#BiodegradablePlastics

Explore tagged Tumblr posts

Text

Cellulose Acetate Market Experiencing Surge as Environmental Regulations Boost Biodegradable Material Usage

The cellulose acetate market has witnessed consistent growth over the past few years, driven by its versatile applications across several end-use industries such as textiles, cigarette filters, eyewear, and plastics. As a derivative of cellulose, cellulose acetate is a biodegradable, thermoplastic polymer that offers favorable characteristics like high transparency, dimensional stability, and chemical resistance. These attributes have enabled it to play a key role in various consumer and industrial products, particularly in an era where sustainability and eco-friendliness are increasingly influencing market preferences.

Market Drivers

One of the primary drivers of the cellulose acetate market is the rising demand for eco-friendly and biodegradable materials. With growing concerns about the environmental hazards of synthetic plastics and non-degradable products, manufacturers and consumers are turning toward greener alternatives. Cellulose acetate, being derived from natural cellulose (primarily wood pulp or cotton linters), fits well into this narrative. It degrades more easily than synthetic plastics and has fewer environmental impacts, making it ideal for companies focused on sustainable development goals.

The growing global population and the expanding middle class in emerging economies are contributing to the demand for textiles and personal care products—two major application areas of cellulose acetate. In the textile industry, cellulose acetate is used to manufacture fibers that offer silk-like aesthetics, quick drying, and excellent drape. This has made it popular for clothing, linings, and home furnishings.

Another significant market driver is the continued use of cellulose acetate in cigarette filters. Although the global tobacco industry has seen some decline in specific regions due to increasing health awareness, many developing countries still witness a steady demand for cigarettes, thereby keeping the demand for cellulose acetate-based filters stable.

Applications and Product Segmentation

Cellulose acetate finds applications in a wide range of products. The most common are:

Cigarette Filters: The single largest consumer of cellulose acetate. These filters are prized for their ability to trap harmful substances while maintaining smoke flavor.

Textiles and Apparel: Used in producing acetate fibers that offer softness, sheen, and comfort.

Eyewear Frames: The polymer’s flexibility, colorability, and aesthetic appeal make it ideal for premium and mid-range spectacle frames.

Films and Sheets: Used for photographic film, packaging films, and membranes.

Coatings and Plastics: Offers chemical resistance and clarity for various plastic applications.

In terms of product segmentation, cellulose acetate is mainly available in two forms:

Cellulose Acetate Tow: Primarily used in cigarette filters.

Cellulose Acetate Flakes: Used in plastics, coatings, textiles, and films.

Regional Insights

Geographically, the Asia-Pacific region dominates the cellulose acetate market due to high demand from countries like China, India, and Japan. The region's large population base, rising disposable incomes, and growing manufacturing sectors have created strong demand across multiple application segments. China, in particular, leads in both production and consumption, thanks to its vast cigarette manufacturing industry and growing textile exports.

North America and Europe also hold significant shares, with increasing adoption of sustainable materials and regulatory support for biodegradable alternatives driving market growth. The shift in consumer preferences towards eco-conscious products is expected to support further expansion in these regions.

Challenges and Opportunities

Despite its advantages, the cellulose acetate market faces challenges. One major issue is the availability and cost of raw materials. As it is derived from natural cellulose, fluctuations in the supply of wood pulp or cotton linters can impact production costs. Additionally, the presence of alternative biodegradable materials, such as polylactic acid (PLA) and other bioplastics, poses competitive pressure.

However, growing research and innovation in the field of green chemistry present opportunities for improving the cost-effectiveness and properties of cellulose acetate. There is also rising potential in emerging applications such as biodegradable packaging, medical products, and sustainable consumer goods.

Future Outlook

The cellulose acetate market is poised for continued growth, driven by regulatory support for biodegradable materials, rising consumer awareness, and advancements in sustainable manufacturing practices. With increased investment in R&D, manufacturers are exploring newer applications and more efficient production techniques. As industries increasingly prioritize sustainability, cellulose acetate is likely to solidify its position as a key material in the global market landscape.

0 notes

Text

Industrial Plastic Bags Market transforming global logistics with sustainable alternatives

Introduction

The Industrial Plastic Bags Market is transforming global logistics with sustainable alternatives that meet environmental mandates and operational efficiency demands. As industries embrace eco-conscious practices, the demand for durable, reusable, and recyclable industrial plastic bags is reshaping traditional supply chains.

Global Shift Toward Sustainability

One of the primary catalysts for the transformation within the market is the shift toward sustainability. Companies across sectors—automotive, pharmaceuticals, food, chemicals, and logistics—are increasingly turning to low-impact packaging materials. This trend is reinforced by government regulations that promote eco-friendly production and disposal practices.

Sustainable industrial plastic bags are designed with materials such as bio-based polymers, recycled plastics, and oxo-biodegradable additives. These alternatives reduce carbon footprints and lessen the environmental burden of waste disposal. Their long lifecycle, combined with minimal environmental impact, makes them a compelling choice for industrial logistics.

Redefining Packaging Norms in Global Logistics

Global logistics relies on consistent, reliable, and protective packaging. Industrial plastic bags, especially those with reinforced structures, provide robust solutions for transporting heavy, bulky, or sensitive products. With the integration of recyclable and reusable plastics, logistics companies are able to meet both performance and environmental standards.

Moreover, smart packaging innovations, including RFID tagging and barcode compatibility, have been seamlessly integrated into sustainable plastic bags. These enhancements help improve supply chain traceability, inventory management, and handling, further positioning plastic bags as central to logistics modernization.

