#Aerospace Software Testing

Explore tagged Tumblr posts

Text

In this house, we cheer Musk

Elon Musk is so skilled he makes it look easy to run SpaceX and a majority of the world's orbital lift, and this leads a lot of people to underestimate him. "He doesn't do shit, he just pays the engineers!" critics say. "I could have done the same if I had a billion dollars!" they imagine.

Well, such critics should pay more attention to Blue Origin, which demonstrates that "just" paying the engineers a billion dollars is not enough.

Blue Origin is a spaceflight company founded by billionaire Jeff Bezos in 2000, two years before SpaceX in 2002. Both spent some time laying groundwork and did their first test launches in 2006, the New Shepard and the Falcon 1 respectively.

SpaceX pushed ahead rapidly and first reached orbit in 2008 with the fourth flight of a Falcon 1. Blue Origin was slower, and first reached orbit in 2025 with the New Glenn. In the intervening time, SpaceX had accomplished several hundred orbital flights and increased its launch pace from "per year" to "per week". (130-something Falcon 9 launches in 2024.)

SpaceX also hit several other milestones like supplying the ISS with the Dragon 1 in 2012, first propulsive (vertical) landing of an orbital rocket stage with Falcon 9 in 2015, taking humans to orbit with the Dragon 2 in 2020. On a more abstract but also more practical note, SpaceX's Booster 1051 went from hopeful "it landed and we might reuse it" plans to definite "cycle it back into service, you know the drill" when it was reused for the tenth time in 2021.

Harder to measure is how much SpaceX decreased the cost of launching people and things to orbit for all their customers, but it's somewhere around an order of magnitude thanks to the combination of mass production and rocket reuse, where previous orbital launches tended to be artisanal one-offs. And it's still dropping.

I will return to that 'majority' point: consider the US and Soviet/Russian space program which are the two big ones, and the Chinese and Indian and Japanese and other government space programs too. Add the private competitors, like Orbital Sciences Corporation which put their Pegasus in orbit in 1990 and went on to relative success with several more orbital missions.

SpaceX first reached orbit in 2008, and by 2024 was outdoing all the above put together. This does not happen by simply throwing money at the problem, the Great Powers have far more money to throw at the problem. This was not replicated by competitors. You can tell nobody even got close, for SpaceX to perform a majority.

Blue Origin? eventually got to orbit this year, planning another launch later this year. Orbital Sciences Corporation that I mentioned above? shut down. Space Services Inc.? technically reached space in the sense of the Karman line (100km up) but not orbit, then shut down. Armadillo Aerospace? never made it.

Wealthy and technically competent people like John Carmack (better known for Id Software, Doom) tried to run private spaceflight companies, lost a lot of money and shut down with little to show for it. Most of them are forgotten quickly. Elon Musk has put SpaceX so far ahead of the real alternatives, people lose sight of those and start comparing him to imaginary alternatives.

99 notes

·

View notes

Text

The MS-07B Gouf

In preparation for the invasion of Earth, Zeon forces modified a number of MS-06 Zaku-II F-types for use under the effects of the planet's gravity. The new "J-type" Zaku-IIs featured a number of internal hardware and software changes to enhance their viability on the ground.

The Zaku-II J-Type would be used as a testbed for new developments with the goal of creating a new mass-production mobile suit for use on the ground. And where the Zaku was intended for anti-ship and anti-aerospace combat, this new platform would be built to fight other mobile suits.

Zimmad and Zeonic would both begin working on this new project, directly competing with one another, but eventually coming up with very similar designs. Zeonic moved forward with the YMS-07A Prototype Gouf, and Zimmad presented the YMS-08A High Mobility Test Type.

While Zimmad's design failed to show a significant increase in performance from the Zaku-II J-Type, Zeonic's "Gouf" showed immense promise. The prototype would be picked up and would see a limited production run as the MS-07A Gouf.

The MS-07A was a pre-production model intended for data gathering. The final mass-production model would feature several additional weapon systems, such as an in-built 75mm machine gun in the left manipulator, and a retractable "Heat Rod" on the left forearm.

The Gouf was used to great effect by Zeon captain Ramba Ral, who went toe-to-toe with the Earth Federation's infamous RX-78-2 Gundam.

Among the Ace pilots who used the Gouf as their personal units, Viche Donahue, Silas Locke, and Norris Packard were among the most well-known. All three of these aces would become battlefield legends, with Packard's MS-07B-3 Gouf Custom becoming especially infamous. The machine's equipment proved so effective that it became a common alternate loadout for many Gouf pilots.

The MS-07 would be customized for a variety of roles and theaters, with many of these variants seeing further developments of their own.

Notable among these was the MS-07W Gouf Combined Test Type, which featured a miniaturized Dopp fighter serving as its cockpit. The development of the machine was heavily influenced by data gathered from the Federation's RX-series of mobile suits. Namely, their "Core Block" system.

The Gouf would also see another fork, being developed into the MS-07H Gouf Flight Type. While both prototypes made use of thermonuclear rocket engines, the final version used thermonuclear jet engines, allowing for greater efficiency in atmospheric flight.

The MS-07B saw further refinement into the MS-07C. While not much is known about its specifications, there are at least three known variants. A number of Goufs were acquired by Zimmad and used as testbeds for systems to be incorporated into the MS-09 Dom series of mobile suits. These Goufs were MS-07Cs.

And finally, in UC 120, nearly 50 years from the initial deployment of the original machine, Mars Zeon would develop and deploy the OMS-07RF RF Gouf. While externally resembling the MS-07B, the OMS-07-RF was a completely new machine which could also operate in space, unlike its predecessors.

The MS-07B Gouf was originally designed by Kunio Okawara for the 1979 Anime "Mobile Suit Gundam".

