#BMS tester

Explore tagged Tumblr posts

Text

#Semco Infratech#Semco Infratech PVT ltd#Semco#Semco Infratech PVT. ltd.#Semco Infratech private limited#BMS tester#Semco spot welding machine#BMS testing machine#Semco battery tester#BMS tester machine#Semco India#lithium battery assembly kit#lithium-ion battery pack assembly process pdf#battery pack assembly line#battery pack assembly process#battery pack manufacturing#dual beam laser welding#energy in battery#how to assemble lithium ion battery

0 notes

Text

Understanding the Battery Pack 'EOL' Test Method: Ensuring Safety and Reliability

In the fast-evolving world of lithium-ion batteries, ensuring the performance and safety of battery packs is crucial. One key procedure to achieve this is the End-of-Line (EOL) test method, a comprehensive quality control measure conducted before batteries leave the factory. This blog delves into the significance, process, and benefits of the EOL test in maintaining battery performance and reliability.

What is the Battery Pack 'EOL' Test Method?

The EOL test is a final validation process that battery packs undergo during production. This method is designed to verify whether the battery meets predefined specifications and standards, ensuring safe and efficient operation. It includes testing the electrical, thermal, and mechanical parameters of the battery pack.

Importance of the EOL Test in Battery Production

Safety Assurance: The EOL test helps identify potential risks such as thermal runaway, overvoltage, or short circuits, which could compromise safety.

Performance Validation: It ensures that the battery pack delivers the expected energy density, capacity, and cycle life.

Compliance with Standards: The process ensures that the battery adheres to regulatory and industry standards, reducing the risk of product recalls or failures.

Key Steps in the Battery Pack 'EOL' Testing Process

Visual Inspection: The process begins with a thorough inspection to detect physical defects like damaged connectors or compromised casings.

Electrical Testing: This involves checking voltage, current, and resistance levels to ensure optimal electrical performance.

Thermal Analysis: The pack is tested under different thermal conditions to validate its temperature control systems.

Communication and BMS Testing: The Battery Management System (BMS) is evaluated to confirm that it communicates effectively with external devices and manages cell balancing.

Leakage and Insulation Testing: Detecting leak currents and ensuring proper insulation is vital for maintaining safety.

Dynamic Load Testing: Simulating real-world conditions, this step assesses the battery's response to varying loads, ensuring reliability during actual use.

Benefits of Implementing the EOL Test

Enhanced Product Quality: By identifying and rectifying issues early, the EOL test ensures a high-quality battery pack.

Customer Satisfaction: Reliable and safe battery packs enhance user confidence and brand reputation.

Reduced Failures: The test minimizes the chances of field failures, saving costs associated with warranty claims.

Challenges in the Battery Pack EOL Testing Process

Complexity of Modern Battery Packs: With increasing pack sizes and functionalities, testing requires advanced systems.

High Costs: Setting up comprehensive EOL test stations can be expensive, especially for small-scale manufacturers.

Time-Intensive: Ensuring thorough testing without compromising production timelines is a delicate balance.

Future Trends in Battery Pack EOL Testing

As technology advances, the EOL test method is expected to integrate features like AI-driven analysis, real-time monitoring, and enhanced automation. These advancements will further improve the accuracy and efficiency of the testing process.

Conclusion

The Battery Pack 'EOL' Test Method plays an indispensable role in the battery manufacturing process, ensuring safety, performance, and reliability. By adopting robust EOL testing procedures, manufacturers can not only comply with industry standards but also build trust with their customers.

#battery management system#Battery Pack EOL Test Method#Battery Pack EOL Testing#BMS#BMS Tester#EOL Test#EOL Test Methods#EOL Testing#EOL Testing Methods#lithium ion batteries#lithium ion battery packs#lithium ion battery pack EOL testing methods

0 notes

Text

Accurate Prismatic Cell Sorting with Semco Systems

The future of clean energy and electric mobility in India relies on one powerful component: the lithium-ion battery. At the heart of high-performance battery packs are Prismatic Cells—widely used for their energy density, flat design, and pack assembly efficiency. But to ensure long-term performance and safety, these cells must be precisely sorted before being assembled. That’s where Semco Infratech delivers unmatched value, offering highly accurate, fast, and scalable Prismatic Cell Sorting solutions built for India’s battery manufacturing industry.

Why prismatic cell sorting matters

In a lithium-ion battery pack, even minor inconsistencies between cells can lead to imbalance, reduced capacity, overheating, or failure. Before integration, every Prismatic Cell must be tested for key parameters like voltage, internal resistance, and temperature. Based on these results, they need to be sorted into matched groups—this process is known as Prismatic Cell Sorting.

For modern Battery Manufacturers in India, this is no longer a manual task—it requires automation, speed, and precision. That’s why top manufacturers choose Semco Systems.

Semco Infratech: setting the standard in cell sorting

Semco Infratech, India’s most trusted supplier of battery production equipment, offers advanced Prismatic Cell Sorting machines that simplify and accelerate production. Designed for Indian conditions and high-volume factories, Semco’s systems deliver accurate results, reliable performance, and full integration into your battery assembly line.

Whether you're manufacturing cells for electric vehicles, grid storage, or industrial applications, Semco provides solutions that ensure consistent quality and efficiency.

Key features of Semco’s prismatic sorting systems

Semco’s Prismatic Cell Tester and Sorting Machines come with industry-leading features:

Multi-parameter testing Each cell is tested for voltage, internal resistance, and temperature—ensuring accurate Prismatic Cell Grading.

High-speed sorting mechanism Handles hundreds of cells per hour, automatically classifying them into performance-based categories.

Barcode scanning and traceability Each cell’s data is logged and linked to its barcode, allowing for traceable sorting and improved quality control.

Smart software interface Easy-to-use touchscreen interface allows technicians to monitor and control operations in real time.

BMS compatibility Works seamlessly with BMS test equipment for a complete cell-to-pack testing workflow.

Built for Indian battery manufacturers

Semco’s sorting systems are trusted by leading Lithium Battery Manufacturers in India because they are:

Cost-effective and scalable

Rugged and durable for local factory environments

Easy to integrate with existing systems

Supported with on-ground technical service

Semco also offers installation, operator training, and maintenance to ensure smooth operation and long-term performance.

Enabling consistent battery quality at scale

In today’s competitive energy market, quality cannot be compromised. With Semco’s Prismatic Cell Sorting machines, manufacturers can:

Improve production speed

Ensure accurate cell grouping

Reduce pack rejection rates

Maintain global safety and performance standards

Powering India’s clean energy future

As India aims to become a global leader in battery manufacturing, automation and precision will be key. Semco Infratech is proud to support this mission by equipping Lithium Ion Battery Manufacturers in India with high-performance sorting systems that simplify complex processes and deliver consistent results.

India’s clean energy revolution is being fueled by advancements in lithium-ion battery technology, where Prismatic Cells are emerging as a cornerstone for EVs and renewable energy storage systems. These cells offer higher energy density, better space utilization, and improved safety—making them ideal for sustainable applications.

The growing adoption of Lithium Ion Prismatic batteries has created a strong demand for precise manufacturing and testing solutions. At the heart of this shift lies advanced BMS test equipment, ensuring accurate monitoring and protection of battery packs. Alongside, Prismatic Cell Testers help manufacturers evaluate voltage, capacity, and internal resistance with high accuracy.

