#BIM Modeling Colorado

Explore tagged Tumblr posts

Text

Colorado BIM Modeling Services - BIMPRO LLC

We provide BIM Services (Modeling and Coordination) in Colorado to architectural, engineering and construction firms across USA.

#BIM Outsourcing Services Colorado#BIM Company in Colorado#BIM Consulting Services Colorado#BIM Modeling Colorado#BIM Services Colorado

1 note

·

View note

Text

Affordable Rebar Detailing Services in New Jersey City, USA

Offshore Outsourcing India, United States’ top CAD Outsourcing Services provider offer high-quality and affordable CAD Rebar Detailing services to various building sectors to fulfil the unique BIM project requirements. Delivering remarkable results with our 3D rebar modelling expertise at low rates, you will gain access to our dedication to excellence and unbeatable value for your investment by choosing us for your CAD services needs. Find out today how your project can uplifted by our low-cost Rebar detailing offered by our CAD professionals.

Our Services

Rebar Shop Drawings Services

Reinforcement Detailing Services

Bar Bending Schedule Services

Rebar CAD Detail Drawings Services

Rebar 2D and 3D Modeling Services

Rebar Walls Detailing Services

We offer CAD Services across the USA with cities like New York City, Indianapolis, Colorado Springs, Charleston, San Diego, Raleigh, Jacksonville, San Antonio, Seattle, Oklahoma City, Nashville etc.

For more details click on the link below

#RebarDetailingServices#ReinforcementDetailingServices#BarBendingScheduleServices#RebarCADDetailDrawingsServices#Rebar2Dand3DModelingServices#RebarWallsDetailingServices#detroit#waynecounty#OklahomaCity#cadservices#california#newyork#texas#Caddetailingservices

1 note

·

View note

Text

✨ Plan Smarter with 4D BIM Modelling Services in Colorado! 🏗️

Looking for easy and cost-saving #4DBIMServices to manage your project timeline? #SiliconOutsourcing offers trusted #4DBIMModeling, smart #4DBIMSchedulingServices, and clear #BIM4DModelling to keep everything on track. 🛠️📐

Our 4D models show how your project moves step by step — helping your team work better, spot issues early, and stay on time. 🎯⏳

✨ Get faster planning, fewer surprises, and better results with our 4D BIM solutions!

📲 Let’s talk today! 🌍 Visit Us: https://shorturl.at/tjFGA 🆕 Check out our latest blog: https://ext-6772492.livejournal.com/1400.html

0 notes

Text

We provide comprehensive BIM services in Colorado, empowering architects, engineers, contractors, and developers with cutting-edge solutions that streamline project delivery and improve collaboration. We provide High-precision architectural, structural, and MEP models using Revit and other leading platforms.

0 notes

Text

How BIM Modeling is changing the Game

Building Information Modeling (BIM) is a digital representation of the physical and functional characteristics of a building. It is a reliable basis for decision-making throughout the entire life cycle of a building, from its inception to its future, because it is a collaborative resource. BIM Modeling is not just about generating a visual 3D model of a building. It includes additional dimensions like adding cost information to a model (5D), adding scheduling information to model construction sequences, and even aspects like sustainability and building management. In a later blog post, I will break down the different levels of BIM modeling which go from 2D BIM up to 8D BIM

Pre-construction digital exploration of a project's physical and functional characteristics is made possible by BIM Modeling, a collaborative process developed by architects, engineers, and construction (AEC) professionals. This virtual model serves as a shared knowledge resource for information about the facility, forming a reliable resource to make high-level educated decisions. BIM Modeling is a versatile and multifaceted tool that has the potential to change the way we design and build buildings in the future. Because it enables a team-like approach to the design and construction of a building, as well as more accurate field collaboration and installation,

BIM Modeling is a game-changer in the AEC industry. With BIM Modeling, AEC professionals can work together in an integrated way, leading to increased efficiency which in turn, leads to increasing the contractors’ bottom line and helps shorten project schedules.

Benefits of BIM modeling in MEP Design

MEP (Mechanical, Electrical, and Plumbing) Engineering and Design utilizing BIM Modeling has endless benefits. Some of the benefits include, improving the accuracy of the design and helps detect any potential clashes between the different systems prior to commencement of construction. The clash detection process allows installing contractors to avoid, or greatly reduce conflicts during the construction phase. The result is decreased field labor hours, decreased material waste, and flushes out any conflicts and/or RFIs early in the process.

Providing a 3D model during the design process enhances collaboration among the various stakeholders involved in a project. The shared model makes it possible for all parties, from architects and engineers to contractors and building managers, to have access to the same information. This makes it easier to communicate and makes it less likely that people will make mistakes or get confused in the future.

Lastly, BIM Modeling in MEP design facilitates the management and maintenance of the building post-construction. This documentation enables building managers to carry out maintenance activities more effectively by providing a detailed, digital representation of the building's mechanical, electrical, and plumbing systems, along with detailed shop drawings and pre-fabrication spools.

BIM Modeling Statistics in the MEP Design Industry

The expanding use of BIM modeling in a variety of industries, as well as government initiatives to promote BIM, is the driving force behind this expansion. Furthermore, BIM has become increasingly popular among residential, commercial, and infrastructure projects all over the globe. In the MEPF design industry, where it is becoming a standard practice for many businesses, the use of BIM Modeling is particularly notable. Since 2012, when I started working as a BIM modeler for a medium-sized mechanical contractor, it has taken some Contrators and field teams some time to get on board. Contractors and field teams are beginning to recognize the advantages and full potential of BIM modeling, and I have observed a significant increase in the number of projects requiring it over the past ten years in Denver, Colorado. At my company, Calloway Design, we also act as an extra project manager in a sense because we make ourselves available throughout the construction process to make sure the field teams have all the information they need to install accurately and efficiently.

