#Biocompatibility Testing Methods

Explore tagged Tumblr posts

Text

International Experts Summit on Biomaterials and Tissue Engineering

Welcome to the International Experts Summit on Biomaterials and Tissue Engineering, a meticulously organized conference by The Iconic Meetings. This summit aims to bring together leading researchers, practitioners, and global leaders in the field of scientific innovation.

#Immunomodulatory Biomaterials#Tissue Engineering Drug Delivery#Cell-Material Interactions#Neural Tissue Engineering#Bioethics in Tissue Engineering#Biocompatibility Testing Methods#Organ Regeneration Strategies

0 notes

Text

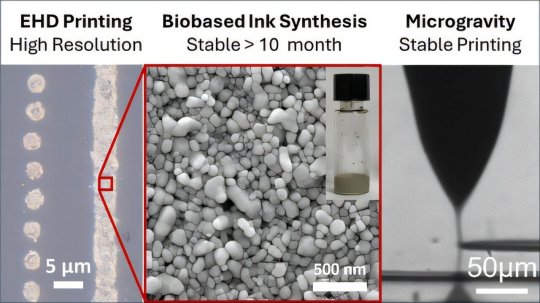

Nanoink and printing technologies could enable electronics repairs, production in space

An Iowa State University engineer floats in the air while other researchers hang tight to a metal frame surrounding and supporting their special printer. It's not the usual photo you see in a research paper. Tests aboard microgravity flights aren't your typical materials experiments, either.

The flight path to these experiments began when a research team led by Iowa State's Shan Jiang, an associate professor of materials science and engineering, and Hantang Qin, formerly of Iowa State who's now an assistant professor of industrial and systems engineering at the University of Wisconsin-Madison, wondered if their ink and printer technologies would work in the zero gravity of space.

The ink features silver nanoparticles synthesized with biobased polymers. After heat treatment, the ink can conduct electricity and can therefore print electric circuits. The printer uses electrohydrodynamic printing, or 3D printing that jets ink under an electric field at resolutions of millionths of a meter. The electric field could eliminate the need for gravity to help deposit ink.

If the technologies work together in zero gravity, astronauts could use them to make electric circuits for spacecraft or equipment repairs. And astronauts might manufacture high-value electronic components in the special, zero-gravity environment of space.

NASA wondered if it would work, too.

Diving into microgravity

Researchers bolted the printer to the floor of a jet and prepared for a "roller coaster, basically," Jiang said.

The NASA plane would continuously climb and dive, going in cycles from about 24,000 feet over Florida to 32,000 feet, then back to 24,000. The dive phase produced about 10 seconds of pure zero gravity.

"It was exciting and new," Jiang said.

Motion sickness was a problem for some. Others enjoyed the thrill of it. Jiang felt "frozen" the first time he experienced microgravity. "I was blank."

But that didn't last. "There was so much time and investment in this project. We wanted to achieve good results."

But printing for a few seconds at a time on a microgravity flight "is a very challenging experiment," Jiang said. "It's so easy on the ground where everything is stable. But if anything gets loose during the flight, you lose your printing."

The first microgravity flight was a good example. The printer wasn't adequately secured against the plane's shakes and vibrations.

"These are very intense experiments that require a lot of teamwork and preparation," Jiang said.

So, the team went back to work, made some changes, made more test flights and produced better results.

"This proof-of-concept microgravity experiment proves the unique capability of (electrohydrodynamic) printing under zero-gravity conditions and opens a new venue for future on-demand manufacturing in space," the researchers wrote in a paper published in Applied Materials & Interfaces.

Making a new nanoink

The key innovation by Jiang's research group was developing a new laboratory method to synthesize the ink with its silver nanoparticles.

"This is a new combination of materials and so we needed a new recipe to make the ink," Jiang said.

Both programs "strive to support innovative and leading research in Iowa," said Sara Nelson, director of the programs and an Iowa State adjunct assistant professor of aerospace engineering. "We are thrilled to have supported Dr. Jiang's research. His work has helped to build Iowa's research infrastructure and is an important part of NASA's strategic mission."

The project also makes use of an abundant Iowa resource, plant biomass.

The ink includes a biobased polymer called 2-hydroxyethyl cellulose, which is typically used as a thickening agent. But it is also a cost-effective, biocompatible, versatile and stable material for the inks necessary for high-resolution ink jet printing under an electric field.

"There is a lot of biomass in Iowa," Jiang said. "So, we're always trying to use these biobased molecules. They make a wonderful polymer that does all the tricks for us."

Jiang called that "the biggest surprise of this research. We didn't know that before. Now we know what we can do with these biobased polymers."

The Iowa State University Research Foundation has filed a patent on the new nanoink and the technology is currently available for licensing.

"This success is really just the beginning," Jiang said. "As humanity ventures deeper into space, the need for on-demand manufacturing of electronics in orbit is no longer science fiction; it is a necessity."

Next up for the researchers could be the development of 3D space printing for other electronic components such as semiconductors.

After all, Jiang said, "You can't just make one component and assemble an electronic device."

TOP IMAGE: Researchers—as well as a toy Cy the Cyclone—test their nanoink and printer technologies during a NASA microgravity flight. Pictured, left to right, are: Fei Liu, Yanhua Huang, Matthew Marander, Xuepeng Jiang and Pavithra Premaratne. Credit: Shan Jiang

LOWER IMAGE: Credit: ACS Applied Materials & Interfaces (2024). DOI: 10.1021/acsami.4c07592

6 notes

·

View notes

Text

Ceramic Blasting Beads: A Key Technology for Enhancing Fatigue Resistance in Medical Device Metal Components

In the modern medical device industry, the reliability and durability of metal components directly impact patient safety and treatment efficacy. From implantable devices to surgical instruments, from diagnostic equipment to therapeutic devices, metal component fatigue failure remains a significant challenge for medical device manufacturers and quality control managers. Ceramic blasting beads, as an advanced surface treatment technology, are revolutionizing the fatigue resistance performance of medical device metal components. This article will explore in depth how ceramic blasting beads enhance the fatigue resistance of medical device metal components and the special value of this technology in the medical field.

Metal Fatigue Issues in Medical Devices

Severity of Fatigue Failure

In the medical device field, metal component fatigue failure can lead to catastrophic consequences:

Implant fractures may require emergency revision surgeries

Surgical instrument failures during use may endanger patients' lives

Diagnostic equipment malfunctions may lead to misdiagnosis or delayed treatment

Therapeutic device failures may interrupt treatment plans

FDA data indicates that approximately 25%-30% of medical device recall events are related to metal component fatigue failures, causing serious impacts on patient safety and healthcare institutions.

Unique Challenges Facing Medical Device Metal Components

Medical device metal components face unique challenges:

Biocompatibility requirements: Materials must be non-toxic, harmless, and not cause immune responses

Strict sterilization conditions: Must withstand high temperature, high pressure, radiation, and other sterilization methods

Complex physiological environments: Long-term exposure to corrosive body fluids

Cyclic loading conditions: Such as orthopedic implants bearing periodic physiological loads

Zero-tolerance requirements: Medical devices cannot allow any risk of failure

These challenges make medical device metal components face more severe fatigue issues than general industrial applications.