To enhance consistency and performance, automated Prismatic Cell Sorting and Prismatic Cell Grading systems are being deployed. These solutions ensure only the best-matched cells are assembled together, reducing failure rates and boosting efficiency.

By integrating such smart technologies, India is not only advancing its clean energy ambitions but also building a robust and self-reliant battery manufacturing ecosystem. These innovations are paving the way for a cleaner, greener, and energy-secure future—powering everything from electric mobility to grid-level storage with confidence and precision.

#Prismatic Cell#Lithium Ion Prismatic#BMS test equipment#Prismatic Cell Tester#Prismatic Cell Sorting#Prismatic Cell Grading

0 notes

Text

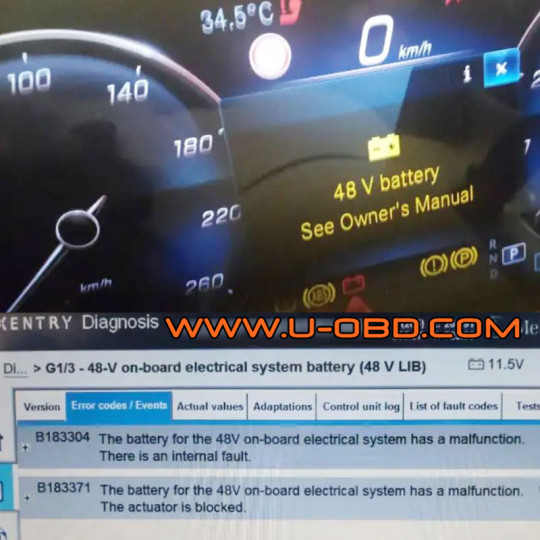

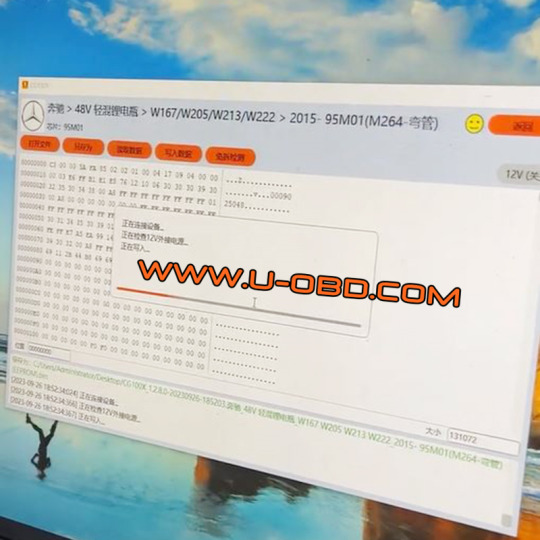

https://www.u-obd.com/product/mecedes-hybrid-48v-test-platform/ Mercedes-Benz W167 W205 W213 W222 Mild-Hybrid 48V Lithium battery pouch BMS, DCDC Inverter bench tester.

w205mhev #w222mhev #W167Battery #w213MHEV #mercedesmhev #mercedes48v #actuatorblocked #a0009823513 #A0009025048 #mercedeshybrid