This article was a request! Requests are always welcome!

I am so terribly sorry for the delay in getting this post out! It's been a very hectic few months, but I'm hoping to get back in the flow of things!

23 notes

·

View notes

Text

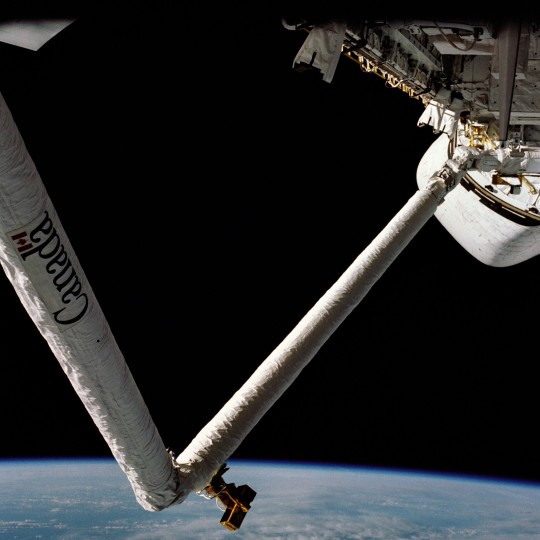

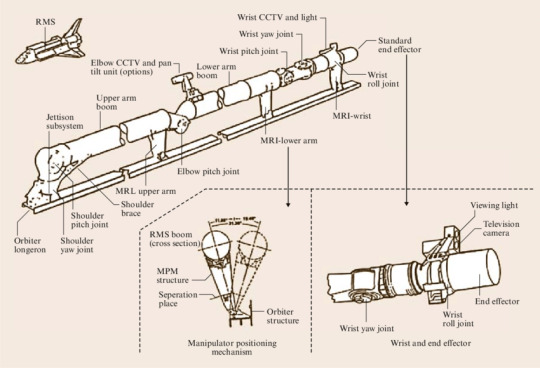

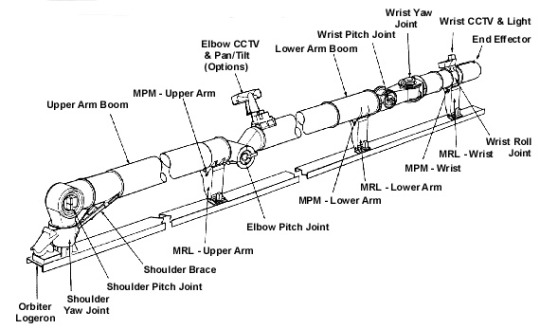

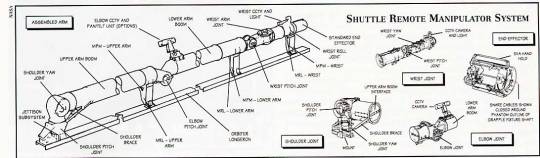

Space Shuttle: Canadarm

Officially named the Shuttle Remote Manipulator System, or SRMS. "In 1969, Canada was invited by the National Aeronautics and Space Administration (NASA) to participate in the Space Shuttle program. At the time what that participation would entail had not yet been decided but a manipulator system was identified as an important component. Canadian company DSMA ATCON had developed a robot to load fuel into CANDU nuclear reactors; this robot attracted NASA's attention. In 1975, NASA and the Canadian National Research Council (NRC) signed a memorandum of understanding that Canada would develop and construct the Canadarm.

NRC awarded the manipulator contract to Spar Aerospace (now MDA). Three systems were constructed within this design, development, test, and evaluation contract: an engineering model to assist in the design and testing of the Canadarm, a qualification model that was subjected to environmental testing to qualify the design for use in space, and a flight unit."

"The Remote Manipulator System is plugged on a side panel (left side) of the pyaload bay. The shoulder is on the front (near the cabin) and 15.3 m long (35.7 cm of diameter). It is fasten by three points on the payload bay. It could have been plugged on the right side of the Orbiter but it has never be done because the Ku antenna must be moved. Only one arm can be controlled by the crew (rear wall), even if the wires are already plugged to control two.

Its weight is 411 kg on Earth (carbon fibre), it can move payload of 29 tons in orbit. But it can't move its own weight on Earth, so to test it, it was lay on wheels. Equipped with video camera (one on the elbow and one wrist), it can move payload, bring them back or even act as a ladder for the astronauts during the EVAs. Finally, due to its high mobility it can also be used to look at different parts of the Orbiter."

"The first Canadarm was delivered to NASA in April 1981. Astronaut Judith Resnik developed the NASA software and onboard operating procedures for the system. In all, five arms – Nos. 201, 202, 301, 302, and 303 – were built and delivered to NASA. Arm 302 was lost in the Challenger accident."

source, source, source, source

NASA ID: STS002

70 notes

·

View notes

Text

What is a Foundry? Why It’s the Key to Chip Manufacturing

In the heart of the global electronics industry lies a quiet giant—the semiconductor foundry. While companies like Apple, NVIDIA, and Qualcomm design the chips that power your favorite devices, it's the foundries that physically bring those designs to life. But what exactly is a foundry, and why is it so critical to chip manufacturing?

What is a Semiconductor Foundry?

A semiconductor foundry, or simply "foundry," is a manufacturing facility that fabricates integrated circuits (ICs). These ICs, also known as microchips or chips, are the brains behind modern electronics—everything from smartphones and laptops to cars and industrial machinery.

Foundries specialize in manufacturing chips designed by other companies, a business model known as pure-play foundry. For example, TSMC (Taiwan Semiconductor Manufacturing Company) is the world’s largest and most advanced foundry, producing chips for tech giants without competing with them in design.

