#AI-automated Steel ERP

Explore tagged Tumblr posts

Text

1 note

·

View note

Text

Driving Industrial Automation Forward: How Automatrix Powers the Future of Smart Manufacturing

As the manufacturing world embraces Industry 4.0, the shift toward industrial automation is no longer optional — it’s a necessity. From minimizing human errors to enabling 24x7 operations, automation is helping manufacturers boost productivity, ensure quality, and remain globally competitive.

At the core of this transformation is Automatrix Innovation, a future-ready technology partner enabling manufacturers to automate, integrate, and intelligently manage their operations. By combining robotic process automation, Analytics, and IIoT solutions, Automatrix Innovation is fast becoming a go-to name in the smart manufacturing revolution.

Why Industrial Automation is the New Normal

Global supply chains are under constant pressure — fluctuating demand, labor shortages, rising input costs, and customer expectations for faster delivery. Traditional factories, which rely heavily on manual processes, simply cannot keep pace.

Industrial automation solves this problem by digitizing and streamlining critical plant functions like:

Production line monitoring and control

Real-time asset management

Quality inspection and compliance

Energy and resource optimization

This isn’t just about replacing labor — it’s about augmenting human capability with smarter systems and decisions.

The Automatrix Approach: Smart, Scalable, Future-Proof

What makes Automatrix Innovation stand out is its comprehensive approach to industrial automation. Instead of offering fragmented tools, Automatrix provides a connected digital ecosystem built on four key pillars:

1️. Plant Digitalization

With legacy machines still prevalent in Indian factories, Automatrix Innovation offers entry-based automation and digital workflows through its Autonect Flow layer. From digital shift logs to automated production reports, it builds the base for smart operations.

2️. IIoT Solution

Through Autonect IoT, Automatrix Innovation enables seamless connectivity across machines, PLCs, and sensors using protocols like OPC, MQTT, and Modbus. This IIoT solution offers real-time data capture, condition monitoring, and downtime tracking — all on a single platform.

3️. Predictive Intelligence via Analytics

Data without context is noise. Automatrix’s Analytics engine converts machine data into actionable insights. Users get dashboards for OEE, productivity trends, maintenance KPIs, and quality benchmarks — in real time. With AI-driven anomaly detection, manufacturers can predict and prevent costly failures.

4️. Robotic Process Automation (RPA)

In addition to shop-floor automation, Automatrix Innovation delivers office automation through its 10G Robot platform. With intelligent robotic process automation, companies can automate procurement approvals, compliance reporting, invoice processing, and more. This frees up valuable time and cuts costs drastically.

🚀 Real Impact, Real Transformation

Factories powered by Automatrix Innovation have achieved measurable success across multiple dimensions:

30% reduction in machine downtime

25% faster response to maintenance alerts

20% improvement in resource utilization

100% digital shift-to-shift handovers

Upto 70% cost savings in back-office operations through robotic process automation

Whether it’s a steel plant in Jamshedpur, a cement plant in Rajasthan, or a food processing unit in Gujarat, Automatrix is driving intelligent outcomes everywhere.

Seamless Integration with Existing Ecosystems

One of the biggest fears manufacturers face is: “Will automation disrupt our current systems?” Automatrix answers that with a resounding NO.

Their solutions are designed to integrate with:

SAP, Oracle, and Tally ERPs

SCADA, MES, PLCs

Excel-based workflows and legacy CRMs

This flexibility makes it easier for manufacturers to adopt industrial automation without overhauling everything at once.

Use Case Snapshot: Smart Steel Manufacturing

A steel company using Automatrix Innovation's platform integrated its billet caster machine data with Autonect IoT. Downtime data was automatically logged. Predictive alerts for mold water leakage were generated based on temperature fluctuations. The result: Zero unplanned outages in a 6-week period — saving over ₹12 lakhs in losses.

Meanwhile, the finance department deployed robotic process automation for invoice matching, reducing manpower dependency by 60% and eliminating month-end backlog.

The Road Ahead: Industry 5.0 Ready

While most companies are still climbing the Industry 4.0 ladder, Automatrix Innovation is preparing them for Industry 5.0 — where human creativity and intelligent automation go hand-in-hand.

The roadmap includes:

Advanced Analytics with what-if scenario simulations

Digital Twin modeling for operations and energy flow

AI bots for production planning and vendor management

Sustainability dashboards for ESG reporting

In other words, not just industrial automation, but strategic intelligence for leadership-level decisions.

Why Choose Automatrix for Industrial Automation?

End-to-end solution from data capture to decision-making

Domain expertise across steel, cement, textiles, chemicals, and more

Fast deployments with hybrid cloud/on-premise options

Future-ready platforms that scale with your operations

Proven ROI across 40+ clients in India

Conclusion

The future of manufacturing belongs to those who embrace industrial automation not just as a tool, but as a strategy. With deep expertise in robotic process automation, Analytics, and IIoT solutions, Automatrix Innovation is empowering Indian manufacturers to become smarter, faster, and future-ready.

From the shop floor to the boardroom, Automatrix is not just solving problems — it’s building the intelligent factories of tomorrow.

0 notes

Text

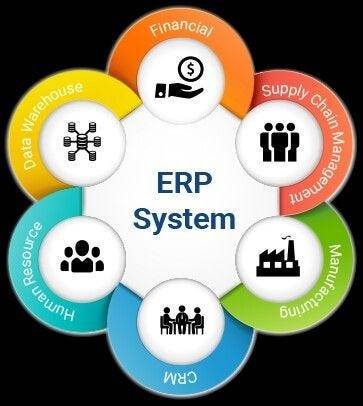

Role of Manufacturing ERP Solutions in African Industries

Africa is undergoing a manufacturing renaissance, with nations like Kenya, Rwanda, and Ethiopia taking bold steps toward industrialization. As demand grows and policies evolve, manufacturers across the continent are turning to technology to overcome long-standing challenges. Manufacturing ERP Software stands out as a transformative solution.

From inadequate infrastructure to skill gaps and fluctuating energy supplies, African manufacturers face numerous barriers. That's where ERP software in Africa plays a critical role. A powerful ERP system integrates all core business processes from finance and inventory to production and procurement ensuring efficiency, transparency, and control.

Matiyas Solutions offers industry-specific ERP systems designed to meet Africa's diverse manufacturing needs. Whether you’re in steel, textile, pharmaceutical, food, or FMCG manufacturing, our ERP solutions can optimize your operations, reduce costs, and improve quality control. We also support both cloud-based ERP for small businesses and on-premise ERP for large enterprises needing local data control.

Key benefits of implementing ERP in Africa include real-time data access, automated workflows, better supply chain visibility, and scalability for growth. With local regulations and connectivity issues in mind, our team at Matiyas ensures seamless deployment and long-term support.

As Africa moves toward smart manufacturing and Industry 4.0, ERP systems are evolving with AI, IoT, and mobile integration. These innovations promise enhanced data-driven decision-making and sustainable growth.

Matiyas Solutions is your trusted ERP partner in Africa. We bring decades of experience, domain expertise, and a commitment to digital transformation. Let us help you select and implement the best ERP system in Africa to drive operational excellence and future-proof your manufacturing business.

Contact Matiyas Solutions today for a free demo and unlock your path to growth! Read More: https://www.matiyas.com/blog/role-of-manufacturing-erp-solutions-in-african-industries/

0 notes

Text

The Secret Behind India’s Fastest-Growing Bolt Suppliers

Have you ever stopped to think about what holds our bridges, buildings, cars, and even machinery together? The humble bolt plays a massive role behind the scenes. And right now, India is seeing an explosion in demand, with some bolt suppliers growing faster than ever. But what's their secret? Let’s take a deep dive into what’s really driving this booming success.

Understanding the Bolt Industry in India

What Are Industrial Bolts?

Bolts aren’t just screws with a fancy name. They’re precision-engineered fasteners designed to withstand extreme forces. Whether it’s holding steel beams or being part of an automobile engine, bolts are the unsung heroes of the industrial world.