Moreover, a survey by Dodge Data & Analytics found that 75% of contractors reported a positive Return on Investment (ROI) on their BIM investments, with a higher percentage in the MEPF sector. The study found that, in comparison to general contractors (10%), trade contractors (14%) receive a return on investment (ROI) greater than 50%. When designing a building's mechanical systems, such as heating, ventilation, and air conditioning (HVAC),

Understanding Mechanical BIM

Mechanical BIM makes use of Building Information Modeling. The integration of Pre-fabrication drawings and on-site Trimble layout for sleeves and hangers with the creation of a detailed 3D model of these systems enables improved design, coordination, and installation. Mechanical BIM enables engineers and detailers to simulate and analyze the performance of the mechanical systems prior to construction. System performance and energy savings may result from this simulation and analysis.

Additionally, Mechanical BIM makes it easier to connect mechanical systems to other building systems. This integration allows for a more coordinated approach to design and construction, reducing the likelihood of clashes and modifications during the construction phase.

Understanding Plumbing BIM

Building Information Modeling is used to design a building's plumbing systems in plumbing BIM, which is similar to mechanical BIM. It allows for a more detailed and accurate design, leading to improved system performance and efficiency.

Plumbing BIM enables engineers and detailers to visualize the plumbing systems in 3D, facilitating a better understanding and communication of the design intent. It also allows for clash detection and resolution prior to construction, saving time and cost which increases the contractors’ bottom line.

In MEP design projects, there are numerous examples of successful BIM modeling. BIM Modeling was used extensively during the construction of the Burj Khalifa in Dubai, which is the tallest building in the world. The BIM model allowed for a more accurate and coordinated design of the building’s complex mechanical, electrical, and plumbing systems, contributing to the successful completion of the project.

Future of BIM Modeling in MEP Design

Another example is the construction of the Beijing National Aquatics Center, also known as the “Water Cube“, for the 2008 Olympics. BIM Modeling was used in the design of the building’s mechanical systems, enabling a more efficient and sustainable design.

These examples demonstrate the potential of BIM Modeling in MEP design, highlighting its ability to improve the accuracy, efficiency, and sustainability of building design and construction.

The future of BIM modeling in MEP design looks more promising the more we use it. With the increasing digitization of the AEC industry, the use of BIM Modeling is likely to become even more prevalent as we move forward.

Advancements in technology, such as the integration of BIM with building performance analysis tools, are expected to further enhance the capabilities of BIM. This integration will make it possible to take a building design approach that is more all-encompassing and sustainable, taking into account things like energy efficiency and the quality of the environment inside the building. Moreover, the increasing emphasis on collaboration and integration in construction projects is likely to further drive the adoption of BIM Modeling. BIM Modeling can help construction projects be more productive and successful by facilitating collaboration and integration.

0 notes

Link

Today, in this scenario of 21st century the manufacturing market is experiencing surge in the overall productivity that leads to the generation of ever increasing requirements to verify that, ultimately the parts being produced must meet the standardized or specified requirements.

In case where timeline is very critical and further delay can’t be tolerated, it is becoming highly important to give priority to the quality process instead of bulk process to reinforce the part’s needs and to consistently adding the value to the manufacturing process.

In this scenario today, the parts that are being manufactured are on increasing side with the demand for the accurate measurements surpassing the traditional system of measurement to measure or more specifically to reverse engineer them.

The process of 3D scanning is one such scenario that can bring versatility as well as accuracy to ever evolving environment of the metrology industry. It is a cost effective solution for getting important benefits for the 3D scanning reverse engineering.

Key Benefits of the 3D Scanning

Coverage

In just a fraction of minutes the 3D scanning devices can effectively collect &measure the data with the help of thousands of data points present on the surface of desired object. This kind of efficiency was unable to get prior to the 3D scanning technology.

Speed

If you measure something manually then it can take time & efforts both and also you will be under the limit while collecting the data practically. Whereas in case of 3D scanning you are getting faster way to collect the data with millions of data points with the speed of light. You can reduce time & efforts both and thus produces CAD models or similar other prototypes or even 2D drawings for the reverse engineering. By the help of accurately increasing the surface data acquisition rate, the 3D scanning device will bring you unmatched, unparalleled faster for inspection.

Accuracy

With the improvement in technology, the accuracy rate has also been improved by the 3D scanners over the period of time. With higher degree of accuracy you can expect better functionality.

Cost

The overall cost associated with the help of 3D scanning is much more competitive as compared to other dimensional control technologies especially in case where saving time is also important. The 3d scanners present in the market are very easier to use & can help you in maintaining the overall training schedules by lowering down the costs.

Summary

Many times the 3D scanner device used is dependent upon the object’s surface characteristics like its transparency, reflectivity, roughness etc. while in some cases it is not really needed but reflection & diffraction both can affect the overall measurements.

