#CIPP Liner Design

Explore tagged Tumblr posts

Text

Little P.Eng. Engineering: Redefining Engineering Services across Canada and the USA

Little P.Eng. Engineering holds a firm foothold in the engineering industry, reigning supreme in both Canada and the United States. Recognized for its unrivaled expertise in piping design, piping stress analysis, tanks design, seismic bracing design, pipe rehabilitation, and structural engineering services, this organization has been a paragon of superior service and innovative solutions in engineering.

Multidisciplinary Capabilities of Little P.Eng. Engineering

Little P.Eng. Engineering's reputation is built on a solid foundation of its comprehensive and multifaceted capabilities, making it the first port of call for diverse engineering service requirements:

Piping Design: The company’s proficiency in piping design is second to none. This includes designing process and utility piping, high-pressure piping, and cryogenic piping. Utilizing advanced 3D modeling and simulation software, Little P.Eng. Engineering crafts innovative and cost-effective solutions that satisfy all operational and safety requirements.

Piping Stress Analysis: The piping stress analysis service offered by Little P.Eng. Engineering is nothing short of superior. They meticulously evaluate the responses in piping systems under thermal, dynamic, and static loads. This careful examination ensures reliability, safety, and extended service life for any piping systems.

Tanks Design: Little P.Eng. Engineering's expertise extends to the design and analysis of storage tanks. They leverage the latest software, complying with international codes and standards, proving time and again their capability in creating secure, reliable, and efficient storage tank solutions.

Seismic Bracing Design: The seismic bracing design services offered by Little P.Eng. Engineering are at the forefront of the industry. The designs ensure structural integrity, protecting buildings and their components against seismic events. They adhere to the most stringent local and national building codes, while providing enhanced durability and resilience.

Pipe Rehabilitation: In the area of pipe rehabilitation, Little P.Eng. Engineering excels with their advanced technology and tried-and-tested methods. Their comprehensive services cover tackling corrosion, leaks, and blockages that threaten the efficiency of pipelines. The company also specializes in CIPP (Cured-In-Place Pipe) liner design as per ASTM F1216, which is a standard practice for rehabilitation of existing pipelines and conduits.

Structural Engineering Services: Little P.Eng. Engineering rounds out their offerings with a complete suite of structural engineering services, encompassing design, analysis, and review of structures like buildings, bridges, towers, and tunnels. These services guarantee the structural integrity, safety, and longevity of all structures involved.

Why Little P.Eng. Engineering Stands Out

Several key factors solidify Little P.Eng. Engineering as a frontrunner in the engineering service sector across Canada and the United States:

A Wealth of Expertise and Experience

With a highly skilled and experienced team of professionals at the helm, Little P.Eng. Engineering has successfully managed countless projects across various scales and sectors. The wealth of knowledge and skills accrued over the years is incorporated into each new project, ensuring bespoke solutions tailored to each client's specific requirements.

Innovation at the Core

Innovation lies at the heart of Little P.Eng. Engineering's operations. The company's commitment to leveraging technological advancements sets it apart in the industry. Utilizing advanced software for design, simulation, and analysis, Little P.Eng. Engineering delivers services that are not only precise and dependable but also forward-thinking and efficient.

Steadfast Regulatory Compliance

Little P.Eng. Engineering is unwavering in its commitment to adhere to all local, national, and international engineering standards and regulations. This dedication ensures that all solutions provided by the company are safe, reliable, and efficient.

Client-Centered Approach

At Little P.Eng. Engineering, clients come first. The company’s dedication to meeting the needs and concerns of its clients is reflected in its top-notch customer service. With a focus on effective communication, punctual delivery, and complete satisfaction, the company ensures a rewarding experience for all clients.

Sustainability in Focus

Little P.Eng. Engineering is dedicated to promoting sustainable and environmentally friendly engineering solutions. The company’s strategies and designs reduce environmental impact and foster resource efficiency.

Unmatched Quality Assurance

The quality assurance at Little P.Eng. Engineering is unassailable. The company’s robust quality management system ensures consistent high standards in all services offered, thereby instilling confidence in its clients and further solidifying its reputation as a dependable engineering service provider.

In conclusion, with its robust multidisciplinary capabilities, coupled with a steadfast commitment to quality, innovation, and customer satisfaction, Little P.Eng. Engineering stands as the go-to company for engineering services across Canada and the USA. Whether you are seeking piping design, piping stress analysis, tanks design, seismic bracing design, pipe rehabilitation, or structural engineering services, Little P.Eng. Engineering guarantees top-tier, reliable, and efficient solutions every single time.

Tags:

Pipe Stress Analysis Services

Meena Rezkallah

Canada

Structural Engineer

Pipe Stress Analysis Company

Pipe Stress Analysis Engineer

USA

Seismic Design

Little P.Eng. Engineering

Seismic Bracing Company

Seismic Bracing Design

Seismic Bracing Solutions

Structural Engineering Services

Piping Stress Analysis

ASTM F1216

tanks design services

Tank Design Consultants

Pipe Rehabilitation

Tanks Design

CIPP Liner Design

Multidisciplinary Capabilities

Storage Tanks

Building Codes

Corrosion

Engineering Services

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Houston Texas; Torrance, California; El Segundo, CA; Manhattan Beach, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

#Pipe Stress Analysis Services#Meena Rezkallah#Canada#Structural Engineer#Pipe Stress Analysis Company#Pipe Stress Analysis Engineer#USA#Seismic Design#Little P.Eng. Engineering#Seismic Bracing Company#Seismic Bracing Design#Seismic Bracing Solutions#Structural Engineering Services#Piping Stress Analysis#ASTM F1216#tanks design services#Tank Design Consultants#Pipe Rehabilitation#Tanks Design#CIPP Liner Design#Multidisciplinary Capabilities#Storage Tanks#Building Codes#Corrosion

0 notes

Text

Advanced Drainage Solutions: The Role of Drain Scope and CIPP Lining in Modern Plumbing

In the ever-evolving field of plumbing technology, two essential services have become game changers for both residential and commercial properties—drain scope inspections and CIPP lining Edmonton solutions. These innovative techniques are designed to diagnose underground pipe issues without major disruption and provide long-lasting repairs that don’t require full-scale excavation. Homeowners and business owners alike are turning to these modern tools to manage their drainage systems with greater efficiency and reliability.

A drain scope is a specialized inspection tool used to examine the interior of sewer and drain lines. It involves inserting a small waterproof camera into the pipe to view blockages, cracks, corrosion, and other issues. Drain scope inspections have revolutionized the way plumbing professionals detect problems. Rather than relying on guesswork or digging blindly, technicians can now pinpoint the exact location and nature of the issue before beginning repairs. This method saves both time and money, offering a clearer and more accurate assessment of the drain’s condition.

Equally impressive is CIPP lining Edmonton, a trenchless pipe repair technique that’s gaining popularity for its effectiveness and minimal disruption. Cured-in-place pipe (CIPP) lining is a process in which a resin-saturated liner is inserted into a damaged pipe. Once the liner is in place, it is cured using heat or UV light, forming a new, durable inner wall within the existing pipe. This method is especially beneficial in older neighborhoods where digging up entire yards or driveways would be costly and impractical.

When used together, drain scope inspections and CIPP lining provide a seamless approach to identifying and solving pipe-related problems. A typical process begins with a drain scope inspection to determine the pipe’s condition and locate any defects. Once the issue is diagnosed, CIPP lining can be applied to reinforce or replace the damaged section without disturbing the surrounding area. The result is a fully functional drainage system that has been restored with precision and care.

