#BioPolymers

Explore tagged Tumblr posts

Text

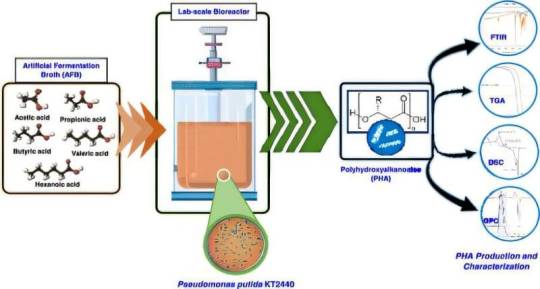

Turning table scraps into biodegradable, single-use plastics

Researchers are using bacteria that eat food scraps to create a new kind of fully biodegradable plastic that reduces waste and could be less expensive to manufacture than current plastics are. The team from the University of Waterloo says this new method produces plastics that are soft and flexible, leading to many potential applications such as food wrap, drug delivery and in the repair of damaged tissues and organs. The study, "Production and Characterization of Biopolymer from Food Waste Using Pseudomonas putida," was recently published in ACS ES&T Engineering. "Using food waste as food for bacteria which can produce bioplastics is a very exciting development," said Dr. Trevor Charles, a professor in the Department of Biology at Waterloo, and one of the authors of the study. "This approach is significant because it has the possibility to reduce the cost of creating biopolymers."

Read more.

#Materials Science#Science#Food#Waste#Plastics#Polymers#Biodegradable#University of Waterloo#Bacteria#Materials processing#Biopolymers#Biomaterials

9 notes

·

View notes

Text

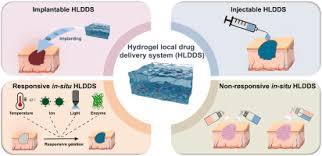

Hydrogel-based Drug Delivery Market adoption trends accelerating global pharmaceutical transformation

The hydrogel-based drug delivery market is witnessing unprecedented traction as pharmaceutical industries globally pivot toward more precise, responsive, and biocompatible drug delivery platforms. A key contributor to this transformation is the growing demand for targeted therapies and controlled release formulations. As companies explore adaptive polymer systems, hydrogel technology stands out.

Rising Strategic Importance of Hydrogels in Pharma

Hydrogels are being rapidly adopted across pharmaceutical product development because of their unique capacity to hold large volumes of water, modulate drug release, and adapt to physiological stimuli. These characteristics are crucial in ensuring drug stability, targeting precision, and minimizing systemic toxicity. The shift toward patient-centric formulations and minimally invasive administration methods has also fueled the integration of hydrogels into a wide array of therapeutic areas.

Therapeutic categories benefiting from hydrogel-based solutions include oncology, cardiology, orthopedics, endocrinology, and ophthalmology. As treatment complexity rises, pharmaceutical stakeholders are aligning R&D efforts to create drug delivery platforms that reduce patient burden while enhancing efficacy — with hydrogels at the core of these innovations.

Surge in Advanced Therapy Integration

One of the most compelling adoption trends is the role of hydrogels in delivering biologics, including peptides, proteins, monoclonal antibodies, and gene-based therapies. These large-molecule drugs often require protection from degradation and targeted delivery to specific tissues. Hydrogel matrices offer a tunable environment that enables encapsulation and controlled release, improving therapeutic outcomes in diseases such as cancer, diabetes, and autoimmune conditions.

Furthermore, smart hydrogels that respond to pH, temperature, or enzymes are enabling dynamic dosing profiles that reflect real-time physiological needs. This evolution supports the pharmaceutical industry’s broader shift toward personalized medicine and adaptive therapies.

Research Pipeline Expansion and Academic Collaborations

The global rise in clinical and translational research centered on hydrogels is significantly influencing market momentum. Academic institutions, biotech startups, and pharmaceutical giants are forming partnerships to explore novel hydrogel compositions that improve drug loading efficiency, biocompatibility, and responsiveness.

These collaborations have yielded promising data in preclinical models for wound healing, post-surgical drug administration, and localized cancer treatments. In addition, regulatory agencies are engaging more openly with hydrogel formulation pathways, providing clear protocols for Investigational New Drug (IND) applications and fast-tracking approvals for high-need therapeutic areas.

Manufacturing Innovations and Scalability Breakthroughs

Manufacturing scalability is another pillar accelerating the global hydrogel-based drug delivery trend. Automation, modular bioprocessing units, and cleanroom-compatible systems now enable the high-throughput production of medical-grade hydrogels with consistent quality and performance.

Contract development and manufacturing organizations (CDMOs) specializing in hydrogel synthesis have emerged, offering integrated services from polymer customization to final product packaging. This outsourcing trend is particularly beneficial for mid-sized and emerging pharmaceutical firms that lack in-house infrastructure but seek to remain competitive in formulation innovation.

Environmental and Regulatory Pressures Favoring Biodegradable Systems

The use of biodegradable hydrogels made from natural polymers such as alginate, gelatin, hyaluronic acid, and chitosan is gaining popularity due to increasing pressure to reduce environmental impact. These materials not only degrade safely within the human body but also eliminate the need for removal procedures in applications like wound care, implants, and ophthalmic devices.

Regulatory agencies are emphasizing green chemistry approaches and safety over the product lifecycle. Hydrogel systems that comply with these expectations provide a dual advantage — smoother regulatory pathways and stronger market appeal among environmentally conscious stakeholders.

Global Demand Trends and Regional Market Dynamics

North America continues to dominate the hydrogel-based drug delivery space due to its advanced pharmaceutical infrastructure, robust innovation ecosystems, and responsive regulatory landscape. However, the Asia-Pacific region is rapidly narrowing the gap, driven by large patient populations, expanding healthcare access, and proactive government support for biotech innovation.

