#AutomationRevolution

Explore tagged Tumblr posts

Text

"AI Is Secretly Running Modern Offices 😳🤖 – Here’s What You’re Not Being Told!"

💼 AI isn’t the future – it’s happening NOW, silently controlling today’s offices! From smart decision-making 🤖 to automated tasks ⚙️, businesses worldwide are being reprogrammed by artificial intelligence… and most people have NO idea! 😨

🧠 What does this mean for your job? For your future? 💥 The answers will shock you – and the opportunities might just surprise you! 🚀

👉 See The Hidden Truth Here ⚠️ Don't get left behind! Tap NOW to learn how AI is reshaping careers and companies. 🔍 Click before your role disappears… 😱

#AIInOffices#FutureOfWork#ArtificialIntelligence#SmartBusiness#AIControl#AutomationRevolution#NextGenTech#OfficeTechnology#AITransformation#MachineLearning#WorkplaceRevolution#DigitalFuture#TechInsider#ShockingTruth#ClickNow

2 notes

·

View notes

Text

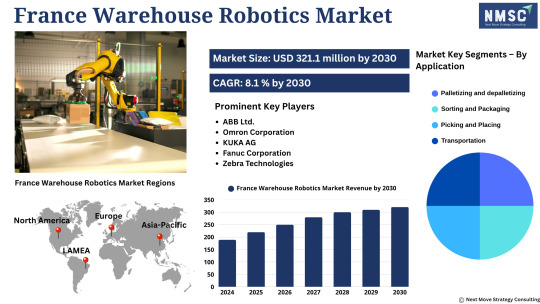

𝗗𝗼 𝗬𝗼𝘂 𝗞𝗻𝗼𝘄 𝗪𝗵𝗲𝗿𝗲 𝗙𝗿𝗮𝗻𝗰𝗲 𝗜𝘀 𝗤𝘂𝗶𝗲𝘁𝗹𝘆 𝗕𝘂𝗶𝗹𝗱𝗶𝗻𝗴 𝘁𝗵𝗲 𝗙𝘂𝘁𝘂𝗿𝗲 𝗼𝗳 𝗟𝗼𝗴𝗶𝘀𝘁𝗶𝗰𝘀?

𝗙𝗿𝗮𝗻𝗰𝗲 𝗪𝗮𝗿𝗲𝗵𝗼𝘂𝘀𝗲 𝗥𝗼𝗯𝗼𝘁𝗶𝗰𝘀 𝗠𝗮𝗿𝗸𝗲𝘁 is gearing up to become one of Europe’s most lucrative automation frontiers – and savvy investors are already placing their bets.

𝗗𝗼𝘄𝗻𝗹𝗼𝗮𝗱 𝗙𝗥𝗘𝗘 𝗦𝗮𝗺𝗽𝗹𝗲

𝗠𝗮𝗿𝗸𝗲𝘁 𝗜𝗻𝘀𝗶𝗴𝗵𝘁 𝗬𝗼𝘂 𝗖𝗮𝗻'𝘁 𝗜𝗴𝗻𝗼𝗿𝗲: 𝗧𝗵𝗲 𝗺𝗮𝗿𝗸𝗲𝘁 𝗶𝘀 𝗼𝗻 𝗮 𝗳𝗮𝘀𝘁 𝘁𝗿𝗮𝗰𝗸 𝘁𝗼 𝗺𝘂𝗹𝘁𝗶-𝗯𝗶𝗹𝗹𝗶𝗼𝗻-𝗱𝗼𝗹𝗹𝗮𝗿 𝗴𝗿𝗼𝘄𝘁𝗵, 𝗱𝗿𝗶𝘃𝗲𝗻 𝗯𝘆: 1. A booming e-commerce landscape 2. Rising labor costs fueling automation 3. Government-backed smart manufacturing policies 4. Accelerated adoption of AI & machine vision in warehousing

From automated picking systems to AI-driven warehouse fleets, France is not just keeping up — it’s leading the charge in the EU warehouse robotics race.

