#Aerial Cable Connectors Factory

Explore tagged Tumblr posts

Text

Mechanical Cable Lugs for 36kV Systems: Essential Components for High-Voltage Connections

In high-voltage electrical systems, ensuring reliable, secure, and safe connections is critical to maintaining power flow and system integrity. One of the unsung heroes in these systems are mechanical cable lugs, which play a vital role in connecting power cables to electrical equipment like transformers, circuit breakers, and busbars. Specifically, 36kV systems, which operate at voltages up to 36,000 volts, require specialized lugs that can handle the high stresses, electrical loads, and environmental challenges associated with such high power transmission.

In this blog post, we will explore the function of mechanical cable lugs in 36kV systems, the key factors to consider when selecting the right lugs, and the advantages they bring to high-voltage applications.

What Are Mechanical Cable Lugs?

A mechanical cable lug is a type of connector used to attach a power cable to electrical equipment. Mechanical lugs are typically made from copper, aluminum, or a combination of both metals, and they provide a solid, reliable electrical connection by using a mechanical force—often through bolts or screws—to clamp onto the cable conductors.

For high-voltage applications like 36kV systems, mechanical cable lugs are engineered to handle high current loads, resist mechanical stresses, and ensure optimal performance in tough environmental conditions. Unlike compression lugs, which rely on a hydraulic or crimping force to connect the cable, mechanical lugs offer a more direct, adjustable solution, making them ideal for certain high-voltage scenarios.

The Role of Mechanical Cable Lugs in 36kV Systems

1. Providing Reliable Electrical Connections

The primary function of mechanical cable lugs is to create a secure electrical connection between power cables and electrical components, such as switchgear, transformers, or distribution panels. In 36kV systems, where voltages can be high and the current loads significant, the quality and reliability of these connections are critical.

Mechanical lugs are designed to minimize the risk of contact resistance—a key factor in ensuring that electrical energy flows efficiently without causing overheating or sparking. Poor connections can lead to energy losses, equipment damage, and even dangerous faults. The bolted, adjustable design of mechanical lugs ensures a strong, consistent connection that can be easily maintained or adjusted as needed.

2. Handling High Electrical Loads

36kV systems, commonly found in power transmission and distribution grids, can carry substantial electrical currents. As a result, the components used to connect cables to electrical systems must be able to handle these high electrical loads without degrading over time. Mechanical lugs are designed to offer superior current-carrying capacity, often rated to handle high short-circuit and continuous current ratings.

The construction of mechanical lugs, usually made from copper or aluminum, provides the necessary conductivity to manage high-voltage power transmission without risk of overheating or failure.

3. Ensuring Mechanical Strength and Durability

In addition to electrical conductivity, mechanical strength is a crucial requirement for lugs used in high-voltage systems. Mechanical lugs need to withstand substantial tensile forces (from the weight of cables, thermal expansion, and other mechanical stresses) without loosening or breaking. The bolted design of mechanical lugs allows them to maintain a firm grip on the cable, preventing movement or slippage, even in environments where vibration or external forces are present.

The durability of mechanical lugs is especially important in 36kV systems, where equipment is often located in challenging outdoor environments or industrial settings. Lugs must resist exposure to weather, chemicals, UV radiation, and temperature fluctuations, ensuring that they provide reliable service over the long term.

4. Easy Installation and Maintenance

One of the significant advantages of mechanical lugs is their ease of installation. Unlike compression lugs, which require special crimping tools or hydraulic presses, mechanical lugs can be easily installed using standard hand tools, such as wrenches or torque drivers. This makes them more accessible for field installations and maintenance, especially in the case of urgent repairs or upgrades.

In high-voltage systems, where downtime can result in significant financial and operational costs, the quick and straightforward installation of mechanical lugs helps reduce downtime and improve system reliability. Additionally, the ability to easily adjust the torque applied to the lug allows for precise and repeatable connections, which are critical to ensuring long-term safety and performance.

Key Features of Mechanical Cable Lugs for 36kV Systems

When selecting mechanical cable lugs for a 36kV system, several key factors must be considered to ensure optimal performance:

1. Material Composition

The material used in mechanical lugs plays a Mechanical cable lugs for 36KV significant role in their performance. The two most common materials are copper and aluminum:

Copper Lugs: Copper is known for its excellent electrical conductivity and is commonly used in high-voltage applications where maximum conductivity is essential. Copper also has high tensile strength, making it ideal for applications where mechanical stress may be present.

Aluminum Lugs: Aluminum is a lightweight, cost-effective alternative to copper. While its conductivity is lower than that of copper, aluminum lugs are often used in 36kV systems because they offer a good balance between performance and cost. Aluminum is also resistant to corrosion, which is essential for outdoor or industrial applications.

2. Voltage Rating and Current Carrying Capacity

Mechanical lugs must be rated for the voltage and current of the 36kV system. These lugs should meet or exceed the system’s maximum voltage rating, which ensures that the electrical connections are safe and reliable under full operational loads.

The current-carrying capacity of the lug is equally important. Mechanical lugs must be sized appropriately to handle the maximum expected current without overheating or causing damage to the cable or connected equipment.

3. Torque and Tightening Specifications

The torque applied during the installation of mechanical lugs is crucial for ensuring the correct electrical connection. Too little torque may lead to a loose connection, while too much torque could damage the cable or the lug. Many mechanical lugs come with torque specifications to ensure the correct amount of tightening, and using a torque wrench during installation helps maintain consistent performance.

4. Environmental Resistance

For outdoor or industrial 36kV applications, mechanical lugs must be resistant to environmental factors such as moisture, dust, UV radiation, and chemicals. This is particularly important for installations in harsh environments, such as power stations, substations, or areas with extreme weather conditions.

Lugs may be coated or treated with materials such as tin or zinc plating to protect them from corrosion, or they may be designed with specific weatherproofing features to ensure long-lasting performance.

5. Size Compatibility

It is essential to select a mechanical lug that is compatible with the cable size being used in the 36kV system. Lugs come in a range of sizes to accommodate different cable diameters, and using a lug that is properly sized for the cable ensures a secure, efficient connection. Incorrect sizing can lead to poor contact, overheating, or even cable damage.

Benefits of Using Mechanical Cable Lugs for 36kV Systems

1. Reliable, Secure Connections

Mechanical cable lugs offer reliable connections with minimal risk of failure. By providing a tight and adjustable connection, they help ensure the stable operation of 36kV systems and reduce the risk of power outages or equipment damage caused by loose or faulty connections.