Countries such as China, India, and South Korea are significantly investing in hydrogel-related drug research and domestic production. This regional shift is helping globalize hydrogel-based platforms and expand access to novel therapies in previously underserved markets.

Market Consolidation and Competitive Strategies

The competitive landscape of the hydrogel-based drug delivery sector is marked by strategic consolidations, licensing agreements, and co-development partnerships. Established players like Johnson & Johnson, Amgen, and Novartis are investing heavily in external innovation by partnering with hydrogel-focused biotech firms. This allows for rapid integration of advanced platforms into existing therapeutic pipelines.

Startups are also receiving venture capital backing based on proprietary hydrogel technology, particularly those offering cross-therapeutic versatility. The emphasis on IP-rich platforms capable of sustained or localized drug delivery is reshaping pharmaceutical deal-making across early and late-stage development programs.

Forward Outlook: Hydrogels as Pillars of Modern Drug Delivery

As the pharmaceutical sector evolves, the importance of sophisticated drug delivery systems becomes increasingly central. Hydrogels — with their adaptability, responsiveness, and compatibility — are positioning themselves as fundamental enablers of next-generation therapies. From targeted cancer treatments to long-acting injectables for chronic disease, hydrogels are enhancing how drugs are delivered, absorbed, and experienced by patients.

Future developments are expected to focus on integrating hydrogels with digital health tools, including biosensor interfaces, to enable real-time monitoring and dosing adjustments. Additionally, advancements in 3D printing are opening new possibilities in hydrogel-based personalized implants and smart delivery devices.

The hydrogel-based drug delivery market is not just responding to existing pharmaceutical needs; it is actively shaping the future of medicine through its transformative potential.

#hydrogeldelivery#pharmaceuticalinnovation#controlledrelease#biopolymers#drugformulation#biotechnologytrends#personalizedmedicine#chronicdiseasetreatment#smartdrugdelivery#healthtechinnovation

0 notes

Video

youtube

Sustainable Packaging Explainer #sciencefather #researchawards #scientist

🌿📦 Biopolymers and their nanocomposites coated paper-based high barrier and sustainable food packaging materials are emerging as eco-friendly alternatives to traditional plastic packaging. These innovative materials combine biodegradable biopolymers with advanced nanocomposite coatings to enhance barrier properties against moisture, oxygen, and oils, making them ideal for preserving food freshness and quality 🍞🍓🥫. The paper-based structure ensures recyclability and compostability, aligning with global sustainability goals 🌍♻️. By replacing petroleum-based plastics, this green technology supports a circular economy while reducing environmental pollution, offering a promising solution for the future of food packaging 🌱🛍️📉.

Natural Scientist Awards

Nomination Link: https://naturalscientist.org/award-nomination/?ecategory=Awards&rcategory=Awardee

Visit Our Website 🌐naturalscientist.org

Contact us [email protected]

Get Connected Here:

LinkedIn: https://www.linkedin.com/in/natural-scientist-466a56357/

Blogger: https://naturalaward.blogspot.com/

Instagram: https://www.instagram.com/natural_scientist/

Pinterest: https://in.pinterest.com/research2805/_profile/

Youtube: https://www.youtube.com/@NaturalScientistAwards

Facebook: https://www.facebook.com/profile.php?id=61574191899176

#youtube#sciencefather#naturalscientistawards#researchawards#biopolymers#nanocomposites#sustainablepackaging#foodpackaging#ecofriendlymaterials#biodegradablepackaging#paperbasedpackaging#greeninnovation#circulareconomy#packagingtechnology#highbarriermaterials#compostablepackaging#environmentallyfriendly#nanotechnologyinfo#sustainablematerials

0 notes

Text

The Remarkable World of Chitin: Nature's Versatile Polymer Revolutionizing Modern Applications

Chitin, the second most abundant natural polymer after cellulose, is a long-chain polysaccharide composed of N-acetylglucosamine units. This remarkable biopolymer forms the structural framework in the exoskeletons of arthropods, cell walls of fungi, and shells of mollusks.

The natural abundance of Chitin is staggering, with an estimated annual production of 100 billion metric tons in marine environments alone.

Get More Insights On - Chitin

0 notes

Text

Chitosan Market Anticipated to Grow Due to Biomedical Demand

Chitosan, a versatile biopolymer obtained through the deacetylation of chitin, finds extensive applications across industries such as healthcare, agriculture, water treatment, cosmetics, and food preservation. Its inherent advantages—biodegradability, biocompatibility, non-toxicity, film-forming ability, and inherent antimicrobial activity—make it an increasingly preferred material for advanced drug delivery systems, wound dressings, and tissue engineering scaffolds. In agriculture, chitosan-based formulations serve as biofertilizers and biopesticides, enhancing crop yield and reducing reliance on synthetic chemicals. In water treatment, its high affinity for heavy metals and dyes enables efficient removal of contaminants, while in cosmetics, it acts as a natural thickener, moisturizing agent, and preservative extender. Rising consumer demand for eco-friendly and sustainable products is propelling R&D efforts to develop novel chitosan derivatives with improved solubility and functional properties. Chitosan Market - https://www.patreon.com/posts/chitosan-market-127799726

#ChitosanMarket#ChitosanMarketShare#EnzymaticProduction#Biopolymers#BiomedicalApplications#CoherentMarketInsights

0 notes

Text

🌿 Biopolymers and Beyond: Sustainable Materials Redefining Industrial Innovation

By Hafiz Muhammad Husnain Azam Researcher, Brandenburg University of Technology Cottbus-Senftenberg 📘 Published 🔗 Read Full Chapter on Wiley

The Material Revolution Starts with Nature

In an era driven by the urgent need for environmental responsibility, industries across the globe are turning to biopolymers—natural, biodegradable materials derived from plants and microorganisms—as sustainable alternatives to petroleum-based plastics. But biopolymers are no longer limited to raw forms.

