#ASTM Manhole Cover Test

Explore tagged Tumblr posts

Text

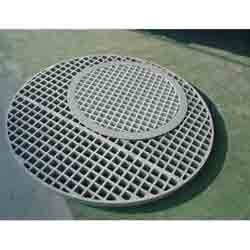

Manhole Cover Compression Testing Machine

Reliable and Accurate Testing for Manhole Covers The Manhole Cover Compression Testing Machine is a specialized testing device designed to assess the structural integrity of manhole covers under extreme pressure. This testing machine plays a crucial role in ensuring that manhole covers meet the required safety standards and durability expectations. Whether used for quality control in…

#ASTM Manhole Cover Test#Civil Engineering Testing#Compression Resistance#Compression Strength Test#Compression Testing#Construction Equipment Testing#Custom Testing Solutions#EN 124 Testing#Hydraulic Load Testing#Hydraulic Testing Machine#Industrial Testing Machines#ISO Manhole Cover Standards#Jinan Wangtebei Instrument#Load Cell Testing#Load Testing#Manhole Cover Compliance#Manhole Cover Deformation Test#Manhole Cover Performance Test#Manhole Cover Quality Control#Manhole Cover Strength#Manhole Cover Testing Equipment#manhole cover testing machine#Pressure Test Machine#Testing Equipment for Infrastructure#Testing Machine Manufacturer

0 notes

Text

Ductile Iron Round Manhole Cover: Ultimate Guide to Specifications, Standards, Installation

Ductile iron manhole covers are indispensable components in urban infrastructure, offering unmatched durability, load-bearing capacity, and corrosion resistance. Designed to meet international standards like EN124, these covers ensure safety in pedestrian zones, highways, and industrial areas. This guide delves into material properties, manufacturing processes, compliance frameworks, and practical solutions for selecting and maintaining ductile iron manhole covers.

1. Material Properties and Advantages of Ductile Iron

Ductile iron, a ferrous alloy containing 3–4% carbon and nodular graphite, combines the castability of gray iron with the tensile strength of steel (60,000–100,000 psi)19. Its unique microstructure provides:

High Load Capacity: Grades like EN124 B125 (12.5-ton load) and D400 (40-ton load) cater to diverse traffic conditions.

Impact Resistance: Graphite nodules absorb shock, reducing fracture risk under heavy vehicular loads.

Corrosion Resistance: Epoxy coatings or bitumen paints extend lifespan in corrosive environments.

Table 1: EN124 Load Classifications for Ductile Iron Manhole Covers

GradeLoad Capacity (kN)Application ScenariosCommon Sizes (mm)Material Thickness (mm)A1515Pedestrian zones, parks600×400, 700×80020–30B125125Sidewalks, residential roads800×900, 850×85030–40D400400Highways, industrial areas1000×100050–60F900900Airports, heavy machinery zonesCustom70+

Note: Sizes and thicknesses vary by manufacturer. Always confirm specifications with suppliers.

2. Manufacturing Processes and Quality Assurance

2.1 Casting Techniques

Ductile Iron Drain Grates are produced via sand casting or shell molding, ensuring precise geometry and surface finish13. Post-casting treatments include:

Heat Treatment: Annealing at 900°C (1,652°F) to enhance ductility.

Surface Coating: Epoxy, bitumen, or fusion-bonded coatings for corrosion protection.

2.2 Quality Certifications

Reputable manufacturers comply with:

ISO 9001: Quality management systems.

EN124: European standard for load-bearing capacity.

ASTM A536: Mechanical properties of ductile iron.

3. Installation and Maintenance Best Practices

3.1 Installation Guidelines

Base Preparation: Ensure a level, compacted substrate to prevent tilting.

Frame Alignment: Use adjustable frames for seamless integration with road surfaces.

Sealing: Apply GRP (glass-reinforced plastic) sealing plates for watertight solutions.

3.2 Maintenance Tips

Annual Inspections: Check for cracks, coating degradation, or frame misalignment.

Debris Removal: Clear drainage channels to prevent blockages.

