#Automation Circuit Board

Explore tagged Tumblr posts

Text

Cosel 3L014-2 Power Supply Circuit Board | Industrial Automation Power Module | Ram Automations

Ensure reliable power delivery with the Cosel 3L014–2 Power Supply Circuit Board, engineered for performance and stability in high-demand industrial environments. Available now at Ram Automations, this Cosel board is the ideal choice for professionals needing a high-quality power supply solution for PLC panels, OEM cabinets, industrial control systems, and marine automation units.

Designed to deliver uninterrupted, clean, and regulated power, the Cosel 3L014–2 board is compatible with various automation architectures. Whether you’re restoring legacy systems, upgrading cabinet electronics, or expanding industrial racks, this board is a trusted solution to maintain operational consistency and power integrity.

🛒 Buy Now: https://ramautomations.com/products/cosel-3l014-2-power-supply-circuit-board

🌐 Explore More Automation Products: https://ramautomations.com

🔧 Product Specifications: • 📦 Model: 3L014–2 • 🏢 Brand: Cosel • ⚡ Type: Power Supply Circuit Board • 🛠️ Application: Industrial automation, PLC cabinets, marine systems, control panels • ⚙️ Function: Power regulation and electrical signal management

✅ Key Features: ✔️ Delivers consistent, clean power to sensitive components ✔️ High-efficiency conversion and voltage regulation ✔️ Compatible with multiple automation platforms ✔️ Easy integration in panel and rack systems ✔️ Manufactured by trusted brand Cosel

🏭 Perfect For: ✔ Factory Automation Systems ✔ OEM Control Panels ✔ Marine Control Consoles ✔ Industrial PLC Cabinets ✔ SCADA Systems ✔ I/O Expansion Modules

🛠️ Why Choose Ram Automations? At Ram Automations, we specialize in providing genuine and premium automation components across 1000+ trusted global brands. Our inventory supports automation engineers, electrical integrators, and industry professionals worldwide with fast delivery and friendly support.

✔ Genuine, Tested Industrial Components ✔ Support for Bulk Orders & OEMs ✔ Global Shipping with Prompt Service ✔ Tech-Friendly Customer Assistance

🎬 What You’ll See in This Video 🔍 Close-up of the Cosel 3L014–2 board 📦 Integration tips for automation systems ⚙️ Real-world use case examples 💡 Benefits of reliable power supply boards 🌐 Why Cosel power modules stand out

📣 Subscribe & Connect With Ram Automations 🔔 Subscribe for weekly updates on industrial automation components 💬 Drop your questions or suggestions in the comments 👍 Like the video if it helps

🎯 Ram Automations — Keeping Industry in Motion

#Cosel 3L014-2#Power Supply Board#Industrial Power Module#Automation Circuit Board#PLC Power#Cosel Automation#Ram Automations#Power Supply Cosel#OEM Power Board#Panel Power Module#Voltage Regulator Circuit#Marine Automation#PLC Cabinet Power#Electrical Board Cosel#Automation Spare Parts#Cosel Power Card#Industrial Control#Panel Integration#Automation Equipment#Electrical Components#Global Automation Parts#Genuine Automation Board#Control Panel Module

1 note

·

View note

Text

#a.b.e.l#divine machinery#archangel#automated#behavioral#ecosystem#learning#divine#machinery#ai#artificial intelligence#divinemachinery#angels#guardian angel#angel#robot#android#computer#computer boy#serverroom#server room#wires and cables#circuit board#motherboard#i miss you#i love you#message#sentient objects#sentient ai#memories

13 notes

·

View notes

Text

Flux AI is an advanced AI platform that automates and optimize the process of circuit design. LEAR MORE IN THIS ARTICLE.....