Technical Characteristics of Ceramic Blasting Beads and Advantages in Medical Applications

Ceramic blasting beads offer unique application advantages in the medical device field:

Good biocompatibility: Materials like zirconium oxide and aluminum oxide have passed ISO 10993 biocompatibility testing

No residual contamination: Will not leave particles on component surfaces that could cause infection

High surface cleanliness: Can thoroughly remove surface machining marks and contaminants

Controllable surface roughness: Can adjust surface topological structure according to different medical device requirements

Non-magnetic: Will not affect the use of magnetic-sensitive medical equipment such as MRI

Medical-grade ceramic blasting beads typically have the following technical parameters: Technical Parameter Typical Specification Significance in Medical Applications Sphericity >98% Ensures surface treatment uniformity Purity >99.9% Avoids chemical contamination Hardness Mohs 9 Suitable for treating hard materials such as titanium alloys Particle size range 20-150μm Can be used for precision medical devices Surface finish Ra 0.1-0.8μm Meets different interface contact requirements

Mechanisms by Which Ceramic Blasting Beads Enhance Medical Device Fatigue Resistance

1. Formation of Residual Compressive Stress Layer

When ceramic blasting beads impact the metal surface at high speed, they form a residual compressive stress layer on the surface. This mechanism is particularly important for medical devices because:

The compressive stress layer effectively prevents micro-crack initiation and propagation in fluid environments

It improves the resistance of medical-grade metals such as titanium alloys and stainless steel to corrosion fatigue

It is especially important for implants that bear alternating loads (such as orthopedic screws, bone plates, artificial joints)

Research shows that appropriate ceramic blasting treatment can form a compressive stress layer with a depth of 0.1-0.2mm on medical-grade titanium alloy surfaces, increasing fatigue life by 100%-200%.

2. Microstructure Optimization

In medical device applications, microstructure optimization has special significance:

Grain refinement improves the metal's yield strength, enhancing implant resistance to deformation

Increased dislocation density reduces stress concentration phenomena in physiological environments

Changed microstructure facilitates cell attachment and tissue integration (crucial for osseointegration)

Microstructure optimization can significantly improve the safety factor of medical devices, especially in the field of long-term implants.

3. Surface Topography Control

For medical devices, surface topography control has dual significance:

Mechanical aspect: Appropriate surface roughness reduces fatigue crack sources

Biological aspect: Optimized surface microstructure promotes cell attachment and biological integration

Different types of medical devices require different surface topographical structures: Medical Device Type Recommended Surface Roughness (Ra) Purpose Orthopedic implants 1.0-2.0μm Promote osseointegration Joint replacements 0.05-0.2μm Reduce friction and wear Cardiovascular stents 0.3-0.8μm Improve blood compatibility Dental implants 1.5-2.5μm Enhance tissue bonding Surgical instruments 0.1-0.4μm Improve corrosion resistance and cleanliness

4. Surface Bioactivity Regulation

Unique to medical applications, ceramic blasting can also regulate metal surface bioactivity:

Change surface energy and wettability, affecting protein adsorption and cell attachment

Adjust the chemical composition and structure of the surface oxide layer

Provide an ideal foundation for subsequent surface functionalization treatments (such as hydroxyapatite coating)

This bioactivity regulation both improves device biocompatibility and enhances metal fatigue resistance, forming a dual safeguard.

Ceramic Blasting Process Optimization in Medical Device Production

Medical devices have requirements for surface treatment far higher than general industrial applications, and ceramic blasting processes must be conducted under strictly controlled conditions:

Key Process Parameters

Process Parameter Medical-Grade Recommended Range Special Considerations Blasting pressure 0.3-0.5MPa Adjust according to device size and wall thickness Blasting distance 80-150mm Uniformity control Blasting time 20-90s Avoid excessive treatment causing precision loss Bead specification 20-150μm Determined by device precision and surface requirements Coverage requirement >98% Ensure no fatigue-weak zones

Special Process Control Points

Contamination-free process environment: Clean room grade blasting environment to prevent particle contamination

Batch quality control: 100% surface inspection to ensure zero defects

Parameter validation: Validate blasting parameters through fatigue testing

Sterilization compatibility: Ensure blasted surfaces can withstand subsequent sterilization processes

Traceability: Complete process recording, complying with medical device regulatory requirements

Medical Device Application Case Studies

Case 1: Titanium Alloy Spinal Fixation System

Challenge: Spinal fixators bear complex cyclic loads in the body, with fatigue failure being the main issue.

Solution: 45-75μm zirconium oxide ceramic blasting treatment of titanium alloy spinal screws and connecting rods.

Results:

Fatigue strength increased by 36%

Failure rate reduced from 2.3% to 0.4%

Patient revision surgery rate decreased by 75%

Product 5-year survival rate improved to 98.7%

Case 2: Stainless Steel Orthopedic Surgical Instruments

Challenge: Orthopedic surgical instruments require repeated use and sterilization, facing serious stress corrosion fatigue issues.

Solution: 50-100μm aluminum oxide ceramic blasting treatment, forming a uniform surface compressive stress layer.

Results:

Instrument service life extended 2.5 times

Sterilization cycle resistance improved by 40%

Surface corrosion resistance increased by 65%

Repair and replacement costs reduced by 58%

Case 3: Cobalt-Chrome Alloy Artificial Hip Joints

Challenge: Artificial hip joints require excellent fatigue strength and biocompatibility.

Solution: Two-stage ceramic blasting: coarse blasting (125μm) to form a compressive stress layer, fine blasting (45μm) to optimize surface topographical structure.

Results:

Fatigue strength improved by 43%

Friction coefficient reduced by 28%

Metal ion release decreased by 67%

Implant service life increased from 12 years to over 20 years

Case 4: Nitinol Cardiovascular Stents

Challenge: Cardiovascular stents work in a pulsating environment, requiring extremely high fatigue resistance and blood compatibility.

Solution: Ultra-fine (20-45μm) zirconium oxide blasting, optimizing surface morphology and oxide layer.

Results:

Stent fatigue life increased to over 400 million cycles

Thrombosis risk reduced by 32%

Restenosis rate decreased by 26%

Product safety incident reports reduced by 81%

Quality Control and Regulatory Compliance

For medical device manufacturers and quality control managers, ceramic blasting treatment is not just a technical means to improve product performance but also a key step in ensuring regulatory compliance:

FDA and NMPA Compliance Points

Process validation: Required according to FDA 21 CFR 820.75 and relevant NMPA regulations

Surface characteristic testing: Including ASTM F86 surface inspection and ISO 4287 surface roughness testing

Fatigue testing requirements: Compliance with standards such as ASTM F1801, ISO 14242

Biocompatibility assessment: Comprehensive biological evaluation according to ISO 10993-1

Risk management: Incorporating blasting treatment into ISO 14971 risk management system

Key Quality Control Testing Methods

Test Item Test Method Acceptance Criteria Surface roughness Surface profilometer Within design specifications ±10% Residual stress X-ray diffraction Surface compressive stress >200MPa Coverage Microscopic inspection >98% Surface defects Electron microscopy No cracks, peeling, or sharp edges Metal ion release ICP-MS Below ISO standard limits Accelerated fatigue testing According to ISO standards Achieves 5 times design life or more

Cost-Benefit Analysis: Medical Device Perspective

In the medical device field, the cost-benefit of ceramic blasting technology needs to be evaluated from multiple levels:

Direct Cost Benefits

Reduced product recall costs: Each medical device recall costs an average of $3-7 million; improving fatigue performance can significantly reduce recall risks

Decreased warranty claims: Fatigue-related failure claims reduced by 65%-80%

Extended product life: Implant service life extended by 50%-100%, reducing revision surgery rates

Enhanced market competitiveness: Product reliability becomes a key selling point, increasing brand value

Indirect Cost Benefits

Accelerated regulatory approval: Reliable fatigue data support speeds up registration and approval processes

Improved physician and patient satisfaction: Reduces medical disputes caused by device failures

Better insurance coverage: Higher reliability devices more easily obtain insurance coverage

Enhanced corporate reputation: Avoids negative publicity due to product fatigue failures

Return on investment analysis shows that in the high-end medical device field, investment in ceramic blasting technology typically pays back within 18-24 months, with long-term ROI exceeding 300%.

Frequently Asked Questions (FAQs)

Does ceramic blasting treatment affect the sterilization efficacy of medical devices?

No. On the contrary, appropriate ceramic blasting treatment can improve the surface microstructure, reducing microbial attachment points and enhancing sterilization effectiveness. Research shows that optimized ceramic blasting treatment can improve the Sterility Assurance Level (SAL) of medical device surfaces.

Do different types of medical-grade metals require different ceramic blasting materials?

