#BioPlastics

Explore tagged Tumblr posts

Text

Researchers are using bacteria that eat food scraps to create a new kind of fully biodegradable plastic that reduces waste and could be less expensive to manufacture than current plastics are. The team from the University of Waterloo says this new method produces plastics that are soft and flexible, leading to many potential applications such as food wrap, drug delivery and in the repair of damaged tissues and organs. The study, "Production and Characterization of Biopolymer from Food Waste Using Pseudomonas putida," was recently published in ACS ES&T Engineering.

Continue Reading.

65 notes

·

View notes

Text

Considering i havent posted on my main crafts account but i have a lot to say i will do a mini post with a few things ive done recently:

Most recently (like, today) corn starch/glycerine/vinegar bioplastics (+yellow onion skin dye for the orange, not yet set fully) Should be good to take out of the plates in like 8 or so days

WIP drying pumpkin out to hopefully make a patterned container, found a pumpkin someone had thrown on the sode of the road and carved a design into it/emptied it out

i'm *hoping* packing it with salt will let it drain of enough water like the last pumpkin i made this way. I think i might not have thinned the walls enough and it'll take a while to dry before i can test this guess

Spun yarn (raw wool washed using saponins extracted from lambsquarters/goosefoot seed coatings)

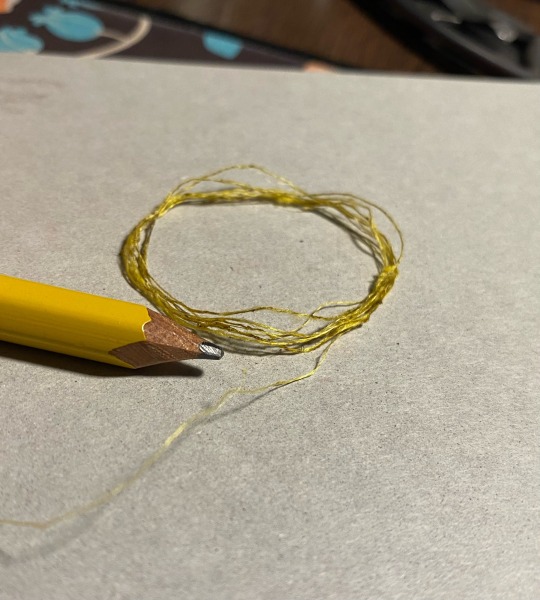

SPIDER SILK plus beginnings of a very tiny weaving attempt again with them; i think it's too tiny for the warp though

A small sampling of plant pigments (usually anthocyanins) i've tried working with recently (mostly mixed with water, some egg tempura experimenting as well)

Hoping that posting this will kickstart my brain to post more about these specific things with even more detailed observations soon

(particularly the anthocyanins)

216 notes

·

View notes

Text

https://news.ku.dk/all_news/2024/06/researchers-invent-one-hundred-percent-biodegradable-barley-plastic/

From the article; Enormous islands of it float in our oceans and microscopic particles of it are in our bodies. The durability, malleability and low cost of plastics has made them ubiquitous, from packaging to clothing to aircraft parts. But plastics have a downside. Plastics contaminate nature, are tough to recycle and their production emits more CO2 than all air traffic combined.

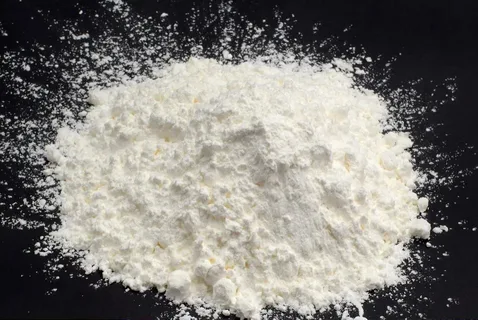

Now, researchers at the University of Copenhagen’s Department of Plant and Environmental Sciences have invented a new material made from modified starch that can completely decompose in nature – and do so within only two months. The material is made using natural plant material from crops and could be used for food packaging, among many other things.