2. Ease of Installation and Maintenance

Mechanical lugs are easier to install than other types of lugs, as they do not require specialized tools for crimping. They are also easy to inspect and maintain, which is crucial for ensuring ongoing system reliability and reducing downtime.

3. Long-Term Performance

Given their durability and resistance to mechanical stress and environmental factors, mechanical cable lugs offer long-term performance, making them a cost-effective solution for high-voltage power systems. Once installed, they provide consistent, dependable service without the need for frequent maintenance or replacement.

4. Cost-Effective Solution

While mechanical lugs may have a higher upfront cost than other types of lugs, their durability, ease of installation, and reduced maintenance needs make them a cost-effective solution over the lifespan of a 36kV system. They also help prevent costly failures or downtime associated with loose or faulty connections.

Mechanical cable lugs are a critical component in the safe, efficient, and reliable operation of high-voltage systems, including those that operate at 36kV. By providing strong, durable, and easy-to-install connections, mechanical lugs ensure the seamless transmission of Underground Cable Connectors power while minimizing risks associated with electrical faults. When selecting mechanical lugs for your 36kV system, it’s essential to consider factors such as material, voltage rating, current capacity, and environmental resistance to ensure optimal performance.

Whether you’re installing new equipment, upgrading existing infrastructure, or performing maintenance, mechanical cable lugs offer a dependable solution to keep your high-voltage systems running smoothly.

#Mechanical cable lugs for 36KV#Low voltage mechanical cable lugs#Underground Cable Termination Manufacturer#Underground Cable Connection Manufacturer#Aerial Cable Connectors#Underground Cable Connectors#Aerial Cable Connectors Factory#Aerial Cable Connectors Factory China

0 notes

Text

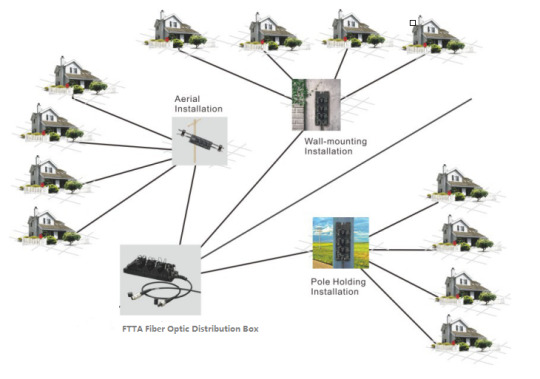

Why Multiport Service Terminal Box Is a Game-Changer for FTTP

The Multiport Service Terminal Box changes the way fiber networks operate. Network operators choose the 8 port fiber optic MST terminal box with pre-insta for its strong build and easy setup. The FTTH network MST terminal assembly with flexible c and the outdoor rated MST distribution box with hardened a both ensure lasting protection in harsh conditions.

Key Takeaways

The Multiport Service Terminal Box makes fiber network installation faster and easier with pre-terminated cables and flexible mounting options, saving time and reducing errors. Its modular design supports network growth by allowing easy upgrades without major changes, helping operators meet increasing demand smoothly. Built with strong, weather-resistant materials, the box protects connections in harsh outdoor conditions, ensuring long-lasting and reliable network performance.

Key Advantages of Multiport Service Terminal Box

Simplified Installation Process Network operators often face challenges when deploying fiber to the premises. The Multiport Service Terminal Box addresses these issues with a technician-friendly design. Factory-sealed or field assembly options make deployment straightforward. Hardened adapters, fully compatible with OptiTap and other industry standards, allow for rapid plug-and-play connections. The IP68 waterproof rating ensures the box performs well in harsh outdoor environments. Multiple mounting options, such as wall, aerial, pole, pedestal, and handhole, provide flexibility for different installation scenarios. The low-profile design and decreased angle surfaces prevent connector interference during operation. Factory pre-terminated cables eliminate the need for fiber splicing or opening the closure, saving time and reducing errors. Effective cable management reduces clutter and enhances network reliability. Tip: Dowell’s Multiport Service Terminal Box helps technicians complete installations up to 40% faster, lowering operational costs and improving service delivery. Enhanced Network Scalability The Multiport Service Terminal Box supports network growth with ease. Providers can choose from multiple port configurations, including 4, 8, or 12 ports, to match current needs and future expansion. The modular design allows for incremental upgrades without major infrastructure changes. For example, a 12-port terminal with pre-connectorized pigtails and externally mounted hardened adapters enables plug-and-play installation. This approach supports future expansions without re-entering the closure, minimizing disruption. Dowell’s solutions ensure that operators can scale their networks efficiently, meeting growing bandwidth demands and supporting new subscribers as needed. Superior Protection and Durability Feature/Material Description/Benefit Material ABS+PC or polycarbonate plastic for strong mechanical strength and environmental resistance Waterproof Rating IP67 or IP68 for water and dust protection Pulling Force Resistance Withstands long-term pulling forces up to 1200N UV Resistance Complies with SO4892-3 standard for outdoor durability Fire Protection Rating UL94-V0 fire retardant properties Cable Glands Torsion-proof glands relieve stress on cables, preventing fiber breakage Installation Flexibility Suitable for wall, aerial, or pole mounting Assembly Options Factory-sealed or field assembly reduces fiber splicing and environmental exposure Compatibility Works with ODVA, H connector, Mini SC, ODC, PTLC, PTMPO, and more Dowell’s Multiport Service Terminal Box uses these advanced materials and design features to ensure long-lasting performance, even in the most demanding outdoor environments. Cost-Effectiveness The Multiport Service Terminal Box delivers significant cost savings for network operators. Factory pre-terminated cables and plug-and-play adapters reduce installation time and labor costs. The robust, sealed design minimizes maintenance needs and extends product lifespan. Flexible mounting options and modularity lower the need for additional hardware or future upgrades. Effective cable management and technician-friendly features further reduce operational expenses. Note: Dowell’s commitment to quality and innovation ensures that every Multiport Service Terminal Box provides excellent value, helping operators maximize their return on investment.