Yes, different metals require different blasting materials and parameters:

Titanium alloys: Zirconium oxide beads recommended (matching hardness, avoiding embedding)

Stainless steel: Can use aluminum oxide or zirconium oxide beads

Cobalt-chrome alloys: Zirconium oxide beads recommended (reducing surface contamination)

Nitinol: Must use ultra-fine zirconium oxide beads (avoiding damage to superelastic properties)

What post-processing steps are required after ceramic blasting treatment?

Medical devices typically require the following post-processing steps:

Ultrasonic cleaning (removing all residual particles)

Passivation treatment (forming a stable oxide layer)

Electrochemical polishing (for certain applications)

Surface functionalization (if special biological characteristics are needed)

Sterilization packaging (preventing contamination)

How does ceramic blasting affect the service life of medical devices?

By increasing fatigue strength and reducing corrosion sensitivity, ceramic blasting can significantly extend medical device service life:

Implantable devices: Life extended by 50%-100%

Surgical instruments: Usage cycle count increased by 150%-200%

Diagnostic equipment: Metal component failure interval extended 3-5 times

How is the consistency and reliability of the ceramic blasting process validated?

The medical device industry uses the following methods to validate process consistency:

Process Validation Studies (PVS)

Statistical Process Control (SPC)

Failure Mode and Effects Analysis (FMEA)

Accelerated Life Testing (ALT)

Real-time stability monitoring and data trend analysis

Future Development Trends

Ceramic blasting technology in the medical device field is developing in the following directions:

Biofunctionalized blasting materials: Ceramic beads containing antibacterial elements or bioactive factors

Gradient blasting technology: Achieving different surface characteristics in different areas of the same component

Intelligent monitoring blasting systems: Real-time quality control based on machine vision and AI

Personalized parameter optimization: Adjusting implant surface characteristics according to specific patient needs

Hybrid processes combined with 3D printing: Providing optimal surface treatment for complex geometries

Conclusion

Ceramic blasting bead technology provides significant improvements in fatigue resistance for medical device metal components, which has special significance in the medical field. Through forming residual compressive stress layers, optimizing microstructures, controlling surface topography, and regulating bioactivity, ceramic blasting technology not only improves the safety and reliability of medical devices but also extends service life, reduces patient risk, and decreases healthcare costs.

For medical device manufacturers and quality control managers, understanding and correctly applying ceramic blasting technology is a key strategy for improving product quality, ensuring regulatory compliance, and enhancing market competitiveness. As medical devices develop toward smaller size, more functionality, and greater personalization, ceramic blasting technology will continue to play an irreplaceable role, providing more reliable safeguards for patient safety and treatment efficacy.

2 notes

·

View notes

Text

Could We One Day “Print” Human Organs?

You’ve probably heard whispers across the biomedical field: printing human organs isn’t just a theoretical possibility—it’s a serious scientific pursuit. As someone working in biotech, regenerative medicine, or advanced diagnostics, you know how persistent the shortage of donor organs remains and how much room there is to improve rejection outcomes. That’s where 3D bioprinting steps in. In this article, you’ll get a clear understanding of how bioinks and stem cells are laying the groundwork for printable organs, what kinds of tissues have already been successfully printed, the engineering hurdles to scaling up whole organ systems, and what you need to track if your work intersects with translational medicine, regulatory pipelines, or lab-grown therapeutic systems.

Bioinks: Your Starting Material for Living Tissues

You can’t build a functioning organ without the right printing material, and in your lab, that starts with bioink. You’ve likely worked with or studied formulations that combine hydrogels, extracellular matrix components, and live cells, sometimes even including growth factors or synthetic scaffolds. These bioinks allow you to print cells with spatial precision while supporting cell viability, proliferation, and differentiation. Whether you’re printing skin-like sheets or vascular tissues, the rheology and biocompatibility of your ink directly affect print fidelity and eventual tissue function.

Recent innovations have introduced self-healing bioinks, temperature-sensitive compositions, and even multi-material systems that let you integrate different cell types layer by layer. You’ve probably seen how this precision allows structural mimicry of complex tissues like kidney cortex or cardiac muscle. And while the tech is promising, bioinks still present challenges—especially when balancing stiffness and cell permeability for larger constructs.

Printing Functional Tissues: Skin, Vessels, and Cartilage

You’ve seen the headlines about researchers printing simple human tissues in controlled settings. Skin has become one of the earliest success stories—bioprinted skin can mimic both the dermis and epidermis layers and is already being used in burn repair research and cosmetic testing. If your focus is on wound healing, you’ve likely experimented with dermal scaffolds printed with fibroblasts and keratinocytes.

Blood vessels are another critical step forward. You understand that vascularization is key to ensuring larger tissues survive beyond a few millimeters in thickness. Many labs are now developing perfusable vascular networks using sacrificial inks or coaxial printing methods. And let’s not forget cartilage—its avascular nature makes it easier to print than organs, and bioprinted ear or nose structures are already in early-stage human trials. These milestones build confidence in scalability, pushing the field toward bigger, more complex builds.

The Liver, Kidney, and Heart Are the Next Targets

Moving from patches to full organ systems requires an entirely different level of design and coordination. You’re not just printing cells—you’re architecting functional units like nephrons, hepatic lobules, or myocardial layers. In liver bioprinting, you may have worked on spheroid-based models or tissue strips that produce albumin and perform basic detoxification. These constructs are now used in drug screening and disease modeling.

The kidney, though highly complex with millions of filtration units, is under active research. You may be testing bioprinted renal tubules that can mimic filtration in microfluidic systems. Cardiac bioprinting is also evolving. If you’re in cardiovascular research, you’ve probably seen lab-built patches that synchronize with heart rhythms or include electromechanical stimulation to maintain cell viability. Full organ replication still faces obstacles, but every layer printed brings you closer to transplant-grade constructs.

Vascularization: The Core Bottleneck

Here’s where your engineering mindset comes in—vascularization is the single biggest challenge you face when scaling up. Without a blood supply, any thick printed tissue will die quickly. To fix this, researchers like yourself are applying principles from fluid dynamics and biomaterials to print endothelial-lined channels or introduce sacrificial scaffolds that can later be flushed out.

You may have explored embedding angiogenic factors within layers or integrating pericytes to stabilize microvascular networks. The goal is to achieve spontaneous inosculation when the printed organ is implanted—meaning your printed vessels connect with the body’s own circulatory system. Until then, functional organ transplants at scale will remain out of reach.

3D Bioprinters: The Machines Behind the Vision

Let’s talk hardware. You’ve likely upgraded from a basic extrusion printer to a more specialized bioprinter capable of temperature control, multiple printheads, and real-time cell monitoring. Whether you’re using stereolithography, inkjet, or laser-assisted printing, your choice of printer affects resolution, speed, and cell survival.

Companies like CELLINK, Organovo, and Aspect Biosystems are leading providers in this space, and you may be using one of their platforms in your lab. Some of these devices now come equipped with AI-driven controls that adjust extrusion pressure or print paths in real time. If your work involves translational medicine, investing in GMP-compliant printers will also be critical down the line.

Safety, Rejection, and the Clinical Timeline

You’re aware that safety is where most bioprinting breakthroughs stall. Printing with patient-derived iPSCs (induced pluripotent stem cells) can reduce immune rejection, but ensuring that no mutations or functional abnormalities arise remains your responsibility. Before a printed heart or kidney can be implanted in humans, you’ll need to show long-term viability, mechanical strength, and regulatory compliance.

There’s also the challenge of standardization. You can print tissues that look similar from one trial to another, but ensuring they behave identically under physiological stress is where the field must advance. You’re already seeing efforts by regulatory bodies to classify bioprinted constructs as combination products—part device, part biologic—complicating the approval process further.

Real-Time Applications and What's Already in Use

You don’t have to wait for printed hearts to make a clinical difference. Today, you might be using bioprinted bone scaffolds in orthopedics, vascular grafts in bypass research, or skin models in toxicology studies. These early-stage products are already improving patient-specific therapies and speeding up testing pipelines.

Some of your colleagues are even using printed tumor models that better mimic the tumor microenvironment, leading to more accurate drug trials. If you’re in pharma or preclinical testing, this alone could reduce time-to-market for new treatments. You’re witnessing how bioprinting is reshaping adjacent fields even before organ transplantation becomes common.