#3d Laser Scanning Services in Georgia#3d Laser Scanning Services in Colorado#dimension control services in Epsom#plant engineering services in Colorado#Point cloud to 3D Model Minnesota#Scan to BIM in Epsom#Scan to BIM in Texas

0 notes

Text

Telluride Glass House, Colorado

Telluride Glass House, Colorado Real Estate Development, USA Architecture Photos

Telluride Glass House in Colorado

Jul 8, 2021

Design: Efficiency Lab for Architecture

Location: Telluride, Colorado, USA

Telluride Glass House

Efficiency Lab for Architecture PLLC, a firm comprising a team of architects, planners, designers, and educators committed to a better understanding of efficiency in the built environment, is proud to unveil the Telluride Glass House, nestled into the steep cliffs of the Telluride Box Canyon in Colorado. Carved into a vertical wall of Aspen trees, rock cliffs, and wandering creeks, on a 3.4-acre lot adjacent to majestic Bridal Falls, the house consists of three cascading glass boxes with a combined floor area of approximately 7,000 sq. ft.

“Every architect dreams about building the proverbial glass house,” notes Aybars Asci, AIA, LEED, President of Efficiency Lab. “It’s a spatial construct that heightens our sensories and allows us to contemplate our natural surroundings with greater focus and appreciation than we otherwise would.”

Simple Complexity Accordingly, when the client approached Efficiency Lab about the desire to build a glasshouse, Asci presented an open plan vision, defined by fluidity, that would blur the boundaries between the landscape and the proposed building environment. The plan focused on the architectural expression of three cantilevered glass boxes. Each 45′ × 45′ glass box is positioned in a moment of suspension, providing a horizontal approach to the vertical terrain of towering Aspens rising from the surrounding mountains and cliffs.

“I came up with the idea of creating something breathtaking in just a few weeks, but it took years of careful refinements to bring the vision to life,” Aybars Asci explains. “While the general concept was quite simple, the project was a reminder that sometimes complexity is the path to achieving such levels of simplicity.”

The steep terrain of the mountainside played a major role in the architectural design, beginning with rockfall and avalanche mitigation elements. The dual hazard conditions required the construction of avalanche and debris flow barriers on the uphill side, while a permanent soil retention system, including anchors tied into the mountainside, created level platforms for the house.

Achieving a Delicate Balance The three cascading pavilions are cantilevered and stacked in recession. Their composite steel and timber floor framing provides a tectonic lightness of the glass boxes that reinforces their anchoring to the stereotomic mass of the retaining walls. Abundant use of natural finishes further contributes to the integration of the built environment and its natural surroundings, including split-face marble brick, with exposed natural patterns, that finishes the exterior retaining walls.

“There is a sort of symbiotic relationship, where the cantilevers create a delicate connection between the light-footed house and the majestic mountain,” says Asci. “The retaining walls merge into the slopes and integrate with the mountain, while the pavilions, suspended in space, create a counterpoint of lightness.”

Panoramic Absorption The interior of the glass pavilions features Northern cedar flat ceiling planes, designed with recessed lighting to eliminate any hanging obstructions to the breathtaking views. The wide-open floor plate is framed in glass courtesy of window panels separated by minimal ¾” wide mullions, providing uninterrupted horizontal views to the south, where only Aspen trees rise in vertical contrast. At more than 9,000 feet of elevation, the insulated window panels presented another challenge, resolved through the insertion of capillary tubes to mitigate atmospheric pressure differences between the manufacturing site of the insulated-glass units and the high altitude of the house.

The design layout of the three-level glasshouse provides a separation between privacy and togetherness. Entry to the glasshouse is accessed from the ground level, where a stone pavilion and mudroom sit adjacent to a garage, guest bedrooms, and a game room. Ascending to the middle level, the open floor plate contains the Glass House common spaces, including an open kitchen, an unobstructed, expansive living room, and an adjacent dining room. The upper level is reserved for the three-bedroom family living quarters.

On the two upper levels of the glasshouse, the interior polished concrete floors extend seamlessly beyond the glass walls to expansive exterior deck space, courtesy of the cascading design of the cantilevered pavilions. An external pathway on the middle level leads to a cylinder wooden-clad soaking tub, designed along with landscapers to be a solitary point of discovery.

Living the Dream The completed project immerses its inhabitants in nature, where lines of snow on the railings and rooftop in winter blend into the striations of snow on the overhanging cliffs. Embraced by the mountains of the moonlit canyon, and framed by the stars above, the concept of living in a glass house is now a dream come true.

“From my very first visit to the site, I knew that this project would require decisiveness and clarity and that it would draw upon everything that I have come to know and feel like an architect,” concludes Aybars Asci. “I felt the responsibility of touching the land, and I understood that that came with the responsibility to create the very best that the human spirit can offer.”

Telluride Glass House in Colorado, USA – Building Information

Architects: Efficiency Lab for Architecture AOR: Tommy Hein Architects Interior Design: Gachot Studios Structural Design: Skidmore, Owings & Merrill LLP MEP: Bighorn Consulting Engineers Civil Engineer: Uncompahgre Engineering Geo-Hazard Engineer: Trautner Geotech Landscape Design: Caribou Design Associates General Contractor: Finbro Construction

About Efficiency Lab for Architecture PLLC “Efficiency is Beautiful” is the ethos behind Efficiency Lab’s research-driven design philosophy for building a more sustainable, inclusive, and equitable future. The firm applies first-principles thinking to every new challenge, combining conceptual clarity and analytical processes, including the use of algorithmic tools and building performance modeling, to pave the road towards greater efficiency in the built environment.

In its quest to develop an architectural language engraved in nature, the firm’s dedicated team of design professionals provides the full range of services, including master planning, feasibility studies, architectural design, interior design, furniture design, product design, efficiency consulting, Building Information Modeling (BIM), data visualization, and more.