"We have an enormous problem with our plastic waste that recycling seems incapable of solving. Therefore, we’ve developed a new type of bioplastic that is stronger and can better withstand water than current bioplastics. At the same time, our material is one hundred percent biodegradable and can be converted into compost by microorganisms if it ends up somewhere other than a bin," says Professor Andreas Blennow of the Department of Plant and Environmental Sciences.

Only about nine percent of plastic is recycled globally, with the rest being either incinerated or winding up in nature or dumped into enormous plastic landfills.

Bioplastics already exist, but the name is misleading says Professor Blennow. While today’s bioplastics are made of bio-derived materials, only a limited part of them is actually degradable, and only under special conditions in industrial composting plants.

"I don't find the name suitable because the most common types of bioplastics don't break down that easily if tossed into nature. The process can take many years and some of it continues to pollute as microplastic. Specialized facilities are needed to break down bioplastics. And even then, a very limited part of them can be recycled, with the rest ending up as waste," says the researcher.

Starch from barley and sugar industry waste

The new material is a so-called biocomposite and composed of several different substances that decompose naturally. Its main ingredients, amylose and cellulose, are common across the plant kingdom. Amylose is extracted from many crops including corn, potatoes, wheat and barley.

Together with researchers from Aarhus University, the research team founded a spinoff company in which they developed a barley variety that produces pure amylose in its kernels. This new variety is important because pure amylose is far less likely to turn into a paste when it interacts with water compared to regular starch. Cellulose is a carbohydrate found in all plants and we know it from cotton and linen fibers, as well as from wood and paper products. The cellulose used by the researchers is a so-called nanocellulose made from local sugar industry waste. And these nanocellulose fibers, which are one thousand times smaller than the fibers of linen and cotton, are what contribute to the material’s mechanical strength.

"Amylose and cellulose form long, strong molecular chains. Combining them has allowed us to create a durable, flexible material that has the potential to be used for shopping bags and the packaging of goods that we now wrap in plastic," says Andreas Blennow.

The new biomaterial is produced by either dissolving the raw materials in water and mixing them together or by heating them under pressure. By doing so, small 'pellets' or chips are created that can then be processed and compressed into a desired form.

Thus far, the researchers have only produced prototypes in the laboratory. But according to Professor Blennow, getting production started in Denmark and many other places in the world would be relatively easy.

"The entire production chain of amylose-rich starch already exists. Indeed, millions of tons of pure potato and corn starch are produced every year and used by the food industry and elsewhere. Therefore, easy access to the majority of our ingredients is guaranteed for the large-scale production of this material," he says.

Could reduce plastic problem

Andreas Blennow and his fellow researchers are now processing a patent application that, once it has been approved, could pave the way for production of the new biocomposite material. Because, despite the huge sums of money being devoted to sorting and recycling our plastic, the researcher does not believe that it will really be a success. Doing so should be seen as a transitional technology until we bid fossil-based plastics a final farewell.

"Recycling plastic efficiently is anything but straightforward. Different things in plastics must be separated from each other and there are major differences between plastic types, meaning that the process must be done in a safe way so that no contaminants end up in the recycled plastic. At the same time, countries and consumers must sort their plastic. This is a massive task that I don’t see us succeeding at. Instead, we should rethink things in terms of utilizing new materials that perform like plastic, but don’t pollute the planet," says Blennow.

The researcher is already collaborating with two Danish packaging companies to develop prototypes for food packaging, among other things. He envisions many other uses for the material as well, such as for the interior trims of cars by the automotive industry. Though it is difficult to say when this biofriendly barley-based plastic will reach the shelves, the researcher predicts that the new material may become a reality in the foreseeable future.

“It's quite close to the point where we can really start producing prototypes in collaboration with our research team and companies. I think it's realistic that different prototypes in soft and hard packaging, such as trays, bottles and bags, will be developed within one to five years," concludes Andreas Blennow.

