#SmartLogistics

Explore tagged Tumblr posts

Text

From real-time tracking to secure drop-offs, this post reveals how Pudo Fast guarantees both speed and security in every delivery.

1 note

·

View note

Text

Revolutionizing Logistics & Energy Management with IoT

MeshTek’s advanced IoT dashboard empowers transportation and logistics companies with real-time fleet tracking, optimized routing, and fuel efficiency insights, ensuring cost savings and enhanced customer satisfaction. In the energy sector, our IoT solutions enable utilities to monitor energy consumption, track equipment performance, and optimize distribution—driving efficiency, cost reduction, and sustainability. Experience smarter operations with MeshTek’s cutting-edge IoT technology!

#MeshTek#IoT#SmartLogistics#FleetManagement#EnergyManagement#IoTPlatform#BLEMesh#DigitalTransformation#SmartTechnology#SupplyChainOptimization#RouteOptimization

1 note

·

View note

Text

🚚📡 Connected Logistics Market to Skyrocket to $423.64 Billion by 2032! – Revolutionizing the Supply Chain 🌐

📊 The global connected logistics market reached USD 14.49 billion in 2018 and is projected to soar to USD 423.64 billion by 2032, growing at an exceptional CAGR of 23.7%.

🌎 North America led the global market in 2018 with a 32.50% share, powered by digital infrastructure and early tech adoption across logistics networks.

🔗 Connected logistics leverages IoT-based platforms (hardware + software + services) to provide real-time visibility of goods in transit—via roadways, railways, airways, and seaways—enhancing supply chain efficiency, tracking, risk mitigation, and route optimization.

🚛 Key Features & Benefits:

📍 Fleet tracking & location monitoring

📡 Cargo traffic management & routing

🔒 Supply chain security management

📊 Real-time analytics & performance optimization

📦 Resilience planning for dynamic logistics operations

🧩 By Component:

Hardware

Solutions

Services

🚢 By Transportation Mode:

Roadway

Railway

Airway

Seaway

🏭 By Vertical:

Manufacturing

Automotive

Food & Beverages

Consumer Goods & Retail

Oil & Gas

Travel & Hospitality

Healthcare & Pharmaceuticals

Others

🏢 Top Connected Logistics Companies:

AT&T Intellectual Property

Robert Bosch GmbH

Cisco Systems, Inc.

Freightgate Inc.

HCL Technologies Limited

Honeywell International Inc

IBM Corporation

Infosys Limited

Intel Corporation

NEC Corporation

One Network Enterprises

ORBCOMM

SAP SE

SIGFOX

Zebra Technologies Corp.

🛠️ Key Industry Developments:

Trimble acquired Kuebix, enhancing TMS offerings with integrated fleet and carrier networks.

Intel introduced the Intel Connected Logistics Platform, a cost-efficient IoT tool for asset condition and location monitoring throughout the supply chain.

📈 With the surge in eCommerce, just-in-time deliveries, smart warehousing, and automation, connected logistics is becoming the backbone of tomorrow’s digitized, agile supply chain.

🔗 Read Full Report Here: 👉 https://www.fortunebusinessinsights.com/connected-logistics-market-102414

#ConnectedLogistics#SupplyChainInnovation#IoTLogistics#FleetTracking#SmartLogistics#LogisticsTechnology#DigitalSupplyChain#AssetMonitoring#RealTimeLogistics#TransportationManagement#IntelLogistics#TrimbleTMS#FutureOfLogistics#LogisticsCAGR2032

0 notes

Text

Global Composite Packaging Market - Industry Trends and Forecast

Composite packaging combines two or more materials—such as paper, aluminum foil, plastic films, or specialized polymers—to deliver high barrier protection, durability, and lightweight performance. It’s widely used in food & beverage cartons (like aseptic packs), pharmaceutical blister packs, flexible pouches, and household products. Composite packaging offers extended shelf life, moisture and oxygen resistance, and customized features like resealable spouts and tamper-indication. As sustainability takes center stage, innovation in mono-material designs, recyclable layers, and smart features (e.g. embedded QR codes, sensors) is accelerating market growth globally.

