#Automatic Batch Blending

Explore tagged Tumblr posts

Text

#Lubricant Oil Blending Plant#Lube Oil Blending Plant#lubeoilblendingindustry#lubeoilblendingmachinery#lubricatingoilblendingproject#barrel heating oven#electric infrared drum heating oven#drum heating oven#lubeoilblendingplantfillingline#lubeoilblendingplant#Nigeria Lubricant Industry#Automatic Batch Blending#In-Line Blending System#Simultaneous Metered Blending#Skid Mounted Lube Oil Blending Plant#Pigging Unit Lube Blending Plant#Drum Decanting Unit#Lubricant Oil Viscosity Index Improver Plant#Lubricant Oil Viscosity Improver Plant

0 notes

Text

Nestled in the heart of Lombard Drive, this exquisite 2.5-bedroom, 2-bathroom residence embodies the elegance of modern French Colonial design. A harmonious blend of light neutrals and bold dark accents graces both the interior and exterior, creating a timeless aesthetic. The home’s grand façade is framed by lush, meticulously curated gardens, where vibrant red and white hydrangeas weave a captivating tapestry around the estate. Beyond the charming exterior, a private backyard oasis awaits—an entertainer’s dream featuring a striking sunken conversation pit seamlessly encircled by a shimmering pool, perfect for intimate gatherings and luxurious outdoor living.

40 x 30

Residential Lot

2 beds, 1 nursery

2 full bathrooms

Furnished

$570,487

Requirements:

Turn bb.moveobjects on before placing. **optional** TwistedMexi has a script mod that does it for you automatically, so there is no reason to always have to type it in.

T.O.O.L by TwistedMexi.

Required CC - Please refer to the included PDF document for downloading items that were not included in the zip file, as some are still in early access.

One of the cabinets is a recolor; download the original mesh here if you load into the lot and something is missing. The file name is [KKB'sMM]Aesthete - Cabinet ver.2.

The lush red hydrangeas are a recolor; download the mesh here.

Terms of Use:

Do not re-upload my lots and claim them as your own.

You're welcome to edit or modify my builds, but please remember to credit me as the original creator!

Do not put my builds behind a paywall.

I've included some of my recolors, please refer to those posts for their TOU.

Thank you to all CC Creators.

Please let me know if there's any problem with the build. Tag @sarahelizasims so I can see your gameplay and any personal touches you've made!

I sincerely apologize for the number of zip files. I had a tough time finding a way to upload everything at once or compress the main folder as a whole. As a result, I had to create multiple folders to split up the CC. If you have any tips on compressing and optimizing large files, I would greatly appreciate your help!

Please note that this is a very CC heavy build, which might cause lag in your game. I organize CC files to their content creator in my downloads. Make sure you're actively running batch fixes on your files.

My game is DirectX11, so you may need to update your images to DX11 in the Sims 4 Studio.

📥DOWNLOAD (Available for FREE on Patreon)

Floor Plan & Photo Gallery:

#sims 4 cc#ts4 cc#sims cc#ts4 build#sims build#sims download#ts4 download#the sims 4 cc#ts4cc#thesims4#sims 4#simblr#ts4#builds#brindleton bay#newcrest#sarahelizasims#*lombard drive

502 notes

·

View notes

Text

Vivien's Morning Routine

If he has to be at work at 9, Vivien's first alarm goes off at 6:30, and it is promptly turned off and ignored.

The next alarm goes off at 6:40, then 6:50, 7:00, 7:15, 7:30, and 7:45. Each successive alarm wakes him up a little more, so by 7:45 he is now 80% awake, enough to get out of bed, even if he does lay around and scroll on his phone for a while.

Each of the alarms is a different bopping song. He specifically only picks songs that are loud and catchy, as quiet, soulful, deep songs will just blend into his dreams instead of waking him up.

Usually he loves listening to these songs, but hearing them waking him out of the gentle caress of sleep is not fun. He changes them every few months to prevent him from permanently hating the song.

Before even getting out of bed, Vivien will send Darling a good morning text and ask how they slept. He eagerly awaits their reply and keeps his phone nearby the entire day, his face lighting up at every phone chime.

He usually sleeps naked or in just his underwear, and the first thing he does after rolling out of bed is head to the bathroom to splash some cool water on his face. Obviously, he doesn't make his bed; he hasn't done that since he was a kid in the foster home.

If it's been a good, productive week, he has meal-prepped his breakfast like cutting up peppers and spices to put in his eggs or baking a batch of muffins to eat during the week.

Unfortunately, it usually isn't a productive week. He'll either buy some baked goods readymade from the store or just make something quick like toast, instant oatmeal, or frozen waffles. They're quick and easy and don't require too much thought so early in the morning from a sleepy guy.

After eating, it is usually 8:30 or so, and he needs to hurry and get ready. He gets a pair of jeans and a work shirt from Laundry Chair and throws them on. He does not care that they are wrinkly; he only cares that they're clean.

He brushes his teeth and runs a brush through his hair. After throwing his shoes and jacket on, he's pretty much ready to go.

He will never admit to this, but he finger-guns himself in the mirror to hype himself up before work. It's kind of cute.

One thing Vivien does not ever forget the night before is to pack his lunch. He loves his sleep, and he knows himself well enough to know that he won't put in the work in the morning. Lunch is usually leftovers from dinner the night before, some fresh fruit, raw vegetables, granola bars, yogurt and honey, and some sort of cracker like goldfish or Cheez-Its. If he's baked recently, he'll throw in something like a cookie or a brownie. He tries to bring a lot of snacks as he has to sustain himself until around 5:00pm.

This isn't obvious, and he's not telling anyone, but there is a secret pocket underneath the main compartment of his lunchbox. That's where he keeps some of his supplies. A bottle or two of pepper spray, an automatic knife, a pocket taser, even some of his sedative herb syrup. The bigger, more obvious stuff is left neatly hidden in his car; this stuff is only if he must protect himself in the immediate. Just in case he needs them.

After filling up his 64oz (half a gallon) water bottle, he grabs his keys off the hook, heads down the stairs, and gets in his car. The garden store is only 8 minutes away, and if he is on time, he will arrive at work at exactly 8:52. He unlocks the shop, flips the sign, and performs a cursory examination of the shop (even though he was there like 16 hours ago and nothing has changed). He puts his lunch in the fridge, and work begins.

He's ready for another day of hanging with the plants!

#soft yandere#yandere#yandere blog#yandere imagine#yandere oc#yandere darling#yandere fluff#yandere headcanons#yandere x darling#yandere x y/n#yandere boy#possesive yandere#yandere bf#yandere drabble#yandere headcannons#yandere headcanon#yandere imagines#yandere male#yandere original character#yandere scenarios#yandere x reader#yandere x willing reader#yandere thoughts#yandere x you#Vivien my oc

68 notes

·

View notes

Text

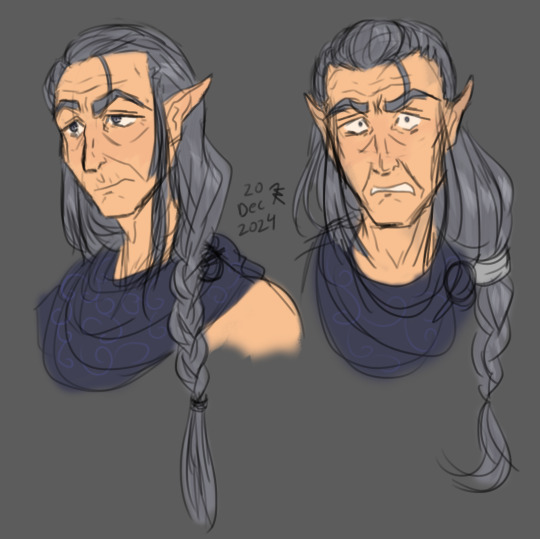

Arcanum: Of Steamworks and Magick Obscura doodle dump

various scribbles or scrapped WIPs from the past few months of some Arcanum NPCs~

September 2024 - Scrapped M'in Gorad scribbles, based on her in-game sprite and one of the female elven portrait options (since she doesn't have an in-game portrait).