In this chapter, we explore the next generation of biopolymer engineering, including:

Blends

Interpenetrating Polymer Networks (IPNs)

Gels

Composites

Nanocomposites

Each form unlocks new levels of functionality, durability, and industrial relevance—setting a new benchmark for sustainable material science.

🔍 What’s Inside the Chapter?

✅ Biopolymer Fundamentals

Derived from natural sources like chitin, starch, and bacterial fermentation, biopolymers offer biodegradability, renewability, and low toxicity—key drivers for their rise in packaging, agriculture, and medical sectors.

✅ Blends & Composites

Blending different biopolymers (e.g., PLA + PBAT) or reinforcing them with natural fibers like hemp and flax creates materials with superior mechanical and thermal properties—ideal for packaging, automotive parts, and construction components.

✅ IPNs (Interpenetrating Polymer Networks)

These materials interlace multiple polymer networks at the molecular level, providing enhanced strength, elasticity, and chemical resistance. Their applications span tissue engineering, drug delivery, and industrial coatings.

✅ Gels & Hydrogels

Engineered for biomedical and pharmaceutical applications, these viscoelastic materials mimic tissue behavior and offer excellent moisture retention, making them useful in wound healing and drug delivery.

✅ Biopolymer-Based Nanocomposites

Infused with graphene oxide, CNTs, and metal nanoparticles, these advanced materials deliver exceptional barrier properties, conductivity, and antimicrobial activity—revolutionizing electronics, sensors, and environmental cleanup systems.

🌍 Applications Across Industries

Sustainable Packaging: Compostable materials replacing traditional plastics

Biomedical Engineering: Smart gels and scaffolds for regenerative medicine

Environmental Remediation: Nanocomposites that adsorb heavy metals and organic toxins

Smart Materials: Biopolymer-based systems with stimuli-responsive behavior

⚠️ Challenges and the Path Forward

Despite immense potential, the commercialization of biopolymer systems is constrained by:

Mechanical performance gaps

Higher production costs

Scalability concerns

Ongoing research focuses on nanofiller optimization, hybrid design, and cost-effective green synthesis to overcome these hurdles. The goal: making sustainable materials mainstream, not niche.

Let’s Redefine the Future of Materials

This chapter is a comprehensive entry point into the world of sustainable, high-performance materials. If you're involved in materials science, product development, environmental policy, or green manufacturing, this research offers actionable insights to guide your innovation pipeline.

📖 Read the full study: Wiley – Biopolymer Blends, IPNs, and Nanocomposites

https://doi.org/10.1002/9781119783473.ch1

https://go.nature.com/4j29x66

#Biopolymers#GreenMaterials#SustainablePackaging#BioComposites#EcoInnovation#Nanocomposites#SmartMaterials#MaterialsScience#CircularEconomy#RenewableResources#GreenEngineering#BiodegradableMaterials#AdvancedPolymers#IPNs#Hydrogels#EcoFriendlyPlastics#SmartPackaging#FutureOfMaterials#EnvironmentalRemediation#TissueEngineering#NaturalPolymers#SustainableDesign#Bioengineering#WasteToWealth#GreenManufacturing#UNSDG12#CleanTechnology#MaterialsInnovation#NatureBasedSolutions#books

1 note

·

View note

Text

#Bioplastics & Biopolymers Market#Bioplastics & Biopolymers#Bioplastics#Bioplastic#Biopolymers#Biopolymer#Bioplastics Market#Biopolymers Market

0 notes

Text

The Medical Polymer Market: Driving Innovation in Healthcare

The medical polymer market is experiencing significant growth, fueled by the evolving demands of the healthcare industry and technological advancements. These polymers—including bioresorbable materials, medical-grade plastics, and elastomers—are revolutionizing healthcare by enabling the creation of safer, more efficient, and patient-friendly solutions. From implants to drug delivery systems, medical polymers are shaping the future of modern medicine by offering unmatched versatility and reliability.

What’s Driving Market Growth?

The rapid growth of the medical polymer market is being propelled by several key factors, including aging populations, rising demand for minimally invasive procedures, and the expansion of healthcare infrastructure worldwide. It’s not just about meeting the rising needs of patients; it’s about doing so with materials that are biocompatible, durable, and cost-effective.

These polymers have become indispensable across healthcare applications. For instance, bioresorbable polymers are changing the game for drug delivery systems and tissue engineering. These materials gradually dissolve in the body, eliminating the need for follow-up surgeries—a breakthrough for both patients and healthcare providers.

Key Applications of Medical Polymers

Medical polymers are versatile, and their use spans several critical areas within the healthcare sector:

Medical Devices and Implants The demand for high-performance materials has led to widespread use of polymers like polyethylene, polycarbonate, and polyetheretherketone (PEEK). These materials are used to create everything from syringes and surgical tools to advanced orthopedic implants. PEEK, in particular, has gained attention in orthopedic surgery because of its exceptional strength, durability, and biocompatibility.

Drug Delivery Systems Controlled drug delivery is one of the most exciting applications of medical polymers. Bioresorbable materials like polylactic acid (PLA) and polyglycolic acid (PGA) allow medication to be released gradually over time, ensuring sustained treatment. For patients, this means fewer doses and better adherence to their treatment plans.

Medical Packaging In healthcare, maintaining hygiene and safety is paramount, and medical-grade plastics like polypropylene (PP) and polyethylene (PE) are essential for sterile packaging. From trays to blister packs, these materials ensure products remain uncontaminated and safe until they reach patients.

Tissue Engineering Innovations in regenerative medicine rely heavily on medical polymers. Bioresorbable scaffolds provide the foundation for tissue regeneration, supporting cell growth while gradually breaking down in the body. This technology is helping to repair tissues and organs in ways that once seemed impossible.