There are also IDMs (Integrated Device Manufacturers) like Intel, which both design and manufacture their own chips. However, the pure-play foundry model has become dominant due to the increasing complexity and cost of chip manufacturing.

The Role of a Foundry in Chip Manufacturing

Chip design is only half the equation. Once a design is finalized using software and simulations, it must be turned into physical silicon wafers through a meticulous and highly precise process involving:

Photolithography: Transferring microscopic circuit patterns onto silicon.

Etching and Deposition: Carving and layering materials to form transistors and interconnects.

Ion Implantation: Modifying electrical properties at the atomic level.

Packaging and Testing: Encasing chips and validating their performance.

This process takes place in ultra-clean, billion-dollar facilities where even a speck of dust can ruin a chip. Foundries provide the scale, expertise, and cleanroom environments necessary to execute this complex task at nanometer precision.

Why Foundries Are the Key to the Chip Industry

Enabling Innovation Through Specialization Foundries allow fabless companies (those that only design chips) to focus on innovation without the burden of operating expensive fabrication plants. This division of labor has accelerated technological progress.

Advanced Process Technology Leading foundries invest billions into R&D and process nodes (like 5nm, 3nm, or 2nm technology), pushing the boundaries of performance and power efficiency.

Scalability and Global Supply Foundries serve a wide range of industries: consumer electronics, automotive, medical, aerospace, and more. Their capacity and scalability make them vital to maintaining the global tech supply chain.

Geopolitical and Economic Importance Countries now consider foundries as strategic assets, essential for national security and economic resilience. Supply chain disruptions in recent years have spotlighted their critical role.

Conclusion

Foundries are the unsung heroes of the digital era. While designers craft the vision for future chips, it’s the foundries that make those visions a reality with unmatched precision and scale. As chip demands surge across AI, IoT, and 5G, the importance of foundries in the semiconductor ecosystem will only grow.

Whether you're holding a smartphone or driving a smart vehicle, chances are a chip built in a foundry is powering the experience—quietly but powerfully behind the scenes.

3 notes

·

View notes

Text

Firefly Aerospace Blue Ghost

Firefly Aerospace Blue Ghost, or simply Blue Ghost, is a class of lunar landers designed and manufactured by Firefly Aerospace. Firefly plans to operate Blue Ghost landers to deliver small payloads to the surface of the Moon. The first Blue Ghost mission was launched at 1:11 a.m. EST (06:11 UTC) on January 15, 2025.[2][3][4][5] It has an expected landing date of March 2, 2025.[6] It is named after the firefly Phausis reticulata known as the Blue Ghost.

Firefly is the prime contractor for lunar delivery services using Blue Ghost landers. Firefly provides or sub-contracts Blue Ghost payload integration, launch from Earth, landing on the Moon and mission operations. Firefly's Cedar Park facility will serve as the company's mission operations center and the location of payload integration, with Rocket Lab serving as the backup mission operations center.

Blue Ghost has four landing legs, communications, heating and solar power systems, and features multiple layers of insulation. The Blue Ghost solar panels, from subcontractor SolAero By Rocket Lab, provide a maximum of 650 W of power. ASI by Rocket Lab provides flight, ground and GN&C software, trajectory design, orbit determination, and software testbed integration. Firefly asserts that in house end to end manufacturing and testing of the Blue Ghost structure is a differentiator among the CLPS landers

2 notes

·

View notes

Text

Bricking the International Space Station

NASA is contemplating bringing astronauts Barry Wilmore and Suni Williamshome from the International Space Station on a SpaceX Crew Dragon and flying the Boeing Starliner back empty. There’s just one problem: Boeing removed the Starliner’s autonomous undocking feature from its software. The aerospace manufacturer wants to push a software update to the spacecraft in orbit, but NASA fears it could do more damage.

It’s been over two months since the Boeing Crew Flight Test launched from Cape Canaveral. Multiple technical issues with the Boeing Starliner have drastically elongated the eight-day mission, with no return date in sight. NASA planned to decide whether the crew should fly the spacecraft back last week....

5 notes

·

View notes

Text

The Power of Precision: Exploring the Benefits of PAUT in NDT

In the realm of industrial inspections, the demand for accuracy and efficiency has never been higher. Phased Array Ultrasonic Testing (PAUT) stands out as a revolutionary method that fulfills these requirements, offering unparalleled precision and speed. As an integral part of Non Destructive Testing, PAUT is widely used across various industries to ensure the integrity and reliability of critical components. Here, we delve into the intricacies of PAUT and its benefits.

PAUT is an advanced method of ultrasonic testing that uses multiple elements and electronic time delays to create beams of sound waves. These beams can be steered, focused, and scanned, providing detailed images of internal structures. Unlike conventional ultrasonic testing, which uses a single transducer to send and receive sound waves, PAUT employs an array of transducers. This allows for simultaneous collection of data from multiple angles, resulting in more comprehensive and accurate inspections.

As part of a broader suite of Non Destructive Testing Services, PAUT plays a crucial role in ensuring the safety and reliability of industrial components. Nondestructive testing (NDT) from RVS QUALITY CERTIFICATIONS PVT LTD encompasses various techniques used to evaluate the properties of a material, component, or system without causing damage. PAUT's advanced capabilities enhance the overall effectiveness of NDT services, providing detailed and reliable data that support maintenance and quality assurance programs.

Applications Across Industries

The versatility of PAUT makes it suitable for a wide range of applications. It is commonly used in the aerospace, automotive, and power generation industries for inspecting critical components such as welds, turbine blades, and composite materials. PAUT's ability to detect minute defects and irregularities ensures that even the smallest flaws are identified before they become critical issues. This level of precision is essential for maintaining safety and performance standards in high-stakes environments.