What sets CIPP lining apart from traditional pipe replacement methods is its long-term reliability and minimal environmental impact. By rehabilitating existing pipes from the inside, this method reduces the need for new materials and avoids the mess of excavation. It's an ideal solution for homeowners seeking a more sustainable and cost-effective option for repairing aging or deteriorating plumbing systems.

Furthermore, CIPP lining Edmonton is suitable for a wide range of pipe materials and diameters, making it a versatile option for various property types. From residential homes to commercial facilities, this technology ensures that water flow is restored quickly and efficiently, with minimal interruption to daily life. It’s particularly useful in colder climates where frozen or cracked pipes can become a recurring problem during winter months.

In addition to repair applications, drain scope inspections are also invaluable in preventive maintenance. By performing regular inspections, property owners can catch small issues before they develop into major repairs. This proactive approach can extend the life of a plumbing system and prevent emergencies that often come with high repair costs. Knowing the exact condition of your drainage system allows for better planning and budgeting when it comes to home maintenance.

Professional plumbing technicians trained in both drain scope and CIPP lining are essential to ensuring a successful outcome. Their expertise not only ensures proper installation but also guarantees that the most suitable methods and materials are used based on the condition of the existing pipes. While some DIY enthusiasts may be tempted to tackle plumbing issues themselves, these advanced techniques require the precision and experience of certified professionals.

The integration of these two services—drain scope diagnostics and CIPP lining solutions—marks a new era in plumbing and sewer maintenance. They provide a less invasive, more accurate, and longer-lasting approach to pipe repair and upkeep. Property owners who take advantage of these services are making a smart investment in the longevity and health of their plumbing infrastructure.

For those looking to enhance their drainage systems with modern technology, choosing a service provider that offers both drain scope inspections and CIPP lining in Edmonton can ensure a comprehensive solution that delivers lasting results. By leveraging the power of these techniques, homeowners and businesses can protect their properties from costly damage and unexpected breakdowns, while maintaining efficiency and peace of mind.

For more info:-

Facebook

Instagram

0 notes

Text

CIPP Styrene Safety in Drain Cleaning and Advanced Drain-Lining Solutions

Proper drain maintenance is crucial for preventing costly repairs, avoiding disruptions, and ensuring an efficient utility system. Modern advancements in drain cleaning and drain-lining solutions have revolutionized the way residential, commercial, and industrial pipelines are maintained. These innovative techniques not only save time but also minimize environmental impact compared to traditional methods.

Importance of Regular Drain Cleaning

Blocked drains can lead to numerous issues such as: - Slow drainage - Bad odors - Water damage caused by backups - Potential health hazards due to bacterial growth

Regular cleaning helps maintain the functionality of the system while preventing long-term damage. By using advanced equipment such as high-pressure water jetting systems or mechanical rodding tools, professionals can efficiently clear blockages caused by grease buildup, debris, and tree roots.

Benefits of Professional Drain Cleaning Services: 1.Cost-Effective Maintenance: Prevents larger issues that may require expensive repairs or replacements. 2.Improved Performance: Restores optimum flow capacity in pipes. 3.Eco-Friendly Practices: Advanced methods reduce reliance on harsh chemicals that could harm the environment.

Introduction to Advanced Drain-Lining Solutions

Drain-lining technology has emerged as a game-changer in repairing damaged pipelines without excavation. These solutions are designed for situations where pipes are cracked, leaking, or corroded but do not require complete replacement.

What is Drain Lining? Drain lining involves inserting a resin-soaked liner into the existing pipe structure to create a new inner surface that adheres seamlessly to the host pipe. This method eliminates the need for digging up entire sections of pipeline infrastructure.

Advantages of Advanced Drain-Lining Technologies

No-Dig Solutions: Eliminate disruptions associated with traditional excavation methods for repairs.

Durability Enhancement: Extends the life expectancy of existing pipes.

Versatility: Works effectively on various materials such as clay, cast iron, PVC, and concrete.

Faster Installation Times: Reduces downtime compared to conventional repair strategies.

Applications of Drain-Lining Technology

Advanced drain-lining systems cater to multiple scenarios across industries: - Repairing small cracks caused by ground movement. - Sealing leaks in pipeline joints. - Reinforcing aging sewer infrastructure without replacing it entirely.

By incorporating both regular drain cleaning practices and innovative drain-lining technologies into maintenance strategies, property owners can ensure reliable performance from their pipeline systems for years to come while reducing environmental disruption and cost overheads associated with conventional approaches.

Exploring Innovative Methods to Reduce Styrene Emissions in Cured-in-Place Pipe (CIPP) Rehabilitation

This trenchless method has revolutionized the way damaged pipelines are repaired, offering numerous advantages over traditional excavation-based replacement techniques.

How Does CIPP Work in Pipe Lining?

This eliminates the need for extensive digging and reduces disruption while ensuring a long-lasting solution.

Important Considerations for Styrene Safety in CIPP

No significant excavation required.

Reduces disturbances to traffic, landscaping, and structures.

Eliminates costs associated with large-scale digging and restoration.

Decreases labor requirements compared to traditional methods.

Creates a corrosion-resistant inner surface.

Extends pipe life by 50 years or more when properly installed.

Reduces waste generated during repairs.

Minimizes carbon footprint by avoiding heavy machinery use.

Suitable for various types of pipes (e. g. , sewer lines, storm drains).

Can navigate bends and diameter changes in pipelines effectively.

Understanding the Role of Styrene in CIPP Technology Applications

Municipal Infrastructure:Rehabilitation of sewer systems in urban areas without disrupting city operations.

Industrial Pipelines:Repairing chemical transport systems while maintaining safety compliance.

Residential Plumbing:Fixing aging drainage systems without damaging surrounding property.

Understanding Advanced CIPP Techniques and Managing Styrene Odor

Improved resins offer enhanced resistance to chemicals.

UV curing reduces installation time significantly compared to conventional heat curing.

Robotics-assisted insertion ensures precision for difficult-to-access pipelines.

By adopting these cutting-edge methods, businesses and municipalities can reduce costs while improving efficiency in pipeline rehabilitation efforts.

Comprehensive Overview of SDS for Styrene and Key Features in Our CIPP Lining Service

Cured-in-Place Pipe (CIPP) lining has emerged as a groundbreaking solution for pipeline rehabilitation, offering efficient and durable results without the need for extensive excavation. Below is an in-depth look at the key features that make our CIPP lining service a reliable and innovative choice.

1. Trenchless Technology

One of the primary features of our CIPP lining service is its trenchless application method.

Roads or highways

Buildings or large structures

Landscaped areas like gardens or parks

Benefits of trenchless technology include reduced disruption to daily activities, minimal property damage, and faster project completion times.

This versatility ensures that aging pipes, regardless of their original construction material, can benefit from a renewed lifespan with our CIPP system.

2. Long-Term Durability

The liners used in our process are crafted from high-quality resin materials designed to offer long-lasting resilience.

Corrosion resistance: Protects pipes from rust and chemical degradation.

Leak prevention: Forms a seamless interior layer that eliminates weak points.

Structural reinforcement: Improves the overall strength of the existing pipeline.

With proper maintenance, these liners are engineered to last 50 years or more.