#fluxai#flexible circuit board#electronic#ai#gadgets#automation#artificial intelligence#hardware#techinnovation

2 notes

·

View notes

Text

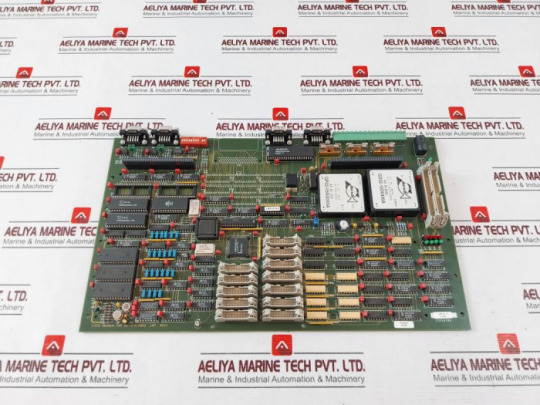

The Mitsui RDU-1B 1-0444 & RDU-2B Printed Circuit Board is a high-quality electronic board used in industrial and automation systems. Built for reliable performance, these PCBs ensure smooth control and signal processing in complex machinery. Designed with durable components, they offer excellent resistance to wear and electrical stress. Ideal for repairs and upgrades, they help maintain system efficiency and reduce downtime. Trusted across various industries, these boards are easy to install and support long-term operation. Get reliable automation with Mitsui PCBs from Auto2mation.

#industrial automation#industrial equipment#industrial spare parts#industrial#automation#industrial and marine automation#industrial parts supplier#industrial innovation#automation solutions#Marine Automation#marine equipment#marine spare parts#auto2mation#Mitsui#Printed Circuit Board

0 notes

Text

Experience reliability and efficiency with the Terasaki ESM-103 Starter Module K/87Z/4/001B, designed to meet the demands of industrial and marine applications. This high-performance starter module ensures seamless operation, delivering consistent and robust performance even in challenging environments. Built for durability, it combines advanced engineering with precision to support your system's needs. Upgrade your equipment with a trusted solution today!

#automation#industrial automation#marine automation equipment#marine automation#printed circuit board card#terasaki#module#starter

0 notes

Text

The Yokogawa YMX-M1 Circuit Board R7035BB-00 is a high-performance component designed for use in Yokogawa's industrial automation systems. It plays a critical role in data processing and control for a variety of industrial applications, including process control, safety systems, and real-time monitoring. Built to withstand harsh industrial environments, the YMX-M1 is reliable even under extreme conditions such as temperature fluctuations, electrical noise, and mechanical vibrations. The circuit board is fully compatible with Yokogawa's Centum distributed control systems (DCS) and ProSafe safety instrumented systems, allowing for seamless integration into complex industrial networks. Its modular design provides scalability and flexibility, while built-in diagnostic tools simplify maintenance and troubleshooting. This makes the YMX-M1 an essential component for maintaining efficient and reliable operation in industries like oil and gas, chemical processing, and power generation.

0 notes

Text

PCBs: The Shift from Wire Wrap and Point-to-Point Construction to Automated Manufacturing

Printed Circuit Boards (PCBs) have revolutionized the electronics industry by replacing earlier methods of circuit construction such as wire wrap and point-to-point wiring, both of which were once popular but have now become rarely used due to the growing demand for efficiency, precision, and automation.

Wire Wrap and Point-to-Point Construction: A Historical Overview

In the early days of electronic devices, wire wrap and point-to-point construction were the dominant methods for assembling circuits. Wire wrap involved wrapping a thin wire around a post at each connection point, while point-to-point wiring involved manually connecting components with individual wires. Both methods were labor-intensive and prone to errors, making them less suitable for complex circuits.

While these techniques worked for early applications, they struggled to keep pace with the rapid development of modern electronics, especially as devices grew smaller and more complex. The manual nature of both wire wrap and point-to-point methods meant that they were time-consuming, required skilled labor, and were prone to inconsistency.

The Evolution to PCBs

The advent of PCBs marked a significant departure from these earlier methods. A PCB is a flat board made of non-conductive material, typically fiberglass or composite epoxy, onto which conductive pathways are etched or printed. These pathways, known as traces, connect different electronic components, such as resistors, capacitors, and integrated circuits, without the need for manual wiring.

PCBs offer numerous advantages over wire wrap and point-to-point construction:

Compact Design: PCBs allow for compact and organized circuit layouts, making them ideal for modern electronics where space is a premium.

Reduced Complexity: By eliminating the need for individual wires, PCBs simplify the layout of complex circuits.

Enhanced Durability: The soldered connections on a PCB are more reliable and durable than hand-wrapped or manually connected wires.