Innovative Trends Shaping the Market

The medical polymer market is dynamic, with constant advancements paving the way for new possibilities. Here are a few trends worth noting:

Eco-Friendly and Bioresorbable Polymers: Sustainability is becoming a priority. The industry is focused on developing materials that meet healthcare standards while reducing environmental impact.

3D Printing for Custom Solutions: Additive manufacturing is changing the game by allowing the production of patient-specific implants and devices. Medical-grade polymers compatible with 3D printing are unlocking new levels of precision and personalization.

Nanotechnology Integration: Nanotechnology is enhancing the capabilities of medical polymers, particularly in drug delivery systems. Nanopolymers enable targeted treatments, minimizing side effects and improving patient outcomes.

Demand for Minimally Invasive Devices: Polymers are enabling the development of smaller, more flexible tools that make procedures less invasive, reducing recovery times and enhancing patient comfort.

Overcoming Challenges

Despite its growth, the medical polymer market faces challenges. Regulatory hurdles, particularly around biocompatibility and safety, are significant. Meeting the stringent standards set by the FDA and EMA requires continuous innovation and rigorous testing. Additionally, the high production costs of advanced polymers can be a barrier for smaller manufacturers.

However, these challenges also open doors for innovation. Companies are investing heavily in R&D to create materials that are not only safer but also more cost-effective. Emerging markets, particularly in Asia-Pacific and Latin America, present enormous opportunities as healthcare systems modernize and demand for advanced materials increases.

The future of the medical polymer market is bright. Experts predict continued advancements in bioresorbable materials, smart polymers, and 3D-printed medical devices. As the healthcare industry focuses on patient-centered care, medical polymers will play a key role in delivering solutions that are innovative, effective, and sustainable.

The demand for polymers isn’t just about materials—it’s about improving lives. From enabling life-saving implants to ensuring medications are delivered precisely and efficiently, these polymers are solving real-world healthcare challenges. The next decade will likely see even greater breakthroughs as technology and material science evolve hand in hand.

Download PDF Brochure :

The medical polymer market stands at the forefront of healthcare innovation. Whether it’s improving drug delivery systems, enabling safer surgical procedures, or advancing regenerative medicine, these versatile materials are shaping the future of patient care. As industry leaders push the boundaries of what’s possible, medical polymers will continue to redefine healthcare standards, ensuring better outcomes for patients and practitioners alike.

#MedicalPolymers#HealthcareMaterials#MedicalInnovation#BioPolymers#MedicalDevices#MedicalPackaging#AdvancedMaterials#HealthcareSolutions#BiocompatibleMaterials#MedicalTechnology#PolymerScience

0 notes

Text

Synthetic And Bio-based Polypropylene Market: Detailed Insights on Size, Share, Growth Potential

The global synthetic and bio-based polypropylene market size is expected to reach USD 178.8 million by 2030, registering a CAGR of 8.8% from 2024 to 2030, according to a new report by Grand View Research, Inc. Growth of key end-use industries such as packaging and automotive in Asia Pacific is expected to drive the global polypropylene market the forecast period. In addition, increasing construction spending particularly in emerging markets of China, India, and Indonesia is also expected to have a positive influence on market growth.

Synthetic And Bio-based Polypropylene Market Report Highlights

Injection molding dominated the market and accounted for a market revenue share of 48.4% in 2023. Polypropylene's attributes, such as high impact resistance, chemical inertness, and ability to be molded into complex shapes, make it highly suitable for injection molding applications.

The Asia Pacific synthetic and bio-based polypropylene market dominated in 2023. This growth owes to significantly increasing environmental awareness and government regulations.

Bio-based polypropylene demand is more dominant in emerged markets of North America and Europe. These markets are characterized by stringent regulations and aware consumers regarding the environmental hazards caused due to petrochemical-based polypropylene.

For More Details or Sample Copy please visit link @: Synthetic And Bio-based Polypropylene Market Report

Volatile propylene prices on account of constantly fluctuating crude oil prices are expected to remain a key challenge for market participants. Stringent environmental regulations regarding the production and disposal of polypropylene are also expected to degrade the market growth over the forecast period. In order to overcome these issues, major participants have shifted their focus towards the development of sustainable polypropylene.

Injection molding emerged as the leading application segment and accounted for 46.1% of total market volume in 2014. The shift towards the replacement of the steel automotive industry in order to improve the fuel efficiency of automobiles is expected to remain a key driving factor for this segment over the forecast period. Films are expected to witness the highest growth rate of 5.7% from 2015 to 2022. Growing demand for BOPP films for a myriad of applications is expected to drive this segment over the forecast period.

List of major companies Synthetic And Bio-based Polypropylene Market

Braskem

Dow Inc.

Borealis AG

LyondellBasell Industries Holdings B.V.

Total S.A.

Trellis Bioplastics

BioAmber Inc.

NatureWorks LLC

Danimer Scientific

Novamont S.p.A.

FKuR Kunststoff GmbH

For Customized reports or Special Pricing please visit @: Synthetic And Bio-based Polypropylene Market Analysis Report

We have segmented the global synthetic and bio-based polypropylene market based on application, end-use, and region.