4. Comparative Analysis: Ductile Iron vs. Alternative Materials

Table 2: Material Comparison for Manhole Covers

MaterialLoad CapacityCorrosion ResistanceCost (USD/kg)Lifespan (Years)Ductile IronUp to 900 kNHigh (with coatings)1.5–2.530–50Cast IronUp to 400 kNModerate1.2–1.820–30Stainless SteelUp to 250 kNExcellent8–1250+AluminumUp to 100 kNHigh3–515–25

Note: Cost and lifespan depend on environmental conditions and maintenance.

5. 6 FAQs About Ductile Iron Round Manhole Covers

FAQ 1: What is the significance of EN124 standards for ductile iron manhole covers?

The EN124 standard categorizes manhole covers based on load-bearing capacity, ensuring suitability for specific applications. For example:

EN124 B125 (125 kN): Suitable for residential roads and sidewalks.

EN124 D400 (400 kN): Designed for highways and industrial zones.

Compliance with EN124 requires rigorous testing, including static load tests and impact resistance assessments. A 2024 study by the European Committee for Standardization found that EN124-certified ductile iron covers reduced infrastructure failure rates by 40% compared to non-certified alternatives.

6. Conclusion

Ductile iron round manhole covers offer unparalleled performance in demanding environments. By adhering to EN124 standards, selecting appropriate coatings, and following installation best practices, municipalities and contractors can ensure long-term reliability. For specialized projects, consult manufacturers offering customizable sizes and locking mechanisms.

0 notes

Text

Manhole covers manufacturers

The role of manhole covers in infrastructure systems is vital, as they ensure safety and access to underground utilities. To meet security standards and regulations, manhole cover manufacturers must adhere to specific rules. PESCO International, a leading producer in this field, recognizes the importance of compliance with these standards. In this article, we will explore how manhole cover manufacturers can ensure conformity to regulations and standards while achieving optimal performance.

Importance of Regulatory Compliance in Manhole Cover Manufacturing

Regulatory compliance is of utmost importance in the production of manhole covers. These covers are critical components of infrastructure systems, providing access to underground utilities such as sewer lines, telecoms, and electrical wiring. Adhering to regulatory requirements ensures the durability, safety, and functionality of manhole covers, reducing the risk of accidents and property damage.

Standards and regulations vary across sectors and regions, encompassing aspects such as load capacities, materials specifications, dimensions, markings, and sizes. Manhole cover manufacturers must stay up-to-date with the latest requirements to deliver products that meet the necessary compliance standards.

Understanding Industry Standards for Manhole Covers

Industry standards provide manufacturers of manhole covers with guidelines to follow during production, design, and testing processes. These standards are developed by organizations like The American Society for Testing and Materials (ASTM), the European Committee for Standardization (CEN), and national regulators.

The industry standards specify requirements related to load-bearing capacity, dimensional accuracy, materials properties, slip resistance, and environmental considerations. Manufacturers must carefully consider and integrate these requirements into their manufacturing processes to ensure their manhole covers are in line with the necessary standards.

Quality Control Measures for Regulatory Compliance

To ensure compliance with standards and regulatory demands, manhole cover manufacturers implement strict quality control procedures throughout the entire manufacturing process. These measures include:

Selection of materials: Manufacturers carefully choose materials that align with industry standards, considering factors such as toughness, durability, and corrosion resistance.

Engineering and design: Manhole covers are engineered to meet load capacity requirements and designed for strength and durability. The use of advanced software and simulation tools allows for analysis and improved design.

Manufacturing procedures: Stringent manufacturing methods ensure consistent quality and conformity. This involves precise casting, machining, and finishing processes, along with appropriate heat treatment and surface coatings.

Testing and certification: Manhole covers undergo rigorous testing to verify load-bearing capacity, dimensional accuracy, slip resistance, and other specifications. Certifications issued by recognized laboratories validate compliance with regulatory standards.

Conclusion

Meeting specific standards and regulatory requirements is crucial for manhole cover manufacturers. Understanding the significance of conformity, adhering to industry standards, and implementing strict quality controls, in partnership with trusted companies like PESCO International, ensures that the manhole covers installed in infrastructure systems comply with all regulations and specifications. This guarantees the safety of the infrastructure and accessibility to underground utilities, providing peace of mind for all users and stakeholders involved. Additionally, PESCO International is a renowned Prefab Manufacturers in the industry.