Photography: Josh Johnson

Telluride Glass House, Colorado images / information received 080721

Location: Telluride, Colorado, USA

Colorado Buildings

Colorado Architecture – selection of contemporary architectural designs:

Colorado Buildings

Owl Creek Residence, Snowmass Architects: Skylab photo : Jeremy Bittermann New Residence in Snowmass

CoorsTek Center at the Colorado School of Mines Architects: Bohlin Cywinski Jackson with Anderson Mason Dale Architects photo : Nic Lehoux CoorsTek Center at the Colorado School of Mines

New Aspen Art Museum Building Design: Shigeru Ban Architects photo by Aspen Art Museum New Aspen Art Museum Building

US Air Force Academy CCLD, Colorado Springs Design: Skidmore, Owings & Merrill LLP (SOM) picture © SOM US Air Force Academy CCLD

La Muna, Aspen Oppenheim Architecture + Design photograph from FTI Aspen House

Colorado Plateau House

Denver Airport Building

American Architect

American Houses

Comments / photos for the Telluride Glass House, Colorado design by Skylab Architecture page welcome

The post Telluride Glass House, Colorado appeared first on e-architect.

0 notes

Text

Structural Engineering Services in Colorado - steel construction detailing

Steel construction detailing is a main basic structural engineering configuration specialist co-op and offers exceptionally proficient and apropos imaginative auxiliary designing administrations covering a wide assortment of common, business, private, mechanical, geotechnical, and ecological task prerequisites. O2I attempts calculated, fundamental, and definite plan extends in the territories of basic building structure and investigation.

We offer other services :-

* Steel detailing Service * Stair and handrail detailing * Pre Engineered Building Service * Precast panel detailing * Steel Fabrication detailing * Point cloud to BIM Services * Structural Engineering Service * Building Information Modeling * Joist detailing services * Rebar detailing Service * Curtain Wall detailing * Laser Scanning

For more info:-

Website:- https://www.steelconstructiondetailing.com/structural-engineering-services.html E-mail:- [email protected] USA : + 1 - 763-270-8285 India : +91-79-4003 -1887 Aus : + 61 - 290-991-755 UK : + 44-208-819-5832 NZ : + 64-210-296-7467

#Structural Steel Detailing#structural steel shop drawings#Steel Structural Detailing#steel structural design#steel structural drawings#structural steel design#structural drafting#Structural Engineering Services

0 notes

Text

Get the Best and Affordable Miscellaneous Steel Detailing Services in Tampa, USA

Partnering with Offshore Outsourcing India for your Miscellaneous Steel Detailing Services requirements in the United States for any commercial, residential, or industrial project will give you access to our dedication to excellence and unbeatable results for your investment by choosing us for your CAD Outsourcing Services requirements. With our 3D Modeling Expertise, we are digitizing AEC Building Sector USA by promptly responding to clients' CAD needs and offering the best CAD drawing solutions for their upcoming BIM projects in the shortest time frame of time with the highest level of efficiency.

Our Services

Steel Fabrication Drawings Services

Steel Shop Drawing Services

Steel Structural Detailing Services

Stair Handrail Detailing Services

Joist Steel Detailing Services

Miscellaneous Steel Detailing Services

We offer Tekla Steel Detailing Services across the USA with cities like New York City, Indianapolis, Colorado Springs, Charleston, San Diego, Raleigh, Jacksonville, San Antonio, Seattle, Oklahoma City, Nashville, San Francisco, San Jose, Houston, New Jersey City, Oakland, Bakersfield, etc.

Visit us

https://www.offshoreoutsourcing-india.com/shop-drawing-services/miscellaneous-steel-detailing.html

#SteelFabricationDrawingsServices#SteelShopDrawingServices#SteelStructuralDetailingServices#StairHandrailDetailingServices#JoistSteelDetailingServices#TeklaSteelDetailingServices#CADServices#California#Florida#Texas#SteelDetailingFirmUSA#Tampa

0 notes

Text

Contact Us SolidWorks Mechanical Detailing Outsourcing Services Provider in New Castle, USA

Get high quality SolidWorks Mechanical Detailing Services at affordable rates. CAD Outsourcing Consultant offers specialized Mechanical Drafting Outsourcing Services including Mechanical 3D Modeling Services, Autodesk Inventor Mechanical Drawing Services, Mechanical BIM Outsourcing Services, Mechanical Shop Drawing Services and Mechanical Fabrication Drawing Services. Our team of skilled Mechanical Design Draftsman and Drafters provide accurate and precise Mechanical Detailing and Drafting Services. Hire us for CAD Services in Inventor, SolidWorks, Revit and AutoCAD. Contact us today to outsource your Mechanical Design and Detailing needs.

Why choose CAD Outsourcing for Mechanical Detailing Outsourcing Services:

- Expertise and Experience

- Comprehensive Services

- Skilled Professionals

- Latest Softwares

- Cost-Effective Solutions

- Time Efficiency

- Quality Assurance

We offer our Mechanical Detailing Services New Castle and covered other cities: California, New Mexico, Kansas, Las Vegas, Arizona, Colorado, Chicago and New York.

Visit Us: https://www.cadoutsourcing.net/mechanical-services/newcastle-mechanical-services.html

Software Expertise: AutoDesk AutoCAD, Revit, Tekla Structures, STAAD.Pro, SOLIDWORKS, ZWCAD, AutoDesk Navisworks, 3Ds Max, Inventor, Showcase, ReCap, Infraworks 360, Civil 3D.