#good news#plastics#plastic pollution#plastic pollution solutions#environmentalism#science#environment#microplastics#bioplastics#recycling#plastic recycling#sustainability

63 notes

·

View notes

Text

Scientists discover fastest degrading bioplastic in seawater

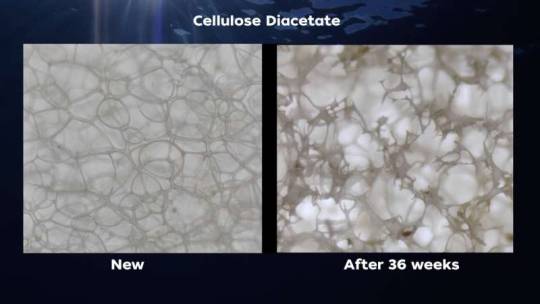

Scientists at the Wood Hole Oceanographic Institution (WHOI) have been working for years to find out what types of plastics have the shortest and longest lifespans in the ocean, and what types of plastic products, like straws and food wrappers, most commonly contribute to plastic pollution. With more biodegradable materials being developed, like cellulose diacetate (CDA)—a plastic-like polymer derived from wood pulp—researchers are racing to ensure they can replace traditional plastics without causing harm to ocean environments. Now after years of testing, a new version of CDA was found to be the fastest degrading bioplastic material tested in seawater—and it's a promising replacement for other foam plastic materials, like Styrofoam, which can linger in the environment for many years.

Read more.

#Materials Science#Science#Seawater#Biomaterials#Bioplastics#Plastics#Polymers#Biodegradable#Cellulose

17 notes

·

View notes

Text

i didnt cook food for myself but i cooked fabric

2 notes

·

View notes

Text

Remediation of Water Pollution by Plastics: A Strategic Approach 🌍💧

The world faces an unprecedented plastic pollution crisis, with plastic production reaching a staggering 330 billion tons annually. While plastic offers convenience, its environmental impact has become undeniable. Our water bodies, covering nearly two-thirds of the Earth, are heavily polluted by plastics, posing grave risks to aquatic ecosystems and human health. This blog explores key strategies to tackle plastic pollution and protect our water resources.

The Global Plastic Pollution Crisis 🛑🌊

Plastics, once seen as a breakthrough innovation, have now become a significant environmental challenge. From packaging to electronics, plastics are used in almost every sector. However, only less than 10% of plastics are recycled, and the rest end up in landfills or, worse, in our oceans and rivers. This ongoing issue has escalated, especially in aquatic environments, where plastics are causing lasting damage to marine life and freshwater ecosystems.

Water: Our Vital Resource Under Threat 💧❗

Water is essential for all life on Earth, making up 60% of the human body and crucial for survival. Yet, water pollution from plastic waste is an alarming issue. Oceans, which cover 98% of Earth’s water, are becoming increasingly contaminated with plastic debris. This pollution not only damages marine ecosystems but also affects freshwater sources, which are already under pressure from population growth and industrial activities.

A Three-Pronged Approach to Tackling Plastic Pollution 🌱🔬📊

To combat this growing crisis, experts propose a three-pronged approach:

Development of Bioplastics 🌿 Bioplastics, derived from renewable resources like plants and algae, present a sustainable alternative to conventional plastics. These biodegradable materials break down more easily in the environment, reducing plastic waste in water bodies. Investment in bioplastics can help phase out traditional plastics and limit further contamination.

Biodegradation Using Microorganisms 🦠 Microorganisms capable of breaking down plastics offer another solution. Certain bacteria and fungi can decompose plastics like polyethylene and polystyrene. Harnessing these natural processes could accelerate plastic breakdown in water bodies and help mitigate the damage.

Raising Awareness and Policy Reform 🗣️📜 Public awareness about the dangers of plastic pollution is crucial. Communities must be educated on sustainable waste management practices, while governments must implement policies that regulate plastic production, promote recycling, and encourage the use of eco-friendly alternatives.