3. Cost-Efficiency

Lower labor costs (no extensive excavation required)

Shorter project timelines

Fewer resources needed for restoration

This cost-saving advantage makes it ideal for municipalities, commercial properties, and residential clients seeking budget-friendly solutions without compromising quality.

4. Eco-Friendly Solutions

Sustainability is a key focus within our services. The trenchless nature of CIPP minimizes environmental impact by reducing the need for heavy machinery and limiting soil disruption.

The process decreases waste generated from excavation.

Rehabilitating existing pipelines reduces demand for new raw materials.

By choosing CIPP lining services, clients can contribute to greener infrastructure practices.

5. Suitable for Varied Applications

Repairing sewer lines

Fixing stormwater drainage systems

Addressing small-diameter drains in residential properties

Restoring large municipal pipelines

Whether addressing minor cracks or major structural damages, CIPP technology provides reliable solutions across diverse settings.

How We Address the Styrene Smell Issue

With expertise in modern pipeline rehabilitation techniques and a commitment to delivering top-notch results, we ensure each project benefits from precision workmanship and advanced technology tools.

By opting for our comprehensive CIPP lining services, clients receive durable results with minimal disruption — all while supporting sustainable infrastructure practices.

Cured-in-Place Pipe (CIPP) lining has redefined pipeline rehabilitation by offering durable, efficient, and minimally invasive solutions for addressing pipeline issues. At the core of this method is its ability to restore the structural integrity of aging or damaged pipelines without requiring extensive excavation or disruptive replacement methods.

What is CIPP Lining?

Pipeline Inspection: Pre-installation inspection using cameras ensures that existing blockages or severe structural damage are identified.

Cleaning: High-pressure water jets or mechanical cleaning tools remove debris and prepare the surface for optimal adhesion.

Final Inspection: Post-installation inspection confirms quality and proper functionality of the rehabilitated pipe.

Why Choose CIPP Lining?

Non-Invasive: Reduces disruption by avoiding extensive digging or destruction of surrounding landscapes.

Cost-Effective: Eliminates high labor costs associated with excavation while offering long-term durability.

Time-Efficient: Repairs can often be completed within hours instead of days.

Environmental Benefits: Minimizes waste generation compared to full pipe replacements.

Applications of CIPP Lining

Rehabilitation of sewer lines and storm drains

Extending life expectancy of critical public utilities

Addressing aging plumbing systems in businesses

Preventing costly downtime caused by leaks

Protecting pipelines exposed to chemicals or corrosive environments

Ensuring compliance with regulatory standards

Fixing household drains without damaging driveways, gardens, or walls

Long-Term Durability You Can Rely On

When performed by experienced professionals, CIPP lining delivers reliable results designed to endure decades under diverse conditions such as high water flow rates, temperature variations, and chemical exposure.

Quality materials combined with expert installation ensure that your rehabilitated pipelines will maintain peak performance while reducing future maintenance needs.

By investing in professional cured-in-place pipe lining services, you secure efficient pipeline functionality while protecting adjacent structures and minimizing operational disruptions.

Exploring Advanced Drain-Lining Options and Their Benefits

Drain-lining technologies have significantly advanced in recent years, offering innovative solutions for repairing and rehabilitating pipeline systems without the need for disruptive excavation. These advanced methods not only enhance the durability of pipelines but also offer cost-effective and environmentally friendly alternatives to traditional repairs. Below, we explore some of the cutting-edge drain-lining options available today and their key benefits.

Advanced Drain-Lining Techniques

Ideal for addressing issues such as cracks, leaks, or root intrusions.

Involves breaking apart existing pipes while simultaneously installing new ones.

Especially effective for replacing severely damaged pipelines with minimal surface disruption.

Insertion of a smaller diameter pipe into an existing pipeline.

Typically used for structural reinforcement or repairing long sections of deteriorated pipes.

A resin-based spray application designed to coat the interior walls of pipes.

Commonly used in smaller-diameter pipelines to restore flow efficiency and seal minor damage.

Key Benefits of Modern Drain-Lining Solutions

Minimized Disruption Traditional excavation methods often disrupt landscapes, roads, and infrastructure. Drain-lining eliminates the need for extensive digging by working within existing pipelines.

Cost-Effectiveness By avoiding large-scale excavation projects, homeowners and municipalities save significantly on labor costs, equipment rental fees, and restoration expenses.

Time Efficiency Many advanced methods allow projects to be completed in hours or days rather than weeks.

Enhanced Durability Materials like epoxy resins and high-grade liners create robust pipelines that can withstand environmental stresses over decades without frequent maintenance.

Environmentally Friendly Alternatives Since no digging is required, there’s limited soil disturbance and reduced construction waste. Some techniques even improve water flow efficiency by smoothing inner pipe surfaces.

Applications Across Different Sectors

Residential: Repairing household sewer lines with minimal disruption.

Commercial: Restoring drainage systems in office buildings and retail spaces.

Municipal: Upgrading aging city infrastructure cost-efficiently while meeting environmental regulations.

Industrial: Reinforcing high-capacity pipelines used in manufacturing processes.

Modern drain-lining technologies provide reliable solutions that balance efficiency with sustainability. By adopting these innovative practices, property owners can ensure the long-term integrity of their drainage systems while reducing overall maintenance costs.

NASSCO

5285 Westview Dr Suite 202, Frederick, MD 21703, United States +1 301-834-1022 https://nassco.org/ https://maps.app.goo.gl/mX2Vyt5fsMWF5b6x5

1 note

·

View note

Text

How Much Can You Save with No-Construction Downspout Repair?

Downspouts are an essential part of any building's plumbing system. They carry wastewater from upper floors to the main sewer system, ensuring hygiene and preventing water damage. When downspouts deteriorate, many property owners assume that breaking walls and floors is the only way to fix them. Fortunately, modern technology now allows for no-construction downspout repair—a cleaner, faster, and often more cost-effective solution. But how much can you really save with this method? Learn more at https://www.entuba.es/servicios/rehabilitacion-de-bajantes/

Let’s break it down.

1. What Is No-Construction Downspout Repair?

No-construction downspout repair (in Spanish, bajantes sin obras) refers to the process of rehabilitating or repairing downspouts without tearing down walls, floors, or ceilings. Companies like Entuba specialize in this method using trenchless technology such as cured-in-place pipe (CIPP) lining. This involves inserting a resin-coated liner into the damaged pipe, which hardens and forms a new, seamless pipe within the existing one.

The result? Fully restored functionality without the mess of traditional construction work.

2. Cost Comparison: Traditional vs. No-Construction Repair

Traditional downspout repair often requires:

Demolishing walls and ceilings to access the pipes

Removing old, damaged pipes

Installing new pipe systems

Rebuilding walls, plastering, and painting

This process is not only time-consuming but can also be very expensive. Here’s an estimated breakdown of average costs (note: actual prices may vary based on property size and location):TaskTraditional RepairNo-Construction RepairDemolition and access€500–€1,500€0Pipe replacement€1,000–€2,500€1,200–€2,000Wall reconstruction & painting€800–€2,000€0Labor and cleanup€600–€1,500€400–€800Total Cost Estimate€2,900–€7,500€1,600–€2,800

As shown above, you can save anywhere from 40% to 70% by choosing a no-construction method.

3. Indirect Savings: Time, Disruption, and Clean-Up

While the upfront cost savings are compelling, there are additional ways no-construction repair can save you money:

Less Time Off Work or Rent Loss: Traditional repairs can take days or even weeks, especially in apartment buildings. Tenants may need to vacate temporarily, causing rental income loss or inconvenience. No-construction repairs are often completed in one day, minimizing disruptions.

