#Battery pack testing solution

Explore tagged Tumblr posts

Text

How Does the Semco SI-I PBCDS 5V 60A 1CH Ensure Consistent Battery Performance?

Achieving consistent battery performance across all cells in a module is critical for reliable lithium-ion battery systems. The Semco SI-I PBCDS 5V 60A 1CH is a cutting-edge battery charge and discharge system engineered to precisely manage individual cell calibration and testing.

This powerful tool is a must-have in any battery making machine setup, as it is designed for accurate lithium battery testing, ensuring cells are optimally aligned in both voltage and capacity. It’s ideal for professionals seeking efficiency and precision in their battery testing and maintenance routines.

Key Features:

High Precision: Voltage accuracy of ±0.001V and current accuracy of ±0.01A.

Wide Voltage Range: Adjustable from 0-5V, suitable for different lithium battery types.

Current Capacity: Handles up to 60A for robust charging and discharging cycles.

Intuitive Display: A 2.4-inch screen offers real-time monitoring and control.

Built-in Safety: Includes protections for under-voltage, over-voltage, over-current, short circuit, and reverse polarity.

Portable & Compact: Weighs just 2.4kg with dimensions of 280mm x 160mm x 94mm.

Optimized Cooling: Operates between -20°C to 40°C in up to 80% humidity.

Applications:

Eliminating voltage imbalances between cells to promote cell consistency.

Battery capacity calibration to ensure each cell meets performance standards.

Widely used in battery R&D labs, battery making equipment, and lithium-ion battery assembly lines.

In summary, the Semco SI-I PBCDS 5V 60A 1CH is a high-precision battery calibration tool designed to enhance battery reliability and extend battery life. Its advanced features and user-friendly interface make it a must-have for anyone involved in lithium battery pack assembly, battery cell making machines, or the lithium-ion battery assembly process.

#5V 60A battery tester#Battery cell testing machine#battery manufacturing equipment#Battery pack testing solution#Battery precision testing equipment#Lithium battery testing machine#Semco battery testing system#Semco SI-I PBCDS 5V 60A 1CH

0 notes

Text

I've now watched 3 YouTubers climb Mount Kilimanjaro.

This is a very high elevation mountain in Tanzania, Africa. It's basically for people who want the thrill seeking experience of Everest without the freezing cold and high risk of death.

Though more people die on Kilimanjaro than on Everest every year. But that is a statistical thing. 30,000 climbers and up to 10 deaths per year vs 600 climbers and 4 deaths per year.

Kilimanjaro is still a huge test of endurance and pushing yourself, but it's a lot safer and you can actually enjoy the experience rather than just be miserable the entire time. Nothing about climbing Everest is fun or enjoyable. It's literally just an exercise in saying you did it. Maybe you get to enjoy the views for a few moments here and there. But most of the time you are just trying not to die. And when you pass "rainbow valley" you are reminded of your possible death.

"Blue, Red, Orange, and Green colored jackets cover the dead bodies forever. Other than bodies, there are colorful garbage dumped, tents, cans, and oxygen tanks. From a distance, this area seems so colorful, like the rainbow; hence it is named the popular Rainbow Valley."

The thing that bothers me about these rich white folks doing this thrill seeking to the top of a mountain is that they don't do it alone. As they are fighting elevation sickness and trying to keep their lunch down, Tanzanian locals are carrying all of their shit up the mountain (while barely breaking a sweat). These porters carry 20kg/44lb packs up and down and get paid $10 per day. And, according to some redditor, tipping them $250 is "sufficient."

But these thrill seeking white people do not actually pay the porters their $10 per day salaries. That would actually be the company hired to arrange all of the trip logistics.

"Ah, so like a Tanzanian travel company books your flights and hires the porters and figures all of that out." you might be thinking.

Of course, that's not how it works.

For Smarter Every Day's trip up the mountain, he paid a company called "Killawarrior."

You pay them $7000.

They arrange everything.

And of that money, your porter gets $90.

The person making sure you get up the mountain alive and carrying all of your shit gets $90 for a 9 day trip on dangerous terrain.

And Gerry from Canada... gets a lot more.

And it's one of those things where... the inclination is to shame and boycott. "Don't go on these trips, the locals are paid nothing." But these are actually very good jobs for them. And they need this work.

It's just like the recent iPhone protest I saw. "Don't buy an iPhone. The battery is made from slave labor in the Congo." (All devices with Li-ion batteries are. And there are 2 billion more Android devices than iPhones. Would someone please start including Google in these protests?)

But if we all stopped buying stuff with batteries, the economy of Congo would collapse. As 9/10ths of their exports are minerals.

I saw a video where they followed a child around who was working on a cocoa farm. There was this 12 year old who would say he is 18, and they ask him how he felt about working on this farm. And he said, "I need this money for my family. My mother is sick and can't work, so I work."

It just seems like if we all stopped purchasing goods made from exploited labor, we'd be screwing a lot of poor and desperate folks. And if rich white folks stopped climbing mountains, those porters would have to settle for lower paying jobs.

So... what is the solution here?

It just seems like everyone is screwed no matter what.

Sorry for the cynical ending. I just got nothing positive or hopeful to say about this.

60 notes

·

View notes

Text

Why does one side of my car's headlights always blow out?

Recurring failure of a headlight on only one side of your car typically signals an isolated electrical, environmental, or mechanical issue affecting that specific circuit. Here’s a step-by-step guide to diagnose and fix the problem:

Common Causes & Solutions Vibration Damage (Most Common)

Why: Rough roads or engine vibrations fatigue the filament in halogen bulbs. The side closer to the engine (e.g., driver’s side in LHD cars) often fails first.

Fix:

Install vibration-resistant bulbs (e.g., Philips XtremeVision, SNGL).

Add anti-vibration pads to the headlight assembly. Moisture Intrusion

Why: A cracked lens, bad seal, or missing dust cap lets condensation corrode contacts or cause thermal shock.

