#Hydraulic Testing Machine

Explore tagged Tumblr posts

Text

Manhole Cover Compression Testing Machine

Reliable and Accurate Testing for Manhole Covers The Manhole Cover Compression Testing Machine is a specialized testing device designed to assess the structural integrity of manhole covers under extreme pressure. This testing machine plays a crucial role in ensuring that manhole covers meet the required safety standards and durability expectations. Whether used for quality control in…

#ASTM Manhole Cover Test#Civil Engineering Testing#Compression Resistance#Compression Strength Test#Compression Testing#Construction Equipment Testing#Custom Testing Solutions#EN 124 Testing#Hydraulic Load Testing#Hydraulic Testing Machine#Industrial Testing Machines#ISO Manhole Cover Standards#Jinan Wangtebei Instrument#Load Cell Testing#Load Testing#Manhole Cover Compliance#Manhole Cover Deformation Test#Manhole Cover Performance Test#Manhole Cover Quality Control#Manhole Cover Strength#Manhole Cover Testing Equipment#manhole cover testing machine#Pressure Test Machine#Testing Equipment for Infrastructure#Testing Machine Manufacturer

0 notes

Text

In industrial applications, where precision and reliability are paramount, hydraulic testing machines play a critical role in ensuring the safety, durability, and performance of various components.

#hydraulic testing machine#pressure testing machine#hydraulic tester#hydraulic testing equipment#industrial pressure testing

0 notes

Text

Hydraulic Universal Testing Machine

Hydraulic Universal Testing Machine LB-10HUT is a digital display unit offers 200 KN test force. Features hydraulic loading with 2 to 100% FS of force measuring range. Designed with 2 columns and leading screws, has oil cylinder underneath work bench for stable performance. Equipped with hand panel for beam movement, metal cover and advance protection system for a reliable performance. With real time display of operating parameters and test curve, it also allows the result printing in excel or word format

0 notes

Text

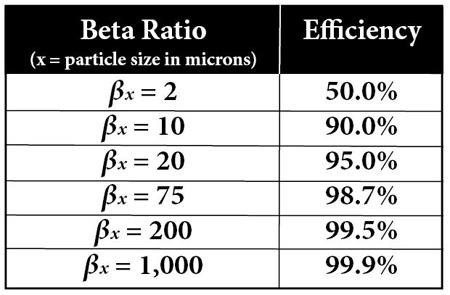

Understanding of the BETA factor

What is the Beta Ratio?

The beta ratio refers to the efficiency in which a given filter element removes the particle of a given size. The Beta Ratio is calculated using the ISO multi-pass test standard 16889:1999.

How is it measured?

Get your filter check today, Call +91 7030901266

So, to purchase a filter with a beta ratio of 2-10 is considered poor, it is advised to use filters with at least a Beta factor of 75 and 98.7% effectiveness. High quality, efficient filter assemblies can achieve 200 to 2000 Beta Ratio for given particle size and should be ideal to achieve a low level of contamination.

Also read: https://www.linkedin.com/pulse/you-buying-right-oil-filter-anshuman-agrawal-mlt-1-/

We at Minimac Systems Pvt Ltd. provide services of Total Lubrication Management and Lubrication Consulting that helps you optimize your Lubrication needs. Minimac stands for MINImum MAChinery Maintenance.

#frf#oil flushing#minimac systems#power#minimac#oil & gas#hydraulic oil#lube oil filter#hydraulic oil filter#contamination#oil purification system#oil purification machine#oil contamination#oil purification#oil testing#oil filter machine#oil filter systems#oil filters#oil industry#oil and gas#turbine oilanalysis maintenance lubrication reliability contaminationcontrol oil powerplants oilfiltration rotatingequipment mechanical bre#turbinemaintenance#wind turbines#gas turbine#steam turbine#steel#metal#mining#oil dehydration systems

2 notes

·

View notes

Text

🛢️ About Us – India’s Trusted Manufacturer for Oil Filtration Machines & Turbine Oil Cleaning Systems

Welcome to OilFilterMachineIndia.com, a leading manufacturer and exporter of industrial oil filtration systems and turbine oil cleaning equipment in India. With decades of industry experience, we provide innovative solutions for transformer maintenance, hydraulic systems, turbine operations, and more.