For more Details: Website: https://www.cadoutsourcing.net/cad-design-drafting/mechanical-services.html

Contact us for more information or to request a quotation. We would be happy to discuss your Mechanical Detailing Services needs.

Check Out my Latest Article "The Benefits of Mechanical Detailing Services in the AEC Industry?" is now available on

#MechanicalDetailing#MechanicalDrafting#InventorMechanicalDesign#Detailing#CADServices#Building#Architecture#Structure#BIM#B1M#Engineering#Construction#CadOutsourcing#CAD#CADD#CADDesign#Architect#Engineer#CADDraftman#BIMModeler#CadOutsourcingCompany#CADDrawing#CADDrafting#AutoCAD#Revit#TeklaStructures#Inventor#SolidWorks

1 note

·

View note

Text

Revit 3D MEP BIM Services Colorado - Steel Construction Detailing

Steel Construction Detailing provide cost-effective Revit 3D MEP BIM Services in all over the world. We offer our Building Information Modeling services by rendering 3D 4D and 5D models that are accurate and standardized. We are experts in Architectural MEP BIM Services, Structural steel detailing, Revit 3D MEP BIM Services, Revit 3D Modeling Service for residential, commercial and industrial buildings.

For More Details : -

URL: www.steelconstructiondetailing.com Email : [email protected]

315, Patel Avenue Opp Grand Bhagwati, S G Road Ahmadabad-380059, India

Office : 07940031887

#Building Information Modeling Services#BIM#Revit#Revit 3D Modeling Service#Structural steel detailing#Architectural BIM Services#Structural BIM Services#MEP BIM Services

0 notes

Text

7 Examples From General Contractors of Wins With Cold-Formed Steel Framing

The use of cold-formed steel (CFS) framing in projects reduces delivery times and cuts costs. Here are 7 examples where general contractors won big with CFS. It may not be the biggest secret in the world, but the “secret sauce” in building construction on many projects today is cold-formed steel (CFS) framing. “The quality is just phenomenal,” says Brandon Bergholz, project manager at Mortenson Construction, a large general contractor.

While companies don’t normally like giving away their secrets, in this case CFS is lowering commercial construction costs and cutting delivery times. The value of CFS framing is catching on among general contractors (GCs).

Here are seven benefits to GCs when CFS framing systems are part of their projects:

1. Shave months off the construction cycle Normally, it would take a year to complete the enclosure of an 831,000-square-foot hospital, but construction on the Exempla Saint Joseph Replacement Hospital in Denver, Colorado was cut by more than seven months. Mortenson Construction used premanufactured cold-formed steel exterior panels. The 30-foot by 15-foot exterior panels, each built off-site in controlled conditions, made installation much quicker than “stick-built” construction on-site.

Construction on Victory Hall, a 163,415-square-foot dormitory at the University of North Texas, Denton, Texas, came in four months ahead of schedule — and just in time for the new school year. The design-build team at the university switched from concrete construction to a load-bearing CFS framed wall system after construction had begun in order to meet stringent schedules and cost constraints.

2. Work during winter A six-story student residence at the Trafalgar Campus of Sheridan College was built over a tough Canadian winter, when temperatures reached -10 to -20 degrees Celsius [14 to -4 degrees Fahrenheit] for three months. The structure’s foundation was poured in the fall, and rather than using concrete during the winter, CFS framing was specified. This was advantageous to the GC since heat was not required to install CFS, which would have been the case for masonry or concrete load-bearing systems.

3. Reduce in-place weight Pound for pound, CFS framing is much lighter than concrete, and it has a high strength-to-weight ratio and resists warping, mildew, and cracking. At City Green condominiums in Milwaukee, Wisconsin, exterior, load-bearing CFS framing walls support nine stories and steel balconies. Yet, the CFS framing design decreased the load on the foundation in comparison to other systems. The developer says the CFS framing system allowed for a reduction in the amount of concrete needed for each footing, which he thinks saved money.

4. Reduce carpentry man-hours Since CFS framing is durable, non-combustible, cost-effective and easy to work with, it’s the perfect framing material for prefabricating panels. At Exempla Saint Joseph Replacement Hospital, panelization reduced the number of carpentry man-hours by 30 to 40 percent.

5. Reduce scaffolding Stephen Bradford, a project manager with South Valley Drywall, likes panelized framing because it eliminates building by piecemeal, which includes setting up scaffolding on site and then framing, sheathing and insulting exterior panels by hand. At Exempla Saint Joseph Replacement Hospital, reducing the scaffolding cut costs and opened up the job site. All trades got on site sooner, and were not obstructed by excess equipment.

6. Integrate with Building Information Modeling (BIM) At Exempla Saint Joseph Replacement Hospital, the Mortenson Construction team met with the architect and framing contractor six to seven months ahead of the installation of prefabricated CFS panels. BIM helped the players understand the design and facilitate collaboration. The BIM integration and advanced work with the architect enabled the framing contractor to make recommendations during the design process rather than holding up construction with decisions required on-site. Approved changes were added immediately to the information modeling software.

7. Cut financing costs By using load-bearing, CFS framing, hollow-core concrete plank floor joists and CFS roof joists, the Sheridan College student residence project was able to shave three months off its construction cycle. As a result, the project saved an estimated $300,000 just in financing costs.

Across North America, GCs are using CFS framing to cut time, save costs, solve problems, improve modeling, and ensure a smoother decision-making process and workflow for all teams involved.