Fix:

Inspect for cracks/haze; reseal with butyl tape or replace the housing.

Use silica gel packs inside the headlight to absorb moisture. Poor Ground Connection

Why: Corroded/loose ground wires cause voltage fluctuations, overheating the bulb.

Fix:

Locate the ground point (near headlight or on chassis).

Clean corrosion with a wire brush, apply dielectric grease, and tighten. Voltage Spikes or Drops

Why: A failing alternator, bad voltage regulator, or weak battery sends uneven power.

Test: Use a multimeter to check voltage at the bulb socket (engine running):

Normal: 13.5–14.5V.

Problem: <12V (wiring issue) or >15V (alternator failure). Damaged Socket or Wiring

Why: Melted/burnt sockets or frayed wires restrict current flow, causing overheating.

Fix:

Replace the socket/harness.

Apply dielectric grease to contacts to prevent corrosion. Faulty Relay or Switch

Why: A failing headlight relay can send erratic power to one side.

Test: Swap the left/right relays (if separate) to see if the problem moves.

Diagnostic Checklist Swap the Bulbs

Move the "good" bulb to the problematic side. If it blows, the bulb isn’t at fault. Check Voltage at the Socket

Test with a multimeter while the headlight is on (ideal: 12–14.5V). Inspect for Moisture

Look for condensation, water droplets, or green corrosion on contacts. Examine the Fuse

Some cars have separate fuses per side; replace even if it looks intact.

Prevention Tips Always replace bulbs in pairs to ensure even performance.

Upgrade to LEDs: More vibration/voltage-tolerant (ensure CANBUS compatibility).

Install a relay harness: Bypasses factory wiring for stable power (e.g., Putco 240008).

Avoid touching halogen bulbs: Skin oils create hotspots that shorten lifespan.

When to See a Mechanic If basic fixes fail, suspect: A short circuit in the wiring harness.

Faulty body control module (BCM).

Parasitic drain overloading the circuit.

⚠️ Ignoring this can lead to:

Repeated bulb replacements ($).

Electrical fires from overheated wires.

Failed safety inspections.

Pro Tip: For recurring issues, a $50 professional electrical diagnostic can save hundreds in guesswork. Most problems stem from grounding faults or voltage irregularities—address these first! 🔧🔦

#led lights#car lights#led car light#youtube#led auto light#led headlights#led light#led headlight bulbs#ledlighting#young artist#race cars#cars#electric cars#classic cars#car#carlos sainz#truck#bmw#lamborghini#porsche#audi#honda#honda555#tohru honda#honda hiroto#kiku honda#toyota#automotive#suzuki#japanese cars

4 notes

·

View notes

Text

INTERMISSION I-IV: BEFORE WE PART WAYS...

Segment taken from Side Quest Story: Lending A Hand

The prosthetic arm looked crude and clunky, a skeletal framework of scrap metal, bolts, and screws. It was functional but basic, powered by an old battery pack.

Nobody expected miracles, but the flaws became more apparent the longer Noam worked on it. The biggest issue was the fingers—they had to be controlled manually with joystick switches, requiring clumsy extra steps.

Clank!

Two fingers and a thumb clamped too hard, shattering a cup in the test.

Jack's eyes widened, alarm bells ringing in her head. There was no way they would put this on the lad and everyone agreed silently.. Noam swept the shards away, terrified as the fingers twitched, almost as if the contraption wanted to grab him, only stopped by its heavy weight.

"That's a bear trap," Freakazoid stated the obvious.

"You don't have to tell me twice. Doesn't help that it needs a 35-kilo battery, and a controller that short-circuits!"

Frustrated, Noam yanked out the wires, watching the disastrous metallic beast power down.

"Alright. What do we need?" Crane asked.

"Nothing," Noam replied, slumping in his seat. "Hate to break it to you, but you're gonna need hardware. Know anyone who can help?"

"If we were in the Outskirts, the Grads might have an idea," Jack offered.

"Any chance they can help out?"

Jack shook her head. "It's hard enough traveling along the Coastline without the military breathing down our necks."

Crane wasn't an engineer, but he knew this mechanical upgrade was a long shot. The prototype on the table wasn't even the first attempt.

"...What about asking Tolga and Fatin?"

Jack's eyes widened in disbelief for hearing the worst suggestion possible. Noam, however, looked confused—those names weren't as infamous to him as they were to both Runners.

Crane already regretted the suggestion before he said it. They were the last people on Earth he'd ever want to ask for anything.

"No," Jack said firmly.

"I don't like it either," he admitted.

"Absolutely not."

"They're difficult, sure-"

"That's not my problem. You're asking two mad scientists to work on a child's arm."

"They're not going to strap a rocket launcher on him," Crane said, though Jack immediately picked on the slight doubt in his voice, narrowing her eyes further.

Because he could actually see those two do the impossible. Not for a kid, hopefully.

Still, what other options did they have?

"Let me talk to them."

All of a sudden, Jack crossed her arms, brow furrowed. Why?

This was the first time Freakazoid had volunteered to talk to someone, let alone two people Jack could barely tolerate.

"I mean, sure. Give it your best shot."

"Trust me. They'll make that hardware for us."

No backing down from Freakazoid—another first for Jack. Was he really sold on the brothers' brilliance for making that harpoon gun? Jack glanced over to Noam, hoping for an alternative. Another safer option.

"I got nothing," Noam said, still lost in the conversation. Any solution seemed better than his failed contraptions so far.

Jack didn't feel any more confident, but she decided to let it play out.

"I hope you know what you're doing," she muttered, both amused and puzzled, as she walked out of the garage.

Crane followed, initially confident. But as soon as he left the garage—with no one paying attention—he groaned, his steps feeling heavier.

"...Maybe they won't recognize me. My voice's fucked anyway."