#CompositePackaging#SmartPackaging#BarrierMaterials#SustainablePackaging#AsepticCartons#FlexiblePouches#PharmaPackaging#RecyclableMaterials#CircularEconomy#FoodPackaging#PackagingInnovation#EcommercePackaging#SmartLogistics#EcoFriendlyPackaging#MaterialsScience

0 notes

Text

Transform your Freight Forwarding with Fresa Global ERP Software - the first AI-Powered Solution globally! 🤖🌍 Achieve superior efficiency and automation in your logistics processes. 🚀📦

For more details, visit here 👇 🔗 https://fresatechnologies.com/products/fresa-global/

📧 For inquiries, contact us at: [email protected]

#FresaGlobalERP#AIPoweredSoftware#FreightForwarding#LogisticsSolutions#SmartLogistics#ShippingSoftware#GlobalTrade#FreightTech#DigitalFreight#AIinLogistics#ERPforFreight#FreightAutomation#FresaTechnologies#LogisticsMadeEasy#Fresa#Freightsolutions#Freightforwarding#Import#FresaAIChatbot#SmartFreightAssistant

0 notes

Text

EDI Integration: A Game-Changer for Supply Chain and Logistics

The pulse of modern supply chains beats in rhythm with rapid, error-free data exchange. EDI integration isn’t just an upgrade—it’s a revolutionary force redefining how businesses transmit invoices, purchase orders, and shipping data with digital precision. Erasing manual processes slashes costly missteps and accelerates operational tempo.

This article unpacks EDI's sweeping transformation to logistics, its strategic leverage, operational refinement, and the tactical blueprint for seamless adoption.

Decoding EDI Integration in Supply Chain Management

Intertwining an electronic data interchange system within a supply chain constructs an autonomous data highway—where purchase orders, invoices, and shipping details transition effortlessly, eliminating manual bottlenecks. This digital nerve centre replaces antiquated processes, slashing inefficiencies while amplifying workflow velocity.

EDI redefines synergy among suppliers, manufacturers, and distributors in supply chain dynamics, fostering instantaneous, error-free data exchange. Automating partner interactions dissolves operational drag, trims financial waste, and fine-tunes logistical precision to an almost frictionless rhythm.

Key Components of EDI in Logistics

Within supply chain management, electronic data interchange orchestrates fluid logistics by digitally synchronising data exchange among trading partners. Its foundational elements include:

EDI Standards & Protocols – Structuring data formats to ensure cross-system cohesion.

EDI Translation Software – Morphing business documents into standardised EDI language.

Communication Networks – Secure conduits (VANs, AS2, APIs) ferrying logistics data.

ERP & WMS Integration – Aligning EDI with enterprise systems for real-time insights.

EDI Compliance & Security – Upholding regulations and fortifying data integrity.

A meticulously designed EDI framework refines efficiency, eradicates errors, and amplifies supply chain transparency.

Benefits of EDI Integration for Supply Chain Efficiency

The age of manual processes giving way to seamless automation has long arrived. Electronic Data Interchange (EDI) is the silent architect of efficiency, refining business operations and minimizing disruptions. Within the intricate web of supply chain management, its benefits remain undeniable.

A. Precision in Order Processing, Elimination of Errors

Data flows where it must, unburdened by human intervention. Purchase orders, invoices, and shipping details transition effortlessly through automation, bypassing the errors that manual data entry invites—incorrect orders, duplicate invoices, and shipping discrepancies. Speeding up these processes speeds up deliveries, strengthens customer satisfaction, and flourishes supplier relationships.

B. Cost Reduction Meets Compliance Assurance

The expenses of paperwork, printing, and labour diminish as transactions shift to digital. No longer does storage space clutter with physical records, nor do businesses wrestle with inefficient tracking. Compliance? A seamless affair. Regulations are met with precision, records remain pristine, and financial penalties for oversight become relics of the past.

C. Unparalleled Visibility, Instantaneous Tracking

Real-time data—a competitive advantage few can afford to ignore. Every order, every shipment, and every inventory update presents itself with clarity. Delays cease to be mysteries, inventory aligns with demand, and customers remain informed at every stage. Insight drives decisions, and businesses navigate complexities with certainty.

D. Inventory: Neither Excessive nor Insufficient

Scarcity and surplus—both adversaries to supply chain equilibrium—are neutralized. EDI ensures inventory levels remain in harmony, automatically replenishing stock before depletion becomes a disruption. Overstocking, an avoidable excess, no longer drains resources or inflates storage costs. The balance maintained translates to operational fluidity and financial prudence.