Do You Know that some of the 𝘄𝗼𝗿𝗹𝗱'𝘀 𝗹𝗮𝗿𝗴𝗲𝘀𝘁 𝗿𝗲𝘁𝗮𝗶𝗹 𝗮𝗻𝗱 𝗹𝗼𝗴𝗶𝘀𝘁𝗶𝗰𝘀 𝗽𝗹𝗮𝘆𝗲𝗿𝘀 𝗮𝗿𝗲 𝗮𝗹𝗿𝗲𝗮𝗱𝘆 𝗽𝗮𝗿𝘁𝗻𝗲𝗿𝗶𝗻𝗴 𝘄𝗶𝘁𝗵 𝗙𝗿𝗲𝗻𝗰𝗵 𝗿𝗼𝗯𝗼𝘁𝗶𝗰𝘀 𝗶𝗻𝗻𝗼𝘃𝗮𝘁𝗼𝗿𝘀 𝘁𝗼 𝗯𝗼𝗼𝘀𝘁 𝘀𝘂𝗽𝗽𝗹𝘆 𝗰𝗵𝗮𝗶𝗻 𝘀𝗽𝗲𝗲𝗱 𝗮𝗻𝗱 𝗿𝗲𝘀𝗶��𝗶𝗲𝗻𝗰𝗲?

𝗞𝗲𝘆 𝗣𝗹𝗮𝘆𝗲𝗿𝘀: ABB Ltd., Omron Corporation, KUKA AG, Fanuc Corporation, JBT Corporation, Teradyne Inc., Zebra Technologies, Dematic, Honeywell International Inc, Vanderlande Industries B.V., KNAPP AG, YASKAWA ELECTRIC CORPORATION, Amazon Robotics LLC, Toshiba Corporation, SSI Schaefer and others.

𝗪𝗵𝘆 𝗦𝗵𝗼𝘂𝗹𝗱 𝗜𝗻𝘃𝗲𝘀𝘁𝗼𝗿𝘀 𝗖𝗮𝗿𝗲? 𝗕𝗲𝗰𝗮𝘂𝘀𝗲 𝗲𝗮𝗿𝗹𝘆 𝗺𝗼𝘃𝗲𝗿𝘀 𝗶𝗻 𝘁𝗵𝗶𝘀 𝘀𝗽𝗮𝗰𝗲 𝘀𝘁𝗮𝗻𝗱 𝘁𝗼 𝗴𝗮𝗶𝗻: 1. Long-term returns in one of Europe’s fastest-scaling tech-industrial markets 2. Access to a sector shielded from recessionary shocks 3. Exposure to a crucial backbone of global e-commerce

𝗙𝗿𝗮𝗻𝗰𝗲 𝗶𝘀𝗻'𝘁 𝗷𝘂𝘀𝘁 𝗮 𝗿𝗼𝗯𝗼𝘁𝗶𝗰𝘀 𝗮𝗱𝗼𝗽𝘁𝗲𝗿 — 𝗶𝘁'𝘀 𝗯𝗲𝗰𝗼𝗺𝗶𝗻𝗴 𝗮𝗻 𝗮𝘂𝘁𝗼𝗺𝗮𝘁𝗶𝗼𝗻 𝗽𝗼𝘄𝗲𝗿𝗵𝗼𝘂𝘀𝗲. Now is the time to position yourself before this market hits its inflection point.

𝗔𝗰𝗰𝗲𝘀𝘀 𝗙𝘂𝗹𝗹 𝗥𝗲𝗽𝗼𝗿𝘁

Ready to explore how this shift could boost your portfolio? Let’s talk opportunities. DM us or connect below.

#France#WarehouseRobotics#SmartLogistics#InvestInInnovation#AutomationRevolution#VentureCapital#PrivateEquity#RoboticsInvesting#NextBigThing#IndustrialTech

0 notes

Text

#manufacturing units#AGV#SmartLogistics#WarehouseAutomation#IndustrialRobotics#EcommerceGrowth#Intralogistics#ManufacturingTech#FactViewResearch#AutoEVTimes#SupplyChainInnovation#Industry40#AutomationRevolution#FutureOfWork#RoboticsTech#electricvehiclesnews#evtimes#evbusines

0 notes

Text

Fresh Perspectives on Building Wealth in the AI Age

Let’s cut through the noise: you’ve heard the mantras—grind harder, hustle nonstop, sleep less, work more. Yet despite all that effort, your bank account isn’t exactly bursting at the seams. Welcome to the era of artificial intelligence, where the game has changed and it’s not just about putting in more hours. It’s about playing smarter.

Why the Old Playbook Doesn’t Work Anymore In traditional hustle culture, success meant showing up early, staying late, and outworking everyone. That made sense in an economy powered by manual labor and simple digital tools. Today, AI is doing tasks that once took humans weeks in a matter of seconds. If you’re still relying on brute-force effort, you’re racing against an opponent who never sleeps and learns from every mistake instantly. The result is diminishing returns on your sweat equity.