1 note

·

View note

Text

Introduction In recent years, the global transition toward sustainable energy has accelerated, with electric vehicles (EVs) playing a central role in reducing carbon emissions and dependence on fossil fuels. As the core component of EVs and hybrid electric vehicles (HEVs), power lithium-ion batteries must meet increasingly stringent requirements in terms of performance, safety, and consistency. Among the various parameters used to evaluate battery quality, internal resistance stands out as one of the most critical indicators for assessing battery health status (SOH), power output capability, thermal management efficiency, and long-term reliability. To address the growing demand for high-precision, high-speed, and non-destructive testing solutions in battery manufacturing, Shanghai LISUN has developed the LS556X series of high-voltage, high-precision battery internal resistance testers, collectively known as the Shanghai LISUN Battery Tester. This innovative product line combines advanced impedance measurement technology, wide voltage adaptability, and seamless automation integration to deliver exceptional accuracy and efficiency across multiple stages of battery production and application. With its superior technical specifications and system compatibility, the Shanghai LISUN Battery Tester is rapidly becoming an indispensable tool for battery manufacturers, automotive OEMs, BMS developers, and recycling enterprises alike. In this article, we will explore the key technical features, operational advantages, and industry applications of the LS556X series, demonstrating how it supports the evolution of intelligent battery testing and contributes to the advancement of the new energy vehicle ecosystem. Battery Tester LS5562 AL3 Technical Advantages of the Shanghai LISUN Battery Tester Ultra-High Measurement Precision for Advanced Battery Analysis One of the defining characteristics of the Shanghai LISUN Battery Tester is its exceptional measurement precision, which is essential for evaluating the subtle differences between individual battery cells and modules. The LS556X series achieves a resistance resolution of 0.1μΩ and a voltage resolution of 10μV, placing it among the most accurate battery testing instruments available on the market today. Such high-resolution capabilities are particularly important when dealing with large-scale parallel or series-connected battery packs, where even minor variations in internal resistance can significantly impact overall system efficiency, thermal stability, and cycle life. By providing highly repeatable and stable results within extremely low resistance ranges, the Shanghai LISUN Battery Tester ensures that battery producers can maintain tight control over product consistency and reliability. This level of precision also enables early detection of anomalies such as micro-short circuits, electrode degradation, and electrolyte dry-out—issues that could otherwise go unnoticed until they lead to more serious performance failures or safety risks. High-Voltage Compatibility Across Diverse Battery Chemistries The LS556X series is engineered to support a wide range of battery technologies currently in use across the EV and energy storage industries. It is compatible with ternary lithium (NCM/NCA), lithium iron phosphate (LFP), and other emerging chemistries, making it suitable for testing both conventional 48V mild-hybrid systems and high-voltage platforms exceeding 700V found in modern electric vehicles. This broad voltage adaptability allows the Shanghai LISUN Battery Tester to be deployed throughout the entire battery lifecycle—from R&D labs conducting material optimization studies to mass production lines performing real-time quality checks. Its ability to operate under high-voltage conditions without compromising test accuracy makes it especially valuable in environments where safety and reliability are paramount. Moreover, the instrument’s robust design ensures stable operation even in the presence of electromagnetic interference (EMI) and temperature fluctuations, further enhancing its suitability for industrial applications. Rapid Response Speed and Seamless Automation Integration As the battery industry embraces smart manufacturing and Industry 4.0 principles, the need for fast, automated, and data-driven testing processes has never been greater. The Shanghai LISUN Battery Tester meets these demands by offering ultra-fast response times and comprehensive interface support, enabling real-time monitoring and integration into complex production ecosystems. Each test cycle on the LS556X platform takes less than one second, allowing for efficient inline sorting and classification during high-volume production runs. This rapid throughput not only improves process efficiency but also reduces the risk of bottlenecks and delays in battery assembly operations. Additionally, the device supports data logging, statistical analysis, and report generation, making it an ideal solution for companies seeking to implement digital twin strategies and predictive maintenance protocols. Core Role of the Shanghai LISUN Battery Tester in the Power Battery Industry Enhancing Battery Pack Consistency and Ensuring Vehicle Performance Battery packs in electric vehicles typically consist of hundreds or even thousands of individual cells connected in parallel or series configurations. Due to natural variations in materials, manufacturing processes, and environmental exposure, each cell may exhibit slight differences in internal resistance. If left unaddressed, these inconsistencies can result in uneven current distribution, localized overheating, and premature aging—factors that reduce the overall lifespan and performance of the battery pack. More critically, they can compromise the safety of the vehicle, increasing the risk of thermal runaway events. The Shanghai LISUN Battery Tester plays a vital role in mitigating these issues by enabling precise internal resistance measurements at the cell level. During the production phase, the LS556X series performs high-throughput screening and classification, ensuring that only cells with matched electrical characteristics are grouped together in the same module. This selective pairing enhances the balance and uniformity of the battery pack, leading to improved energy utilization, extended driving range, and enhanced thermal stability. By integrating the Shanghai LISUN Battery Tester into their production workflows, battery manufacturers can significantly reduce field failures, warranty claims, and post-sale service costs, thereby improving customer satisfaction and brand reputation. Supporting BMS Development and Validation to Optimize Battery Management Systems A well-designed Battery Management System (BMS) is crucial for maximizing the performance and longevity of lithium-ion batteries. The BMS monitors critical parameters such as voltage, current, temperature, and internal resistance, using this data to manage charge/discharge cycles, prevent overloads, and ensure safe operation. Accurate internal resistance data serves as a foundational input for BMS algorithms, influencing everything from state-of-charge (SOC) estimation to fault detection and isolation (FDI). However, many traditional testing methods lack the precision required to capture these subtle changes effectively. The Shanghai LISUN Battery Tester fills this gap by delivering real-time, high-resolution impedance data that reflects the true condition of each battery cell. This information can be used to develop more sophisticated BMS models capable of predicting performance degradation and optimizing energy distribution dynamically. Furthermore, during the validation phase of BMS development, the LS556X series can simulate different impedance scenarios, allowing engineers to test the system’s responsiveness under varying load conditions. This capability is particularly useful for verifying the BMS’s ability to handle abnormal states such as short circuits, imbalances, and external faults. Facilitating Battery Recycling and Tiered Utilization Assessments With millions of electric vehicles expected to reach end-of-life in the coming decade, the issue of battery recycling and second-life utilization has become a pressing concern for the industry. Retired EV batteries often still retain significant capacity—typically around 70% to 80%, making them viable candidates for use in stationary energy storage systems, grid balancing applications, and backup power supplies. However, determining the residual value of a used battery requires accurate assessment of its remaining capacity, cycle life, and internal resistance. Traditional testing methods are often time-consuming, destructive, or insufficiently sensitive to detect subtle changes in battery health. The Shanghai LISUN Battery Tester offers a non-invasive, rapid, and reliable solution for evaluating retired batteries on a large scale. By measuring internal resistance quickly and accurately, the LS556X series enables recyclers and repurposing facilities to categorize batteries based on their SOH, facilitating efficient grading and reuse. This capability not only helps maximize resource recovery but also supports the development of a circular economy in the battery sector—one that minimizes waste, reduces raw material consumption, and lowers environmental impact. Specific Application Scenarios of the Shanghai LISUN Battery Tester in the Automotive Industry Quality Control in Cell Manufacturing Plants At the heart of any battery production facility is the need for strict quality assurance measures. In cell manufacturing plants, the Shanghai LISUN Battery Tester is typically installed at the final stage of the production line to perform impedance testing and automatic grading of each individual cell. By analyzing internal resistance values in real time, the LS556X series ensures that only cells meeting predefined thresholds are allowed to proceed to the next stage of module assembly. This prevents mismatched cells from entering the production pipeline, thereby minimizing potential performance issues and safety hazards downstream. Automated sorting based on resistance data also streamlines inventory management and reduces manual intervention, contributing to higher productivity and lower labor costs. Incoming Inspection and Assembly Testing in Module and PACK Factories During the assembly of battery modules and PACKs, mechanical connections such as welding points and busbars play a critical role in ensuring low-resistance pathways between cells. Any defects in these connections, such as poor welds, oxidation, or misalignment, can introduce additional resistance and create hotspots that threaten the integrity of the entire system. The Shanghai LISUN Battery Tester is employed at this stage to conduct contact resistance measurements on critical junctions, identifying and flagging any abnormalities before the final assembly is completed. This proactive approach helps eliminate defective units early in the process, preventing costly rework and recalls later on. Research and Development and After-Sales Testing in Vehicle Manufacturers Beyond the manufacturing realm, the Shanghai LISUN Battery Tester also finds application in R&D centers and after-sales service networks. For automotive OEMs, the LS556X series is used to validate new battery designs, assess the performance of prototype cells, and monitor long-term degradation trends under simulated usage conditions. In the after-sales domain, service technicians deploy the tester to diagnose battery-related issues in the field. By measuring the internal resistance of individual cells within a vehicle’s battery pack, they can quickly identify weak or failing units and recommend targeted repairs or replacements. This not only improves repair turnaround times but also enhances customer trust in the brand. Promoting Standardization and Intelligent Transformation in the Battery Industry The Shanghai LISUN Battery Tester is more than just a high-precision analytical tool, it is a catalyst for industry-wide transformation. Its integration into battery testing workflows promotes the adoption of standardized methodologies, unified data formats, and interoperable systems that facilitate collaboration across the supply chain. By supporting cloud-based data storage, remote access, and AI-driven analytics, the LS556X series empowers manufacturers to transition from reactive to predictive maintenance models. It also lays the foundation for building smart factories where every aspect of battery production is monitored, optimized, and controlled in real time. Under the backdrop of China’s “dual carbon” strategy—aimed at achieving carbon peak by 2030 and carbon neutrality by 2060, the Shanghai LISUN Battery Tester plays a pivotal role in advancing clean energy technologies and fostering sustainable development in the transportation sector. Conclusion The Shanghai LISUN Battery Tester represents a major breakthrough in the field of battery testing technology. With its ultra-high measurement precision, broad voltage compatibility, and seamless automation integration, it addresses the evolving needs of the power battery industry across multiple domains—from cell manufacturing and module assembly to BMS development and battery recycling. As the demand for electric vehicles continues to rise and the complexity of battery systems increases, tools like the Shanghai LISUN Battery Tester will become even more essential for ensuring product quality, operational efficiency, and environmental sustainability. Looking ahead, continued innovation in battery testing equipment will be key to unlocking the full potential of next-generation energy storage solutions and driving the global transition toward a cleaner, smarter future. Read the full article

0 notes

Text

Kinh nghiệm mua VIA Việt chạy quảng cáo mới nhất 2025

Kinh nghiệm mua VIA Việt chạy quảng cáo mới nhất 2025

Bạn đang tìm cách mua VIA Việt chạy quảng cáo để phục vụ chiến dịch Facebook Ads nội địa hiệu quả? Vậy thì đừng bỏ qua bài viết này! Với những cập nhật mới nhất năm 2025, bạn sẽ biết được VIA Việt là gì, các loại via phổ biến, mua VIA Việt ở đâu uy tín, giá bao nhiêu là hợp lý, và cách sử dụng sao cho không die, không checkpoint.

VIA Việt là gì?