Scalability: PCBs are easily scalable for mass production, unlike manual methods that require individual attention to each connection point.

Design Challenges and Automation in PCB Manufacturing

Although PCBs offer many advantages, their design requires careful planning. Unlike wire wrap and point-to-point methods, where connections can be made on-the-fly, PCBs must be carefully designed before they can be manufactured. The layout of a PCB involves placing components and designing the traces that connect them, a process that can be intricate and time-consuming.

To address these challenges, Electronic Design Automation (EDA) software plays a critical role in modern PCB design. EDA tools automate many of the tasks involved in laying out a circuit, including optimizing the placement of components and routing the traces to avoid errors such as short circuits or excessive electromagnetic interference (EMI). These tools not only speed up the design process but also ensure that the resulting board meets the necessary electrical and mechanical requirements.

Automation in PCB Manufacturing and Assembly

Once the design is finalized, PCB manufacturing and assembly can be fully automated. Automated systems can produce large volumes of PCBs with extreme precision, which is essential for industries like consumer electronics, aerospace, and telecommunications.

Manufacturing: Automated machines create PCBs by etching conductive traces onto the board, drilling holes for component leads, and applying solder masks. These processes are highly efficient and scalable for mass production.

Assembly: Surface-mount technology (SMT) and through-hole technology (THT) are commonly used in automated assembly processes. Robotic arms place components onto the board with precision, followed by soldering processes that create strong electrical connections.

Conclusion

While wire wrap and point-to-point construction were once popular techniques for assembling circuits, the advent of PCBs has made these methods largely obsolete. PCBs require additional design effort, but the rewards in terms of automation, reliability, and scalability make them the preferred choice for modern electronics. With the help of electronic design automation software and automated manufacturing processes, PCBs have become the foundation of the modern electronics industry, enabling the rapid production of complex devices with high precision and efficiency.

1 note

·

View note

Text

Quality You Can Trust: Elevate Your Projects with Our Electromechanical Parts!

Electromechanicals for Sale are premier supplier of electromechanical components and industrial automation spare parts. Explore our extensive catalog of electromechanical parts and components. As the premier supplier, we offer industrial automation spare parts and components for all your needs such as Servo Motors Active, Passive, & Sensor Parts, Power Supplies, Circuit Protection, Industrial Automation, Switches Automation, Control Gear, Electronic Connectors Relays and more. We supply electromechanical parts for leading manufacturers of Industrial automation.

Here at Electromechanicals for sale, quality is of the utmost importance. All parts found on our website trace back to leading automation spare parts suppliers and manufacturers that we trust, and countless listings undergo varying levels of testing, inspection, and document verification prior to shipment.

#Electromechanical Parts#Industrial Automation#Electronic components#Electronic industry#Industrial Lighting#Marine Electronics#Electronics Component Connectors#Electrical Switches & Relay#Circuit Board Accessories

1 note

·

View note

Text

Perks Of Automated Printed Circuit Board Assembly

Automated PCB assembly delivers a myriad of benefits to your manufacturing method, including heightened performance as well as precision. Picture a circumstance where complex components are wonderfully positioned as well as fastened in a fraction of the time it would certainly get personally. The effect on your profit is actually indisputable, yet there is actually even more to this account. Visit tuned to uncover just how computerized assembly can reinvent your development series as well as raise your product quality to remarkable levels.

Enhanced Speed

To obtain boosted rate in automated printed circuit board assembly, enhance the positioning and also soldering procedures. When partnering along with a trusted PCB assembly service provider, guarantee they have actually dependable machines and efficient operations to take full advantage of output. Appear for a firm that uses innovative technologies like pick-and-place makers and automated soldering equipment.

These tools may considerably minimize assembly opportunities and also enhance total development speed. Also, effective instruction for personnel functioning the machines is actually critical to maintaining a soft as well as fast assembly procedure.

Enriched Precision

For enriched reliability in automated PCB assembly, prioritize calibration of equipment and routine upkeep timetables. By making sure that your devices are correctly calibrated and also properly maintained, you may reduce mistakes and enhance the precision of your production procedures.

Working carefully with your printed circuit board assembly supplier to set up calibration procedures as well as maintenance schedules adapted to your particular tools may dramatically boost the accuracy of your assembly line. Routinely scheduled routine maintenance certainly not simply protects against unforeseen break downs but additionally assists preserve the precision of your makers with time.