Benefits for Industrial Operations

Sustainable industrial plastic bags bring multiple benefits to industrial operations. Their light weight reduces shipping costs while maintaining durability. The bags can be produced in custom shapes and sizes, enabling businesses to reduce unnecessary packaging and optimize space during transport.

Industries such as chemicals and pharmaceuticals rely on moisture-proof and tamper-evident packaging, which plastic bags offer. Innovations in barrier technologies and heat sealing ensure the safe transport of volatile or sensitive products, while maintaining compliance with safety standards.

Cost Efficiency and Reusability

One of the most attractive features of sustainable plastic bags is their reusability. Reusable plastic bags reduce the need for repeated packaging production, thus minimizing cost and material waste. For logistics providers, this translates to long-term cost savings without compromising on quality.

In addition, many modern industrial plastic bags are designed to withstand multiple cycles of loading, transport, and unloading. Their toughness helps eliminate frequent replacements, making them an economically viable option for high-volume distribution networks.

Regulations Encouraging Adoption

Many countries are enforcing regulations that favor recyclable and compostable materials in industrial applications. This regulatory push encourages businesses to adopt packaging solutions that are compliant with national and international environmental standards.

For example, in Europe and North America, strict restrictions on single-use plastics and landfilling have increased demand for environmentally safe packaging materials. Industrial plastic bags that meet these guidelines are rapidly becoming standard in global logistics strategies.

Future Outlook and Growth Potential

The future of the industrial plastic bags market is geared toward greater sustainability and smarter logistics solutions. Emerging economies are experiencing rapid industrialization, and their growing demand for industrial packaging will drive global expansion.

Simultaneously, companies are investing in R&D to develop even more sustainable materials and processing techniques. As circular economy models gain traction, the recycling and reuse of industrial bags will likely become a key area of focus. This will further solidify their role in efficient and eco-friendly logistics systems.

Conclusion

The industrial plastic bags market is undergoing a remarkable transformation as global logistics embraces sustainable alternatives. These modern bags offer a compelling mix of durability, cost-efficiency, and eco-responsibility. As industries strive to align their operations with global sustainability goals, industrial plastic bags will remain at the forefront of packaging innovation.

#industrialplasticbags#sustainablepackaging#logisticsinnovation#recyclableplastics#circulareconomy#biodegradableplastics#industrialpackaging#supplychaintrends#ecoindustrialbags#greenerlogistics

0 notes

Text

Biodegradable Plastic Additives Industry: Shaping a Greener Tomorrow

The global war on plastic waste has sparked a major shift in how we think about packaging, consumer goods, and materials at large. With rising environmental concerns and stricter regulatory mandates, industries are pivoting to solutions that leave a lighter footprint. That’s where the Biodegradable Plastic Additives Industry steps in—offering a realistic and scalable route toward sustainability.

These additives are quietly changing the way we use plastics. They’re not a complete replacement, but they bridge the gap between performance and eco-responsibility, helping conventional plastics degrade faster and more efficiently under appropriate conditions. Let’s break down what’s driving this industry, where it’s headed, and why it matters for businesses and the planet.

What Are Biodegradable Plastic Additives?

Biodegradable plastic additives are compounds blended with traditional polymers like polyethylene (PE), polypropylene (PP), or polystyrene (PS) to accelerate the degradation process. They allow plastics to break down more quickly when exposed to natural elements like heat, oxygen, moisture, or microorganisms—transforming long-lasting waste into carbon dioxide, water, and biomass.

These additives don’t compromise product performance. They retain the strength, clarity, and flexibility required in everything from food packaging to agricultural films—making them a valuable upgrade in sectors that depend on plastics but are under pressure to go green.

Market Drivers: Why Demand Is Surging

The global biodegradable plastic additives market was valued at USD 1.49 billion in 2024 and is projected to reach USD 2.20 billion by 2029, growing at 8.1% cagr from 2024 to 2029.

1. Environmental Regulations Are Getting Tougher

Governments worldwide are cracking down on single-use plastics. Europe’s Single-Use Plastics Directive, India’s ban on plastic carry bags, and various state-level mandates in the U.S. are driving companies to seek alternatives. Biodegradable additives help businesses stay compliant without a complete overhaul of materials.

2. Consumer Pressure for Sustainable Packaging

From coffee cups to e-commerce packaging, customers today are scrutinizing what their products are made of. Brands that offer biodegradable or eco-friendly alternatives have a competitive edge—especially in retail, food & beverage, and personal care industries.

3. Corporate Sustainability Goals

Companies are under pressure from investors, shareholders, and watchdogs to demonstrate climate-conscious operations. Incorporating biodegradable additives into plastic production is a low-barrier strategy to move closer to sustainability targets.

4. Innovation in Additive Technology

Early additives had limitations, but the new generation is smarter and more effective. Manufacturers now offer additives that work in various environments—landfills, industrial composting units, and even marine conditions—broadening the range of viable applications.

Key Application Areas

– Packaging Industry

Single-use plastic packaging continues to be a major contributor to plastic waste. Biodegradable additives help mitigate the impact of food wrappers, shopping bags, and shrink films without sacrificing durability or appearance.

– Agriculture

In agriculture, mulch films, greenhouse covers, and irrigation components often use plastic. Biodegradable additives enable these materials to break down after their lifecycle, reducing plastic buildup in soil.

– Consumer Goods

Cutlery, plates, containers, and straws are increasingly incorporating biodegradable plastic additives to reduce their long-term environmental impact.

– Textile and Medical

Nonwoven fabrics, medical packaging, and hygiene products are beginning to use biodegradable solutions to minimize post-use waste.