VIA Việt là tài khoản Facebook của người dùng thật tại Việt Nam, có lịch sử tương tác như bài viết, bạn bè, like, comment... Thường được dùng để chạy quảng cáo Facebook, tạo BM nội địa, seeding, hoặc nuôi profile dài hạn.

So với via clone hay via quốc tế, VIA Việt có nhiều lợi thế khi target thị trường Việt Nam:

IP Việt, hành vi người dùng nội địa → trust cao

Login dễ, không cần fake IP hoặc proxy nước ngoài

Dễ tạo BM, fanpage, add thẻ ngân hàng nội địa

Lý do nên mua VIA Việt chạy quảng cáo Facebook

Nếu bạn đang chạy quảng cáo ở thị trường Việt Nam thì mua VIA Việt chạy quảng cáo Facebook là lựa chọn tối ưu vì:

✅ Dễ login – không checkpoint, không cần proxy

✅ Camp cắn tiền đều, dễ duyệt quảng cáo

✅ Tạo BM nhanh, nuôi lâu dài không sợ die bất ngờ

✅ Giá hợp lý hơn nhiều so với via US hoặc via cổ

✅ Có nhiều lựa chọn: từ via thường, XMDT đến loại 902 siêu khỏe

Đặc biệt trong năm 2025, khi Facebook ngày càng siết chặt chính sách, thì việc có một tài khoản via chất lượng là điều bắt buộc nếu bạn muốn chạy ads ổn định.

Các loại VIA Việt phổ biến năm 2025

Loại VIA Việt

Mô tả chính

Đối tượng phù hợp

VIA thường

Có tương tác thật, chưa xác minh danh tính

Người mới, seeding, test ads

VIA Việt XMDT

Đã xác minh CCCD/hộ chiếu, trust cao

Người chạy ads chính, tạo BM

VIA Việt 902

Vượt checkpoint 902, độ trust cực cao

Media buyer, team scale hệ thống

📌 Lưu ý: VIA XMDT và 902 đều có khả năng vượt CP tốt, chạy camp bền hơn nhiều so với via clone hoặc via thường không xác minh.

VIA Việt giá bao nhiêu?

Dưới đây là bảng giá tham khảo mới nhất 2025 từ các nguồn uy tín:

Loại via

Giá tham khảo (VNĐ)

Ghi chú

VIA thường

150.000 – 300.000

Dùng seeding, tài khoản backup

VIA Việt XMDT

400.000 – 700.000

Tạo BM, chạy ads chính

VIA Việt 902

800.000 – 1.200.000+

Scale lớn, camp sống 7–10 ngày

💡 Mẹo: nên mua combo 3–5 via để test trước, chọn ra via trust nhất để dùng lâu dài.

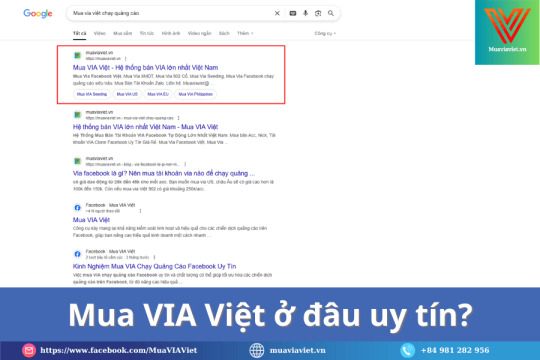

Mua VIA Việt ở đâu uy tín, giá tốt?

Nếu bạn đang tìm nơi mua VIA Việt chạy quảng cáo uy tín, chất lượng, có bảo hành và hạn chế tối đa checkpoint, thì dưới đây là 3 địa chỉ được cộng đồng chạy ads đánh giá cao:

1. Muaviaviet.vn

Đây là một trong những website chuyên bán VIA Việt lâu năm, uy tín trong giới quảng cáo Facebook. Tại đây, bạn có thể tìm thấy nhiều loại via khác nhau, từ via thường, via cổ đến VIA XMDT, VIA 902.

Điểm nổi bật:

Mỗi tài khoản đều được cung cấp đầy đủ UID, cookies, Gmail, mật khẩu gốc

Có chính sách bảo hành checkpoint rõ ràng từ 24h đến 3 ngày tùy loại via

Giao hàng nhanh chóng qua file hoặc hệ thống tài khoản tự động

Phù hợp cho những bạn chạy ads cá nhân, tester hoặc muốn chọn via chất lượng cao để scale ngân sách lớn.

2. ThegioiMMO.net

Nếu bạn cần mua via theo combo số lượng lớn hoặc đang vận hành team chạy ads, thì ThegioiMMO.net là một địa chỉ đáng tin cậy.

Điểm nổi bật:

Giá tốt, thường xuyên có ưu đãi theo combo số lượng

Có sẵn tài liệu và hướng dẫn login via đúng cách để tránh checkpoint

Hệ thống quản lý đơn chuyên nghiệp, chăm sóc khách hàng nhanh

Phù hợp với team agency, media buyer hoặc những ai đang chạy nhiều tài khoản song song.

3. Sellviaviet.com

Trang này không chỉ bán via mà còn có hệ sinh thái đầy đủ dành cho người làm quảng cáo: VIA, BM, fanpage, thẻ ads, proxy, và công cụ login.

Điểm nổi bật:

Hỗ trợ kỹ thuật tận tình, đặc biệt phù hợp cho người mới (newbie)

Có team tư vấn loại via phù hợp với ngành hàng

Cung cấp tools login, fake IP, tạo môi trường nuôi via an toàn

Đây là lựa chọn lý tưởng nếu bạn đang tìm một đơn vị hỗ trợ toàn diện từ A-Z khi triển khai quảng cáo.

Lưu ý khi mua:

Tránh mua qua Facebook cá nhân không rõ nguồn

Yêu cầu test UID, cookie, ảnh thật trước khi mua

Hỏi kỹ chính sách bảo hành checkpoint

Kinh nghi���m dùng VIA Việt không die, không checkpoint

Để sử dụng VIA Việt chạy quảng cáo Facebook hiệu quả, cần thực hiện đúng các bước sau:

1. Chuẩn bị môi trường sạch

Sử dụng IP Việt ổn định (tránh IP spam)

Dùng trình duyệt ẩn danh như SVB Care

2. Login đúng cách

Không login trực tiếp bằng Chrome

Không đổi pass, ảnh đại diện, mail trong 2–3 ngày đầu

Tương tác nhẹ: like vài post, join group, comment thật

3. Chạy test ads nhỏ

Tạo BM sau 1–2 ngày login ổn định

Chạy camp $3–5 để kiểm tra trust

Nếu camp sống → scale dần, không tăng quá nhanh

4. Sao lưu & backup

Lưu lại UID, Gmail, cookie

Dùng phần mềm quản lý via nếu chạy nhiều tài khoản

Tổng kết

Mua VIA Việt chạy quảng cáo đúng cách sẽ giúp bạn giảm rủi ro checkpoint, giữ camp sống dài và tối ưu ngân sách khi làm Facebook Ads. Trong năm 2025, với xu hướng siết chặt tài khoản quảng cáo, đầu tư vào một via chất lượng sẽ giúp bạn yên tâm hơn rất nhiều.