Efficiency and Accuracy Combined

One of the standout features of PAUT is its efficiency. The ability to steer and focus sound waves electronically means that inspections can be performed more quickly compared to traditional methods. This not only reduces downtime but also increases the number of inspections that can be completed within a given timeframe. Additionally, the detailed images produced by PAUT provide a clearer understanding of the inspected material's condition, allowing for more accurate assessments and decision-making.

Enhanced Tube Inspections

A specific area where PAUT excels is in Tube Inspection Services. Tubes, often found in heat exchangers and boilers, are prone to various types of degradation such as corrosion and cracking. PAUT's ability to inspect from multiple angles simultaneously makes it particularly effective for tube inspections. It can detect flaws that may be missed by conventional methods, ensuring that tubes are thoroughly evaluated for any signs of wear or damage. This comprehensive approach helps prevent failures and extends the lifespan of critical equipment.

Advancing with Technology

The continuous evolution of technology has significantly impacted PAUT. Advances in digital signal processing and software have improved the resolution and clarity of the images produced. Portable PAUT equipment from RVS QUALITY CERTIFICATIONS PVT LTD has made it possible to conduct inspections in challenging environments, further expanding its applicability. These technological advancements ensure that PAUT remains at the forefront of nondestructive testing techniques, providing industries with cutting-edge solutions for maintaining safety and quality.

In conclusion, PAUT is a powerful tool that combines precision and efficiency to deliver superior inspection results. Its ability to provide detailed images from multiple angles makes it invaluable for identifying defects and ensuring the integrity of critical components. As a key component of Non Destructive Testing, PAUT supports industries in maintaining high standards of safety and performance. Whether it's for welds, turbine blades, or Tube Inspection Service, PAUT continues to set the standard for advanced nondestructive testing methodologies.

5 notes

·

View notes

Text

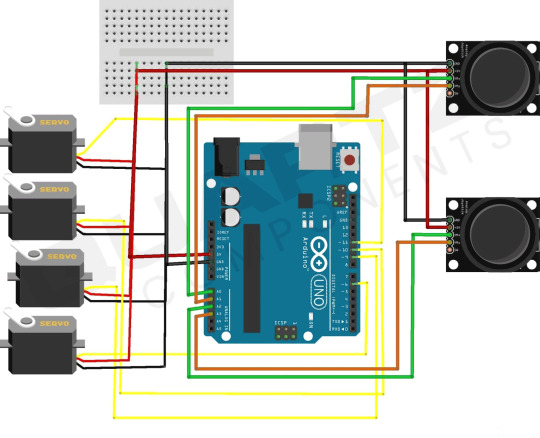

Build Robotic Arm Using Arduino

A robotic arm is a type of mechanical arm, usually programmable, that is designed to move materials, parts, tools, or specialized devices through various types of programmed motions for the purpose of manufacturing, assembly, testing, inspection, and other tasks. Robotic arms are widely used in a variety of industries, including automotive, aerospace, electronics, food processing, and pharmaceuticals.

COMPONENTS REQUIRED

Robotic Arm Kit

Arduino Board (UNO)

USB –A to micro-USB cable

Servo motor

Dual Axis XY Joystick Module

Connecting wires

Software Required

Arduino IDE

Circuit Diagram

youtube

41 notes

·

View notes

Text

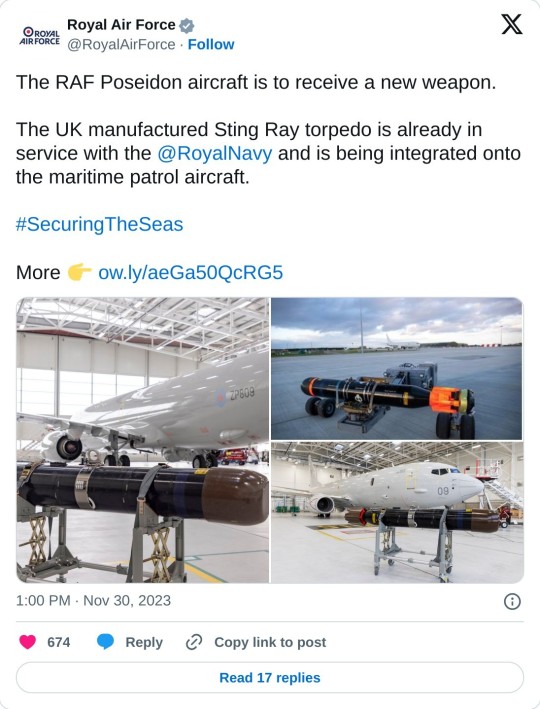

RAF chooses UK-made Sting Ray torpedo for its Poseidon fleet

Fernando Valduga By Fernando Valduga 12/02/2023 - 15:00 In Armaments, Military

The United Kingdom Ministry of Defense chose the British-made Sting Ray torpedo as its future torpedo capability, along with the continued use of the U.S. Navy's Mk54 weapon in the RAF's Poseidon maritime patrol aircraft.

The program to integrate the Sting Ray Mod 1 with Poseidon is underway and will give the United Kingdom a powerful and sovereign torpedo capability, providing flexibility to the Poseidon fleet.

In service in the Royal Navy, the Sting Ray Mod 1 is capable of integration into aerial and surface platform mission systems. The Sting Ray Mod 1 is a light anti-submarine war torpedo launched from the air, launched from frigates, helicopters and maritime patrol aircraft against submarine targets of all kinds.

It has a sophisticated acoustic return system and a high-precision navigation system. The torpedo can detect, classify and attack targets autonomously. It has low costs over its useful life and does not require intrusive maintenance throughout its useful life.