While Raven's hair is described as "dark crimson, almost black," I like to think M'in Gorad's hair is a dark green, almost black hue.

October 2024 - Scrapped/unfinished Torian Kel sketch from my endgame team headshots. I restarted this dude's portrait like three times because golly it's so hard to capture his likeness in my style.

?? November 2024 - scrapped armor concept for Torian Kel, inspired by a blend of in-game armor, 17th-century Dutch infantry armor, and 19th-century Zouave infantry uniforms.

November 15, 2024 - My take on Hieronymous Maxim, the Master of Repair and (in his words) the "inventor of the mechanized gun and the recently absconded aeroplane." You know, the same planes that shot down the IFS Zephyr in the game's intro.

I took reference for the clothes from an 1882 fashion plate. For Hieronymous Maxim's face, I referenced his namesake, Sir Hiram Stevens Maxim, creator of the first automatic machine gun who also experimented with heavier-than-air flying machines.

I'm thinking of making similar portraits for the other Master Trainers.

December 20, 2024 - island hermit Nafroodinski

February 17, 2025 - My interpretation of a younger (Age of Legends-era) and a present-day (1885) K'an Hua. I imagine he had a Gollum-like transformation in the 2000ish years between to become what the game describes as "[... a hunched, robed figure...you are taken aback by his hideous appearance. An air of dank, foul evil emanates from him, warping his elven features.]" (although he ended up looking like Brad Dourif's portrayal of Grima Wormtongue lmao)

Early April 2025 - Headshots of Jayna Stiles and Garfield Thelonius Remington III, much like this previous batch of follower portraits I did~

#stellastra's art#Arcanum#arcanum: of steamworks and magick obscura#arcanum of steamworks and magick obscura#M'in Gorad#Torian Kel#Hieronymous Maxim#Nasrudin#K'an Hua#Jayna Stiles#Gar#Garfield Thelonius Remington III

16 notes

·

View notes

Text

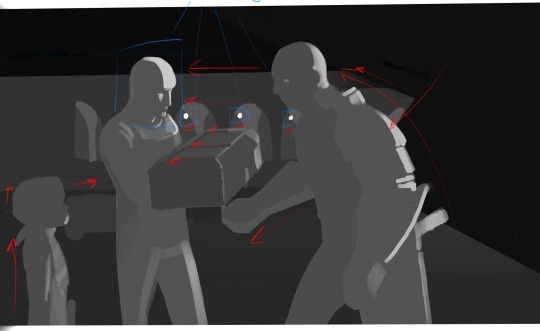

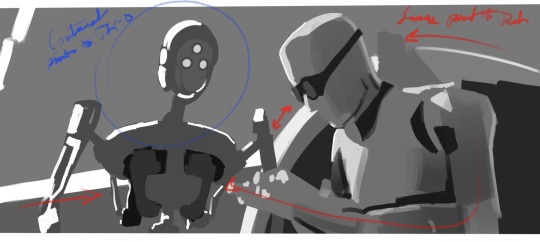

Because I have a tendency to get stuck in art blocks and s t r u g g l e badly with composition, and because I think The Bad Batch is a beautifully shot show, I’ve started doing rough grayscale studies of bad batch to unpack how line and value can be used to direct a viewer’s eye to where people want the audience to look. (I’m doing it with other movies and shows, but I do really like TBB, so….) That way, if I’m sitting in a period where I can’t draw, then maybe I can at least learn something. It’s not fan art, it’s just trying to break the composition down and make it make sense to me, but I think it’s interesting so I figured I’d throw them all here.

So! Potentially very boring things under the cut:

The thing that started this off was getting sent a gifset of the scene in “The Return” where Wrecker gives Crosshair his armor back. It’s a great scene, and one of the things that allows for the show to pull that moment off is the way that most everything in many of the shots is designed to draw the viewer’s attention to Crosshair’s face so that we’re paying attention to his reaction. For example:

It’s not a very high contrast shot, but if we block out the basics, most of the lines in the scene are directing us towards Crosshair. Both Wrecker and Omega make movements towards him in this shot, and then this movement is sort of carried over to Crosshair via the various lines in the background/Wrecker’s arm/even the crate. Additionally, our eyes tend to be drawn towards points of highest contract, which, in this shot, include the lamps in the far background against the pillars (forming a line from Wrecker to Crosshair) and the light hitting Crosshair’s face against the much darker background. Between all of this most people in the audience are going to end up automatically looking right at Crosshair who is, of course, the main person we’re supposed to paying attention to here.

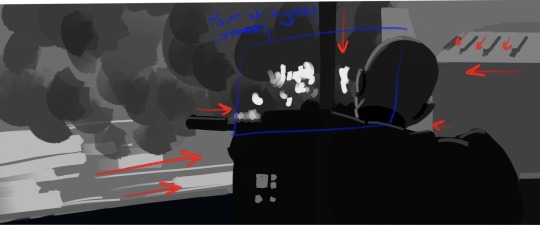

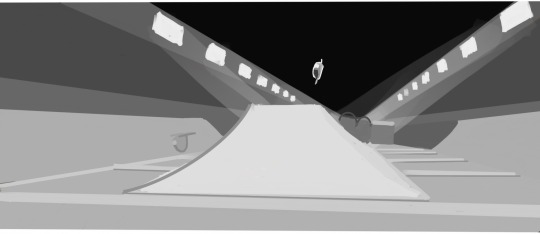

This isn’t actually a full frame. I sort of grabbed a screenshot over the interwebs for this one, but The Bad Batch actually has a very wide aspect ratio. From what I understand it’s shot and aired in a CinemaScope ratio (2:39:1 or 2:35:1, though TBB is 2:39:1). It’s basically super ultra widescreen, an aspect ratio used when a filmmaker wants to make something feel more epic or cinematic, and as far as I know it’s the same aspect ratio used for the original trilogy before any cropping happened. (For reference, The Clone Wars was also shot in a CinemaScope ratio, 2:35:1, but was cropped to 16:9 for airing on Cartoon Network, and Rebels was shot and aired in 1:78/more or less 16:9.) So an uncropped screenshot of TBB would look more like this:

This is from “The Outpost.” It’s actually a fairly dark shot with Crosshair faced away from the camera and the value of his figure blending right into the rest of the foreground, which actually comes communicate a sense of someone who isn’t trying to draw attention to themselves (to me, anyway), but our eyes are drawn to Crosshair anyway by every major line in the shot as well as the highest point of contrast converging right over Crosshair’s shoulder. That, and the line of his rifle/shoulder and the support pole forming a big, well, cross-hair right in that same spot. Otherwise, he would blend right into the foreground and be easier to miss.