Hãy chọn đúng loại via phù hợp (thường, XMDT, 902), mua từ nơi uy tín, và đặc biệt là sử dụng đúng kỹ thuật – để mỗi tài khoản trở thành tài sản thật sự.

📌 Cần mua VIA Việt chất lượng, bảo hành uy tín?

Chúng tôi cung cấp đầy đủ: VIA Việt thường – XMDT – 902, bảo hành checkpoint, hỗ trợ login Svb Care, tư vấn chọn loại via phù hợp theo ngân sách & mục tiêu.

👉 Nhắn ngay Zalo 0981 282 956 để nhận bảng giá & combo ưu đãi mới nhất!

#mua via việt#mua via việt chạy quảng cáo#mua via việt chạy quảng cáo facebook#mua via facebook việt#mua via việt xmdt#mua via việt 902

0 notes

Text

Growth of the EV Battery Testing Equipment Market

The EV Battery Electrical Testing Equipment Market plays a critical role in ensuring the safety, performance, and reliability of electric vehicle batteries. The necessity of stringent testing, inspection, and certification procedures has been highlighted by the rise in EV battery component failures. Additionally, the emergence of digital technologies is changing testing practices and making real-time, more accurate diagnosis possible. Manufacturers are investing in cutting-edge testing apparatus that supports battery cells, modules, packs, and Battery Management System (BMS) Hardware-in-the-Loop (HIL) simulation as battery technologies advance, opening the door for improved quality control and market expansion.

Key Growth Drivers

Increase of EV Battery Issues: High-accuracy testing solutions are in greater demand as the failure rate of EV battery components rises. To guarantee long-term safety, dependability, and battery life, these instruments are crucial for identifying even the smallest defects.

Testing's Digital Transformation: Battery testing is becoming much more accurate and efficient thanks to technologies like artificial intelligence (AI), machine learning, and real-time analytics. The market's growth is further supported by these tools, which make predictive maintenance, more intelligent diagnostics, and quicker decision-making possible.

Market Challenges

Regulatory Standards Are Changing: Manufacturers are constantly under pressure to upgrade their testing procedures and equipment due to changing testing laws, which can be expensive and time-consuming.

Connecting Legacy Systems: There may be financial and technical challenges when integrating cutting-edge testing technology with outdated infrastructure. This intricacy could increase implementation costs and hinder market penetration.

Key Market Players

Arbin Instruments

Tektronix

Keysight Technologies

Rohde & Schwarz

Dynamic Manufacturing, Inc.

ATEC

Chroma ATE

Fluke Corporation

Yokogawa Electric Corporation

Market Segmentation

By Application

Battery Cell

Battery Module and Pack

BMS HIL

By Product

Oscilloscopes

Digital Multimeters

Source Measure Units (SMUs)

Battery Management System Testers

By Region

North America

Europe

Asia-Pacific

Rest of the World

Download TOC for this report!

Learn more about Automotive Vertical. Click Here!

Conclusion

The need for dependable battery testing equipment is anticipated to increase significantly as the global shift to electric vehicles picks up speed. Stricter regulations, quick technological breakthroughs, and a quest for safer, better-performing batteries are all influencing the industry. The emphasis on digital precision and innovation places this market as a pillar of the EV industry's future success, despite obstacles including legacy system integration and standardization.

#EV Battery Testing Equipment Market#EV Battery Testing Equipment Industry#EV Battery Testing Equipment Report#automotive

0 notes

Text

0 notes

Text

0 notes

Text

IPCS GLOBAL KOCHI

IPCS Global Kochi is an ISO certified company that operates in several fields of education which includes Automation, BMS and CCTV, Embedded and IOT, Python and Data Science, Digital Marketing, Artificial Intelligence, Software Testing, Corporate Training, In Campus Training and Technical Partners. IPCS Global offers a wide range of goods to students including drives, sensors, DCS systems,Supervisory Control and Data Acquisition, HMI systems, and PLCs.

Software Testing

Master software testing from methodologies to test case execution. Their program enhances your skills with comprehensive training. Learn testing approaches, design test cases effectively, and gain hands-on experience. Become a proficient tester, ready for industry challenges. Elevate your career with IPCS Global today.

Digital Marketing

Enhance your online presence and become a digital marketing expert with their comprehensive course. Learn cutting-edge strategies, tools, and techniques to boost your brand's visibility and achieve exceptional results. Join IPCS Global and leverage the power of digital marketing to propel your brand's success.

Python

Explore with python and data science. Enrol in their Python course to begin an exceptional journey that will take you forward as an expert programmer. Their vast program thoughtfully covers the fundamentals and advanced elements of Python, providing you with the data and skills you need to succeed as a developer.

Industrial Automation

Explore industrial automation with their specialised course. Develop essential skills for success in this dynamic field through hands-on projects and real-world case studies. Gain practical experience and stay ahead in the ever-evolving world of industrial automation. Enrol now to propel your career forward with confidence.

Embedded System and IOT

Discover CCTV system fundamentals and delve into Building Management Systems (BMS) principles with IPCS Cochin's specialised course. Gain insights into surveillance technology and optimise building operations. Enhance your skills for the evolving security and facility management industries.

BMS and CCTV

Master CCTV system basics and explore Building Management Systems (BMS) principles with IPCS Cochin's specialised course. Dive into surveillance technology fundamentals and optimise building operations. Elevate your skills for evolving security and facility management industries.

Many people with IPCS GLOBAL training today work successfully in well known international corporations and they take precautions to guarantee total student satisfaction.