Challenges Facing the Industry

While the biodegradable plastic additives market is booming, it’s not without hurdles:

Lack of Universal Standards: There’s still confusion around what qualifies as biodegradable. Regulatory inconsistencies make it tough for companies to scale globally.

End-of-Life Infrastructure: Most biodegradable additives require specific environments (like industrial composters) to fully break down. Without the right disposal systems, they may not reach full effectiveness.

Cost Factors: Biodegradable additives can be more expensive than traditional plastic solutions, which may deter smaller companies or price-sensitive industries.

Key Players and Innovation

Companies like BioSphere Plastic, Willow Ridge Plastics, TDPA by EPI, and Mango Materials are leading the charge. Many are developing additives that work with a wide range of polymers and are designed for custom degradation timelines, ensuring maximum flexibility for clients.

Regional Insights

North America is seeing strong demand, especially in food service, packaging, and agriculture. State-driven policies and green consumers are pushing adoption.

Europe continues to lead in legislation, with high demand across industries thanks to robust environmental directives.

Asia-Pacific is the fastest-growing market, with China and India emerging as manufacturing hubs and simultaneously facing intense scrutiny over plastic waste.

Stay ahead with the latest trends – Download the PDF brochure.

Conclusion :

The Biodegradable Plastic Additives Industry isn’t the silver bullet to solve plastic pollution—but it’s a practical and impactful step forward. These additives give existing materials a second chance—one that aligns better with circular economy goals, consumer values, and regulatory frameworks. For companies in packaging, agriculture, food service, or manufacturing, integrating biodegradable plastic additives is no longer a novelty—it’s becoming a necessity.

#BiodegradablePlastics#SustainablePackaging#EcoFriendlySolutions#PlasticAdditives#GreenManufacturing#EnvironmentalInnovation#CircularEconomy

0 notes

Text

Tackling Plastic Pollution: The Path to a Circular Economy and Zero Waste

View On WordPress

#alternativematerials#biodegradableplastics#carbonfootprint#circulareconomy#circularplastics#circularproductdesign#circularsolutions#climateaction#climatechange#ecosystemprotection#environment#environmentalimpact#environmentalresponsibility#environmentalsustainability#extendedproducerresponsibility#globalactiononplastic#globalplasticoutlook#globalplasticpollution#globalwarming#greeneconomy#greenerfuture#greenhousegases#greenpolicies#greentechnologies#innovation#oceansprotection#oceansustainability#plasticalternatives#plasticbans#plasticdebris

0 notes

Text

Biodegradable Plastics Market worth $20.9 billion by 2028

The report "Biodegradable Plastics Market by Type (PLA, Starch Blends, PHA, Biodegradable Polyesters), End Use Industry (Packaging, Consumer Goods, Textile, Agriculture & Horticulture), and Region( APAC, Europe, NA, South America, MEA) - Global Forecast to 2028", is projected to reach USD 20.9 billion by 2028, at a CAGR of 21.3% from USD 7.9 billion in 2023.

The Biodegradable plastic market is driven by the demand for green based plastics in various industries, including packaging, consumer goods, textiles, and agriculture & horticulture among other end-use industries. The biodegradable plastics market includes both bio-based biodegradable plastics and synthetic/petrochemical-based biodegradable plastics. The market is witnessing significant growth across the world due to the increasing awareness and stringent government regulations about the use of non-biodegradable plastics.

Download pdf- https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=93

“PLA based biodegradable plastic is projected to grow at fastest CAGR, in terms of value, during the forecast period.”

PLA is the most used type of biodegradable plastic. As the world becomes more aware of the environmental impact of traditional plastics derived from fossil fuels, there has been a growing demand for sustainable and eco-friendly alternatives. PLA offers a solution by reducing dependence on non-renewable resources and minimizing plastic waste. There is a growing demand for eco-friendly packaging, disposable cutlery, food containers, and other consumer goods made from biodegradable materials. PLA satisfies this demand by offering a renewable and biodegradable alternative to conventional plastics.

“Consumer goods is projected to be the second largest application type in the biodegradable plastic market, in terms of value.”

Consumer goods are the second-largest end-use industry of biodegradable plastics. The major consumer goods considered under this segment are electrical appliances, domestic appliances, and others. The major consumer goods manufacturers are shifting their focus from traditional plastics to biodegradable plastics to reduce the negative impact on the environment. Biodegradable plastics are used for manufacturing consumer goods such as touchscreen computer casings, loudspeakers, mobile casings, and vacuum cleaners.

Request Sample- https://www.marketsandmarkets.com/requestsampleNew.asp?id=93

“Europe is expected to be the fastest growing market for biodegradable plastics during the forecast period, in terms of value.”

Europe is the largest consumer of biodegradable plastics. The packaging industry is the largest end-use industry of biodegradable plastics in Europe. The political and economic conditions have also driven the market penetration of these products. The EU Commission has focused on the Lead Markets Initiative, where bioplastics has been identified as one of the most important potential markets. The strict government norms and economic conditions have also driven the biodegradable plastics market. These factors have been responsible for developing biodegradable plastics, with collaborative research, in the region.

New product launches and expansions are the major growth strategies adopted by the key players in the market. The key global players in the biodegradable plastics market include BASF (Germany), NatureWorks (US), Total Corbion (Netherlands), Novamont (Italy), Biome Bioplastics (UK), Mitsubishi Chemical Holding Corporation (Japan), Toray Industries (Japan), Plantic Technologies (Australia), Danimer Scientific (US), and Fkur Kunstsoff (Germany).