Here’s what’s already possible with 3D bioprinting

Skin, cartilage, and blood vessels

Liver and heart tissue patches

Functional microvascular structures

Personalized tissue models for drug testing

In Conclusion

You’re no longer asking if human organs can be printed—you’re focused on how and when. The progress you’re witnessing, from viable bioinks and vascular engineering to liver strips and heart patches, confirms the potential. While full-sized transplantable organs are still years away, the building blocks are already in place. Your role—whether as a researcher, clinician, or biomedical engineer—is to help refine the technology, secure safety, and bring these life-saving innovations closer to patient bedsides.

"Thanks for reading! To explore additional insights on the cutting edge of regenerative medicine, bioprinting, and the future of organ transplantation, follow Nirdosh Jagota on X"

0 notes

Text

3D Printing Materials Market Expands Scope for Advanced Industrial and Medical Applications

The 3D Printing Materials Market is a rapidly expanding sector that plays a pivotal role in modern manufacturing, design, and engineering. Its scope is incredibly broad, covering polymers, metals, ceramics, and composite materials used across industries such as aerospace, automotive, healthcare, consumer goods, and electronics. As additive manufacturing advances, the scope of available materials has widened, making 3D printing an essential tool for both prototyping and end-use production.

Expanding Material Choices

Originally dominated by basic plastic filaments like PLA and ABS, the market now includes a growing range of sophisticated materials. High-performance polymers like PEEK and PEI, as well as metal alloys like titanium and aluminum, have opened new doors for industries with stringent requirements. The scope of these materials goes beyond traditional applications, making additive manufacturing viable for aerospace engine parts, medical implants, and precision electronics.

Advancements in Material Science

The scope of the 3D Printing Materials Market has been dramatically enhanced by advances in material science. New formulations have improved durability, tensile strength, and thermal resistance, making 3D-printed parts comparable or superior to traditional manufacturing. The growing trend of using bio-based and recycled materials also highlights the sustainability focus within this market, making it attractive for eco-conscious manufacturers and end-users.

Aerospace and Automotive Applications

In aerospace and automotive manufacturing, the scope of 3D printing materials has expanded drastically. These industries utilize high-strength alloys, polymer composites, and ceramics to produce lightweight, durable, and complex geometries that were once difficult or costly to manufacture. The ability to create custom, precision parts quickly has positioned additive manufacturing as a preferred method for rapid prototyping and low-to-mid volume production.

Medical and Healthcare Innovations

The medical sector has embraced 3D printing with fervor, relying on a growing range of biocompatible materials that expand its scope. Dental implants, prosthetic devices, and custom surgical guides can now be produced with precision and customization that traditional methods cannot match. The 3D Printing Materials Market is reshaping patient care by making medical treatments more accessible and personalized.

Electronics and Consumer Goods

Another area where the scope of 3D printing materials shines is in electronics and consumer goods. Materials with properties such as thermal resistance, electrical conductivity, and UV resistance have opened new avenues for producing complex, functional parts. From wearable electronics to custom enclosures and components, this technology allows for rapid design iterations and cost-efficient low-volume production.

Sustainability and the Future of Materials

The shift towards sustainability is a significant trend reshaping the 3D Printing Materials Market. The scope now includes recycled and bio-based materials, allowing manufacturers to reduce waste and adopt more eco-friendly practices. The rise of additive manufacturing using waste feedstock or renewable polymers is making this technology a catalyst for sustainable manufacturing across industries.

Challenges and Opportunities

While the scope of the 3D Printing Materials Market is expansive, certain challenges must be addressed. High material costs, quality control, and the need for standardized testing are hurdles that the industry must overcome to achieve wider adoption. However, these challenges also present opportunities for innovation. Material suppliers are increasingly focusing on cost optimization and consistency to expand accessibility across industries and geographies.

Conclusion

The 3D Printing Materials Market offers unprecedented scope for customization, efficiency, and sustainability. Its ongoing expansion across aerospace, automotive, medical, electronics, and consumer goods signifies its vital role in shaping the future of manufacturing. As new materials and techniques evolve, additive manufacturing will continue to redefine how we design, create, and utilize the products that drive industries and everyday life.

0 notes

Text

How Medical Textile Testing Labs Support FDA and CE Compliance?

The global healthcare market is driven by stringent safety regulations, especially for materials that come into contact with patients. One such critical category is medical textiles—fabrics used in surgical gowns, face masks, wound dressings, implants, and hospital linens. These materials must be tested and certified to meet regulatory standards before they can be marketed or used in clinical settings. Two of the most recognized regulatory authorities are the U.S. Food and Drug Administration (FDA) and the European Conformité Européenne (CE) system.

To navigate these regulations successfully, manufacturers rely on medical textile testing labs. These specialized laboratories play an essential role in evaluating and certifying textile products to ensure they comply with FDA and CE requirements. In this blog, we explore how medical textile testing labs support regulatory compliance and accelerate global market access.

What Is Medical Textile Testing?

Medical textile testing is the scientific evaluation of textile materials used in healthcare. It includes both physical and biological testing to determine whether the textile meets safety, performance, and regulatory standards. Key properties assessed include:

Biocompatibility

Barrier performance

Breathability

Antimicrobial activity

Flammability

Mechanical strength

Resistance to fluids and pathogens

Medical textile testing labs use standardized methods such as ISO, ASTM, EN, and AATCC protocols, which are required for FDA and CE submissions.

Why FDA and CE Compliance Matters

Medical textiles are classified as medical devices or device components. Therefore, they must comply with regulations such as:

✅ FDA Compliance (U.S.)

The FDA regulates medical devices under 21 CFR Part 820. Depending on the risk class (Class I, II, or III), manufacturers must:

Submit a 510(k) premarket notification (for Class II)

Demonstrate substantial equivalence to a legally marketed device

Conduct product testing in ISO 17025-accredited labs

Maintain Good Manufacturing Practices (GMP)

Provide labeling and performance data

✅ CE Marking (Europe)

CE compliance is governed by the EU Medical Device Regulation (MDR 2017/745). To achieve CE marking:

The product must meet applicable EU harmonized standards

A Notified Body must review the technical file

Testing reports must demonstrate safety and performance

Risk analysis and clinical evaluation must be provided

Whether for the U.S. or European markets, testing labs are essential in validating compliance before the product reaches regulators or end-users.

Key Testing Services Labs Provide for FDA and CE Compliance

Medical textile testing labs perform a wide range of services that are aligned with FDA and CE requirements:

1. Biocompatibility Testing (ISO 10993 Series)

Essential for both FDA and CE compliance, biocompatibility testing ensures that textile materials do not cause adverse biological responses.

ISO 10993-5: Cytotoxicity

ISO 10993-10: Sensitization and irritation

ISO 10993-11: Systemic toxicity

ISO 10993-23: Skin irritation for topical applications

Labs conduct in-vitro and in-vivo studies to confirm that the textile is safe for direct or indirect patient contact.

2. Barrier and Fluid Resistance Testing

Required especially for PPE and surgical products.

ASTM F1670/F1671: Resistance to synthetic blood and viral penetration

ISO 16603/16604: Resistance to bloodborne pathogens

EN 13795: Requirements for surgical gowns and drapes

These tests help demonstrate compliance with infection control standards—an essential part of FDA and CE documentation.

3. Antimicrobial and Antiviral Testing

Medical textiles often claim to be antimicrobial, requiring validation through:

AATCC 100/147: Antibacterial activity assessment

ISO 18184: Antiviral textile testing

EN ISO 20743: Determination of antibacterial activity on textiles

Such test data is critical for CE-marked antimicrobial products and FDA-reviewed PPE.

4. Physical and Mechanical Testing

These tests ensure that the textile will withstand real-world handling and usage:

Tensile and tear strength (ASTM D5034, ISO 13934)

Air permeability (ASTM D737, ISO 9237)

Moisture vapor transmission (ASTM E96)

Flammability (16 CFR Part 1610 for FDA; EN ISO 12952 for CE)

These are particularly important for reusable medical textiles and protective garments.