No Damage to Interior Spaces: Rebuilding walls, repainting, and cleaning up after construction all add hidden costs. These are avoided entirely with trenchless methods.

Fewer Hidden Surprises: Once walls are opened, unexpected issues often surface (mold, electrical issues, asbestos). No-construction repair avoids these risks entirely.

4. Environmental and Structural Savings

Another often overlooked benefit is preserving the structure of the building. Every time walls or ceilings are demolished, there's a risk of damaging supporting elements or creating weak points. Non-invasive downspout rehabilitation helps protect the building’s original structure, potentially saving thousands in future maintenance costs.

Additionally, no-construction methods generate less waste and use fewer materials, making them a more eco-friendly choice.

5. Long-Term Value and Durability

Many worry that no-construction solutions are temporary fixes—but that’s far from true. The cured-in-place pipe lining method used by companies like Entuba is designed to last up to 50 years, depending on usage and maintenance. This long lifespan means fewer repairs over time and greater return on investment.

Conclusion: A Smart, Cost-Effective Choice

If your building’s downspouts need repair, it’s worth considering no-construction alternatives. With savings that can range from 40% to 70%, faster turnaround, less disruption, and long-term durability, the economic and practical advantages are clear. Companies like Entuba in Spain are leading the way in offering modern, non-invasive solutions for both residential and commercial properties.

In the end, no-construction downspout repair is not only a smart financial decision—it’s also a more comfortable, clean, and future-proof investment.

0 notes

Text

Little P.Eng. for Engineering Services

BUSINESS ADDRESS:

330 St Mary Ave

Winnipeg, MB

R3C 3Z5

BUSINESS PHONE NO:

(587) 802-4050

BUSINESS EMAIL ADDRESS:

WEBSITE:

ABOUT US:

Little P.Eng. Engineering delivers expert engineering services across North America. We specialize in Bulk Material Handling Engineering, Seismic Hazards Analysis & Bracing Design, and Structural Engineering, ensuring safe and efficient industrial systems. Our team excels in Piping Stress Analysis, Above-Ground Tank Design, and Pressure Vessel Design, adhering to leading industry codes. We also offer CRN Registration support for Canadian compliance. With advanced Discrete Element Modeling (DEM), we optimize bulk flow systems, and our CIPP Liner solutions provide reliable Pipeline Rehabilitation. Trust Little P.Eng. for innovative, code-compliant, and cost-effective engineering services.

WORKING HOURS:

Mon - Fri: 6:00 am - 6:00 pm

PAYMENT METHODS:

All Methods

SOCIAL LINKS:

https://x.com/Little_P_Eng

https://www.linkedin.com/company/little-p-eng-for-engineering-services

#Piping Stress Engineer#Seismic Bracing Engineer#Silo Design#Tank Design#Belt Conveyor Design#Pressure Vessel Design#CRN registration

1 note

·

View note

Text

Trenchless Sewer Repair in Surrey: The Smart Solution by Blue Sky Plumbing Heating And Electric

As homes and properties across Surrey age, sewer and drainage systems often need repair or replacement. Traditional methods involved invasive digging that disrupted landscaping and driveways, leading to costly restorations. However, with trenchless sewer repair technology, Surrey residents now have a minimally invasive option to restore their sewer lines efficiently and with minimal disruption. Blue Sky Plumbing Heating And Electric, a trusted provider of Plumbing & Heating Services in Greater Vancouver, specializes in trenchless sewer repair services in Surrey. Known for their expertise in Residential Plumbing Services in Vancouver and Sewer & Drain Services in Vancouver, they deliver high-quality solutions for homeowners looking to solve sewer issues with minimal hassle. This guide will cover the benefits of trenchless sewer repair, how it works, and why choosing Blue Sky Plumbing Heating And Electric ensures a smooth, professional experience.

Why Trenchless Sewer Repair in Surrey is Essential

Aging infrastructure can lead to frequent sewer problems, especially in older neighborhoods. From tree roots invading pipes to the natural wear and tear of materials, many issues can compromise the efficiency of sewer systems. Trenchless sewer repair in Surrey addresses these challenges quickly and effectively, using modern technology to restore sewer lines without extensive property damage.

Advantages of Trenchless Sewer Repair:

Minimally Invasive: This method requires less digging, preserving landscaping and hardscaping.

Cost-Effective: Although it may seem expensive upfront, trenchless repair often eliminates the additional costs associated with restoring lawns and driveways.

Time-Saving: With reduced excavation, trenchless repair can often be completed in a day, minimizing inconvenience for homeowners.

How Trenchless Sewer Repair Works

Trenchless sewer repair can be accomplished through methods like pipe bursting and pipe relining.

Pipe Bursting: In this method, the old pipe is broken apart as a new pipe is pulled through. This replacement technique is ideal for pipes that are severely damaged.

Pipe Relining: Also known as Cured-In-Place-Pipe (CIPP) relining, this technique involves inserting a liner coated with epoxy resin into the damaged pipe.

Blue Sky Plumbing Heating And Electric uses these advanced methods as part of its commitment to providing reliable Plumbing & Heating Services in Greater Vancouver. With their expertise in Sewer & Drain Services in Vancouver, they ensure each trenchless repair is conducted with precision and efficiency.

Why Choose Blue Sky Plumbing Heating And Electric for Trenchless Sewer Repair in Surrey?

When it comes to residential plumbing services, Blue Sky Plumbing Heating And Electric stands out for its commitment to excellence. They are well-versed in all aspects of Residential Plumbing Services in Vancouver and have a dedicated team trained in the latest trenchless repair techniques. Their trenchless sewer repair services in Surrey are designed to provide lasting solutions, ensuring homeowners don’t face recurring sewer problems.

Their reputation as a provider of Plumbing & Heating Services in Greater Vancouver highlights their dedication to quality. With years of experience and a solid reputation, they offer peace of mind to homeowners by handling every aspect of the repair process professionally and transparently.

Key Benefits of Working with Blue Sky Plumbing Heating And Electric:

Experience and Expertise: With a team skilled in trenchless technology, they ensure each repair is executed with care and accuracy.

Transparent Pricing: Blue Sky Plumbing Heating And Electric provides upfront pricing with no hidden fees, allowing customers to make informed decisions.

Customer-Centered Service: Their team prioritizes customer satisfaction, offering prompt responses and thorough consultations.

Environmentally Friendly Practices: By using trenchless technology, they reduce the environmental impact associated with traditional sewer repairs.

Conclusion

Trenchless sewer repair in Surrey has become a preferred solution for homeowners seeking efficient and non-invasive sewer repairs. With fewer disruptions and faster completion times, this modern method is ideal for maintaining the beauty of residential properties while ensuring functional sewer systems.

Blue Sky Plumbing Heating And Electric is an industry leader in Plumbing & Heating Services in Greater Vancouver, offering expertise in both traditional and advanced plumbing solutions. As experts in Residential Plumbing Services in Vancouver and Sewer & Drain Services in Vancouver, they provide reliable and durable trenchless sewer repair solutions to keep Surrey homes in top condition.

If you're facing sewer issues and want a professional, minimally invasive solution, consider trenchless sewer repair from Blue Sky Plumbing Heating And Electric. Their experienced team ensures that every repair is handled with precision, keeping your home and property intact while restoring functionality to your sewer system.