0 notes

Text

DLO Cable Manufacturers

1X Technologies DLO Cable - Diesel Locomotive Cable

What is a DLO cable?

DLO Cable stands for "Diesel locomotive cables". DLO Cable was originally developed for wiring diesel-electric locomotive trains dating back before the 1920's, over 100 years ago. Back then, these heavy duty 2KV Diesel Locomotive cables were used as power-leads in traction motors. The DLO Cables were were used as open wiring to the Diesel Electric motors where they were made to take a massive amount of wear and tear. In today's world, DLO cables (Also called Type DEL Cable) are still used in wiring diesel-electric locomotives, but more commonly used in applications such as Submersible Pump cable, battery cable, Belden DLO Cable, control panel power distribution, VFD power feed and as motor leads, earth moving equipment, drilling rigs, marine shipboard cable, in open air or in conduit wherever durability and wear and tear are prevalent. DLO cables are (UL) listed as RHH/RHW-2 2kV and available in sizes 14 AWG through 1111 Kcmil, temperature rated 90 degree C. When DLO Cable is used as conductors for general wiring practices according to NEC Article 310 based on their RHW/RHW-2 listing the conductors cable class is subject to the requirements of NFPA 70 / NEC Article 310 the same as any other RHW insulated conductors. Contact us today at 1-888-651-9990 to get updated pricing on your DLO Cable, we'll quickly get you a DLO cable cost to price your job.

1X Technologies Diesel Locomotive Cable Construction:

Nominal voltage: RHH/RHW-2 600V and 2000V, RW-90 CSA, 1kV, DLO 2kV Conductors: Flexible strand tin coated copper conductor, B-172, ASTM B-33 Separator: Tape separator between conductor and insulation DLO Insulation: Ethylene-propylene rubber (EPR), UL, CSA, ICEA, AAR RP-588, 90ºC DLO Jacket: Black heavy duty, thermoset CPE, ICEA S-95-658 NEMA WC70, AAR RP-586

DLO Cable Applications

wiring diesel-electric locomotives for over 100 years General Building Wire (UL 44) RHH/RHW-2 Deep Well Submersible Pump cable Petrochemical drilling rigs - Offshore and Onshore - MSHA Battery Cable Arc Welding Cable control panel power distribution VFD power feed and as motor leads Telecom Power Supply (Central Office Power Cable) earth moving equipment drilling rigs marine shipboard cable In open air or in conduit wherever durability and wear and tear are prevalent Jobs flexible heavy duty power cables portable or fixed installations Leads for motors, generators, batteries, jumper cables For use in renewable energy applications such as Solar Photovoltaic, Wind Power, and more.

DLO cable chart, Cut sheet, Data Sheet - Specification

Specs: https://1xtechnologies.com/dlo-cable/

DLO cable ampacity / DLO cable amps / DLO cable current rating

DLO Cable Ampacity varies from 35 Amps up to 1115 Amps depending on which size you require. Diesal Locomotive Cable "Ampacity" is defined as the maximum current, in amperes, that a DLO Cable conductor can carry continuously under the conditions of use without exceeding its 90C temperature rating. This is also described as dlo cable current rating, its current-carrying capacity. The ampacity of a DLO conductor depends on its ability to dissipate heat without damage to the conductor or its EPDM Rubber insulation. DLO cable amps is a function of the insulation temperature rating, the electrical resistance of the conductor material, the ambient temperature, and the ability of the insulated conductor to dissipate heat.

DLO Cable UL, NEC, CSA

1.1 UL 44 - This (UL) Standard specifies the requirements for single-conductor and multiple-conductor thermoset-insulated wires and cables rated 600 V, 1000 V, 2000 V, and 5000 V, for use in accordance with the rules of the Canadian Electrical Code, Part I, CSA C22.1, in Canada, Standard for Electrical Installations, NOM-001-SEDE, in Mexico, and the National Electrical Code (NEC), NFPA 70, in the United States of America. See Annex a for the complete list of types and voltage ratings covered by this Standard and the specific electrical codes for which they are intended, and Annex b for a summary of construction and test requirements for these types. 1.2 Table 1 provides a summary of the maximum conductor temperature, voltage ratings, and the number of insulated conductors for the types to which this Standard applies. 1.3 This Standard also specifies the requirements for submersible pump cables, with or without jackets, in Deep Well Submersible Water-Pump Cable, Section 7. No type-letter designations are assigned to these cables. 1.4 Products within this Standard might have applications not covered by the electrical codes listed in 1.1. UL: (CPE jacket) RHW-2 90C wet and dry, VW-1, Sun Res, for 1/0 and larger ST-1, FT-4, IEEE1202, for CT use C(UL): TYPE RW90 EP; 1000V; FT1 CSA: RW-90 90C; FT1; FT4; -40C; for 1/0AWG and larger: OIL RES, Tray Cable, Sun Res

