development kits.

Kits are available for a wide range of application cases and all geographical locations. To find out how to buy, go to Altera’s Partner Showcase website.

Read more on govindhtech.com

#Agilex3FPGA#NextGen#CloudTechnology#TensorFlow#Agilex5FPGA#OpenVINO#IntelAgilex3#artificialintelligence#InternetThings#IoT#FPGA#LPDDR4XMemory#Agilex5FPGAEseries#technology#Agilex7FPGAs#QuartusPrimePro#technews#news#govindhtech

2 notes

·

View notes

Text

I know it’s kinda old news at this point but I realized a bit ago that, in the Helluva Boss episode with Fizz and the Clown Competition, the competition itself is kinda the perfect metaphor for greed and capitalism in this day and age? Cuz Mammon, being the prince of Greed, is the picturesque greedy fat billionaire who is cruel unless you make him money, then he’s only slightly less cruel. If he were overseeing a factory, you can bet he’d pull a Jeff Bezos and have the workers on the floor for ridiculous hours, no breaks, they’re peeing in bottles, and there’d be all kinds of union busting tactics. And as weird as it is, Clowning is a pretty great metaphor for working a creative job in a capitalist dystopia. Being a performer is an inherently creative job, and with Clowning it’s also physically demanding. But the real sticking point is that Clowning as most people think of it is a very cooperative profession. You usually don’t have one clown at a circus, that’s more like a single jester in a king’s court. What you usually have is a load of clowns filing out of a tiny clown car, multiple clowns providing support to make the jokes land, it’s a job where you’re usually among your peers. But Mammon has different ideas. He started this Clown Competition, pitting performers against each other. He makes it so there can only be one winner, and that’s the cash cow he’ll milk dry. But it doesn’t stop there, not with greed. Because it’s one thing to isolate a performer and capitalize on their success so you can make money off them and simultaneously not have to pay multiple performers, it’s another thing to automate that performer to make more money off their likeness. Because Mammon made the Fizz bots, and I can’t help seeing that as a commentary on greedy corporations turning to AI to make art instead of paying human artists. The way Mammon isolates Fizz, turns Clowning into a competition, and takes advantage of Fizz’s lower status as an imp to jerk him around while making boatloads of money off him, it’s just the perfect allegory for corporate greed and capitalism.

2 notes

·

View notes

Text

How Are Robots Used in Real Industries?

Robots are no longer just science fiction—they are real, hard-working machines used in industries across the world. From factories and hospitals to farms and space stations, robots help make work faster, safer, and smarter.

At Silicon Institute UAE, students learn how the robots they build in class are connected to real-world applications. This opens doors to future careers in engineering, manufacturing, AI, and automation.

Where Are Robots Used in the Real World?

Here’s how robots are transforming major industries:

1. Manufacturing & Assembly Lines

Robots build cars, electronics, and machinery

Tasks include welding, painting, and part assembly

Benefits: Speed, precision, and no fatigue

Example: Car factories use robotic arms to assemble vehicles 24/7 with minimal errors.

2. Healthcare & Surgery

Surgical robots assist doctors in performing delicate operations

Cleaning robots disinfect hospitals

Delivery robots move medicine or food to patients

Example: The da Vinci Surgical Robot allows doctors to perform complex surgeries with robotic precision.

3. Logistics & Warehousing

Robots sort packages and manage inventory

Autonomous forklifts and carts carry goods

AI-powered bots optimize warehouse operations

Example: Amazon uses over 750,000 robots in its warehouses to speed up deliveries.

4. Agriculture & Farming

Robots plant seeds, harvest crops, and monitor soil conditions

Drones spray pesticides or scan crop health

Reduces manual labor and improves food production

Example: Agri-bots use sensors to pick ripe fruits without damaging them.

5. Construction & Infrastructure

Robots lay bricks, paint buildings, and inspect structures

Drones survey construction sites

Improves safety and reduces human error

6. Defense & Space Exploration

Robots are used in bomb disposal and surveillance

Space rovers explore planets where humans can’t go

AI and sensors help operate in extreme conditions

Example: NASA’s Perseverance Rover explores Mars to search for signs of life.

#siliconinstitute#creativelearning#stemeducationdubai#roboticsforkids#stemeducationuae#futureinnovators#codingforkids#stemeducation

0 notes

Text

The Role of Collaborative Robots (Cobots) in Modern Automotive Manufacturing

The automotive manufacturing industry is about to undergo a transformative stage after several years of precision, speed, and innovation having been the main criteria synonymous with the industry. As the pressure to produce personalized automobiles in shorter intervals, decrease the costs of operations, and to enhance safety at the workplace, assembly lines are being reconsidered by manufacturers. Among the most disruptive changes that are engulfing the industry is the adoption of collaborative robots — usually referred to as cobots. That said, what exactly are cobots in automobile manufacturing doing to the next generation of the manufactories evolution? What is the reason behind the automotive manufacturing in auto industries automation that is closely gravitating towards human-robot collaborations in the automotive environment?