Role of Bolts in Industrial Applications

Bolts are critical in sectors like construction, automotive, oil & gas, aerospace, and even renewable energy. They ensure safety, durability, and reliability, the foundation of any solid infrastructure.

Market Landscape: The Surge in Demand

Construction Boom and Infrastructure Growth

India is undergoing rapid urban development, from smart cities to metro projects. And guess what every project needs? Bolts. The growth in infrastructure has created a ripple effect, sending bolt demand through the roof.

Automotive and Engineering Sectors Fueling Demand

India's rise as a global auto manufacturing hub means more machinery, more parts, and yes, more bolts. Engineering exports, heavy equipment, and public sector investments are also fueling this upward trend.

Technology: The Game Changer

Automation in Manufacturing

Modern bolt suppliers invest in CNC machines, robotic arms, and advanced QC tools. This minimizes error and speeds up production, a winning combo.

Smart Inventory & Logistics Systems

Tech-savvy suppliers use ERP systems and AI to track inventory, predict demand, and deliver faster. No more waiting weeks for an order to show up.

Quality: The Uncompromising Factor

ISO Certifications & Global Standards

Fast-growing suppliers understand the power of certification. ISO 9001, IATF 16949, and other standards aren’t just fancy badges; they scream quality assurance to clients worldwide.

Raw Materials and Precision Engineering

Using high-grade steel, following exact torque requirements, and investing in in-house labs for testing give these companies an edge. They don’t just meet specs, they exceed them.

Exports: Going Global

Countries Driving Indian Bolt Exports

Indian bolts are in demand across the U.S., Middle East, Europe, and Africa. Exporters are capitalizing on lower labor costs and high product quality to make serious global gains.

Compliance with International Norms

To break into global markets, companies follow ASTM, DIN, BS, and JIS standards. Quality checks and proper documentation are key here.

Sustainability and Green Manufacturing

Eco-Friendly Coating & Processes

Zinc-nickel plating, solvent-free painting, and chromium-free coatings are now common. It’s about being strong on sustainability, not just on paper, but in practice.

Waste Reduction and Energy Efficiency

Recycling scrap, using solar energy, and optimizing water use make these manufacturers more efficient and eco-conscious.

The Future of Bolt Manufacturing in India

AI, IoT, and Predictive Maintenance

The next-gen bolt factories are connected, smart, and self-diagnosing. Using IoT sensors and AI helps them predict machine issues and avoid downtime.

Bolt Supplier with Heavy-Duty Strength

Bhansali Fasteners is a trusted Bolt Supplier in India, known for delivering high-quality and durable fastening solutions for various industries, including construction, automotive, and heavy machinery. As one of the leading bolt manufacturers in India, we offer a comprehensive range of bolts that meet international standards and are available in various sizes, materials, and coatings to suit specific project requirements.

The company’s core function is to manufacture and supply premium-grade bolts that ensure strength, reliability, and safety in all applications. With a strong commitment to quality, innovation, and customer satisfaction, we have built a reputation for being a dependable Bolt Supplier in both domestic and international markets.

Using advanced technology and a skilled workforce, the company maintains strict quality control throughout the manufacturing process. Whether it's standard bolts or customized fastener solutions, we ensure timely delivery and competitive pricing.

If you're looking for a reliable bolt supplier in India, Bhansali Fasteners is your ideal partner for industrial and commercial bolt requirements. Their experience and commitment to excellence make them a preferred choice among engineers, builders, and procurement professionals across the country.

We are also a Bolt Supplier in Saudi Arabia, Bolt Supplier in UAE.

So, what’s the secret behind India’s fastest-growing bolt suppliers? It’s not just one thing, it’s a cocktail of quality, innovation, customer focus, tech adoption, and global ambition.

0 notes

Text

Why Allied Ispat India Stands Out as a Trading Coil Manufacturer in India for Prefab & Smart Cities

Introduction: Allied Ispat India – Trading Coil Manufacturer in India Leading the Future of Smart Steel Supply Chains

Allied Ispat India, a name trusted by industrial giants and infrastructure pioneers, is setting new benchmarks as a top-tier Trading Coil Manufacturer in India. As industries race toward automation, prefabrication, and sustainable construction, the demand for intelligent steel solutions is stronger than ever. Allied Ispat India rises to the occasion by integrating cutting-edge technologies like AI, smart systems, and automation to redefine how steel coils are traded, processed, and utilized in modern manufacturing and construction.

In this blog, we explore how Allied Ispat India empowers businesses to stay ahead with tailor-made trading coils designed for prefabricated housing, modular infrastructure, and Industry 4.0-compatible manufacturing environments. We dive deep into how our brand is helping businesses reduce costs, improve delivery speed, and enhance product longevity through innovation.

Smart Coil Manufacturing: Revolutionizing the Indian Steel Market

In the age of digitization, traditional manufacturing alone cannot meet the evolving needs of industrial buyers. Allied Ispat India leverages smart production systems to maintain a consistent edge.

AI-Powered Coil Processing: We employ intelligent systems to control decoiling, slitting, and recoiling machines for enhanced precision and consistency.

Automated Quality Checks: With real-time sensors and machine vision, each batch undergoes automated inspection to meet strict dimensional tolerances.

Cloud-Based Inventory Tracking: Our digital inventory is updated live, enabling proactive stock management and reducing lead times.

Smart Labeling for Traceability: Barcoded coils allow our clients to trace every shipment back to production data and material origin.

Energy-Efficient Steel Handling: Automated workflows reduce energy consumption while maintaining high throughput for large-scale projects.

Reinventing Industrial Supply with Digitalized Logistics

Industrial clients need more than just steel; they need streamlined logistics, predictive stocking, and transparency. Allied Ispat India delivers on all fronts.

ERP-Driven Fulfillment Process: Orders are tracked via an integrated enterprise resource planning system, ensuring smooth communication and dispatch.

Predictive Demand Planning: Using AI algorithms, we forecast supply needs and optimize dispatch cycles for each region.

Secure Digital Documentation: Invoices, test reports, and shipping documents are sent digitally for hassle-free procurement.

Client Portal Access: Regular customers get secure access to our digital portal for order status, stock availability, and batch certificates.

Geo-Fencing for Transport Safety: Our fleet is monitored in real time to ensure safe, timely deliveries across India and abroad.

Supporting the Prefab & Modular Boom with Tailored Coil Solutions

India’s rising interest in prefab construction and modular buildings is transforming how steel is applied in infrastructure. Allied Ispat India plays a central role in this shift.

Pre-Coated and Galvanized Coils: Our coils are corrosion-resistant and ideal for external cladding, roofing, and wall systems.

High Tensile Strength: Engineered for framing, our coils provide load-bearing strength in modular housing structures.

Lightweight for Easy Installation: Reduced thickness without compromising structural integrity ensures quicker prefab assembly.

Versatility in Application: Coils are compatible with roll forming, bending, punching, and other automated fabrication processes.

Weatherproofed Products: Our coils maintain integrity under extreme environmental conditions, including coastal and desert zones.

Precision Customization: Sizing, Slitting, and Finishing

Allied Ispat India understands that no two industrial clients have the same requirements. Our ability to deliver exact coil dimensions makes us a preferred choice.

Slitting Tolerances Within Microns: Coils are slit to exact widths to fit diverse industrial applications like ductwork, shelving, and automotive components.

Multi-Gauge Options: From ultra-thin sheets to heavy-gauge coils, we provide a complete range of thicknesses for both light and heavy industries.

Protective Film Wrapping: Coils are wrapped with anti-scratch films for safe transport and storage.

Precision Recoiling: Recoiling is done with uniform tension to prevent shape distortion during unwinding.

Tailored Coil Lengths: Whether you need small batch cuts or full-length jumbo coils, we deliver as per your exact specifications.

Industry Certifications & Quality Compliance

Allied Ispat India ensures every coil meets global benchmarks. Our quality assurance programs help clients maintain regulatory compliance across various markets.