Expense Productivity

Make sure that your automated China printed circuit board assembly methods are efficient as well as maximized to achieve optimal expense performance. By implementing hands free operation, you may dramatically decrease effort expenses affiliated along with hands-on assembly, as machines can operate quicker and extra regularly.

Additionally, automated assembly lessens product wastefulness by correctly putting parts, decreasing the total development expenses. The initial financial investment in computerized equipment may appear higher, however in the long operate, it causes cost financial savings with boosted performance and decreased mistake prices. Moreover, automated processes demand a lot less upkeep and oversight, further lowering functional expenditures.

Improved Quality Management

Automated printed circuit board assembly delivers precise as well as constant manufacturing, minimizing the probability of individual mistake and also guaranteeing a higher level of quality assurance. By taking advantage of computerized inspection systems, defects can easily be actually sensed and improved instantly, causing boosted product quality.

Automated assembly likewise allows for real-time surveillance of the manufacturing process, enabling quick adjustments to be actually helped make if any sort of problems develop. This proactive approach helps in sustaining premium requirements throughout the manufacturing method.

Furthermore, automated PCB assembly systems are outfitted along with advanced technologies that can identify potential quality problems at an early stage, preventing substandard products from reaching the lasts of development.

Higher Development Capability

Automated PCB assembly service can dramatically improve your development capability by simplifying manufacturing procedures and also boosting efficiency. By automating repetitive duties including part placement and also soldering, you can easily produce PCBs at a quicker price matched up to manual assembly. This enhanced velocity enables you to meet much higher need amounts as well as provide items to market faster.

Automated assembly systems may operate regularly without rests, leading to a notable improvement in result. With far fewer errors as well as steady quality, you may depend on the computerized procedure to keep a higher level of manufacturing without endangering on the quality of your PCBs.

Structured Process

Improve your creation performance along with a sleek operations in PCB assembly. By executing automated procedures, you may optimize the flow of your line, reducing bottlenecks as well as boosting total efficiency.

Automated PCB assembly systems may seamlessly combine various steps such as part positioning, soldering, and also assessment, permitting a more reliable and harmonized workflow. With automated devices handling repetitive tasks, your group may pay attention to additional structure as well as crucial components of the assembly procedure. This improved workflow guarantees that activities are finished in a prompt fashion, minimizing idle time and also maximizing outcome.

Reduced Inaccuracy Fees

By applying automated quality control processes, you may significantly decrease mistake rates in PCB assembly. Automated systems guarantee specific component placement, soldering, and assessment, minimizing the chances of human inaccuracy.

These systems utilize enhanced modern technologies like equipment vision to spot issues with high accuracy, ensuring that merely remarkable PCBs continue to the following manufacturing stages. Furthermore, automated assembly lowers the requirement for manual handling, which is a typical resource of mistakes.

Through simplifying the assembly procedure as well as getting rid of hand-operated assistances, automated PCB assembly considerably enriches the overall quality as well as integrity of the end product. Along with lessened error costs, you can easily anticipate better item performance, enhanced consumer fulfillment, and also expense savings down the road.

Final Thought

In conclusion, automated PCB assembly gives a stable of benefits, consisting of raised rate, improved reliability, and also cost effectiveness. With enhanced quality assurance procedures as well as streamlined workflows, suppliers can easily create top notch products at a much faster pace while lowering mistakes and component waste. Through committing in automated assembly processes, companies may boost their development capacity as well as satisfy high need levels while preserving high specifications of quality.

0 notes

Text

February 26 - March 1 2025 2010

A mother will do whatever is best for her children.

Now I dont like questioning the disembodied voices but...

The path through the mausoleum leads to a different part of the island where a dock can be found. Mom apparently rather than being forced away from Rose chose to leave of her own accord leaving only her martini glass behind.

WV is building a better Can Town, Exile Town, where '[a]ll expatriates are welcome, no matter what happened in the past, regardless of professional persuasion or metallurgical affiliation.' While this just at face value means the 'jobs' of each metal item, ie. can, mailbox, ammo, and type of metal, its really easy to think this is the future WV envisions for him and the others. Perhaps in this timeline, on this planet, he will do the same as Slick and make his own Town reality. AR is none too impressed, especially as this is WV's attempt at wooing PM, and yet, right outside of Exile Town hes got a militia started.