From mobile & portable filtration units to advanced oil contamination sensors and centrifugal oil cleaners, our systems are designed for efficiency, durability, and long-term performance across industrial sectors.

⚙️ Our Expertise Includes:

Turbine Oil Cleaning systems for power plants and heavy industries

High-efficiency Oil Filtration Machines and skids

Vacuum-based Transformer Oil Filtration setups

Precision-grade Industrial Oil Filters

Cutting-edge Oil Testing Equipment for real-time contamination tracking

Compact Mobile & Portable Filtration units for on-site maintenance

Smart Oil Contamination Sensors & moisture detectors

Durable Centrifugal Oil Cleaners for rotating equipment

Regenerative Oil Reclamation and reconditioning units

Turnkey Vacuum Impregnation Plant exporters in India

Custom solutions for Hydraulic Oil Filters & Thermic Oil Filtration

High-velocity Oil Flushing services and machines

Reliable Particle Counters for ISO cleanliness standards

Engineering-grade Varnishing Machines for electric motor applications

Full-scale Industrial Oil Filtration Systems for plant-level operations

🌐 Why Choose OilFilterMachineIndia.com?

Indian manufacturer with global reach

Exporters of oil purification, testing, and filtration equipment

End-to-end solutions from design to installation

In-house R&D and quality control

Trusted by OEMs, power stations, refineries, transformer manufacturers, and service providers

📍 Based in India | Serving Global Markets 🔗 Learn more about our company and commitment to quality: https://oilfiltermachineindia.com/about-us.html

#Turbine Oil Cleaning#Oil Filtration Machines#Transformer Oil Filtration#Industrial Oil Filters#Oil Testing Equipment#Mobile & Portable Filtration#Oil Contamination Sensors#Centrifugal Oil Cleaners#Oil Reclamation#Vacuum Impregnation Plant Exporters in India#Hydraulic Oil Filters#Thermic Oil Filtration#Oil Flushing#Particle Counters#Varnishing Machines#Industrial Oil Filtration Systems.

0 notes

Text

Optimize Equipment Life with Advanced Industrial Oil Purification Units from Omsai PS Enterprises

In industries where machinery performance and reliability are mission-critical, the quality of lubricating and hydraulic oil can make or break operations. Contaminated oil leads to wear, energy loss, and system breakdowns. That's why Omsai PS Enterprises, in collaboration with AR Engineering, offers a range of Industrial Oil Purification Units and Oil Filtration Machines designed to purify, clean, and maintain the oil quality at optimum levels.

What Is an Industrial Oil Purification Unit?

An Industrial Oil Purification Unit is a specialized oil processing solution that removes water, particulate matter, and gases from various types of industrial oils, such as transformer oil, hydraulic oil, turbine oil, gear oil, and thermic fluid. These units are essential for any industry that relies on heavy machinery and precision equipment.

Our Comprehensive Oil Filtration & Purification Offerings

🔧 Industrial Oil Filter Machine

Our Industrial Oil Filter Machines are engineered for high throughput and can handle various oil types. They play a vital role in preventing contamination-related failures in machinery.

💡 Oil Filtration Systems & Units

We offer complete Oil Filtration Systems and Oil Filtration Units tailored to your application. These systems are easy to install, operate, and maintain, ensuring clean oil in the most efficient way.

⚡ Double Stage Oil Transformer Machine

Our Double Stage Oil Transformer Machine is a high-vacuum purification system ideal for removing moisture, gases, and particles from transformer oil. It's widely used in power plants and substations for industrial oil treatment and insulation restoration.

🛠 Oil Filtration Elements

We provide superior-grade Oil Filtration Elements that enhance the efficiency of your filtration system. These components are designed to trap fine particulates, extending oil life and equipment durability.

Specialized Oil Purification Equipment

Our Oil Purification Systems include a range of advanced oil purifiers for various industrial needs. Whether it's for hydraulic oil, lube oil, or thermic fluids, we deliver purpose-built Oil Purification Equipment that ensures the oil meets required purity standards.

Advanced Technologies and Solutions

🔄 Hydraulic Oil Online Filters

Our Hydraulic Oil Online Filters allow for real-time, in-operation oil filtration. These are perfect for CNC machines, hydraulic presses, and other precision systems that require uninterrupted oil circulation and protection from contaminants.