Taking advantage of the investment in the original Mod 0 variant of the torpedo and its support infrastructure, the improved Mod 1 weapon sustains the position of the Sting Ray as the world's leading light and autonomous underwater weapon in the coming decades.

The Sting Ray Mod 1 is designed to defeat the double threats of fast and deep double-hull submarines operating in the ocean environment and the silent and conventional submarine in coastal waters. The improved performance of Sting Ray Mod 1 is supported by the development of a new acoustic and tactical software, taking advantage of the knowledge acquired in extensive water tests with the Mod 0 weapon.

The RAF P-8 Poseidon is a multifunctional maritime patrol aircraft, equipped with sensors and weapon systems for anti-submarine and surface warfare, as well as surveillance and search and rescue missions.

Tags: weaponsMilitary AviationP-8A PoseidonRAF - Royal Air Force/Royal Air Force

Sharing

tweet

Fernando Valduga

Fernando Valduga

Aviation photographer and pilot since 1992, has participated in several events and air operations, such as Cruzex, AirVenture, Dayton Airshow and FIDAE. He has work published in specialized aviation magazines in Brazil and abroad. Uses Canon equipment during his photographic work in the world of aviation.

Related news

MILITARY

To combat laser weapons, USAF improves pilots' eye protection

02/12/2023 - 13:00

Turkish Aerospace Industries developed the Anka-3 unmanned aerial combat vehicle to operate alongside its new national KAAN fighter. Anka will make its first flight in mid-December, while the first KAAN flight is scheduled for December 27.

MILITARY

Turkey prepares the first flights of the ANKA-3 drone and KAAN poaching for this month

02/12/2023 - 12:00

MILITARY

Russia destroys Ukrainian Su-25 jet and then discovers that it attacked a model used as bait

02/12/2023 - 09:00

MILITARY

Venezuelan military aircraft present painting clamoring for the Essequibo region

01/12/2023 - 23:15

MILITARY

Czechs have already raised 500,000 euros to offer Black Hawk helicopter to Ukrainian intelligence

01/12/2023 - 21:46

The new helicopters delivered to the Indonesian military.

HELICOPTERS

Indonesia receives eight new Airbus H225M helicopters assembled in the country

01/12/2023 - 18:30

10 notes

·

View notes

Text

Sentinel-2C operators complete final rehearsals

A quiet atmosphere pervades ESOC's Main Control Room. The operations team is in the process of placing a satellite into orbit. We are one minute away from passing over one ground station and the tension is rising as we eagerly wait to receive the first telemetry from the satellite.

Then, suddenly, an alarm is triggered, the light changes color and crackling sounds can be heard. A fire has broken out in the room. The evacuation is ordered. The control room must be abandoned, and the satellite operations relocated to an adjoining room.

This was just a simulation of what could happen during a satellite's first and most critical moments in space. To ensure a smooth start to operations, the control team must consider every possible scenario, whether it happens in space or on the ground—such as a fire alarm.

This summer, as the launch of the Copernicus Sentinel-2C satellite approaches, the control team located at ESOC, ESA's operations center in Germany, has been performing a crucial phase of the launch preparation, reviewing and revising the satellite's and ground segment's plans and procedures to guarantee the success of the mission.

This "team of teams" effort involved more than 40 engineers and scientists—working on the ground segment, flight dynamics, software and networks—all ready to assume control of the satellite following lift off.

After weeks and weeks of simulations, the team has completed this phase and is now fully prepared for the launch and deployment of the European Commission's latest Earth observation mission, to be lifted into orbit by a Vega rocket from Europe's Spaceport in Kourou, French Guiana on 4 September at 03:50 CEST.

"This is not the first Sentinel mission we operate here at ESOC. Our experience has helped us standardize our approach so that we are able to test ourselves on the widest range of anomalies while still facing the most challenging situations," says Franco Marchese, Flight Operations Director for Sentinel-2C.

"One of our main challenges has been the knowledge transfer to the partially new team, as the previous models of Sentinel-2 were launched more than seven years ago," says Pete Collins, Deputy Flight Operations Director for Sentinel-2C.

"Our team has been flying Sentinel satellites and performing routine operations, including the A and B models of Sentinel-2, but putting a spacecraft into orbit is always a complex phase with its own unique challenges. We have prepared very well and have achieved this in a relatively short time."

'Like throwing monsters at the operators'

From a room in the basement, the true conductors of the simulation campaign, the simulation officers lead by aerospace engineer Gustavo Bardo Carvalho, are running the show and they always have more than one string to their bow.

"The role of this exercise is to test the team's capabilities to detect problems, adapt their timeline and, more generally, adapt to the scenario under stress and time pressure," explains Gustavo. "It feels like setting up a role-playing game. We confront the team with 'monsters'—in this case, anomalies of minor or major magnitude—and let them come up with solutions, think outside the box, have creative ideas, and learn from their mistakes."

From the simulations room, where flight data is simulated and fed to the control room, Gustavo and his team have been challenging the Sentinel-2C control team with an exhaustive list of issues to solve, from errors injected in the data, to the loss of ground stations, absence of team members (simulated sickness), and instrument and transmission failures.

Some are common and anticipated, others require the mission control team to brainstorm and exercise the communication between many multidisciplinary teams, such as the flight control team, industry partners, flight dynamics, the ESA space debris office, mission control system software and the ground stations.

"We made sure to not necessarily give a clear solution. Just like in real life, sometimes the best response is just to try to avoid the worst consequences, and we always remind them that reality can be much nastier than any simulation we may invent."

Some exceptional scenarios were also included to force the team to adapt without their usual equipment and deviate totally from the nominal timeline, such as space debris hazards, disruptions resulting from the solar wind or the evacuation of the control room.