E. Disputes Diminished, Compliance Simplified

Discrepancies over invoices, payment misalignments, or shipment inconsistencies—challenges businesses know too well. Yet, with EDI, every transaction leaves a digital footprint, disputes find swift resolutions, and operational slowdowns recede. Partner expectations and industry mandates—were fulfilled effortlessly, trust was reinforced, and business relationships strengthened.

Steps to Implement EDI Integration in Logistics Operations

Implementing EDI integration in logistics operations requires a structured approach to ensure seamless electronic data exchange between systems. Here’s a how-to do it:

Step 1: Define Business Priorities, Identify Automation Scope

Optimization begins with awareness. Where does inefficiency reside? What logistics functions stand to benefit? Pinpoint the essential documents—be they invoices, shipping notices, or purchase orders—that demand automation. Efficiency is engineered, not assumed.

Step 2: Selecting an EDI Framework That Fits

Customization is key. Will in-house management grant better control, or does outsourcing promise a leaner setup? The right electronic data interchange solution aligns with business capacity, ensuring scalability without unnecessary complexity.

Step 3: Establish Standards, Secure Communication Protocols

Order in digital exchange is non-negotiable. Formats like ANSI X12 or EDIFACT dictate structure, while secure channels such as AS2 or FTP safeguard transmissions. Precision at this stage prevents data inconsistencies later.

Step 4: Integrate EDI With Existing Logistics Systems

Standalone solutions create silos; integrated systems drive intelligence. Seamlessly embedding EDI within Warehouse (WMS) and Transportation Management Systems (TMS) ensures streamlined workflows, fewer manual interventions, and minimal error margins.

Step 5: Synchronize Data Exchange With Logistics Partners

Connectivity extends beyond internal operations. Suppliers, carriers, and warehouses must align to ensure flawless data exchange. Testing precedes execution—disruptions are better addressed before full deployment.

Step 6: Validate Accuracy, Conduct Trial Transactions

A single discrepancy can ripple across operations. Running simulated transactions exposes weak links, allowing errors to be corrected proactively. The objective: seamless, error-free execution upon launch.

Step 7: Continuous Monitoring, System Evolution

Implementation is not the end—it’s the beginning of optimization. Performance tracking, issue resolution, and periodic updates ensure that EDI remains an asset, not an overlooked infrastructure.

Logistics is a symphony of moving parts. With EDI integration, businesses synchronize these elements into an orchestrated, data-driven flow—where delays diminish, accuracy prevails, and efficiency reaches new heights.

Conclusion

EDI integration transforms supply chain and logistics by automating processes, reducing errors, and improving efficiency. Manual data exchange leads to costly delays, but with XLNC Technologies’ seamless EDI solutions, businesses can streamline operations, track inventory accurately, and enhance supplier communication. As supply chains grow more complex, partnering with XLNC Technologies ensures you stay competitive with faster, error-free data exchange and optimized workflows.

FAQs

What function does EDI integration fulfill within supply chain management?

Consider EDI the unseen orchestrator of supply chain symphonies, replacing manual lag with digital immediacy. Orders materialize, invoices reconcile, and shipments mobilize synchronized, eliminating friction and driving precision to near perfection.

In what ways does EDI amplify logistical effectiveness?

With EDI in place, logistics ceases to be a guessing game. Documents travel at digital speed, missteps dwindle, and a synchronized interplay between suppliers, warehouses, and carriers transforms fulfilment into a well-tuned mechanism of cost-saving accuracy.

Why does EDI integration stand as a linchpin for supply chain efficiency?

Inefficiencies dissolve when EDI takes command—misfiled paperwork, garbled orders, and sluggish workflows become relics of the past. What emerges is pinpoint accuracy, velocity in execution, financial savings, and fortified business relationships that stand the test of time.

What obstacles emerge when integrating EDI?

EDI adoption isn't plug-and-play—enterprises grapple with upfront investments, cross-system compatibility tangles, partner compliance hurdles, security vulnerabilities, and an ever-evolving need for refinement to keep pace with technological shifts.

How should a business pinpoint the ideal EDI solution for logistics dominance?

A mere EDI solution won’t suffice—true mastery demands one that scales with precision, fortifies digital perimeters, fuses seamlessly into operations, adheres uncompromisingly to regulations, orchestrates automation with intelligence, refines expenditures strategically, and is reinforced by steadfast expert guidance.