The Role of Policy and Global Cooperation 🌎🤝

Plastic pollution is a global issue that requires cooperation across borders. Governments, international organizations, and research institutions must collaborate to create policies that regulate plastic production, improve waste management systems, and support sustainable practices. Strong policy reforms can help reduce plastic use, encourage bioplastics, and raise awareness.

Conclusion: A Call for Action 🚨🌱

The pollution of our water bodies by plastics is a growing environmental threat. Immediate action is required to develop bioplastics, utilize biodegradation techniques, and implement strong policies to protect our water resources. By adopting these strategies, we can restore the health of our aquatic ecosystems and ensure a cleaner, safer planet for future generations.

Read Full Article: Remediation of Water Pollution by Plastics: A Strategic Approach

https://go.nature.com/4jp7f0I

https://doi.org/10.1007/978-3-030-52395-4_3

#academia#books#literature#nature#university#PlasticPollution#WaterPollution#Bioplastics#SustainableSolutions#EcoFriendly#PlasticWaste#MarineConservation#ClimateAction#GreenInnovation#WaterConservation#Biodegradation#EnvironmentalImpact#SaveOurOceans#EcoAwareness#PollutionSolution#EnvironmentalPolicy#SustainableFuture#ProtectOurPlanet#PlasticFree#GlobalCooperation#ReducePlastic#CleanWater#EcoRevolution#GreenTechnology

2 notes

·

View notes

Text

#Bioplastics#Cassava bioplastics#Green alternatives#Eco-friendly plastics#Bioplastics in India#Nagaland bioplastics#Cassava plastic#Sustainable plastic

1 note

·

View note

Text

There are things in life I can only receive as gifts🏄

2 notes

·

View notes

Text

Fashion designer: LIZA KEANE

18 notes

·

View notes

Text

#lore soong#st tng#star trek borg#Dominar of The Borg#Tumblr hates that tag for some reason#borg king#bioplastics#gold gold gold#lore star trek#lore tng#androids#cyborgs

3 notes

·

View notes

Text

What if there was plastic-like material that could absorb excess nutrients from water and be used as a fertilizer when it decomposes? That product—a "bioplastic" material—has been created by University of Saskatchewan (USask) chemistry professor Dr. Lee Wilson and his research team, as detailed in a paper recently published in RSC Sustainability. The research team includes Ph.D. candidate Bernd G. K. Steiger, BSc student Nam Bui and postdoctoral fellow trainee Bolanle M. Babalola. "We've made a bioplastic material that functions as an absorbent and it takes phosphate out of water, where elevated levels of phosphate in surface water is a huge global water security issue," he said. "You can harvest those pellets and distribute them as an agricultural fertilizer."

Continue Reading.

113 notes

·

View notes

Text

Film Forming Starches Market trends shaping innovation across packaging industries worldwide

The global Film Forming Starches Market is witnessing a surge in interest as industries increasingly prioritize sustainable alternatives to traditional packaging. This trend is being driven by growing environmental concerns, regulatory pressures, and consumer demand for eco-friendly products. As a result, starch-based films are emerging as a key innovation supporting the transition to greener packaging solutions.

Introduction: The Rise of Sustainable Packaging

The packaging industry is undergoing a fundamental shift toward sustainability, driven by increasing public awareness and strict environmental policies. Businesses are now exploring biodegradable materials that align with the principles of a circular economy. Film forming starches, derived from renewable sources such as corn, potato, and tapioca, have emerged as a viable replacement for synthetic plastics in various packaging applications.

These starches form flexible, transparent, and biodegradable films that can protect products without contributing to long-term waste. Their adoption is helping packaging manufacturers meet sustainability goals while delivering the performance required for modern applications.

What Are Film Forming Starches?

Film forming starches are modified natural starches capable of creating thin, cohesive films that serve as protective layers. These films can be used to wrap food, coat tablets, and even serve as agricultural mulch. Their composition is completely biodegradable and often compostable, making them an ideal choice in the search for sustainable material options.

Unlike petroleum-based plastics, film forming starches degrade naturally in the environment, reducing the burden on waste management systems. They also offer desirable properties such as moisture resistance, elasticity, and barrier capabilities when properly formulated.