#BiodegradablePlastics#SustainableMaterials#EcoFriendly#GreenTech#SustainablePackaging#PlasticAlternatives#EnvironmentalInnovation#GreenProducts#Bioplastics#SustainableFuture

0 notes

Text

Bio-polybutadiene Market| Insights: Trends, Innovation Future Projections

The Growing Influence of Bio-polybutadiene in Sustainable Markets

In recent years, the Bio-polybutadiene Market has witnessed significant growth, driven by the increasing global focus on sustainability and environmental consciousness. With a projected CAGR of 21.9%, reaching a valuation of USD 598.7 million by 2023, the market showcases promising prospects for the forecast period (2023-2032). This article delves into the dynamics, scope, and regional analyses of the bio-polybutadiene market, shedding light on its pivotal role in various industries.

Get a Free PDF Sample Copy of This Report@ https://dimensionmarketresearch.com/report/bio-polybutadiene-market/request-sample

Market Dynamics

The United States stands as a prominent consumer in the bio-polybutadiene market, fueled by a burgeoning demand for eco-friendly solutions across diverse sectors. Notably, the automotive industry utilizes bio-polybutadiene in tire manufacturing, leveraging its sustainable properties. Additionally, the construction sector adopts bio-based polybutadiene in adhesives, sealants, and other materials, further driving market growth. Despite challenges such as higher production costs compared to synthetic rubber, the tire sector is increasingly embracing bio-polybutadiene to enhance product performance and align with environmental initiatives.

Research Scope and Analysis

By Type

By Application

Recent Developments in the Bio-polybutadiene Market (2023-2024):

Growing Market:

Key Takeaways:

Buy This Report Here Click Here@ https://dimensionmarketresearch.com/checkout/bio-polybutadiene-market

Regional Analysis

The Asia Pacific region leads the global bio-polybutadiene market, accounting for 47.5% of the share in 2023. This dominance stems from the region's escalating demand for eco-friendly products and government initiatives aimed at reducing carbon emissions. Notably, the automotive sector's growth in countries like Japan, India, and China further propels the demand for bio-based polybutadiene, with key manufacturers contributing to market expansion.

Prominent Players

Several key players contribute to the Global Bio-polybutadiene Market, including:

These players actively engage in enhancing manufacturing capabilities and innovating offerings to meet the growing demand for bio-polybutadiene worldwide.

Conclusion

The Bio-polybutadiene Market stands at the forefront of sustainable innovation, offering eco-friendly solutions to diverse industries. With increasing emphasis on environmental conservation and stringent regulations, bio-polybutadiene emerges as a vital component in reducing carbon footprint and promoting sustainable development globally. As key players continue to invest in research and development, the market is poised for exponential growth, shaping a greener and more sustainable future for industries worldwide.

#BioPolybutadiene#SustainablePolymers#GreenChemistry#RenewableMaterials#BiodegradablePlastics#EcoFriendlyPolymers#BiopolymerMarket#SyntheticRubberAlternatives#BiobasedElastomers#EnvironmentalInnovation

0 notes

Link

#Biodegradableplastic#Bioplasticsinconstruction#CircularEconomy#GreenBuildingMaterials#PHApolymers#Renewablebuildingmaterials#Sustainablebioplastic#sustainablepackaging

0 notes

Text

Innovative Solutions to Microplastic Pollution in Soil & Water

May 29, 2025Microplastics—tiny plastic particles less than 5 millimeters in size—have become a major environmental concern, infiltrating not just oceans but also agricultural soils. Recent research reveals that microplastics in soil may be even more damaging than previously thought, potentially disrupting soil fertility, microbial ecosystems, and even food safety.According to a report by EcoWatch, microplastics can reduce plant growth, alter soil structure, and introduce harmful chemicals into the food chain. As awareness of these threats increases, scientists and startups are racing to develop innovative technologies that can capture, degrade, or eliminate microplastics before they cause irreversible harm. According to a 2024 study by the UN Environment Programme, over 12 million metric tons of microplastics are released into agricultural soils globally each year—more than what ends up in the oceans.

Why Reducing Soil and Water Microplastics Is Critical for Agriculture and Ecosystem Health

While marine microplastic pollution has received significant media attention, soil contamination is an equally urgent issue. Agricultural fields accumulate plastic residues through sources such as plastic mulch films, compost, and biosolids. Over time, these plastics fragment into micro- and nanoplastics, which can be absorbed by plant roots or leach into groundwater. - Reduced soil quality and fertility - Disruption of soil microbiomes - Contaminated food chains - Potential health risks to humans and animals Given the global reliance on healthy soil for food production and climate resilience, finding solutions to microplastic contamination is crucial. For example, a recent German study found that microplastics can inhibit earthworm activity, which is essential for soil aeration and nutrient cycling—key processes in sustainable agriculture.

Breakthrough Green Tech: Biodegradable Filters to Capture Microplastics from Wastewater

One of the most promising new inventions in the fight against microplastics comes from researchers at ETH Zurich, who have developed a biodegradable filter system designed to trap microplastics from wastewater and runoff before they reach agricultural land. How It Works These filters use nanocellulose fibers—a biodegradable material derived from plant waste—to attract and bind microplastic particles. Unlike traditional plastic-based filters, this innovation does not introduce more plastic into the environment. The filters can be integrated into drainage systems, irrigation pipelines, and even water treatment facilities. The system has already undergone successful pilot testing in two wastewater treatment facilities in Switzerland and is now being considered for broader implementation across Europe. Why It’s Game-Changing - Eco-friendly: Fully compostable after use. - Scalable: Easily implemented in urban and rural infrastructures. - Affordable: Uses agricultural waste as a raw material. This aligns with a broader movement toward sustainable plastics. For example, our article on revolutionary biodegradable plastics explores how plant-based alternatives are helping reduce reliance on fossil fuel-derived materials.