#BioPolypropylene#SyntheticPolypropylene#Polypropylene#BioBasedMaterials#SyntheticPolymers#SustainableMaterials#GreenChemistry#PlasticsIndustry#BioPolymers#EcoFriendlyPlastics#InnovationInMaterials#PolymerScience#BioPlastics

0 notes

Text

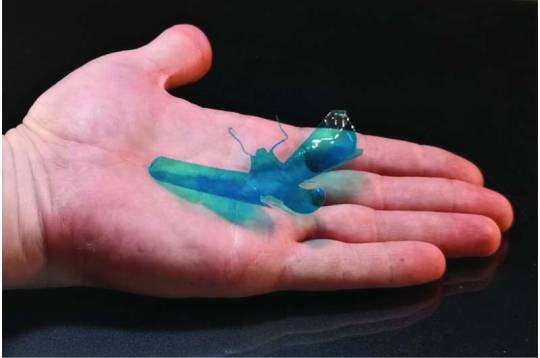

Scientists find key to engineering water-responsive biopolymers

Scientists at the Advanced Science Research Center at the CUNY Graduate Center (CUNY ASRC) have developed a novel approach to better understand and predict the behaviors of water-responsive materials—solid matter that can change shape by absorbing or releasing water in response to humidity fluctuations. These materials, commonly found in nature, have the potential to revolutionize a range of industries, from robotics and smart textiles to bioelectronics and clean energy generation systems. Despite water-responsive materials' growing popularity in research and development, a gap exists in the theoretical understanding of how these materials generate mechanical stress when they absorb and release water. A research team led by Professor Xi Chen at the CUNY ASRC Nanoscience Initiative and City College of New York's Chemical Engineering Department has pioneered a new quantitative method to correlate the structure of confined water with the macroscopic water-responsive properties of materials like silk.

Read more.

10 notes

·

View notes

Text

Making agriculture more resilient to climate change

New Post has been published on https://thedigitalinsider.com/making-agriculture-more-resilient-to-climate-change/

Making agriculture more resilient to climate change

As Earth’s temperature rises, agricultural practices will need to adapt. Droughts will likely become more frequent, and some land may no longer be arable. On top of that is the challenge of feeding an ever-growing population without expanding the production of fertilizer and other agrochemicals, which have a large carbon footprint that is contributing to the overall warming of the planet.

Researchers across MIT are taking on these agricultural challenges from a variety of angles, from engineering plants that sound an alarm when they’re under stress to making seeds more resilient to drought. These types of technologies, and more yet to be devised, will be essential to feed the world’s population as the climate changes.

“After water, the first thing we need is food. In terms of priority, there is water, food, and then everything else. As we are trying to find new strategies to support a world of 10 billion people, it will require us to invent new ways of making food,” says Benedetto Marelli, an associate professor of civil and environmental engineering at MIT.

Marelli is the director of one of the six missions of the recently launched Climate Project at MIT, which focus on research areas such as decarbonizing industry and building resilient cities. Marelli directs the Wild Cards mission, which aims to identify unconventional solutions that are high-risk and high-reward.

Drawing on expertise from a breadth of fields, MIT is well-positioned to tackle the challenges posed by climate change, Marelli says. “Bringing together our strengths across disciplines, including engineering, processing at scale, biological engineering, and infrastructure engineering, along with humanities, science, and economics, presents a great opportunity.”

Protecting seeds from drought

Marelli, who began his career as a biomedical engineer working on regenerative medicine, is now developing ways to boost crop yields by helping seeds to survive and germinate during drought conditions, or in soil that has been depleted of nutrients. To achieve that, he has devised seed coatings, based on silk and other polymers, that can envelop and nourish seeds during the critical germination process.

A new seed-coating process could facilitate agriculture on marginal arid lands by enabling the seeds to retain any available water.

In healthy soil, plants have access to nitrogen, phosphates, and other nutrients that they need, many of which are supplied by microbes that live in the soil. However, in soil that has suffered from drought or overfarming, these nutrients are lacking. Marelli’s idea was to coat the seeds with a polymer that can be embedded with plant-growth-promoting bacteria that “fix” nitrogen by absorbing it from the air and making it available to plants. The microbes can also make other necessary nutrients available to plants.

For the first generation of the seed coatings, he embedded these microbes in coatings made of silk — a material that he had previously shown can extend the shelf life of produce, meat, and other foods. In his lab at MIT, Marelli has shown that the seed coatings can help germinating plants survive drought, ultraviolet light exposure, and high salinity.

Now, working with researchers at the Mohammed VI Polytechnic University in Morocco, he is adapting the approach to crops native to Morocco, a country that has experienced six consecutive years of drought due a drop in rainfall linked to climate change.

For these studies, the researchers are using a biopolymer coating derived from food waste that can be easily obtained in Morocco, instead of silk.

“We’re working with local communities to extract the biopolymers, to try to have a process that works at scale so that we make materials that work in that specific environment.” Marelli says. “We may come up with an idea here at MIT within a high-resource environment, but then to work there, we need to talk with the local communities, with local stakeholders, and use their own ingenuity and try to match our solution with something that could actually be applied in the local environment.”

Microbes as fertilizers

Whether they are experiencing drought or not, crops grow much better when synthetic fertilizers are applied. Although it’s essential to most farms, applying fertilizer is expensive and has environmental consequences. Most of the world’s fertilizer is produced using the Haber-Bosch process, which converts nitrogen and hydrogen to ammonia at high temperatures and pressures. This energy intensive process accounts for about 1.5 percent of the world’s greenhouse gas emissions, and the transportation required to deliver it to farms around the world adds even more emissions.

Ariel Furst, the Paul M. Cook Career Development Assistant Professor of Chemical Engineering at MIT, is developing a microbial alternative to the Haber-Bosch process. Some farms have experimented with applying nitrogen-fixing bacteria directly to the roots of their crops, which has shown some success. However, the microbes are too delicate to be stored long-term or shipped anywhere, so they must be produced in a bioreactor on the farm.

MIT chemical engineers devised a metal-organic coating that protects bacterial cells from damage without impeding their growth or function.

To overcome those challenges, Furst has developed a way to coat the microbes with a protective shell that prevents them from being destroyed by heat or other stresses. The coating also protects microbes from damage caused by freeze-drying — a process that would make them easier to transport.