#drain services#drain cleaning#sewer and drain services#plumbing#professional sewer cleaning#plumbing services#drain sewer#commercial plumbing#heating service#heating and plumbing services

0 notes

Text

Efficient Drain Relining Services in Melbourne – J.O. Plumbing

When it comes to maintaining the integrity of your drainage system, J.O. Plumbing offers top-tier drain relining services in Melbourne. Drain relining is an innovative, no-dig solution designed to repair damaged drains without the need for extensive excavation, making it a preferred choice for both residential and commercial properties.

What is Drain Relining?

Drain relining, also known as cured-in-place pipe (CIPP) lining, involves inserting a flexible liner into the damaged drain. This liner is coated with a special resin and then inflated, pressing it against the walls of the existing pipe. Once the resin cures, it forms a durable new pipe within the old one, sealing cracks and preventing further damage.

Benefits of Drain Relining

Minimal Disruption: Unlike traditional methods that require digging up your yard or driveway, drain relining is a trenchless technology that preserves your landscape.

Cost-Effective: By avoiding extensive excavation, drain relining reduces labor costs and the need for expensive restorative work.

Quick and Efficient: The process is typically completed in a day, minimizing downtime and inconvenience.

Durable Solution: Relined pipes are highly resistant to root intrusion, leaks, and corrosion, extending the life of your drainage system by decades.

Environmentally Friendly: Drain relining reduces waste and environmental impact compared to conventional pipe replacement methods.

Why Choose J.O. Plumbing for Drain Relining in Melbourne?

At J.O. Plumbing, we pride ourselves on providing high-quality drain relining services tailored to the needs of our Melbourne clients. Our team of experienced professionals uses state-of-the-art equipment and techniques to ensure the job is done right the first time. We conduct thorough inspections to assess the extent of the damage and determine the most effective relining solution for your drains.

Our commitment to customer satisfaction means we offer transparent pricing, clear communication, and reliable service from start to finish. When you choose J.O. Plumbing, you can trust that your drainage system is in capable hands.

Conclusion

If you’re experiencing issues with your drainage system, don’t wait for the problem to escalate. Contact J.O. Plumbing today for expert drain relining services in Melbourne. Our efficient, cost-effective, and durable solutions will restore your drains to optimal condition, ensuring the smooth operation of your plumbing system for years to come. Reach out to us to learn more about our services and how we can help you maintain a healthy, functional drainage system.

Telephone No.+61 422 653 347 Full Address:- 38 Mock street, forest hill, Victoria, australia

#plumber hampton park#plumbing services#plumber lysterfield#emergency plumber pakenham#plumber vermont#plumber#water tap repair#plumber pakenham#plumbing#toilet cistern seals

1 note

·

View note

Text

How does cured-in-place pipework?

A RESIN FELT TUBE, FIBERGLASS FABRIC, OR SEVERAL OTHER MATERIALS THAT ARE SUITABLE FOR RESIN IMPREGNATION, REVERSED OR DRAWN IN A DAMAGED PIPE. THIS IS USUALLY DONE FROM THE UPSTREAM ACCESS POINT (MEN OR EXCAVATION).

It is possible to reverse the upstream layer (for samples from downstream access points), but it carries a higher risk. It is possible to install liners from downstream access points, upstream at the blind tip. However, this is often the very best risk of all CIPP installation methods. Small digging, this trenchless process is involved for the potentially more profitable and less disturbing method than traditional methods of repair of pipes.

Tips FOR CURED IN PLACE PIPES

Broadcasting the Pipeline.The pipe is checked with a camera to find a problem.Pipe must be cleaned to remove roots, dirt, debris, and potential objects that can interfere with the layer.

TAKE STEPS

Measuring pipe diameter, depth, and length were taken. The layer and calibration tube are then turned off from the construction site according to the measurements obtained.

MIX RESIN AND MEASUREMENT

Resin is also measured and mixed according to the measurements obtained

POUR IN LAYERS

Resin is then poured into the layer and rolled or “wet” several times to ensure the complete impregnation of resin to the liner.

LOAD ON THE INVERTER

The layer tube and the infused calibration are then loaded into the inverter.

LOADING IN THE LINE

The liner is then put into an existing pipe using a pipe direction and head of an inversion. This provides appropriate insertion.

BACK WITH ATMOSPHERIC PRESSURE

Air pressure then turned in the resin that connects and is sealed with the existing hosts. Balloon calibration tube to maintain layers as a drug.

LOANS FOR SERVICE

After recovering, the calibration tube is removed, and the pipe is ready for service.

THE BENEFITS ARE CLEAR

As a technology without a trench, CIPP does not require excavation to rehabilitate pipes that run away or structurally. “Depending on design considerations, excavations are often made, but liners are often installed through access holes or existing access points.” Even though CIPP can repair pipes with curves, special design considerations must be taken into consideration to stop wrinkles and stretches.

0 notes

Text

50′ of 2″ IPT CIPP Liner Installed in Under 3 Hours

Internal Pipe Technologies had another successful on-site training with a contractor where nearly 50’ of 2″ IPT CIPP Lining was installed and pulled in under 3 hours of labor on-site. The project took place in a living room and hallway underneath hardwood and tile flooring.

This begs us to ask the question, “Why would anyone coat a 2” cast iron pipe when they can give their customer a superior CIPP product in less time?”

Pipe corrosion continues after pipe lining takes place with any product. By installing a CIPP Liner, your customers can feel safe about the pipe’s structural integrity even after 100% pipe degradation. An added benefit of up to 104% flow capacity increases after lining(15-year-old cast iron) based on ASTM 1216 specifications.

At Internal Pipe Technologies, we design and manufacture our pipe lining material to line around elbows as sharp as street 90’s even in 2” pipe.

Learn more about IPT CIPP Lining Products.

0 notes

Text

Cured in Place Pipe

One of the most well-known trenchless restoration method for existing pipelines is using a cured-in-place pipe (CIPP). Mi-Tech’s Professional Engineers use ASTM F1216, F2019, and ASCE MOP –145 procedures to deliver stamped/signed liner consistency designs and provide the finest services in replacing pipelines. For more details visit our website at https://www.mi-tech.us/

#Communication Design Management#Cured in Place Pipe Lining#Utility Pole Installation#Building Surveying Services

1 note

·

View note

Text

CIPP Video Inspection as a Prevention Tactic

For pipe repairs, a CIPP video inspection helps prevent unnecessary problems that make the operation take longer. When a pipe bursts or begins having lowered pressure, the ideal response is a pipe repair service that can avoid pitfalls and complete the job. Water or chemical seepage is not a scenario that you want to drag out by any means.

After all, the effects can create a hard-to-clean environmental disaster that will result in fines and property damages. For any property owners who have investors, this is never a good way to maintain a strong reputation. The tenets are sure to be unhappy as well. CIPP, which stands for cured-in-place pipe methods, is a prevention tactic that helps to avoid costly spills that damage your finances and reputation.

A CIPP video inspections designed to identify the areas where leaks are and prevent extra procedures, such as ditch digging. Trench work is fairly common with underground, horizontal piping. In fact, some pipe repair jobs cannot be completed until the specialist gains access to the area. As foundational structures would have it, concrete and tile flooring can prevent an accurate look under the surface.

CIPP contractors use remote tactics to infiltrate an area, followed by the appropriate procedure. In many cases, the specialist can send a flexible camera into the depths of a pipeline, ultimately capturing footage and images of the affected sections or grounds.