Quest Stories, Special Delivery, Out With a Bang and Lending a Hand can be found at these links: FFN and AO3.

#dying light#dying light game#DL: The Descent#dyinglight#fanfiction#dying light fanfiction#intermission chapters#intermission#Kyle Crane#Mad Jack#ocs#fanfic#quest stories#Dying Light: The Descent

10 notes

·

View notes

Text

In one fluid motion, the director slings the battery compartment of the exo-pack over her shoulder before sealing the mask tight over her face; its application has become old hat. Stepping outside the steel airlock door of the module, sharp eyes search the SecOps patrol sent to be their escorts. The need to relocate this lab is long overdue with large aerial transports into and out of this region a no-go. With time ticking and delicate specimens of fungi in various testing stages for biofuel production inside, it seems HQ finally figured out a solution.

A glance is taken at the mammoth-sized jungle terrain vehicle before sight falls on one of the two Project Phoenix’s recoms sent with the patrol. Good, she thinks, her steps darting towards the military-clad hybrid, her chin lifting incrementally to match his eyeline. Better use of these expensive soldiers than simply sending them after Sully.

“Corporal. Director Landry. Glad you could make it.” Curt but polite introduction comes with a small nod before her hands fold at her front. “So, the decision is to haul it out by ground? What’s the trajectory?”

@badtrigger (Mays) // p.s.

20 notes

·

View notes

Text

US Army's Next-Gen Hybrid Tactical Vehicle To Replace Humvee Tested In Germany

The US Army's 3rd Brigade, 10th Mountain Division, recently tested General Motors Defense's Infantry Squad Vehicle (ISV), built on the chassis of a Chevrolet Colorado truck, in the snowy Bavarian mountains of Germany.

GM Defense's mobility solutions team designed the ISV with commercial off-the-shelf parts. ISV is based on the Chevrolet Colorado ZR2 midsize truck platform, using a 2.8L Duramax turbo-diesel engine with an advanced 12-module battery pack.

"The testing occurred during the annual Combined Resolve 25-1 exercise, where the Army's 3rd Brigade, 10th Mountain Division, maneuvered the vehicle across various operational scenarios, demonstrating its adaptability and effectiveness in challenging terrains," Interesting Engineering wrote in a note, adding, "The trial emphasized ISV's capabilities in advanced reconnaissance missions, which are crucial for troops to collect and transmit vital battlefield intelligence, especially in adverse conditions."

By 2024, the ISV completed trials with the United Arab Emirates Armed Forces, testing the vehicle's offroad capabilities in a 1,250-mile journey across highways, dunes, soft sand tracks, and rocky walls while carrying maximum payload capacities.

4 notes

·

View notes

Text

How it's going:

Came home from work on the morming of the 16th and noticed that some things were moved around that I don't remember touching. (A shelf under my bed and some stuff on my coffee table)

I had a wedding that I was attending that afternoon, so didn't really have time to look into it and just kinda chalked it up to maybe I just like knocked them out of place by accident at some point and just didn't notice. Immediately went to bed.

Woke up and immediately left to go to the wedding. Had a wonderful time, drank a good bit, and got back home around 8pm.

Now noticing things aren't just moved. Somethings are missing. Snoop a bit further and find purposeful damage to a piece of furniture and signs of forced entry on my basement back door. Someone broke into my house.

Notably and weirdly nothing valuable was stolen. My PC, TVs, Switch, Monitors, Tablets, etc. were all fine. To the best of my knowledge they stole: A Bluetooth speaker (annoying but not the worst thing to lose), a knife my Grandad gave me before he died (the one thing i actually really hate that I lost), a half used pack of AAA batteries (rude, also why?), and a junk box I kept behind my computer monitor that was 90% full of old birthday/ Christmas cards that I just couldn't bring myself to throw away. (???)

After filling a police report, proceeded to order brackets to reinforce my basement door, better locks, and some outdoor security cameras.

The problem is, that stuff isn't showing up for a few days and I'm due back at work tonight for one last night shift before a long weekend and I'm worried this might have just been a casing break-in.

So the plan:

Step 1: reinforce basement door.

Not a prefect solution, but trying to force the lock and deal with the wedged 2x4 isn't going to be easy, they'd have better luck breaking the glass, which I'm hopeful is too risky to try.

Step 2: Create the illusion that the house is occupied.

External lights and most internal lights are on. Ace up my sleeve though is the 11 hour VOD of Jerma playing Seaman on my living room TV. It's long enough to cover the entire duration of my shift and it's mostly just audio of someone talking with very few sound effects.

(Note the damaged record console, spot that hid the sound bar was sliced open by whoever broke in)

Step 3: Call upon "The Boys"

My wonderful amazing friends agreed to help watch a livestream of my Webcam to keep an eye out for movement. (A special thanks to @nermish @cefpodoxime @admiralpickle among some other non tumblr mutuals)

Step 4: finishing touches.

A) Set up an alt account on discord so I could watch my own camera stream from work on my laptop.

(Shout-out to @cefpodoxime for this amazing alt pfp that he slammed out in record time for my new laptop account.)

B) Since the camera doesn't have great view of the entire living room decided to rig a noise trap to alert the stream if some one comes up from the basement.

Ended up adding another 4 or 5 cans after this pic was taken and stacked them taller to ensure a good clatter noise. Tested how it sounded on the stream and it was definitely distinctive.

And C) Nermish asked if we could rig up a mirror so the stream security could watch Jerma in the reflection.

So, I give you the final view:

Note the absolutely miniscule reflection coming from the couch in the next room. There's your jerma stream. Combined with the muffled audio that accurately sounds like Jerma is in the next room. This is easily the worst best way to watch a jerma stream.

At time of writing I am 4ish hours into my 10 hour shift and so far no sign of trouble. Will update if something happens or not. But honestly the absurdity of this set up has made the entire ordeal easier to stomach.