ISO 9001:2015 Certified Facility: Ensures quality consistency across procurement, production, and dispatch.

Regular In-House Testing: Tests for elongation, yield, tensile strength, and coating thickness.

Independent Lab Certifications: Third-party validation on chemical and mechanical properties as per BIS, ASTM, JIS, and EN standards.

Batch-Level Documentation: Every coil comes with MTC (Material Test Certificates) and barcoding for traceability.

Eco-Friendly Compliance: Our steel is RoHS compliant, suitable for international markets focusing on sustainability.

Versatility of Allied Ispat Coils Across Sectors

Our coils are not just for construction – they serve diverse industries that demand strength, finish, and reliability.

Automobile Sector: Used in chassis frames, panels, and fuel tank components.

Appliances and Consumer Goods: Ideal for refrigerators, ovens, and metal casings.

Infrastructure & Smart Cities: For metro rail roofing, light poles, ducts, and street furniture.

Solar & Renewable Energy: Galvanized coils used in panel mounting structures and shelters.

Pre-Engineered Buildings: Support both purlins and roof sheeting with high load-bearing performance.

Why Industrial Buyers Trust Allied Ispat India

Our long-standing reputation in India’s steel market is backed by performance, service, and innovation.

Consistent Coil Availability: With well-stocked warehouses and scalable production capacity, clients face no downtime.

Custom Contracts for Bulk Buyers: Structured agreements for repeat clients including credit terms, dispatch schedules, and pricing.

After-Sales Technical Support: Our engineering team supports clients in coil application, roll forming compatibility, and thickness optimization.

Dedicated Relationship Managers: Every B2B partner is assigned a personal representative for seamless communication.

Global Export Ready: Our packing, labeling, and documentation meet international shipping and customs standards.

Strategic Fit for Prefab and Fast Track Projects

Prefab projects demand speed, reliability, and quality values that Allied Ispat India delivers consistently.

Disaster-Relief Housing: Lightweight coils speed up assembly of emergency shelters.

Portable Office & Retail Units: Coils are used in sandwich panel systems for pop-up commercial setups.

Industrial Warehouse Construction: Our coils form structural and external panels in wide-span buildings.

Green Construction Initiatives: Using recyclable steel for sustainable modular building practices.

Cold Chain & Insulation Units: Moisture-resistant coils are ideal for refrigerated enclosures.

Final Thoughts: Building Tomorrow with Allied Ispat India

As a pioneering Trading Coil Manufacturer in India, Allied Ispat India has evolved into a critical partner for B2B manufacturers, infrastructure developers, and modular builders. Our focus on quality, innovation, and customer-first service ensures we remain ahead in an ever-demanding market.

If you're looking for reliable steel trading coils that match your project timelines, structural needs, and compliance benchmarks, Allied Ispat India is your ideal partner.

Connect with Allied Ispat India Today

Corporate Office: Allied Ispat Mumbai Central 69, Chotta Sonapur, Maulana Shaukat Ali Road, Mumbai - 400008 Phone: +91 98211 77009

Manufacturing Unit: Plot No. C-17/9, MIDC Taloja, Behind Bank of Baroda, District Raigad - 410208 Phone: +91 87790 51606

Direction Link: Click Here Website: https://alliedispatindia.com

0 notes

Text

From Work Orders to Final Dispatch: A Step-by-Step ERP Integration Guide

In today’s fast-paced manufacturing industry, managing work orders, production, inventory, and dispatch manually can lead to inefficiencies, delays, and higher costs. An ERP system integrates all these processes into a single streamlined workflow, ensuring faster production cycles, accurate order tracking, and on-time deliveries.

In this blog, you’ll learn:

✔ How ERP automates and optimizes each stage of manufacturing ✔ Step-by-step integration from work order creation to dispatch ✔ Real-world benefits of ERP-driven production workflows

Step 1: Work Order Creation & Scheduling

📌 Manual Challenge:

Tracking work orders manually can lead to missed deadlines, incorrect job allocations, and inefficient production planning.

✅ ERP Solution:

Auto-generated work orders based on sales orders or MRP (Material Requirement Planning).

AI-powered production scheduling to optimize machine and labor utilization.

Live dashboard for tracking work orders in real time.

🔹 Example: A capital goods manufacturer receives a bulk order. The ERP automatically generates work orders, assigns tasks to machines, and schedules operators for seamless execution.

Step 2: Material Requirement Planning (MRP) & Procurement

📌 Manual Challenge:

Stock shortages or overstocking due to inaccurate demand forecasting.

Procurement delays leading to stalled production.

✅ ERP Solution:

Automated MRP calculates required materials based on BOM (Bill of Materials) and order demand.

Smart procurement system triggers purchase orders to suppliers.

Supplier management & tracking ensure on-time raw material availability.

🔹 Example: An auto-component manufacturer needs precision steel parts. The ERP automatically places purchase requests to pre-approved vendors, ensuring just-in-time inventory.

Step 3: Production Execution & Quality Control

📌 Manual Challenge:

No real-time tracking of production progress.

Inconsistent quality checks lead to defects and rework.

✅ ERP Solution:

Workstation-wise tracking to monitor each production stage.

Automated quality control checks with defect detection alerts.

Live production dashboards to ensure on-time completion.

🔹 Example: A processing industry uses ERP to track heat treatment cycles in real time, reducing rejection rates by 30%.

Step 4: Job-Work Outsourcing & Vendor Collaboration

📌 Manual Challenge:

Difficulty in tracking subcontracted job-work and vendor performance.

High costs due to poor vendor coordination.

✅ ERP Solution:

Job-work tracking module assigns work to vendors and monitors progress.

Real-time vendor communication portal ensures smooth coordination.

Automated material reconciliation prevents losses.

🔹 Example: A machine parts manufacturer outsources anodizing. The ERP ensures live job tracking and accurate costing.

Step 5: Inventory & Warehouse Management

📌 Manual Challenge:

Inaccurate stock levels leading to order fulfillment errors.

Warehouse mismanagement causing delays in locating items.

✅ ERP Solution:

Barcode/RFID-enabled inventory tracking for real-time stock updates.

Automated warehouse workflows optimize storage space and movement.

Dynamic stock alerts prevent shortages or overstocking.

🔹 Example: A furniture manufacturer uses ERP to track finished goods inventory and optimize warehouse space utilization.

Step 6: Order Processing & Dispatch Planning

📌 Manual Challenge:

Shipping delays due to poor order visibility.

Frequent mismatches between invoices and shipments.

✅ ERP Solution:

Order-to-dispatch automation ensures correct picking, packing, and shipping.

AI-based route optimization reduces logistics costs.

Digital invoicing and documentation ensure compliance.

🔹 Example: A consumer goods manufacturer automates dispatch scheduling in ERP, cutting delivery lead times by 20%.

Step 7: Customer Tracking & After-Sales Support

📌 Manual Challenge:

Difficult to track warranty claims and service requests.

Delayed response times affect customer satisfaction.

✅ ERP Solution:

Integrated CRM module tracks warranty claims and service history.

AI-driven analytics improve predictive maintenance.

Customer portal enhances after-sales engagement.

🔹 Example: A medical device manufacturer uses ERP for predictive service scheduling, reducing downtime for hospitals.

Real-World Impact: How ERP Transforms Manufacturing Efficiency

🏭 A capital equipment manufacturer faced delays in production and dispatch due to poor coordination. After implementing PrismERP, they achieved:

✔ 30% faster production cycle with automated scheduling. ✔ 50% reduction in inventory costs through optimized MRP. ✔ 20% lower defect rates with AI-powered quality control. ✔ 35% improvement in on-time deliveries using smart dispatch planning.

🚀 Result: Increased efficiency, reduced costs, and better customer satisfaction!