🌡 Thermic Oil Filtration Systems

Used in heat transfer applications, our Thermic Oil Filtration Systems remove carbon, sludge, and moisture to keep the thermal systems efficient and safe.

🧪 On-Site Oil Testing

With On-Site Oil Testing, we help clients assess oil quality without halting operations. We analyze key parameters and suggest corrective actions based on accurate diagnostics.

Why Choose Omsai PS Enterprises?

🛡 Proven collaboration with AR Engineering

🧠 Decades of expertise in Industrial Oil Filtration and purification

🛠 Robust, high-efficiency Oil Filtration Machines and systems

🔄 End-to-end support including testing, treatment, and maintenance

♻️ Sustainable solutions for oil reuse and equipment longevity

Serving Multiple Industries

Our Industrial Oil Purification Units are trusted by clients across:

Power generation and utilities

Automotive manufacturing

Steel and cement industries

Petrochemical plants

Heavy machinery and engineering sectors

#Industrial Oil Filter Machine#Oil Filtration Systems#Double Stage Oil Transformer Machine#Oil Filtration Elements#Oil Filtration Machine#Oil Filtration & Cleaning Systems#Thermic Oil Filtration Systems#On-Site Oil Testing#Hydraulic Oil Online Filters#Industrial Oil Purification Unit#Oil Purification Systems#Industrial Oil Filtration#Oil Purification Equipment#Oil Filtration Unit#Industrial Oil Treatment#Omsai Enterprises#AR Engineering#Oil Processing Solutions#Advanced Oil Purifiers#Oil Filtration Machines"

0 notes

Text

Powerful Drain Cleaning Machines for Industrial Use

Discover high-performance drain cleaning machines designed for industrial use. Engineered for efficiency, these machines tackle tough blockages with ease, ensuring smooth and uninterrupted drainage. Ideal for professionals, they offer durability, power, and reliability. Upgrade your maintenance process with cutting-edge technology from Rothenberger Singapore. Explore the best solutions for drain cleaning today!

Visit Our Website: https://aaron-accessories.com/industrial/rothenbergersingapore/

#DRAIN CLEANING MACHINES#MANUAL & ELECTRICAL HYDRAULIC PIPE BENDING MACHINES#ROTHENBERGER PIPE TOOLS#TEST PUMPS#VACUUM PUMPS

0 notes

Text

From Humidity Chambers to Testing Machines - India’s Expert Equipment Manufacturer

Kant Plastology has established itself as a leader in the field of manufacturing high-quality testing and processing equipment. With a strong focus on innovation and precision, we are dedicated to delivering solutions that meet the diverse needs of industrial, research, and development sectors across India and beyond. Our products are engineered with cutting-edge technology to ensure superior performance and reliability, making us a trusted partner for businesses and institutions.

We take pride in offering a comprehensive range of machinery that caters to different industries, including materials testing, manufacturing, and quality control. Our commitment to customer satisfaction drives us to continuously innovate and create products that help our clients achieve accurate and repeatable results. With strict quality control and advanced manufacturing practices, Kant Plastology ensures that every machine leaving our facility meets the highest industry standards.

Reliable Manufacturing Equipment for Industrial, Research, and Quality Control Needs

One of our standout products is the universal tensile testing machine, designed to deliver precision in evaluating material strength, elasticity, and tensile properties. This machine is vital for industries requiring consistent quality assurance in their production processes. Additionally, as a leading hydraulic press machine manufacturer in India, we offer robust solutions tailored for applications requiring high-pressure operations, ensuring efficiency and durability in every project.

Kant Plastology is also renowned as a humidity chamber manufacturerin India, providing equipment that offers controlled environments for testing materials under various temperature and humidity conditions. Furthermore, as a trusted tensile testing machine manufacturer, we focus on creating customizable solutions that cater to the specific testing needs of our clients.

At Kant Plastology, we believe in building relationships based on trust, quality, and exceptional service. Our goal is to empower businesses with reliable machinery that enhances their operational efficiency and supports their growth. Partner with us today and experience the expertise and dedication that set Kant Plastology apart in the industry.