By first feeding a camera line in, the CIPP specialist can follow-up with slip-liners in the same way. These liners are eventually cemented to the pipe’s interiors, sealing off any potential leaks. Thanks to a CIPP video inspection, a pipeline can be reinforced from the inside. The fact that the specialist knows exactly what the situation makes it all the easier to accomplish.

A CIPP video inspection also helps to find the cause of poor performance pipes and prevent them from spreading. Often, loud rattling noises can signify that a pipe section is on the decline. Likewise, unfamiliar odors and a slow, trickling output can certainly point towards the need for a repair job. A pipe specialist can determine how many sections are at fault or where the origin point is.

Nature itself can cause bad pipe performances by invading pipelines. Roots can wrap around and dislodge pipes, pinching off the needed flow of pressure. Clogs are sometimes attributed to rodents as well, who can unfortunately become lodged inside pipes. Obviously, having the upper hand in this situation is enough of a reason to rely on CIPP as the go-to for bad pipe performances.

Once an inspection is concluded, pipe owners/overseers have a higher chance of bringing problems to an end. CIPP video inspections are an important evolution for pipe repair, one that eliminates the “unforeseen issue” that often plagued traditional repair and maintenance. With cured-in-place pipe repair, the specialist knows what to do from the very beginning.

0 notes

Text

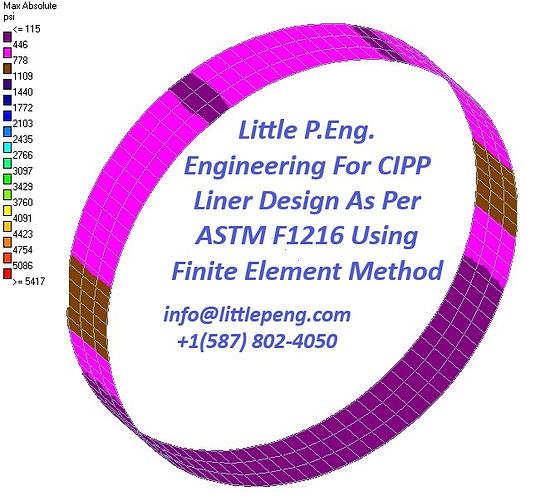

Little P.Eng. Engineering For CIPP Liner Design As Per ASTM F1216 Using Finite Element Method

In the realm of civil engineering, the rehabilitation of pipelines is a critical task that ensures the longevity and safety of underground infrastructure. One of the most innovative and efficient methods for pipeline rehabilitation is Cured-in-Place Pipe (CIPP) lining. This technique not only offers a less intrusive alternative to traditional pipeline repair but also significantly reduces the environmental impact and cost associated with excavation. Little P.Eng. Engineering, a pioneering firm in the engineering consultancy landscape, has taken strides in optimizing CIPP liner design to comply with ASTM F1216 standards through the application of the Finite Element Method (FEM).

Understanding ASTM F1216 and its Significance

ASTM F1216 is a standard that outlines the procedures for rehabilitating existing pipelines using the CIPP method. This standard is critical as it provides guidelines for the design, installation, and testing of CIPP liners, ensuring that rehabilitated pipelines meet specific safety and performance criteria. Compliance with ASTM F1216 is essential for any project involving CIPP lining, as it not only guarantees the structural integrity of the rehabilitated pipeline but also its longevity.

Little P.Eng. Engineering's Approach to CIPP Liner Design

Little P.Eng. Engineering has embraced the challenges of CIPP liner design by leveraging the Finite Element Method (FEM), a sophisticated computational technique that simulates how materials behave under various conditions. FEM allows engineers to model the complex interactions between the CIPP liner and the host pipe, taking into account factors such as material properties, external loads, and environmental conditions. By using FEM, Little P.Eng. Engineering can predict the performance of CIPP liners with high accuracy, ensuring that designs are not only compliant with ASTM F1216 but also optimized for durability and efficiency.

The Role of Finite Element Method in Ensuring Compliance and Optimization

The Finite Element Method plays a pivotal role in Little P.Eng. Engineering's design process by providing a detailed analysis of stress distribution, deformation, and potential failure points within the CIPP liner. This detailed analysis is crucial for two main reasons:

Compliance with ASTM F1216: FEM analysis helps ensure that the designed CIPP liner can withstand the intended service life under varying conditions, as stipulated by ASTM F1216. This includes assessing the liner's ability to handle internal pressures, ground movement, and other environmental factors without compromising its structural integrity.

Optimization of Design: Beyond compliance, FEM enables Little P.Eng. Engineering to optimize the thickness, material composition, and installation parameters of CIPP liners. This optimization not only reduces material costs but also minimizes the risk of over-engineering, ensuring that resources are used efficiently without sacrificing performance.

Case Studies and Success Stories

Conclusion

The innovative approach of Little P.Eng. Engineering to CIPP liner design, grounded in the rigorous application of the Finite Element Method and adherence to ASTM F1216 standards, represents a significant advancement in pipeline rehabilitation technology. This method not only ensures the structural integrity and longevity of CIPP liners but also exemplifies how engineering innovation can lead to more sustainable and cost-effective infrastructure solutions. As the demand for efficient and environmentally friendly rehabilitation methods grows, the work of Little P.Eng. Engineering in this field is set to become increasingly important, paving the way for future advancements in civil engineering practices.

Read More:

Innovating Pipeline Rehabilitation: Pipe CIPP Lining Engineering Design Services as per ASTM F1216

Pipeline Rehabilitation Engineering Design Services as per ASTM F1216 Using CIPP and PVC

Little P.Eng. Engineering For CIPP Liner Design As Per ASTM F1216 Using Finite Element Method

Revolutionizing Pipe Rehabilitation: Little P.Eng. Engineering's Mastery of CIPP Liner Design via Finite Element Method in Accordance with ASTM F1216

Tags:

Little P.Eng. Engineering

ASTM F1216

structural integrity

design optimization

engineering innovation

material properties

Finite Element Method

underground infrastructure

performance prediction

industry guidelines

CIPP liner design

material optimization

infrastructure longevity

safety criteria

environmental impact

maintenance cost reduction

pipeline rehabilitation

simulation techniques

performance criteria

durability assessment

compliance standards

computational modeling

non-invasive repair methods

failure point identification

sustainable solutions

installation parameters

stress distribution analysis

external loads

civil engineering practices

cost reduction

Engineering Services

•

Pipe Rehabilitation

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Houston Texas; Torrance, California; El Segundo, CA; Manhattan Beach, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

#Little P.Eng. Engineering#ASTM F1216#structural integrity#design optimization#engineering innovation#material properties#Finite Element Method#underground infrastructure#performance prediction#industry guidelines#CIPP liner design#material optimization#infrastructure longevity#safety criteria#environmental impact#maintenance cost reduction#pipeline rehabilitation#simulation techniques#performance criteria#durability assessment#compliance standards#computational modeling#non-invasive repair methods#failure point identification#sustainable solutions#installation parameters#stress distribution analysis#external loads#civil engineering practices#cost reduction

0 notes

Text

CIPP Brings Trusted Solution With Advanced Epoxy Coating

When it comes to trenchless pipe repairs, there is no better name to trust than that of Nu Flow Technologies. They are the innovative minds behind the trusted and reputable epoxy coating solution that serves as a chemical-free and safe to use a barrier against toxins in your water supply. Over time the material of your pipe system will deteriorate and once this takes place, this deteriorated material will release a range of chemicals into your water supply. These chemicals can result in a range of health concerns for you and your loved ones.