#EDIIntegration#SupplyChainEfficiency#LogisticsAutomation#DigitalTransformation#ErrorFreeOperations#SupplyChainSolutions#EDIinLogistics#OperationalExcellence#InventoryManagement#RealTimeTracking#CostReduction#ComplianceMadeEasy#BusinessAutomation#SmartLogistics#StreamlineOperations#WarehouseOptimization#TechnologyDriven#DigitalSupplyChain#FutureOfLogistics#XlncTechnologies

0 notes

Text

Tuticorin’s Pioneer in GMT Pallets Production

In the heart of Tuticorin’s industrial corridor, TECHNOVENT ENGINEERING began its journey with a vision to innovate. With a focus on sustainability and durability, the company entered the world of GMT Pallets, a revolutionary material known for its strength and recyclability. Starting with small-scale production and a passionate team of engineers, TECHNOVENT quickly gained traction among industries seeking eco-friendly alternatives to traditional wooden pallets.

Mastering the Art of GMT Pallets Manufacturing As demand grew, so did TECHNOVENT’s ambition. The company invested in cutting-edge equipment and world-class manufacturing processes, transforming itself into a benchmark in GMT Pallets Manufacturing. Every pallet that leaves their facility reflects quality, precision, and environmental consciousness. Clients across industries—from automotive to logistics—recognized the value of TECHNOVENT’s engineered solutions.

A Trusted Name in GMT Pallets Manufacturing Tuticorin With deep roots in the local economy, TECHNOVENT ENGINEERING became synonymous with GMT Pallets Manufacturing Tuticorin. Their commitment to local employment, regional growth, and technological excellence has made them a proud contributor to Tuticorin’s industrial landscape. The factory buzzes with energy, driven by a skilled workforce dedicated to producing reliable GMT pallets tailored to diverse applications.

Expanding Horizons: GMT Pallets Manufacturing Thoothukudi From a local startup to a regional leader, TECHNOVENT’s footprint now extends beyond city limits as a key player in GMT Pallets Manufacturing Thoothukudi. The company continues to innovate, expanding its capabilities while maintaining its core values. With a growing customer base and a reputation for timely delivery, TECHNOVENT is shaping the future of pallet technology in Tamil Nadu and beyond.

Contact Details: TECHNOVENT ENGINEERING 📍 Tuticorin, Tamil Nadu – 628002 📞 +91 80125 51234 📧 [email protected] 🌐 www.technovent.in

#GMTpallets

#GMTpalletsManufacturing

#PalletSolutions

#ThermoplasticPallets

#SustainablePackaging

#IndustrialPallets

#Tuticorin

#TuticorinBusiness

#TamilNaduIndustry

#MadeInTamilNadu

#SouthIndiaManufacturing

#TechnoventEngineering

#TechnoventTuticorin

#InnovativeManufacturing

#EngineeringExcellence

#IndianManufacturers

#B2Bsolutions

#ExportReady

#SmartLogistics

#EcoFriendlyProducts

#QualityManufacturing

#gmt pallets#gmt pallets manufacturing#gmt pallets manufacturing tamilnadu#gmt pallets manufacturing tutcorine#gmt pallets manufacturer#B2Bsolutions#TechnoventTuticorin#SmartLogistics#QualityManufacturing#PalletSolutions

0 notes

Text

#ManufacturingERP#InventoryManagement#SupplyChain#QatarBusiness#DigitalSolutions#ERPSoftware#SmartLogistics#BusinessGrowth#erp in dubai#dubai business software

0 notes

Text

Tips to Reduce Freight Costs Without Sacrificing Quality

By Richmond Kofi Adjapong

Let’s face it—freight costs can feel like quicksand. The more you move, the deeper it pulls. Whether you're a first-time exporter or a seasoned supply chain manager, there’s always pressure to keep freight budgets in check without compromising timelines or damaging your cargo—or your relationships.

At Rich Freight Services Ltd here in Ghana, we work with clients from across industries: agriculture, textiles, construction, even pharmaceuticals. One thing they all ask? "How can we bring costs down, but keep quality up?"

It’s a fair question. And the truth is, it’s possible. But it’s not about cutting corners. It’s about working smarter—strategically. Over the years, we’ve found a few practical ways to make freight more efficient without giving up the standards your business relies on.