The coatings can vary in composition, but they all consist of two components. One is a metal such as iron, manganese, or zinc, and the other is a polyphenol — a type of plant-derived organic compound that includes tannins and other antioxidants. These two components self-assemble into a protective shell that encapsulates bacteria.

Play video

Mighty Microbes: The Power of Protective Polymers

Video: Chemistry Shorts

“These microbes would be delivered with the seeds, so it would remove the need for fertilizing mid-growing. It also reduces the cost and provides more autonomy to the farmers and decreases carbon emissions associated with agriculture,” Furst says. “We think it’ll be a way to make agriculture completely regenerative, so to bring back soil health while also boosting crop yields and the nutrient density of the crops.”

Furst has founded a company called Seia Bio, which is working on commercializing the coated microbes and has begun testing them on farms in Brazil. In her lab, Furst is also working on adapting the approach to coat microbes that can capture carbon dioxide from the atmosphere and turn it into limestone, which helps to raise the soil pH.

“It can help change the pH of soil to stabilize it, while also being a way to effectively perform direct air capture of CO2,” she says. “Right now, farmers may truck in limestone to change the pH of soil, and so you’re creating a lot of emissions to bring something in that microbes can do on their own.”

Distress sensors for plants

Several years ago, Michael Strano, the Carbon P. Dubbs Professor of Chemical Engineering at MIT, began to explore the idea of using plants themselves as sensors that could reveal when they’re in distress. When plants experience drought, attack by pests, or other kinds of stress, they produce hormones and other signaling molecules to defend themselves.

Strano, whose lab specializes in developing tiny sensors for a variety of molecules, wondered if such sensors could be deployed inside plants to pick up those distress signals. To create their sensors, Strano’s lab takes advantage of the special properties of single-walled carbon nanotubes, which emit fluorescent light. By wrapping the tubes with different types of polymers, the sensors can be tuned to detect specific targets, giving off a fluorescent signal when the target is present.

For use in plants, Strano and his colleagues created sensors that could detect signaling molecules such as salicylic acid and hydrogen peroxide. They then showed that these sensors could be inserted into the underside of plant leaves, without harming the plants. Once embedded in the mesophyll of the leaves, the sensors can pick up a variety of signals, which can be read with an infrared camera.

Sensors that detect plant signaling molecules can reveal when crops are experiencing too much light or heat, or attack from insects or microbes.

These sensors can reveal, in real-time, whether a plant is experiencing a variety of stresses. Until now, there hasn’t been a way to get that information fast enough for farmers to act on it.

“What we’re trying to do is make tools that get information into the hands of farmers very quickly, fast enough for them to make adaptive decisions that can increase yield,” Strano says. “We’re in the middle of a revolution of really understanding the way in which plants internally communicate and communicate with other plants.”

This kind of sensing could be deployed in fields, where it could help farmers respond more quickly to drought and other stresses, or in greenhouses, vertical farms, and other types of indoor farms that use technology to grow crops in a controlled environment.

Much of Strano’s work in this area has been conducted with the support of the U.S. Department of Agriculture (USDA) and as part of the Disruptive and Sustainable Technologies for Agricultural Precision (DiSTAP) program at the Singapore-MIT Alliance for Research and Technology (SMART), and sensors have been deployed in tests in crops at a controlled environment farm in Singapore called Growy.

“The same basic kinds of tools can help detect problems in open field agriculture or in controlled environment agriculture,” Strano says. “They both suffer from the same problem, which is that the farmers get information too late to prevent yield loss.”

Reducing pesticide use

Pesticides represent another huge financial expense for farmers: Worldwide, farmers spend about $60 billion per year on pesticides. Much of this pesticide ends up accumulating in water and soil, where it can harm many species, including humans. But, without using pesticides, farmers may lose more than half of their crops.

Kripa Varanasi, an MIT professor of mechanical engineering, is working on tools that can help farmers measure how much pesticide is reaching their plants, as well as technologies that can help pesticides adhere to plants more efficiently, reducing the amount that runs off into soil and water.

Varanasi, whose research focuses on interactions between liquid droplets and surfaces, began to think about applying his work to agriculture more than a decade ago, after attending a conference at the USDA. There, he was inspired to begin developing ways to improve the efficiency of pesticide application by optimizing the interactions that occur at leaf surfaces.

“Billions of drops of pesticide are being sprayed on every acre of crop, and only a small fraction is ultimately reaching and staying on target. This seemed to me like a problem that we could help to solve,” he says.

Varanasi and his students began exploring strategies to make drops of pesticide stick to leaves better, instead of bouncing off. They found that if they added polymers with positive and negative charges, the oppositely charged droplets would form a hydrophilic (water-attracting) coating on the leaf surface, which helps the next droplets applied to stick to the leaf.

Graduate student Maher Damak (left) and associate professor of mechanical engineering Kripa K. Varanasi, have found a way to drastically cut down on the amount of pesticide liquid that bounces off plants.

Later, they developed an easier-to-use technology in which a surfactant is added to the pesticide before spraying. When this mixture is sprayed through a special nozzle, it forms tiny droplets that are “cloaked” in surfactant. The surfactant helps the droplets to stick to the leaves within a few milliseconds, without bouncing off.

In 2020, Varanasi and Vishnu Jayaprakash SM ’19, PhD ’22 founded a company called AgZen to commercialize their technologies and get them into the hands of farmers. They incorporated their ideas for improving pesticide adhesion into a product called EnhanceCoverage.

During the testing for this product, they realized that there weren’t any good ways to measure how many of the droplets were staying on the plant. That led them to develop a product known as RealCoverage, which is based on machine vision. It can be attached to any pesticide sprayer and offer real-time feedback on what percentage of the pesticide droplets are sticking to and staying on every leaf.