Reframe Your Mindset around Leverage Leverage used to mean borrowing money to amplify returns. In the AI era, leverage means harnessing technology—AI agents, automation scripts, data analytics—to multiply your impact. Imagine having a personal assistant that drafts your emails, a researcher that summarizes market trends, or an ad optimizer that tweaks your campaigns in real time. Instead of spending hours on repetitive tasks, you focus on big-picture strategy—ideation, relationship building, creative problem solving.

Identify High-Value Activities Time is your most precious resource. In the AI landscape, some activities are uniquely human and impossible for machines to replicate—empathy-driven customer service, authentic networking, nuanced negotiation, and visionary leadership. These high-value activities deserve front-row attention. Ask yourself: which parts of my work generate the most impact? Delegate the rest to AI tools.

Build Your AI Toolkit Getting comfortable with AI doesn’t require a computer science degree. Start small:

AI Writing Aids: Tools that help you draft blog posts, social media captions, or ad copy. They can save you hours of writer’s block.

Data Analytics Platforms: Dashboards that visualize customer behavior and sales trends, helping you make data-driven decisions without wrestling with spreadsheets.

Automation Workflows: Simple scripts or no-code platforms that automate routine tasks like scheduling posts, sending invoices, or following up with leads.

Experiment with free or low-cost versions before committing to enterprise plans. The goal is to get familiar with capabilities and limitations so you can integrate AI seamlessly into your workflow.

Cultivate an AI-First Skill Set The next decade will reward those who understand how to work alongside AI. Develop these skills: · Prompt Engineering: Learning how to ask AI the right questions. A slight tweak in wording can mean the difference between mediocre outputs and game-changing insights. · Model Selection: Understanding which type of AI (text, image, voice, or data analytics) suits your objectives. · Critical Evaluation: AI can hallucinate or misinterpret. Hone your ability to spot errors, bias, or irrelevant suggestions. · Continuous Learning: Technologies evolve fast. Set aside time each week to explore new tools, read industry newsletters, or attend webinars.

Spot the Right Opportunities, Not Just Any Opportunity You might have a dozen side hustles—dropshipping, online courses, affiliate marketing—floating in your orbit. Instead of spreading yourself thin, pick one or two ideas where AI can genuinely amplify your edge. For example, if you’re passionate about health coaching, use AI to analyze client progress data, generate personalized meal plans, or create interactive chatbots for 24/7 support. That focused approach often yields better returns than a scattershot hustle.

Network with AI Enthusiasts and Early Adopters In every booming industry, the insiders know each other. Join online forums, LinkedIn groups, or local meetups centered around AI entrepreneurship. Swap stories about what’s working, commiserate over what’s failed, and exchange tool recommendations. You’ll stay on the cutting edge and avoid costly missteps by learning from others’ experiences.

Focus on Value, Not Vanity Metrics When you log into your analytics dashboard, it’s easy to get distracted by likes, views, or follower counts. Those vanity metrics can feel good but don’t automatically translate to revenue. Instead, track conversion rates, customer acquisition cost, lifetime customer value, and profit margins. AI-powered analytics can help you connect the dots between your content, marketing spend, and actual dollars in the bank.

Balance Speed with Sustainability AI can supercharge your pace—content can be produced at lightning speed, ads optimized in real time, customer queries answered in milliseconds. But unchecked growth can lead to burnout or subpar quality. Set guardrails. Establish a human-in-the-loop review for critical outputs, maintain brand voice consistency, and ensure compliance with privacy or industry regulations. Sustainable growth beats a fleeting spike any day.

Embrace Failure as a Learning Catalyst AI experiments will sometimes flop—maybe an automated email series underperforms or a chatbot miscommunicates. That’s okay. Rapid iteration is the name of the game. Use AI analytics to pinpoint where things went wrong, adjust your approach, and try again. The speed of AI means you can learn and pivot faster than ever before.

Case in Point: Real People Winning with AI Consider a freelance graphic designer who used AI image generators to prototype concepts in minutes, freeing up time to refine and customize them. By offering faster turnaround, she attracted more clients and increased her rates. Or a boutique online retailer who implemented AI-driven product recommendations on their website. Within weeks, average order value climbed by double digits. These success stories share a common thread: they didn’t rely on working harder, but on integrating AI thoughtfully into their core value proposition.

The Myth of Overnight Success You’ll still see headlines about someone “making six figures in a month with AI.” But remember that behind the headline is usually months or years of groundwork—building an audience, testing products, refining messaging, and yes, learning the quirks of AI tools. Focus on steady progress and real milestones: your first sale, first repeat customer, or first time you reclaim five hours a week from automation.