"Recently, we simulated a space debris collision alert which required the team to make the satellite ready to engage in a collision avoidance maneuver. This meant skipping the usual steps and commissioning the satellite as early as possible."

On top of testing their technical knowledge, the simulation campaign plays a role in building the team.

"There are many events that can harm the team spirit: from people being sick to managers being rude or non-cooperative. We tried to simulate these moments to test the nerves of the team and make them more resilient."

Dress rehearsal

Lastly, teams at ESOC worked with the joint ESA, Arianespace and industry launch team in Kourou to complete the comprehensive final simulation of the countdown and launch sequence.

During the rehearsal, the mission control team received live signals from the satellite via an umbilical connection that will be disconnected shortly before launch. With this last step completed, the mission control team is now ready to launch the satellite.

2 notes

·

View notes

Text

Advancing Material Testing with Servo Tensile Testing Machines by Star EMBSYS

Tensile testing is a fundamental procedure in materials science, used to determine a material’s strength and behavior under tension. As industries increasingly demand higher accuracy and efficiency in quality control, servo tensile testing machines have emerged as the preferred solution. Star EMBSYS, a leading provider of precision testing equipment, has become a trusted name in delivering advanced servo tensile testing machines that cater to the exacting needs of various industries.

A servo tensile testing machine is designed to measure the tensile strength, elongation, and mechanical properties of materials such as metals, polymers, composites, and textiles. Unlike traditional testing machines, servo-driven systems use servo motors to provide highly controlled movement and precise force application. This results in improved accuracy, smoother operation, and greater repeatability of test results. The integration of modern electronics and data acquisition systems makes servo tensile machines an essential tool for research, development, and quality assurance.

Star EMBSYS manufactures servo tensile testing machines that are built with precision and reliability at their core. These machines are equipped with high-resolution load cells, robust grips, and advanced control systems, allowing them to perform a wide range of tensile tests with exceptional consistency. Whether for basic material strength analysis or more complex stress-strain evaluations, Star EMBSYS provides versatile solutions that cater to industries such as automotive, aerospace, construction, and academic research.

One of the standout features of Star EMBSYS's servo tensile testing machines is their user-friendly interface. With intuitive software and real-time graphical displays, users can monitor load, displacement, stress, and strain during testing. The system also enables easy data recording and analysis, helping engineers and researchers make informed decisions quickly and accurately.

The servo control technology used in these machines allows for precise speed and position control during testing. This is particularly useful for conducting complex testing protocols like cyclic loading, stress relaxation, and creep testing. The machine's flexibility makes it suitable for a wide range of standards, including ASTM, ISO, and other international testing requirements.

Durability and long-term performance are other key strengths of the machines from Star EMBSYS. Manufactured using high-quality components and engineered for continuous operation, these systems are ideal for environments that demand both precision and endurance. The company also offers customization options, allowing clients to tailor machine specifications based on material types, testing needs, and industry standards.

In addition to their technical excellence, Star EMBSYS is known for strong customer support and service. From initial consultation to installation, training, and ongoing maintenance, the company ensures that its clients receive full value and support throughout the product’s lifecycle.

In conclusion, servo tensile testing machines by Star EMBSYS represent the next level of advancement in materials testing. By combining accuracy, reliability, and intelligent design, these machines help industries meet rigorous quality standards and foster innovation. For any organization focused on material performance and safety, investing in a Star EMBSYS servo tensile testing machine is a forward-looking choice that delivers both precision and productivity.

Visit:- https://www.starembsys.com/servo-tensile-testing-machine.html

0 notes

Text

The Future in Layers: Understanding 3D Printing

3D printing, also known as additive manufacturing, is transforming how we design, create, and innovate. What once belonged to the realm of science fiction is now a powerful tool used in industries ranging from healthcare to aerospace. By building objects layer by layer from digital models, 3D printing offers flexibility, customization, and speed that traditional manufacturing often can’t match. 3D Printing

How 3D Printing Works At its core, 3D printing begins with a digital design, usually created using computer-aided design (CAD) software. The model is then sliced into thin horizontal layers. The 3D printer reads these slices and deposits material — usually plastic, resin, metal, or even food — layer by layer until the final object takes shape.

There are several types of 3D printing technologies, including:

Fused Deposition Modeling (FDM) — Melts plastic filament and extrudes it layer by layer.

Stereolithography (SLA) — Uses UV light to cure liquid resin into solid layers.

Selective Laser Sintering (SLS) — Uses lasers to fuse powdered material, often metals or plastics.

Applications of 3D Printing

Healthcare: 3D printers are used to create prosthetics, dental implants, and even bioprinted tissues. Customization is key — no two patients are the same, and 3D printing makes it possible to tailor medical devices to individual needs.

Manufacturing: Prototyping with 3D printing is faster and more cost-effective than traditional methods. Companies can test and modify designs before full-scale production.

Education: Schools and universities use 3D printing to bring concepts to life in science, engineering, and art.

Architecture: Architects can produce detailed models and even explore 3D-printed housing for rapid, affordable construction.

Fashion & Art: Designers use 3D printing to create unique jewelry, clothing, and sculptures, often unachievable by hand.

Advantages of 3D Printing

Customization: Easily adapt designs for specific users or needs.

Speed: Rapid prototyping accelerates product development.

Reduced Waste: Additive processes use only the material needed.

Accessibility: Desktop 3D printers make production possible at home or in small businesses.

Challenges and Limitations Despite its promise, 3D printing faces challenges. Materials can be expensive or limited in strength and durability. Printing large objects can be time-consuming, and the technology still requires skilled operators for optimal results. Regulatory and safety standards are also developing to catch up with rapid innovation.