#jerma985#burglary#i can not express how much i love my friends#how all of them were ready to drop anything to help out#warms my heart#long post

7 notes

·

View notes

Text

Well I have

My emergency inhaler

My allergy nasal spray

Usually a vape

Possibly my weekly med containers depending on where I'm going

A small travel hairbrush

Nail clippers

2-3 disposable menstrual discs

My keys (which have a set of ear picks on them)

A phone cord

My Kindle and charger cable for that

Usually a USB wall box

An external battery pack. A big one. My battery sucks ass and I have a lot of devices.

A set of earbuds

A hard-covered spiral notepad and a few pens

Avmechanical pencil and lead

A pocket knife

Aome band-aids

Neosporin

Mini sewing kit

Eyeglass repair kit

Some rescription-strength Aleve

A mini bottle of contact lens solution

A contact lens case

Eye rewetting drops

Mini playing cards

Chapstick

A few Tylenol packets

Matches and a lighter

Dental floss

Wound seal swabs

Rolaids

My blood sugar testing kit (which has a bunch of alcohol swabs in it to go with the band-aids and neosporin).

Sometimes I also remember to stock a few single-use super glue packs in there.

I often lock my wallet up in my car bc my neighborhood is ridiculous and I have a car that looks like hot garbage. it's a biggish wallet, billfolfld-style, so I actually use like a purse that's a mini backpack.

If I'm just going to run an errand, I'll usually just bring my phone and my keys. My phone fits in the wallet (which is in the car) and the keys clip on to the wallet's zipper pull.

But see, the thing about being any age older than like.... 28? Is that you wind up waiting in lines or for your name to be called a lot. You want to have a lot of resources to alleviate boredom because otherwise you're going to wind up on the news for taking a building full of office workers hostage or some stupid shit.

@ people who carry bags everywhere what do you put in them what is there to bring other than chapstick, keys, phone and maybe a tampon why are you packing a suitcase to be outside for 5 hours

54K notes

·

View notes

Text

Is Your Child Safe Outdoors? Discover the Benefits of a GPS Tracker for Kids

In today’s fast-paced world, keeping children safe has become every parent's top priority. Whether it’s a crowded mall, a school trip, or a playground, it’s easy for kids to wander off. This is where Trakbond’s tracking device for kids proves to be a game-changer—offering parents real-time location updates and peace of mind.

Why Use a Kids’ Tracking Device?

Children are naturally curious and adventurous. While that’s a great trait, it can also lead to unexpected situations. A GPS tracking device designed specifically for kids is a modern parenting solution that combines safety, security, and smart technology.

With Trakbond’s compact and wearable tracking devices, you’ll always know where your child is, even when they’re out of sight. This helps prevent emergencies, enhances independent mobility, and builds trust between children and their caregivers.

Key Features of Trakbond’s Kids Tracker

Trakbond’s child tracker is packed with smart, parent-friendly features:

Real-Time GPS Tracking

Always stay informed about your child’s exact location with live updates on your smartphone, no matter where you are.

Geo-Fencing Alerts

Create safe zones like home, school, or daycare. You’ll instantly get notified when your child enters or exits these boundaries.

SOS Emergency Button

In case of danger or confusion, your child can press the SOS button to alert you immediately.

Lightweight and Kid-Friendly Design

Designed for comfort and safety, Trakbond devices are small, lightweight, and easy to wear—whether clipped onto clothes or worn as a watch.

Long Battery Life

With extended battery performance, you won’t have to worry about constant recharging during school hours or outings.

Location History

Review where your child has been during the day with location history logs—great for checking routes and routines.

Benefits of Using Trakbond for Parents

Peace of Mind: Know your child’s whereabouts at all times.

Safe Independence: Let your child explore the world while staying connected.

Quick Response: Respond faster in case of emergencies or unexpected detours.

Improved Communication: Some devices offer alerts, enhancing parent-child interaction.

When and Where to Use a Tracking Device

Trakbond’s kids’ GPS tracker is ideal for:

School travel and bus commutes

Field trips and camps

Visits to theme parks or crowded public places

Children with special needs or medical conditions

Independent activities like cycling or sports practice

Why Choose Trakbond?

At Trakbond, we understand that child safety isn't just a product feature—it's a promise. Our GPS tracking devices are designed with advanced technology, tested for reliability, and backed by responsive customer service. With thousands of happy families already using Trakbond, we are proud to be a trusted name in child safety.

Final Thoughts

A tracking device for kids is no longer a luxury—it’s a practical necessity in today's digital world. With Trakbond, you're not just buying a gadget; you're investing in your child's safety, your peace of mind, and your ability to stay connected.

Discover more about Trakbond's child trackers and explore our full range of wearable safety devices today.

Visit Trakbond’s Website to Learn More Safe. Smart. Reliable. Only with Trakbond.

0 notes

Text

How Small Integrators Use Semco for Large-Scale Battery Production

In India’s rapidly expanding EV and energy storage landscape, small and mid-sized integrators are no longer confined to limited output or low-end technology. Thanks to Semco Infratech, even small players can now access industrial-grade equipment for large-scale battery pack manufacturing. Semco Infratech PVT ltd has engineered a range of modular, scalable, and cost-efficient machines that allow smaller integrators to match the productivity and precision of legacy giants. With the right tools and automation, growth is no longer constrained by scale.

Smart entry into battery pack manufacturing

For small integrators, the biggest challenge is bridging the gap between basic lab setups and full-scale battery pack assembly lines. Semco Infratech private limited addresses this with a product ecosystem that supports every stage of the lithium-ion battery pack assembly process. From high-precision Semco battery testers to fully integrated Semco spot welding machine systems and BMS tester machine solutions, Semco provides a plug-and-play manufacturing environment with no compromise on technical performance. Integrators can now start lean and scale on demand without over-investing.