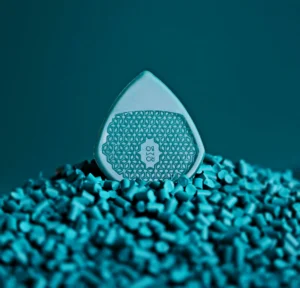

Symbolic representation of innovative microplastic filtration using biodegradable materials, illustrating emerging green technology for environmental protection

Emerging Technologies to Remove and Break Down Microplastics

- Microplastic-eating enzymes: Scientists are engineering enzymes that can break down plastic polymers into harmless compounds. - Magnetic microplastic collectors: Startups like Matter. have developed laundry filters that use magnetism to collect synthetic fibers from clothing. - Phytoremediation: Certain plants such as willow and hemp are being tested for their ability to absorb microplastics from contaminated soils, offering a natural and scalable solution. As biodegradable materials continue to evolve, the recycling landscape is also shifting. Read more about this in our feature on the future of plastics and how bio-based alternatives are revolutionizing recycling.

How You Can Reduce Microplastic Pollution

- Use natural fiber clothing instead of synthetics. - Install microfiber filters in your washing machine. - Support brands with sustainable packaging and biodegradable materials. - Avoid single-use plastics whenever possible. - Stay informed and advocate for plastic regulation in agriculture. Installing a microfiber filter in your washing machine can reduce synthetic fiber emissions by up to 90%, according to a study by Ocean Wise and Patagonia.

Conclusion

The war against microplastics is far from over, but thanks to technological innovation and growing public awareness, we are beginning to turn the tide. From biodegradable filters to enzyme-based degradation, the future of environmental protection lies in creative, science-driven solutions. As these inventions continue to evolve, they offer a glimmer of hope for a cleaner, healthier planet.

FAQ – Microplastics and Innovative Reduction Solutions

What are microplastics and why are they dangerous? Microplastics are plastic particles smaller than 5mm, often originating from larger plastic items breaking down. They pose environmental and health risks because they can enter soil, water, and even the food chain, disrupting ecosystems and potentially harming humans and animals. How do biodegradable filters help reduce microplastic pollution? Biodegradable filters, like those made from nanocellulose fibers, trap microplastic particles from water and wastewater before they reach soil or rivers. Unlike plastic-based filters, they break down naturally without adding to pollution. Can microplastics be removed from soil? Currently, complete removal is extremely difficult. However, innovations such as magnetic remediation, phytoremediation (using plants), and improved composting methods are being researched. Prevention remains the most effective strategy. Can Biodegradable and Bio-Based Plastics Help Solve Microplastic Pollution? Biodegradable plastics can help reduce the formation of microplastics, especially if designed to break down under natural conditions. Their effectiveness depends on environmental factors. Read more here. What can individuals do to help stop microplastic pollution? You can reduce your plastic footprint by using natural fabrics, installing filters in washing machines, avoiding single-use plastics, and supporting sustainable brands. Can home gardeners do anything to reduce microplastics in soil? Yes. Avoid using plastic mulch films, choose compost with verified low plastic content, and opt for natural fiber weed barriers. These steps can help minimize plastic residues in your garden soil. Here is another article with similar topic, https://www.ecotechnews.world/eu-plastic-bag-regulation-vs-usa-practices/ Read the full article

0 notes

Text

youtube

Japanese researchers from RIKEN and the University of Tokyo have developed “PHAmix,” a groundbreaking biodegradable plastic that dissolves in seawater within hours and degrades in soil within ten days. Made from food-safe compounds, it leaves no microplastics, emits no CO₂, and is fully recyclable. This innovation offers a powerful solution to plastic pollution and environmental sustainability.

New Scientists Awards

4th Edition of New Scientists Awards | 25-26 June 2025 | Dubai, United Arab Emirates

Nomination Link: https://newscientists.net/award-nomination/?ecategory=Awards&rcategory=Awardee

Web Visitors: https://newscientists.net/

For Enquiry: [email protected]

#sciencefather #scientist #scienceinnovation #researchexcellence #scientificbreakthrough #NewScientistsAwards #BiodegradablePlastic #PlasticPollution #SustainableInnovation #EcoFriendly #PHAmix #GreenTechnology #CleanOceans #MicroplasticFree #JapanInnovation #RIKEN #CircularEconomy #ZeroWaste #climateaction

Get Connected Here: =================

You Tube: https://www.youtube.com/@scienceawards-i6o

Twitter: https://x.com/awards67811

Instagram: https://www.instagram.com/afreen202564/

Pinterest: https://in.pinterest.com/scienceawards/

blogger: https://www.blogger.com/blog/posts/8014336030053733629?hl=en&tab=jj

0 notes

Text

Industrial Biotechnology

Industrial biotechnology, also known as white biotechnology, applies biological systems, organisms, or processes to produce industrial goods in a more sustainable and eco-friendly manner. It leverages microorganisms like bacteria, yeast, and fungi, as well as enzymes, to develop and optimize processes used in manufacturing sectors such as chemicals, energy, textiles, food, and pharmaceuticals.

One of the key goals of industrial biotechnology is to replace traditional chemical processes with biological ones, reducing energy consumption, greenhouse gas emissions, and reliance on fossil-based raw materials. This field plays a significant role in developing bio-based products such as biofuels, biodegradable plastics, bio-based chemicals, and industrial enzymes.