So, let’s talk strategy. Not theory—real-world things you can apply.

Consolidate Shipments Where Possible One of the simplest ways to save on freight is by consolidating your cargo. Instead of sending out multiple smaller shipments, bundling them together into a single container or truckload can reduce your per-unit transport cost significantly.

We recently supported three SME exporters—each shipping food products to different buyers in Southeast Asia. By consolidating their cargo into one LCL (less-than-container load) container, we saved each of them nearly 30% compared to sending individual shipments.

It takes coordination—but the savings are real.

Choose the Right Mode (Not Just the Fastest) Many businesses default to air-freight, assuming it’s the only way to meet timelines. And sometimes, it is. But sea freight, even with a slightly longer transit time, can be a fraction of the cost.

Ask yourself: does the cargo really need to be there in 3 days, or will 15 days do? And is partial air + sea freight (multimodal) a better compromise?

At RFS, we often map out multiple routing options for clients—so they can compare price vs speed. Often, there’s a sweet spot.

Understand Incoterms—They Affect Your Cost Believe it or not, many importers and exporters misunderstand who’s responsible for what. FOB, CIF, DDP… these aren't just acronyms—they shape where risk and cost shift along the chain.

For example, choosing Ex-Works means you're paying for everything from factory gate to destination. But with FOB, the seller covers the local transport and export clearance. Choosing the right Incoterm can reduce surprise charges and give you more cost control.

Leverage Off-Peak Shipping Schedules Freight rates, especially for ocean shipping, fluctuate with the season. Demand spikes during certain months—pre-holiday periods, harvest seasons, year-end rush.

If your business allows for it, schedule your shipments during off-peak windows. We've helped clients time their exports strategically—like shifting a cocoa shipment from early December to late January—saving thousands in the process.

Optimize Your Packaging Over-packaging doesn’t just waste materials—it eats up space, which can increase your volumetric shipping cost. Likewise, under-packaging can lead to damage, returns, and added insurance claims.

It’s a balance.

One of our clients, an electronics distributor, was able to reduce air-freight costs by 18% simply by using space-saving, shock-resistant packaging that lowered the shipment’s volume without compromising safety.

Build Long-Term Relationships with Your Forwarder This isn’t a plug. It’s a real tip.

When you work consistently with a logistics partner—like us at Rich Freight Services Ltd—you gain access to negotiated rates, quicker service, and a deeper understanding of your operations. That relationship can lead to cost-saving recommendations you wouldn’t get from a one-time transactional quote.

We’ve saved clients money just by advising on alternate ports, recommending lighter container stuffing methods, or bundling multiple shipments into monthly contracts.

Digital Documentation Reduces Errors (and Penalties) Mistakes in customs paperwork can lead to delays, inspections, and extra fees. By digitizing documentation—like commercial invoices, packing lists, and declarations—you reduce the chance of human error and speed up approvals.

At RFS, we use digital checklists and internal reviews before anything is submitted. It’s a small step that prevents big costs down the line.

Plan Ahead (Always!) Last-minute freight is almost always more expensive. It limits your options, leaves no room to negotiate, and puts you at the mercy of whatever capacity is available.

The earlier we can plan a shipment with our clients, the more options we can explore—alternate carriers, better routes, even better insurance rates.

If you remember nothing else, remember this: freight rewards the prepared.

Looking Ahead

Freight costs aren’t going away. But they don’t have to spiral out of control, either. With a bit of planning, the right guidance, and some operational tweaks, businesses—especially here in Ghana—can build a logistics model that’s both cost-effective and reliable.

And as we look forward to attending the 2025 Go Global Awards in London this November, we carry these insights with us. Because while the event is a celebration, it’s also a meeting of minds—businesses from across the globe sharing what’s working, what’s changing, and how to stay competitive in an unpredictable world.

We at Rich Freight Services Ltd are proud to be part of that dialogue. Our message? You don’t have to choose between cost and quality. You just have to work smarter—and with the right partner.