Yes, GCs benefit when projects use CFS framing systems. Do you agree? Let us know, and share tips you have for working with CFS framing in the comments area below.

roll forming steel c purlin roll forming machine price china roll forming machine metal roofing machine prices

#metal roofing machine prices#roll forming steel#c purlin roll forming machine price#china roll forming machine

0 notes

Text

The evidence is in 20+ stats that prove that BIM Technology delivers ROI

Building Information Modeling helps in generating an intelligent multi-dimensional digital representation of the functional and physical characteristics of a facility. It gives engineers, architects, and construction professionals/builders key insights for planning, designing, and building infrastructural facilities efficiently by facilitating seamless team collaboration. The successful implementation of BIM results in increased productivity, reduced wastage, cost control, and an improved ROI on the overall construction investment. But is that just what we say?Well no. BIM application in construction has been transforming the construction industry ever since the mid-‘80s. Thirty years later, today, the world has taken to BIM technology to streamline and ease the infrastructural designing and execution. Countries around the world have benefited from BIM integration into their Construction Services Management.As per a

McGraw Hill report

, two-thirds of the users of

Architectural BIM Modeling

have reported a positive ROI on their investments.

83% of the expert BIM users experienced a positive ROI

93% of the users strongly believed in the potential of gaining more value in the future

The report offers some great examples of construction projects across the globe that have benefitted from the use and implementation of

BIM services

. There are, of course, other such great examples too. Here are 15 stats that prove that BIM delivers value:

University of Colorado, Denver Health Sciences Centre

An 11-story bio-medical facility spread over 540,000 sq ft area with an expected budget of USD 201 million. BIM delivered:

74% reduction in construction Request for Information (RFI) during the foundation phase

47% reduction in construction RFI during the steel erection phase

An overall decrease of 37% in the coordination of RFI

The project progressed two months ahead of the scheduled completion timeline and six months ahead of another comparable project

The project team estimated a reduction of 50% in both labour and in crashing of the work schedule

Sutter Health Medical Centre, Castro Valley

This is a notable project that implemented BIM. A USD 320 million project that reported a savings of over USD 1.2 million!

Department of Energy, US

A USD 100 million project spread over 45,000 sq ft area saved a whopping USD 10 million on the estimated project cost through the clash detection features of BIM. The team found about 500 serious problems that were rectified during the design stage driving the massive cost saving on the project.

Aquarium Hilton Garden Inn, Atlanta

An expansive project constructed at an estimated budget of USD 46 million. The facility is spread over an area of 484,000 sq ft. It consisted of 14 stories, 242 hotel rooms, parking space for 700 vehicles and a 25,00 sq ft retail space at the ground level. By using BIM at design phase:

55 clashes were identified at early design development stage, helping in reducing the cost by USD 124,500

Over the period of the entire design phase, more than 590 more clashes were detected

The overall estimated cost savings on the project were USD 800,000

Nagpur Metro Rail Project, India

It is one of the major infrastructure development projects in India today. In this project, an elevated metro corridor, spanning over 38.2 km across the city with 36 stations and 2 depots is being constructed. The construction team has reported that with BIM:

12% of cost savings have been reported so far in terms of logistics and staff days. This is expected to rise to 15% by the end of the project

The anticipated reduction in overhead costs by the end of the project is 5%

An 8% cost saving is expected over the DPR projected costs

An overall cost saving of 10% has been recorded so far which amounts to be INR 800 crore approximately

6. Tata Consultancy (TCS) Mumbai, IndiaThe Indian IT giant was duplicating an already built building at one of its campuses spread over an area of 74,000 sq ft. The biggest challenge the team faced was the unavailability of as built data. The construction drawings that were available only available were substantially different from the actual building and no accurate as-built data was available. The team used BIM to build a model focussing on Clash Detection and Resolution (CDR).

Estimated time-frame using conventional method for coordination was three months

With BIM, the team completed this in one month which resulted in time-saving of around 66%

Of course, these savings in time, cost, effort, and improvement in construction quality is the norm rather than the exception when using BIM. And

Mechanical Electrical Plumbing

(MEP) and Building Services Engineering folks agree.An elaborate survey to assess the many characteristics of BIM usage and implementation by Becerik-Gerber and Rice highlighted the following:

41% of the respondents realized an overall increase in project profitability

55% of respondents said that BIM helped in cutting project costs

Out of that 55 %, 50% claimed a staggering 50% cut in the project costs

58% of respondents found a 50% reduction in the overall project duration

There is no longer any room for doubt. These stats prove the importance of BIM in delivering higher ROI from the investments made in construction. BIM achieves this through controlling costs, better planning, saved time and accurate estimations for raw material and time. It’s time for you to consider your own

BIM Implementation

Plan and BIM Execution strategy.

3d Architectural Visualization Services Revit Family Creation Point Cloud to Bim Architectural Bim Services Bim Modeling Services Structural Bim Services

0 notes

Text

CFC Construction and Cypress Real Estate Advisors Utilize Prescient’s Digital Thread for Denargo Phase III

Latest Project in Denver Marks Third Collaboration Amongst Companies

Demonstrates Increased Value Prescient Brings to Each Stage of Construction Process

DURHAM, N.C. and GOLDEN, Colo. and AUSTIN, Texas, Jan. 29, 2019 (GLOBE NEWSWIRE) — CFC Construction, Cypress Real Estate Advisors and Prescient today announced a collaboration whereby CFC Construction and Cypress Real Estate Advisors will utilize Prescient’s digital thread for Denargo Phase III. Denargo Phase III is the third phase of developments in the Denargo area of Denver for Cypress, and Prescient’s fully integrated BIM design and building platform will dramatically reduce the time and cost of construction.