1 note

·

View note

Text

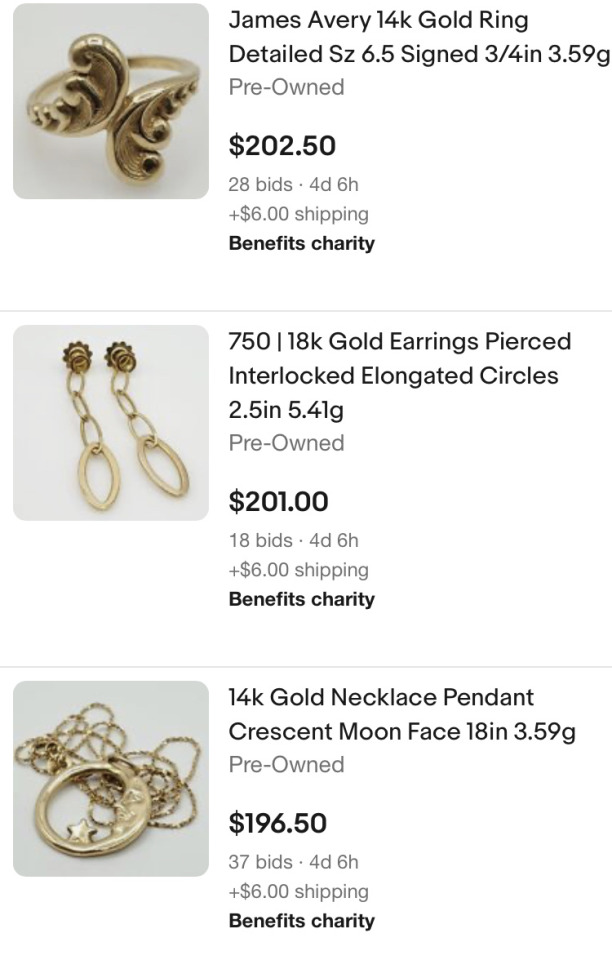

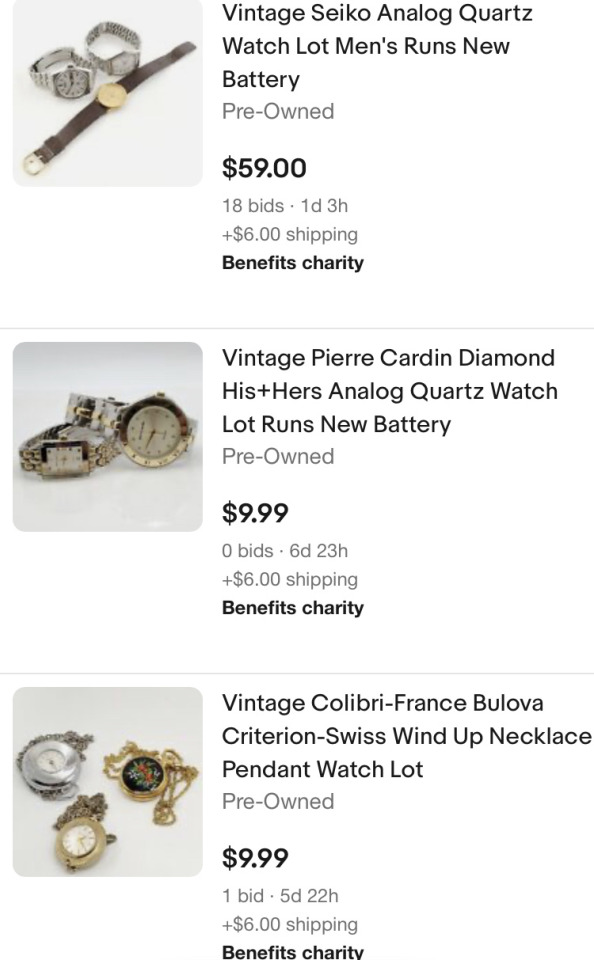

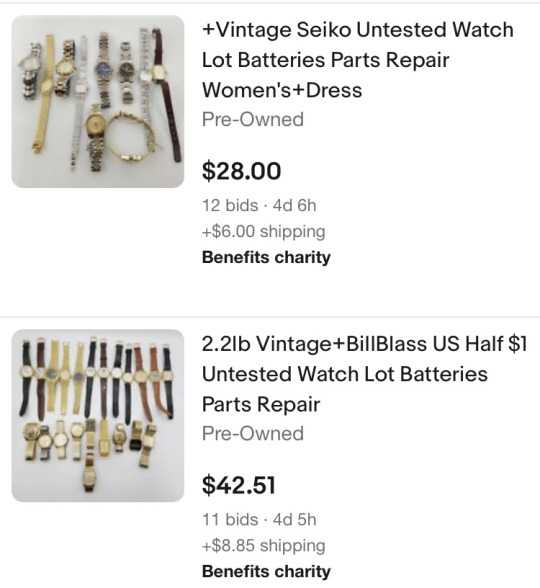

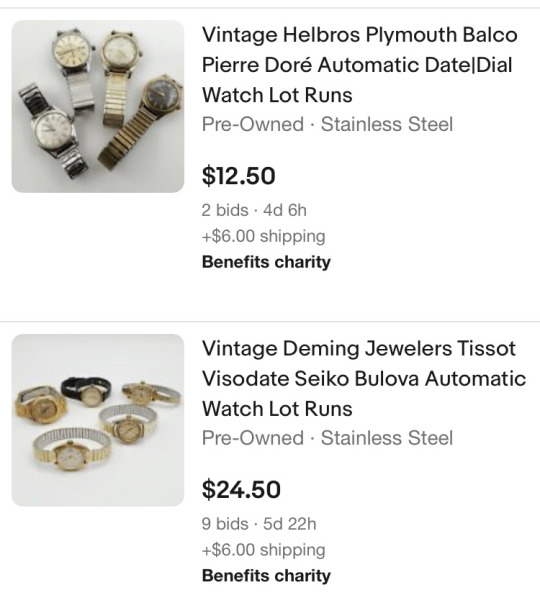

H a p p y 🥳

🎉🎊

#shopping for a good reason and worthwhile #charity

B e N e f i t

🛍️🚛🤩

Less than

🏪

To bid

⌚️👀💥

#vintage #Rotary Savannah #Swiss

Retail $399👆

👇👀

🖱️

@tumblr @youtube @thewritershelpers @wgaw @wgaeast-blog @aljazeera-blog @ap @press @twitter @yahoo @newshour @pbsarts @cnn @mlb @nba @wnba @vintage @fashion @thr @variety

#fine #gold @goldjewellerybuyeringurgaon

Want to see more

🖱️👇

#gemstones too💥

1 note

·

View note

Text

Empowering Performance: Unveiling BMS Tester for Battery Packs

In the dynamic realm of energy storage technology, innovation continues to redefine the benchmarks of performance, reliability, and safety. It is with great excitement that we present to you a game-changing advancement – the Battery Management System (BMS) Tester by Semco Infratech.

In this edition of our newsletter, we invite you to explore the cutting-edge features, unparalleled precision, and transformative potential of our latest offering, poised to elevate battery pack manufacturing to unprecedented heights.

As energy storage systems become increasingly integral to our modern lives, the BMS Tester emerges as a vital tool in the pursuit of optimal performance and utmost safety. From its intricate design to its powerful capabilities, this innovation promises to shape the future of battery management. Join us as we delve into the heart of this revolutionary solution and shed light on its potential to redefine how we approach energy storage technologies.

Precision at the Core: The BMS Tester for battery packs embodies precision engineering at its finest. With battery technology evolving at a rapid pace, the need for accurate and thorough testing has never been more crucial. Our BMS Tester is engineered to meticulously analyze every aspect of the battery management system. Its real-time monitoring capabilities allow for the assessment of voltage control, cell balancing, and fault detection, providing manufacturers with unparalleled insights into battery performance and health.

Seamless Integration for Efficiency: Integration into battery assembly lines is seamless, ensuring that the BMS Tester becomes an integral part of the production process. Its intuitive interface and customizable testing parameters make it adaptable to a wide range of battery chemistries, sizes, and types. This adaptability not only enhances manufacturing efficiency but also future-proofs your operations against evolving industry trends.

Upholding Safety and Reliability: Safety is paramount in energy storage applications, and the BMS Tester stands as a vigilant guardian. By identifying potential issues at an early stage, the tester prevents hazardous situations arising from overcharging, over-discharging, or voltage irregularities. This proactive approach not only enhances the reliability of the battery pack but also safeguards against risks associated with suboptimal performance.

A Technological Leverage: Leveraging the latest advancements in testing technology, the BMS Tester is a testament to our commitment to pushing the boundaries of innovation. Its modular design facilitates easy integration and customization, while its real-time reporting capabilities provide manufacturers with comprehensive data insights to optimize production processes.

Future-Ready Solutions: As energy storage technology continues to evolve, Semco Infratech remains at the forefront of innovation. The BMS Tester is designed with adaptability in mind, ready to accommodate emerging battery chemistries and configurations. Our tool's versatility positions manufacturers to be proactive in meeting future industry demands while maintaining the highest standards of quality and performance.