RealCoverage was used on 65,000 acres of farmland across the United States in 2024, from soybeans in Iowa to cotton in Georgia. Farmers who used the product were able to reduce their pesticide use by 30 to 50 percent, by using the data to optimize delivery and, in some cases, even change what chemicals were sprayed.

He hopes that the EnhanceCoverage product, which is expected to become available in 2025, will help farmers further reduce their pesticide use.

“Our mission here is to help farmers with savings while helping them achieve better yields. We have found a way to do all this while also reducing waste and the amount of chemicals that we put into our atmosphere and into our soils and into our water,” Varanasi says. “This is the MIT approach: to figure out what are the real issues and how to come up with solutions. Now we have a tool and I hope that it’s deployed everywhere and everyone gets the benefit from it.”

#000#2024#Accounts#adhesion#agriculture#air#ammonia#approach#atmosphere#Bacteria#billion#Biological engineering#biopolymers#Brazil#Building#Capture#carbon#Carbon dioxide#carbon emissions#carbon footprint#carbon nanotubes#career#career development#Cells#challenge#change#chemical#Chemical engineering#chemicals#chemistry

0 notes

Text

Biopolymers Market - Forecast(2024 - 2030)

Biopolymers Market Overview

The Biopolymers Market size is projected to reach US$27.5 billion by 2030, after growing at a CAGR of 11.5% over the forecast period 2024–2030. The various benefits associated with the biopolymers such as polyesters, polylactic acid, polyhydroxy butyrate, polybutylene succinate and more include biocompatibility, biodegradability, renewability and more. These benefits make biopolymers a sustainable replacement for petroleum-derived materials. The bolstering food & beverage industry, including poultry products, dried food and more is the primary factor driving the biopolymers market growth. For instance, the FAO’s food outlook published in June 2023 expects global poultry meat production to reach more than 142 million mt, a 1.3% increase compared to 2022’s value. However, The COVID-19 pandemic resulted in restrictions affecting various aspects of the supply chain, including logistics, which had a detrimental impact on production activities in the biopolymers industry. Following the pandemic, government measures aimed at rejuvenating production activities played a crucial role in fueling the recovery and growth of the biopolymers industry. Moreover, the growth of the medical and healthcare industry is fueling the demand for biopolymers. As a result, the biopolymers market size will grow throughout the forecast period.

Request Sample Report:

Report Coverage-The “Biopolymers Market Report — Forecast (2024–2030)” by IndustryARC, covers an in-depth analysis of the following segments in the Biopolymers Market.

By Type: Bio-based Polyesters [Polylactic Acid (PLA), Polyhydroxybutyrate (PHB), Polybutylene Succinate (PBS), Polybutylene Succinate Adipate (PBSA), Polytrimethylene Terephthalate (PTT) and Others], Bio-based Polyolefins, Bio-based Polyamides (Bio-PA) (Homopolyamides, Bio-PA 6, Bio-PA 11, Copolyamides and Others), Polyurethanes, Polysaccharide Polymers (Cellulose-based Polymers and Starch-based Polymers) and Others.

Inquiry Before Buying:

By Molding Process: Extrusion, Injection, Melt compounding and Others.

By Application: Packaging (Rigid Packaging and Flexible Packaging), Fibers, Paper & Cardboard Coatings, Agricultural Seed Coatings, Automotive Interiors & Exteriors, Medical Implants, Circuit Boards, Insulators, Laminates and Others.

By End-use Industry: Food & Beverage (Fresh Food, Bakery, Frozen Food, Dried Food, Poultry Products, Dairy Products, Confectionery, Alcoholic Beverages, Non-alcoholic Beverages and Others), Medical & Healthcare (Pharmaceuticals, Medical Devices and Others), Agriculture, Consumer Electronics (Computers, Smartphones, Refrigerators and Others), Automotive [Passenger Vehicles (PV), Light Commercial Vehicles (LCV) and Heavy Commercial Vehicles (HCV)], Textile, Aerospace (Commercial, Military and Others), Building & Construction (Residential, Commercial, Industrial and Others) and Others

By Geography: North America (the USA, Canada and Mexico), Europe (UK, Germany, France, Italy, Netherlands, Spain, Russia, Belgium and the Rest of Europe), Asia-Pacific (China, Japan, India, South Korea, Australia and New Zealand, Indonesia, Taiwan, Malaysia and Rest of APAC), South America (Brazil, Argentina, Colombia, Chile and Rest of South America), Rest of the World [Middle East (Saudi Arabia, UAE, Israel and Rest of Middle East) and Africa (South Africa, Nigeria and Rest of Africa)]

Key Takeaways

• Europe dominated the Biopolymers Market, owing to the growth of the fresh food industry in the region. For instance, according to the Federal Statistical Office of Germany,roughly 6,100 agricultural holdings in Germany harvested a total 3.8 million tonnes of vegetables in 2022.

• The government initiatives for green initiatives are fuelling the demand for Biopolymers such as polyesters, polyethylene and more are driving the market growth.

• Moreover, the increasing adoption of Biopolymers in packaging applications is also accelerating market growth.

For More Details on This Report — Request for Sample

Biopolymers Market Segment Analysis — by Application

The packaging segment held the largest Biopolymers Market share in 2023 and is estimated to grow at a CAGR of 10.4% over the forecast period 2024–2030. Biopolymers such as polyesters, polylactic acid, polyhydroxybutyrate and more are frequently deployed in packaging because they enhance the shelf-life of the product and also it reduces the overall carbon footprint related to food packaging. The films composed of biopolymers such as polysaccharides and protein-composed increase mechanical and optical properties. As a result, biopolymers packaging is employed across various end-use industries, including food & beverages, medical & healthcare and more. Thus, owing to the above-mentioned benefits, the adoption of biopolymers is surging in packaging applications, which is accelerating market growth.