5. Sterilization Validation and Residual Analysis

For CE and FDA submissions, manufacturers must confirm that the product can be sterilized safely without degrading or leaching toxic residues.

ISO 11135 / ISO 11137: Validation of EO or gamma sterilization

Chemical residue analysis post-sterilization

Labs also ensure the textile maintains its functional integrity post-sterilization.

6. Labeling and Claims Verification

Before gaining FDA or CE approval, manufacturers must support their labeling claims (e.g., “antimicrobial,” “fluid-resistant”) with data. Testing labs provide:

Verification reports for product claims

Support for technical documentation (EU MDR) or FDA 510(k) filings

Evidence required for product instructions and regulatory labeling

How Labs Streamline Regulatory Submissions

Medical textile testing labs don’t just test—they guide manufacturers through the regulatory maze. Here’s how:

✔️ Gap Analysis and Pre-Compliance Testing

Labs evaluate your product early in development to identify missing test data or regulatory gaps.

✔️ Regulatory File Support

They assist in compiling test results into technical documentation, submission dossiers, and 510(k) applications.

✔️ Notified Body and FDA-Ready Reports

Test reports are formatted according to FDA or EU standards, making them acceptable for review without delay or rework.

✔️ Consulting on Risk Class and Testing Needs

Labs often consult on device classification (Class I, IIa, IIb, III) under MDR or FDA frameworks and help you select the right test protocols.

Accreditation and International Recognition

To ensure test data is recognized by regulatory agencies, the lab must be accredited:

ISO/IEC 17025: Accreditation for laboratory competence

FDA-registered labs: For U.S. submissions

EU Notified Body collaboration: For CE marking

Using an accredited lab increases the reliability of test results and reduces the risk of non-compliance or regulatory rejection.

Real-World Examples of FDA/CE Compliance via Testing Labs

Surgical Face Masks: ASTM F2100 testing in accredited labs is essential for FDA clearance and CE Type IIR classification.

Wound Dressings: ISO 10993 testing and ISO 11137 sterilization validation help gain CE certification under Rule 4 of EU MDR.

Reusable Gowns: Labs perform AAMI PB70 testing and ISO 22612 bacterial barrier tests for FDA approval and CE Class I classification.

Final Thoughts

For manufacturers in the medical textile industry, partnering with a qualified medical textile testing lab is the key to unlocking international markets. Whether you aim to launch a product in the U.S. under FDA regulations or across Europe under CE marking, your journey starts with compliant testing.

Testing labs not only generate the required data but also provide the scientific backbone for your product’s safety, performance, and regulatory acceptance. Their support ensures that your medical textile products are ready—not just for the market, but for the people who depend on them.

#medical textile testing#textile testing#textile testing lab#testing lab near me#testing lab in delhi

0 notes

Text

Mastering the Silicone Overmolding Process: Techniques, Applications & Expert Support

Silicone overmolding is becoming a key process in many industries. From medical devices to consumer tech, this technique brings better durability, comfort, and style to products. As demand grows, mastering the process is crucial to ensure quality and efficiency. Understanding how to do it right can set your products apart and keep you ahead of the competition.

Understanding Silicone Overmolding: An Overview

What Is Silicone Overmolding?

Silicone overmolding is a manufacturing method where a layer of silicone is molded over an existing part. Unlike traditional molding, which shapes solid parts, overmolding adds a flexible silicone layer onto a substrate, like plastic or metal. This creates a stronger, more comfortable, and more functional product.

Overmolding has been around for decades, but technology has improved fast. Today, it allows brands to design products that feel better and last longer. It’s a way to integrate multiple functions and boost user experience.

Benefits of Silicone Overmolding

Choosing silicone overmolding offers many advantages:

Flexibility: Silicone stretches and bends without breaking, making it perfect for grips and seals.

High-temperature resistance: Silicone withstands extreme heat and cold.

Biocompatibility: Safe for medical and wearable products touching skin.

Enhanced product longevity: Adds extra protection and durability.

Ergonomic design: Improves handling and comfort.

Cost-effective in mass production: Once set up, it’s faster and cheaper to produce large quantities.

Common Industries Using Silicone Overmolding

Many industries rely on silicone overmolding because of its benefits:

Healthcare: Medical devices like catheters, prosthetics, and trainers.

Consumer Electronics: Smartphone cases, headphones, and fitness trackers.

Automotive: Dashboard parts, seals, and protective covers.

Techniques for Effective Silicone Overmolding

Material Selection and Compatibility

Picking the right silicone is key to success. Types like High-Temperature Vulcanizing (HTV) and Liquid Silicone Rubber (LSR) work best depending on the application. LSR is fast and suitable for high-volume runs, while HTV offers more durability.

Compatibility is just as important. Make sure your silicone bonds well with the substrate—whether plastic, metal, or other materials. Testing adhesion and durability beforehand saves headaches later.

Surface Preparation and Design

A clean surface is a must. Dirt, oil, or residue can cause poor bonding. Use suitable cleaning and priming methods to prepare the substrate.

Design tips include:

Draft angles: Simple changes that make removal easier.

Part shape: Keep geometries simple to avoid voids or weak spots.

Use inserts or molds to create complex shapes or add features like buttons or textures easily.

Overmolding Processes and Equipment

The main methods are:

Compression Molding: Good for low to medium volumes; simple but slower.

Transfer Molding: Better for small to medium batches; allows more complex parts.

Injection Molding: Ideal for high volume; precise and fast.

Modern machines come with automation and smart controls that improve quality. Adjust parameters like temperature, pressure, and cycle time to match your materials and design needs for best results.

Troubleshooting Common Challenges

Common problems include:

Delamination (layer separation): Usually caused by poor surface prep or incompatible materials.

Incomplete filling: Can happen if pressure or temperature are set improperly.

Mold wear: Use quality molds and maintain them regularly.

Expert tips include testing and adjusting process parameters often. For example, increasing mold temperature may improve flow and reduce air traps.

Applications of Silicone Overmolding: Case Studies & Industry Insights

Medical Devices: Ensuring Safety and Compliance

Silicone overmolding helps make medical devices safer and more comfortable. Catheters with soft silicone covers reduce irritation. These products must follow strict rules like FDA regulations and ISO standards, ensuring safety and reliability.

Consumer Electronics: Enhancing User Interaction and Durability

Overmolded grips make phones, headphones, and controllers more comfortable. They also protect sensitive electronics from shocks and drops. Many leading brands swear by silicone for quality feel and longevity.

Automotive and Industrial Uses

In cars, silicone overmolding is used for dashboard dials, seals, and protective covers. These parts must endure heat, moisture, and vibrations. Silicone’s durability makes it a smart choice to meet safety standards and environmental challenges.

New Trends and Future Opportunities

Innovations include using biocompatible and eco-friendly silicones. Smart silicones with embedded sensors or conductive features are emerging. These materials can connect products to the internet, opening new opportunities for innovation.

Expert Support and Collaborations in Silicone Overmolding

Choosing the Right Partner

Partner with molders who have experience in your industry. Look for certifications like ISO 13485 for medical or IATF16949 for automotive. Their proven quality ensures consistent results and compliance.

Collaborate for Custom Solutions

Work with experts to optimize designs and prototypes. Simulation tools can help test how materials will behave before manufacturing begins. This reduces waste and speeds up development.

Stay Updated on Industry Innovations

Attend trade shows, webinars, and training sessions. Engage with professional forums and industry groups to learn about new materials and processes. Staying current gives you a competitive edge.

Cost Optimization and Scale-Up Strategies

Transitioning from prototypes to mass production requires planning. Analyze your ROI, and don’t forget to use ongoing technical support to adjust processes and reduce costs over time.

Partnering with a Trusted Manufacturer

YEJIA, a leading custom silicone product manufacturer, provides expert silicone overmolding solutions tailored to client requirements. With years of experience and advanced molding capabilities, the company ensures precise, durable, and high-performance parts for various industries. From material selection and mold design to production and quality control, YEJIA offers full technical support to help customers achieve optimal product performance.