The Future of 3D Printing Looking ahead, 3D printing is poised to revolutionize supply chains, reduce environmental impact, and even explore new frontiers like space manufacturing. As the technology matures, we may see everyday products — from shoes to electronics — custom-printed just for us.

0 notes

Text

Top Career Paths After a Mechanical Engineering Degree in India

Mechanical engineering is one of the most versatile and foundational branches of engineering. It plays a crucial role in designing, analyzing, and manufacturing machines and systems that drive industries worldwide. From electric vehicles and smart factories to energy systems and robotics, the need for skilled mechanical engineers continues to grow.

For students enrolled in or exploring mechanical engineering colleges in India, understanding the career options available after graduation is essential. Here are some of the top career paths you can pursue with a mechanical engineering degree.

1. Design and Product Development Engineer

Design engineers are responsible for conceptualizing and developing new products. They utilize software tools such as AutoCAD, SolidWorks, and CATIA to create prototypes and test their functionality. This role is ideal for students who enjoy creative problem-solving and technical precision.

2. Manufacturing and Production Engineer

In this role, mechanical engineers oversee the production process in industries such as automotive, aerospace, and heavy machinery. Responsibilities include process planning, quality assurance, and optimizing manufacturing systems. The role is particularly relevant as India focuses more on self-reliance and smart manufacturing.

3. Maintenance and Operations Engineer

Maintenance engineers are essential in keeping machines and production systems running efficiently. These professionals work in sectors like oil and gas, power plants, chemical industries, and manufacturing units. Their job is to identify technical problems, plan preventive maintenance, and ensure operational safety.

4. HVAC and Energy Systems Engineer

Mechanical engineers are increasingly involved in designing heating, ventilation, and air conditioning (HVAC) systems, as well as managing energy systems. This field is important in green building projects, urban infrastructure, and renewable energy sectors, making it a strong option for environmentally conscious engineers.

5. Automotive and Aerospace Engineer

Graduates in this field can work in the design, testing, and development of vehicles and aircraft systems. Mechanical engineers are crucial in improving fuel efficiency, safety, and structural design. Many global and Indian automotive companies actively recruit for these roles.

6. Robotics and Mechatronics Engineer

Mechanical engineering students who develop skills in electronics and automation can move into the field of robotics and mechatronics. These engineers build and maintain intelligent machines used in manufacturing, healthcare, and logistics. It is a fast-growing field with international demand.

7. Public Sector and Government Jobs

Many mechanical engineers choose to enter government organizations and public sector undertakings such as BHEL, ISRO, ONGC, and Indian Railways. These roles often require clearing competitive exams like GATE. They offer job security, growth, and the opportunity to work on high-impact projects.

8. Higher Education and Research

Students interested in specialization or academic careers can pursue M.Tech, MS, or PhD programs in areas such as robotics, thermal systems, or fluid mechanics. Others may opt for an MBA to transition into management roles in engineering companies.

9. Entrepreneurship

Some graduates take the startup route, launching ventures in sectors like 3D printing, custom machinery, and green technologies. A mechanical engineering background provides a strong foundation for building innovative products and services.

Why College Choice Matters

Success in mechanical engineering depends heavily on the quality of education and practical exposure. Choosing from among the top mechanical engineering colleges in India can provide better opportunities in terms of lab facilities, experienced faculty, industry connections, and campus placements.

NMAM Institute of Technology, NITTE – Your Foundation for Success

NMAM Institute of Technology (NMAMIT), under NITTE University, is recognized among the leading mechanical engineering colleges in India. The institute offers a strong academic framework along with modern labs, hands-on training, and interdisciplinary project work. Students are guided by experienced faculty and gain real-world exposure through internships and industry-linked projects.

NMAMIT also provides excellent placement support, helping students launch successful careers in core engineering and emerging technology sectors.

Conclusion

Mechanical engineering offers diverse and rewarding career paths, whether in traditional industries or cutting-edge technologies. With the right college and commitment, you can build a future that combines innovation, stability, and impact.

If you are considering mechanical engineering colleges in India, NMAMIT, NITTE provides the environment, education, and opportunities you need to thrive.

0 notes

Text

R&D Measurement and Software Engineer

Overview:is on the forefront of technology innovation, delivering breakthroughs and trusted insights in electronic design, simulation, prototyping, test, manufacturing, and optimization. Our ~15,000 employees create world-class solutions in communications, 5G, automotive, energy, quantum, aerospace, defense, and semiconductor markets for customers in over 100 countries. Learn moreOur culture…

0 notes

Text

Heavy and Light Fabrication Services in Delhi – Excellence in Engineering Solutions

Construction services play an important role in industries, making the spinal cord of infrastructure, machinery and custom-made solutions for various applications. In Delhi, finding a stirring center of industrial and commercial activity, finding a reliable and professional heavy and light fabrication services in Delhi can lead to a game-changer for your projects. Whether it is complex heavy-fee structures or mild components, our construction services provide accurate, durability and value.

Why choose us for heavy and light fabrication services in Delhi?

When it comes to construction, the accurate and quality is paramount. We are proud to be a reliable name in Delhi's construction industry, offering services to fulfill your specific needs. Our team of skilled engineers and technicians brings years of experience and technical expertise for every project. With a commitment to state -of -the -art equipment and excellence, we ensure that whatever components we become meet the highest industry standards. Our focus on customer satisfaction motivates us to provide timely solutions, ensuring that your projects remain on the schedule. From initial consultation to final delivery, we maintain clear communication, inform you at every stage of the process. In addition, our competitive pricing structure ensures that you get top notch services without more than your budget.

Does make us the best heavy and light fabrication services in Delhi?