Modular equipment for scalable workflows

Semco India offers modular machines that are ideal for expanding production lines without overhauling infrastructure. A small integrator may begin with a single-channel Semco BMS tester and scale up to a 32-channel BMS testing machine as orders grow. Similarly, compact versions of Semco spot welding machines or portable laser welders allow low-footprint setups that can evolve into fully automated stations with robotic arms and barcode scanning integration. This modularity makes the lithium battery assembly kit from Semco a growth enabler for businesses navigating high-demand environments.

Automation without complexity

One of the common bottlenecks for small integrators is the fear of automation complexity. Semco Infratech PVT. ltd. solves this with user-friendly interfaces, customizable testing parameters, and systems pre-configured for standard battery chemistries. Whether it’s a cylindrical cell module or a prismatic pack, Semco's machines require minimal programming and deliver high repeatability. With barcode integration and automated result logging, manual errors are eliminated, leading to more predictable performance and faster cycle times. This helps small integrators maintain tight production schedules with limited workforce.

Use cases in real-world manufacturing

Many of Semco Infratech’s clients are startups or regional integrators supplying battery packs for e-rickshaws, solar streetlights, industrial UPS systems, and power walls. Using Semco battery tester systems and BMS tester machines, they validate every cell group, ensure thermal stability, and test for real-time faults. The Semco spot welding machine plays a critical role in delivering high-strength tab connections, which are crucial for maintaining energy in battery durability. By leveraging Semco’s workflow tools, these integrators can produce hundreds of packs per day, even with lean teams and limited space.

Cost benefits and ROI for small operations

Semco Infratech understands the financial constraints of small integrators and provides systems that offer unmatched ROI. Machines like the Semco battery tester or dual beam laser welding units are designed for durability, low maintenance, and energy efficiency. Since they can operate continuously with minimal supervision, labor costs are drastically reduced. Additionally, with fewer quality rejections and consistent testing output, integrators save on warranty claims and gain client trust. Investing in Semco Infratech private limited products translates into faster breakeven and long-term profitability.

Training and after-sales support

What truly sets Semco apart from generic competitors is its robust training and after-sales ecosystem. Small integrators often lack technical personnel for handling calibration or troubleshooting. Semco India resolves this with comprehensive onboarding, on-site installation, and remote diagnostics. Every purchase includes documentation such as the lithium-ion battery pack assembly process pdf, SOPs for how to assemble lithium ion battery modules, and access to Semco University content. This empowers integrators to become technically proficient and independent over time.

Competing with larger players

Equipped with Semco’s technology, small integrators are successfully competing with larger OEMs. High-speed testing from the Semco BMS tester machine and flawless welds from Semco’s spot welding solutions result in production quality that rivals any large-scale setup. Barcode traceability, automated QC data, and customizable configurations allow even small teams to meet stringent client specifications and certification norms. In an industry that rewards precision, speed, and data compliance, Semco gives integrators the tools to outclass legacy workflows.

Final thoughts

Semco Infratech PVT ltd has redefined what’s possible for small integrators. By offering a complete, scalable, and intelligent manufacturing suite — from Semco battery testers and Semco spot welding machines to advanced BMS testing solutions — the company enables even modest teams to produce at enterprise-level output and quality. In a time when the demand for clean energy and high-efficiency battery packs is surging, Semco Infratech is the ultimate ally for integrators aiming to lead without limitations.

#Semco Infratech#Semco Infratech PVT ltd#Semco#Semco Infratech PVT. ltd.#Semco Infratech private limited#BMS tester#Semco spot welding machine#BMS testing machine#Semco battery tester#BMS tester machine#Semco India#lithium battery assembly kit#lithium-ion battery pack assembly process pdf#battery pack assembly line#battery pack assembly process#battery pack manufacturing#dual beam laser welding#energy in battery#how to assemble lithium ion battery

0 notes

Text

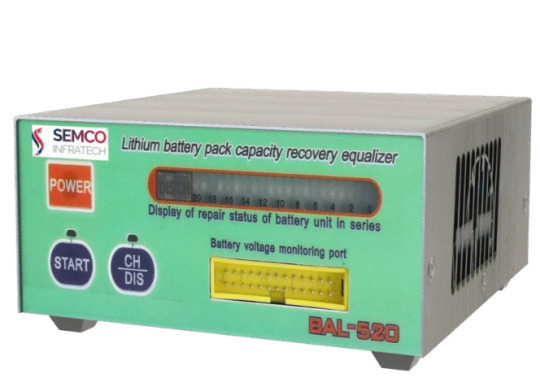

Enhance lithium battery performance with Semco SI BAL 520. Ensure balanced charging, longer lifespan, and safe battery pack operation with this reliable battery balancer.

#battery balancer#lithium battery balancer#Semco SI BAL 520#battery cell balancing machine#battery pack balancing system#lithium battery management#EV battery balancing equipment#cell balancing solution#battery equalizer for lithium-ion#advanced battery testing equipment

0 notes

Text

Automobile Parts Manufacturing Companies: Everything You Need to Know

In today’s rapidly evolving automotive landscape, Automobile Parts Manufacturing Companies form the core of the vehicle production ecosystem. These companies are responsible for designing, engineering, and producing the vast range of components that come together to create various types of vehicles from small passenger cars and commercial vehicles to electric and hybrid systems.

Automotive parts manufacturing is not just a support function, it's a driving force behind innovation, safety, and efficiency in the global automotive sector. From high-performance engines to advanced driver-assistance systems, these manufacturers are pushing the boundaries of what's possible on the road.

This blog explores everything you need to know about Automobile Parts Manufacturing Companies, including their roles, the technologies they use, key industry trends, and how to choose the right supplier for your needs.