Conclusion

The BMS Tester by Semco Infratech represents a quantum leap in battery pack testing technology. Its precision, adaptability, and emphasis on safety set it apart as a cornerstone solution in energy storage manufacturing.

As the energy landscape transforms and consumer expectations rise, the BMS Tester stands as a beacon of innovation, guiding the industry toward a future marked by superior battery performance and unparalleled reliability.

For technical specifications, inquiries, and demonstrations, feel free to reach out to our dedicated team. Join us on this journey as we reshape the energy storage landscape and forge ahead into a brighter, more efficient future.

#battery management system#battery pack manufacturing#BMS Tester#electric vehicles#energy storage system#lithium ion batteries#lithium ion battery packs

0 notes

Text

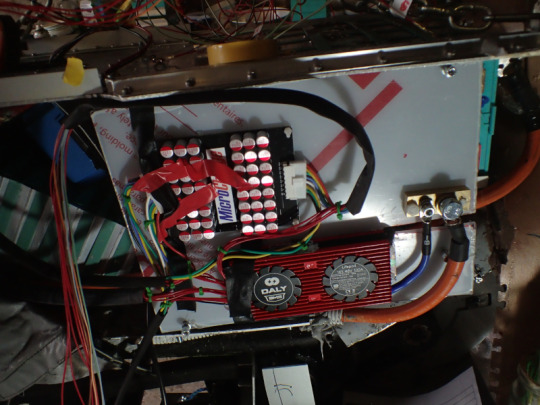

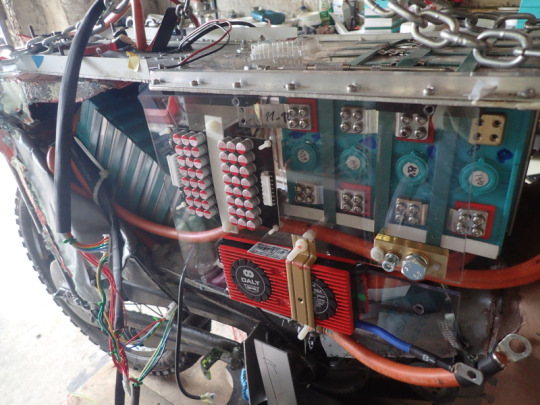

- Ich nutze den Feiertag, um die Halteplatte fertig zu machen und die Balancer- und BMS-Kabel für den ersten Batterieblock anzuschließen und durchzumessen. - I use the holiday to finish the retaining plate and connect and check the balancer and BMS cables for the first battery block. - Je profite de ce jour férié pour terminer la plaque de maintien et pour brancher et tester les câbles de l'équilibreur et du BMS pour le premier bloc de batteries. - Aprovecho las vacaciones para terminar la placa de retención y conectar y probar los cables del equilibrador y del BMS para el primer bloque de baterías. -- Ik gebruik de vakantie om de bevestigingsplaat af te werken en de balancer- en BMS-kabels voor het eerste batterijblok aan te sluiten en door te meten.

0 notes

Text

https://www.u-obd.com/product/audi-48v-battery-test-platform/

The Audi mild Hybrid car with 48 volt lithium battery, this 9.6 Ah, 13 strings battery cells usually have problems on output voltage, which caused by BMS locked. sometimes single cells capacity lose. for the Audi Hybrid car repair engineer we highly recommend this battery bench tester, can read the battery info, data stream, diagnose, trigger the battery output on bench…

#AUDI #AUDIhybrid #AUDImhev #AUDImildhybrid #AUDI48V #AUDI48Vbatterypouch #AUDIDCDC #DCDCinverter #DCDCconverter #5QF915105 #LGchem #4N0915105 #4K0959663 #4M0959663

1 note

·

View note

Text

DXC'S Masterlist

Do not rewrite or copy my work. Do not repost them on any platform without my permission. All of my stories are in this list just click "keep reading."

(*) 𝐬𝐭𝐚𝐧𝐝𝐬 𝐟𝐨𝐫 𝐬𝐦𝐮t

Chris Evans

BM ➞ "Trying to get her busy schedule organized along with being a single mom on top of the fame from the baby's father, it gets overwhelming."

BM2 ➞ "I mean, who going to believe a man when he says he wants you but he’s getting married."

BM3 ➞ "Reality always comes back and bites you in the ass."

BM4 ➞ "They meet for the planned lunch date. Chris still has a lot of things on his mind that he wants to speak about."

Steve Rogers

𝐌𝐚𝐫𝐫𝐢𝐚𝐠𝐞 ➞ Hermione is in an arranged marriage with Steve. He’s being an asshole but in the end, he realizes his mistake.

(*)𝐘𝐨𝐮𝐫 𝐖𝐢𝐟𝐞 ➞ Steve calls Peggy the love of his life even though he’s married to you. Set during Endgame.

𝐂𝐚𝐩𝐭𝐚𝐢𝐧 𝐀𝐦𝐞𝐫𝐢𝐜𝐚 𝐢𝐬 𝐚𝐥𝐰𝐚𝐲𝐬 𝐛𝐮𝐬𝐲. ➞ Steve misses your anniversary because he is always so busy.

𝐁𝐚𝐛𝐲 ➞ Instead of Hank and Bruce asking for Tony to help them with the quantum realm, they try to fix it themselves and ask for Hermione to be their tester.

↳ 𝐏𝐭. 𝟐 ➞ Aftermath of Hermione being a baby!

(*) 𝐈'𝐦 𝐧𝐨𝐭 𝐢𝐧𝐬𝐞𝐜𝐮𝐫𝐞. ➞ Hank and Bruce messed with something they don't know fully about. They bring back Peggy from the past which leads to some problems.

𝐂𝐡𝐞𝐚𝐭 ➞ Y/N and Steve get into a big argument, she leaves for the night so they could have some space apart. When Y/N comes back, secrets are revealed.

Happy Birthday ➞ It's Steve's birthday and Y/N has something up her sleeve.

As she should ➞ Y/N comes to one of Tony Stark's parties looking bad as ever after her breakup with Steve, as she should.

Adopted ➞ Armoni (Are- Money) is the newly adopted daughter of Steve Rogers. She doesn't know what she is getting into but eventually she will know they love her dearly.

↳ How he got her back ➞ After the events of Armoni going back to her birth parents. Steve finally worked through his problems to get his daughter back.

↳ "Bullshit" ➞ Armani sneaks out and Steve finds out.

Chris Evans ➞ wash my mouth out with soap ➞ All because of what Y/N said but did he already have plans to do it?

Bucky Barnes

𝐉𝐞𝐚𝐥𝐨𝐮𝐬 𝐁𝐮𝐜𝐤𝐲. ➞ Bucky doesn’t like sharing his girl.

𝐖𝐡𝐞𝐧 𝐡𝐞 𝐜𝐡𝐞𝐚𝐭𝐬 ➞ Y/N comes home from a meeting to find Bucky cheating.

↳ 𝐖𝐡𝐞𝐧 𝐡𝐞 𝐭𝐫𝐢𝐞𝐬 ➞ Little Melanie has an allergic reaction when she is at school. Instead of the teacher calling y/n, she calls bucky.