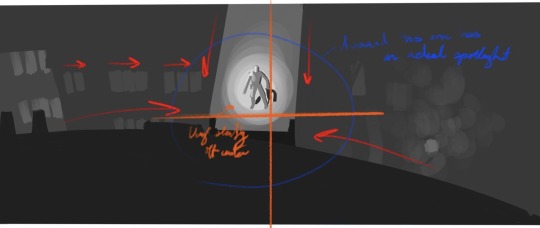

Unlike Hunter in this shot from “Plan 99”

Where basically you’ve got the exact same thing happening, every line in the shot converges on Hunter’s location, but instead of using just high contrast to draw our attention, we’ve got a fairly middle-gray scene with our eyes being drawn to the focal point by having one bright spotlight.

The orange cross mark I’ve drawn here is just to mark the center of the frame, which I wanted to point out since, at least as far as I’ve noticed, TBB has a tendency to save center and slightly off-center shots for really specific moments. I’d have to check on that and what the pattern is, though, since a few of the remaining shots in this post are center shot. (Filmmakers area generally taught shoot in thirds or, alternatively, on a phi grid or other away from center set of focal points, though you do get some center shot movies and shows. I think Raiders of the Lost Arc has a lot of center shots.)

In fact, a pretty good example of shooting in thirds (or on a phi grid—I laid it out and I think it fits the phi grid slightly better) is this shot from “Faster”

Where you’ve got Tech and Tay-0 placed on slightly close thirds on either side of the frame. If we’re just looking at line and value, with this shot we actually get this sort of interesting back and forth between where our eye is being drawn. A lot of the lines in the shot are directing us to look at Tech, but then you’ve got one of the lines going through, and the sweep of Tech’s arm and datapad pointing towards, Tay-0, whose face and body are outlined with a much higher contrast in value. And then we have that one very bold arc connecting the two. The result of this is that our eyes sort of bounce back and forth between these two characters as they get into their conversation.

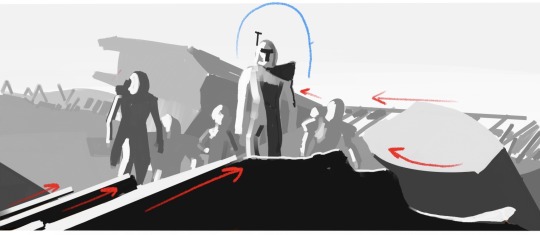

Most of these shots have had just one or two (at most three) characters, and there are many scenes of TBB with everyone where our gaze is sort of directed to the group collectively, but sometimes you’ll have group scene where our attention is directed more towards one individual than others, like with this shot from “Battle Scars”

Once again, you’ve got most of the lines in the shot converging towards Rex as well as Rex’s person serving as the point of highest contrast while everyone else sort of melds into the background in terms of value. He’s also the first (and maybe only) figure who breaks fully above objects in the background to be shot directly against the sky. Line and value aren’t the only things directing the audience’s gaze towards Rex in this shot—there’s actually a lot of desaturation happening as we move from Rex, to the other characters, to the far background that helps as well, buuuuut this is a grayscale breakdown so that unfortunately doesn’t show up...here. (This is a center shot scene if we’re going horizontally, but Rex’s head, which is really the focal point, is right around the top third of the frame; it’s not exactly a low angle shot, but we are still looking up at him.)

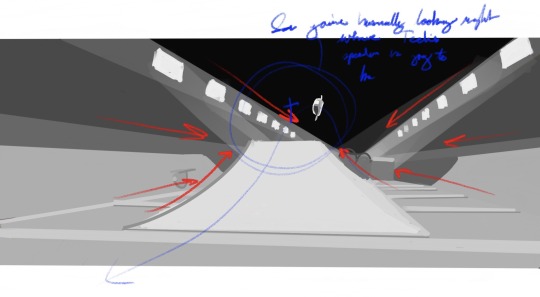

Anyway, the reason any of this is important is because when you’re shooting with an incredibly wide aspect ratio like this, there’s a LOT of information being conveyed with every frame. You can fit a lot of stuff on screen at once. And while people generally going to rewatch and pay attention to background details (if nothing else, TBB is a goldmine for those background details), you do want to draw your audience’s attention to the most important parts of the frame—especially when an individual shot typically lasts only a few seconds. Or less. Like with this:

So this shot from "Faster" is up for less than a second before the camera turns to follow the speeders and then changes to another shot, and I had a devil of a time even getting screengrab of it. (Mostly because I was trying to grab it on my phone, but that's not really the point.) In less than a second the people making this have to communicate where Tech's speeder is, what's happening, what we're even looking at, while the objects in the scene are all moving incredibly fast. .

So, to communicate that, you've got multiple speeders moving in the shot, but only one (Tech's) standing out in terms of value against a fairly dark ceiling, as well as a combination of some real direct one-point linear perspective and the more or less arrow shape of the ramp pointing directly at the point Tech's speeder is going to be when it reaches the peak of its crest over the ramp. That way we're already looking at where Tech is going to be before he gets there and end up following his speeder as he zooms by.

#the bad batch#so anyway it's a very pretty show#and a very visually deliberate one too#(I think it's deliberate in other ways too but that's the kind of stuff I save for my endless old lady yells we're not done at clouds box)#there's no real conclusion to this#I just have a hard time getting my head around composition so I thought the way TBB does it is neat#also I know in animation it’s scene and sequence instead of shot and scene#but it’s easier to communicate it with shot and scene

26 notes

·

View notes

Text

Another batch planned, because I can: second attempt at a ginger-lemon not quite cyser!

This time, we've got some cloudy apple juice, that apple-ginger-lemon "shot" (claiming 34% ginger juice), and trying some of what is essentially Scandinavian golden syrup instead of honey. It's cheaper, and I thought the warm flavor might work well with everything else.

This also seemed like a decent excuse to try that pack of Belgian ale yeast which accidentally got sent in an order. It's supposed to be good for the stronger types of Belgian beer, and give off some tropical fruit and spicy notes. Really not a neutral choice, and I haven't been sure what to do with the stuff since I don't even enjoy beer all that much and don't particularly want to get into brewing my own GF varieties.* But, this combo of ingredients doesn't seem like it would be wrong with the distinctive flavor notes that you get in those types of Belgian ales--a lot of which probably do come from the yeast strains used.

Anyway, I guess we'll see how this works out. Current plan is to start off with the apple juice and syrup, and then add the ginger-lemon stuff in secondary once it's otherwise about done. Hopefully that will help keep more of the flavors in there. I was disappointed before at how little ginger came through in the end from that juice blend that tasted noticeably gingery before fermentation, and I'm hoping that adding the spice component in later will leave more flavor from it.

Not as concerned about the lemon for this batch, or I would probably add in some extra peel later on too.

_________

* I have also been a CAMRA member for around 20 years now, funnily enough --and good-sported along to several beer festivals over the years. Where I kept hitting the cider and perry. 😊 Though I do rather enjoy the Belgian ale styles that this yeast is supposed to be good for. My partner just automatically signed me up as part of a family membership, and I didn't see any real reason to object. Still think it's sorta funny, tbh. Don't actually know if he's kept that going since we left the UK, now that I think about it.