Understanding Automobile Parts Manufacturing

Automobile Parts Manufacturing Companies are engaged in producing components that make up a complete automobile. These parts can be broadly classified into:

Mechanical Components: Engines, gearboxes, suspensions, clutches, and braking systems.

Electrical & Electronic Components: Battery systems, sensors, control modules, wiring harnesses, infotainment systems.

Body & Interior Components: Seats, doors, dashboards, lighting, steering wheels.

Consumables & Accessories: Tires, filters, spark plugs, brake pads, lubricants, wipers.

These manufacturers either supply original equipment components directly to vehicle assembly lines or operate in the aftermarket to provide parts for maintenance, upgrades, and repairs.

Categories of Automobile Parts Manufacturers

1. OEM Suppliers

These manufacturers provide parts that are used during the original assembly of vehicles. They must adhere to strict quality, safety, and consistency standards. Their products are engineered to meet exact specifications and are usually approved by the original vehicle manufacturers.

2. Aftermarket Suppliers

Aftermarket manufacturers produce components for vehicle repairs and customizations. While some parts replicate original specifications, others are tailored for performance, aesthetics, or cost-effectiveness. The aftermarket segment offers flexibility but requires careful selection for reliability.

3. Tiered Manufacturing Ecosystem

The automotive supply chain is structured into tiers:

Tier 1 Suppliers deal directly with vehicle manufacturers and deliver complete systems or major modules.

Tier 2 and Tier 3 Suppliers provide subcomponents or raw materials to Tier 1 companies.

This structured approach ensures that production remains streamlined, scalable, and cost-efficient.

How These Companies Operate

Most Automobile Parts Manufacturing Companies operate in highly controlled environments using standardized processes. Some of the key steps involved include:

Design & Prototyping: Engineers develop part designs using CAD software and simulate performance digitally.

Tooling & Production Setup: Specialized machinery is customized for mass production.

Manufacturing: Using materials such as steel, aluminum, plastic, or composites, manufacturers create parts through processes like molding, forging, stamping, machining, or casting.

Testing & Quality Control: Every part goes through rigorous inspections, from dimensional accuracy to functional testing.

Packaging & Logistics: Finished parts are carefully packed for safe delivery to clients or export markets.

Technology Driving the Industry

Modern Automobile Parts Manufacturing Companies are highly reliant on new technologies that enhance precision, efficiency, and flexibility. Some of the leading technologies include:

1. Automation and Robotics

Manufacturing lines are increasingly automated using robotic arms and conveyors to ensure high-speed and consistent production, reducing human error and enhancing safety.

2. AI and Machine Learning

Artificial intelligence supports predictive maintenance, fault detection, quality control, and demand forecasting, helping manufacturers minimize downtime and waste.

3. IoT and Connected Devices

Sensors and smart systems enable real-time tracking of machine performance and product quality, facilitating smart decision-making on the shop floor.

4. 3D Printing and Rapid Prototyping

Additive manufacturing accelerates the development of prototypes and allows for small-batch production with less tooling cost.

5. Sustainable Manufacturing

Eco-conscious methods like water recycling, energy efficiency, and biodegradable packaging are becoming standard practices.

Key Trends in the Industry

The automotive component manufacturing sector is undergoing a rapid transformation. Here are some of the most notable trends:

1. Shift Toward Electric Vehicle Components

The transition from combustion engines to electric powertrains is reshaping what parts are in demand. Manufacturers are increasingly focusing on components like battery enclosures, inverters, electric motors, and high-voltage wiring.

2. Increased Demand for Smart Components

Modern vehicles rely heavily on sensors, connectivity modules, and electronic control units. This trend has fueled demand for intelligent and software-integrated parts.

3. Flexible Manufacturing for Customization

Consumers today want personalized vehicles. Manufacturers are adapting by implementing modular assembly systems that allow for greater flexibility and customization in parts.

4. Localization of Supply Chains

Disruptions in global supply chains have led to a shift toward localized sourcing. Companies are now prioritizing partnerships with nearby manufacturers for quicker turnaround times and lower logistics risks.

5. Data-Driven Production

Digitization of the production floor allows companies to use real-time data for monitoring inventory, ensuring quality, and optimizing workflows.

Quality and Certification Standards

To remain competitive and compliant, Automobile Parts Manufacturing Companies must meet stringent quality and safety standards. Commonly recognized certifications include:

Quality Management Systems to ensure consistency and traceability.

Environmental Management Standards for sustainable operations.

Occupational Health and Safety Certifications to ensure a safe workplace.

Component-Specific Testing Protocols that meet global or regional regulations.

These certifications build trust among clients and ensure the longevity and performance of the parts produced.

How to Choose the Right Manufacturing Partner

Selecting a reliable partner among numerous Automobile Parts Manufacturing Companies is critical for the success of your automotive business. Here’s a checklist to guide your selection process:

Experience and Track Record: Choose companies with proven expertise in your required product category.

Manufacturing Capabilities: Ensure they have modern equipment, sufficient capacity, and the ability to scale.

Certifications and Compliance: Verify all relevant quality and safety certifications.

Client References: Ask for case studies or referrals from previous customers.

R&D and Innovation: A company with a focus on product development is more likely to offer cutting-edge solutions.

Logistics and Lead Times: Ensure they can deliver products on time, especially if your operations are time-sensitive.

After-Sales Support: Good support services like warranties and technical help can add long-term value.

What the Future Holds

The future of Automobile Parts Manufacturing Companies looks promising, especially for those that embrace innovation, sustainability, and global standards. Some key areas of growth include:

Electric and Hybrid Vehicle Components: As more manufacturers switch to electrified platforms, demand for new categories of components will rise sharply.

Lightweight Materials: To improve fuel efficiency and reduce emissions, manufacturers will invest in lightweight materials like carbon composites and aluminum alloys.

Software-Driven Components: Integration of hardware and software will become essential as vehicles get smarter and more autonomous.