#tensile testing machine manufacturer#humidity chamber manufacturerin India#hydraulic press machine manufacturer#universal tensile testing machine

0 notes

Text

youtube

Computerised Tensile Testing Machine, Servo Based Computerised UTM, for metals, plastics, textiles

🔬⚙️ Precision Meets Strength with the Servo-Controlled Tensile Testing Machine! ⚙️🔬

Engineered for high-accuracy material testing, this advanced machine measures tensile strength, elongation, and mechanical properties across various materials – metals, plastics, textiles, rubbers, and composites. 💡🔍

💪 Why Choose a Servo Controlled System? ✅ Precision & Control – Servo motor-driven for accurate force, speed, and displacement control 🎯 ✅ Versatile Applications – Ideal for research, quality control, and industrial testing 🏭🔬 ✅ Reliable & Efficient – Ensures consistent and repeatable results for all material testing needs 📊

Related Standards: ISO 6892-1, ISO 2062, ISO 527-1, ASTM D638, ASTM D882, ASTM D5034

TEXCARE Testing Instruments : 24x7 Customer support: +91-8802270444

📧 Email: [email protected]

🌐 Web: www.texcareindia.com

📞 Contact Us: 91-9899309879, +91-9990592299 📞

📍 Visit us at I-84, Road No. 19, UPSIDC Site-C, Surajpur Industrial Area, Greater Noida-201306 (UP) 📍

. .

Precision #Strength #Testing #Accuracy #Innovation #Technology #Engineering #Material #Quality #Research #Industry #Tensile #Control #Efficiency #Performance #Durability #Reliability #Measurement #Science #Lab #Mechanical #Manufacturing #Structure #Development #Industrial #Solutions #Advanced #TestingLab

elongation of Plastic tensile testing machine, servo controlled universal bending in kolkata, What is the use of UTM tensile testing machine? Servo Controlled Universal Testing Machine Manufacturer in India, Servo Controlled Universal Testing Machine Supplier in India, What is the use of UTM tensile testing machine? for metals, plastics, textiles, rubbers, and composites

#Servo Controlled Universal Testing Machine Near Me#universal tensile testing machine price#Servo Controlled Hydraulic Universal Testing Machines near me#servo controlled universal testing machine standards#computerised servo controlled universal bending test machine in India#Digital Servo Controlled Tensile Testing Machine in Delhi#Servo Controlled Tensile Testing Machine for Rubber#servo control universal testing machine for metal#tensile strength testing machine in Pune#Youtube

0 notes

Text

1 note

·

View note

Text

What is ultrasound condition monitoring?

Caravan Reliability Services Provide Best bearing maintenance training and preventive and predictive maintenance for the Industries.

What if we could monitor the condition of the machine on a regular schedule without stopping the machine?

The advantages of regular condition monitoring are:

Reduction of the Duration of Scheduled Maintenance: As the condition of the machine will be known well before the machine is stopped for maintenance, lesser time can be spent in visually inspecting components.

Reduction in the number of Unplanned Stops: Regular condition monitoring will reduce the number of unplanned stops as the condition and life of the various components can be predicted and a plan can be put in place to replace or repair them.

ABOUT US

Caravan Oil Suppliers has been offering solutions in lubrication of machines for the past 40+ years. It is with this experience that we have launched our new division; Caravan Reliability Services.Through Caravan Reliability Services, we aim to give our customers proactive technical maintenance for their machines using the latest technology which allows the machine to continue operation while being analysed. We also provide training on effective continued bearing and lubricant maintenance.

Our expert, Pratap Kemble, is a professional mechanical engineer with over 25 years of experience in the field of bearing technology, bearing maintenance, bearing lubrication, bearing lubrication methods. centralized lubrication systems, bearing failure analysis, and Ultrasound condition monitoring.. He and our team can not only analyses the condition of the machines but interpret the results and give a comprehensive report that helps customers make a more informed decision.

Ultrasound Condition Monitoring (Predictive Machine Maintenance):-

We can provide predictive machine maintenance . We can help you plan repairs ahead of time and increase machine life by accurately predicting the condition of machine components using our ultrasonic listening device.