3 notes

·

View notes

Text

Melt Flow Index Tester – Importance, Working, and Applications

Pacorr brings you a highly reliable and accurate Melt Flow Index Tester, specially designed to evaluate the melt flow properties of thermoplastic materials. In industries where plastic is used for molding, extrusion, or packaging, knowing how a material behaves when melted is essential. The Melt Flow Index (MFI), also known as Melt Flow Rate (MFR), is a standard measure that helps determine the viscosity and processability of polymers.

In this article, we will take a closer look at how a Melt Flow Index Tester works, why it is critical for quality control, and how manufacturers, exporters, and suppliers can benefit from using it.

What is a Melt Flow Index Tester?

A Melt Flow Index Tester is a laboratory instrument used to measure the flow rate of molten thermoplastic polymers. The test is conducted under specified conditions of temperature and load, and the result is expressed in grams of material flowing through a capillary die in ten minutes.

This value is known as the Melt Flow Index, and it provides key insights into the polymer’s molecular weight and flow behavior. A high MFI indicates low molecular weight and high fluidity, while a low MFI indicates a high molecular weight and lower flowability.

Why is MFI Testing Important?

The MFI test is critical for various reasons in the plastic and packaging industries:

1. Material Selection

Choosing the right polymer for injection molding, blow molding, or extrusion requires understanding its flow properties. MFI helps engineers and manufacturers select materials with appropriate characteristics.

2. Quality Control

Manufacturers can use MFI testing to ensure batch-to-batch consistency. Any deviation in MFI may indicate problems in material composition or blending.

3. Process Optimization

Knowing the melt flow rate helps set the correct processing parameters, reducing defects like warping, short shots, or poor surface finish.

4. Compliance with Standards

MFI testing is often required to meet international quality standards such as ASTM D1238 and ISO 1133. Many buyers and regulatory bodies demand this data.

Working Principle of Melt Flow Index Tester

The working of an MFI Tester is based on the movement of molten polymer under controlled temperature and pressure. Here’s how it works:

A sample of the polymer is placed inside the barrel of the tester.

The machine heats the sample to a specific temperature depending on the type of plastic (e.g., 190°C for polyethylene).

A standard weight (typically 2.16 kg or 5 kg) is applied to a piston or plunger.

The molten plastic is forced through a narrow capillary die.

The material that extrudes in 10 minutes is collected and weighed.

The result is expressed in g/10 min, which represents the Melt Flow Index.

This simple yet effective test provides accurate, repeatable data on a polymer's melt behavior.

Who Should Use a Melt Flow Index Tester?

The Melt Flow Index Testung is widely used by:

Plastic manufacturers producing components, containers, or sheets

Resin suppliers and exporters dealing in raw polymer materials

PET bottle and preform producers for ensuring strength and consistency

Masterbatch and compound manufacturers to evaluate flow uniformity

Research laboratories and quality control centers

Key Features of Pacorr Melt Flow Index Tester

At Pacorr Testing Instruments, we offer both manual and digital models of MFI Testers with industry-leading features:

Digital PID temperature controller for precise thermal management

Rugged, powder-coated body for corrosion resistance and long life

Standard-compliant barrel and die assembly

Interchangeable test loads (2.16 kg, 5 kg, 10 kg, etc.)

User-friendly interface with accurate timer and display

Available with automatic sample cutting in digital models

Benefits of Using Pacorr’s MFI Tester

✅ Reliable Results – Ensures accurate and repeatable MFI values ✅ Compliant with ASTM D1238 and ISO 1133 standards ✅ Durable Design – Built for industrial conditions ✅ Affordable and Efficient – High ROI for manufacturers ✅ Technical Support & Calibration Services available across India

Applications of Melt Flow Index Tester

Injection Molding – For parts like containers, caps, automotive components

Blow Molding – For PET bottles, jerry cans, and drums

Film and Sheet Extrusion – Ensuring consistent thickness and strength

Masterbatch Testing – Verifying flowability of colored resins

Recycling Plants – Monitoring quality of reprocessed polymers

Why Choose Pacorr?

Pacorr is one of India’s Top 10 Scientific Instrument Manufacturers (2023), with a strong reputation for delivering reliable, ISO-certified, and CE-marked testing machines. Our commitment to quality and innovation makes us the preferred choice among manufacturers, suppliers, and exporters across various industries.

We provide:

High-precision instruments

Customization options

Nationwide support and service

Expert consultation for choosing the right model

Conclusion

The Melt Flow Index Tester is an essential quality control tool for any company dealing with plastic and polymer materials. By providing accurate melt flow rate values, it helps ensure product consistency, optimizes production, and complies with international standards.

With Pacorr’s advanced MFI Tester, you not only test your materials—you build trust in your brand.

📞 Need Help Choosing the Right MFI Tester?

Call us at +91-8882149230 or email us at [email protected] Visit 👉 www.pacorr.com

#MeltFlowIndexTester#MFITester#PlasticTesting#PolymerTesting#QualityControl#PlasticManufacturers#PETPreformTesting#InjectionMolding#BlowMolding#ResinTesting#TestingInstruments#MaterialTesting#ASTMD1238#ISO1133#PlasticIndustry#TestingSolutions#ScientificInstruments#QualityAssurance#Manufacturers#Suppliers#Exporters#PacorrTestingInstruments

0 notes

Text

Balancing efficiency and environmental needs in NPK blending fertilizer production lines

Against a backdrop of rising agricultural demands and stricter environmental rules, finding the balance between efficiency and eco-standards in NPK blending fertilizer production lines have become a key industry focus. By refining production methods and equipment setup, it’s entirely possible to achieve both high efficiency and green manufacturing.

1.Better Raw Material Management

Use enclosed raw material storage to cut down dust leaks.

Adopt precise batching technology, keeping errors within ±1%.

Apply low-dust pretreatment processes, reducing dust emissions by 30%.

2.Upgraded Production Processes

Install high-efficiency dust removal systems that capture up to 99% of dust.

Use low-energy mixing equipment, cutting unit energy use by 15–20%.

Optimize NPK blending fertilizer production line layout to shorten material transport distances and save energy.

3.Smart Control Systems

Monitor energy use in real time using IoT technology.

Build data analytics platforms to fine-tune production parameters.

Enable automatic alerts and responses for abnormal emissions.

4.Resource Recycling

Reuse collected dust, achieving 99.5% raw material utilization.

Centralize and fully recycle packaging waste (100% recovery).

Install waste heat recovery systems, boosting thermal efficiency by 25%.

In short—through tech innovation and scientific management—NPK blending fertilizer production lines can absolutely meet the goal of efficient, clean, low-carbon production.

0 notes

Text

NPK Fertilizer Production: The Art of Precision Nutrition

Core Value of Automated Systems

Modern NPK fertilizer production lines serve as "nutrition formulators" in agricultural technology, expertly blending nitrogen, phosphorus, and potassium in scientific ratios to create perfect formulas for various crops. This automated system ensures each granule contains stable nutrient proportions through precise raw material batching and advanced process control - like customized "nutrition meals" for plants.

The line's intelligent capabilities are astounding - from raw material crushing to final packaging, the entire process is monitored by central control systems with accuracy within ±0.5%. This precision boosts fertilizer efficiency while reducing waste, making agriculture more sustainable.