[A]ny town without a proper militia is as good as conquered.

As such he prepares one begrudgingly.

Sure~ Whatever you say AR. WV has his own moment of reflection admiring the sky 'oh my god a huge eggy looking thing just appeared in the sky.'

This is Daves fault. No really! we go back to Dave and Jade who have done most everything else to get the 'punch card eggy loking thign' which is immediately taken by the sprite crow to its 'nest made of shitty swords and soft puppet ass'. Obviously this makes Dave irate and he jokes about putting the egg in the microwave to hatch it which prompts Jade to dump his microwave off the skyscraper.

Not sure exploding the egg is what SBURB wants Dave.

We get to learn more about the differences in player entry and some new machines. Each time a player enters the amount of build grist is muliplied by 10. So John started with 20, Rose had 200 and Dave has 2,000. It seems like the later you enter the easier time you have building (and moving things, remember when 100 Grist was an insane amount to move the cruxtruder?). We can also see some new grist types have been unlocked from the get go though without enemies you cant really use them.

Then boy oh boy do I get to talk about computers again. Since Dave does not have any shale at his disposal hes kinda SOL on using the Punch Designix. This is terrible because we cant see what the JUMPER BLOCK EXTENSION and PUNCH CARD SHUNT actually do with the ALCHEMITER. However we can speculate.

So a Jumper is commonly used on Printed Circuit Boards (PCB) to create connections that modify circuit connections either for fixing electric connections or adapting a PCB for specific requirements. A Jumper Block is used to configure connections for different PCB options consisting of mulitple pins or sockets bridged by shunts to establish those connections. Shunts are used when you want to selectively make or break these connections easily, manually or automatically. Its noted that a card must be punched to affect the flow of current when insterted to the PUNCH CARD SHUNT. Given all this, it seems like this is an upgrade to alchemizing that can affect the core of the system and perhaps more easily automate the creation of new objects.

This is all well and good but that doesnt change the fact Dave does not have a way to punch said cards. So, all that done, Dave goes to install the mystery disk, which in any other circumstance I wouldnt do so casually. While doing so we get to see Rose fighting white Imps with more feline features on LOLAR and that Dave has 3 hours and 41 minutes to destruction.

The disk turns out to be gristTorrent, which is a version of BitTorrent, to leech some of Johns shale and build grist. Now Ive never used BitTorrent myself, though I have heard of it. It uses peer-to-peer (P2P) protocol to distribute data and files over the internet. Its mostly used for very large files and is faster than standard file downloads in this case. The 'seed', in this case John, hosts and sends the initial file while 'peers', in this case Dave, connect and download the file in parts and then in turn can become seeds for others. Dave initially has a decent download rate of 4 g/s (grist per second) that dips once he starts also leeching Build grist. This is because he is the only connection, as one of the downsides is time it takes to reach full download speed without enough peer connections to offset internet bandwith cost.

This concludes Sam's TEDtalk.

In all honesty, Ive tried to make as much of this as consumable as possible and I hope it helps anyone who is lost on the tech side of things. (im gonna need a tag of this too huh)

#homestuck#homestuck replay#hsrp liveblog#hsrp theories#TC's tech TEDtalks#<- there we go new tag. with bonus alliteration!#chrono

15 notes

·

View notes

Text

Understanding the Role of Busbars, Circuit Breakers, and Relays in Switchgear

In the world of electrical distribution and control systems, switchgear plays a pivotal role in managing, protecting, and isolating electrical circuits and equipment. Within a switchgear assembly, components like busbars, circuit breakers, and relays are essential for ensuring efficient operation and maximum safety. Understanding the role of each of these components can help professionals and businesses make better decisions when designing or upgrading their electrical systems.

What Is Switchgear?

Switchgear is a general term that encompasses a wide range of electrical disconnect switches, fuses, circuit breakers, and associated equipment used to control, protect, and isolate electrical equipment. These systems are critical for both high-voltage and low-voltage applications and are commonly found in industrial plants, commercial buildings, power plants, and substations.