Circular Economy Practices: Emphasis on recycling and eco-friendly disposal methods will become integral to operations.

Cross-Sector Collaboration: Partnerships between parts makers, software developers, and mobility service providers will become increasingly common.

Conclusion

Automobile Parts Manufacturing Companies are at the heart of the global automotive industry. They not only supply the parts that keep vehicles running but also lead the innovation that defines the future of mobility. As the industry moves toward electric, autonomous, and connected transportation, these manufacturers must evolve their processes, technologies, and offerings.

For businesses looking to enter this space or collaborate with a manufacturing partner, understanding the complexities of this ecosystem is the first step toward success. Looking for trusted Automobile Parts Manufacturing Companies. Connect with Ace Forge today for quality, reliability, and on-time delivery. Visit https://www.aceforge.in/ to know more details.

1 note

·

View note

Text

Zip Ties: The Unsung Hero of Every Aussie Car Toolbox

In the world of cars, most drivers focus on the big-ticket items – engines, tyres, batteries. Yet one of the most practical tools often gets overlooked: zip ties. Also known as cable ties, these small plastic strips are absolute legends in the automotive industry.

What Are Zip Ties?

Zip ties are simple plastic fasteners designed to secure cables, wires, or loose parts. They might look basic, but their strength and reliability make them incredibly useful in automotive tasks. Whether it’s a quick fix or a neat wiring job, zip ties get it done. For a clean and professional finish, black cable ties are a popular choice – blending in nicely with most car interiors and engine bays.

How Zip Ties Help Aussie Drivers and Mechanics

From weekend DIY projects to workshop repairs, zip ties are an essential part of the toolkit. Here’s how they come in handy:

1. Keeping Wires Tidy

Modern cars carry dozens of cables running behind dashboards, under seats, and along the chassis. Zip ties help group them neatly, avoiding tangles and reducing wear caused by rubbing or vibration.

2. Quick Temporary Fixes

A loose bumper, sagging undertray, or rattling hose can be held in place with a few zip ties. These aren’t permanent solutions, but they’re ideal for holding things together until proper repairs take place.

3. Perfect for Custom Modifications

Installing aftermarket lights, audio equipment, or accessories? Zip ties make mounting and wiring easier without drilling or damaging original parts. They’re perfect for test fits or securing parts during setup.

4. Track Day Support

Motorsport enthusiasts often carry zip ties for urgent fixes. On the track, fast repairs matter – and a handful of cable ties can keep panels secure or prevent loose cables from causing trouble.

5. Underbody and Engine Bay Use

Zip ties hold splash guards, plastic panels, and small parts in place – especially handy for older cars where clips may have broken or gone missing. They're also used for routing vacuum lines or securing looms.

Choosing the Right Zip Ties for Automotive Use

Not all zip ties are created equal. For car-related tasks, go for high-grade nylon ties with UV resistance – especially in Australia’s hot climate. Black cable ties are preferred due to their durability and discreet appearance.

Avoid bulk-buying low-quality versions. Flimsy ties tend to snap under pressure or in high heat, leading to more frustration than they’re worth.

Also, unless the job involves heavy components, there’s no real need to use "heavy duty" ties. Standard strength ones usually offer more than enough grip for day-to-day tasks in the automotive space.

Final Thoughts

Small, simple, and seriously underrated – zip ties have earned their spot in every car enthusiast’s toolkit. Whether it’s a quick cable tidy-up or a makeshift repair on the side of the road, these plastic wonders provide a level of convenience that few tools can match. So next time you’re in the garage, packing for a road trip, or heading to the track, make sure to throw in a few zip ties. They’re cheap, reliable, and always up for the job.

0 notes

Text

Top 9 Challenges in Consumer Electronics Product Design and How to Solve Them

The era of intelligent houses, wearable devices, and mobile entertainment has made consumer electronics an essential element of our daily routine. Nevertheless, every shiny device conceals a difficult process of product design, which is full of challenges. To the businessman or start-up developing new electronics, it is necessary to learn about these challenges and how they can be handled.

Since we are a major Consumer Electronics Product Design Company in India, we are aware of all the details behind designing products that are not only functional and commercially feasible but also user-friendly. Now, it is time to visit the top 10 product design challenges in consumer electronics (and, more to the point, how to address them).

1. Striking the So-called Aesthetic-Functional Balance

The Challenge:

Consumers in the competitive market are not only interested in products with high performance capability but also have good looks as well. Designers have the problem of settling between the aesthetic side and the functional side.

The Solution:

Introduce industrial design to engineering at an early stage. The synergy guarantees the design does not sacrifice utility or functionality in the name of appearance. Iterative prototyping and user testing can be used to improve the form and the functionality.

2. Taming the goose of rapid technological changes

The Challenge:

Consumer electronics technology grows so fast. What is new now is probably an out-of-date tomorrow.

The Solution:

Implement a design thinking that is future-ready. Consider modularity and scalability so that the products become easy to update. A Consumer Electronics Product Design Company in India that also has the capabilities of carrying out R&D, can advise you to pick components and platforms that provide life.

3. Guaranteeing Compactness without compromising performance

The Challenge:

People desire more compact versions of gadgets that are slimmer yet give them robust performance. The need to shrink personal computing devices packs more functionality than can be cooled, batteried, or the component itself can actually hold up.

The Solution:

Adopt circuit board layouts that are space-efficient, such as multi-layer PCBs and flexible PCBs. Smart enclosure engineering and the level of thermal design also play an important role. One can predict performance in the tight space without the need for physical prototyping through the use of simulation tools.

4. Power and Batteries Configuration

The Challenge:

Consumers consider battery life to be transactional. One of the greatest technical issues with designing electronics is the power efficiency of electronics.

The Solution:

employ low-power elements and make firmware as power-constrained as possible. Add efficient Battery Management Systems (BMS). Partner with a Consumer Electronics Product Design Company in India, which has expertise in embedded systems and battery optimisation.