Symphony of Key Equipment

The NPK production line operates like a well-orchestrated ensemble:

Raw material processing: Crushers and batching systems form the "percussion section," preparing perfect "notes" for subsequent processes

Mixing & granulation: Dual-shaft mixers and drum granulators compose the "string section," creating uniform blends and shaping particles

Post-processing: Dryers, coolers, and screeners constitute the "wind section," finalizing product quality

Notably, modern lines feature coating equipment that "dresses" particles in protective layers - preventing moisture while controlling nutrient release for longer-lasting effects.

Innovation-Driven Future Trends

With precision agriculture advancing, NPK lines are undergoing three key transformations:

Modular designs: Enable quick adjustments for different formulas, reducing changeover time by 70%

IoT integration: Real-time monitoring enables predictive maintenance, minimizing downtime

Eco-upgrades: Exhaust treatment systems recover 99% of dust for cleaner production

These innovations boost efficiency while making large-scale customized fertilizer production feasible. As AI technology develops, NPK lines will grow "smarter," automatically adjusting formulas based on soil data and crop needs - truly realizing precision agriculture's vision of "right fertilizer, right place, right time."

0 notes

Text

Efficient Data Management for Predictive Models – The Role of Databases in Handling Large Datasets for Machine Learning

Predictive modelling thrives on data—lots of it. Whether you are forecasting demand, detecting fraud, or personalising recommendations, the calibre of your machine-learning (ML) solutions depends on how efficiently you store, organise, and serve vast amounts of information. Databases—relational, NoSQL, and cloud-native—form the backbone of this process, transforming raw inputs into ready-to-learn datasets. Understanding how to architect and operate these systems is, therefore, a core competency for every aspiring data professional and hence, a part of every data science course curriculum.

Why Databases Matter to Machine Learning

An ML workflow usually spans three data-intensive stages:

Ingestion and Storage – Collecting data from transactional systems, IoT devices, logs, or third-party APIs and landing it in a durable store.

Preparation and Feature Engineering – Cleaning, joining, aggregating, and reshaping data to create meaningful variables.

Model Training and Serving – Feeding training sets to algorithms, then delivering real-time or batch predictions back to applications.

Databases underpin each stage by enforcing structure, supporting fast queries, and ensuring consistency, and hence form the core module of any data science course in Mumbai. Without a well-designed data layer, even the most sophisticated model will suffer from long training times, stale features, or unreliable predictions.

Scaling Strategies for Large Datasets

Horizontal vs. Vertical Scaling Traditional relational databases scale vertically—adding more CPU, RAM, or storage to a single machine. Modern workloads often outgrow this approach, prompting a shift to horizontally scalable architectures such as distributed SQL (e.g., Google Spanner) or NoSQL clusters (e.g., Cassandra, MongoDB). Sharding and replication distribute data across nodes, supporting petabyte-scale storage and parallel processing.

Columnar Storage for Analytics Column-oriented formats (Parquet, ORC) and columnar databases (Amazon Redshift, ClickHouse) accelerate analytical queries by scanning only the relevant columns. This is especially valuable when feature engineering requires aggregations across billions of rows but only a handful of columns.

Data Lakes and Lakehouses Data lakes offer schema-on-read flexibility, letting teams ingest semi-structured or unstructured data without upfront modelling. Lakehouse architectures (Delta Lake, Apache Iceberg) layer ACID transactions and optimised metadata on top, blending the reliability of warehouses with the openness of lakes—ideal for iterative ML workflows.

Integrating Databases with ML Pipelines

Feature Stores To avoid re-computing features for every experiment, organisations adopt feature stores—specialised databases that store versioned, reusable features. They supply offline batches for training and low-latency look-ups for online inference, guaranteeing training-serving consistency.

Streaming and Real-Time Data Frameworks like Apache Kafka and Flink pair with databases to capture event streams and update features in near real time. This is crucial for applications such as dynamic pricing or anomaly detection, where stale inputs degrade model performance.

MLOps and Automation Infrastructure-as-code tools (Terraform, Kubernetes) and workflow orchestrators (Airflow, Dagster) automate database provisioning, data validation, and retraining schedules. By codifying these steps, teams reduce manual errors and accelerate model deployment cycles.

Governance, Quality, and Cost

As datasets balloon, so do risks:

Data Quality – Referential integrity, constraints, and automatic checks catch nulls, duplicates, and outliers early.

Security and Compliance – Role-based access, encryption, and audit logs protect sensitive attributes and meet regulations such as GDPR or HIPAA.

Cost Management – Partitioning, compression, and lifecycle policies curb storage expenses, while query optimisers and materialised views minimise compute costs.

A modern data science course walks students through these best practices, combining theory with labs on indexing strategies, query tuning, and cloud-cost optimisation.

Local Relevance and Hands-On Learning

For learners taking a data science course in Mumbai, capstone projects frequently mirror the city’s fintech, media, and logistics sectors. Students might design a scalable order-prediction pipeline: ingesting transaction data into a distributed warehouse, engineering temporal features via SQL window functions, and serving predictions through a feature store exposed by REST APIs. Such end-to-end experience cements the role of databases as the silent engine behind successful ML products.

Conclusion

Efficient data management is not an afterthought—it is the foundation upon which predictive models are built and maintained. By mastering database design, scaling techniques, and MLOps integration, data professionals ensure that their models train faster, score accurately, and deliver value continuously. As organisations double down on AI investments, those who can marry machine learning expertise with robust database skills will remain at the forefront of innovation.

Business Name: ExcelR- Data Science, Data Analytics, Business Analyst Course Training Mumbai Address: Unit no. 302, 03rd Floor, Ashok Premises, Old Nagardas Rd, Nicolas Wadi Rd, Mogra Village, Gundavali Gaothan, Andheri E, Mumbai, Maharashtra 400069, Phone: 09108238354, Email: [email protected].

0 notes

Text

How My Meal Guru Adapts to Your Household Size and Lifestyle

Cooking for one or for a crowd? My Meal Guru scales recipes and shopping lists to fit your household, saving time, money, and food waste.

Cooking dinner might seem simple, but it becomes a whole different challenge depending on how many people you’re feeding. Planning meals for yourself, a partner, or a full household each brings its own set of questions. How much should I cook? Will there be leftovers? Will we waste food? My Meal Guru answers all of those questions with one smart solution. Whether you live alone, share meals with someone, or have a family to feed every night, the app adjusts to your lifestyle — automatically. One of the first things the app asks when you sign up is: How many people are you cooking for? This single input changes everything.

No more guessing, just right-sized planning -:

Traditional meal planning tools often give you fixed recipes — usually designed for four servings. If you’re only cooking for one, that means a lot of waste or leftover management. If you’re cooking for five, it might not be enough. My Meal Guru avoids this problem by scaling every recipe based on your household size.

Once you enter how many people you’re feeding, the app adjusts ingredient quantities for every meal in your plan. This makes grocery shopping more precise, cooking simpler, and leftovers predictable.

Cooking for one? You’ll only buy what you need. Cooking for a family? You’ll get portions that make sense without having to double recipes manually.

Visit us for more information :- personalized meal planning

A day in the life: from solo to shared meals -:

Take Jenna, for example. She lives alone and works from home. She wants variety in her meals but doesn’t want to waste food or spend hours cooking. With My Meal Guru, she plans for one and gets individual portions — no unnecessary bulk, no forgotten leftovers. And if she wants to batch cook for the week, the app can help with that too.

