#Belt Conveyors

Explore tagged Tumblr posts

Text

#psychrometric labs#belt conveyors#3 axis servo robots#pick and place robots#psychrometrc labs#environmental test chambers#test chambers

0 notes

Text

Methods India: Bulk Material Handling Equipment Manufacturers in Bangalore | Chennai | India

Looking for reliable bulk material handling equipment manufacturers in Bangalore, Chennai, Hyderabad, Mumbai, and across India? Methods India offers high-performance conveyors, silos, hoppers & more—custom-engineered to boost industrial efficiency. Trusted by top industries. Get a free quote today!

For more info, visit: https://methodsindia.com/methods-india-leading-structural-design-fabrication-bulk-material-handling-company/

#bulkmaterialhandling#bulkmaterialhandlingsystems#bulkmaterialmanufacturersinindia#methodsindia#structural steel fabrication#pipe conveyors#belt conveyors#bulkmaterialhandlingequipmentmanufacturersinindia#bulkmaterialhandlingequipmentmanufacturersinchennai#bulkmaterialhandlingequipmentmanufacturersinbangalore

0 notes

Video

youtube

conveyor belt

Welcome friends from all over the world to purchase conveyor belts in Qingdao.

Email:[email protected]

www.bqrubber.cn

0 notes

Text

Effective Solutions for Dust Control in Quarries

As environmental regulations become stricter, dust control in quarries has become a key focus of the industry. Screening equipment and belt conveyors are essential machinery in quarries. However, the dust generated during their operation not only affects the production environment but also poses health risks to employees. Therefore, customized dust control engineering solutions are crucial.

Dust Control for Screening Equipment

Implementing sealed devices and dust collection hoods is a primary measure for dust control in screening equipment. This approach involves fully or partially enclosing the screening equipment and installing dust collection hoods to effectively reduce dust emissions. The design of these hoods must consider dust diffusion characteristics and airflow organization to ensure effective dust collection and minimize environmental pollution.

In addition, efficient dust removal equipment is indispensable. We recommend using bag-type pulse dust collectors. These devices achieve dust removal efficiency of over 99%, meeting the demands for high air volume processing. The selection of dust collectors should be tailored to the specific dust characteristics and processing needs.

Dust Control for Belt Conveyors

For dust control on belt conveyors, bag-type pulse dust collectors are also the preferred choice. These collectors effectively manage dust generated during material transport, keeping the work environment clean. To enhance dust removal efficiency, we suggest placing dust extraction openings at the head, tail, and other dust-prone areas of the belt conveyor. The design of these openings must ensure they do not interfere with material transport, preventing secondary dust emissions.

System Control and Safety Measures

System control is also critical. Linking the dust collector's control system with the belt conveyor ensures that the dust collector operates automatically as needed. This integration improves system responsiveness. Additionally, installing pressure and temperature monitoring safety devices can further ensure the safe and stable operation of the dust collector under harsh conditions.

Site Survey and Customized Design

Before implementing dust control solutions, conduct a site survey to understand the specific layout and dust characteristics of the quarry. After thorough analysis, develop a targeted dust control design plan. This customized plan will ensure the appropriate model, specifications, quantity, and installation locations of the dust collectors, meeting production needs while reducing costs and enhancing space utilization.

Installation and Maintenance

During the installation phase, strictly follow the design plan and perform thorough testing before the dust control system goes live. Regular maintenance of the dust collectors is essential to ensure the cleanliness of the filter bags, which will extend the equipment's lifespan.

Conclusion

In summary, quarries can effectively improve their production environment and enhance employee safety through customized dust control solutions. The industry's development relies on recognizing and implementing environmental technologies. The future of the quarry industry urgently requires deeper exploration and technological innovation in environmental protection.

For more information or professional advice, please contact us.