Your Roadmap to Wealth in the AI Era

Audit Your Workflow: List every recurring task you do. Which ones AI could handle?

Choose One AI Tool: Master it before layering in another.

Redesign Your Day: Block out time for creative, strategic work and block off automation review sessions.

Measure What Matters: Define key performance indicators linked to revenue.

Iterate Rapidly: Tweak prompts, test new features, experiment with different models.

Scale Responsibly: When something works, systematize it and then explore adjacent opportunities.

It’s Not About Hustle, It’s About Leverage If you’re wondering why you’re not rich yet in this AI era, the answer isn’t more hustle—it’s smarter leverage. Hustle culture tells you to endure the grind. AI culture tells you to multiply your effort, focus on your unique human strengths, and learn constantly. Embrace that shift and you’ll not only survive but thrive. The wealth you’re aiming for won’t arrive overnight, but by playing the long game—strategically integrating AI, honing in on high-value activities, and iterating quickly—you’ll be light-years ahead of anyone still believing that hustle alone is the secret sauce.

Ready to stop grinding and start leveraging? The AI era is here—let’s make it work for you.

0 notes

Text

Flap Closure to Palletizing

Seamless. Smart. Automated. From flap closure to palletizing—watch how automation levels up your end-of-line operations! Speed, precision, and zero human error—Welcome to the Future of Packaging.

#BoxPalletizer#EndOfLineAutomation#SmartFactory#PackagingInnovation#Industry40#ZeroTouchAutomation#ManufacturingEfficiency#AutomationRevolution#Koldpack#iRobolution#GameChangerAutomation#SmartManufacturing#FMCG#Agrochemical#PaintIndustry#LogisticsOptimization#SeamlessIntegration

0 notes

Text

Day 2 Starts Now – Join Us at TCN Booth 2739! 📅 May 7–9 | Booth 2739 | Las Vegas Convention Center Here’s a quick look back at Day 1 at Booth 2739 — thanks to everyone who stopped by! From hot pizza vending to weight sensing technology and beyond, we’re proud to showcase our latest innovations in automated retail. Day 2 is underway — come see it all in person. We’re here and ready to connect.

#NAMAShow2025#ExhibitAtNAMA#LasVegasConventionCenter#Booth2739#TCNAtNAMA#NAMA2025#TradeShowSuccess#VendingMachines#SmartVending#AutomatedRetail#SmartTechnology#VendingInnovation#RetailTech#VendingSolutions#AutomationRevolution#IntelligentRetail#PizzaVending#PickupLockers#SnackVending#DrinkVending#HotFoodVending#SelfServiceSolutions#SmartLockers#TechInnovation#SmartMachines#Automation#RetailInnovation#FutureTech

0 notes

Text

youtube

Watch how the AI-Unmanned Weighbridge System is transforming logistics with smart automation no operator needed, just seamless, real-time vehicle weighing in action!

0 notes

Text

The AI Revolution That Will Change Everything by 2025! | Tech Ai Vision

youtube

Artificial Intelligence is evolving faster than ever, and by 2025, it will completely change the way we live and work. In this video, we explore the latest AI breakthroughs, how they are shaping the future, and what you can expect in the coming years.

#FutureTech#Innovations2025#AugmentedReality#SmartHomeDevices#AppleVisionPro#MetaQuest4#FoldableTablets#ai2025#artificialintelligence#futuretechnology#aitrends#technews#machinelearning#automationrevolution#aiinnovation#roboticsfuture#techupdates#latestai#futuretech#artificialintelligencetrends#aitransformation#Youtube

0 notes

Text

How a Course in Digital Manufacturing Prepares You for Industry 4.0?

The manufacturing world’s getting a huge makeover thanks to Industry 4.0 transforming old production techniques. By mixing in automation, data analytics, artificial intelligence, and the Internet of Things (IoT), companies are switching to smarter manufacturing processes. For professionals and students wanting to keep up in this fast-changing industry, switching to a digital manufacturing program could be a smart move.

This article explores how such a course equips you with the necessary skills to thrive in the age of Industry 4.0.

Understanding Industry 4.0 and Its Impact on Manufacturing

Industry 4.0 represents a shift toward digitized and interconnected production systems. Traditional manufacturing relied on mechanical and manual operations, but today’s factories are leveraging real-time data, cloud computing, and advanced robotics.