CONTACT US

Address

106 Road Number 4, 2nd Phase, Jigani Industrial Area, Anekal Taluk, Bangalore Disctrict 562102

Call Us

+91 99728 10317

Email

#ultrasound condition monitoring#shell high temp grease#shell hydraulic oil 68#lubricant oil suppliers#lubricants distributorship#lubricant suppliers#3m tape distributors in bangalore#shell lubricants#lubricant oil distributor#shell lubricants distributors#grease distributor#machine bearing#root cause analysis tools#thermography testing#lubricating oil uses#maintenance services#laser alignment tool#bearing lubricant#industrial maintenance#preventive maintenance#predictive maintenance#preventive and predictive maintenance#machine preventive maintenance#bearing maintenance#mounting of bearing#bearing guide#training on machine maintenance#Bearing Training Course#lube management#machine maintenance

0 notes

Text

Computerized Universal Testing Machine Front Open with Hydraulic Grip

Computerized universal testing machine with a front-open design and hydraulic grip is a versatile testing instrument used for evaluating the mechanical properties of various materials. This type of machine offers a front-opening configuration, allowing easy sample loading and positioning, while hydraulic grips provide secure and reliable clamping of the test specimens. Consider the maximum load capacity of the testing machine, which determines the range of materials and specimen sizes it can handle. Machines typically have load capacities ranging from a few kilonewtons to several hundred kilonewtons or more, depending on the application requirements.

Universal Testing Machines supplied completed with UTM Software. It has a wide range of applications. A number of materials and metals in different forms and shapes can be tested for a variety of tests like tension, Compression, Transverse, Bend, Shear, Brinell Hardness, etc. Special attachments are also available for testing of flat belts, chain links, wire ropes etc.

Universal Testing Machines have a wide range of applications and number of materials, metals in different form and shapes can be tested for variety of tests like Tension, Compression, Transverse, Bend, Shear, Brinell Hardness etc. Special attachments are also available for testing of Flat Belts, Chain Links, Wire Ropes etc.

Hydraulic grips provide a reliable clamping mechanism for securing the test specimen during testing. The hydraulic system allows for controlled and consistent gripping force application, ensuring accurate and repeatable results.

testing machine, universal testing machine, computerized universal testing machine, universal testing machine with hydraulic, computerized universal testing machine with hydraulic, universal testing machine with front open, universal testing machine with hydraulic front open

#manufacture#industrial equipment#metallurgical#manufacturer#testing#metallographicequipments#testing machine#universal testing machine#front open universal testing machine#hydraulic universal testing machine#computerized universal testing machine#universal testing machine with hydraulic#universal testing machine with front open

1 note

·

View note

Text

Recording the pressure, the system can identify any possible container defects or leaks that could endanger its safety. To ensure the safety and longevity of devices under operational pressure, the hydraulic testing machine and unit are crucial for pressure vessels.

#hydraulic testing machine#pressure testing machine#hydraulic tester#hydraulic testing equipment#industrial pressure testing

0 notes

Text

Hydraulic Universal Testing Machine

Hydraulic Universal Testing Machine is a digital display unit offers 200 KN test force. Features hydraulic loading with 2 to 100% FS of force measuring range. Designed with 2 columns and leading screws, has oil cylinder underneath work bench for stable performance. Equipped with hand panel for beam movement, metal cover and advance protection system for a reliable performance. With real time display of operating parameters and test curve, it also allows the result printing in excel or word format.

0 notes

Text

Efficient Transformer Oil Filtration | High-Performance Machine

Introduction

Welcome to the world of transformer oil filtration, the key to maximizing the performance and efficiency of your power transformers. In this article, we will explore the importance of this critical maintenance process and how it can significantly enhance the lifespan and reliability of your equipment.

Transformer oil, also known as insulating oil, is responsible for several crucial functions in power transformers, such as heat dissipation, insulation, and arc quenching. Over time, however, contaminants and impurities can accumulate in the oil, compromising its effectiveness and putting your entire power system at risk. That's where “Transformer Oil Filtration” comes into play. By removing contaminants, moisture, and gases from the oil, this process ensures optimal performance and extends the lifespan of your transformers. It not only eliminates the risk of costly breakdowns but also improves energy efficiency, reducing maintenance and downtime expenses. At Minimac Systems, we understand the importance of maximizing performance and efficiency while minimizing operational costs. Our transformer oil filtration system is designed to deliver exceptional results, offering unmatched reliability and ensuring the smooth operation of your power transformers. Experience the power of transformer oil filtration and take a transformative step towards optimal performance and long-lasting reliability of your power systems.