Multiport Service Terminal Box in Real-World FTTP Deployments

Overcoming Space Constraints Network operators often face limited space in dense urban environments. The Multiport Service Terminal Box provides a compact solution for these challenges. The Mini-MST design supports multiple fiber connections in a single, small unit. Operators can install the box in tight spaces without losing performance. The device allows for high-density connectivity, which is essential in crowded city areas. Dowell offers models with dimensions as small as 210x105x93mm, making them easy to fit in limited locations. Multiple mounting options, such as wall, pole, and aerial, give flexibility for different sites. Miniaturized connectors and universal mounting brackets help technicians install the box quickly, even in hard-to-reach spots. These features help network operators maximize connectivity while using minimal physical space. Environmental Protection for Outdoor Networks Outdoor fiber networks must withstand harsh weather and environmental hazards. The Multiport Service Terminal Box uses rugged, weather-resistant materials to protect connections. Factory-sealed, hardened connectors keep out dirt, moisture, and dust. The enclosure meets IP68 standards, ensuring reliable operation in rain, snow, or extreme temperatures. Dowell designs both underground and aerial models to handle different outdoor conditions. The box resists UV rays and mechanical stress, which extends its service life. These qualities make the terminal box a dependable choice for outdoor FTTP networks. Maintenance and Upgrade Efficiency Efficient maintenance and upgrades are vital for network reliability. The Multiport Service Terminal Box simplifies these tasks with its modular and pre-terminated design. Technicians can add or replace ports without opening the enclosure or splicing fibers. The modular structure allows for quick network expansion with minimal disruption. Dowell’s solution supports rapid troubleshooting, thanks to features like modular fault detection. Compatibility with standard connectors, such as OptiTap and DLX, ensures easy integration with existing infrastructure. These advantages reduce labor time and help operators keep networks running smoothly. Faster Network Rollouts and Reduced Downtime Speed matters in FTTP deployments. The Multiport Service Terminal Box helps operators roll out networks faster and with less downtime. Pre-terminated connectors allow for plug-and-play installation, which saves time and reduces errors. The compact, modular design supports quick upgrades and expansions. Durable materials lower the need for frequent maintenance or replacement. Dowell’s terminal boxes include features for rapid fault detection, so technicians can fix issues quickly. These benefits lead to faster service delivery and improved network uptime. Customer Satisfaction and Long-Term Value Reliable connectivity and easy maintenance lead to higher customer satisfaction. The Multiport Service Terminal Box delivers long-term value for both operators and end-users. The robust design ensures stable performance over many years. Flexible mounting and scalable port options allow operators to meet changing customer needs. Dowell’s commitment to quality means fewer service interruptions and better user experiences. Network operators who choose this solution can build trust with their customers and protect their investment. The Multiport Service Terminal Box delivers unmatched efficiency, reliability, and cost savings for FTTP projects. Feature MST Box Traditional Terminal Installation Efficiency Fast, pre-connectorized Labor-intensive Environmental Protection IP68, UV resistant Less robust Optical Performance Low loss, high reliability Higher loss MST technology supports cost-effective, scalable, and future-proof fiber networks. Operators meet current and future demands with longer transmission distances and flexible expansion. By: Eric Tel: +86 574 27877377 Mb: +86 13857874858 E-mail: [email protected] Youtube: DOWELL Pinterest: DOWELL Facebook: DOWELL Linkedin: DOWELL Read the full article

0 notes

Text

Aerial Cable Connectors Factory

An aerial cable connectors factory specializes in manufacturing high-quality connectors for overhead cable systems used in telecommunications, power, and data transmission. These factories produce durable connectors designed to withstand harsh environmental conditions, such as extreme weather and UV exposure. The products are crafted from corrosion-resistant materials like aluminum, stainless steel, and durable plastics. The factory ensures precision in design and manufacturing to offer connectors that provide secure, reliable connections, easy installation, and long-lasting performance. They produce a variety of connectors, including splices, junctions, and termination units, catering to diverse outdoor cable network needs.

0 notes

Text

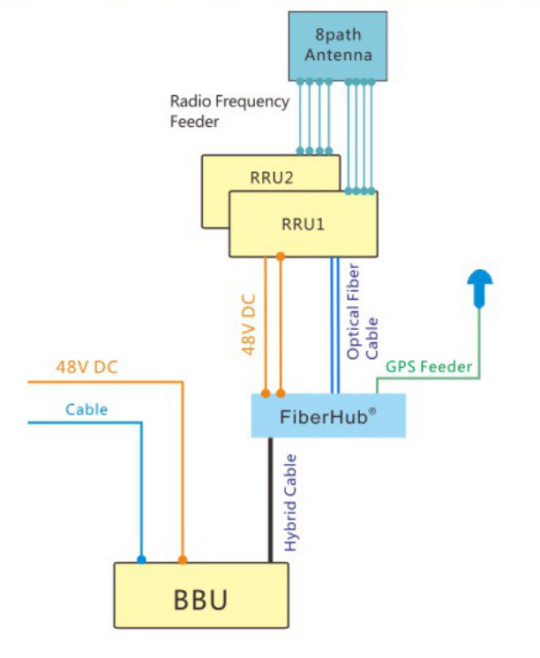

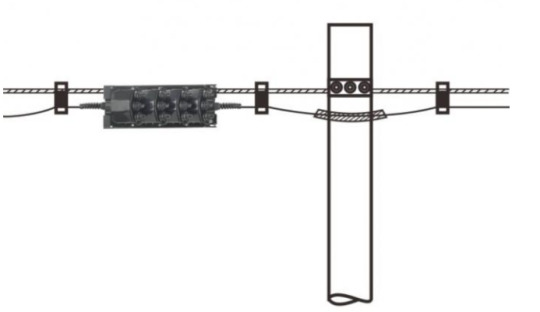

FTTA Fiber Optic Distribution Box: Ideal Solution for 5G Network Application

FTTA (Fiber-to-the-Antenna) fiber optic distribution box is used for network access points terminals in the FTTx network. It has inlet and outlet cables pre-connected, eliminating the need for closure opening and fiber splicing. All ports are equipped with hardened adapters. The operators do not need to splice fibers or open boxes during optical distribution network (ODN) deployment, which improves service provisioning efficiency. This article discusses the FTTA fiber optic distribution box.

What is FTTA Fiber Optic Distribution Box?

FTTA fiber optic distribution box is a new economic fiber distributed solution for outdoor use. It is easy to operate and has high compatibility. It is used for wall-mounting, aerial, and holding pole installations.

Features and Benefits

High compatibility: can be assembled ODVA, Mini SC, ODC, H-connector

Factory-sealed or field assembly

1200N pulling force long term

From 6 to 12 ports for single or multi-fiber waterproof connectors

Available with PLC or splice sleeve for fiber divide

IP68 waterproof rating

Wall mounting, an aerial installation, or holding pole installation

Meet IEC 61753-1 standard

Application Scenarios

FTTH

Traditional solutions use ONU or FDH (Optical Network Unit/Fiber Distribution Hub) when trunk optical cable arrives outside mansions and villas. FTTA fiber optic distribution box can replace ONU or FDH because of the fiber distribution function. Inside, it can be fixed 2-4pcs 1*8 or 1*16 PLC and can be put 24pcs fiber splice protection sleeves. After mating with a 1-48F IP67 pre-assembled waterproof connector, the FTTA fiber optic distribution box can directly connect each mansion and villa or low-voltage silo. It can reduce signal loss through the fewer connecting nodes.