Applications of Industrial Biotechnology

Biofuels: Production of ethanol, biodiesel, and advanced biofuels from biomass such as algae, crop residues, and waste materials.

Biopolymers and Bioplastics: Creation of biodegradable and eco-friendly alternatives to conventional plastics.

Enzymes for Industry: Development of enzymes used in detergents, textiles, paper processing, and food production to enhance efficiency and reduce environmental impact.

Bioprocessing and Fermentation: Large-scale fermentation to produce vitamins, antibiotics, amino acids, and other bio-based chemicals.

Waste Management and Bioremediation: Use of biological processes to treat industrial waste, convert waste into bioenergy, and remove pollutants from the environment.

Sustainable Agriculture Inputs: Production of biofertilizers, biopesticides, and plant growth enhancers.

Advantages of Industrial Biotechnology

Sustainability: Reduces the use of non-renewable resources by utilizing biomass and renewable feedstocks.

Lower Environmental Impact: Minimizes greenhouse gas emissions, chemical waste, and energy consumption.

Economic Benefits: Generates bio-based alternatives that can compete with traditional petrochemical products.

Innovation Potential: Drives innovation in fields such as bioengineering, synthetic biology, and metabolic engineering.

Challenges

Despite its numerous benefits, industrial biotechnology faces challenges such as high production costs, scalability issues, regulatory hurdles, and competition from conventional chemical industries. However, ongoing research, government incentives, and advances in genetic engineering and bioprocessing are helping to overcome these barriers.

Biotechnology Scientist Awards

Visit Our Website : http://biotechnologyscientist.com

Contact Us : [email protected]

Nomination Link : https://biotechnologyscientist.com/award-nomination/?ecategory=Awards&rcategory=Awardee

#sciencefather#researchawards#Scientist#Scholar#Researcher#IndustrialBiotechnology #WhiteBiotechnology #Bioeconomy #Biofuels #Bioplastics #SustainableManufacturing #EnzymeTechnology #Bioprocessing #Biocatalysis #GreenBiotechnology #Bioengineering #SyntheticBiology #BioInnovation #BiotechRevolution #RenewableEnergy #BiodegradablePlastics #BiotechnologyApplications #CircularEconomy #WasteToEnergy #EcoFriendlySolutions #FutureOfBiotech #BioManufacturing #FermentationTechnology #BioBasedProducts #SustainableBiotech

👉Don’t forget to like, share, and subscribe for more exciting content!

Get Connected Here: =============

Facebook : https://www.facebooFk.com/profile.php?id=61572562140976

Twitter : https://x.com/DiyaLyra34020

Tumblr : https://www.tumblr.com/blog/biotechscientist

Blogger: https://www.blogger.com/u/1/blog/posts/3420909576767698629

Linked in : https://www.linkedin.com/in/biotechnology-scientist-117866349/

Pinterest : https://in.pinterest.com/biotechnologyscientist/

0 notes

Text

Cellulose Acetate Market Future Prospects in the Rise of Eco-Friendly Materials and Packaging

Cellulose acetate, a derivative of cellulose, plays a vital role in multiple industries due to its versatile properties. Derived from the cellulose found in plants, it is modified to create a range of products with enhanced qualities like flexibility, transparency, and ease of handling. This article will explore the current trends and future projections in the cellulose acetate market, shedding light on its applications, drivers, and challenges.

What is Cellulose Acetate?

Cellulose acetate is a synthetic polymer created by acetylating cellulose, a natural polymer extracted from plants, especially wood and cotton. The process involves replacing hydroxyl groups in cellulose with acetyl groups, resulting in a material that retains the structural properties of cellulose but with improved resistance to degradation, heat, and water. The material is typically available in the form of fibers, films, and plastics and is commonly used in various industries, including textiles, pharmaceuticals, and the production of photographic films.

Key Applications of Cellulose Acetate

Textile Industry: One of the most significant applications of cellulose acetate is in the textile industry, where it is used to produce fabrics and fibers. Acetate fibers, known for their silk-like appearance and feel, are widely used in the fashion and apparel industries. Cellulose acetate fibers offer the advantage of being biodegradable, making them more environmentally friendly compared to synthetic alternatives like polyester.

Film and Photography: Historically, cellulose acetate has been a crucial component in the production of photographic films and X-ray films. The material’s transparency and flexibility made it an ideal base for film manufacturing. Even though digital imaging has largely replaced photographic film, cellulose acetate is still used in niche applications where high-quality, archival films are needed.

Medical and Pharmaceutical Applications: In the pharmaceutical industry, cellulose acetate is used in the formulation of controlled-release tablets, where the material serves as a coating to manage the release of active ingredients. The biocompatibility and stability of cellulose acetate make it an excellent choice for these applications. Furthermore, cellulose acetate is utilized in the production of surgical dressings and other medical products.

Plastic Industry: Cellulose acetate is also used as an alternative to petroleum-based plastics. It is found in the production of items like eyeglass frames, coatings, and other plastic products. It is considered more environmentally friendly than conventional plastics because of its biodegradable nature. The growing demand for sustainable materials has driven the use of cellulose acetate in various sectors seeking to reduce their environmental footprint.

Packaging Industry: The packaging industry is increasingly incorporating cellulose acetate for food packaging due to its biodegradability. It provides a safe, transparent alternative to plastic films and has the added advantage of being derived from renewable resources. As the demand for sustainable packaging grows, cellulose acetate is expected to see further adoption in the food and beverage sector.