𝐑𝐞𝐦𝐞𝐦𝐛𝐞𝐫 𝐌𝐞? ➞ Y/N meets Bucky in the red room. Soon they separate. Years later, they reunite. (Towards the end is set during tfatws 1 episode)

𝐖𝐡𝐞𝐧 𝐡𝐞 𝐬𝐞𝐞𝐬 𝐦𝐞 ➞ Empriss prepares for her first date with Bucky.

𝐓𝐡𝐞𝐫𝐚𝐩𝐢𝐬𝐭 ➞ Y/N is a well-known respected therapist in Washington D.C. H.Y.D.R.A threatened Y/N to give therapy to the Winter Soldier to know his strength and weakness. Or they would kill her and the baby.

↳ 𝐏𝐚𝐫𝐭 𝟐 ➞ 4 months after the mishap of S.H.I.E.L.D, Bucky and Y/N settled down in Bucharest. During the arrival of Luca, Bucky has to leave.

↳ Part 3 ➞ It's too rainy for Y/N to go to work, so her, Bucky, Steve and Luca spend the day morning together.

(*) 𝐒𝐮𝐜𝐡 𝐚 𝐭𝐞𝐚𝐬𝐞 ➞ Y/N and Bucky always tease each other. One day at the tower by themselves, they find themselves not being able to keep their hands off each other.

𝐁𝐞𝐚𝐮𝐭𝐲 𝐚𝐧𝐝 𝐁𝐞𝐚𝐬𝐭𝐲 𝟏. ➞ Devora is the babysitter of President Barnes's children. To the kids, she is the best babysitter in the world because she lets them have their freedom. On the other hand, President Barnes is uptight, angry all the time, and strict. Today she had to put him in check.

↳ Part 2 ➞ This goes into Devora's back story a bit. When she comes home from picking the kids up from private school, James there waiting for them. She finally gets into contact with her best friend Alexis who is married to King Steve Rogers of Brooklyn. James makes way downstairs for a midnight snack to find her in the kitchen...

You've barely even danced with me ➞ Y/N and Bucky's relationship is starting to blossom but first, you have to make it through the shy stage.

TFATWS ➞ Y/N rides along with Sam, Zemo, and Bucky to Madripoor.

Little girl in a box ➞ Bucky and Y/N come home from their date to find a sweetheart in a box.

Evaluation ➞ Bucky nightmares are too much.

Cravings + Contractions ➞ Going into Emmie’s third trimester, the cravings hit but the contractions hit harder.

Sebastian Stan ➞ It's not perfect ➞ Imani is tired of Sebastian's shit. He doesn't understand that if he doesn't act right, she won't be in the picture long.

Blind ➞ Bucky is blinded by love from his girlfriend who is secretly just using him for good looks and money. Elara loves Bucky as a friend until she hung out with him more and the feelings for him grew.

↳ Blind 2 ➞ Roles has reverse on the best friends, monday morning he starts on trying to get Elara back but someone has caught her eye.

The Avengers

𝐃𝐨𝐮𝐛𝐥𝐞 𝐀𝐠𝐞𝐧𝐭 ➞ The team goes out for a normal date night but someone had different plans. Empriss has her true identity revealed.

Vacation ➞ The avengers finally have a break off from avenging the world. The first place they go for vacation? Maui Hawaii.

Overprotective ➞ Y/N is the adopted daughter of Howard and Maria Stark. She goes to school with all her siblings and today seems different than other days.

Stop following me ➞ The team wants to know what Y/N does in her past time which results in them following her to work.

Thor Odinson

𝐈 𝐜𝐚𝐧'𝐭 𝐭𝐫𝐮𝐬𝐭 𝐲𝐨𝐮 ➞ Y/N is best friends with Bucky even though it's problems between him and Thor.

Caught my eye ➞ Love at first sight, who doesn't love it.

Chris Hemsworth ➞ Tonight ➞ Chris spots Loni (Lon-E) in the club, completely fucked up. He spends the night protecting her and making sure she has the most fun.

Tonight's Ball ➞ Y/N finds her way to Asgard to win her boyfriend back but the night doesn't even so well.

Clark Kent

School ➞ Y/N had to set the record straight with Clark bullies.

New York ➞ After not being in contact for so long, someone decides to make a visit.

Tony Stark

Assistant ➞ It's Y/N day off and she needed to come to work for one thing but Tony had other plans.

Settled Down ➞ Tony's proposing and his daughter Y/N is in charge. Hopefully, everything goes right!

She flinches ➞ Getting disrespected by the workers and being hit by Tony's close 'friend'. Y/N doesn't get the respect she deserves until Stark shows up to make it known that she is in charge.

Loki Laufeyson

Wrong Idea ➞ Y/N does get back on Loki for him not always being around but it doesn't turn out right and he has to slice a couple of hands-off, not exaggerating.

Oscar Diaz

Mr.Spooky. ➞ Summer used to be Spooky's girlfriend until before he went to jail, he decides to cheat. Summer never wants to see them again until she decided to get drunk.

Geralt of Rivia

"Mine." ➞ Geralt lets Yennefer who Y/N belongs to after Yennefer tries to steal Y/N.

"Golden." ➞ Geralt is known to everyone that he is not the relationship type. After having an recurring dream, one woman is stuck on his mind and he can’t let this one get away.

Nick Jonas

Once Again ➞ This is the second version of my Camp Rock 2 story. In that story, Nova meets Nate at Camp Rock, and they spend their entire time at camp together. It’s years later, and they meet again, but his name is not Nate; it’s Nick. Nick Jonas.

Series

𝐏𝐫𝐞𝐭𝐭𝐲 𝐠𝐢𝐫𝐥 - Sebastian Stan ➞ Euphoria is the worker that takes orders from the cast and goes to pick their food up. She finds friends along the way. ↳

Part 1 | Part 2 | Part 3 | Part 4 | Part 5 | Part 6 |

Part 7 | Part 8 | Part 9 | Part 10 | Part 11

𝐂𝐡𝐚𝐫𝐦𝐚𝐢𝐧𝐞- Bucky Barnes ➞ A series about a girl who is Tony Stark's daughter and she falls for the man with a metal arm.

#marvel#the avengers#black mcu imagines#mcu imagine#steve rogers x you#bucky barnes fluff#more coming soon#sebastian stan x fem!reader#geralt the witcher#the witcher#thor x ofc#oscar diaz x reader#loki x black!reader#loki layfeyson x reader#geralt x oc#tony stark one shot#tony stark fluff#avengers x reader#clark kent x black!reader#clark kent fluff#thor x you#thor x reader#nick jonas x oc#chris evans x poc!reader#chris hemsworth fanfiction#chris evans x reader

444 notes

·

View notes

Note

Realistically Ace Race was probably taken out because they haven't finished the new map and the old ones are a little too practiced now, I think the maps will have more longevity now that the testers are not allowed to post vids of it so the players will need to find skips organically instead. Also Ace Race hasn't been skipped I think since its introduction, contrary to popular belief, BM has been.

yes this was exactly what i was saying, they don’t have a new ace race map ready and every current ace race map has been played several times, meaning all the long time mcc participants know the maps well enough lowering the margin of error making it even harder for the newer players,, i get wanting to see dream pop off at it but team wise this is a good thing for emerald since they have charlie

24 notes

·

View notes