Companies that adopt these technologies enhance productivity, reduce waste, and improve product quality. A well-structured program in digital manufacturing covers these critical aspects, ensuring that learners understand how Industry 4.0 technologies integrate into modern production lines.

With manufacturing becoming more reliant on intelligent systems, professionals need specialized knowledge to navigate this transition effectively.

Core Skills You Gain from a Digital Manufacturing Course

A comprehensive course in digital manufacturing prepares you with both technical and strategic skills. Some of the key competencies you develop include:

1. Automation and Robotics

Learn how to integrate automated systems into production lines.

Understand robotic programming and human-robot collaboration.

Gain insights into industrial automation tools and processes.

2. Data Analytics in Manufacturing

Discover how data is collected, processed, and used to improve efficiency.

Learn predictive maintenance techniques using real-time analytics.

Explore machine learning applications in manufacturing optimization.

3. Additive Manufacturing and 3D Printing

Study the role of 3D printing in modern production.

Learn about materials and techniques used in additive manufacturing.

Understand the cost and efficiency benefits of digital fabrication.

4. Cyber-Physical Systems and IoT

Gain expertise in integrating IoT devices within industrial environments.

Understand how smart sensors enhance production efficiency.

Learn about cloud computing and digital twins in manufacturing.

5. Supply Chain Digitization

Explore how digital tools optimize supply chain management.

Learn about real-time tracking and inventory control systems.

Understand the role of blockchain in secure and transparent transactions.

Practical Applications: Bridging Theory and Industry Needs

A program in digital manufacturing does not only focus on theory. Many courses incorporate hands-on training through industry collaborations, lab work, and real-world case studies. This practical approach helps bridge the gap between classroom learning and workplace expectations.

For example:

Students work on digital twin simulations to test production efficiencies before implementation.

Hands-on robotics training allows learners to develop automation workflows.

Case studies on successful smart factories provide valuable industry insights.

By engaging with real-world applications, students develop problem-solving skills and gain direct experience with cutting-edge technologies.

Career Opportunities in Digital Manufacturing

With Industry 4.0 driving significant changes in production methods, companies are actively seeking professionals with expertise in digital manufacturing. Graduates from such programs find roles in various sectors, including automotive, aerospace, electronics, and consumer goods.

Some career paths include:

Manufacturing Engineer – Designs and optimizes production processes using digital tools.

Automation Specialist – Implements robotics and automated systems in factories.

Industrial Data Analyst – Uses data-driven insights to enhance efficiency and reduce costs.

IoT Specialist – Develops and manages smart factory solutions.

Supply Chain Manager – Leverages digital tools to streamline logistics and inventory management.

The demand for professionals with digital manufacturing expertise continues to grow, making it a promising career choice for those looking to work at the forefront of technological advancements.

Choosing the Right Digital Manufacturing Course

Not all programs in digital manufacturing offer the same depth and specialization. When selecting a course, consider the following factors:

Curriculum – Ensure the course covers key Industry 4.0 topics, including automation, AI, and IoT.

Faculty and Industry Ties – Look for programs that offer instruction from experienced professionals and partnerships with leading manufacturers.

Hands-on Learning – Opt for courses that provide laboratory sessions, internships, or industry projects.

Global Recognition – Choose an institute with a strong reputation in the manufacturing industry.

Final Thoughts

A program in digital manufacturing is more than just a course—it is a gateway to future-proofing your career in an industry undergoing rapid technological advancements. With Industry 4.0 shaping the future of production, acquiring expertise in automation, data analytics, and smart manufacturing will place you at the forefront of industrial innovation.

0 notes

Text

yo kreo k si tmbn m ha costado dormir desde k sé k enserio hai gente k compra echo dots para desirles:

"alexa, reproduce música"

0 notes

Text

#AutonomousConstruction#SmartConstruction#AIinConstruction#ConstructionAutomation#SelfDrivingEquipment#RoboticsInConstruction#FutureOfConstruction#ConstructionTech#HeavyEquipmentAutomation#AutonomousMachinery#ConstructionInnovation#AIHeavyMachinery#SmartInfrastructure#DigitalConstruction#AutomationRevolution

0 notes

Text

How to Tackle AI Integration Challenges in Accounting: Best Practices and Solutions

AI has stepped into accounting! But, implementing it isn’t all smooth sailing. Many businesses face challenges like:

🔍 Data Quality Issues: Inaccurate or incomplete data can throw AI systems off track.

🔗 Integration Hiccups: Connecting AI to legacy systems takes serious effort.