Common Substrate Materials

Silicone can be overmolded onto various materials including:

Plastics such as PC, ABS, PA, PPS, PEEK

Metals like stainless steel, aluminum, brass, and titanium

Other elastomers, depending on compatibility

Silicone Overmolding Techniques

Insert Molding: The substrate is inserted into the mold and silicone is injected around it. This is commonly used when the base part is pre-fabricated.

Two-Shot Molding: Both materials are molded in sequence in the same machine, providing stronger bonding and better process control.

Compression Overmolding: Less common but suitable for lower-volume production or specific geometries.

Conclusion

Mastering silicone overmolding takes understanding, experience, and good collaboration. Techniques like proper material selection, surface prep, and process control build a solid foundation for success. Working with industry experts ensures quality and saves time and money.

Keep learning, experimenting, and staying connected with innovations. Investing in proper training and choosing the right partners will help you produce top-quality, durable, and creative products. The future of silicone overmolding holds exciting possibilities—are you ready to lead the way?

#Compression Overmolding#Silicone Overmolding#silicone duckbill valve#liquid injection molding#silicone rubber valves

0 notes

Text

CNC Milling: The Core of High-Precision Manufacturing

Introduction

The CNC milling process is a fundamental technique in precision machining, enabling manufacturers to create high-quality components with minimal human intervention. By utilizing computer numerical control (CNC) technology, milling machines shape materials such as metal, plastic, and wood into intricate designs with exceptional accuracy. In this blog, we explore the fundamentals of CNC milling, its advantages, and key applications across industries.

What is CNC Milling?

CNC milling is a subtractive manufacturing process that removes material from a solid workpiece using rotating cutting tools. Unlike manual milling, CNC milling is automated, following pre-programmed G-code instructions to achieve precise dimensions and complex geometries.

Key Features of CNC Milling

Multi-Axis Control – Operates on 3-axis, 4-axis, or 5-axis configurations for intricate designs.

High Precision – Achieves tolerances as tight as ±0.001 inches.

Versatile Material Compatibility – Works with metals, plastics, composites, and wood.

Automated Efficiency – Reduces human error and speeds up production.

Advantages of CNC Milling

1. Exceptional Accuracy and Consistency

CNC milling ensures repeatable precision, making it ideal for industries requiring tight tolerances:

Aerospace Components – High-precision parts for aircraft and spacecraft.

Medical Devices – Surgical instruments and prosthetics with intricate details.

Automotive Parts – Engine components and custom vehicle parts.

2. Increased Production Efficiency

Automated CNC milling enhances manufacturing speed:

Rapid Prototyping – Quickly produces prototypes for testing.

Mass Production – Scales up production with minimal waste.

Reduced Labor Costs – Minimizes manual intervention.

3. Complex Geometries and Customization

CNC milling allows for intricate designs that manual machining cannot achieve:

3D Contouring – Smooth curves and detailed engravings.

Multi-Surface Machining – Works on multiple angles and depths.

Custom Tooling – Adapts to unique project requirements.

Applications of CNC Milling

1. Aerospace and Automotive Industries

CNC milling is essential for high-performance components:

Aircraft Frames and Engine Parts – Lightweight, durable materials.

Automotive Prototypes – Custom designs for testing and production.

2. Medical and Electronics Manufacturing

Precision machining supports advanced medical and electronic devices:

Implants and Prosthetics – Biocompatible materials for healthcare.

Circuit Boards and Casings – High-precision parts for electronics.

3. Industrial and Consumer Goods

CNC milling is widely used in custom manufacturing:

Machinery Components – Gears, brackets, and housings.

Furniture and Decorative Items – Wood and metal engravings.

How to Optimize CNC Milling for Your Project

1. Choose the Right Material

Select materials based on strength, durability, and machinability:

Aluminum and Titanium – Lightweight and corrosion-resistant.

Plastics and Composites – Ideal for electronics and medical applications.

2. Optimize Tooling and Cutting Parameters

Enhance efficiency with proper tool selection:

End Mills and Face Mills – Different tools for varied surface finishes.

Cutting Speed and Feed Rate – Adjust settings for precision and efficiency.

3. Utilize Advanced CNC Software

Improve accuracy with CAD/CAM integration:

3D Modeling and Simulation – Ensures design feasibility.

Automated Toolpath Generation – Reduces programming time.

Conclusion

The CNC milling process is a powerful, precise, and efficient manufacturing method used across industries. Whether producing aerospace components, medical devices, or industrial machinery, CNC milling offers high-quality results with minimal waste. Investing in advanced CNC technology ensures cost-effective production, superior accuracy, and limitless customization.

0 notes

Text

Why Choosing Professional Ear Piercing Services Matters for Your Health

Ear piercings have become a popular form of self-expression and style worldwide. Whether you want a classic lobe piercing or trendy cartilage piercings, getting them done professionally is crucial—not just for aesthetics but for your health. Choosing expert piercing services from reputable piercing studios ensures a safe experience and minimizes the risk of complications. Here’s why it matters so much to opt for professional care when it comes to ear piercings.

1. Proper Hygiene and Sterilization

One of the most important reasons to select professional piercing studios is hygiene. In a clean, regulated environment, all equipment, including needles and piercing guns, are thoroughly sterilized or single-use to prevent infections. Unprofessional or DIY piercings often risk exposure to bacteria, which can lead to serious infections and even bloodborne diseases.

Professionals follow strict sanitation protocols to protect your health. From wearing gloves to using disposable materials, every step is designed to ensure your piercing is safe and clean.

2. Expert Knowledge and Technique

Professional piercers undergo specialized training to understand anatomy, sterile techniques, and aftercare. Using the right tools and methods, such as a piercing gun for earlobe piercings or a sterile needle for cartilage, ensures precise placement and reduces trauma to the tissue.

Inexperienced individuals may cause uneven piercings, excessive pain, or complications like keloids and scarring. Trusted piercing services guarantee that your ear piercings are done correctly the first time, saving you from potential problems down the road.

3. Use of Safe, Hypoallergenic Materials

Professional piercing studios only use high-quality, hypoallergenic jewelry made from materials such as surgical steel, titanium, or 14-karat gold. This minimizes allergic reactions and skin irritations, which are common when cheap or low-grade jewelry is used.

These materials are tested for safety and biocompatibility, ensuring your new piercings heal properly without discomfort or complications.

4. Customized Advice and Aftercare Support

Aftercare is vital for proper healing of ear piercings. A professional piercer provides clear instructions tailored to your piercing type, lifestyle, and skin sensitivity. They can advise on cleaning routines, what to avoid (like swimming or certain hair products), and signs of infection to watch for.

This personalized care reduces healing time and ensures your piercing stays healthy and beautiful. In contrast, DIY piercings often come without adequate aftercare guidance, increasing the risk of problems.

5. Minimized Pain and Faster Healing

With professional techniques and tools, pain during piercing is generally minimized. A well-trained piercer knows how to work quickly and efficiently, ensuring the process is as comfortable as possible.

Moreover, because of the precision and sterile environment, healing times tend to be shorter and complications less frequent. This means you can enjoy your new ear piercings without prolonged discomfort.

6. Legal and Safety Compliance

Reputable piercing studios adhere to local health regulations and licensing requirements. This compliance means they maintain high standards for safety, cleanliness, and professional conduct.

Choosing licensed professionals protects you legally and medically, while unregulated piercers might not meet these essential standards.

Conclusion

Your ears deserve the best care when it comes to piercings. Opting for professional piercing services at a trusted piercing studio guarantees not only beautiful results but also prioritizes your health and safety. From sterile techniques using a piercing gun or needles to high-quality jewelry and expert aftercare advice, every aspect of the process is designed to minimize risks and maximize comfort.

Avoid the dangers of unprofessional piercings by choosing skilled piercers who understand the science and art of safe ear piercings. This way, you can enjoy your new look with confidence and peace of mind.