Final Thoughts: Why ERP is a Must for End-to-End Manufacturing Control

🔹 Challenges Without ERP ❌ 🚫 Poor work order tracking & scheduling inefficiencies. 🚫 Frequent material shortages & procurement delays. 🚫 High defect rates due to inconsistent quality control. 🚫 Lack of visibility into outsourced job-work. 🚫 Inefficient inventory & warehouse management. 🚫 Shipping delays & inaccurate dispatch planning.

✅ How an ERP Solves These Issues ✔ Automates work orders & schedules production efficiently. ✔ Optimizes procurement & ensures just-in-time inventory. ✔ Enhances quality control with real-time defect detection. ✔ Streamlines job-work tracking & vendor coordination. ✔ Improves dispatch planning & customer service.

🚀 Upgrade to PrismERP for a Smarter, Faster, and More Reliable Manufacturing Process!

🔹 Want to see ERP in action?

📢 Book a Free Demo of PrismERP & Transform Your Manufacturing Operations Today!

0 notes

Text

7 Key Features to Look for in Steel Industry ERP Software

In the intensely competitive steel production industry, companies need ERP software that can automate production, inventory, and supply chain management. A powerful Steel Industry ERP system improves efficiency, cost management, and real-time tracking of data to ensure streamlined operations. The right ERP software is important for steel producers who want to maximize processes and profitability.

Following are seven important features to look for in an ERP for the steel industry.

Production Planning & Scheduling Optimized production planning plays a critical role in steel manufacturing to attain best-in-class resource utilization, minimal waste generation, and high productivity. Real-time scheduling, forecasting of demands, and machine usage monitoring have to be provided by an ERP system to efficiently manufacture steel.

Inventory & Material Management A robust ERP for steel production offers precise inventory management, raw material purchasing, and stock optimization. It ensures smooth supply chain coordination, minimizing material shortages and excess inventory expenses.

Supply Chain & Logistics Integration Steel supply chain operations are difficult to manage because of bulk transport and varying demand. A Steel Industry ERP must incorporate logistics tracking, supplier management, and automated order processing to improve efficiency and delivery schedules.

Quality Control & Compliance Management Quality standards must be high in steel manufacturing. The ERP system should facilitate real-time quality control, compliance tracking, and defect analysis to guarantee adherence to industry regulations and customer requirements.

Cost & Financial Management Cost structures are complicated in steel manufacturing. An ERP for steel manufacturers must facilitate cost analysis, budgeting, expense tracking, and automated financial reporting to enhance profitability and cost control.

Real-Time Data & Business Intelligence An updated Steel ERP solution should provide real-time data analytics, reporting dashboards, and AI-driven insights to support informed decisions and streamline production efficiency for manufacturers.

Customization & Scalability Each steel business will have special requirements. The perfect ERP software must be customizable and scalable to help manufacturers adapt to changing markets, business growth, and emerging technology.

Conclusion

Selecting an appropriate ERP for the steel sector is vital for enhancing productivity, efficiency, and cost-effectiveness. An efficiently integrated Steel Industry ERP solution integrates production, inventory, and supply chain management, while guaranteeing compliance and real-time decision support.

#SteelIndustryERP#ERPForSteelManufacturing#SteelManufacturingSoftware#SteelERPSystem#ERPForManufacturingIndustry#SteelProductionPlanning

0 notes

Text

Top ERP for Steel Industry: Boost Efficiency & Profits with Smart Solutions

The steel industry is one of the most complex and competitive manufacturing sectors, requiring advanced resource planning, inventory control, supply chain management, and cost optimization. Managing operations manually or using outdated systems leads to inefficiencies, higher costs, and production delays.

To stay ahead in this competitive landscape, implementing a powerful ERP system for the steel industry is essential. ERP software streamlines business processes, enhances productivity, and improves profitability. In this blog, we will explore the benefits, features, and top ERP solutions for the steel industry.

Why Does the Steel Industry Need ERP?

Steel manufacturing involves raw material procurement, production, inventory management, sales, and distribution. Without a well-integrated system, managing these complex operations becomes a challenge.

A steel industry ERP system centralizes data, automates workflows, and provides real-time insights, helping businesses tackle:

✔ Fluctuating Raw Material Prices – Managing iron ore, coal, and scrap metal price changes. ✔ Complex Production Processes – Handling various grades, alloys, and production cycles efficiently. ✔ Supply Chain Disruptions – Ensuring smooth logistics and timely material procurement. ✔ Regulatory Compliance – Adhering to strict industry safety and environmental regulations. ✔ High Operational Costs – Controlling energy consumption and manufacturing expenses.

Key Benefits of ERP for the Steel Industry

An ERP solution tailored for the steel sector offers multiple advantages, transforming business operations:

1. Streamlined Inventory & Material Management

Monitors real-time stock levels for raw materials, semi-finished, and finished products.

Reduces material wastage and overstocking issues.

Automates stock replenishment alerts to avoid shortages.

2. Optimized Production Planning & Scheduling

Automates batch production scheduling for efficiency.

Reduces downtime and resource wastage.

Tracks real-time production performance for quick adjustments.

3. Enhanced Supply Chain & Logistics Management

Improves vendor management and procurement tracking.

Enhances demand forecasting for better material planning.

Reduces logistical delays and transportation costs.

4. Advanced Quality Control & Compliance

Ensures compliance with ISO, ASTM, and industry safety standards.

Automates quality testing and defect tracking.

Maintains detailed audit reports and regulatory documentation.

5. Cost & Financial Management

Provides real-time expense tracking and budgeting tools.

Helps optimize cost distribution across production stages.

Reduces overall operational and manufacturing costs.

6. Real-Time Business Intelligence & Reporting

Generates customized reports for financials, production, and sales.

Offers AI-powered analytics for better decision-making.

Tracks market trends and demand fluctuations.

Must-Have Features in an ERP for Steel Industry

To ensure maximum efficiency, a steel industry ERP should include:

✔ Material Requirement Planning (MRP) – Optimizes raw material usage. ✔ Production & Process Automation – Streamlines workflows for better output. ✔ Supply Chain & Vendor Management – Enhances procurement and logistics. ✔ Financial Management & Accounting – Tracks costs, revenue, and profitability. ✔ Quality Control & Compliance Management – Ensures product standards and regulations. ✔ CRM & Sales Management – Strengthens customer relationships and sales tracking. ✔ Business Intelligence & Analytics – Provides real-time insights and reports.

Top ERP Solutions for the Steel Industry

Here are some of the best ERP systems designed for steel manufacturers:

1. SAP S/4HANA

✔ AI-driven real-time analytics and reporting. ✔ Best suited for large steel enterprises. ✔ Advanced supply chain and financial management tools.

2. Oracle ERP Cloud

✔ Highly scalable and cloud-based. ✔ Strong integration with third-party applications. ✔ Best for steel manufacturers with complex supply chains.

3. Microsoft Dynamics 365

✔ User-friendly and best for mid-sized steel businesses. ✔ Offers seamless integration with Microsoft tools. ✔ AI-powered business intelligence and data analytics.

4. Infor CloudSuite Industrial

✔ Tailored for process manufacturing industries. ✔ Powerful inventory and supply chain management tools. ✔ Ensures strict quality control and compliance adherence.

5. Epicor ERP

✔ Ideal for steel fabrication and production tracking. ✔ Highly customizable with intuitive dashboards. ✔ Offers excellent cost and energy management features.

How to Choose the Right ERP for Your Steel Business?

When selecting an ERP system for the steel industry, consider the following factors:

✔ Customization & Flexibility – Ensure the ERP can be tailored to your production needs. ✔ Scalability – The software should grow with your business. ✔ User Experience – An easy-to-use system boosts employee adoption. ✔ Integration Capabilities – The ERP should work with your existing systems. ✔ Data Security & Compliance – Protects sensitive business data and ensures regulatory compliance.

The Future of ERP in the Steel Industry

With digital transformation accelerating, modern ERP solutions are integrating AI, IoT, and cloud computing for better efficiency, real-time tracking, and automated workflows. The future of steel manufacturing will be:

✔ Cloud-based for remote access. ✔ AI-driven for predictive analytics. ✔ Automated for increased productivity and cost efficiency.