👩💻 Employee Adaptability: Team members may resist AI or struggle to adapt to new tech.

🔒 Security Concerns: With data at the core, keeping it safe is a top priority.

💡 So, how do we overcome these hurdles?

1️⃣ Prioritize Clean Data: Ensure accurate, complete data for smooth AI functioning.

2️⃣ Gradual Implementation: Test AI on smaller processes before full-scale adoption.

3️⃣ Upskill Teams: Equip your employees with the knowledge to embrace AI confidently.

4️⃣ Secure Systems: Protect sensitive financial data with robust cybersecurity measures.

AI might bring challenges, but the rewards—like automation, efficiency, and real-time insights—are worth the effort. 🌟

👉 Read the full blog to learn how to tackle these challenges and experience the true potential of AI in accounting: AI Integration Challenges.

Start your AI journey with the right steps and transform your accounting processes! ✨

0 notes

Text

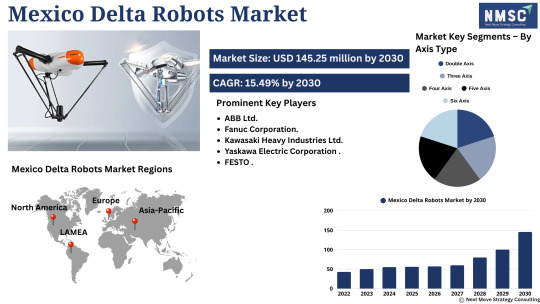

𝗟𝗼𝗼𝗸𝗶𝗻𝗴 𝗳𝗼𝗿 𝘆𝗼𝘂𝗿 𝗻𝗲𝘅𝘁 𝗵𝗶𝗴𝗵-𝗴𝗿𝗼𝘄𝘁𝗵 𝗶𝗻𝘃𝗲𝘀𝘁𝗺𝗲𝗻𝘁 𝗶𝗻 𝗶𝗻𝗱𝘂𝘀𝘁𝗿𝗶𝗮𝗹 𝗮𝘂𝘁𝗼𝗺𝗮𝘁𝗶𝗼𝗻? 𝗠𝗲𝘅𝗶𝗰𝗼 𝗗𝗲𝗹𝘁𝗮 𝗥𝗼𝗯𝗼𝘁𝘀 𝗠𝗮𝗿𝗸𝗲𝘁 is quietly gearing up for a major leap! 𝗗𝗼𝘄𝗻𝗹𝗼𝗮𝗱 𝗙𝗥𝗘𝗘 𝗦𝗮𝗺𝗽𝗹𝗲

With automation becoming non-negotiable in industries like electronics, pharmaceuticals, food & beverage, packaging, and automotive, Mexico is rapidly transforming into a hotbed for Delta Robot adoption — thanks to its growing manufacturing sector and increasing foreign investments. 𝗞𝗲𝘆 𝗣𝗹𝗮𝘆𝗲𝗿𝘀 : ABB Ltd., Fanuc Corporation, Kawasaki Heavy Industries Ltd., Yaskawa Electric Corporation, FESTO, Weiss GmbH, Omron Corporation and others.

𝗪𝗵𝘆 𝗶𝗻𝘃𝗲𝘀𝘁𝗼𝗿𝘀 𝗮𝗿𝗲 𝗲𝘆𝗲𝗶𝗻𝗴 𝘁𝗵𝗶𝘀 𝗺𝗮𝗿𝗸𝗲𝘁:

Surging CAGR backed by automation demand across sectors

Strategic proximity to the U.S. and booming nearshoring trend

Cost-effective skilled labor + pro-robotics government incentives

Strong influx of capital from global robotics giants and venture funds

The combination of speed, precision, and efficiency offered by Delta Robots is becoming a game-changer for Mexico’s factories aiming to dominate global supply chains. 𝗔𝗰𝗰𝗲𝘀𝘀 𝗙𝘂𝗹𝗹 𝗥𝗲𝗽𝗼𝗿𝘁

𝗦𝗺𝗮𝗿𝘁 𝗰𝗮𝗽𝗶𝘁𝗮𝗹 𝗶𝘀 𝗮𝗹𝗿𝗲𝗮𝗱𝘆 𝗺𝗼𝘃𝗶𝗻𝗴. 𝗔𝗿𝗲 𝘆𝗼𝘂 𝗽𝗼𝘀𝗶𝘁𝗶𝗼𝗻𝗲𝗱 𝘁𝗼 𝗿𝗶𝗱𝗲 𝘁𝗵𝗲 𝗻𝗲𝘅𝘁 𝗮𝘂𝘁𝗼𝗺𝗮𝘁𝗶𝗼𝗻 𝘄𝗮𝘃𝗲 𝗶𝗻 𝗠𝗲𝘅𝗶𝗰𝗼?