This article examines why collaborative robots are not a thing of the future but are currently in the present. Cobot enriching automotive assembly has become the lynchpin of the current robotic development in car-manufacturing because of the expansion of efficiency in production, safety and flexibilities of the workers.

Understanding the Rise of Cobots in Automotive Factories

However, unlike its traditional industrial robot counterparts that have to operate in safety cage and need isolation between human operators and the robot, collaborative robots are planned to operate shoulder-to-shoulder with human colleagues. These are sensor-equipped nimble machines that are transforming the way production floors are run. Intelligent cobots for automotive industry Smart wheels can now be found sharing a workspace along with humans in many automotive factories because it can detect its environment, reacts to human intervention and can perform repetitive work in a pinpoint accurate manner. These developments are a powerful reflection of how robotics in automotive factories are being redesigned around agility and interaction.

The main difference between industrial cobots applied in line production of cars and conventional ones is adaptability. Such robots are fitted with safety devices like force-limiting sensor and AI-enabled vision systems which enable them to identify and avoid possible collision with other human workers. The combination of artificially intelligent machines and human oversight has made them quite invaluable at the international assembly lines. The adoption of industrial cobots for car production has given rise to safer, more responsive workspaces and revolutionized conventional factory norms.

Why Automotive Manufacturing Automation Needs Cobots

The ever-differentiated and elaborate car models have seen a tremendously high need to have flexible automation. The conventional robots are speedy and robust but they are mostly rigid and costly to convert to another task. Automobile production automation is involved with the automation systems that are able to keep up the pace with product modification rapidly.

That is where automotive manufacturing cobots excel. They are able to be relocated to do other jobs with little idle time. Automotive production is a bright example of customized cobot applications, as systems can be deployed to help install windshields, to tighten engine compartment bolts, and much more.

Read Full Article: https://www.automotive-technology.com/articles/the-role-of-collaborative-robots-cobots-in-modern

0 notes

Text

Exploring LCD Screen Technology: Innovation in Modern Display Solutions

In today’s digital era, LCD screen display technology has become an integral part of our everyday lives. From smartphones and tablets to industrial machines and public signage, screens built on LCD technology are everywhere. Known for their clarity, energy efficiency, and versatility, LCD screens continue to evolve to meet the growing demands of both consumer and industrial markets.

LCD (Liquid Crystal Display) screens work by manipulating light through liquid crystals, producing clear and vibrant images with minimal power consumption. Compared to older technologies like CRT, LCD screens are thinner, lighter, and much more energy-efficient. These characteristics make LCD panels ideal for portable electronics and fixed installations alike.

Among the many types of LCDs, TFT LCD (Thin-Film Transistor Liquid Crystal Display) is the most popular. A TFT panel offers faster response times, better image quality, and wider viewing angles. The term display TFT typically refers to a full-color, active matrix display used in applications like car dashboards, industrial control systems, and medical devices.

When discussing advanced displays, the touch screen display is another revolutionary development. With the integration of touch screen panels or touch panels, users can interact directly with the screen using fingers, styluses, or even gloved hands. These are particularly valuable in settings like kiosks, ATMs, factory automation, and point-of-sale systems. A touch screen panel adds both functionality and efficiency, enhancing the user interface and simplifying control systems.

For specialized uses, the transparent LCD display has emerged as a game-changer. These displays allow viewers to see both the displayed content and the objects behind the screen. Transparent LCDs are increasingly being adopted in retail displays, museums, and even smart refrigerators—offering a futuristic, engaging way to present information.

Display LCD modules come in various shapes, sizes, and technologies to meet the requirements of diverse industries. Manufacturers now offer LCD panel options ranging from small wearable screens to large-scale industrial monitors. From 1.44-inch wearables to 65-inch advertising panels, the range is vast and constantly expanding.

Industrial applications demand displays that are not only clear and bright but also rugged and reliable. LCD panel designs for industrial use are built to endure harsh environments, with features like wide temperature ranges, sunlight readability, and anti-glare coatings. These panels are often mounted with touch screen panels to enable interactive control in places like warehouses, production lines, and outdoor kiosks.

As display technology continues to innovate, LCD screen display solutions will become even more intelligent and adaptive. Integration with IoT systems, enhanced connectivity, and AI-based controls are already transforming how we use display LCD modules.

In conclusion, whether you're sourcing for a commercial project or an industrial automation system, LCD, TFT LCD, and touch screen display technologies offer reliable, customizable, and cost-effective solutions. With continuous advancements and wider adoption across industries, the future of LCD panel displays is bright, clear, and interactive.

For more LCD display information,click here.

#Hmi Screen Monitor#LCD Torch Screen Service#Panel Mount Usb Cable#Lcd Touch Panel#Touch Panel Display#LCD Module#LCD Touch Panels#14.1 Touch Screen#Plastic Injection Machine LCD#TFT LCD Monitor#LCD Touch Screen Monitors#TFT LCD Module#Industrial LCD Screen

0 notes