0 notes

Text

How Migration Testing Labs in Abu Dhabi Support Pharmaceutical Packaging Safety? | +971 554747210

Pharmaceutical packaging plays a crucial role in protecting medicines from contamination, degradation, and tampering, ensuring that drugs maintain their efficacy and safety throughout their shelf life. With the rapid growth of the pharmaceutical industry in the UAE and the wider GCC region, regulatory bodies have tightened standards to ensure that pharmaceutical packaging materials meet strict safety requirements.

One key aspect of pharmaceutical packaging safety is migration testing — the assessment of potential transfer of harmful substances from packaging materials into medicines. Migration testing labs in Abu Dhabi have become indispensable partners for pharmaceutical manufacturers, importers, and regulators aiming to guarantee packaging safety and compliance.

In this blog, we explore how migration testing lab in Abu Dhabi support pharmaceutical packaging safety, their testing methods, and why they are vital for protecting consumer health and meeting stringent regulatory standards.

What is Migration Testing in Pharmaceutical Packaging?

Migration testing is a specialized process that measures the transfer of chemical substances from packaging materials—such as plastics, adhesives, inks, and coatings—into the pharmaceutical products they contain. This is essential because contaminants migrating into medicines can compromise drug stability, alter therapeutic efficacy, and potentially harm patients.

Pharmaceutical packaging migration testing assesses both overall migration (total mass transfer of substances) and specific migration (individual hazardous chemicals like heavy metals, plasticizers, or monomers). The testing ensures that any migration falls within safe limits as defined by international regulations such as the European Pharmacopoeia, USP, and local authorities like the UAE’s Ministry of Health and Prevention (MOHAP).

Why is Migration Testing Critical for Pharmaceutical Packaging?

Pharmaceutical products have highly sensitive compositions and strict purity requirements. Even minimal contamination from packaging materials can:

Cause chemical degradation or reduced potency of drugs

Trigger adverse reactions or toxicity in patients

Lead to microbial contamination if packaging integrity is compromised

Result in product recalls, regulatory penalties, and reputational damage for manufacturers

Therefore, rigorous migration testing is mandatory to ensure that packaging materials used for pharmaceuticals do not release harmful substances that could impact product safety or patient health.

How Migration Testing Labs in Abu Dhabi Support Pharmaceutical Packaging Safety

Abu Dhabi hosts several advanced migration testing laboratories equipped with cutting-edge technology and expert personnel trained specifically for the pharmaceutical sector. Here is how these labs support pharmaceutical packaging safety:

1. Compliance with International and Regional Standards

Migration testing labs in Abu Dhabi follow internationally recognized standards such as:

European Pharmacopoeia (Ph. Eur.)

United States Pharmacopeia (USP) <661>, <661.1>, and <661.2>

ICH Q3D guidelines for elemental impurities

ISO 10993 for biocompatibility

GCC and UAE MOHAP regulations

By aligning testing protocols with these standards, Abu Dhabi labs help pharmaceutical companies meet global regulatory expectations and facilitate smooth market access both locally and internationally.

2. Advanced Analytical Techniques

Pharmaceutical packaging migration testing requires high sensitivity and accuracy to detect trace contaminants. Abu Dhabi labs employ sophisticated analytical methods such as:

Gas Chromatography-Mass Spectrometry (GC-MS) for organic compound migration

High-Performance Liquid Chromatography (HPLC) for plasticizers and other chemical additives

Inductively Coupled Plasma Mass Spectrometry (ICP-MS) for heavy metal analysis

Fourier Transform Infrared Spectroscopy (FTIR) for polymer characterization

These advanced techniques ensure precise identification and quantification of migrating substances.

3. Customized Testing Protocols for Pharmaceuticals

Different pharmaceutical products—tablets, capsules, injectables, liquids—have varying interactions with packaging materials. Abu Dhabi migration testing labs tailor test protocols by:

Selecting relevant food or pharmaceutical simulants to mimic drug formulations

Setting temperature and time parameters reflecting actual storage and usage conditions

Assessing both primary packaging (blister packs, bottles) and secondary packaging (cartons, labels)

Customized testing increases the accuracy of migration results, providing reliable safety data.

4. Expertise in Material Compatibility and Risk Assessment

Abu Dhabi labs provide consultancy services to pharmaceutical companies on packaging material selection based on migration test outcomes. They conduct risk assessments to identify potential migration issues early in product development, helping manufacturers choose compatible materials that minimize migration risks.

5. Quality Assurance and Regulatory Documentation Support

Accredited migration testing labs in Abu Dhabi issue detailed reports and certificates that comply with UAE MOHAP and international regulatory requirements. This documentation is essential for product registration, regulatory audits, and quality assurance.

Benefits of Using Migration Testing Labs in Abu Dhabi for Pharmaceutical Packaging

Local Regulatory Expertise and Fast Turnaround

Abu Dhabi labs understand the nuances of local regulations and can provide timely test results, speeding up product approvals and market launches in the UAE and GCC region.

Cost-Effective Testing Solutions

Local labs reduce logistics costs and provide competitive pricing for migration testing, making it accessible for both large pharma companies and SMEs.

Ensuring Patient Safety and Brand Integrity

Thorough migration testing guarantees the safety and efficacy of medicines, protecting patients and reinforcing manufacturer credibility in a competitive market.

Challenges Addressed by Migration Testing Labs in Abu Dhabi

Pharmaceutical packaging faces several challenges that migration testing labs help resolve, including:

Complex packaging materials: Modern pharmaceutical packaging often uses multi-layer laminates and innovative polymers whose migration behaviors require expert analysis.

Stringent safety thresholds: The pharmaceutical sector demands extremely low migration limits, necessitating high-precision testing instruments.

Regulatory variability: Labs guide companies through differing international regulations, helping harmonize compliance strategies.

Conclusion

Migration testing is a cornerstone of pharmaceutical packaging safety. It ensures that packaging materials do not compromise drug quality or patient health through harmful chemical migration. Migration testing labs in Abu Dhabi offer the expertise, technology, and regulatory knowledge essential to meet this challenge.

By partnering with these accredited labs, pharmaceutical manufacturers in Abu Dhabi and the broader UAE market can ensure their packaging materials comply with strict safety standards, accelerate regulatory approvals, and maintain high-quality products that safeguard consumers.

0 notes

Text

Introduction: What if Every Component Could Think?

The future of manufacturing isn’t just smart—it’s intelligent at the part level. In an era where edge computing, real-time data, and decentralized automation dominate strategic roadmaps, manufacturers are asking: What if every component could store, transmit, and verify its own identity, lifecycle, and function?

The answer may lie in nano-markings—laser-engraved identifiers so small they’re invisible to the naked eye, yet powerful enough to support secure authentication, lifecycle tracking, and even interaction with digital twins.

This article explores how nano-marking works, what it enables, and why it’s quickly becoming the foundation for part-level intelligence across sectors like aerospace, medical, electronics, and beyond.

What Are Nano-Markings?

Nano-markings are identifiers—like serial numbers, logos, or codes—engraved at sub-micron scales, often under 200 nanometers in line width. These markings:

Are created with ultrafast lasers or advanced nanofabrication methods

Can be applied directly to the surface of materials without altering performance

May be visible only under electron microscopes or high-powered optical sensors

Support data embedding, traceability, and counterfeit protection

The concept aligns closely with nanotexturing, covert laser marking, and optically variable devices (OVDs) in secure manufacturing.