Packaging Industry Trends Fueling Market Growth

1. Environmental Regulations Driving Change

Many countries have introduced bans or heavy taxes on single-use plastics. These regulatory pressures have accelerated the demand for biodegradable packaging materials. Film forming starches offer a compliant and environmentally responsible option, helping companies avoid penalties while aligning with future-ready packaging strategies.

2. Innovation in Coating and Blending Techniques

Technological advancements have improved the performance of starch films through blending with natural plasticizers or additives. These developments have expanded the functional capabilities of starch films, making them more resistant to moisture and wear. New coating technologies also enable multilayer applications that enhance protection without compromising biodegradability.

3. Market Push for Transparency and Clean Labels

In both food and personal care sectors, there's a growing demand for packaging materials that are visibly clean and free of synthetic additives. Starch-based films provide an attractive option for brands looking to promote transparency and health-conscious values, particularly in packaging that touches consumables directly.

Application Segments Experiencing Rapid Growth

Food Packaging

Film forming starches are extensively used in the food sector for packaging fresh produce, snacks, and baked goods. Their transparency, breathability, and edible nature make them especially appealing for direct-contact packaging. They also extend shelf life by reducing moisture and oxygen exposure, all without introducing synthetic compounds.

Pharmaceuticals

In pharmaceutical manufacturing, starch-based films are applied as coatings for tablets and capsules. These coatings serve several purposes—masking taste, protecting ingredients from oxidation, and enabling controlled release of active substances. As the pharmaceutical industry shifts toward plant-based and hypoallergenic options, film forming starches are becoming more prominent.

Agriculture and Industrial Sectors

Starch films are also gaining traction in agricultural applications such as seed coatings and mulch films. These films degrade naturally, returning nutrients to the soil while reducing plastic pollution. In industrial sectors, they're being explored for protective wrapping of goods that require short-term packaging with low environmental impact.

Innovation and R&D Initiatives

Partnerships Driving Breakthroughs

Companies are increasingly forming cross-industry partnerships to improve starch film formulations. R&D collaborations between biopolymer manufacturers, food tech firms, and research institutions are leading to breakthroughs in mechanical strength, water resistance, and shelf life.

Investment in Production Technologies

Investments in advanced extrusion and film-forming technologies are making it easier to scale up production while maintaining quality. Pilot programs focused on cost-efficient starch film manufacturing are helping overcome the price gap compared to synthetic plastics.

Challenges Hindering Broader Adoption

Despite their promise, film forming starches face limitations. These include sensitivity to humidity, shorter shelf life compared to synthetic films, and higher production costs in certain applications. Further innovation is required to address these issues while maintaining the material’s natural and biodegradable qualities.

Additionally, supply chain constraints for high-quality starch sources and the lack of standardized testing protocols across industries are slowing down global adoption.

Future Outlook: A Material with Long-Term Promise

As sustainability continues to influence packaging decisions across the globe, film forming starches are expected to occupy a central role in innovation. From biodegradable bags to edible wrappers, their potential applications are diverse and continually expanding. With ongoing technological improvements and stronger regulatory support, the Film Forming Starches Market is poised to lead the shift toward greener, more responsible packaging.

Conclusion

The rise of film forming starches signals a meaningful change in how industries approach packaging. Their renewable origin, biodegradability, and adaptability make them a natural fit for sectors looking to reduce plastic usage and embrace sustainability. As more businesses recognize their potential, this market is set to expand rapidly and influence the next generation of packaging solutions.