#FreightSavings#RichFreightServices#SmartLogistics#FreightForwarding#TemaPort#GhanaTrade#GoGlobalAwards#SupplyChainStrategy#ExportTips#SMELogistics#RichmondAdjapong

0 notes

Text

Digital Freight Brokerage Market Estimated to Reach USD 46.15 Billion by 2034 | CAGR: 23.1%

Digital Freight Brokerage Market Analysis: Opportunities, Innovations, and Growth Potential Through 2034 Global Digital Freight Brokerage Market size and share is currently valued at USD 5.79 billion in 2024 and is anticipated to generate an estimated revenue of USD 46.15 billion by 2034, according to the latest study by Polaris Market Research. Besides, the report notes that the market exhibits…

#AIlogistics#DigitalFreight#digitalplatforms#digitaltransportation#ecommercefreight#freightautomation#FreightBrokerage#freightvisibility#logisticsinnovation#logisticstechnology#onlinelogistics#smartlogistics#supplychain#transportationtech

0 notes

Text

Uncovering the Real ROI: How Data Science Services Are Driving Competitive Advantage in 2025

Introduction

What if you could predict your customer’s next move, optimize every dollar spent, and uncover hidden growth levers—all from data you already own? In 2025, the real edge for businesses doesn’t come from owning the most data, but from how effectively you use it. That’s where data science services come in.

Too often, companies pour resources into data collection and storage without truly unlocking its value. The result? Data-rich, insight-poor environments that frustrate leadership and slow innovation. This post is for decision-makers and analytics leads who already know the fundamentals of data science but need help navigating the growing complexity and sophistication of data science services.

Whether you’re scaling a data team, outsourcing to a provider, or rethinking your analytics strategy, this blog will help you make smart, future-ready choices. Let’s break down the trends, traps, and tangible strategies for getting maximum impact from data science services.

Section 1: The Expanding Scope of Data Science Services in 2025

Gone are the days when data science was just about modeling customer churn or segmenting audiences. Today, data science services encompass everything from real-time anomaly detection to predictive maintenance, AI-driven personalization, and prescriptive analytics for operational decisions.

Predictive & Prescriptive Modeling: Beyond simply forecasting, top-tier data science service providers now help businesses simulate outcomes and optimize strategies with scenario analysis.

AI-Driven Automation: From smart inventory management to autonomous marketing, data science is fueling a new level of automation.

Real-Time Analytics: With the rise of edge computing and faster data streams, businesses expect insights in seconds, not days.

Embedded Analytics: Service providers are helping companies build intelligence directly into products, not just dashboards.

These services now touch nearly every business function—HR, operations, marketing, finance—with increasingly sophisticated tools and technologies.

Section 2: Choosing the Right Data Science Services Partner

Selecting the right partner is arguably more critical than the tools themselves. A good fit ensures strategic alignment, faster time to value, and fewer rework cycles.

Domain Expertise: Don’t just look for technical brilliance. Look for providers who understand your industry’s unique metrics, workflows, and regulations.

Tech Stack Compatibility: Ensure your provider is fluent in your existing environment—whether it’s Snowflake, Databricks, Azure, or open-source tools.

Customization vs. Standardization: The best data science services strike a balance between reusable IP and tailored solutions.

Transparency & Collaboration: Look for vendors who co-build with your internal teams, not just ship over-the-wall solutions.

Real-World Example: A retail chain working with a generic vendor struggled with irrelevant models. Switching to a vertical-focused data science services provider with retail-specific datasets improved demand forecasting accuracy by 22%.

Section 3: Common Pitfalls That Derail Data Science Projects

Despite strong intent, many data science initiatives still fail to deliver ROI. Here are common traps and how to avoid them:

Lack of a Clear Business Goal: Many teams jump into modeling without aligning on the problem statement or success metrics.

Dirty or Incomplete Data: If your foundational data layers are unstable, no algorithm can fix the problem.

Overemphasis on Accuracy: A highly accurate model that no one uses is worthless. Focus on adoption, interpretability, and stakeholder buy-in.

Skills Gap: Without a strong bridge between data scientists and business users, insights never make it into workflows.

Solution: The best data science services include data engineers, business translators, and UI/UX designers to ensure end-to-end delivery.

Section 4: Unlocking Hidden Opportunities with Advanced Analytics

In 2025, forward-thinking firms are using data science services not just for problem-solving, but for uncovering growth levers:

Customer Lifetime Value Optimization: Predictive models that help decide how much to spend and where to focus retention.

Dynamic Pricing: Real-time adjustment based on demand, inventory, and competitor moves.