The answer lies in our dedication to innovation, quality and customer-focus. We contact every project with a deep understanding of our unique challenges and needs. Our construction processes are directed by a commitment to use the best materials and follow the stringent quality control protocol. For heavy construction, we specialize in preparing strong structures that can withstand excessive loads and environmental conditions. From industrial machinery components to large structural structures, we complete industries such as construction, manufacturing and energy. On the other hand, our lighting services, motor vehicles, aerospaces and applications in consumer goods focus on creating a durable component yet. We use advanced techniques to get high precision and fine details, making us a favorite option for customer designs and customers looking for better craftsmanship. Additionally, our in-house design team works closely with customers so that they can turn their concepts into reality. Using advanced software and design tools, we ensure that each product align with customer's vision and functional requirements. This overall approach has earned us the trust of a diverse customers beyond Delhi and from it.

Benefits of choosing our heavy and light fabrication services in Delhi

Supporting with us starts a host of advantages, starting with our ability to handle any scale or complexity projects. Our expertise in both heavy and light fabrication services in delhi enables us to provide us an end-to-end solution under one roof, which can save you time and effort. Our commitment to quality ensures that each fabricated component is finalized. We create a source of high-grade materials and follow industry-under practices to distribute products that meet expectations. With our rigorous testing processes, you can be confident in the reliability and durability of every product produced by us. Another important benefit is our focus on stability. We are committed to reduce waste in our construction processes and adapt resource uses. By choosing us, you not only get high quality products, but also contribute to a greenery, more sustainable future. Finally, our excellent after -sales support ensures that you always have access to expert assistance. Whether you need modifications, repair or guidance on installation, our team is here to help.

0 notes

Text

Top Electronics Manufacturing Companies in Bangalore: Powering India’s Tech Future

India is fast becoming a global destination for high-quality, cost-effective electronics manufacturing. Backed by the government’s Make in India initiative and the Production Linked Incentive (PLI) scheme, the country is attracting global OEMs and startups alike looking for trusted, scalable EMS partners.

At the center of this shift is Bangalore — a city once synonymous with software, now transforming into a major hub for electronics manufacturing companies in India. With world-class engineering talent, cutting-edge infrastructure, and a growing cluster of EMS firms, Bangalore is enabling faster prototyping, smarter manufacturing, and reliable product delivery across sectors like telecom, automotive, IoT, aerospace, and medical devices.

Here are 10 top electronics manufacturing companies in Bangalore to watch in 2025:

🔹 Gemni Electro Corporation (GECor)

Established in 2008, GECor combines decades of experience in telecom, industrial electronics, and engineering consultancy. Today, it's a trusted EMS provider known for precision design, PCB assembly, and system integration.

🔹 LeePra Technologies Pvt. Ltd.

ISO 9001 and IATF 16949-certified, LeePra offers full-cycle electronics manufacturing — from BGA rework and SMT assembly to final box builds — supporting clients across automotive and industrial sectors.

🔹 Rantronics Technology

Rantronics delivers fast-turn PCBs, 3D-printed enclosures, and low-volume assembly services tailored for hardware startups and OEMs. Known for flexibility and speed, it's a preferred partner in IoT and embedded sectors.

🔹 ZREYAH Semiconductor Systems

With more than 15 years of experience, ZREYAH provides comprehensive EMS solutions — including PCB layout, prototyping, testing, and volume production — especially for aerospace and mission-critical industries.

🔹 Octane Circuits

From embedded systems to RF design and IoT hardware, Octane supports complete product development. Their expertise in both design and manufacturing makes them a key electronics partner for tech-forward companies.

🔹 Raghasai Technologies

A legacy name since 1987, Raghasai offers a complete suite of services: PCB layout, fabrication, assembly, and reverse engineering. Their longevity and reliability have made them a trusted player in India’s EMS space.

🔹 OMGVH Electronics

OMGVH supports full turnkey EMS — PCB assembly, soldering, testing, and functional validation — trusted by industrial control and automotive OEMs for its attention to quality and detail.

🔹 Micron EMS Tech

Ideal for high-mix, low-to-mid volume production, Micron EMS Tech delivers quick prototypes, reliable box builds, and flexible EMS solutions that meet the evolving needs of startups and midsize companies.

🔹 Nigama Circuits

With nearly two decades of experience, Nigama Circuits integrates PCB design, fabrication, and assembly under one roof. Known for competitive pricing and dependable turnaround times, it's a go-to for cost-conscious electronics manufacturing in India.

🔹 Confluence Circuits Pvt. Ltd.

A family-owned EMS provider catering to telecom, medical, automotive, and automation industries, Confluence offers PCB assembly, testing, and complete product build services for local and international clients.

Why Bangalore Is a Leading Electronics Manufacturing Destination in India

Skilled Workforce – Access to thousands of trained engineers in electronics, embedded systems, and design.

Strong Infrastructure – Government-backed electronics clusters and smart manufacturing parks.

Global Connectivity – Proximity to R&D centers, tech parks, and international logistics.

Collaborative Ecosystem – A strong network of OEMs, startups, and contract manufacturers drives innovation.

Quality & Certification – Most companies are ISO/IATF certified and meet international compliance standards.

💡 Final Thoughts

As global brands search for alternate supply chains and reliable EMS partners, India is rising fast as a competitive electronics manufacturing hub. Bangalore, in particular, is home to some of the most capable and quality-focused manufacturers in the country.

Whether you're looking for PCB prototyping, turnkey EMS, or full-scale product builds, these Bangalore-based companies reflect the best of electronics manufacturing company in India

#top 10 electronics manufacturing companies in Bangalore#electronics manufacturing#electronics manufacturing companies

0 notes