FTTA

Traditionally, remote radio units (RRU) and building baseband units (BBU) connected by fiber optic cable, formed star network topology. Each RRU needs one duplex outdoor cable link to BBU. The installation will need more time, and the cost will be high. FTTA fiber optic distribution box works as an Aggregation/Demark box, linking RRU and BBU together. From BBU to FTTA fiber optic distribution box, only need one multi-fiber hybrid cable. Then FTTA fiber optic distribution box divides fibers to each RRU through IP67 pre-assembled waterproof cable assemblies. RRU can get power through assembled power connector on the FTTA fiber optic distribution box. It can avoid needless duplication.

Trunk Cable Connecting

Trunk cable is fusion welded frequently because each drum cable's length is limited. So connecting point is weak and needs to be protected very well. When the trunk cable comes into the FTTA fiber optic distribution box, it will be sealed and fixed by a torsion-proof cable gland (plastic or metal type). For 5mm/14mm out diameter cable, the FTTA fiber optic distribution box has different accessories to fit.

The torsion gland can release stress when the trunk cable bends and protects fiber to avoid breaking. Inside the FTTA fiber optic distribution box, the main cable and strength member are fixed by a fastener, ensuring that the box can stand 1200N pulling force long term.

Military Communication

Connectors and cables cannot stand frequently, and high strength pulling and reuse. Inside the FTTA fiber optic distribution box, armored cable and strength member are fixed by a fastener, so ensure that the box can stand 1200N pulling force long term. High-strength material and arc interface design make sure the FTTA fiber optic distribution box works abnormally when suffering shocks.

Conclusion

FTTA fiber optic distribution box provides waterproof protection for use in harsh environments. It reduces the total cost of operation and has high compatibility and flexibility.

Sun Telecom specializes in providing one-stop total fiber optic solutions for all fiber optic application industries worldwide. Contact us if you have any needs.

#suntelecom#fiberoptic#telecommunications#fttx#telecomengineering#cabling#osp#fiberopticcable#catv#telecomconsult

1 note

·

View note

Text

There are many manufacturers of radio

When you wire the radio, you are going to wire the radio just as you would for a standard radio that would be in this vehicle, but you are going to make one minor change to the new radios ground wire. The new radios ground wire is going to be plugged into the plastic connector that had originally been plugged into the rear of the Infinity radio. This connector is a ground wire to an "Infinity" amplifier which is located away from the radio. When you plug the new radios ground wire into this ground wire for the "Infinity" amplifier, the "Infinity" amplifier will turn on and power the speakers inside the vehicle.How to install Aftermarket radio in Vauxhall VectraOne of the joys of driving a car is listening to tunes while on the highway.

Music is a car driver's perfect companion and having the right stereo in your vehicle definitely makes driving much more enjoyable.Over the years, car manufacturers have become more attentive to the needs of the driver adding in much better stereo systems, however for music purists.You will still have to buy an aftermarket radio to get the kind of features and sound that you are looking for.The good news for those that are looking to install a new stereo into their vehicle is that car manufacturers have long ago made sure to make it easy to swap.Wiring for car's is usually the same for one single car manufacturer meaning that once you purchase the right wire harness you can easily connect an aftermarket stereo into your vehicle.

Now the only hard part is making sure the vehicle fits into the dash and the speakers fit with your new stereo receiver.Besides the head unit, it is important to put lots of thought into the speaker's amps and wiring you will use.IO CONNECT provides a cost effective solution for music integration on the move. Have in-car access to your music on the move, wherever you are, whatever your mood.With Io CONNECT you can take your music with you and create your own soundtrack for a journey via any of your portable devices.The SOT series leads are designed to install aftermarket hands free kits such as Parrot with ISO connections.

They are provided in two parts, one converting Car Wiring loom to ISO the second lead is then ISO from the Car Kit and plugs back into the Car Radio.An adaptor usually required when replacing factory fitted speakers with aftermarket replacements.Fixing screws and adaptor leads are included where applicable.Kit contains sufficient components for two speakers :An interface kit to connect a compatible Clarion aftermarket radio to your Vauxhall Vectra's factory-fitted remote control stalk .Kit comprises of universal interface control box plus Vauxhall Vectra adaptor cable .This aerial adaptor will enable you to replace a Vauxhall Vectra factory fitted radio with a Clarion aftermarket unit, and use your original aerial connecting plug.This fascia adaptor will enable you to replace a Vauxhall Vectra factory fitted radio with a Clarion aftermarket unit, and retain the original appearance of your dashboard.This adaptor is required to replace a Vauxhall Vectra factory fitted radio with a Clarion aftermarket model.It converts the car's original power and speakers wiring connector to a standard ISO connector, as used on all our radios.

Simply plug one end of the adaptor into your cars wiring harness, and the other end into your new radio; no cutting of wires is necessary.The integrated DVD/CD/MP3/WMA-player.Playback of CD, CD-R/RW, MP3, WMA, DVD, DVD-R/RW, DVD-MP3, VCD, SVCD, MPEG4, DivX6, JPEG and Picture CD: Region code 2, Integrated Dolby Digital decoder, Last-playback-memory function.In my opinion this is the best way to set up your stereo if you decide to switch it up. I did it to get a better quality sound out of my subs, and also to have the touch screen for my IPod.A word about the radio installation kit you are Solar Panels about to install.

There are many manufacturers of radio installation kits for this vehicle. Each manufacturer produces slightly different variations of the same kit, and a few make individual kits for specific vehicles. The pictured installation kit shown in the illustrations below is a standard kit used for many. Radio installation kits change with the model and years of production of the vehicle. When selecting a kit for this vehicle, make sure the kit you purchase states on the package the installation kit will work with your vehicle model and year. Some kits may require additional setup. Certain kits may be multi function kits designed to work with multiple vehicles and may require the installer to remove break away screw mounting tabs attached to the kit that are not required for your particular vehicle.