Now consider Sam and Emma, a couple with two kids. Their evenings are busy, and their meals need to be quick but satisfying. With My Meal Guru, they plan for four and receive family-friendly recipes that are easy to prepare and portioned just right. They even use the leftovers from larger meals for lunches the next day.

Built-in flexibility for your changing needs -:

What makes My Meal Guru stand out is its adaptability. If your situation changes — even just for the week — you can update your household size anytime in the app. Hosting guests? Cooking for just yourself while others are away? Simply change the number of people and get a meal plan that fits.

This flexibility is especially helpful for blended families, roommates, or anyone with an unpredictable schedule. No more planning around a static template. My Meal Guru adjusts on the fly.

Save time, save money, reduce waste -:

Right-sized meal plans aren’t just convenient — they’re practical. By preparing only what you need, you save money on groceries, avoid overbuying, and drastically reduce food waste. Smaller households benefit from avoiding expired produce and leftovers that never get eaten. Larger households save by not needing to constantly order out or make emergency grocery runs. Everyone wins.

Batch cooking, made smarter-:

If you’re the type who likes to cook once and eat twice, My Meal Guru can support that too. To plan for leftovers, all you need to do is increase the number of servings when setting your household size. The app will automatically adjust ingredient quantities, making it easy to cook extra portions for lunch the next day or dinner later in the week.

The result? Less time spent in the kitchen, and more meals covered with less effort.

Tailored meal planning, whatever your lifestyle-:

Whether you live alone or with others, your meals should reflect your lifestyle — not the other way around. My Meal Guru understands that, which is why it tailors everything from portion sizes to grocery lists based on your input.

You get meals that are right-sized, easy to prepare, and matched to your schedule and taste. With fewer decisions to make and more support in the kitchen, cooking becomes less of a chore and more of a daily win.

The takeaway?

No matter your household size, My Meal Guru has you covered.

Visit us for more information :- meal planning without the hassle

0 notes

Text

EViews Software: A Powerful Platform for Econometric Analysis and Forecasting

By Dr. Chinmoy Pal

In the fields of economics, finance, and social sciences, quantitative analysis plays a vital role in policymaking, investment decisions, and academic research. EViews (Econometric Views) is one of the most widely used statistical packages for time series analysis, econometrics, and forecasting. Combining the power of a modern spreadsheet with the flexibility of a statistical programming language, EViews stands as a preferred tool for data analysts, economists, and financial researchers.

🔍 What is EViews?

EViews is a statistical software package developed by IHS Markit (now part of S&P Global), designed primarily for econometric modeling, time series analysis, and forecasting. First introduced in 1994, EViews has continually evolved to meet the needs of professional and academic users working with macroeconomic, microeconomic, and financial data.

EViews blends a user-friendly graphical interface with a powerful scripting language, offering both beginners and advanced users a flexible environment for complex statistical computations.

🧠 Key Features of EViews

✅ 1. Time Series Analysis

Automatic handling of time series data (daily, monthly, quarterly, yearly).

Seasonality detection, smoothing, trend extraction.

Autocorrelation and partial autocorrelation analysis.

✅ 2. Econometric Modeling

Linear and nonlinear regression

ARIMA, VAR, VECM models

Error Correction Models (ECM)

Panel data analysis

GARCH and ARCH models for volatility

Structural Equation Models

✅ 3. Forecasting Tools

Scenario analysis

Dynamic simulation

Forecast evaluation statistics (MAE, RMSE, MAPE)

Graphical forecast evaluation

✅ 4. Data Management

Support for large datasets from multiple file formats (Excel, CSV, Stata, SPSS, SAS, SQL databases).

Built-in support for FRED, DBNomics, Moody’s, and World Bank databases.

✅ 5. Powerful Visualization

Time series plots, histograms, boxplots, correlograms

Forecast graphs and impulse response functions

High-quality charts exportable to Excel, Word, or PowerPoint

✅ 6. Programming Language

EViews has its own scripting language for:

Batch processing

Automating repetitive tasks

Running Monte Carlo simulations

📊 Popular Applications of EViews

🏛️ Economics & Macroeconomics

GDP forecasting, inflation modeling, unemployment trends

🧾 Finance & Banking

Volatility modeling, risk analysis, asset pricing models

🧠 Academic Research

Thesis and dissertation modeling for economics students

🌍 Public Policy & Development

Policy impact evaluation, time series forecasting for planning

💼 Corporate Analytics

Financial planning, demand forecasting, ROI projections

📥 How to Get Started with EViews

Download Trial or Buy: Visit https://www.eviews.com

Install: Available for Windows OS (Mac/Linux via emulation or remote desktop)

Import Data: Use Excel, CSV, Stata, SAS, SQL, or online databases

Analyze: Choose econometric models, estimate parameters, test significance

Forecast: Generate future values with confidence intervals and graphs

Export Results: Save outputs to Excel, Word, PDF, or LaTeX

💡 Example Workflow: Inflation Forecasting

Import CPI time series data

Test for stationarity (ADF test)

Estimate an ARIMA model

Check model diagnostics (ACF, PACF, residual plots)

Forecast future inflation rates

Export graph and forecast table

This entire process can be completed with just a few clicks or via a script for automation.

⚠️ Limitations of EViews

Windows-only: No native version for macOS or Linux.

Primarily focused on time series and econometrics (less ideal for generalized machine learning workflows).

Paid license: Academic versions are more affordable but still require purchase.

Limited support for modern deep learning tools compared to R or Python.

🔮 The Future of EViews

EViews continues to enhance support for panel data, Bayesian econometrics, and cloud-based collaboration. The integration with global economic data sources and focus on interactive forecasts ensures its relevance in modern policy research and financial analytics.

✅ Conclusion

EViews remains a gold standard for econometricians, economists, and forecasters. With its balance of ease of use and deep analytical power, it supports both introductory-level researchers and high-level modeling experts. For those working in macroeconomics, finance, or development planning, EViews is a must-have analytical tool.

Author: Dr. Chinmoy Pal Website: www.drchinmoypal.com Published: July 2025

0 notes

Text

Industrial Use Potato Flakes Manufacturer – Fanidhar India

From Farm to Flakes: Inside the Operations of a Top Dehydrated Potato Flakes Manufacturer – Fanidhar

Introduction In the fast-moving world of food manufacturing, few ingredients are as versatile and widely used as dehydrated potato flakes. From ready meals to snack mixes, these flakes serve as the silent foundation of many modern recipes. But behind every high-quality potato flake is a dependable manufacturer who understands not only the technical process, but also the importance of food safety, consistency, and scalability.

That’s where Fanidhar comes in—recognized as a leading dehydrated potato flakes manufacturer in India and trusted by global buyers. This blog gives you an inside look into our production process, capabilities, and why so many food brands choose to work with us.

What Makes Dehydrated Potato Flakes So Valuable? Dehydrated potato flakes are produced by steam-cooking and drying mashed potatoes into light, flat flakes that can be instantly rehydrated. They retain the natural taste, color, and nutrition of fresh potatoes—without the need for cold storage.

They’re essential in:

Instant mashed potatoes

Savory snacks and extrusions

Frozen food items (like aloo tikkis, nuggets, etc.)

Soup mixes and thickening agents

Baby food blends

Gluten-free bakery products

As a dehydrated potato flakes manufacturer, Fanidhar ensures that every batch is optimized for such applications, with maximum consistency and hygiene.