0 notes

Text

vimeo

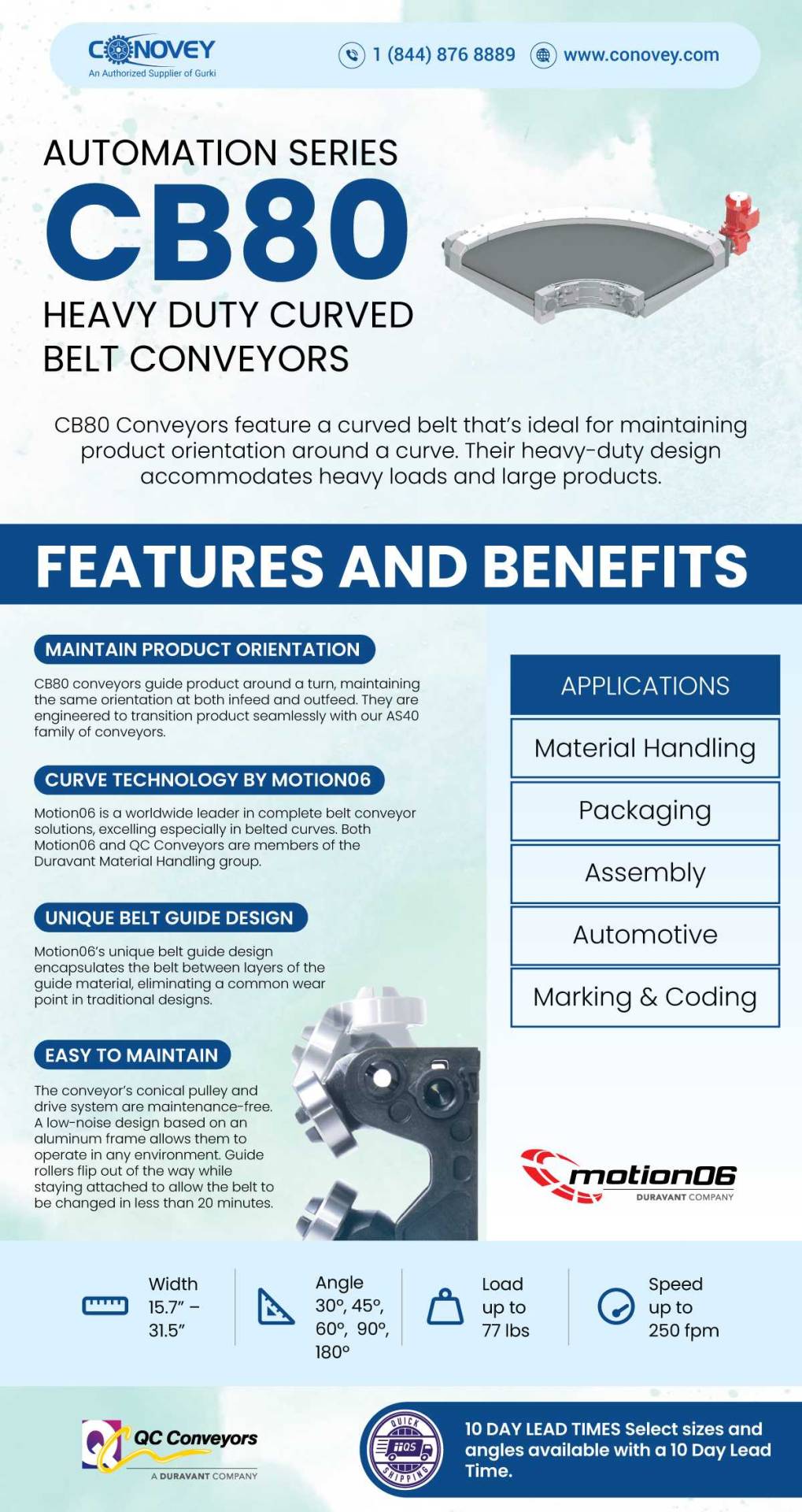

Automation Series CB80 Heavy Duty Curved Belt Conveyors

CB80 Conveyors feature a curved belt that's ideal for maintaining product orientation around a curve. Their heavy-duty design accommodates heavy loads and large products.

0 notes

Text

Belt conveyors streamline material handling with efficiency and versatility, perfect for industries like mining, manufacturing, and logistics. Enhance productivity with durable, customizable conveyor systems.

0 notes

Text

Automation Series CB80 Heavy Duty Curved Belt Conveyors

CB80 Conveyors feature a curved belt that's ideal for maintaining product orientation around a curve. Their heavy-duty design accommodates heavy loads and large products.