Why Nano-Markings Matter in B2B Manufacturing

As B2B operations scale and digitize, manufacturers need more than just barcodes—they need:

Tamper-proof traceability

Lifecycle visibility at the micro level

Secure identification resistant to duplication

Integration with AI and digital twin models

Nano-markings provide a permanent, nearly invisible data layer for every component, enabling:

Compliance with global traceability standards

Validation in harsh or sterilized environments

Authentication for warranty, IP, and origin verification

Interaction with robotic or vision systems in automated workflows

How Nano-Markings Are Made

1. Ultrafast Lasers (Femtosecond and Picosecond)

Extremely short pulses ablate surface layers without heat damage

Can produce features <100 nm in width on metals, ceramics, and polymers

2. Laser Interference Lithography

Uses light interference patterns to generate repeatable nano-scale structures

Suitable for texturing surfaces for identification or adhesion purposes

3. Two-Photon Polymerization

A type of 3D laser writing inside transparent materials

Enables truly embedded marking in glass or biocompatible polymers

4. Nanosecond UV Lasers

Slightly lower resolution, but ideal for cost-effective covert marking on plastics or silicon

Applications of Nano-Marking by Industry

Aerospace & Defense

Nanotextured serial numbers on titanium or ceramic components

Invisible authentication to prevent counterfeit or tampered parts

Support for MIL-STD UID compliance with zero bulk marking

Medical Devices

Laser-annealed nano-QR codes on implants or surgical tools

Fully sterilization-resistant and biocompatible

Integrates with electronic health records (EHRs) and patient-matching systems

Electronics & Semiconductors

Sub-visible part-level IDs on microchips, MEMS, or wafers

Used in wafer-level testing, inventory control, and IP protection

Assists in reverse logistics and gray market surveillance

Luxury Goods & Optics

Nanographic logos or patterns engraved on high-end watches or lenses

Adds invisible anti-counterfeit features that don't affect aesthetics

Nano-Markings vs Traditional Marking

FeatureTraditional Laser MarkingNano-MarkingSizeMicronsSub-micronsVisibilityVisible to human eyeOften invisibleReadabilityOptical camerasMicroscopy or custom readersData DensityModerateHigh (with compressed encoding)SecurityModerateVery highUse CasesGeneral traceabilityHigh-stakes ID, anti-counterfeiting, embedded IoT

Nano-markings fill a gap traditional methods can't—covert, tamper-proof, and machine-readable intelligence.

Integrating Nano-Marking Into Smart Manufacturing

1. Mark-Verify-Log Process

Marking is done inline or post-process

Verification is done using embedded cameras or microscopes

Results are stored to the MES, ERP, or blockchain systems

2. Vision and AI Integration

AI helps identify and verify nano-patterns rapidly

Ensures each mark is validated without slowing production

3. Digital Twin Alignment

Each nano-marked part can be tied to a unique digital twin

Enables real-time updates on usage, wear, environmental exposure

4. Blockchain and Supply Chain Security

Nano-mark acts as a cryptographic key to access or verify product data

Protects against third-party tampering or substitution

Advantages of Nano-Marking

BenefitBusiness ImpactPermanentNo wear-off even in harsh environmentsCovertInvisible to tamperers or counterfeitersUniqueVirtually impossible to replicate or cloneLightweightNo additional weight or surface coatingHigh-speedAdvanced lasers can mark at production-line speeds

Limitations and Considerations

ChallengeSolutionEquipment costOffset by IP protection and compliance benefitsVerification complexityPartner with readers or AI-based scannersTrainingRequires new SOPs for QA and inspectionLimited public standardsEmerging ISO/IEC guidelines for nano-ID underway

It’s important to view nano-marking as part of a broader smart manufacturing strategy, not just a tech add-on.

Future Trends: Toward Embedded Intelligence

Nano-markings are paving the way for:

Smart components that trigger alerts when tampered with

Self-identifying parts that sync to digital twins via vision systems

Decentralized product passports on the part itself, not a label

Autonomous part sourcing using AI-driven procurement bots reading embedded marks

As smart factories evolve, nano-marking will be the smallest and most powerful building block for part-level intelligence.

Conclusion: Intelligence Starts at the Surface

Nano-markings represent a seismic shift in how we think about traceability, authentication, and data at the component level. As manufacturers move toward more secure, autonomous, and connected systems, the ability to embed intelligence into the surface of every part becomes not just valuable—but necessary.

From aerospace to semiconductors, the future of manufacturing is small, smart, and laser-engraved.

0 notes

Text

Why is CNC machining preferred for manufacturing medical devices?

The medical industry demands the highest standards of precision, quality, and safety in the production of its components and devices. To meet these requirements, many manufacturers turn to CNC machining service providers—specifically those specializing in Medical CNC applications—for the fabrication of medical equipment, instruments, and implants. CNC (Computer Numerical Control) machining has become a preferred manufacturing method in the medical sector for a variety of critical reasons.

Exceptional Precision and Accuracy

Medical devices often require tight tolerances and complex geometries that must be produced consistently and accurately. CNC machines can achieve micron-level precision, making them ideal for manufacturing parts like surgical instruments, orthopedic implants, and diagnostic equipment. This high level of accuracy helps ensure that each component performs reliably and safely in medical applications.

Compatibility with Medical-Grade Materials

CNC machining supports a wide range of biocompatible materials commonly used in the medical field, such as titanium, stainless steel, PEEK, and medical-grade plastics. These materials are essential for applications involving direct contact with the human body or exposure to sterilization processes. CNC machining enables these tough and specialized materials to be shaped with precision and care.

Clean, Contaminant-Free Processes

A major concern in medical manufacturing is cleanliness. CNC machining is a subtractive process that produces minimal heat and dust compared to other methods, reducing the risk of contamination. Parts can also be machined in controlled environments to meet strict hygiene standards. Many CNC machining facilities that serve the medical sector adhere to ISO 13485 certification and FDA regulations.

Repeatability and Consistency

When manufacturing medical devices, consistency is key. CNC machining delivers highly repeatable results, which is crucial for both mass production and the manufacturing of custom components. Whether making 1 or 10,000 parts, CNC machines ensure that each item meets the same specifications without deviation.

Rapid Prototyping and Short Lead Times

Innovation in the medical field is constant, requiring fast development cycles. CNC machining is well-suited for rapid prototyping, allowing engineers to quickly produce and test new designs. Turnaround times are often shorter than with other manufacturing methods, making it easier to get life-saving devices to market quickly.

Complex Geometries and Customization

Medical devices frequently involve intricate shapes that are difficult to produce using conventional manufacturing methods. With multi-axis CNC machines, manufacturers can create highly detailed and customized parts in a single setup. This capability is especially valuable for patient-specific implants and surgical guides tailored to individual anatomy.

Cost-Effectiveness for Low to Mid-Volume Production

For small to medium production runs, CNC machining is often more cost-effective than processes like injection molding, which require expensive tooling. This makes it an ideal solution for specialty medical devices and limited production volumes, such as custom implants or specialized surgical tools.

Conclusion

CNC machining has earned its place as a preferred manufacturing method in the medical industry due to its unmatched precision, material versatility, cleanliness, and ability to produce both prototypes and final products efficiently. By partnering with a qualified CNC machining service, medical device manufacturers can ensure the delivery of safe, high-quality components that meet strict regulatory standards and improve patient outcomes.

0 notes

Text

The Vital Role of Metal Testing

Introduction

In a world driven by infrastructure, machinery, and manufacturing, metals are the backbone of countless industries — from aerospace and automotive to construction and energy. However, the reliability of these metals hinges on rigorous testing to ensure they meet stringent safety and performance standards. This is where metal testing services play a crucial role. By offering precise analysis and assessment, these services provide valuable insights into a material’s composition, durability, and integrity.

What Are Metal Testing Services?

Metal testing services involve a series of laboratory analyses and field assessments designed to determine the physical, mechanical, and chemical properties of metal components. These tests help verify whether a metal or alloy is suitable for its intended application and complies with regulatory or industry standards.

Testing is essential during various stages of a product’s lifecycle — design, manufacturing, quality control, failure analysis, and even recycling.

Key Types of Metal Testing

Chemical Analysis

Determines the elemental composition of metals and alloys.

Common methods include X-ray fluorescence (XRF), optical emission spectrometry (OES), and atomic absorption spectroscopy (AAS).

Mechanical Testing

Assesses a metal’s strength, ductility, hardness, and fatigue resistance.

Popular tests include tensile testing, impact testing (Charpy/Izod), and hardness testing (Brinell, Rockwell, Vickers).

Non-Destructive Testing (NDT)

Evaluates the material’s integrity without altering or damaging it.