Can DLO cable be used in conduit?

When used as General Wiring in accordance with the NEC, DLO Cable can be used in Conduit. DLO Cable is listed as UL 44 RHH-RHW-2 which is a building wire. When DLO Cable is used as conductors for general wiring practices according to NEC Article 310 based on their RHW/RHW-2 listing the conductors cable class is subject to the requirements of NFPA 70 / NEC Article 310 the same as any other RHW insulated conductors, and therefore just as any other RHW insulated conductors such as XLP-USE building wire, may be used in conduit. DLO cable conduit fill may be calculated using any of the accessible calculators commonly found online.

DLO Cable Bending Radius

During electrical installation, DLO cables are bent or flexed in various environmental conditions. Diesel Locomotive Cables are often bent around a curve in conduits or underground ducts. Cables are also bent when pulling a DLO electrical cable around a sheave, which is a pulley set up in a manhole to help ease a cable around a curve. Type DEL Cables (DLO) are composed of different components that may become compromised if bent too far and stress is placed on the electrical cable. To prevent cable damage, cable standards such as The National Electrical Code (NEC) and the Insulated Cable Engineers Association (ICEA) formed requirements for minimum bend radius. DLO Cable Bending radius: For fixed installation – minimum 4 x O.D., for flexible or temporary installation – minimum 6 x O.D. Diameter of the cable.

DLO Cable Cost - Price Per Foot

Diesel Locomotive Cable costs more than your typical general building wire due to its construction being composed of extremely durable components. Being a super flexible stranded tinned copper 2KV cable with an extra durable EPDM insulation and CPE jacket makes for a really amazing cable, but it can be pricey if you are comparing to standard THHN or XHHW. Pricing can range from $.25 cents per foot for 14 AWG to upwards of $40.00 per foot for 1111 MCM DLO Cable. Pricing depends on how many feet are ordered, where it is shipping, what copper base is at time of order and a variety of other factors. To get your current DLO cable cost give us a call today at 1-888-651-9990.

1XTech Diesel Locomotive Cable Sizes

14 AWG Diesel Locomotive Cable 2KV

Voltage: RHH/RHW-2 600V & 2000V, RW-90 CSA, 1kV, DLO 2kV Amperage: 35 Amps Weight per 1000 Feet: 30 lbs. Outside Diameter O.D. -- .218 In. Bend Radius Fixed (x4): .872 In. Bend Radius Flexible (x6): 1.308 In. Low Smoke? Yes MSHA: Yes UL / CSA: Yes

12 AWG Diesel Locomotive Cable 2KV

Voltage: RHH/RHW-2 600V & 2000V, RW-90 CSA, 1kV, DLO 2kV Amperage: 40 Amps Weight per 1000 Feet: 46 lbs. Outside Diameter O.D. -- .240 In. Bend Radius Fixed (x4): .960 In. Bend Radius Flexible (x6): 1.44 In. Low Smoke? Yes MSHA? Yes UL / CSA: Yes

10 AWG Diesel Locomotive Cable 2KV

Voltage: RHH/RHW-2 600V & 2000V, RW-90 CSA, 1kV, DLO 2kV Amperage: 55 Amps Weight per 1000 Feet: 67 lbs. Outside Diameter O.D. -- .266 In. Bend Radius Fixed (x4): 1.064 In. Bend Radius Flexible (x6): 1.596 In. Low Smoke? Yes MSHA? Yes UL / CSA: Yes