0 notes

Text

Conveyor Manufacturer in India

In the fast-paced world of manufacturing and logistics, conveyors play a crucial role in moving products, packaging, foodstuffs, and equipment efficiently from one location to another. As a vital component of automated manufacturing and finishing processes, conveyors come in a variety of configurations to meet the diverse needs of manufacturers and distributors globally.

Understanding Conveyor Systems

Conveyors are designed to handle a wide range of goods, with different types available for specific applications. The most common types include:

Belt Conveyors: Ideal for transporting bulk materials and packaged goods.

Chain Conveyors: Suitable for heavy loads and durable transportation.

Roller Conveyors: Perfect for smooth movement of items and easy integration into existing systems.

Spiral Conveyors: Space-saving solutions for vertical transportation.

Overhead Conveyors: Efficient for manufacturing processes that require elevated transportation.

Vertical Conveyors: Designed to move goods between different levels.

Combination Conveyors: Customized systems that integrate various types for enhanced flexibility.

Sawhney Industries: Expertise in Custom Solutions

With over four decades of experience in designing and manufacturing material handling equipment, Sawhney Industries stands out as a leading conveyor manufacturer in India. Our expertise allows us to provide tailored solutions that meet the unique material handling requirements across a wide range of industries, including automotive, ceramics, chemicals, pharmaceuticals, electronics, food and agriculture, and many more.

The Importance of Conveyors in Automation

As industries increasingly invest in automation to enhance efficiency, conveyors have become essential to internal logistics processes. Each application demands specific capabilities, and our team at Sawhney Industries is dedicated to helping clients select the right conveyor system, custom-designed to meet their functional needs.

By combining simplicity with innovative design, our conveyors seamlessly integrate into your existing systems, making operations smoother and more efficient.

Benefits of Using Conveyors

Investing in conveyor systems offers numerous advantages:

Increased Efficiency: Conveyors speed up the production process, allowing for higher output.

Cost Reduction: They help lower labor costs by automating material handling tasks.

Streamlined Assembly: Conveyors enhance the assembly process, making it faster and more organized.

Our Commitment to Excellence

Founded with a commitment to serving our customers, Sawhney Industries strives to deliver ideal transport and material handling solutions. We understand that each industry has unique challenges, and our extensive experience allows us to address these effectively.

As the leading conveyor manufacturer in India, we are dedicated to driving innovation in material handling and ensuring that our clients achieve their operational goals.

For more information about our conveyor systems and how we can assist you, please visit our website or contact our team today!

#sawhneyindustries#belt conveyors#conveyers manufacturing#conveyersmanufacturinginindia#madeinindia#manufacturing

0 notes

Text

Conveyors

0 notes

Text

What Are the Main Uses of Belt Conveyors?

A belt conveyor is a mechanical system that transports materials from one location to another, commonly found in industries like mining, agriculture, and manufacturing. It consists of a continuous loop of material (the belt) that moves over pulleys. Belt conveyors are efficient for moving bulk items, offering reliability and cost-effectiveness in handling tasks. DEWSON is a top belt conveyor manufacturer in India, offering durable, efficient, and cost-effective material handling solutions for various industries with superior quality standards.

0 notes

Text

Best conveyor supplier and manufacturer in faridabad, India

#conveyor manufacturer#conveyorbelt#conveyorsystems#conveyor rollers#conveyorsolutions#belt conveyors

0 notes

Text

#robotics in food industry#psychrometric labs#belt conveyors#side entry iml robots#3 axis servo robots

0 notes

Text

How Belt Conveyors Streamline Modern Supply Chains

Belt Conveyors are widely used in industries for efficient material handling. These systems facilitate smooth transportation, reduce manual labor, and enhance productivity. They help minimize downtime and ensure that supply chains operate seamlessly. With their ability to handle bulk materials over long distances, they have become an essential part of industrial operations. Their efficiency in reducing operational costs makes them a key component in various sectors, including manufacturing, mining, and logistics.

0 notes

Text

Our company's rubber conveyor belts are delivered to customers by truck.