Growth Drivers of the Cellulose Acetate Market

Environmental Sustainability: As global awareness of environmental issues grows, there is a heightened demand for biodegradable materials. Cellulose acetate, being biodegradable and derived from renewable resources, presents a sustainable alternative to petroleum-based plastics. This environmental appeal has significantly boosted its use, especially in industries such as packaging, textiles, and medical applications.

Rising Demand for Biodegradable Materials: With increasing environmental regulations, industries are turning to biodegradable materials for packaging and other applications. Cellulose acetate is a preferred choice due to its decomposition rate and low environmental impact. The push for greener products in various industries is a significant factor driving the cellulose acetate market forward.

Technological Advancements in Manufacturing: The development of advanced technologies in the production of cellulose acetate has improved its efficiency and cost-effectiveness. Innovations in manufacturing processes are enabling better control over the material’s properties, allowing for its use in a wider range of applications. This has opened up new opportunities for the market, especially in high-value sectors like pharmaceuticals and medical devices.

Challenges in the Cellulose Acetate Market

Despite its many advantages, the cellulose acetate market faces certain challenges. One of the main hurdles is the high cost of production compared to synthetic alternatives. The process of deriving cellulose acetate from natural resources and its subsequent processing requires significant investment in technology and infrastructure, which can limit its widespread adoption in cost-sensitive industries.

Additionally, there is competition from synthetic fibers and plastics, which are often cheaper and more widely available. While cellulose acetate offers environmental benefits, its higher production cost and the need for sustainable sourcing may hinder its growth in certain sectors.

Future Outlook of the Cellulose Acetate Market

The cellulose acetate market is expected to continue expanding in the coming years. As sustainability becomes a central focus for businesses worldwide, the demand for biodegradable and eco-friendly alternatives like cellulose acetate is likely to grow. The increasing shift towards sustainable textiles, biodegradable packaging, and medical-grade materials positions cellulose acetate as a key player in the future of multiple industries.

In conclusion, the cellulose acetate market is poised for steady growth as technological advancements, sustainability trends, and eco-conscious consumer behavior drive demand. While challenges related to production costs remain, the material’s versatility, biodegradability, and role in environmentally friendly applications will continue to contribute to its expanding market potential.

#CelluloseAcetate#SustainableMaterials#EcoFriendlyProducts#BiodegradablePlastics#SustainablePackaging#GreenMaterials

0 notes

Text

Beverage Processing Polymers 🥤🔬 – Flowing up to $7.8B by 2034! 6.4% CAGR brewing!

Beverage Processing Polymers Market is set to grow from $4.2 billion in 2024 to $7.8 billion by 2034, at a CAGR of 6.4%. This growth is driven by rising demand for packaged beverages, sustainable materials, and advanced processing technologies.

To Request Sample Report : https://www.globalinsightservices.com/request-sample/?id=GIS23320 &utm_source=SnehaPatil&utm_medium=Article

Key Market Insights & Trends

Top Segments:

Filtration & Clarification Polymers lead the market due to stringent quality standards and increasing beverage safety regulations.

Packaging Polymers follow, reflecting the demand for lightweight, durable, and recyclable materials.

PET (Polyethylene Terephthalate) dominates with a 45% market share, followed by PP (30%) and PC (25%).

Regional Overview:

North America leads, with the United States dominating due to technological advancements and premium beverage demand.

Europe follows closely, with Germany excelling in sustainable packaging innovations.

Asia-Pacific is emerging, fueled by rapid industrialization and growing consumer preferences for eco-friendly beverage packaging.

Key Players: Major companies like Amcor, Berry Global, Sealed Air, Dow Inc., and SABIC are driving innovation with sustainable and efficient polymer solutions.

Future Market Outlook

With sustainability becoming a core focus, the market is set for further advancements in biodegradable polymers, bio-based plastics, and circular economy initiatives. Companies investing in recyclable materials and energy-efficient processing technologies will lead the next wave of growth in beverage packaging.

#beverageindustry #sustainablepackaging #beverageprocessing #packaginginnovation #petbottles #recyclableplastics #foodgradepolymers #greenmanufacturing #plasticrecycling #packagingtrends #biodegradableplastics #polymerengineering #carbonfootprint #ecoengineering #circularpackaging #environmentallyfriendly #industrytrends #plasticalternatives #marketexpansion #consumerdemand #carbonateddrinks #nonalcoholicbeverages #alcoholicdrinks #dairypackaging #juicepackaging #foodandbeverage #advancedpolymers #packagingmachines #manufacturingtrends #futureofpackaging #marketgrowth #plasticalternatives #lightweightpackaging #regulatorycompliance #sustainablematerials #plasticinnovation #highperformancematerials #materialscience #injectionmolding #blowmolding #thermoforming #flexiblepackaging #compostablematerials #marketforecast #circularplastics

Would you like to highlight any specific sustainability initiatives or innovations in beverage packaging? 🌱

0 notes

Text

Revolutionizing Sustainability: Pioneering the Future with Biodegradable Plastic Additives

Environmental concerns are pushing individuals and businesses alike to rethink their reliance on traditional plastics. Among the various solutions, biodegradable plastic additives are emerging as a game-changer. These innovative compounds enhance the breakdown of plastic, offering a sustainable path forward. For health-conscious consumers, understanding the importance and impact of these additives is essential to making informed, eco-friendly choices.

Biodegradable Plastic Additives Market size was USD 1.49 billion in 2024 and is projected to reach USD 2.20 billion by 2029, at a CAGR of 8.1%, between 2024 and 2029.