Implementing an ERP system for the steel industry is no longer an option—it’s a necessity for businesses looking to scale and maximize profits. If you want to revolutionize your steel manufacturing processes, invest in the right ERP today! 🚀

#ERP for steel industry#steel manufacturing ERP#steel ERP software#best ERP for steel industry#ERP for metal industry#steel plant ERP system#ERP solution for steel business

0 notes

Text

Choosing the Right Automatic Tablet Inspection Machine: Key Factors for Efficiency and Accuracy

Introduction

In the pharmaceutical industry, ensuring product quality and compliance with regulatory standards is paramount. Automatic Tablet Inspection Machines (ATIMs) play a crucial role in maintaining consistency, detecting defects, and improving production efficiency. However, selecting the right ATIM requires careful evaluation of various factors to maximize accuracy, efficiency, and compliance.

1. Inspection Capabilities and Accuracy

The primary function of an automatic tablet inspection machine is to inspect tablets for defects, inconsistencies, and contamination. When evaluating a machine, consider:

Defect detection precision – Can it identify cracks, chips, discoloration, and coating inconsistencies?

Dimensional accuracy – Can it detect size and shape deviations?

Foreign particle detection – Does it use hyperspectral or infrared imaging to identify contaminants?

High-resolution cameras, AI-driven machine vision, and multi-angle inspection capabilities improve detection accuracy.

2. Speed and Throughput Capacity

Pharmaceutical manufacturers need ATIMs that can keep up with production demands. Key factors to assess include:

Inspection speed (tablets per minute) – Ensure it matches your production line’s capacity.

Batch processing ability – Can it efficiently handle large volumes without performance degradation?

Automated rejection systems – Does it swiftly remove defective tablets without halting production?

Selecting an ATIM with high-speed processing and minimal false rejections enhances operational efficiency.

3. Machine Vision and AI Integration

Modern ATIMs leverage AI and machine vision to improve accuracy and adaptability. Look for:

Deep learning algorithms that refine defect detection over time.

Multi-spectral imaging for comprehensive inspection beyond human-visible defects.

Real-time analytics and reporting for continuous quality improvement.

AI-driven ATIMs reduce manual intervention, minimize errors, and optimize defect classification through adaptive learning.

4. Regulatory Compliance and Traceability

Compliance with international regulatory bodies like FDA, EMA, and WHO is crucial. Ensure the machine supports:

21 CFR Part 11 compliance (electronic records and signatures).

Comprehensive audit trails for full inspection history.

Cloud connectivity for remote monitoring and data storage.

Choosing an ATIM that aligns with regulatory requirements helps avoid penalties, recalls, and compliance issues.

5. User-Friendliness and Integration with Production Lines

A well-designed ATIM should be easy to operate and integrate seamlessly into your existing manufacturing process. Consider:

Intuitive touchscreen interface with multi-language support.

Automated calibration and self-learning capabilities.

Compatibility with existing production lines and ERP systems.

User-friendly machines reduce operator training time and improve overall efficiency.

6. Durability, Maintenance, and Cost of Ownership

The long-term reliability of an ATIM depends on build quality and maintenance requirements. Assess:

Robust construction materials (stainless steel, corrosion-resistant components).

Ease of maintenance and availability of spare parts.

Energy efficiency and operational cost savings.

Investing in a durable, low-maintenance machine reduces downtime and ensures long-term cost-effectiveness.

7. Customization and Scalability

Different pharmaceutical manufacturers have unique requirements. Consider an ATIM that offers:

Modular design for future upgrades.

Customization options based on tablet size, shape, and coating requirements.

Scalability to adapt to increased production demands.

Choosing a scalable machine ensures long-term investment protection as your business grows.

Conclusion

Selecting the right Automatic Tablet Inspection Machine requires evaluating key factors such as inspection accuracy, speed, AI integration, regulatory compliance, user-friendliness, durability, and scalability. Investing in a high-quality ATIM ensures consistent product quality, regulatory adherence, and efficient production. By carefully considering these aspects, pharmaceutical manufacturers can enhance operational efficiency, reduce defects, and maintain a competitive edge in the industry.

0 notes

Text

In Industry 4.0, Steel ERP systems transform steel manufacturing by integrating IoT, AI, and big data. These systems enable real-time monitoring, predictive maintenance, and supply chain optimization. By leveraging digital twins and smart factories, Steel ERP enhances efficiency, reduces downtime, and improves quality, driving innovation and competitiveness in the digital age

#modern ERP#Steel Business#ERP Automation#Steel Industry#Production ERP Software#Steel ERP 4.0#ERP Systems#Artificial Intelligance

0 notes

Text

Looking For The Best ERP software Company in Delhi? Look No Further!!

ERP refers to Enterprise Resource Planning and such software find favour among industries to transform their workflow as smoother streams. In modern times, by involving any prominent ERP software development company, one can gain a range of business aspects, such as Business Intelligence (BI), Artificial Intelligence (AI), Internet of Things (IoT) and automation which makes it a single- stop solution for a wide array of needs as required by modern day business.

Talking of Delhi, there are scores of major industries located in Delhi and to empower these industries, a prime digital solution is called for, that would pave the way for industrial automation, industry 4.0 and a bunch of robust analytics. Clearly, ERP software application is a flawless digital solution that helps business corporations across the world to manage and monitor all types of operations.Digital platforms are fast gaining popularity and industries look for a solution that would infuse more business efficiency into their business handling. ERP software development company in Delhi is a highly sought after resource for such a purpose, as business corporations look for automation at all levels. Not only this, but ERP solutions also help companies in prioritizing the tasks and resources are utilized in the best manner to boost output and to secure great results.

How is ERP Software a great help to us?

Within the ERP, modules are designed, which are connecting points to departments and divisions present inside the company. Such interconnected modules anthology, establish swift communication within with crucial data access ensured and productivity is being focussed upon. As a result, industry delays are avoided and growth occurs and balance sheets are made appealing with great profits. In the same way, there is Business Intelligence, which helps in easy data analysis and reflects numerous insights that enable the best decision making in the best possible time.

No doubt, with the automation aspect etched in ERP software, we can reduce workforce involvement and can prevent delays too as industry gets to accomplish tasks that would be time-consuming otherwise. Now, we have the Internet of Things, which helps us in overlooking the operations and with this, ERP software can be used to alert the target personnel if any error occurs in any of the devices or at any point and disasters and accidents can be checked.

Which is the best ERP software company in Delhi?

IT Nucleus is considered among the leading ERP software providers, which has enabled numerous industries by unleashing tailor-made ERP application software to suit end needs. Not only the software that we design, but a wholesome experience through it, is carved out which uncovers a range of insights. In fact, since 2010, our ERP software is continuously evolved and is now fully equipped to take control of your business needs. Every business is run by individuals who have different plans and strategies and therefore ERP needs to be customized for such a purpose.

As we have completed around 3K ERP projects so far for various companies across industries, we are fully equipped in unrolling affordable solutions to time your business performance such as ERPs, CRMs, HRMS and other mobility solutions. We meticulously plan business modules by utilizing all resources that are at our disposal which streamline business functions effectively. For such a reason, many of our clients speak so highly of us as the best ERP software development company in Delhi NCR.

For instance, in the plastic industry, textile industry, steel industry, fastener industry, trade and commerce, civil engineering and so forth, an integrated ERP application that is loaded with prime function must to guide ahead. Such players need customized ERP solutions to move ahead and at the back, IT Nucleus has been taking their care since 2005 with our utmost skill.

For more info and details, please call us and experience the change in your operations.

0 notes

Link

Enterprise Resource Planning a.k.a ERP is software that enables industries to control and monitor their operations and smoothen the workflow. ERP software is extremely effective in larger industries where myriad intricate operations take place simultaneously. ERP software is continuously upgrading, and ERP software these days cater to all the modern requirements of industries. ERP is not just software, but a one-stop standalone solution to industries that require a helping hand to complete its operations.