Step-by-Step: How Fanidhar Produces Dehydrated Potato Flakes Fanidhar follows a controlled, efficient, and traceable process:

Step 1: Sourcing from Contract Farms We grow potatoes in partnership with local farmers across India’s best potato-growing regions. Our agronomists monitor every stage—ensuring disease-free, high-starch, and uniform potatoes.

Step 2: Cleaning & Sorting Raw potatoes are cleaned using air jets and water sprays. Stones, clods, and damaged tubers are automatically removed.

Step 3: Steam Cooking The sorted potatoes are peeled and steam-cooked to ensure soft, evenly textured mash without nutrient loss.

Step 4: Mashing & Drum Drying The cooked potatoes are mashed and spread onto heated drums for drying. This results in thin flakes with consistent moisture content and a smooth, light texture.

Step 5: Sieving & Quality Testing The flakes are sieved, checked for contaminants, and tested for:

Microbial content

Moisture level

Texture and rehydration rate

Taste and appearance

Step 6: Packing & Storage Based on client needs, the flakes are packed in kraft paper bags, laminated sacks, or vacuum-sealed pouches. Each pack is batch-coded and stored under temperature-controlled conditions.

Certifications & Global Standards Fanidhar meets the highest standards required by global food importers:

FSSAI (India)

HACCP

ISO 22000

APEDA (for agricultural exports)

We provide full documentation including:

Certificate of Analysis (CoA)

Phytosanitary Certificate

Certificate of Origin

Lab test reports (upon request)

These credentials position us as a trusted dehydrated potato flakes manufacturer ready for both domestic and global markets.

Bulk Supply & Packaging Options Fanidhar specializes in scalable supply for industries and exporters:

Bulk Flakes: 25kg / 50kg kraft paper bags

Laminated Bags: For extended protection

Vacuum Packs: For sea-freight storage

Private Label Packs: For retail clients

Our MOQ is flexible, and we support orders ranging from 1 MT to 500+ MT with dependable lead times.

Export Capabilities: Why Global Brands Choose Us Fanidhar exports to over 20 countries across:

Middle East (UAE, Saudi Arabia, Qatar)

Africa (Kenya, Nigeria, Ghana)

Southeast Asia (Vietnam, Philippines, Indonesia)

Europe & North America

We provide complete export assistance:

Custom labeling and multi-language printing

International logistics and freight support

INCOTERMS flexibility (FOB, CIF, etc.)

Local compliance advisory

Who Can Benefit From Our Potato Flakes? Our product is ideal for:

Frozen food producers

Instant meal brands

Snack manufacturers

Baby food developers

Gluten-free product lines

Foodservice and institutional kitchens

Being a customer-first dehydrated potato flakes manufacturer, we can adjust moisture content, granule size, and packaging to suit specific needs.

Sustainability Built In Fanidhar is committed to responsible production:

Water-efficient drum drying

Minimal use of chemicals

Ethical labor practices

Crop waste recycling

Biodegradable packaging options

Our efforts make us a reliable, eco-conscious choice for clean-label brands.

Conclusion The food industry runs on trust, reliability, and consistency. As a leading dehydrated potato flakes manufacturer, Fanidhar brings together deep agricultural roots, world-class production, and seamless global delivery. Whether you’re a startup or an established food conglomerate, we’re here to support your journey with quality you can taste—and service you can depend on.

#Potato Flakes Processor In India#Dehydrated Potato Flakes Manufacturer#Potato Flakes Exporter India#Best Potato Flakes Supplier#Bulk Potato Flakes For Export

0 notes

Text

What Really Happens Inside an Automatic Interlocking Block Making Machine

If you’ve ever walked past a building site and seen workers stacking blocks that fit together almost like Lego, there’s a good chance those blocks were made by an Automatic Interlocking Block Making Machine.

These machines have changed the game for builders, contractors, and even small entrepreneurs looking to make strong, affordable blocks quickly and with less hassle. But what exactly goes on inside this machine? How does it turn piles of soil, sand, and cement into neat blocks that just click together? Let’s break it down in plain language.

What Makes Interlocking Blocks Special?

Before we get into the machine itself, it helps to understand what makes interlocking blocks so popular. Unlike traditional bricks or blocks that need lots of mortar to hold them together, interlocking blocks are shaped with ridges and grooves that let them slot into place.

This saves money on mortar, speeds up construction, and makes it easier to build straight, sturdy walls — even with a smaller team.

What Exactly Is an Automatic Interlocking Block Making Machine?

At its simplest, it’s a machine that mixes raw materials, shapes the blocks, and presses them under high pressure so they’re dense and durable. Because the process is mostly automated, you get uniform blocks every time, without needing dozens of workers to mix, mold, and stack by hand.

Here’s How It Works — Step by Step

1. Get the Right Mix

Everything starts with the raw materials. Most people use a mix of local soil, a bit of sand, and some cement. Some mixes include fly ash or lime. The exact blend depends on what you have and how strong you want the blocks to be.

Many automatic machines have a built-in batching system. This just means they measure out each ingredient in the right proportion so every batch is the same. Good consistency means strong blocks.

2. Feed the Hopper

Next, the mix goes into the machine’s hopper — basically a big bin that feeds the material down into the press. In fully automatic setups, this happens on its own. In semi-automatic machines, someone may shovel or load the material in.

3. Mix It Well

Inside the machine, everything gets blended so the cement spreads evenly through the soil and sand. Good mixing makes sure every block comes out solid — not crumbly or weak.

4. Mold and Press

Here’s the main part: the mixed material drops into a mold that shapes the block — not just the size, but the interlocking ridges too. Then, a hydraulic or mechanical press pushes down with a lot of force to compact the block tightly.

This compression is key. It’s what makes the block dense enough to last for years, even in harsh weather.

5. Eject the Block

Once the block is shaped and pressed, the machine pops it out. Fully automatic machines handle this smoothly, pushing the fresh block onto a tray or conveyor, ready to be stacked.

6. Curing

Fresh blocks can’t go straight into a wall — they need time to cure. This is where the blocks harden and gain their full strength. Most builders cure blocks for at least 7 days, often up to 21 days, spraying them with water daily to keep them from drying out too fast.

Why So Many Builders Use These Machines

People don’t just buy an Automatic Interlocking Block Making Machine because it looks impressive — it solves real problems on site.

1. Saves Time and Labor One machine can do the work of many hands, day in and day out. That means fewer workers mixing and molding blocks by hand.

2. Better Quality Blocks Handmade blocks can be uneven — a bit bigger here, smaller there — which makes walls wavy and wastes mortar. Machine-made blocks come out the same every time.

3. More Affordable Builds Because the blocks fit together so well, you use less mortar and finish walls faster. You can even dismantle walls later without wasting blocks.

4. Good for the Environment Interlocking blocks often use local soil and less cement, cutting down on costs and carbon footprint.

5. Flexible Production Need different sizes? Many machines let you swap molds so you can make blocks for walls, paving stones, or even special shapes.

Where Do People Use These Blocks?

Interlocking blocks are showing up everywhere:

Low-cost housing projects — They’re strong, quick to build with, and cut costs.

Boundary and retaining walls — Good for straight, sturdy fences.

Driveways and footpaths — With a different mold, you can make interlocking pavers too.