Importance of Transformer Oil Filtration:

Transformer oil plays a vital role in insulation, cooling, and protecting internal components. Over time, contaminants such as water, sludge, and oxidation by-products degrade the oil's properties, leading to inefficiency and potential failure. Regular oil filtration is essential to prevent costly breakdowns and prolong transformer life. Investing in an advanced filtration machine ensures your transformers operate reliably, minimizing maintenance costs and ensuring compliance with industry standards.

What is Transformer Oil Filtration?

Transformer oil filtration removes contaminants and restores the oil’s properties. The process involves coarse and fine filtration, vacuum dehydration, and degassing. This restores the oil's dielectric strength, maintains cooling efficiency, and prevents electrical failures. Regular filtration as part of a maintenance program reduces the need for frequent repairs, minimizes downtime, and ensures the reliable performance of the electrical system.

Benefits of Efficient Transformer Oil Filtration

Improved Performance and Reliability:Removing impurities ensures better insulation and cooling, which enhance transformer reliability and reduce the risk of electrical failures.

Extended Transformer Lifespan:Filtration slows down the aging process of transformer components, helping you avoid premature breakdowns and extend equipment life.

Reduced Maintenance Costs:Efficient filtration decreases the frequency of oil changes and transformer repairs, leading to significant cost savings over time.

Enhanced Energy Efficiency:Clean oil improves transformer efficiency, which reduces energy losses and operating costs while also lowering the organization’s carbon footprint.

Regulatory Compliance: Maintaining clean oil through proper filtration helps meet industry standards and ensures the responsible operation of electrical infrastructure.

Common Contaminants in Transformer Oil

Water:Even minimal water contamination can significantly reduce oil’s dielectric strength, leading to electrical failures and degraded insulation.

Sludge:Formed due to oxidation, sludge can clog filters and hinder heat transfer, reducing cooling effectiveness.

Oxidation By-products:Prolonged heat and oxygen exposure lead to varnish-like deposits that corrode components and compromise the oil's insulating properties.

Particulate Matter: Dust, metal filings, and other particles in the oil cause abrasive wear on transformer parts, leading to more frequent maintenance.

Dissolved gases:Gases like hydrogen and acetylene formed during transformer operation indicate internal issues and require immediate attention and filtration.

Understanding the Transformer Oil Filtration Process

Coarse Filtration:This initial stage removes large particles like dust, metal filings, and sludge, protecting downstream filter components from clogging.

Fine Filtration: In this stage, smaller contaminants like water, fine particulates, and oxidation by-products are removed, restoring the oil’s insulating properties.

Vacuum Dehydration:his step extracts any remaining water from the oil, further enhancing its dielectric strength and preventing electrical issues.

Continuous monitoring throughout the filtration process ensures the oil meets the required safety and performance standards.

Features of our Filtration Machine

High-Efficiency Filtration:Our multi-stage system combines coarse and fine filtration, vacuum dehydration, and degassing to comprehensively remove contaminants, restoring oil to optimal condition.

Automated Control System:The system is equipped with real-time monitoring and adjustments to maximize efficiency, reducing the need for manual intervention.

Compact and Portable Design:Our machine’s design makes it easy to transport and set up at different locations, ensuring flexible and efficient on-site filtration.

User-Friendly Interface:Operators can easily monitor and adjust settings through an intuitive control panel, minimizing errors and ensuring smooth operation.

Robust Construction:Built to withstand tough industrial conditions, the machine is durable and requires minimal maintenance.

Steps to Efficiently Filter Transformer Oil

Preparation:Ensure the transformer is isolated and the oil is at the correct temperature. Set up the necessary equipment and workspace.

Coarse Filtration:Use a coarse filter to remove large contaminants like dust, metal filings, and sludge.

Fine Filtration:Move on to fine filtration to eliminate smaller impurities, such as water and oxidation by-products, restoring the oil-insulating strength.

Vacuum Dehydration: If needed, perform vacuum dehydration to remove any residual water from the oil.