0 notes

Video

youtube

Reviews TV Antenna, [2019 Strongest] Indoor Digital HDTV Amplified Antennae ...Special discount TV Antenna, [2019 Strongest] Indoor Digital HDTV Amplified Antennae Aerial Freeview 4K 1080P HD VHF UHF for Local Channels 120 Miles with Amplifier Support All Television-13ft Coax Cable CLICK HERE https://amzn.to/2wEHh3Z Gift $10 + Up to 5% Cash Back: http://bit.ly/2WgjzKp http://bit.ly/2IpgePF http://bit.ly/2WePH13 I like the product. It shows real good. And I like how it have the percentage of how good it will show. I had to move it around a couple of times to get a pretty picture. But I love it. 【Full Free HD Channels】With This TV antenna you will never pay HUGELY expensive cable or satellite fees again! Get access to FREE HD channels forever including ABC, CBS, NBC, PBC & Fox in 120 mile rang from Broadcast Tower. Enjoy crystal clear HDTV shows, 720p, 1080i, 1080p,4k | ATSC available. This smart tv antenna support all types of TV converter boxes and digital televisions/4K Ultra High Definition TVs. 【3 Stages Amplification】Integrated with USB powered Smart Amplifier, This antenna could provide 3 stages amplification. The reception of this HDTV antenna has optimized to the strongest condition within similar products, which allows you you picks up signals within maximal 120 miles range. 【Military Level RG174 Coaxial Cable】Our antenna adopts Military Level RG174 High frequency Coaxial cable, the purity of cable core is up to 99.7%. The Coaxial cable screen rate is 95%, which could decease signal interference in its best effort. 【Kindly Note】Signal reception can vary around US,if within 35 miles from the Transmitter,Try Not install with a signal booster.Now,get our this set of indoor aerial antenna with coaxial cable,signal amplifier booster,installation guiding.A quality life start with enjoying more fun on your TV! 【LIFETIME WARRANTY&100% INSPECTION】 This antenna all have acquired CE,Rohs, FCC,PSE certification and done a 100% inspection before leaving factory. We have been 10 years in antenna field and responsible for every item. You are always welcomed to contact us at anytime. Unbox and reviews TV Antenna, [2019 Strongest] Indoor Digital HDTV Amplified Antennae Aerial Freeview 4K 1080P HD VHF UHF for Local Channels 120 Miles with Amplifier Support All Television-13ft Coax Cable Get the free HD Channels over 120 miles from Broadcast Tower, Enjoy crystal clear HDTV shows 720p, 1080i, 1080p | ATSC available. Specification: 1. Working Frequency : VHF(172-240Mhz) \UHF(470-860Mhz) 2. Impedence : 75 Ω 3. LNA Gain : 25dB 4. Reception Range: 120 miles 5. Size:330*230*0.6mm 6. Cable : 1.5C-2V / Black L=3M+1M 7. Voltage : 5V Set up guide: 1 Connect the end(F-male) of attached coaxial cable to the ANT/IN connector on the back of the TV or DVB-T tuner 2 Set the tuner mode to "Antenna" or "Air" 3 Set TV to scan for channels 4 Fix the antenna at the optimal position you found Package Include 1 * Indoor tv antenna with 9.84ft / 3m coaxial cable 1 * Antenna Amplifier Booster and USB Power Supply (1m Cable) 1 * Instructional manual Attention While Using this indoor hdtv antenna: 1 Keep away from interference source, such as metal structure, it may weak signal reception. 2 Low floor may affect signal reception, it is recommended to put the antenna to a higher position. 3 Within 35 miles from the transmitter, Try Not install the aerial with signal amplifier! 4 Please go through your TV manual to make sure your TV is with built-in tuner for free view. 5 You must re-scan whenever you move the portable digital tv antenna. 6 The signal strength is depends on many factors, including the distance to the TV towers, terrain, obstacles, weather etc. Reviews TV Antenna, [2019 Strongest] Indoor Digital HDTV Amplified Antennae Aerial Freeview 4K 1080P HD VHF UHF for Local Channels 120 Miles with Amplifier Support All Television-13ft Coax Cable

0 notes

Text

heat shrink joint for sale

Our History Shanghai Jiameng Electrical Equipment Co., Ltd., also known as MELEC, was founded in 1992. In 2011, both of our subsidiaries, Jiangsu Jiameng Electrical Equipment Co., Ltd and Shanghai Jiameng International Trading Co., Ltd, were formed. We are specialized in production of high quality cable accessories. Our company has expended to more than 500 employees with a factory compound of more than 50,000 square meters. Our Factory MELEC factory is located in Jiangsu Province Binhai Industrial Park, occupying an area of 48,000 square meters, equipped with the most advanced production line and production equipment, strictly complies with scientific production processes, and builds up a strong and leading manufacturing platform. Our Product Our products include cable lugs, cable connectors, aerial bundle cable accessories, and heat shrink accessories. Product Application Low and medium voltage power transmission, distribution and cable connection. Our Certificate ISO9001 quality management system. Products follow NFC, IEC, EN, GB standards. Production Equipment CNC Tapping Center, Friction Welding Machine, CNC Turning Center, Automatic Dieing out Press and etc. Our service We offer you analysis of products in various markets and carry on fieldwork to make strategies based on market demands. We offer you a full range of product training, operation training and technical knowledge training. We will provide you the most professional and accurate Certification Report.heat shrink joint for sale website:http://www.melec-connector.com/ from Frage.de - dein Frageportal - Neue Fragen und Antworten https://ift.tt/2RnEF2y via Best Link Shortener

0 notes

Text

8S 80A PCM/PCB/BMS for 25.6V LiFePO4 Lithium Battery for Electric Bicycle and Scooter and Tools Protection Circuit Board

8S 80A PCM/PCB/BMS for 25.6V LiFePO4 Lithium Battery for Electric Bicycle and Scooter and Tools Protection Circuit Board

8S 80A PCM/PCB/BMS for 25.6V LiFePO4 Lithium Battery for Electric Bicycle and Scooter and Tools Protection Circuit Board