#AutomationRevolution#DeltaRobots#MexicoManufacturing#InvestorAlert#HighGrowthMarket#RoboticsInvestment#EmergingMarkets#CAGR#VentureCapital#IndustrialAutomation#NextBigThing#RoboticsGoldRush

0 notes

Text

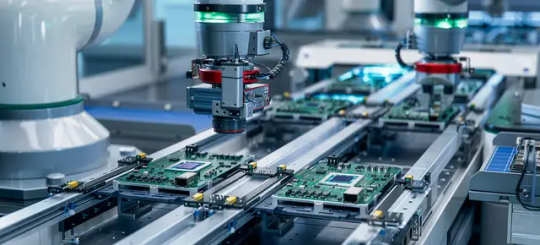

The Benefits of Automation

Automation is taking over electronics manufacturing — and for good reason. From pinpoint precision to major cost savings and faster production, automated machinery is changing the way things get made. Companies looking to stay competitive are leaning into this evolution, and it’s paying off with higher-quality products and lower operational costs. Progress never looked so efficient.

0 notes

Text

Transforming the Food & Beverage Industry Through Automation

Behind the Automation Revolution in the Food and Beverage Industry: Accord has been at the forefront of the shifting environment in food and beverage manufacturing and processing since 2002, providing ground-breaking solutions that transform how food and beverage companies work. Kiln Scale Automation and complete automation solutions have enabled us to help thousands of businesses keep pace with change and retain competitive edges.

Boosting Efficiency in Food Manufacturing

The food processing industry has seen a tremendous uptake in automation, most particularly on critical processes like ingredient handling and processing. With our state-of-the-art Rice Fortification System, we have significantly transformed the process of how nutricity uniformity is achieved within the final product of manufacturers. Through this innovation, coupled with MCC Panels Automation Services experience, we can control the entire process in high precision.

The FRK Blending Machines change the way manufacturers handle ingredient mixing to ensure that quality is maintained with minimized waste. These systems are intended to work in harsh environmental conditions with a d

eep control in blending processes and, thus, generally applied in most food manufacturing applications.

Our Grain Monitoring System provides manufacturers of real-time visibility on storage conditions and quality parameters, thus providing manufacturers with optimal levels of inventory and product quality. This is but one way by which our automation solutions are enhancing the efficiency and productivity of food manufacturers.

Innovations in Beverage Packaging and Bottling

The beverage industry comes with specific challenges that require niche-specific automation solutions. Our comprehensive Weighing and Batching Automation solutions help guarantee proper ingredients measurement and identical quality of the finished product in every batch. Allied with state-of-the art MCC Panels Automation Services, this technology holds tremendous promise for bottling and packaging process control.

Our state-of-the art advanced control systems can be fully integrated with existing infrastructure, so that beverage manufacturers can:

Optimize Filling Speed and Accuracy

Minimize waste creation

Adequate quality

Sanitary condition maintained at a high standard

Ensuring Quality and Safety with Automated Systems

The food industry is strongly concerned about the safety of food as well as the quality control of food products. Our fortified Rice System is equipped with sophisticated monitoring capabilities, which keep a check on the nutrient-level distribution in the final product, thus providing high-quality consistency of the products. With our Grain Monitoring System, these products give 360° assurance in the manufacturing process.

FRK Blending Machines equipped with quality control facilities allow for consistent product standards with minimum chances of contamination. Our automation solutions include:

Real-time monitoring of quality

Automated sampling and testing

Digital record keeping in line with regulatory compliance

Predictive alerts for maintenance

Optimizing Supply Chain Operations

Highly sophisticated modern food and beverage supply chains call for similarly advanced automation solutions in order to maintain efficiency and traceability at every step. Our MCC Panels Automation Services are the backbone for integrated supply chain management systems in real-time monitoring and control of multiple processes.

Our Weighing and Batching Automation system-integrated supply chain management software ensures the following:

Proper inventory tracking

Efficient usage of resources

Minimal wastage

Enhanced traceability

Integrating AI and IoT for Smart Food Processing

The future of food processing is in the intelligent automation solutions with AI and IoT technologies. Our research team constantly engineers new applications that upgrade our solutions, from Grain Monitoring System to Rice Fortification System, with smart capabilities.