8 AWG Diesel Locomotive Cable 2KV

Voltage: RHH/RHW-2 600V & 2000V, RW-90 CSA, 1kV, DLO 2kV Amperage: 80 Amps Weight per 1000 Feet: 105 lbs. Outside Diameter O.D. -- .3363 In. Bend Radius Fixed (x4): 1.3452 In. Bend Radius Flexible (x6): 2.0178 In. Low Smoke? Yes MSHA? Yes UL / CSA: Yes

6 AWG Diesel Locomotive Cable 2KV

Voltage: RHH/RHW-2 600V & 2000V, RW-90 CSA, 1kV, DLO 2kV Amperage: 105 Amps Weight per 1000 Feet: 146 lbs. Outside Diameter O.D. -- .3807 In. Bend Radius Fixed (x4): 1.5228 In. Bend Radius Flexible (x6): 2.2842 In. Low Smoke? Yes MSHA? Yes UL / CSA: Yes

4 AWG Diesel Locomotive Cable 2KV

Voltage: RHH/RHW-2 600V & 2000V, RW-90 CSA, 1kV, DLO 2kV Amperage: 140 Amps Weight per 1000 Feet: 205 lbs. Outside Diameter O.D. -- .4503 In. Bend Radius Fixed (x4): 1.8012 In. Bend Radius Flexible (x6): 2.7018 In. Low Smoke? Yes MSHA? Yes UL / CSA: Yes

2 AWG Diesel Locomotive Cable 2KV

Voltage: RHH/RHW-2 600V & 2000V, RW-90 CSA, 1kV, DLO 2kV Amperage: 190 Amps Weight per 1000 Feet: 293 lbs. Outside Diameter O.D. -- .502 In. Bend Radius Fixed (x4): 2.008 In. Bend Radius Flexible (x6): 3.012 In. Low Smoke? Yes MSHA? Yes UL / CSA: Yes

1 AWG Diesel Locomotive Cable 2KV

Voltage: RHH/RHW-2 600V & 2000V, RW-90 CSA, 1kV, DLO 2kV Amperage: 220 Amps Weight per 1000 Feet: 392 lbs. Outside Diameter O.D. -- .650 In. Bend Radius Fixed (x4): 2.600 In. Bend Radius Flexible (x6): 3.900 In. Low Smoke? Yes MSHA? Yes UL / CSA: Yes

1/0 AWG Diesel Locomotive Cable 2KV

Voltage: RHH/RHW-2 600V & 2000V, RW-90 CSA, 1kV, DLO 2kV Amperage: 260 Amps Weight per 1000 Feet: 525 lbs. Outside Diameter O.D. -- .6900 In. Bend Radius Fixed (x4): 2.760 In. Bend Radius Flexible (x6): 4.140 In. Low Smoke? Yes MSHA? Yes UL / CSA: Yes

2/0 AWG Diesel Locomotive Cable 2KV

Voltage: RHH/RHW-2 600V & 2000V, RW-90 CSA, 1kV, DLO 2kV Amperage: 300 Amps Weight per 1000 Feet: 660 lbs. Outside Diameter O.D. -- .7300 In. Bend Radius Fixed (x4): 2.920 In. Bend Radius Flexible (x6): 4.380 In. Low Smoke? Yes MSHA? Yes UL / CSA: Yes

3/0 AWG Diesel Locomotive Cable 2KV

Voltage: RHH/RHW-2 600V & 2000V, RW-90 CSA, 1kV, DLO 2kV Amperage: 350 Amps Weight per 1000 Feet: 760 lbs. Outside Diameter O.D. -- .810 In. Bend Radius Fixed (x4): 3.240 In. Bend Radius Flexible (x6): 4.860 In. Low Smoke? Yes MSHA? Yes UL / CSA: Yes

4/0 AWG Diesel Locomotive Cable 2KV

Voltage: RHH/RHW-2 600V & 2000V, RW-90 CSA, 1kV, DLO 2kV Amperage: 405 Amps Weight per 1000 Feet: 930 lbs. Outside Diameter O.D. -- .870 In. Bend Radius Fixed (x4): 3.480 In. Bend Radius Flexible (x6): 5.220 In. Low Smoke? Yes MSHA? Yes UL / CSA: Yes