8S 80A PCM/PCB/BMS for 25.6V LiFePO4 Lithium Battery for Electric Bicycle and Scooter and Tools Protection Circuit Board A3 12 pin radio installation and operation. FAKRA Series - PTM Preview. Car Radio Antenna Aerial Adapter Cable. fit for Volkswagen 2 Fakra male to 1 Fakra Audi VW Radio Antenna Amplified Adapter Diversity System Dual Fakra. . Audi A4 antenna fix cab bad radio reception .. Banggood vw original antenne 2. Car Antenna probleme reception VW with new radio from aliexpress. Raydiall Fakra connectors one step crimping. Mercedes Video Connection Explained. Audi A3 Aerial Adapter Booster. Adapting Older Sirius XM Tuners ( Fakra Style )To The Newer Antennas. CAVO AUTORADIO ISO ADATTATORE ANTENNA AUDI VW SEAT SKODA. Adding fm direct satellite and aftermarket antenna adapters - I go over all of 'em. Find great deals on eBay for fakra aerial adaptor and fakra aerial adaptor 2 Diversity Twin Double Fakra-Din Radio Antenna Aerial Adapter Cable Fakra. . DAB Splitter for Fakra Antennas (SMA Connector). Audi A3 A4 A6 RNS E RNSE adapter retrofit kit DIVERSITY ANTENNA GPS ANTENNA FAKRA RADIO REMOVAL KEY. FAKRA - FME / SMA Adaptor. РекламаНизкие цены. Гарантия. Сервисное обслуживание. Отдел заказов. · пн-сб 10:00-20:00, вс 10:00-19:00 · Димитровград. . Jumper Antena conectores FAKRA. So baust Du Dein Autoradio ein | Zubehör-Anleitung | ARS24. ZENEC ZE-NC3131D - Montage / Installation (Auflösung:1920x1080). ADATTATORE ANTENNA DA DIN A FAKRA - 57205. CAVO AUTORADIO ISO ADATTATORE ANTENNA DIVERSITY AUDI VW - 59195. How to Wire in a PC5-136 / PC5-52 / PC5-90 | JustAudioTips. ACV 1524-03 DIN Fakra Antennenadapter/Phantomeinspeisung. Antennenadapter Female Fakra - Female DIN ISO Antenne adapter stecker VW AUDI SEAT SKODA OPEL. 2 Fakra to DIN Car Stereo Radio To solve the weak FM signal / signal disturbing problems by installing diversity antenna systems. 1 X Diversity Antenna Adapter.. . Is the FM reception bad after installing a new car stereo a German car. INSTALLING THE GPS ANTENNA. HitCar Factory Antenna Adattatore per cruscotto auto Aftermarket DVD Head Unit Radio Adatta. Antenna tetto - Pinna, Audi & VW - Originale.

8S 80A PCM/PCB/BMS for 25.6V LiFePO4 Lithium Battery for Electric Bicycle and Scooter and Tools Protection Circuit Board

YI Action Camera 1080P 60/30fps Sports Mini Camera 16.0MP 155 Degree Ultra-wide Angle Lens Built-in WiFi 3D Noise

YI Action Camera 1080P 60/30fps Sports Mini Camera 16.0MP 155 Degree Ultra-wide Angle Lens Built-in WiFi 3D Noise

Parts BB Black Package E with BeagleBone Black Board ,512MB DDR3 4GB 8bit eMMC 1GHz ARM Cortex-A8 + camera+Cape,Expansion Board

Parts BB Black Package E with BeagleBone Black Board ,512MB DDR3 4GB 8bit eMMC 1GHz ARM Cortex-A8 + camera+Cape,Expansion Board

DHL free shipping Q999S kaamera statiivile aluminum digital camera tripod better than Q666 Q999 fit for camcorder folded 360mm

DHL free shipping Q999S kaamera statiivile aluminum digital camera tripod better than Q666 Q999 fit for camcorder folded 360mm

1.5W 16ch wrieless transceiver 0.9-1.3Ghz Wireless image drone transmitter FPV Video Audio Transmitter Receiver AV sender

1.5W 16ch wrieless transceiver 0.9-1.3Ghz Wireless image drone transmitter FPV Video Audio Transmitter Receiver AV sender

Pixco Adjustable Focusing Macro To Infinity L.ens Mount Adapter Suit For Nikon F Mount G Lens to Sony E Mount Camera NEX

Pixco Adjustable Focusing Macro To Infinity L.ens Mount Adapter Suit For Nikon F Mount G Lens to Sony E Mount Camera NEX

FREE SHIPMENT Original DLP Projector Module Lamp LMP-C162 HSCR165W with a 180-day Warranty for So ny VPL-CS20 VPL-CX20 VPL-ES3

FREE SHIPMENT Original DLP Projector Module Lamp LMP-C162 HSCR165W with a 180-day Warranty for So ny VPL-CS20 VPL-CX20 VPL-ES3

20V 4000mAh Power Tools Batteries Replacement Cordless for Dewalt DCB181 DCB182 DCD780 DCD785 DCD795+USB Power Source

20V 4000mAh Power Tools Batteries Replacement Cordless for Dewalt DCB181 DCB182 DCD780 DCD785 DCD795+USB Power Source

HEONYIRRY Universal Cable Organizer Electronics Accessories Case Travel Carry Bag Pouch Cable Management Clip For xiaomi

HEONYIRRY Universal Cable Organizer Electronics Accessories Case Travel Carry Bag Pouch Cable Management Clip For xiaomi

Eachine EX2H Brushless 5.8G FPV With 720P HD Camera Alititude Hold RC Drone Quadcopter RTF W/ LED Black/White 3D Tumbling Models

Eachine EX2H Brushless 5.8G FPV With 720P HD Camera Alititude Hold RC Drone Quadcopter RTF W/ LED Black/White 3D Tumbling Models

FREZEN Smart Wristband V587 Color Screen Fitness Tracker Smart bracelet Heart Rate Blood Pressure IP68 Waterproof Sports Watch

FREZEN Smart Wristband V587 Color Screen Fitness Tracker Smart bracelet Heart Rate Blood Pressure IP68 Waterproof Sports Watch

additional reading

0 notes

Text

Stainless Steel Bands: The Unsung Heroes of Strength, Durability, and Versatility

When it comes to ensuring the strength, security, and longevity of structures, equipment, and installations, the stainless steel band stands as one of the most reliable and versatile solutions. While often overlooked, stainless steel bands play a crucial role in a wide range of industries and applications—from cable management and construction to automotive and packaging.

In this blog post, we’ll take a deep dive into what stainless steel bands are, their key benefits, common uses, and why they are often the go-to choice for many professionals.

What is a Stainless Steel Band?

A stainless steel band is essentially a strip or band made from stainless steel, a corrosion-resistant alloy primarily composed of iron, chromium, and, in some cases, nickel or molybdenum. These bands are manufactured in a range of widths, thicknesses, and lengths, and can be either flexible or rigid depending on the intended application.

Stainless steel bands are often used for fastening, bundling, or securing items in place. They are highly resistant to corrosion, making them suitable for use in harsh environments where durability and long-term performance are required.

The most common type of stainless steel used in these bands is grade 304 (general-purpose stainless steel), but in more demanding environments, grade 316 (marine-grade stainless steel) might be used for even higher resistance to corrosion, especially in coastal or industrial settings.