ERP software relies on its modules for working. Modules in ERP software connect various divisions and departments to form a interconnected network. This helps all the divisions and departments in easy and seamless communication. These modules are finance & accounts, inventory management, production planning, supply chain management, and logistics and movement. These modules supply necessary information to each other automatically so that ERP software can help in smoother operations in industry.

ERP software is constantly upgrading to render all the services to digital and modern industry. These are some of the trends listed below to make ERP more robust.

Cloud Adoption or Cloud ERP Traditionally ERP software was implemented on-premise or in the industry of the client. Though offering a complete solution to operations in the industry, on-premise implementation of ERP software has some drawbacks. Data security is a major demerit of the on-premise installation of ERP. As on-premise ERP software is installed locally, all the data and information has to be handled by the client, which can pose a major threat in data safeguarding and data security. Furthermore, mobile accessibility can also be a problem with the on-premise installation of ERP. Cloud-based ERP solves the majority of problems for the client as well as for ERP vendors. Information and data are safe, stored on the cloud and regular back-ups are performed on data to ensure the safety and security of data. Cloud-based ERP is also quick to implement and saves the total cost of implementation as the client does not require additional hardware as the installation is done by a vendor and also hosted by the vendor. These advantages give cloud-based ERP an edge over the traditional on-premise installation of ERP software.

Direct Machine Integration or IoT (Internet of Things) Direct machine integration or the Internet of Things refers to a way of connecting computers and machines directly with each other. IoT is in a boom in today’s digital era, and integrating it with ERP software can aid the ERP software in performing better and efficiently. Internet of Things seamlessly works with ERP software to avoid major problems and flaws which were earlier ignored by ERP manufacturers. IoT integration in ERP software can give a major uplift to the working and functioning of ERP software. IoT provides real-time information and statistics by tracking assets, machine, and equipment. Industries like the steel industry, manufacturing industry, and plastic manufacturing industry can relay information in real-time to ERP software related to any malfunctioning during the manufacturing process. This makes ERP software more competent in its working and helps the industry to avoid any type of disaster during the manufacturing process. When IoT coupled with ERP software, an effective solution can be obtained. This makes IoT and ERP software a good pair to implement in future ERP. Internet of Things is the best feature to couple with manufacturing ERP software.

Mobile ERP solutions Mobile phones or cell phones are the future of technological advancement. Every user is mobile dependent in the current era, and mobile solutions are becoming more and more efficient. People these days rely heavily on mobile phones or laptops as it gives a great degree of portability. Portable devices are becoming popular due to their convenience. With the era of instant access to information, large companies are providing mobile integrated solutions to their clients to facilitate quick results. ERP software is also moving towards complete mobiles solutions. The features like quick notification and alerts in ERP software are gaining popularity due to real-time notification alerts to the user. A person or group of people can easily manage the operations in the industry from their mobile devices instead of using computers which is not possible every time. ERP software can push notify, lets you create events, manage sales and approve orders from mobile phones. This makes mobile ERP solutions a necessity and a trend of 2021 in ERP software.

Artificial Intelligence Artificial Intelligence or AI is booming in every industry. We do not have cars that can drive themselves without any human intervention, or machines that are coded to complete operations without any human interaction. This makes AI a powerful tool to have in ERP software. AI can easily bring on absolute automation and machine learning coupled with AI can prove tremendously efficient. A great AI will not only facilitate easy working but also can shed down a plethora of work. Artificial Intelligence when integrated with ERP software, can take decisions, work faster, and make fewer mistakes. AI can greatly help in sales and marketing by introducing a new form of marketing to improve the overall performance of sales and marketing. Inventory management can also improve with the integration of Artificial Intelligence with ERP software. AI greatly reduces the risk of over or under production, plus procurement of raw material becomes easy with the help of AI. Artificial Intelligence can also help in sending promotional bulk emails and SMS to clients to let them know about new updates.

Conclusion

Putting 2021 trends in ERP laconically, the above mentioned trends will give major boost in working of ERP software. ERP software has already proven to be effective solutions to all the industries, and implementing and integrating these features into ERP software will further enhance the functionality of ERP software.

Digital Trend in ERP

0 notes

Text

Best ERP for Steel Industry: Top Features & Benefits You Must Know

Introduction to ERP for Steel Industry

The steel industry is one of the most complex and demanding manufacturing sectors, requiring robust solutions to manage production, inventory, supply chain, and compliance efficiently. Implementing Enterprise Resource Planning (ERP) software tailored to the steel industry can streamline operations, reduce costs, and improve overall efficiency.

Why the Steel Industry Needs ERP Software

The steel industry faces multiple challenges that can be effectively addressed with a specialized ERP system:

Complex Inventory Management: Managing raw materials, semi-finished, and finished goods efficiently.

Quality Control: Ensuring high-quality standards through real-time monitoring.

Production Planning & Scheduling: Optimizing production cycles for better productivity.

Supply Chain Management: Coordinating suppliers, vendors, and distributors efficiently.

Regulatory Compliance: Meeting government regulations and environmental standards.

Key Features of ERP for Steel Industry

When choosing an ERP system for the steel industry, consider the following essential features:

1. Raw Material & Inventory Management

Automated stock tracking to manage coils, sheets, and billets.

Forecasting tools to optimize inventory levels and prevent shortages or excess stock.

Barcode & RFID Integration for real-time tracking.

2. Production Planning & Control

Dynamic scheduling to maximize efficiency.

Bill of Materials (BOM) management for accurate planning.

Real-time monitoring to identify production bottlenecks.

3. Quality Control & Assurance

Defect tracking and rejection analysis.

Automated quality checks at every stage of production.

Compliance tracking for safety standards.

4. Supply Chain & Logistics Management

Seamless integration with suppliers and vendors.

Automated purchase orders and delivery tracking.

Route optimization for efficient distribution.

5. Finance & Accounting Management

Automated invoicing and billing.

Cost analysis tools for profit margin optimization.

Tax compliance & reporting features.

6. Sales & Customer Relationship Management (CRM)

Quotation & order management.

Customer service tracking and feedback integration.

Sales forecasting & analytics.

7. Regulatory & Compliance Management

Environmental regulations tracking.

Occupational safety compliance tools.

Automated documentation for audits.

Benefits of Implementing ERP for Steel Industry

An ERP system brings significant advantages to the steel industry, including:

Enhanced Efficiency: Automates processes and reduces manual intervention.

Cost Reduction: Minimizes waste and optimizes resource utilization.

Better Decision Making: Provides real-time insights through data analytics.

Scalability: Supports business growth and expansion.

Improved Customer Satisfaction: Ensures timely deliveries and quality assurance.

How to Choose the Best ERP for Steel Industry

Selecting the right ERP system for the steel industry involves considering:

Customization: Does the ERP cater to your specific industry needs?

Scalability: Can it grow with your business?

Ease of Use: Is it user-friendly and requires minimal training?

Integration: Does it integrate seamlessly with existing tools?

Cost: Is the pricing structure affordable and value-driven?

Top ERP Software for Steel Industry

Here are some of the best ERP solutions tailored for the steel industry:

SAP S/4HANA – Advanced AI-driven ERP with strong automation capabilities.

Oracle NetSuite – Cloud-based ERP with real-time analytics.

Microsoft Dynamics 365 – Customizable and scalable for large-scale industries.

Infor CloudSuite Industrial – Specially designed for manufacturing sectors.

Epicor ERP – Offers excellent supply chain management features.

Conclusion: Why Your Steel Business Needs ERP Software

Investing in the best ERP for the steel industry is essential for staying competitive in today’s fast-paced market. A well-implemented ERP solution streamlines operations, enhances productivity, and ensures compliance, ultimately leading to higher profitability.