262 MCM Diesel Locomotive Cable 2KV

Voltage: RHH/RHW-2 600V & 2000V, RW-90 CSA, 1kV, DLO 2kV Amperage: 467 Amps Weight per 1000 Feet: 1130 lbs. Outside Diameter O.D. -- .920 In. Bend Radius Fixed (x4): 3.680 In. Bend Radius Flexible (x6): 5.520 In. Low Smoke? Yes MSHA? Yes UL / CSA: Yes

313 MCM Diesel Locomotive Cable 2KV

Voltage: RHH/RHW-2 600V & 2000V, RW-90 CSA, 1kV, DLO 2kV Amperage: 518 Amps Weight per 1000 Feet: 1400 lbs. Outside Diameter O.D. -- .9680 In. Bend Radius Fixed (x4): 3.872 In. Bend Radius Flexible (x6): 5.808 In. Low Smoke? Yes MSHA? Yes UL / CSA: Yes

373 MCM Diesel Locomotive Cable 2KV

Voltage: RHH/RHW-2 600V & 2000V, RW-90 CSA, 1kV, DLO 2kV Amperage: 588 Amps Weight per 1000 Feet: 1545 lbs. Outside Diameter O.D. -- 1.0650 In. Bend Radius Fixed (x4): 4.260 In. Bend Radius Flexible (x6): 6.390 In. Low Smoke? Yes MSHA? Yes UL / CSA: Yes

444 MCM Diesel Locomotive Cable 2KV

Voltage: RHH/RHW-2 600V & 2000V, RW-90 CSA, 1kV, DLO 2kV Amperage: 649 Amps Weight per 1000 Feet: 1820 lbs. Outside Diameter O.D. -- 1.1320 In. Bend Radius Fixed (x4): 4.528 In. Bend Radius Flexible (x6): 6.792 In. Low Smoke? Yes MSHA? Yes UL / CSA: Yes

535 MCM Diesel Locomotive Cable 2KV

Voltage: RHH/RHW-2 600V & 2000V, RW-90 CSA, 1kV, DLO 2kV Amperage: 725 Amps Weight per 1000 Feet: 2023 lbs. Outside Diameter O.D. -- 1.240 In. Bend Radius Fixed (x4): 4.960 In. Bend Radius Flexible (x6): 7.440 In. Low Smoke? Yes MSHA? Yes UL / CSA: Yes

646 MCM Diesel Locomotive Cable 2KV

Voltage: RHH/RHW-2 600V & 2000V, RW-90 CSA, 1kV, DLO 2kV Amperage: 814 Amps Weight per 1000 Feet: 2560 lbs. Outside Diameter O.D. -- 1.359 In. Bend Radius Fixed (x4): 5.436 In. Bend Radius Flexible (x6): 8.154 In. Low Smoke? Yes MSHA? Yes UL / CSA: Yes

777 MCM Diesel Locomotive Cable 2KV

Voltage: RHH/RHW-2 600V & 2000V, RW-90 CSA, 1kV, DLO 2kV Amperage: 900 Amps Weight per 1000 Feet: 3050 lbs. Outside Diameter O.D. -- 1.382 In. Bend Radius Fixed (x4): 5.528In. Bend Radius Flexible (x6): 8.292 In. Low Smoke? Yes MSHA? Yes UL / CSA: Yes

929 MCM Diesel Locomotive Cable 2KV

Voltage: RHH/RHW-2 600V & 2000V, RW-90 CSA, 1kV, DLO 2kV Amperage: 1014 Amps Weight per 1000 Feet: 3123 lbs. Outside Diameter O.D. -- 1.670 In. Bend Radius Fixed (x4): 6.680 In. Bend Radius Flexible (x6): 10.020 In. Low Smoke? Yes MSHA? Yes UL / CSA: Yes

1111 MCM Diesel Locomotive Cable 2KV

Voltage: RHH/RHW-2 600V & 2000V, RW-90 CSA, 1kV, DLO 2kV Amperage: 1115 Amps Weight per 1000 Feet: 4354 lbs. Outside Diameter O.D. -- 1.840 In. Bend Radius Fixed (x4): 7.360 In. Bend Radius Flexible (x6): 11.040 In. Low Smoke? Yes MSHA? Yes UL / CSA: Yes