Denargo Phase III marks the third project in the Denver area in which CFC Construction and Cypress Residential have employed Prescient’s Digital Thread. This project, on a 2.5-acre site, is a 337-unit apartment building with a garage for more than 400 cars, approximately 10,000 square feet of retail space and 8,000 square feet of restaurant space in the RiNo’s Denargo Market area.

CFC Construction, Cypress and Prescient have collaborated on a number of projects, strengthening their integrated approach that leverages Prescient’s proprietary software and hardware platform to deliver even greater value to clients. Previous projects include 13th & Delaware Apartments and Jefferson View Apartments, which have served as the prototype for Prescient’s latest innovation: external sheathing. CFC Construction collaborated with Prescient to develop and implement this first in the nation use of Prescient’s innovative external sheathing system. This advancement means that external panels are finished at the same rate that Prescient completes construction on each floor, allowing other trades that require a “dried-in” environment to start working sooner, therefore saving months on the overall project schedule.

“I am thrilled to be able to work with Prescient once again on another exciting new development in the Denver area,” said Chase Hill, Denver Partner for Cypress Real Estate Advisors. “We choose to partner with Prescient for a number of reasons, including the speed in which they deliver on site, the efficiency of their design and the environmental benefits. At Jefferson View, we were able to complete 248 units on a 0.8 acre site which would not have been possible with concrete. Additionally, Prescient projects produce minimal waste, which helps us to earn an NGBS certification. We always look forward to our collaboration with the Prescient team, and the speed and ease at which they help us to complete our projects.”

“We have a proven track record of success when we collaborate with Prescient,” said EJ Olbright, Chief Executive Officer of CFC Construction. “We started our first project with Prescient at the request of Cypress. We soon discovered the value and many benefits of working with their digital technology platform, including the increased speed and precision manufactured products. We were impressed when Prescient finished their work eight weeks ahead of schedule on the 13th & Delaware Apartments, which allows us to further compress other trades’ schedules. We continue to apply “lesson’s learned” from each project on to the next one, and we are implementing many advancements in timing and efficiency at Denargo Phase III. That’s also why we pushed them to develop the external sheathing for Jefferson View. Working with Prescient is a huge advantage in the construction industry, and we look forward to beginning this new project together soon.”

“It has been a pleasure to work on consecutive projects in the Denver area with both Cypress and CFC Construction,” said Magued Eldaief, Chief Executive Officer of Prescient. “They’ve challenged us to innovate on our approach and ultimately deliver the overall project much faster, with closer integration and collaboration among key subcontractors. There is no doubt we improve as a team with each new project. Along with this, both CFC and Cypress capture additional ‘soft’ benefits of working with our team, including compressed and predictable schedules, faster time to both market and rental income and increased efficiency in designs yielding greater income per acre. Denargo Phase III will be our 19th development in the Denver area and once again validates the unique value proposition of our technology and its growth potential in additional U.S. markets.”

To date, Prescient has completed 35 buildings for a total of 5.5M square feet of construction with another 4.7M under development. Prescient has active projects underway or completed in 16 states: California, Colorado, Florida, Georgia, Illinois, Kansas, Kentucky, Michigan, Missouri, Nebraska, New York, North Carolina, Oklahoma, South Carolina, Texas and Virginia.

Since Prescient’s founding here in Denver in 2012, the platform has been utilized for eleven finished buildings, eight in-progress projects and soon Denargo Phase III, accounting for more than 2.9 million square feet of construction in the Denver area.

CFC Construction has delivered comprehensive and reliable preconstruction and construction services in Colorado for over 40 years. From the Front Range to the mountains, experience, professionalism and dedication to our clients has earned CFC success in project delivery and client loyalty. We are proud to continue our partnership with Prescient and Cypress Real Estate Advisors.

About Prescient

The foundation for Prescient’s revolution is a standardized light gauge framing system that utilizes proprietary software applications which create a design and construction platform. Prescient’s proprietary software utilizes a Digital Thread that connects projects from the initial architectural design through the finished building. Prescient’s precision manufacturing technology, including robotics, laser-cutting systems and state-of-the-art numerically controlled flexible manufacturing systems, creates a seamless approach, meaning higher productivity, higher quality, fewer last-minute conflicts on site, less waste, shorter schedules and a better ROI.

Bringing the Digital World to the Physical World. The Prescient Digital Thread is based on a model-centric design and planning platform that liberates project stakeholders to plan better and execute better. Our thread connects projects from the initial architectural design through the finished building. As a result, a project is no longer a series of isolated steps with familiar breakdowns and gaps. Instead, it becomes an orderly progression through a repeatable flow, connecting developer, designers, suppliers and contractors at every step. This seamless approach means higher productivity, higher quality, fewer last-minute conflicts on site, less waste, shorter schedules and a better ROI.

Integrated Manufacturing. Prescient uses precision manufacturing technology including robotics, laser cutting systems and state-of-the-art numerically controlled flexible manufacturing systems to deliver buildings with very tight tolerances, comparable to the automotive industry. Prescient’s digital thread integrates planning & design with manufacturing & installation.

Established in 2012, Prescient is aiming for nothing less than a revolution in the way buildings take shape through new levels of cost efficiency, environmental sustainability and quality of outcome for all participants. Prescient’s platform ensures buildings perform better, cost less and take less time to build by employing a digital thread for leading-edge integrated design, engineering, manufacturing & installation.

We are Prescient. Our mission is Attainable Housing for All and we are achieving that by Revolutionizing The Building Environment.