#ERPforSteelIndustry#SteelIndustrySolutions#ManufacturingERP#SteelIndustrySoftware#EnterpriseResourcePlanning#SteelManufacturing#IndustrialAutomation#SupplyChainManagement#ERPImplementation#BusinessEfficiency

0 notes

Text

Optimizing Stainless Steel Production with ERP: Features, Benefits, and Future Trends

ERP for Stainless Steel Manufacturing

Steel manufacturing requires perfection and precision in delivering efficiency. Enterprise Resource Planning (ERP) systems streamline complex processes, integrating core business functions such as raw material management, production scheduling, and quality control into a single system. A customized ERP for Stainless Steel Manufacturing ensures cost efficiency, operational excellence, and compliance with industry standards.

Key Features of ERP for Stainless Steel Manufacturing

Inventory Management – Tracks raw materials to minimize waste and optimize stock levels.

Production Scheduling – Automates planning and scheduling for improved efficiency.

Quality Control – Ensures consistent product quality and regulatory compliance.

Supply Chain Coordination – Optimizes procurement and delivery processes.

Real-Time Analytics – Provides data-driven insights for better decision-making.

Benefits of ERP for Stainless Steel Manufacturing

Enhanced Efficiency – Automation reduces manual efforts and boosts productivity.

Improved Traceability – Tracks materials and processes to minimize waste.

Scalability – Adapts to growing business demands and production capacity.

Better Customer Service – Ensures timely deliveries with accurate tracking.

Regulatory Compliance – Helps meet industry standards and reporting requirements.

Future Trends in ERP for Stainless Steel Manufacturing

AI Integration – Provides predictive analytics for better forecasting and decision-making.

IoT Connectivity – Enables real-time monitoring of production processes and equipment.

Cloud-Based ERP – Offers flexibility, cost savings, and seamless remote access.

Implementing an ERP for Stainless Steel Manufacturing is key to optimizing operations, reducing costs, and staying ahead of market demands. As technology advances, AI, IoT, and cloud solutions will further enhance efficiency and competitiveness in the steel industry.

#ERPforSteelIndustry#StainlessSteelManufacturing#SteelIndustrySolutions#SteelManufacturingERP#QualityControl#ERPSoftware#ManufacturingEfficiency#SupplyChainManagement#IndustrialAutomation#SmartManufacturing#ProductionOptimization

0 notes

Text

The Impact of ERP on Steel Manufacturing: Smarter Operations, Higher Profits

Introduction

Steel production is one of the most complicated and challenging industries, with demands for precision, efficiency, and streamlined processes. With fluctuating raw material prices, regulatory needs, and tough competition, steel producers must keep up with innovative technological solutions to remain competitive. Enterprise Resource Planning (ERP) systems are just what they need. The installation of ERP software in steel production increases productivity, lowers costs, and maximizes operations, and the end result is increased profit.

The Role of ERP in Steel Manufacturing

ERP systems combine several business processes into one platform, offering real-time visibility and control over all aspects of the operation. In steel production, an ERP system can handle anything from raw material purchasing to production planning, inventory management, quality control, and distribution. The key advantages of ERP in steel production are:

Enhanced Production Efficiency : The processes of steel manufacture include several activities like melting, rolling, and finishing. An ERP system facilitates efficient scheduling of production, maximizing downtime, and optimal use of equipment. Equipped with data analytics in real-time, also helps in estimating equipment maintenance, thereby reducing downtime due to untimely breakages.

Supply Chain Management Optimized : Supply chain interruptions may severely affect steel production. ERP helps maintain a smooth coordination between suppliers, vendors, and logistics. It facilitates raw material tracking, automating purchase orders, and just-in-time inventory, thus minimizing wastage and cost.

Improved Quality Control : Quality is an essential aspect of steel manufacturing. ERP software allows manufacturers to track and implement quality measures at each level of the process. With quality management modules integrated, businesses can perform real-time inspections, produce detailed reports, and maintain industry regulation compliance.

Cost Reduction and Waste Minimization : By automating multiple manual operations and streamlining resource allocation, an ERP system enables manufacturers to save on operational costs. Tracking of raw materials and finished goods in real-time prevents overstocking and reduces wastage of material.

Regulatory Compliance and Reporting : The steel sector is governed by strict environmental and safety regulations. ERP systems aid in automating compliance monitoring, such that all processes are compliant with the law. The system also aids in producing correct reports for audits and inspections.

Choosing the Right ERP for Steel Manufacturing

All ERP solutions are not the same. Steel producers need to keep the following in mind while choosing an ERP system:

Industry-Specific Features: Look for an ERP that is designed specifically for steel manufacturing requirements, such as production planning, quality management, and inventory management.

Scalability: The ERP must be scalable to accommodate future growth and expansions.

Cloud-Based vs. On-Premise: Cloud ERP provides greater flexibility, accessibility, and reduced infrastructure costs.

Integration Capabilities: The ERP needs to integrate directly with installed machinery, IoT gadgets, and external applications.

User-Friendly Interface: A friendly UI/UX guarantees easy adaptation and optimal utilization of the system.

The Future of ERP in Steel Manufacturing

The destiny of ERP in steel production is being determined by new technologies like Artificial Intelligence (AI), Machine Learning (ML), and the Internet of Things (IoT). These technologies improve automation, enhance predictive maintenance, and continue to optimize supply chain management. With continued digital transformation, intelligent ERP solutions will become a must-have for steel producers that wish to remain competitive.

Conclusion

The effect of ERP on steel production cannot be denied. Whether it is enhanced production efficiency or cost savings, quality control or compliance, intelligent operations and higher profits are induced by ERP systems. It's no longer an option but an imperative for steel producers to make an investment in a solid ERP solution if long-term success is the goal within a more and more competitive business environment.

#ERP#SteelManufacturing#SmartManufacturing#DigitalTransformation#SupplyChainManagement#QualityControl#CostReduction#BusinessIntelligence#ManufacturingTechnology#AIinManufacturing#Industry40#EnterpriseResourcePlanning#SteelIndustry#SmartERP

0 notes

Text

Quick and Easy Fix for ISO 22301 Certified BCMS Lead Auditor (CBC LA)

ISO 22301 Certified BCMS Lead Auditor (CBC LA) Certification Exam Credential With protection taking centre stage throughout the enterprise, the position of the CSO or CISO is fitting more and more complex and challenging, however pleasing, having said that. As these admiral discover new roles in which they could deliver their adventure and imaginative and prescient to bear, we’ll preserve you up so far on new accessories and actions on earth of cybersecurity.

auto components maker Motherson has made Mohit Gupta its neighborhood chief suggestions security officer, advertisement to the neighborhood CIO. In his new position, he will assignment to enrich the common safety posture of Motherson group agencies, which employ , staff in forty one countries.

Gupta has over two decades of journey in IT. prior to now, he was CISO of MothersonSumi INfotech and Designs intellect, Motherson’s IT capabilities subsidiary.

Gomeet blow has been appointed as vp and head of infosec capabilities at ABB’s world enterprise service – assistance methods GBS IS.

blow, who had currently been appointed as CISO and head of IT operations at Vedanta Zinc overseas, moved to ABB in April to tackle his world position.

ABB’s GBS-IS gives IT features to over ninety international locations during which ABB has a presence.

above senior supervisor of advice safety at Flipkart, Ambarish Singh has been appointed because the new arch tips safety administrator CISO at accomplishment company Godrej & Boyce.

A pro cybersecurity chief, Singh served as associate administrator of the Indian navy’s on the net incidents response group, where he oversaw agenda forensics and become involved within the planning, accomplishing, and beheading of vulnerability and possibility assessment. He also performed a key position in defining and imposing procedures and guidelines.

Singh is an EC-certified licensed moral hacker, and holds licensed tips systems auditor CISA and licensed suggestions systems supervisor CISM certifications from ISACA, as well as a grasp’s degree in cybersecurity and online law from the country wide legislations institution.

formerly international chief of cybersecurity at Max Healthcare, Kapil Madaan is taking on as arch assistance protection administrator at auto part manufacturer atom Minda.His career in cybersecurity began all the way through a stint at Ashtech Infotech, where he became answerable for managing amount IT basement and security. He has more than years of event in managing cybersecurity operations, analysis and accreditation, infosec, statistics privateness, strategic planning, and disaster restoration planning. He additionally constructed advantage within the enviornment of regulatory acquiescence—chiefly in carrier company manage SOC, ISO, and company continuity management programs BCMS.

above CISO at amazon Pay India, Ashok Kumar has abutting Encora as Sr director, international GSRC babyminding safety possibility and compliance and head of digital safety.