The team at Nu Flow Technologies spent years developing their sophisticated solution that offers an easy application at a much-reduced price compared to replacing your pipes. They rely on a CIPP solution that is short for cured-in-place-pipe. It is a form of trenchless restoration or rehabilitation of existing pipe systems.

The success of this solution lies in its two main components. One is a textile liner tube and the other is a liquid resin that contains a specially formulated hardener that delivers fast and lasting results. During the first stage of the treatment, also known as the wet-out stage, one of their many skilled professionals across the globe, will make sure that they saturate the fabric liner with the resin.

In general, the industry divides piping systems into two main categories. On the one side, we have pressurized pipes that can handle increased water pressure in these systems and the other is non-pressurized pipes. When they treat non-pressurized pipes, the process allows them to completely restore and renew the entire system, adding many additional years to the life span of the existing system without the need to dig any trenches through our property, damaging your landscapes.

The stages of the process require that they first cut the water supply in the pipes. The next step would be to ensure that the core surface is clean. They do this by relying on several advanced techniques that help them to ensure that all blockages and build-up in the pipe are cleared. During the next treatment phase, they apply the saturated fabric to the inner surface of the pipe. As the epoxy is so advanced it delivers an easy application that is set within no time. Lastly, their team of experts will evaluate the work they’ve done on your premises to ensure that it is of an optimal standard so that you can enjoy years of problem-free water flow.

The epoxy is part of their patented technology that enables their clients to continue with their daily activities with minimal to even no disruption in some cases. It is the most effective way to rehabilitate the host pipe system you have in place without the need of replacing what you have. This on its own is already a massive savings factor.

This type of trenchless pipe lining repair is affordable to many and is a suitable solution for a wide range of pipe diameters. It is also highly flexible and you can opt to apply this solution to a range of different pipes such as metal, clay, PVC, concrete, or even fiberglass.

There is quite simply no other alternative to pipe restoration and rehabilitation that will bring you the same lasting results, affordability, and ease of application. Due to their team’s international presence, you will be able to find the solution you need near to you in most countries.

Trenchless pipe lining repair is one of the most advanced solutions, taking the plumbing industry into a new direction that will result in a far lesser contribution to our massive global waste accumulation that has gotten completely out of hand.

About Us: When we opened our doors in Canada in 1998, our focus was to manufacture and install patented trenchless sewer and drain linings. Yet, technology soon took us into a much more advanced direction and today we are proud to say that we offer a wide selection of advanced solutions to all kinds of piping problems. We can do this as our teams are always busy improving existing designs and our researchers are working without end to find even more ground-breaking developments with which we set the benchmark in our industry. Visit our website at https://www.nuflowtechnologies.com/ and see how our trusted team can resolve your piping concerns.

0 notes

Text

Shower Liner Anaheim California

Contents

Ecologically-friendly custom faucets

Full-service plumbing company

Water heater repair

Exclusive milguard

protection

The ACLU spent nearly a year compiling a litany of alleged harm at the Courtyard shelter in Santa Ana, Bridges at Kraemer …

California Faucets creates beautifully designed, high quality, ecologically-friendly custom faucets, drains, & shower systems in California.

View 53 homes for sale in Gridley, CA at a median listing price of $239,000. See pricing and listing details of Gridley real estate for sale.

Shop for usa at Nordstrom.com. Free Shipping. Free Returns. All the time.

Do sewer line problems have you feeling upset in Newport Beach, California? … Our plumbers know everything about CIPP (Cured-in-Place Pipe Lining) and all … repair specialists at 1230 North Jefferson Street Suite H Anaheim, CA 92807. … Bathtubs and Showers · Kitchens & Bathrooms · Garbage Disposals · Water …

Shower Enclosure Insert Installation for Residents of Southern California. A shower enclosure insert is an affordable alternative to replacing the tile and grout of …

OneStop Plumbers is a full-service plumbing company that specializes in hot water heater installation and water heater repair, water leak detection, slab leaks, leak in ceiling, drain cleaning, water leak reroutes, faucet leak and shower valve repair, to common everyday kitchen, bathroom and water line plumbing service, repair and improvement services.

Shower Enclosures for Homes in Southern California … Our shower liner enclosures also come with exclusive milguard

protection that prevents mold and …

Shower-curtain liners are important for two reasons: First, of course, they keep water from getting out of your shower. And second, those fancy shower curtains you’re coveting? Liners keep them from …

Had I known these protectors were not flame retardant I would not have ordered them. The pict in the catalog show you can put right up to the burner, the directions say the hole of the protector must be trimmed so the hole edges are at least ½ to 1" from the flame when on the highest setting.

The basic components of your shower curtain system are comprised of the shower curtain (which is primarily decorative), an optional curtain liner (which is primarily … best because it has ads a …

Shower Inserts Santa Ana California Wed. July 10th & Thur. July 11th, 10 am to 5 pm • 2019 neal blaisdell Center • 777 Ward ave. • honolulu, Hawaii The Design Your Bathroom Orange County Ca It will provide a larger, more unified space to serve more visually impaired children, adults and seniors from Orange, Los Angeles and Riverside Counties. Ware Bathroom Tub Remodel Ideas Anaheim Ca Mar 11, 2019 – Rent from people in Palm Springs, CA from $20/night. Find unique places to stay with local hosts in 191 countries. Belong

© 2019 Contenko – Home – About – Contact – Privacy – TermsHome – About – Contact – Privacy – Terms

via Check This Out More Resources

0 notes

Text

CIPP – Pipe Lining and HRS Lateral Tools a Perfect Combination

Why Cured-In-Place Piping Is Becoming Popular & What You Need for The Process

There are a variety of plumbing issues that occur regularly and can take a considerable amount of time to fix. This is especially true when it comes to sewer piping. While many of these fixes may be simple, they are time-consuming. Much of this is driven by the fact that the piping may need to be removed before it can be repaired. This is a hassle that everybody wants to avoid, including plumbers and homeowners.

This has led many plumbers to look for quick and easy ways to fix these problems while still being effective. The end result must be a quality repair, regardless of how long it takes. There are a few ways that this can be done, with cured-in-place piping (CIPP) being one. Despite the process becoming increasingly more common, there are many plumbers who mightn't know much about it. That’s a shame, as it can offer quite a significant number of benefits alongside being a quick and effective way to fix a pipe.

What Is Cured-In-Place Piping?

Cured-in-place piping (CIPP) is a process of repairing and restoring existing pipes using liquid resin and textile liner. This is typically done through a trenchless rehabilitation method. CIPP usually starts with a resin mixture being inserted into the textile liner. This mixture should contain an epoxy base that uses a pre-determined hardener such as steam. Once this has been done, the liner is inverted into the pipe using air pressure or water pressure. This means the side of the liner covered with resin will be pressed against the inside of the damaged pipe.

After this is done, a calibration tube is then inserted to hold the liner in place as it is cured or hardened. Curing the liner can be done using the ambient temperature, steam, or hot water. Typically, there isn't a difference in the results offered by any of these, so you should be able to choose whichever one you want. When the liner is cured, the resin will become hard, creating a smooth and fitted pipe wall. This should be just as corrosion-resistant, if not more so, than the previous wall. Essentially, this means that you're creating a pipe within an existing pipe.