For more information, visit the company website, Twitter feed or Facebook page.

Media Contact, for Prescient Blair Hennessy, Abernathy MacGregor 212-371-5999 [email protected]

CFC Construction Contact: Sean Smith, Business Development Manager 303-277-8600 [email protected]

Source Article

The post CFC Construction and Cypress Real Estate Advisors Utilize Prescient’s Digital Thread for Denargo Phase III appeared first on UP-LABEL.

Learn More: http://www.up-label.com/cfc-construction-and-cypress-real-estate-advisors-utilize-prescients-digital-thread-for-denargo-phase-iii/

0 notes

Text

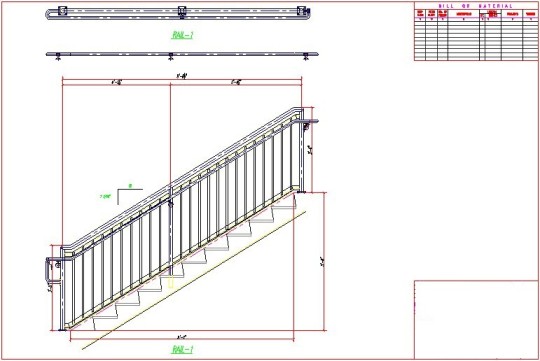

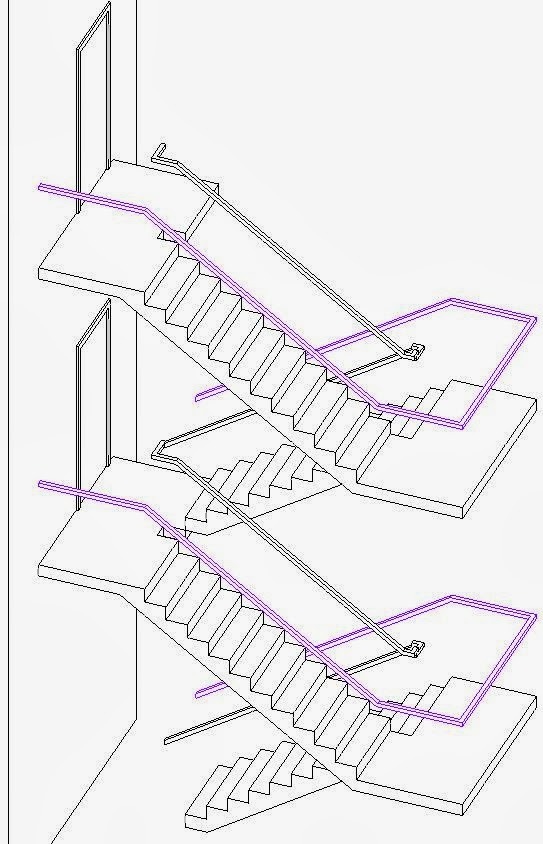

Stair and Handrail Detailing in Colorado - steel construction detailing

Steel Construction Detailing is an expert flight of staircase handrail design organization worked in stair handrail design and itemizing Services. stair handrail design steel is one of the most significant strides for development industry. The procedure of steel step specifying requires more consideration of steel detailers as it requires numerous monotonous estimations to decide the necessary measurements. Steel Construction Detailing is your finished redistributing accomplice in the field of stainless steel stair handrail design, flight of stairs drawings and flight of stairs structures. We pride our master's steel detailers who bolster inventive, on-schedule and seriously cost redistributing steel flight of stairs specifying administrations to our overall customers.

We offer other services :-

* Steel detailing Service * Stair and handrail detailing * Pre Engineered Building Service * Precast panel detailing * Steel Fabrication detailing * Point cloud to BIM Services * Structural Engineering Service * Building Information Modeling * Joist detailing services * Rebar detailing Service * Curtain Wall detailing * Laser Scanning

For more info:-

Website:- https://www.steelconstructiondetailing.com/stair-handrail-detailing.html E-mail:- [email protected] USA : + 1 - 763-270-8285 India : +91-79-4003 -1887 Aus : + 61 - 290-991-755 UK : + 44-208-819-5832 NZ : + 64-210-296-7467

#staircase handrail design#stair handrail design#stair handrail design steel#staircase handrail design steel#staircase railing design stainless steel#stainless steel stair handrail design#stair and railing design

0 notes

Text

Get the Best Shop Drawing Services in New York City, USA

Offshore Outsourcing India's experience in the AEC Sector makes us one of the best Companies in the USA for Outsourcing Shop Drawing Services at unbeatable rates. We are the leading CAD Outsourcing Services provider in the United States, providing detailed, high-quality CAD drawings for various BIM projects utilizing our excellent 3D Modeling Technology in the building business. Contact us today to learn how our low-cost CAD services can help you with your project.

Our Services

Architectural Shop Drawings Services

HVAC duct Shop Drawings Services

Steel Fabrication Drawings Services

Facade Shop Drawings Services

Mep Shop Drawings Services

Structural Shop Drawings Services

We offer CAD Drawing Services across the USA with cities like Indianapolis, Colorado Springs, Charleston, Columbus, Raleigh, Jacksonville, San Antonio, Seattle, Oklahoma City, Nashville, etc.

For more information click on the link below

#ArchitecturalShopDrawingsServices#HVACductShopDrawingsServices#SteelFabricationDrawingsServices#FacadeShopDrawingsServices#Chicago#California#Texas#NewYorkCity#CADservices#BIMproject#CADShopDrawingSolutions#CADDrawingSolutions#CADServicesUSA

0 notes