Encora is a global agenda engineering company headquartered in Arizona, US with a + powerful team and becoming.

The business assists corporations in driving addition in AIML, cloud, IoT, automation, and mobility in addition to other enterprise know-how options.

In his new role, Kumar will activate Encora’s digital protection practice. he ll also be developing and instituting the framework for technology touching on governance, chance and acquiescence GRC. moreover, he should be accountable for the implementation of international safety, risk, and acquiescence requisites and frameworks at the firm.

Kumar accumulated huge experience for his current position all through his administration at Unisys, the place he developed and installation the enterprise’s protection and acquiescence Centre of excellence for global operations protecting over workplaces within the Americas, Europe and Asia.

He has accomplishing adventure in dissimilar specifications and frameworks, together with ISO , ISO , ISO -, ISO , NIST, HIAHITECH, ISAE SSAE sixteen SOC & SOC , SOX, FedRAMP, Fisma and PCI-DSS.

In his stint with amazon, he led the adoption, implementation and localization of corporate, transactional and regulatory protection requirements from US & ceramics to India & South Asia.

Gomeet blow has been appointed arch of IT Operations & Cybersecurity at South Africa-based mostly Vedanta Zinc international VZI.

In his old position pant was heading cybersecurity at cairn Oil and gasoline – a vertical of the Vedanta neighborhood. In his new function at Vedanta Zinc overseas VZI, he might be overseeing IT infrastructure in addition to cybersecurity.

The seasoned cybersecurity chief has been linked to Vedanta on the grounds that June when he joined the company as community advance, IT protection and acquiescence.

His new role makes him accountable for Operational technology OT safety at VZI. answer his new position, pant stated: “I’m now on the Vedanta neighborhood’s safety committee and should be leading as the community’s safety anchor.”

As Vedanta Zinc international is a South African article, pant should be relocating to SA in two months from now. moreover his new responsibilities, there’s a portion of IT protection he ll proceed to control for the Vedanta community in India.

being responsible for OT methods’ safety, pant aggregate his concepts on what makes OT protection extra crucial than IT security: “records may also be recovered after an attack on a corporation’s IT, but if there’s a cyberattack on OT techniques, it may cause a major affect on animal security and the environment.”

He brought that a cyberattack on IT outcomes in fiscal accident, however unlike attacks on OT systems, animal lives are not at stake.

Neha Taneja will now be heading cybersecurity at abundance Oil and gas. A tenured cybersecurity chief, Taneja become in the past Asst. VP-IT at GE capital business system management functions.

She then abutting SBI agenda as agent VP-IT and served years months within the business before her avenue as VP-IT Controllership.

former CISO at Adani companies, Dharmesh Rathod has joined the Welspun community as head of Cybersecurity. established in , Welspun group is a multinational amassed with investments in steel, power and textiles.

in advance of his assignment at Adani, Rathod played the role of a CISO as arch-IT assurance and assistance safety at Essar functions India Ltd. for six years.

At Adani agencies, he led safety approach, audits, possibility management and compliance, probability administration, and IT & OT safety. he s credited with developing a security assessment framework in accordance with global security necessities. He additionally designed the OT protection program, together with POCs and reviews and played a key function in riding ISO certification and assessment for the community.

In a profession spanning over years, Rathod has been the recipient of a couple of leadership awards. He has fabricated his mark as an eminent apostle at international and home platforms and has authored articles on cybersecurity for reputed publications.

Rathod is certified in ITIL V, ISO LI and LA, to identify a couple of, and is additionally a expert certified information techniques security expert CISSP. apart from being a cybersecurity chief, he has also played the function of an IT & cybersecurity strategist, architect & adviser and changed into an trade mentor for the Standford advanced Cybersecurity program.

unique Kumar, who during the past, headed protection operations at Max Healthcare, Aviva India and Aptara, has been appointed as the neighborhood CISO at CK Birla group.

besides his wide event in cybersecurity, in his outdated stints, Kumar was answerable for enforcing new IT applied sciences, agenda transformation, IT infrastructure, datacentre, large calibration ERP rollouts, IT automation and billow computing.

He also has adventure in mergers & acquisitions and retaining stakeholder relationships. He has the know-how in managing risk and audits and is licensed in ISO compliance, tips know-how basement Library ITIL and venture management knowledgeable PMP.

In , Kumar bagged his d after CSO award for spearheading key security initiatives at Max Healthcare – this included intrusion apprehension programs, email security, phishing simulators and id and entry administration IdAM.

Maya R Nair appointed as director & CISO at credit standing suggestions features of India constrained CRISIL

Maya R Nair, former CISO at assurance capital Ltd. and head-information protection at conception cellular has abutting credit standing assistance capabilities of India constrained CRISIL as director & chief counsel safety administrator.

In her old stints, Nair also served as arch of safety operations at reliance Jio and become CISO & arch-IT basement at Lentra AI Ltd.

An experienced adept within the credit counsel space, Nair served as assistant vice president-InfoSec at TransUnion credit counsel agency limited TUCIBIL for close to a decade. besides conserving TUCIBIL from inner and exterior threats, she played a key position in developing the ISMS framework to comply to ISO :; she helped revamp and migrate the datacentre with zero downtime and also install the BCP and DR website for the business.

Nair is an authorized tips device auditor CISA and a certified suggestions safety administration system ISMS advance accountant for ISO . among her record of accreditation are BS advance Implementer and DSCI-licensed privateness lead assessor.

former CISO at IDFC aboriginal financial institution, Rajesh Hemrajani has joined Paytm funds bank as the chief suggestions protection officer.

He has over years of event in framing corporate information and cybersecurity policies & strategies, environment security standards for IT infrastructure, possibility assessment, and constructing enterprise chain plans and repair standards.

At IDFC first financial institution, Hemrajani managed global tips security capabilities and verticals with an eighty five-member crew of professional cybersecurity and chance professionals. He became a champ of the CSO award in .

above CISO at yes financial institution, Rajesh Thapar has been appointed as the head of IT and assistance safety at OakNorth. OakNorth is a UK bank featuring loans to small and mid-sized corporations in the UK. A adept CISO within the banking area, Thapar has huge competencies in ISO , IT approach, administration, Pre-revenue, and management counsel systems MIS.

in advance of alive at yes financial institution, Thapar was with IBM India as counsel security and possibility administration advance, delivering IT safety and risk management features across assorted strategic outsourcing clients. He has additionally worked with Citigroup world capabilities now TCS eServe and IDBI bank.

former SVP - arch of information technology & Cybersecurity at ENAM, Kiran Belsekar joined Aegon lifestyles as vice president - tips security. Belsekar has collected over years of adventure in IT features in BPOs & KPOs, accomplishment, retail, cyberbanking, life assurance & the media area.

He has confirmed his advantage in managing IT, assistance security & possibility management, IT operations, IT basement, ERP, managing IT budgets, and enterprise mobility options. moreover, Belsekar has demonstrated the skill to assignment in established companies in addition to startups.

above Sr. GM-counsel know-how at WNS international functions, Allwyn Pereira, joins SPi global as arch of IT protection

Allwyn Pereira has joined SPi global as head of IT protection. Pereira is an ISACA-certified counsel security manager and changed into the Sr. neighborhood supervisor - counsel expertise at WNS world features.

prior to becoming a member of WNS, Pereira changed into the director of information technology at Sutherland world services, where he worked for over four. years.

above arch of expertise at Motilal Oswal fiscal functions, Amit Jaokar joins NKGSB financial institution as CISO & CDO

0 notes