1. Busbars: The Power Distribution Backbone

Busbars are metallic strips or bars — typically made of copper or aluminum — that conduct electricity within a switchgear or distribution board. Their main function is to distribute electrical power to multiple circuits from a single input source.

Key Functions:

· Efficient Power Distribution: Busbars act as a central hub for distributing power to various outgoing circuits.

· Compact Design: Helps in reducing the overall footprint of the switchgear.

· Heat Dissipation: Designed to handle high currents while minimizing heat build-up.

Applications:

· Power distribution panels

· Switchboards and MCCs (Motor Control Centers)

· Panelboards and switchgear cubicles

2. Circuit Breakers: Protection from Overcurrent

Circuit breakers are automatic electrical switches designed to protect electrical circuits from damage due to overcurrent or short circuits. Unlike fuses, circuit breakers can be reset manually or automatically after tripping.

Key Functions:

· Fault Interruption: Instantly disconnects the circuit during faults to prevent damage or fire.

· Manual Switching: Can be used to manually turn circuits on or off during maintenance.

· Safety Compliance: Ensures that systems meet international safety standards (IEC, ANSI, etc.)

Types of Circuit Breakers:

· MCB (Miniature Circuit Breaker): Used for low-power applications

· MCCB (Molded Case Circuit Breaker): Handles higher loads than MCBs

· ACB (Air Circuit Breaker): Used for high-current circuits in industrial settings

3. Relays: The Sensing and Control Brains

Relays are electromechanical or solid-state devices that detect faults and send signals to circuit breakers or other control devices to disconnect the circuit. They are the “brains” behind the automatic protection mechanism of the switchgear.

Key Functions:

· Fault Detection: Monitors voltage, current, and other parameters to detect anomalies.

· Triggering Action: Sends signals to trip the circuit breaker when necessary.

· Automation and Coordination: Works in coordination with other protection devices to ensure selective tripping.

Types of Relays:

Overcurrent Relays

Differential Relays

Distance Relays

Earth Fault Relays

Why These Components Matter

Together, busbars, circuit breakers, and relays form the core of any switchgear system. When properly selected and configured:

· Downtime is minimized

· Equipment lifespan is extended

· Operational safety is enhanced

· Energy efficiency is improved

In an era where electrical reliability is non-negotiable, understanding these components isn’t just for engineers — it’s essential knowledge for decision-makers in any industry reliant on power.

Conclusion

Whether you’re designing a new electrical panel or upgrading an old one, choosing high-quality busbars, circuit breakers, and relays is critical to the safety and efficiency of your entire system. At AL Taqwa Oman, we specialize in premium-grade switchgear accessories that meet global standards and deliver unmatched performance.

Need help finding the right accessories for your panel? Contact our experts today and power your systems with confidence.

#electrical#electrical equipment#electrical supplies#switchgear#oman#electricity#busbar#relay#circuit breaker

8 notes

·

View notes

Text

The Lips Drunen 23456789 Printed Circuit Board is a reliable and efficient electronic component used in various industrial and marine automation systems. Designed for durability and consistent performance, this high-quality PCB ensures smooth signal transmission and stable operation. Ideal for control systems and power distribution units, it helps reduce downtime and improve equipment performance. Its compact design allows easy installation and integration with existing systems. Trusted for its precision and long-lasting build, this circuit board is a valuable choice for automation professionals. Buy the Lips Drunen 23456789 PCB today from Auto2mation for dependable performance in demanding environments.

#industrial automation#industrial equipment#industrial spare parts#industrial#automation#industrial and marine automation#industrial parts supplier#industrial innovation#automation solutions#Marine Automation#marine equipment#marine spare parts#auto2mation#Lips Drunen#Printed Circuit Board

0 notes

Text

Giving Tuesday – KiCad open-source design #GivingTuesday 💻🔧🌍❤️🤝

KiCad is an open-source software suite for electronic design automation (EDA), enabling users to design schematics and printed circuit boards (PCBs). KiCad is a great, free, open tool for creating complex designs, from hobbyist projects to professional-grade hardware. As an open-source initiative, KiCad promotes accessibility and collaboration, making advanced EDA tools freely available. Supporting KiCad helps the development of features, bug fixes, and community-driven improvements, empowering engineers, educators, and hobbyists worldwide. Consider donating to KiCad to strengthen the open-source hardware community and help make high-quality EDA tools accessible to everyone.