In this context, the above intelligent systems are available:

Facilities of predictive maintenance

Real-time optimization of processes

Advanced analytics of data

Remote monitoring and control

Innovations don’t stop at the improvement of our FRK Blending Machines and other automation solutions to ensure that they are up-to-date with technology while continuing to be robust and user friendly.

Since 2002, Accord has been a leader in turnkey electrical and automation solutions in food and beverage setting innovation.

Our respect, professionalism, and perseverance form the strong pillars guiding us as we develop solutions changing lives and industries.

Our success is based on:

Close relationship with customers

Continuous Research and Development

Practical and easy-to-use solution

Commitment to quality and safety

Be it a new system for Rice Fortification, upgrades of the existing MCC Panels Automation Services, or any other customized solutions to specific challenges in manufacturing processes, Accord is committed to pushing the boundaries for state-of-the-art automation solutions for the food and beverage industry.

The future of food and beverage manufacturing is in intelligent integrated automation solutions that bring more efficiency, assure quality, and lay emphasis on sustainability. And with our huge portfolio of solutions and ceaseless commitment to innovation, Accord has all it takes to keep driving that evolution and change in the years to come.

#FoodAutomation#BeverageAutomation#IndustrialAutomation#FoodProcessing#SmartManufacturing#IoTInFood#AIAutomation#EfficientProduction#QualityControl#SupplyChainOptimization#SustainableManufacturing#FoodSafety#BeveragePackaging#InnovativeSolutions#RiceFortification#GrainMonitoring#MCCPanels#FRKBlending#AutomationRevolution#AccordAutomation

0 notes

Text

Industrial Robotics Market: Market Size, Share, and Growth Projections

The global industrial robotics market size is expected to reach USD 60.56 billion by 2030, expanding at a CAGR of 10.5% from 2023 to 2030, according to a new study by Grand View Research, Inc. The increasing trend of mass production, predominantly in the manufacturing of automobiles, electronics, and packaged food, among others, is expected to drive market growth. For instance, in March 2022, Ford Motor Company integrated industrial robots in its factories to operate 3D printers which produced small car parts.

Moreover, the increasing demand for products to be available at a fast rate has resulted in producers opting for high-volume goods production. For instance, in December 2022, Taiwan Semiconductor Manufacturing Company Limited announced that it had begun mass manufacturing its 3-nanometer chips due to global demand. Therefore, the factories are using industrial robotics and automation systems as they can complete processes in shorter timelines without significant human intervention.

Additionally, governments around the world are pushing for automation and robotics in the industrial sector to boost national exports, increase technology penetration, and attract foreign investment. For instance, in September 2022, the crown prince of Dubai launched The Dubai Robotics and Automation Program to boost robotics in the country. Under the program, around 200,000 robots will be provided to the industrial and logistics sectors to boost production.

The COVID-19 pandemic had a significant impact on the industrial robotics industry as almost all industries were affected due to government lockdowns and regulations. During this time, there was a decline in the manufacturing of industrial robots itself. However, social distancing and partial workforce regulations during the pandemic increased the demand for automation robots and systems in the industrial sector to keep up with manufacturing and industrial processes demand. Moreover, the demand for industrial robots has remained constant post-pandemic due to the ongoing trend of automation in factories.

For More Details or Sample Copy please visit link @: Industrial Robotics Market Report

Industrial Robotics Market Report Highlights

Based on end-use, the chemical, rubber, & plastics segment is expected to grow at the highest CAGR of over 12% over the forecast period as the robots can work around the clock and help avoid health issues to laborers due to toxic fumes and harmful chemicals

Based on application, the handling segment recorded the largest market share in 2022 owing to the trend of e-commerce shopping, and increasing demand for robotics in logistics & warehouse applications

Based on geography, the Middle East & Africa is expected to grow at the highest CAGR over the forecast period owing to favorable government initiatives for automation and robotics along with significant foreign investment

Gain deeper insights on the market and receive your free copy with TOC now @: Industrial Robotics Market Report

We have segmented the global industrial robotics market based on application, end-use, and region.

#IndustrialRobotics#RoboticsMarket#AutomationRevolution#SmartManufacturing#RoboticSolutions#FutureOfWork#ManufacturingInnovation#AIInRobotics#IndustrialAutomation#TechInManufacturing#RoboticAutomation#Industry4#PrecisionEngineering#NextGenRobotics#AutomationTechnology

0 notes