5. Towards a Smooth Hardware-Software Integration

The Challenge:

With little synchronization of software and hardware, a poor performance may be experienced in smart devices, delays, or the product may even fail.

The Solution:

Make hardware and software teams work closely with each other in the development process. Carry out an integrated test early on. Make use of APIs and middleware optimized to improve the compatibility of the two systems.

6. Heat Control in high-performance devices

The Challenge:

The performance, safety, and life of compact electronics are susceptible to heat build-up. The non-compliance with the regulations may also be built up by overheating.

The Solution:

Carry out thermal simulations at the design stage in order to detect hotspots. Use heat sinks, ventilation, and thermal interface material. Select a structural firm that has experience in Thermal management techniques and material engineering.

7. Specification to Compliance and Regulatory Requirements

The Challenge:

Consumer electronics are subject to a number of local and international standards regarding safety, EMI/EM, and RoHS compliance, to name a few. Non-compliance may result in a product recall or prohibition, which is also expensive.

The Solution:

Get compliance experts at the table early on in the design process. An established Consumer Electronics Product Design Company in India already knows about BIS, CE, FCC, and other similar certifications. They have the ability to incorporate the compliance checks at the design level.

8. Assuring Durability and Reliability

The Challenge:

Consumer electronics are applied on an everyday basis and usually under adverse circumstances, thermo-hygrometrical, shock, or fall. The brand reputation is necessary in designing products that will be resistant to common wear and tear.

The Solution:

The material of enclosures and connectors should be durable. Conduct environmental and mechanical stress testing. When looking at waterproof or dust-proof devices, devices should have IP ratings (Ingress Protection).

9. Shortening Time-to-Market

The Challenge:

In consumer electronics, it is all about the timing. Any product delay may cost it important selling points or beat the competition.

The Solution:

Adopt the agile development culture. Do parallel testing and build a rapid prototype. Conduct business with long-established design partners able to predict frequent obstacles and accelerate product production by using off-the-shelf platforms and instruments.

Final Thoughts

In the course of designing a consumer electronic device, multiple aspects need to be considered, including advanced technical knowledge, a good understanding of the target user's needs, and an effective development cycle. With proper foresight and planning, by overcoming these 10 major challenges, your product stands a great chance of success in the highly competitive market.

Selecting the appropriate design partner becomes the key to resolving such issues. One of the most reliable Consumer Electronics Product Design Companies in India unites under a single roof an industrial designer, a hardware engineer, a software developer, and a compliance expert to form cross-functional teams. It not only speeds up the development process, but also allows all the facets of your product, be it form or performance, to be geared towards real-life operations.

And when you are preparing to introduce the next consumer electronics items, you would consider associating with professionals who can sense out the triggers of design, engineering, and market trends. Once it has been properly guided and implemented, your idea will turn into a consumer favorite, as well as their support line.

0 notes

Text

Invisible Risks, Powerful Protection: Why Process Gas Analyzers Are Essential in Electronics Manufacturing

In the fast-paced world of electronics, where semiconductors and battery packs shape our tech future, one invisible danger lurks silently: gas leaks. From toxic HF to explosive SiH₄ and oxygen-sensitive cleanrooms, safety can't be an afterthought. Enter the process gas analyzer—your smart guardian for a safer, smarter factory floor.

Why the Electronics Industry Can't Afford to Ignore Gas Safety

Modern electronics manufacturing—from semiconductor fabrication to PCB assembly—relies heavily on gases. Some are flammable, some toxic, and others need to remain ultra-pure. Whether it’s OLED deposition or battery abuse testing, one tiny leak can halt production or cause real harm.

That’s why process gas analyzers are more than tools—they’re life-saving systems. These analyzers constantly monitor gas levels in real time and integrate with ventilation, alarms, and shutdown protocols to protect workers and assets before a crisis unfolds.

Where Are Process Gas Analyzers Used in Electronics?

Let’s break it down:

Semiconductor Fabrication Processes like etching and doping use dangerous gases (e.g., HF, NH₃, SiH₄). A leak can ruin wafers—or worse, endanger lives.

OLED & Display Production Organic vapors must be kept under control. Analyzers ensure a clean, inert atmosphere to maintain quality and prevent contamination.

PCB Soldering & Assembly Reflow soldering releases VOCs and fumes. Gas analyzers protect both electronics and personnel by keeping indoor air quality in check.

Battery Testing During thermal runaway, batteries emit CO, HF, and methane. Early detection via gas analyzers ensures engineers can react before it escalates.

How Do Process Gas Analyzers Improve Safety?

Here’s how they work:

✅ Continuous Monitoring: Never stop watching. Gas analyzers work 24/7, even when people can’t.

✅ Early Warning: If gas levels rise, they sound alarms, activate fans, or shut systems down—automatically.

✅ SIS Integration: Feed data into Safety Instrumented Systems to meet IEC SIL standards.

✅ Regulatory Compliance: Meet OSHA, EPA, and ISO 14644 standards with ease, complete with audit-ready data logs.

What Gases Do They Detect?

Toxic & Reactive: HF, HCl, NH₃, VOCs, SiH₄

Flammable: Methane, PFCs

Oxygen & Moisture: For cleanrooms

CO/CO₂: Especially in battery and soldering zones

Different tech like FTIR, TDLAS, NDIR, and electrochemical sensors are used depending on the gas and application.

💡Real Benefits That Go Beyond Safety

Enhanced Worker Safety

Reduced Downtime & Product Waste

Data-Driven Process Control

Lower Insurance & Maintenance Costs

Ready to Power Up Your Plant’s Safety?

In a world where gas risks hide in plain sight, process gas analyzers deliver peace of mind. Whether you're building the next-gen microchip or testing EV batteries, ESEGAS solutions give you the confidence to innovate—safely.

0 notes