Fraud Detection & Risk Management: ML models can now flag anomalies within seconds, preventing millions in losses.

ESG & Sustainability Metrics: Data science is enabling companies to report and optimize environmental and social impact.

Real-World Use Case: A logistics firm used data science services to optimize delivery routes using real-time weather, traffic, and vehicle condition data, reducing fuel costs by 19%.

Section 5: How to Future-Proof Your Data Science Strategy

Data science isn’t a one-time investment—it’s a moving target. To remain competitive, your strategy must evolve.

Invest in Data Infrastructure: Cloud-native platforms, version control for data, and real-time pipelines are now baseline requirements.

Prioritize Model Monitoring: Drift happens. Build feedback loops to track model accuracy and retrain when needed.

Embrace Responsible AI: Ensure fairness, explainability, and data privacy compliance in all your models.

Build a Culture of Experimentation: Foster a test-learn-scale mindset across teams to embrace insights-driven decision-making.

Checklist for Evaluating Data Science Service Providers:

Do they offer multi-disciplinary teams (data scientists, engineers, analysts)?

Can they show proven case studies in your industry?

Do they prioritize ethics, security, and compliance?

Will they help upskill your internal teams?

Conclusion

In 2025, businesses can’t afford to treat data science as an experimental playground. It’s a strategic function that drives measurable value. But to realize that value, you need more than just data scientists—you need the right data science services partner, infrastructure, and mindset.

When chosen wisely, these services do more than optimize KPIs—they uncover opportunities you didn’t know existed. Whether you’re trying to grow smarter, serve customers better, or stay ahead of risk, the right partner can be your unfair advantage.

If you’re ready to take your analytics game from reactive to proactive, it may be time to evaluate your current data science service stack.

#DataScience2025#FutureOfAnalytics#AdvancedAnalytics#AITransformation#MachineLearningModels#PredictiveAnalytics#PrescriptiveAnalytics#RealTimeData#EdgeComputing#DataDrivenDecisions#RetailAnalytics#SupplyChainOptimization#SmartLogistics#CustomerInsights#DynamicPricing#FraudDetection#SaaSAnalytics#MarketingAnalytics#ESGAnalytics#HRAnalytics#DataEngineering#MLOps#SnowflakeDataCloud#AzureDataServices#Databricks#BigQuery#PythonDataScience#CloudDataPlatform#DataPipelines#ModelMonitoring

0 notes

Text

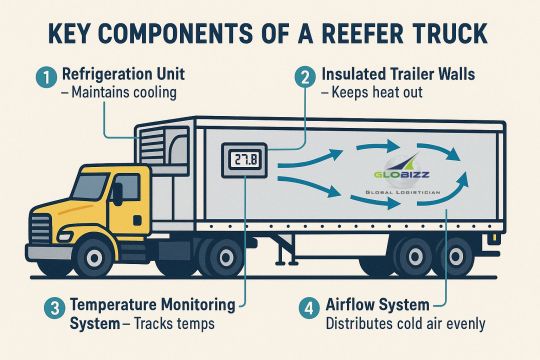

🚛 Unlocking the Cold Chain: Inside a Reefer Truck ❄️

Ever wondered how perishable goods stay fresh across thousands of miles? Meet the heroes behind the scenes — Reefer Trucks.

Here are the 4 key components that make cold transport possible:

1️⃣ Refrigeration Unit – Keeps products at the perfect temperature 2️⃣ Insulated Trailer Walls – Blocks external heat 3️⃣ Temperature Monitoring System – Ensures temperature stays consistent 4️⃣ Airflow System – Evenly circulates cold air to prevent spoilage

From fresh produce 🍓 to pharmaceuticals 💊, these systems work in harmony to deliver quality and safety.

💡 In logistics, every degree matters.

#ColdChain#LogisticsSolutions#ReeferTruck#SupplyChain#TemperatureControlled#FreightTransport#SmartLogistics#PharmaLogistics#FoodSafety#GlobizzSynergy#RefrigeratedTransport#InnovationInLogistics

0 notes

Text

🚀 Revolutionize your supply chain with advanced 🤖 AI capabilities for seamless operations. 🌐 Experience Fresa Global ERP Software, the World's Premier AI-Powered ✈️📦 Freight Forwarding Solution!