Biopolymers Market Segment Analysis — by End-use Industry

The food & beverage segment held a significant Biopolymers Market share in 2023. The key properties of biopolymers are high strength, lightweight and heat resistance. As a result, biopolymers are frequently used in the food and beverage industry. Moreover, due to their superior quality, functionality, affordability and composability, they are an ideal replacement for single-use plastic food & beverage packaging. The surging development of food & beverage facilities, governmental initiatives and others are the crucial variables propelling the food & beverage industry’s growth. For instance, according to Invest India, the food processing sector in India is one of the world’s largest, with output anticipated to reach US$535 billion by 2025–2026. Hence, the growth of the food & beverage industry is expected to fuel the demand for biopolymers. As a result, the market growth will accelerate during the upcoming years.

Schedule a Call:

Biopolymers Market Segment Analysis — by Geography

Europe is the dominating region as it held the largest Biopolymers Market share in 2023. The economic growth of Europe is driven by the growth of the various industries, including food and beverage, medical & healthcare and other similar industries. The food and beverages industry growth are vital for food security in the European region. For instance, according to Food Drink Europe, the food and drink industry in Europe produced a 107.7 production index in the fourth quarter of 2022 and a 109.2 production index in the first quarter of 2023, an increase of 1.4 percent. Also, according to the European Union, in 2022, the production of fruits in the European Union countries was about 35.9 million metric tons and out of this, apples and pears production were the highest at 14.7 million metric tons, which was 40.9% of the total fruit production. Therefore, the booming food & beverage industry in Europe is boosting the demand for biopolymers. This, in turn, is proliferating the biopolymers market size growth.

Biopolymers Market Drivers Government Initiatives for Biopolymers

The transformation of the current linear material system into a circular economy necessitates national and international legislation. This is due to the globalized industry’s complex worldwide supply chains. Governments at the global level are taking initiatives for biopolymers. For instance, In March 2023, the European Commission adopted a policy framework on biobased, biodegradable, and compostable plastics, marking an initiative to drive the biopolymers market. Aligned with the European Green Deal, this non-legislative framework aimed to clarify environmental benefits, set strict standards, and guide future policies on green claims, ecodesign, carbon removal, and microplastics. Thus, the growing government initiatives for biodegradable packaging are driving the demand for biopolymers, which is aiding market growth.

Growth of the Medical Devices Industry

In the production of medical devices such as replacement joints, heart valves, arteries, teeth, tendons, ligaments and eye lenses, biopolymers are used to replace or repair some diseased, damaged, or non-functional pieces of tissue or bone. Factors such as technological improvements in medical equipment and an aging population are accelerating the medical device industry’s growth. For instance, in global comparison, most revenue will be generated in the United States US$182.00bn in 2024. Thus, the growth of the medical device industry is boosting the demand for biopolymers, which, in turn, is driving market growth.

Biopolymers Market Challenge Higher Cost Associated with Biopolymers

Biopolymers such as polyesters, polylactic acid, polyhydroxy butyrate and more have the advantage of easy disposable and regeneration. However, one disadvantage of biopolymers is that they necessitate the use of expensive industrial processors and composters, particularly for those that must be broken down at high industrial temperatures. For instance, according to Plastmart, the major drawback of biopolymers is their higher price tag when compared to traditional polymers. While the typical, conventional polymers cost between US$1000 and US$1500 per metric tonne (MT), biopolymers can cost anywhere from US$4000 to US$15,000 per MT for materials like polyhydroxy butyrate. Therefore, the high price associated with biopolymers may restrict the growth of the biopolymers industry in the coming years.

Buy Now:

Biopolymers Industry Outlook

Technology launches, acquisitions and increased R&D activities are key strategies adopted by players in the Biopolymers Market. The top 10 companies in the Biopolymers market are

Recent Developments:

• In October 2023, Braskem opened a Tokyo office, advancing bio-based solutions in the biopolymers market. With over 15 years in Japan, it reflects their commitment to sustainability. Concurrently expanding in Brazil and Thailand, Braskem focuses on delivering low-carbon alternatives globally.

• In August 2022, DSM Engineering Materials launched StanylB-MB (Bio-based Mass Balanced), a more environmentally friendly version of its mainstay polyamide (PA) product that contains up to 100% bio-based material. It enables DSM Engineering Materials to halve the carbon footprint of this product line.

• In June 2022, a global polymer manufacturer based in Germany launched VerdessenceTM RiceTouch, a new biopolymer used for various personal care products.

Relevant Reports

Polymers Market — Industry Analysis, Market Size, Share, Trends, Application Analysis, Growth and Forecast Analysis

Bio-Based Construction Polymers Market — Industry Analysis, Market Size, Share, Trends, Application Analysis, Growth and Forecast Analysis

Bio-based Polymer Market — Industry Analysis, Market Size, Share, Trends, Application Analysis, Growth and Forecast Analysis

For more Chemicals and Materials Market reports, please click here

0 notes

Text

#biopolymerfilms#biopolymers#biopolymer#environmentallyfriendly#environmentalprotection#polymerscience#plasticsindustry#biopolymerfilmsmarketreport#biopolymerfilmsmarketsize#grandresearchstore

0 notes

Text

NatureWorks made significant progress on the construction of the new PLA facility in Thailand

NatureWorks, a leading manufacturer of polylactic acid (PLA) biopolymers made from renewable resources headquartered in Minnesota (USA), made significant progress on the construction of their new fully integrated Ingeo PLA biopolymer manufacturing facility in Nakhon Sawan Province, Thailand. Continue reading Untitled

View On WordPress

0 notes

Text

Bioplastics and biopolymers are produced or derived from living organisms, such as plants and microbes. The primary sources of biopolymers are renewable.

0 notes