Key Benefits of Stainless Steel Bands

1. Exceptional Durability

The standout feature of stainless steel bands is their strength and durability. Stainless steel is inherently resistant to corrosion, rust, and staining, making it the perfect material for use in outdoor, industrial, and marine environments. Whether used in high-temperature conditions, humid spaces, or environments exposed to chemicals or salts, stainless steel bands hold up much better than other materials like plastic, aluminum, or iron.

This durability means stainless steel bands provide long-lasting performance even in harsh environments. They won’t degrade or lose their strength over time, ensuring a reliable and secure connection for years.

2. Corrosion and Weather Resistance

One of the most significant advantages of stainless steel is its corrosion resistance. The chromium content in stainless steel forms a passive layer of oxide on the surface of the metal that protects it from rust and corrosion. This makes stainless steel bands ideal for outdoor and marine applications, as they won’t rust or degrade when exposed to moisture, rain, snow, or salt.

For industries that require continuous exposure to chemicals, oils, or extreme weather conditions—such as agriculture, construction, or marine transportation—stainless steel bands provide peace of mind by maintaining their integrity despite the tough conditions.

3. High Tensile Strength

Stainless steel bands possess excellent tensile strength, meaning they can handle high amounts of stress without breaking or losing their shape. This makes them ideal for applications that require tightness and pressure, such as securing cables, pipes, or heavy equipment in place.

In industries like electrical infrastructure, stainless steel bands are commonly used to secure and bundle power cables, ensuring they stay in place even when subjected to environmental forces like wind, temperature changes, or mechanical stress.

4. Versatility in Use

Stainless steel bands are incredibly versatile and can be used in a wide array of industries and applications. They can be used to secure, fasten, bundle, or attach items to structures. Their versatility extends beyond just mechanical tasks—these bands also have aesthetic appeal in some design and architectural projects, where a sleek, metallic look is desired.

5. Ease of Installation and Adjustment

Stainless steel bands are typically easy to install, and many types come with adjustable tensioning systems or tools, which allow for a snug, secure fit. Depending on the application, you can use manual tools, tensioning tools, or even automated machines to adjust the band for precise fitting.

Once installed, stainless steel bands stay in place without requiring constant adjustments or maintenance. This makes them ideal for securing cables, pipes, or even as part of a larger fastening system.

Common Uses of Stainless Steel Bands

1. Cable Management and Securing

One of the most common applications for stainless steel bands is in cable management. In both residential and commercial settings, stainless steel bands are used to secure and bundle power cables, telecommunications cables, and other types of wiring.

The durability and strength of stainless steel bands prevent cables from sagging, rubbing against surfaces, or getting tangled, ensuring a tidy and organized installation. Stainless steel bands are also used in electrical infrastructure, such as power grids, to secure cables and keep them in place against wind, temperature changes, or mechanical stress.

2. Pipe Securing

In plumbing, construction, and industrial settings, stainless steel bands are frequently used to secure pipes. Whether it’s securing pipes to beams or mounting them to walls, stainless steel bands provide the tensile strength needed to hold pipes in place, even in heavy-duty applications.

Their resistance to corrosion also makes them ideal for use in plumbing systems exposed to moisture, chemicals, or varying temperatures.

3. Automotive and Mechanical Uses

In the automotive and mechanical industries, stainless steel bands are used to fasten components, such as exhaust systems, fuel lines, or hoses, ensuring that all parts remain securely attached and functional over time. The bands can withstand the high heat, vibrations, and pressure found in automotive applications.

In addition, stainless steel bands are used in various machinery and equipment to hold parts together, bundle wires, or attach components to structures, helping maintain the integrity and performance of machines in industries ranging from manufacturing to aerospace.

4. Construction and Engineering

In construction and engineering, stainless steel bands are used for securing heavy equipment, reinforcing structures, and bundling materials. They’re also used in architectural projects, for example, to fasten or secure elements in bridges, buildings, and large infrastructure projects.

For example, stainless steel bands are often used to secure structural components in concrete or steel frameworks, where they can maintain tightness and stability under high stress.

5. Marine and Coastal Applications

In coastal and marine environments, stainless steel bands are essential for keeping equipment, cables, and pipelines secure and resistant to the corrosive effects of saltwater. This includes use in marinas, docks, ships, and offshore oil rigs, where high-strength, corrosion-resistant bands prevent deterioration of cables and structures.

Stainless steel bands are also used to secure sails, rigging, and other critical elements on boats, where strength and durability are paramount for safe operations.

6. Packaging and Bundling

Stainless steel bands are commonly used in industrial packaging to securely bundle products or materials. They can hold heavy packages or pallets tightly together during storage or transportation, ensuring that items don’t shift, move, or get damaged.

This type of packaging is particularly beneficial for goods that will be transported over long distances or that require extra protection from external forces.

How to Choose the Right Stainless Steel Band

When selecting a stainless steel band for a specific application, there are several factors to consider:

Grade of Stainless Steel: Choose a grade based on the level of corrosion resistance you need. For general applications, 304 stainless steel works well, while more demanding environments (marine or highly corrosive environments) may require 316 stainless steel.

Band Width and Thickness: Choose the appropriate width and thickness for the task. A wider, thicker band is necessary for securing heavier items, while a narrower band might be better for lighter-duty applications.

Tensioning Tools: Consider whether you will need tensioning tools to install the band. Some bands come with built-in tensioning systems for easy installation.

Environmental Factors: Think about the environment in which the stainless steel band will be used. High temperatures, exposure to chemicals, or constant moisture could all influence the choice of material and band design.

Stainless steel bands are incredibly versatile, durable, and essential Aerial Cable Connectors components in a wide range of industries and applications. From securing power cables to bundling materials in construction or even managing automotive parts, these bands provide strength, reliability, and corrosion resistance that are hard to beat. Whether you're working in an industrial setting, managing infrastructure projects, or simply organizing cables at home, the stainless steel band is one tool that can ensure long-lasting performance and security. By choosing the right stainless steel band for your needs, you can maximize efficiency, safety, and durability in your projects for years to come.

#Stainless steel band for power cable networks#Stainless steel band#Stainless Steel Band Manufacturer#Aerial Cable Connectors#Underground Cable Connectors#Aerial Cable Connectors Factory#Aerial Cable Connectors Factory China

1 note

·

View note

Text

10-Year Forecast – Fiber Optic Sensors

According to ElectroniCast, the combined use of Distributed and Point fiber optics sensors are forecast to reach $5.98 Billion in 2026…

ElectroniCast Consultants, a leading market/technology forecast consultancy, today announced the release of their market forecast and analysis of the global consumption of Fiber Optic Sensors.