DLO cable lugs & Connectors

1X Technologies provides DLO Cable Lugs and Connectors for each size we sell. If you require a special connector or lug type we can manufacture that for you or source something specific from many of our supply chain partners such as Burndy, 3M, Belden, and more! Contact us today to order your DLO Cable lugs and connectors. Read the full article

0 notes

Text

Hydrophobic Mastic Waterstop with High Adhesion

Hydrophobic Mastic Waterstop For Concrete Construction Mastic waterstop is a hydrophobic watertight product with similar appearance of butyl rubber waterstop but totally different natures. With single component of mastic, the waterstop will not expand and create any internal joint pressure when exposed to water, so minimal concrete coverage is needed during installation.

https://www.jointwaterstop.com/product/mastic-waterstop.html

A coil of black mastic strip waterstop on the white background. Black color mastic strip waterstop.A coil of red mastic strip waterstop on the white background. Red color mastic strip waterstop. Features & benefits:

Excellent self-sealing and self-healing properties. Applied in any weather and temperature. Excellent adhesion to dry and clean surface. Easy and quick to install. Long service time without shrinking, hardening and oxidation over time. Minimum clear cover is needed. Suitable to be installed outside rebar to protect the steel form corrosion. No harm to surrounding concrete. Applications:

Ideal for all non-moving joints. Retaining or foundation walls. Pipe penetrations. Box culverts. Vaults and tunnels. Slab and manholes. Storage tanks. Any cast-in-place applications. Note: Not appropriate for moving joints.

Sizes: 6 mm × 25 mm, 15 mm × 20 mm, 20 mm × 30 mm, 20 mm × 50 mm, 30 mm × 50 mm, 10 mm × 40 mm or others as your request.

Package:

15 mm × 20 mm and 20 mm × 30 mm: 25 meters / box 30 mm × 50 mm: 10 meters / box Your nominated types of packages are also available.

Properties:

Physical properties Test method Results Specific gravity ASTM D-71 1.22 to 1.41 Flash point ASTM D-92 450 °F Fire point ASTM D-92 475 °F Ash inert materials ASTM D-482 35% Volatile materials ASTM D-6 1.20% Five coils of black butyl rubber waterstops are packed with plastic film and cardboard box The package of mastic waterstops

0 notes

Text

The Lineman's and Cableman's Handbook (13th Edition) - eBook

Check out https://duranbook.com/shop/the-linemans-and-cablemans-handbook-13th-edition-ebook/

The Lineman's and Cableman's Handbook (13th Edition) - eBook

Thoroughly updated to reflect the 2017 National Electrical Safety Code® (NESC®), this authoritative resource, The Lineman’s and Cableman’s Handbook 13th edition (PDF) explains the principles and practices of electric transmission and distribution line operation, construction, and maintenance. You will get comprehensive coverage of the latest equipment, newest techniques, and procedures along with current ANSI, OSHA, and ASTM regulations. Throughout, detailed photographs and illustrations make it easy to understand the material, and self-test exercises and questions reinforce key concepts.

The Lineman’s and Cableman’s Handbook, 13th Edition, covers:

* Electric systems * Electrical principles * Transmission and distribution circuits * Substations * Wood, aluminum, concrete, fiberglass, and steel structures and poles * Construction specifications * Distribution automation and the smart grid * Emergency system restoration * Unloading, hauling, erecting, setting, and guying poles * Insulators, crossarms, and conductor supports * Line conductors * Laying conduit * Manhole construction * Distribution transformers * Lightning and surge protection * Fuses and substation relays * Switches, sectionalizers, and reclosers * Voltage regulators * Transmission tower erection * Stringing, sagging, and joining line conductors * Live-line maintenance * Climbing wood poles * Grounding * Pulling and splicing cable * Underground distribution * Vegetation management * Distribution transformer installation * Electrical drawing symbols * Protective grounds * Street lighting * Underground systems * Single-line and schematic diagrams * Units of measurement, electrical formulas, electrical definitions, and calculations * Maintenance of transmission and distribution lines * Voltage regulation * Rope, knots, splices, and gear * Protective equipment * OSHA 1910.269 * Resuscitation * Pole-top and bucket truck rescue * And much more!

0 notes