Degassing:In cases where dissolved gases are present, degassing will improve oil quality and performance.

Continuous Monitoring:Track key parameters such as dielectric strength, water content, and dissolved gas levels to ensure that the oil meets the required specifications.

Disposal and Recycling:Dispose of waste materials following environmental regulations. In some cases, the filtered oil may be reusable, contributing to sustainable maintenance practices.

Maintenance and Care for the Filtration Machine

Proper care and maintenance of your transformer oil filtration machine ensure long-term reliability and efficiency. Here’s how to maintain your equipment:

Regular Inspections:Check for wear, damage, and changes in performance. Identifying issues early reduces the risk of malfunctions.

Scheduled Maintenance: Follow the manufacturer’s maintenance schedule, including filter replacements and component lubrication, to ensure peak performance.

Calibration and Testing:Regularly calibrate the machine’s sensors to ensure accurate monitoring and filtration.

Operator Training:Ensure all operators are trained on the machine’s features, functions, and maintenance requirements to avoid user errors.

Spare Parts Management:Keep an inventory of essential spare parts like filters, gaskets, and seals to avoid unnecessary downtime during repairs. By following these maintenance guidelines, you can ensure that your transformer oil filtration machine operates efficiently and remains reliable over the long term.

Conclusion

Investing in our transformer oil filtration system helps ensure your transformers operate efficiently with minimal downtime and reduced maintenance costs. With a multi-stage filtration process, user-friendly controls, and robust construction, our system is designed to meet the highest industry standards. Regular filtration keeps transformer oil clean, extends transformer lifespan, and optimizes energy efficiency. Choose our advanced filtration machine to safeguard your power systems and achieve long-lasting reliability.

#frf condition systems#frf machine#frf#oil flushing#minimac systems#power#minimac#oil & gas#hydraulic oil#contamination#lube oil filter#hydraulic oil filter#oil purification machine#oil testings#minimac technology#oil technology#technology#innovation#efficiency#iiot#flushing systems#flushing machine#condition monitioring

1 note

·

View note

Text

🛢️ Oil Filtration Machines & Turbine Oil Cleaning Solutions in India – OilFilterMachineIndia.com

OilFilterMachineIndia.com is your trusted destination for turbine oil cleaning, transformer oil filtration, and advanced industrial oil filters across India. We specialize in designing and manufacturing high-performance systems for on-site, mobile, and continuous oil purification across industries like power generation, manufacturing, automotive, and heavy engineering.

Whether you require portable & mobile oil filtration units, centrifugal oil cleaners, or online oil cleaning systems, we offer the most effective solutions to extend machinery life, reduce downtime, and improve energy efficiency.

⚙️ Our Core Offerings Include:

Turbine Oil Cleaning Machines for power and energy sectors

Robust Oil Filtration Machines for industrial and mobile use

Precision-based Transformer Oil Filtration systems

Heavy-duty Industrial Oil Filters India for gear, lube, and hydraulic oils

Smart Oil Testing Equipment India with real-time data output

Advanced Online Oil Cleaning & purification setups

High-speed Centrifugal Oil Cleaners for rotating equipment

Laser Particle Counters for cleanliness verification

Moisture Measurement devices to protect oil integrity

Custom Hydraulic & Gear Oil Filtration units

Durable Transformer Evacuation Systems

End-to-end Oil Reclamation Units India

Professional On-Site & Online Oil Testing in India

🌍 Why Choose OilFilterMachineIndia.com?

Industry-grade filtration & testing systems

Made-in-India technology with global standards

Energy-efficient and eco-friendly operations

Fast delivery and expert support team

Trusted by power plants, transformer repair units, and OEMs

📍 Serving clients across India and internationally 🔗 Learn more: https://oilfiltermachineindia.com

#Turbine Oil Cleaning#Oil Filtration Machines#Transformer Oil Filtration#Industrial Oil Filters#Portable & Mobile Oil Filtration#Industrial Oil Filters India#Oil Testing Equipment India#Online Oil Cleaning#Centrifugal Oil Cleaners#Laser Particle Counters#Moisture Measurement#Hydraulic & Gear Oil Filtration#Transformer Evacuation Systems#Oil Reclamation Units India#On-Site & Online Oil Testing India

0 notes