0 notes

Text

Solutions for Belt Misalignment in Belt Conveyors

Belt misalignment is a common and challenging problem in the operation of belt conveyors. The root cause of misalignment lies in the net external forces acting on the belt in the width direction, which is not zero, or uneven tensile stress perpendicular to the belt width. This imbalance causes the reaction force from rollers or drums to exert a sideways force on the belt, leading to misalignment. This article analyzes the causes of belt misalignment and provides effective corrective measures.

Causes of Belt Misalignment

1. Misalignment of Centers

The head, tail, and middle frames may not align properly. This misalignment often occurs due to improper installation, causing the belt's longitudinal centerline to be non-perpendicular to the drum axis, affecting operation.

2. Incorrect Roller Position

All rollers must be installed perpendicular to the belt centerline and parallel to the horizontal plane. If this requirement is not met, the belt will shift to one side.

3. Improper Belt Joint

Whether using mechanical or vulcanized joints, any irregularities in the joint can lead to uneven tension on both sides, causing misalignment during operation.

4. Misaligned Roller Frame

The centerline of the roller group must align with the centerline of the machine frame. The allowable error is no more than 3.0 mm. If the roller frame is improperly installed or bolts are loose, the belt may misalign.

5. Belt Damage

If the degree of damage is inconsistent on both sides of the belt, it may cause uneven stretching and result in misalignment.

6. Improper Discharge Point

Uneven material discharge can lead to uneven force distribution on the belt, causing it to misalign. If the discharge point is off-center, it should be adjusted promptly.

7. Impact from Material Drop

When material falls onto the belt, its weight and inertia can cause the belt to shift.

8. Accumulated Material

Sticky materials can accumulate on rollers or drums, leading to uneven tension and causing misalignment.

9. Incorrect Roller Angle

If the roller installation angle is not accurate, it can cause the belt to shift in the carrying section.

10. Belt Quality Issues

If the density of the belt is uneven, this can lead to uneven tension and result in misalignment.

11. Tensioning Device Issues

Improper installation or adjustment of the tensioning device can lead to uneven tension and cause misalignment.

12. Aging from Long-Term Use

Over time, belts can loosen, increasing the risk of misalignment.

13. Frame Inclination

If the frame is tilted, it can exert lateral force on the belt.

14. Equipment Vibration

Severe vibrations during operation, particularly radial movement of rollers, can cause the belt to misalign.

15. Small Curvature Radius

If the curvature radius of a concave section is too small, the belt may lift during startup.

Corrective Measures for Belt Misalignment

To address the above causes, the following measures can be implemented:

Align the Head, Tail, and Middle Frames: Ensure all three components are aligned on the same centerline.

Correct Roller Position: Ensure the roller axis is perpendicular to the belt and parallel to the horizontal plane.

Adjust Belt Joints: Remove any improperly aligned joints and ensure they are straight.

Realign Roller Frames: Move the roller frame on the misaligned side and recalibrate as necessary.

Enhance Maintenance: Regularly inspect the belt and promptly repair or replace any damaged sections.

Adjust Discharge Point: Ensure the discharge point is centered on the belt.

Design Appropriate Material Guides: Avoid direct drops of large objects and install buffer rollers at the discharge point.

Clear Accumulated Material: Keep roller and drum surfaces clean and maintain the operation of cleaning devices.

Adjust Roller Group Position: Modify the installation holes based on the direction of misalignment.

Choose Reputable Manufacturers: Ensure quality equipment and good after-sales service.

Install Tensioning Devices Properly: Make sure the centerline is perpendicular to the roller axis and follow installation requirements.

Conduct Regular Inspections: Replace aging or deformed belts promptly.

Correct Frame Inclination: Reinstall the frame to ensure it is level.

Identify and Address Vibration Issues: Resolve any sources of equipment vibration.

Add Pressure Rollers: Install pressure rollers in concave sections to prevent the belt from lifting.

In the operation of belt conveyors, it is essential to monitor belt misalignment closely. Timely identification of the causes and implementation of appropriate measures are key to maintaining efficient and stable operation. By following these corrective actions, you can effectively reduce the risks associated with misalignment and enhance production efficiency.For further inquiries or assistance, please feel free to contact us! We are here to help and support you.

0 notes