For more details, visit here 👇 🔗 https://fresatechnologies.com/products/fresa-global/

📧 For inquiries, contact us at: [email protected]

#FresaGlobalERP#AIPoweredSoftware#FreightForwarding#LogisticsSolutions#SmartLogistics#ShippingSoftware#GlobalTrade#FreightTech#SupplyChainInnovation#DigitalFreight#AIinLogistics#ERPforFreight#FreightAutomation#FresaTechnologies#LogisticsMadeEasy#Fresa#Freightsolutions#Freightforwarding#Import#FresaAIChatbot#SmartFreightAssistant#FreightForwardingMadeEasy

0 notes

Text

Why Dardania Logistics Stands Out Among Cold Storage Logistics Companies in Sydney?

Looking for a reliable partner to handle temperature-sensitive goods in Sydney? This infographic breaks down how Dardania Logistics ensures top-tier cold chain logistics through:

Temperature-controlled warehousing

Specialized refrigerated fleet

Real-time temperature monitoring

Protective insulated packaging

Compliance with health & safety standards

Seamless last-mile delivery

From food to pharmaceuticals, Dardania Logistics delivers precision, safety, and efficiency — everything you’d expect from a trusted cold storage logistics company in Sydney. Get in touch with Dardania Logistics today and keep your goods in perfect condition from start to finish!

#ColdStorageLogistics#ColdChainSydney#LogisticsSolutions#RefrigeratedTransport#SupplyChainExcellence#ColdChainLogistics#TemperatureControlledLogistics#DardaniaLogistics#SydneyLogistics#ColdStorageCompanies#LastMileDelivery#FoodLogistics#PharmaLogistics#AustralianLogistics#SmartLogistics

0 notes

Text

Smarter Logistics. Faster Results. At Ash Logistics, we use technology that tracks, predicts, and delivers — ensuring real-time visibility, optimized routes, and faster transport operations across India. 📦 Think Logistics. Think Ash.

#bestlogisticscompanyinindia#besttransportationcompanies#thirdpartylogisticscompanies#SmartLogistics#LogisticsIndia#DigitalLogistics

0 notes

Text

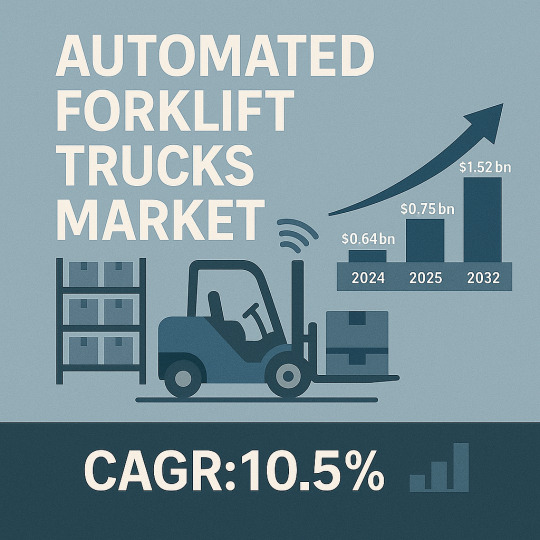

Automated Forklift Trucks Market Size, Trends & Forecast 2032

🚜🤖 The global automated forklift trucks market size was valued at USD 0.64 billion in 2024 and is projected to grow from USD 0.75 billion in 2025 to USD 1.52 billion by 2032, showcasing a healthy CAGR of 10.5% during the forecast period. 🌏 Asia Pacific dominated with a 37.5% share in 2024, reflecting rapid industrial automation and smart warehousing trends.

📌 Key Market Insights:

Market Size (2024): USD 0.64 billion

Forecast Size (2032): USD 1.52 billion

CAGR (2025–2032): 10.5%

Dominant Region: Asia Pacific held 37.5% in 2024

Growth Drivers: Rising demand for efficient material handling, labor cost savings, AMR navigation tech (Laser, Magnetic, Vision Guided), and booming e-commerce & F&B sectors.

🚀 Market Trends: Automated forklift trucks, also known as autonomous mobile robots (AMRs), are revolutionizing transportation, storage, assembly, and packaging in industries like automotive, food & beverage, and e-commerce. Expect more pallet movers, counterbalance, outriggers, and reach trucks with smarter navigation and IoT integration.

👉 Full report: https://www.fortunebusinessinsights.com/automated-forklift-trucks-market-102617

0 notes