#sustainablepackaging#bioplastics#filmformingstarches#greenmaterials#packaginginnovation#cleanlabel#biodegradablefilms#ecoalternatives#plantbasedpackaging#marketinsights

0 notes

Text

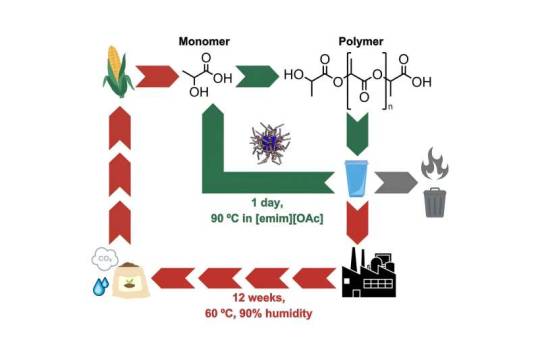

An enzyme used in laundry detergent can recycle single-use plastics within 24 hours

Scientists at King's College London have developed an innovative solution for recycling single-use bioplastics commonly used in disposable items such as coffee cups and food containers. The novel method of chemical recycling, published in Cell Reports Physical Science, uses enzymes typically found in biological laundry detergents to "depolymerize"—or break down—landfill-bound bioplastics. Rapidly converting the items into soluble fragments within just 24 hours, the process achieves full degradation of the bioplastic polylactic acid (PLA). The approach is 84 times faster than the 12-week-long industrial composting process used for recycling bioplastic materials. This discovery offers a widespread recycling solution for single-use PLA plastics, as the team of chemists at King's found that in a further 24 hours at a temperature of 90°C, the bioplastics break down into their chemical building blocks. Once converted into monomers—single molecules—the materials can be turned into equally high-quality plastic for multiple reuse.

Read more.

#Materials Science#Science#Enzymes#Plastics#Polymers#Recycling#King's College London#Bioplastics#Biomaterials#Polylactic acid

54 notes

·

View notes

Text

Avantium signed an offtake agreement with PLIXXENT for FDCA in insulation foams

CEO Tom Van Aken and Her Majesty Queen Maxima. Source: Avantium Avantium, a leading company in renewable and circular polymer materials, signed a conditional offtake agreement for five years with PLIXXENT, a leading producer of polyurethane systems. Under this offtake agreement, PLIXXENT will purchase FDCA (furandicarboxylic acid), produced in Avantium’s FDCA Flagship Plant, for the use in foams…

View On WordPress

0 notes

Text

Sustainable Materials on the Rise: Inside the Bioplastics Boom

The bioplastics market is revolutionizing the global plastics industry by offering a greener, more sustainable alternative to traditional petroleum-based plastics. Derived from renewable sources like corn starch, sugarcane, or even algae, bioplastics are gaining traction across packaging, agriculture, automotive, and consumer goods sectors.

Market Overview

Bioplastics are either biodegradable, bio-based, or both. They offer a significant reduction in carbon footprint and align with growing consumer demand for eco-friendly products. As governments impose bans and taxes on single-use plastics, industries are rapidly switching to sustainable alternatives.

Key Market Drivers

Environmental Regulations: Global bans on single-use plastics are accelerating the shift to biodegradable materials.

Consumer Demand for Sustainability: Eco-conscious buyers are pushing brands to adopt greener packaging and materials.

Corporate Sustainability Goals: Major companies are pledging to reduce plastic waste and switch to bioplastics.

Technological Advancements: New-generation bioplastics like PHA and PLA offer performance similar to traditional plastics with less environmental impact.

Challenges

Higher Cost Compared to Conventional Plastics: Raw material sourcing and production remain expensive.

Limited Industrial Composting Infrastructure: Biodegradable plastics often require specific conditions to break down.

Competition from Traditional Plastics: Petrochemical plastics still dominate in price and scalability.

Market Outlook

The global bioplastics market is projected to grow at a robust CAGR over the next decade. Asia-Pacific leads production, while Europe dominates consumption due to stringent environmental policies. Packaging remains the largest segment, followed by textiles, consumer electronics, and automotive interiors.

Applications of Bioplastics

Food & beverage packaging

Agricultural films

Biomedical devices

3D printing filaments

Automotive interior components

Single-use items (bags, cutlery, containers)

Conclusion

The bioplastics market is not just a trend—it’s a transformative movement toward a circular economy. As innovation continues and costs fall, bioplastics are set to become a mainstream material, reshaping industries and protecting the planet.

0 notes