If necessary, you may need to take additional steps. The most notable of these is the insertion of a cutting device to reinstate any connections. The need for this will vary from case to case, which means that you should be prepared to do so by ensuring that you have all the tools with you that you might need.

Why CIPP?

Many people may wonder why CIPP has become popular over the past few years. This is because it offers a variety of advantages when compared to traditional techniques, with the most significant being that it helps to save time and effort. Much of this is because it's 100% trenchless, which means that you'll be able to spend less time digging in order to gain access to the piping. This also results in less damage to the surrounding area, which can be beneficial to customers and why plumbing professionals like Spartan Plumbing, Heating & Cooling utilize Perma-Liner.

The time saving is also seen in the fact that this is one of the few options where you can treat just the affected area instead of needing to fix or replace an entire pipe. Replacement can be a relatively expensive process, which means that many customers will want to avoid it. By offering this option, customers are more likely to be able to afford it up-front. This also results in the process being much quicker end-to-end, with professionals being able to avoid waiting for payment.

You'll also be able to save time by avoiding the need to order special materials and you should see a reduction in labor costs associated with these types of project. As a result, there are savings across the board.

This doesn't mean that the CIPP process is less effective than traditional options. In contrast, it can often be just as effective, if not more so, than other ways of addressing an issue. This also helps to successfully prevent pipe failure, which may not be the case with different options. CIPP offers a more flexible alternative to many other treatment and repair options. This is because it can be used on any area of a pipe, including turns, bends, and angles. This makes it one of the few options that can effectively treat almost any part of a pipe.

What Tools Help with CIPP?

The tools that you use can make a significant impact on the job you're doing. While much of this is seen in how well the finished work is done, it also makes the project itself quicker and easier. This means that you'll need to ensure that you're using high-quality tools. There are a few that you'll need on-hand for a CIPP project. The first of these is a cutter, which you'll need to get through the plumbing. Pipes are built to withstand a significant amount of damage, which means that you'll need a product that's been designed to get through them.

One that comes recommended for this is a Tornado Reinstatement Cutter, which can come in a variety of sizes. One of the primary benefits to these is that they can reinstate a service lateral in between 15 and 30 seconds, which is significantly faster than much of its competition. Along with this, there’s the fact that it can get through more reinstatements than other devices in a short amount of time. This is something that the majority of us will want to take advantage of, especially on larger projects. The Tornado Reinstatement Cutter can come in 2", 3" or 4", depending on your needs. Larger sizes will be better for larger projects and vice versa.

Alongside a cutter, you'll need a few other tools to perform a CIPP fix. One of the more notable of these is waterproofing equipment, which will be needed to ensure the piping is properly waterproof once you've finished the job. This will prevent any issues from developing after you've completed the work.

You may also need maintenance hole removal equipment. While this isn't always the case, it can be beneficial for a variety of jobs. This is because the majority of piping will only be accessible through a maintenance hole, which will be difficult to open without the proper equipment. While there are a variety of other ways to get through them, it will be a lot quicker and easier with the equipment. None of us want to spend too much time getting to the piping.

Naturally, you'll also need something to create air pressure in the pipe, as well as the tools that you'll typically use while repairing a pipe. With how efficient cured-in-place piping can be, knowing as much as possible about the process will be helpful for any plumber. Despite being a relatively straightforward process, it can be easy to make a mistake that leads to issues in the future. This means that you should ensure that you know what you're doing when you start using this process. By making sure that you have each of the tools that we mentioned above, you should be covered for any eventuality.

While the CIPP process can be basic, this doesn't mean that you should use basic tools. The speed and ease with which you complete the repair is often affected by the quality of the tools that you use. This means that you should ensure you only use the best tools available. While these can be more expensive, they can also be well worth the extra cost. They'll ensure that every job you do is of the highest quality possible. As a result, you should see significantly more business in the future.

Your customers will remember that you performed your job efficiently and left them with a quality repair. If they have a satisfactory experience, they will think of you when they have more plumbing issues. They'll also be more likely to recommend you to friends or family, which is one of the best ways to generate more business.

0 notes

Text

New Post has been published on Qube Magazine

New Post has been published on http://www.qubeonline.co.uk/pipe-lining-preserves-drains-historical-town-hall/

Pipe lining preserves drains at historical town hall

The drainage system at one of Sheffield’s most iconic buildings has been rehabilitated with an extensive programme of remote structural repairs.

Sheffield City Council commissioned Lanes Group plc to carry out the planned drain maintenance work at the Grade I Listed Sheffield Town Hall.

Drainage engineers from the Lanes Sheffield depot have installed 64 structural liners in pipes beneath the 120-year-old civic building in the centre of the city.

The cure in place pipelining (CIPP) technique, often referred to as patch lining, allows drainage systems to be renewed without the need for extensive excavations.

Arnold Morton, Minor Works Supervisor for Sheffield City Council, said: “The way the Lanes team has gone about its work has been impressive. The town hall is a high-profile building in a prominent city-centre location, so setting the highest standards of health and safety and work-site management has been very important. Lanes has delivered on both.”

The patch lining programme has involved Lanes drainage teams working both inside and outside the building, late in the evening and at night to avoid inconvenience for its users and the general public.

Lanes, the UK’s largest independent drainage specialist, has extensive experience of surveying, repairing, and rehabilitating the drainage systems of historical buildings like Sheffield Town Hall.

David Cheesman, Area Development Manager for the Lanes Sheffield depot, said: “This was one of the largest number of patch liners installed in one go by our depot.

“The process is a highly effective way to rehabilitate drains. A patch liner extends the life of the section of pipe it’s installed in by up to 25 years. Effectively, it’s the equivalent of a new pipe.

“Many of the sections of pipe we were renewing under the town hall were in such hard-to-reach places that this no-dig drain repair solution was the only realistic option.

“Patch lining is often more cost effective than excavating and replacing drain lines, and can be completed more quickly. In this case, the work was scheduled to take a month, but was completed it in less than three weeks.”

The work at Sheffield Town Hall was carried out by a three-person team, led by CCTV drainage survey engineer Scott Sorsby.

He said: “The work has gone very smoothly, despite the size of the project. We installed up to six patch liners a night, most of them a metre long.

“In some cases, we installed up to five liners sequentially, with each liner overlapping the other, to rehabilitate a longer section of pipe. And in one case we had to traverse the liner 30 metres along the pipe to where it needed to be placed.

“With patch lining, the worksite can be kept small, and can be set up and taken down very quickly. In a live environment, like the town hall, where we were working inside and outside the building, that’s a big advantage.”

Sheffield Town Hall, built over a seven-year period from 1890 to 1897, is the venue for most official meetings, and many civic events, held by Sheffield City Council. It was designed by architect Edward William Mountford, who went on to design the Old Bailey law courts in London.

The need to rehabilitate the town hall’s drainage system, made up mainly of 150mm-diametre clay pipes, was established by a CCTV drainage survey, also carried out by Lanes Group.

Patch lining is one of a range of CIPP techniques used to rehabilitate sewers and drains.

A flexible glass-reinforced matting liner impregnated with resin is inserted into the pipe, where the resin cures, creating a durable pipe-within-a-pipe.

With CIPP drain rehabilitation, the resin can cure in ambient temperature, as was done with this point lining programme. Or the curing process can be accelerated with hot water or ultra-violet light.

Lanes Group: www.lanesfordrains.co.uk

Pipe lining preserves drains at historical town hall

0 notes