According to the study, the combined use of Distributed and Point (local) fiber optics sensors reached $3.38 Billion last year (2016), and the worldwide value is forecast to reach $5.98 Billion in 10-years (2026). Market forecast data in this study report refers to consumption (use) for a particular calendar year; therefore, this data is not cumulative data.

Both the American region and the EMEA region held similar market share in the overall (distributed- and point-types) fiber optic sensor value last year. The Europe, Middle East, Africa region (EMEA) held a very slight lead in relative market (value) share last year; however, the Asia Pacific region (APAC) is projected to take-over the leadership position during the forecast period.

The EMEA region is forecast to have a strong role in the use of distributed fiber optic systems, driven by the region’s use of systems in aviation, as well as in the

Petrochemical, Natural Resources, Energy/Utility application categories.

In terms of fiber optic point sensors, the American region is forecast to maintain the market share lead throughout the 1st-half of the forecast period (2016-2021), mostly led by the use of Fiber Optic Gyros (FOGs) in the Military/Aerospace application category. The consumption values are based on the end-user application and the end-user region.

FOGs held a 65 percent market share of the worldwide Point fiber optic sensor consumption value in 2016. “All regions, thanks mainly to increases in the use in aviation and military critical mission applications (Unmanned Aerial Vehicle/UAV and missile guidance, navigation, north finding/tracking, robotics, aviation and aeronautics and other) are forecast to show impressive increase consumption quantity (volumes) and values for the FOG systems,” said Stephen Montgomery, Director of the Fiber Optics Components group at ElectroniCast Consultants.

The market forecast of the Distributed Sensors is segmented by the following applications:

Manufacturing Process/Factory

Civil Engineering/Construction (buildings, bridges, tunnels, etc)

Military/Aerospace/Security

Petrochemical/Energy/Utilities/Natural Resources

Biomedical/Science

The Fiber Optic Point Sensor Forecast further segmented by the following sensing/measuring quantity (measurand) types:

Mechanical Strain

Temperature

Pressure

Chemical, Gas, Liquid

Vibration, Acoustic, Seismic

Displacement, Acceleration, Proximity

Electric, Current and Magnetic Field - Fiber Optic Sensors

Rotation (such as Fiber Optic Gyroscopes: FOGs)

“ElectroniCast counts each Point fiber optic sensor as one unit; however, the volume/quantity (number of units) of Distributed fiber optic sensors is based on a complete optical fiber line/link, which we classify as a system. Since a distributed optical fiber line (system) may have 100s of sensing elements in a continuous-line, it is important to note that we count all of those sensing elements in a distributed system as one (system) unit – only. Distributed fiber optic sensor systems involve the optic fiber with the sensors embedded with the fiber; also included is the optoelectronic transmitter/receiver, connectors, optical fiber, cable (fiber jacket) the sensor elements, and other related components,” Montgomery added.

According to ElectroniCast, the combined use of Distributed and Point fiber optics sensors reached $3.38 Billion in 2016…

Continuous Distributed and Point Fiber Optic Sensor

Global Consumption ($3.38 Billion in 2016)

Source: ElectroniCast Consultants

Tags: CWDM Multiplexer, DWDM Multiplexer,19" rack mount chassis CWDM, CWDM MUX/DEMUX Module, LGX CWDM Module,8CH CWDM Module, 16CH CWDM Module, 100GHz DWDM Mux/Demux, 200GHz DWDM Mux/Demux

DK Photonics – www.dkphotonics.com specializes in designing and manufacturing of high quality optical passive components mainly for telecommunication, fiber sensor and fiber laser applications,such as 1064nm High Power Isolator,1064nm Components, PM Components, (2+1)x1 Pump Combiner,Pump Laser Protector,Mini-size CWDM,100GHz DWDM,Optical Circulator,PM Circulator,PM Isolator,Fused Coupler,Mini Size Fused WDM.

0 notes

Text

The key issues of selecting prefabricated branch cables for mine communication cables

The solid insulated and filled cable is suitable for pipeline laying of coal mine pipeline network, mainly used for pipeline laying. The inner and outer surfaces of the aerial bundled cable ASNS 1418 core and the shielding layer are filled or poured with petroleum jelly to prevent the intrusion of water in the coal mine. Under the environmental conditions of 30~C-60~C that are common in coal mines, the mechanical and electrical properties of communication cables for coal mines remain unchanged. It is used for communication lines in flat lanes, inclined lanes and electromechanical chambers, and used for main signal transmission in flat lanes, shafts or inclined shafts.

A prefabricated branch cable with good quality must be a mining cable with excellent performance. For domestic products, its conductor performance, insulation performance, and mechanical and physical properties of the material should meet the GB12706-91 standard-because the performance of the cable is prefabricated The basic index of branch cable products.The prefabricated branch aerial bundled cable (abc)ASNS 1418 is a series of special production equipment in the factory according to the main and branch cable types, specifications, cross-sections, lengths and branch positions of the main and branch cables required by the cable users. The branch cables are completed on the assembly line.

The performance of the branch connector is very important, which is the key performance of the prefabricated branch cable. The branch connector connects the conductors of the main cable and the branch cable as a whole, and is insulated and moisture-proof. From the appearance point of view, it is impossible to know the quality of the internal joint. There are two important tests that can detect the performance of the joint, namely contact resistance and thermal cycle test.

The ratio of the contact resistance requirement to the reference resistance of the branch cable of equal length R1 / R2 (R1: contact resistance of the connector, R2: reference resistance of the branch cable) ≤ 1.2; for the thermal cycle test, when the main aerial bundled cable NFC 33-209 and the branch cable pass the rated working current, Heating for 5 hours, natural cooling for 3 hours is a cycle, a total of 125 cycles, after the 25th cycle, the surface temperature of the coupling body should not exceed 75℃, and for each subsequent cycle, the surface temperature of the joint should not be higher than the surface temperature of the 25th cycle 8℃ high.

Resistance will cause the change of electron flux, the smaller the resistance, the decrease of electron flux, and vice versa. Substances that have no resistance or resistance that cannot form current transmission are called electrical insulators, or insulators for short.

YFD series qualified branch cables have been tested by the National Mining Cable Quality Supervision and Inspection Center. The contact resistance R1 / R2 is 0.7, the surface temperature of the connecting body in the 25th thermal cycle is 43℃<75℃, and the maximum temperature of the 26~125th time: 47 ℃<51℃.

0 notes