The Growing Plastic Problem

Plastics like polyethylene, polypropylene, and polystyrene dominate our daily lives because of their durability and versatility. Unfortunately, this durability means these plastics can persist in the environment for centuries. Landfills overflow, marine ecosystems suffer, and harmful microplastics find their way into food chains. Furthermore, the production and eventual degradation of conventional plastics release toxic chemicals that pose risks to human health and the environment.

What Are Biodegradable Plastic Additives?

Biodegradable plastic additives are chemical compounds integrated into traditional plastic formulations. They alter the material’s structure, making it easier for microorganisms to break down the plastic. Unlike conventional plastics that degrade into microplastics, these additives enable complete decomposition into water, carbon dioxide, and organic matter. Importantly, this process leaves no harmful residues behind.

Why Health-Conscious Consumers Should Care

1. Mitigating Environmental Harm

Plastic pollution affects not only ecosystems but also public health. By choosing products with biodegradable additives, consumers can significantly reduce the long-term impact of plastic waste on the planet. For those committed to a healthier lifestyle, this is a tangible way to align personal values with daily consumption habits.

2. Safer Alternatives for Personal Use

The leaching of chemicals like BPA and phthalates from traditional plastics into food and beverages is a well-documented concern. Biodegradable plastics, designed to avoid such harmful substances, provide a safer option for items like food containers, bottles, and packaging.

3. Fostering a Sustainable Lifestyle

Incorporating biodegradable products into daily life supports the broader concept of a circular economy, where resources are reused or responsibly disposed of. This lifestyle shift is not just about reducing waste—it’s about creating a healthier environment for everyone.

Everyday Applications of Biodegradable Plastic Additives

The versatility of biodegradable plastic additives means they’re finding their way into various industries:

Food Packaging: Grocery bags, takeaway containers, and disposable cutlery made with biodegradable plastics offer an eco-friendly alternative to single-use plastics.

Agriculture: Mulch films and other agricultural tools degrade naturally in the soil, reducing pollution while enriching the land.

Healthcare: Products like disposable gloves, syringes, and medical packaging ensure hygiene and safe disposal without long-term environmental consequences.

Everyday Essentials: Items such as straws, plates, and water bottles cater to consumers seeking sustainable options in their routine purchases.

Challenges to Overcome

While the promise of biodegradable plastics is exciting, several challenges remain:

Incomplete Breakdown: Degradation often requires specific conditions such as heat, moisture, and microbial activity, which may not always be present in natural environments.

Recycling Confusion: Mixing biodegradable plastics with conventional plastics can disrupt recycling processes. Clear guidelines and labeling are needed to address this.

Misleading Claims: Not all products labeled “biodegradable” meet rigorous standards. Consumers must look for certifications to ensure the product’s authenticity.

A Future Built on Biodegradability

The demand for sustainable alternatives is spurring rapid advancements in biodegradable plastic additives. Researchers are working to improve their efficiency, broaden their applications, and reduce costs. Governments are also stepping in, promoting these solutions through incentives, regulations, and public awareness campaigns. The collective effort of industries, consumers, and policymakers could redefine our relationship with plastics.

Download PDF Brochure :

Biodegradable plastic additives represent a practical and impactful way to address the environmental and health concerns linked to traditional plastics. For health-conscious individuals, choosing biodegradable alternatives is more than an eco-friendly decision; it’s a commitment to a better, safer world. By making thoughtful choices and encouraging systemic change, consumers can help accelerate the transition to sustainable materials, ensuring a healthier planet for generations to come.

#Sustainability#BiodegradablePlastics#EcoFriendlySolutions#PlasticAdditives SustainableFuture#EnvironmentalImpact#GreenInnovation#PlasticRevolution#EcoConscious#BiodegradableFuture

0 notes

Text

💉🔬 **The Future of Healthcare Innovation: India’s Medical Plastics Market** 🇮🇳🌱

Did you know that the **medical plastics industry in India** is growing rapidly? With advancements in **medical devices**, **surgical instruments**, and **drug delivery systems**, the demand for high-quality medical plastics is skyrocketing. 📈💡

Explore the **market trends, growth drivers**, and **key opportunities** shaping the future of healthcare in India! From **sustainability initiatives** to innovations in **biodegradable plastics**, the Indian medical plastics market is set to revolutionize patient care. 🌍💊

👉 **Link in bio** to learn more about how this industry is evolving and the trends shaping its future.

#MedicalPlastics #HealthcareInnovation #IndiaMarket #MedicalDevices #PlasticIndustry #HealthcareTrends #SustainableHealthcare #BiodegradablePlastics #MedicalTechnology #IndiaGrowth #PlasticMarket #HealthcareOpportunities #MedicalManufacturing

---

0 notes

Text

Oxo-biodegradable masterbatches manufacturers

Capital Colours are best Oxo-biodegradable masterbatches suppliers in Hyderabad.With increasing public concern over plastic waste, the requirement for biodegradable plastics is increasing. We all know that Plastic is the best material for the majority of packaging. Saving the environment from pollution has become need nowadays. Our biodegradable masterbatch is one such step towards environment safety. The shelf & service life of degradable and biodegradable plastic products can be modified based on customer requirements varing from a few months to years.

Benefits of Oxo-biodegradable masterbatches

Ø Help to reduce the collision of plastic waste on the environment.

Ø Add more value to other products and brands.

Ø Has all the characteristics of normal plastic without any harmful effects on this Environment.

Ø Small addition make standard polyolefins oxo-biodegradable.

Ø No investment in machinery needs for manufacturing.

Ø Cost effective method to enhance environment credentials of plastics.

1 note

·

View note