Storage tanks and silos — Some people even build circular tanks with them.

A Few Things to Keep in Mind

No machine is magic. A few practical things to remember:

It’s an investment. A good automatic machine isn’t cheap, but the savings on labor and materials add up quickly.

You need basic training. Someone on your team should know how to operate and maintain the machine.

Your raw materials matter. Soil quality makes a difference. Many people test their soil before starting production.

Final Thoughts

At the end of the day, an Automatic Interlocking Block Making Machine is just a smart tool. It does what it’s built to do: help you make strong, uniform blocks, faster and with less hassle. If you’re a builder trying to finish projects on time (and on budget) or someone looking to start a small block-making business, this machine can be a game-changer.

#automaticflyashbrickmakingmachine#automaticpaverblockmakingmachine#automaticsolidblockmakingmachine#automaticinterlockingblockmakingmachine#interlockingblockmakingmachine#hydraulicshearingmachinemanufacturers#arecaleafplatesmakingmachine#brickandblockmanufacturers#fullyautomaticflyashbrickmakingmachine#concretepanmixermachine

0 notes

Text

Using AI vs Professional Editors for Deep Etching

In today’s fast-paced digital world, image editing has become a fundamental part of eCommerce, photography, marketing, and publishing.

Among various image enhancement techniques, deep etching plays a crucial role in removing backgrounds, isolating products, and creating sharp, clean visuals.

With the rise of automation, many businesses wonder whether using AI tools can replace professional editors for deep etching.

In this article, we compare AI vs Professional Editors for deep etching, providing insight into their accuracy, consistency, and real-world impact.

In the midst of this growing conversation, many are turning to experienced providers like Deep etching service for reliable, high-quality, and affordable deep etching solutions.

What Is Deep Etching?

Deep etching is the process of removing the background of an image to highlight the subject — often used in product photography, catalogs, online stores, and advertisements.

Unlike basic background removal, deep etching focuses on clean, precise outlines, even in complex image areas such as hair, fur, or transparent objects.

The Rise of AI-Powered Image Editing

AI tools have revolutionized image editing. Applications like Adobe Photoshop’s AI features, Canva’s background remover, and online tools such as Remove.bg have gained popularity due to their speed and accessibility.

These tools use machine learning to detect the foreground and automatically erase the background.

But how do they compare to a professional editor’s human touch?

AI vs Professional Editors: A Deep Etching Comparison

Let’s dive deep into the differences and review both options across important parameters.

1. Accuracy

AI Tools: AI often struggles with complex edges like hair, semi-transparent materials, or busy backgrounds. While good for basic edits, it can leave behind halos or crop out details.

Professional Editors: Human editors pay close attention to details. They can use manual tools like the pen tool, layer masking, and advanced techniques to deliver pixel-perfect results — especially critical for high-end product images.

Verdict: Professionals win in accuracy, especially for detailed and high-value visuals.

2. Consistency and Quality Control

AI Tools: AI tools can produce inconsistent results when working with diverse image sets. Batch processing is fast but not always reliable.

Professional Editors: At Deep etching service, our skilled editors ensure consistency across every image batch. We maintain strict quality checks to ensure that every image meets brand standards.

Verdict: Professional editors provide more reliable and consistent output.

3. Turnaround Time

AI Tools: Instant processing is a major advantage. Great for tight deadlines or simple tasks.

Professional Editors: Human editing may take a few hours to a day depending on volume. However, top services like ours offer fast delivery without compromising quality.

Verdict: AI is faster for simple tasks; professionals are still efficient for high-quality results.

4. Cost Effectiveness

AI Tools: Most AI tools offer freemium models or subscriptions. They’re cheaper upfront but often require manual post-editing.

Professional Editors: Deep etching service provides affordable pricing with high accuracy and satisfaction. You get more value for the price, especially with our Free Trial and Get Quotation options available on our website.

Verdict: Professionals provide better value for money when quality matters.

5. Human Creativity and Customization

AI Tools: Limited by algorithms. Cannot make subjective decisions or apply custom preferences.

Professional Editors: We understand your brand, tone, and specific needs. Editors can adjust shadows, lighting, crop styles, and artistic elements based on your vision.

Verdict: Human editors offer creative flexibility and brand alignment.

Why Choose Deep Etching Service?

At Deep etching service, we blend expertise, technology, and personalized care to deliver stunning deep-etched images. Whether you’re a photographer, eCommerce store, agency, or brand, our services ensure that your images look sharp, clean, and professional. Our team guarantees:

Affordable pricing for all types of clients

Fast delivery without sacrificing quality

Free Trial so you can see our quality before committing

Get Quotation form to easily receive custom pricing

100% manual editing — no automated shortcuts

Frequently Asked Questions

1. Is AI deep etching good enough for product photography?

A: AI can handle basic images but often lacks precision for professional product photography. For polished results, professional deep etching is the better option.

2. How much does professional deep etching cost?

A: At Deep etching service, we offer highly competitive pricing. Costs depend on the complexity and quantity of images, but we’re known for our low amount price.

3. How long does it take to deep etch an image professionally?

A: We offer quick turnaround times — most single image edits are returned within 12–24 hours. Bulk orders may vary but remain efficient.

4. Do you offer a free trial for first-time users?

A: Yes! You can use our Free Trial to test our deep etching quality before making any commitment.

5. How do I get a quotation for my project?

A: Just visit our website and use the Get Quotation form. We’ll respond quickly with a customized offer based on your image needs.

Conclusion

While AI tools offer convenience, they still fall short in delivering the high precision and creative customization required for professional deep etching.

When image quality, brand presentation, and fine detail matter — human editors are still the gold standard.

Deep etching service stands out by combining expertise, affordability, and care in every edit.

With our low pricing, Free Trial option, and custom Quotation system, we make professional deep etching accessible for everyone.

0 notes

Text

What are the outstanding advantages of NPK fertilizer production lines?

In modern agriculture, NPK compound fertilizers are widely popular due to their balanced nutrient ratios and efficient application results. Professional NPK fertilizer production lines, with their unique technical strengths, are crucial equipment for fertilizer manufacturers to boost competitiveness.

1.Precise Blending

Modern NPK fertilizer lines use advanced automatic batching systems. This ensures accurate control over the ratios of nitrogen, phosphorus, potassium, and other nutrients, with errors kept within ±1%.

2.Process Flexibility

High-quality NPK fertilizer production lines can make various fertilizer formulas. This includes general-purpose types, specialty blends, slow-release formulas, and more. By adjusting the recipe and process settings, producers can create fertilizers tailored to specific crops and growth stages.

3.High Efficiency and Energy Saving

Modern NPK lines feature energy-saving designs. Techniques like heat recycling and waste heat recovery can cut energy use by up to 30%. High automation reduces manual work, significantly increasing output while lowering labor costs.

4.Environmental Compliance

Advanced NPK production lines come with comprehensive environmental protection systems. These include dust collection and exhaust gas treatment units, ensuring all emissions meet environmental standards.

5.Smart Control

These lines enable fully automated control and real-time monitoring of the entire production process. Key equipment has early-warning systems to prevent breakdowns, ensuring smooth and stable operation.

Choosing a high-quality NPK fertilizer production line helps improve product quality and efficiency. It also allows companies to respond quickly to market changes and gain an edge in a competitive market.

0 notes