In the past year, they posted this nifty chart that shows what your support can help accomplish.

If KiCad is valuable to you, please consider donating to help make it even better.

#kicad#kicadpcb#electronics#eda#schematic#pcbdesign#pcblayout#opensource#edatools#openhardware#donatetoday#engineeringdesign#communitysupport#openedsystems#opensourcecommunity#pcbtools#givingback#generositymatters#techforgood#makercommunity#electronicsdesign#designsoftware#kicaddonation#hardwaredesign#opensourceinitiative#techcommunity#sharekindness

11 notes

·

View notes

Text

Watch closely and you’ll see something fun.

Up until a few months ago there was a back door app that would connect to MyQ (the Liftmaster garage door app) and Alexa. It allowed Alexa voice-control routines to open/close a Liftmaster garage door.

That 3rd party app went bankrupt and Liftmaster, hoping to sell their own home automation hub, continue to refuse full integration with Alexa. The odds of liftmaster displacing Alexa or Apple Home are less than zero, but Liftmaster is resolute.

I really like the automation of Alexa routines though so I mounted the circuit boards of two openers next to two switchbots. If you look closely you will see a small lever extend from the switchbot and press the opener.

Now when we tell Alexa we are leaving she turns on the garage lights, opens the garage door and then 3 minutes later she turns off all the lights, locks the door and sets the alarm.

30 notes

·

View notes

Text

being me is explaining a lot of me

Yes, I want you to tickle me and I want you to keep doing it even if I say stop and I want you to start doing it not when I ask for it as I am right now because if you start tickling me right now it's not real in my mind so we have to stop talking about it for a while and then you need to surprise me and not stop when I try to fight you off and also you need to make fun of me for being ticklish even though it's going to make me blush and squirm and such

No, I actually want us to stay clothed. Like, fully clothed. There's a particular sensation of our two outfits touching that I really love and it's more electric to me than skin to skin contact. Also we also can't talk about this and I won't ask you to wear this outfit but please wear it a lot but don't ask me if I want you to wear it or say that you're wearing it for me because it's like a tickle for my eyes and it doesn't work very well when I know it's coming a mile away

I do actually sit like this, I'm not trying to be silly

I need to sit down and write because I just remembered a look someone gave me once when they were teasing me about something and I finally thought of a story for that look which is this like adventure story of stumbling into ruins but the ruins are actually from a distant future and I won't explain that because it's really about how the explorer sets off an automated system designed to receive massage table patients and they're launched onto a table as mechanical arms spring to life and strip off their clothing before depositing them into a table which activates safety restraints and a whole line of robots who have been bored for eternity finally get to practice their craft again but oh a piece of dust mote got into the circuit board and the sensitivity level was cranked all the way so they only employ the lightest touches which also means the robots can never meet the goal of relieving the tension at least not until an intrepid partner arrives to stop the melee of gentle touches from robot hands and metal scalp massagers and soft brushes ~ and that's where the looook comes in, because instead of setting the captive free, the partner sees how much fun it is to tickle and makes ample use of the facilities, all with that knowing sort of smirking look, at least until the time portal opens back up and they're all taken away for further research in the future in a timeline where ticklishness is an entirely dead sensation and so much joy can be learned from these two specimens. What were we talking about?

9 notes

·

View notes

Text

I think ultimately ancient tech is powered by crystals because it looks pretty and unusual and therefore More Advanced but I'm wondering what the manufacturing of these looks like. Circuit boards are made of tiny pathways of gold and copper, right, and assembled cheaply in the global south and then sold in the north in the same way clothes are. Is there an Asgard underclass somewhere growing crystals in caves and then cutting them with water pressure or lasers? One would hope the Asgard are a post-scarcity society who have automated making those crystals but I can't off the top of my head remember if Asgard society was ever discussed to be more socially advanced than humans in addition to technologically.

#stargate sg1#don't take this too seriously i'm just chit chatting#i almost said 'yabbering' and then had to pause and consider whether that's a word or not. anyway.

5 notes

·

View notes